Abstract

The present study deals with capacity of Cephalosporium species to degrade high-density polyethylene (HDPE). HDPE was treated with nitric acid to make it susceptible to microorganisms. Chemical treatment with nitric acid introduces carbonyl and nitro functional groups in HDPE as confirmed by Fourier transform infrared spectroscopy analysis. Gravimetric analysis showed a decrease in weight of the polymer by 7.18 ± 0.15% after 20 days of incubation period. Reduction in the weight of polymer confirmed the ability of Cephalosporium species to utilize HDPE for their growth. The pH of liquid culture media was found to decrease, whereas total dissolved solids and conductivity increase with the incubation period. Scanning electron microscopy analysis showed changes in morphology of films inoculated with Cephalosporium species. Decrease in crystallinity observed using X-ray diffraction studies further confirmed the degradation of pre-treated HDPE. The observed results reveal that the Cephalosporium species could be effectively used for the degradation of pre-treated HDPE under laboratory conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Plastics such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene (PP), polystyrene (PS), polyurethane (PU) and polyethylene terephthalate (PET) are synthetic polymers derived from petroleum-based products (Hahladakis et al. 2018). Among these polymers, polyethylene is used for wide range of applications (Devi et al. 2015). HDPE is used in textile industry, wrapping and packing of food products, automotive parts, laboratory equipment etc., because of its durability, light weight and easy processability (Rivard et al. 1995; Witt et al. 2001; Arutchelvi et al. 2008). Recycling of polyethylene (PE) is not economically viable as the cost associated with the production of plastics is lesser than the cost associated with recycling (Tolinski 2012). Therefore, a large amount of such plastics are discarded after the use and thus increase the quantity of plastic wastes in the environment (Álvarez-Barragán et al. 2016). Both the landfill disposal of plastics and incineration release huge quantity of CO2 and increase the global warming (Eriksson and Finnveden 2009). Bioremediation using biological agents such as bacteria, fungi and algae was reported to be the best way to reduce plastic wastes in an eco-friendly way (Pathak and Navneet 2017). Two different approaches such as to synthesize biodegradable plastics or to use microorganisms to biodegrade the plastic waste have been carried out to overcome the adverse effects of plastics verges on the environment (Zheng et al. 2005). Synthetic biodegradable polymers (polyesters, starch-based polymers etc.,) are associated with major problems like its higher cost and durability in contrast to synthetic polymers such as polyethylene, polypropylene, polystyrene and polyethylene terephthalate (Leaversuch 2002; Leja and Lewandowicz 2010).

PE is non-biodegradable due to its hydrophobic character, which limits diffuseness of water and other enzymes, acids and bio-surfactants produced by microorganisms. Use of additives such as antioxidants, stabilizers during the production process and higher molecular weight also makes the polyethylene non-biodegradable (Albertsson and Banhidi 1980; Zheng et al. 2005; Koutny et al. 2006; Krueger et al. 2017). Otake et al. (1995) observed partial biodegradation of polyethylene film in moist soil over a period of 32 years. Tribedi and Sil (2013) reported that the polyethylene persists in the environment for a longer period as it is not susceptible to microbial attack due to the absence of functional groups. Pre-treatment using abiotic factors such as temperature, UV, chemical treatments or incorporation of the additives such as pro-oxidants or starch is required prior to biodegradation process for the highly resistive materials such as polyethylene because of its hydrophobic nature and larger molecular weight (Koutny et al. 2006). The pre-treatment process introduces carbonyl or hydroxyl groups and decreases the hydrophobicity of polyethylene. Several studies have reported the synergistic effect of UV irradiation (Zahra et al. 2010), thermal treatment (Awasthi et al. 2017) or treatment with nitric acid (Rajandas et al. 2012) on the microbial activity. Treatment with sulfuric acid and chromic acid also introduces polar groups in LDPE (Wang et al. 2009). Microbial degradation of HDPE is highly favoured by these pre-treatment processes (Sowmya et al. 2015). The ability of microorganisms to use the polymer as a carbon source suggests one promising approach to overcome the plastic waste problem.

Brown et al. (1974) reported that the fungus, Cephalosporium species (sp.), survived on pre-treated plastic materials like polyethylene for 19 days. However, studies of the potential use of Cephalosporium sp. in degradation of pre-treated HDPE under physiological conditions are not reported elsewhere. In the present work, the biodegradability of pre-treated HDPE films in the presence of Cephalosporium sp. has been carried out. The correlation of total dissolved solids (TDS) and conductivity measurements of the liquid culture media was studied to determine the extent of biodegradation.

2 Materials and methods

2.1 Pre-treatment of high-density polyethylene with nitric acid

The pre-treatment of HDPE samples was carried out by similar to the method as reported by Rajandas et al. (2012). In the present study, high-density polyethylene (HDPE) bags (8 µm thickness) were cut into 4 × 4 cm size and were immersed in 69% nitric acid solution for a period of 6 days. The samples were rinsed several times with distilled water to clean the surface of plastic strips and then with 99.9% ethanol solution to make it pathogen free. Further, these samples were rinsed with water and kept in an oven at 60 °C for 6 h.

2.2 Source of biodegrading culture

Fungal culture of Cephalosporium sp. with trade name NCIM 1251 was purchased from the National Collection of Industrial Microorganism (NCIM), NCL, Pune, India. Fungal culture was maintained on potato dextrose agar at 28 °C and was stored at 4 °C.

2.3 In vitro degradation study

Mineral salt media were prepared by using K2HPO4, KH2PO4, NaCl, CaCl2·2H2O, (NH4)2SO4, MgSO4·7H2O, FeSO4 each of 0.5, 0.04, 0.1, 0.002, 0.2, 0.02, 0.001 g/l of distilled water, respectively. For the biodegradation process, 100 ml of mineral salt media was taken in 250-ml conical flask along with pre-treated HDPE films. All experiments were performed in the laminar airflow chamber to make the environmental condition sterile. Experiments were carried out with positive (mineral salt media + pre-treated HDPE + fungus) and negative (treated as control sample) (mineral salt media + pre-treated HDPE) controls, respectively. These flasks were incubated in a rotary shaker at 120 rpm for 20 days at 28 °C.

2.4 Analysis of biodegradation

2.4.1 Weight reduction measurement

The initial weight of pre-treated HDPE sample and the weight after 20 days of incubation period were measured. Variations in the mass of the pre-treated HDPE films in positive and negative controls after an incubation period represent the weight reduction. The percentage of weight reduction is calculated by using Eq. (1),

where W1 = initial weight of pre-treated HDPE, W2 = weight of pre-treated HDPE after an incubation period.

2.4.2 Polymer reduction rate

The rate constant of pre-treated HDPE samples on the weight basis was determined by using first-order kinetics using Eq. (2) (Auta et al. 2018),

where k = first-order rate constant, t = incubation period (in days), W = weight of pre-treated HDPE samples after an incubation period (in mg) and Wo = initial weight of pre-treated HDPE sample (in mg).

The half-life of pre-treated HDPE was calculated by using the formula,

2.4.3 Measurement of pH, TDS and conductivity

pH, TDS and conductivity of the liquid culture were measured by using WENSER LMMP-30 apparatus.

2.4.4 Fourier transform infrared spectroscopy (FTIR)

FTIR analysis was carried out for HDPE, pre-treated HDPE and pre-treated HDPE inoculated with fungus samples in the frequency range of 4000–400 cm−1 by using FTIR spectroscopy (Thermo Scientific NICOLET iS5, iD5 ATR).

2.4.5 Scanning electron microscopy (SEM)

HDPE films were washed with sodium dodecyl sulfate (SDS) solution, ethanol and distilled water after incubation with Cephalosporium sp. for 20 days. SEM analyses were performed using scanning electron microscopy (SEM) (JEOL, JSM-6380A) at different magnifications for pre-treated HDPE and pre-treated HDPE after inoculation with microorganisms. With the help of carbon tape, the samples were sticked onto SEM holder stub and after sputter coating of gold, scanning electron microscope analysis was carried out.

2.4.6 X-ray diffraction (XRD)

The crystallinity of polyethylene films was analyzed by using X-ray diffraction technique (PANalytical—X ‘Pert’ Pro) under Cu Kα radiation (1.54060 Å) operated at 45 kV and 40 mA with θ/θ geometry. The divergence slit was fixed to divergence slit size 0.4785°. The XRD patterns were recorded between 10° and 100° at a scan rate of 10.336 s−1 with a step size of 0.0170 at 25 °C. The percentage of crystallinity is calculated by using Eq. (4),

3 Results and discussions

The studies on degradation of pre-treated HDPE by Cephalosporium sp. in liquid culture media were carried out and interpreted in terms of various parameters. Results were interpreted as an average of three experimental values along with standard deviation.

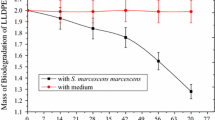

3.1 Weight loss and degradation rate constant measurement

Weight loss measurement is a simple technique to determine the biodegradation of plastics. Approximately 7.18 ± 0.15% of weight loss is observed after inoculation with Cephalosporium sp. for 20 days (Fig. 1). The weight loss of the pre-treated HDPE films inoculated with Cephalosporium sp. is attributed to the reduction in carbon content due to consumption of plastics. Similar observations for the HDPE degradation by Aspergillus flavus strain with gravimetric weight loss of about 8.51 ± 0.1% in 30 days of incubation period have been reported by Devi et al. (2015).

The rate of HDPE degradation by fungal isolate is calculated in terms of per day by using first-order kinetics. As k values remain approximately constant at different interval of inoculation, the first-order model was adopted to study the kinetics of HDPE degradation (Auta et al. 2018). The degradation rate constant of polyethylene is calculated to be 0.0036/day. The half-life of polyethylene is also calculated, and obtained half-life of polyethylene is approximately equal to 192.5 days. Thus, the weight loss measurement reveals that the fungus Cephalosporium sp. has the ability to degrade pre-treated HDPE films and confirms that Cephalosporium sp. has the ability to survive on the surface of pre-treated HDPE sample (Brown et al. 1974).

3.2 Changes in pH, TDS and conductivity of nutrient media

The change in values of pH, TDS and conductivity during the course of the experiment is shown in Table 1. Metabolic activity of microorganisms in the media is related to changes in the pH of liquid culture, as metabolic activity of microorganisms occurs due to biodegradation process. The pH of the mineral salt media was measured on a regular interval of time during the experiment. Reduction in pH is observed after 20 days of incubation with Cephalosporium sp. The variation in pH confirms that the microorganisms are able to use HDPE as a source of carbon and energy for its growth (Arutchelvi et al. 2008; Awasthi et al. 2017). The biological degradation of HDPE decreased the pH of nutrient media toward acidity. Cephalosporium sp. has shown to be metabolically active in the pH range of 3.0–8.5 in the presence of nutrient media (Kita and Heights 1957; Stasinopoulos and Seviour 1989).

Total dissolved solid (TDS) of media is the sum of all the organic and inorganic substances such as salts and various nutrients present in colloidal, molecular or suspended form. Table 1 shows the increase in TDS after 20 days of incubation. This may be due to either secretion of exoenzymes by microorganisms or production of acid during biodegradation process when inoculated with Cephalosporium sp. in nutrient media (Gu 2003; Álvarez-Barragán et al. 2016). A similar increase in the value of TDS due to secretion of enzymes, acids and bio-surfactant is reported by Cassidy et al. (2001) and Mukherjee et al. (2016). Similar to TDS, the conductivity of mineral salt media also increases (Cassidy et al. 2001) after biodegradation of pre-treated HDPE (Table 1), which confirms that the fungus Cephalosporium sp. is effective in degrading pre-treated HDPE.

3.3 Fourier transform infrared spectroscopy (FTIR)

The FTIR spectrums of HDPE sample are shown in Fig. 2a. Characteristics bands at wave number 2913.46 cm−1 (CH2 asymmetric stretching), 2846.49 cm−1 (CH2 symmetric stretching), 2357.73 cm−1 (δ CH2), 1472.21 and 1461.72 cm−1 (bending deformation), 1367.57 cm−1 (wagging deformation), 730.33 and 718.79 cm−1 (rocking deformation) are seen for HDPE (Gulmine et al. 2002). Formation of two new functional groups is seen in Fig. 2b at 1628.75 cm−1 and 1557.62 cm−1 for HDPE samples after treatment with nitric acid. The peak at wave number 1628.75 cm−1 corresponds to the carbonyl group (Rajandas et al. 2012) which is due to oxidation of HDPE sample (Coates 2006). The peak at 1557.62 cm−1 is related to nitro group (Garaeva et al. 2010).

The peak at 2357.73 cm−1 for HDPE is shifted to 2358.32 cm−1 when pre-treated HDPE is treated with Cephalosporium sp. (Fig. 2c). The shifting of peak occurs due to degradation of HDPE in the presence of microbial culture (Ojha et al. 2017). The peak at wavelength 2358.32 cm−1 is broad, unlike the spectrum of the pre-treated HDPE. Peak intensified at 2358.32 cm−1 and shifted from the peak at 2357.73 cm−1. The peak formation at 1274.56 cm−1 is related to C–O stretching (Jeon and Kim 2013). Formation of another peak at 859.81 cm−1 occurs and Sheik et al. (2015) had observed the formation of the similar functional group at 864 cm−1 when pre-treated HDPE subjected to microbial treatment with endophytic fungi. The increment in the intensity of the band and the formation of new peaks supported the fact that the microorganisms utilize polyethylene and used it as a source of carbon for their growth (Nowak et al. 2011).

3.4 Scanning electron microscopy (SEM) analysis

Changes in the surface morphology of the HDPE films before and after nitric acid treatment are shown in Fig. 3. A protuberance on the surface of HDPE films after nitric acid treatment is seen as compared to smooth and neat surface in HDPE films without acid treatment (Fig. 3a, b). No morphological changes were observed in the pre-treated HDPE sample after an incubation period of 20 days in negative control, without microorganisms (Fig. 3c). However, adherence of microorganisms on the surface of pre-treated HDPE films occurs after an incubation period of 20 days in positive control (Fig. 3e). It implies that the fungus Cephalosporium sp. was colonized on the surface of pre-treated HDPE and be the basis for surface damage (Ojha et al. 2017). Incubation with Cephalosporium sp. leads to the formation of rough surfaces, cracks (indicated by yellow circles) and tiny holes (indicated by blue arrows) as compared to the pre-treated HDPE films (Fig. 3b, d). These morphological changes after microbial inoculation are similar to that reported by Kowalczyk et al. (2016) and Das et al. (2018). Consumption of plastics and secretion of enzymes during degradation process by the microorganisms leads to formation of cracks and holes in HDPE (Esmaeili et al. 2013; Skariyachan et al. 2018). It reveals that the fungus Cephalosporium sp. contributed to the degradation of pre-treated HDPE.

3.5 X-ray diffraction (XRD)

X-ray diffraction of samples shows two different peaks at 2θ = 21.5832 and 23.9204 for untreated HDPE, at 21.6165 and 23.9847 for HDPE sample treated with nitric acid and at 21.6359 and 23.9857 for pre-treated HDPE sample inoculated with fungus. The peak at 2θ = 21°–22° represents 110 reflections and other peak formed at 2θ = 23.5°–24° represents 200 reflections (Musuc et al. 2013). These reflections correspond to the orthorhombic crystal structure of HDPE (Morancho et al. 2006). The decrease in the peak intensity is observed in pre-treated HDPE inoculated for 20 days in the presence of Cephalosporium sp. as compared to pre-treated HDPE (Fig. 4b, c). The decrease in peak intensity is related to decrease in the crystallinity of HDPE. The percentage crystallinity decreased from 21.28 ± 0.09 to 17.01 ± 0.01% after nitric acid treatment. This reduction in crystallinity is due to the formation of carbonyl and nitro groups after acid treatment in the amorphous portion of HDPE, which inhibits packing of HDPE chains for crystallization (Avalos-Belmontes et al. 2009). Further, the crystallinity of pre-treated HDPE reduced to 14.67 ± 0.14% after incubation with fungal strain. Thus, the combined effect of chemical treatment and fungal attachment showed 6.61 ± 0.05% decrease in the crystallinity of HDPE. Similar reduction in the crystallinity after incubation with bacterial strains to the extent of 7% has been reported by Balasubramanian et al. (2010). Thus, the decrease in crystallinity confirms the ability of Cephalosporium sp. to degrade HDPE films (Esmaeili et al. 2013; Musuc et al. 2013).

4 Conclusions

Unavailability of land spaces for the safe disposal of plastic wastes makes the plastic waste pollution a major problem in recent years. Biodegradation is a safe and eco-friendly approach to degrade the plastic wastes. In the reported study, chemical changes in HDPE by oxidation with nitric acid have been detected by FTIR, which changes the structure of HDPE and convert into the form which is susceptible to microorganisms. The degradation of pre-treated HDPE films by the Cephalosporium sp. was studied by using pH, TDS and conductivity of liquid culture media which is not reported elsewhere. These observations confirmed the biodegradation of HDPE by the fungus Cephalosporium sp. and indicate that this fungus could be useful in plastic waste management through the bioremediation of HDPE.

References

Albertsson, A. C., & Banhidi, Z. G. (1980). Microbial and oxidative effects in degradation of polyethene. Journal of Applied Polymer Science,25(8), 1655–1671. https://doi.org/10.1002/app.1980.070250813.

Álvarez-Barragán, J., Domínguez-Malfavón, L., Vargas-Suárez, M., González-Hernández, R., Aguilar-Osorio, G., & Loza-Tavera, H. (2016). Biodegradative activities of selected environmental fungi on a polyester polyurethane varnish and polyether polyurethane foams. Applied and Environmental Microbiology,82(17), 5225–5235. https://doi.org/10.1128/AEM.01344-16.

Arutchelvi, J., Sudhakar, M., Arkatkar, A., Doble, M., Bhaduri, S., & Uppara, P. V. (2008). Biodegradation of polyethylene and polypropylene. Indian Journal of Biotechnology,7(1), 9–22.

Auta, H. S., Emenike, C. U., Jayanthi, B., & Fauziah, S. H. (2018). Growth kinetics and biodeterioration of polypropylene microplastics by Bacillus sp. and Rhodococcus sp. isolated from mangrove sediment. Marine Pollution Bulletin Journal,127, 15–21.

Avalos-Belmontes, F., Zapata-Gonzalez, I., Ramos-Devalle, L. F., Zitzumbo-Guzman, R., & Alonso-Romero, S. (2009). Thermo-oxidative degradation of HDPE as a function of its crystalline content. Journal of Polymer Science Part B: Polymer Physics,47, 1906–1915. https://doi.org/10.1002/polb.21785.

Awasthi, S., Srivastava, P., Singh, P., Tiwary, D., & Mishra, P. K. (2017). Biodegradation of thermally treated high-density polyethylene (HDPE) by Klebsiella pneumoniae CH001. 3 Biotech,7(5), 1–10. https://doi.org/10.1007/s13205-017-0959-3.

Balasubramanian, V., Natarajan, K., Hemambika, B., Ramesh, N., Sumathi, C. S., Kottaimuthu, R., et al. (2010). High-density polyethylene (HDPE)-degrading potential bacteria from marine ecosystem of Gulf of Mannar, India. Letters in Applied Microbiology,51(2), 205–211. https://doi.org/10.1111/j.1472-765X.2010.02883.x.

Brown, S. B., Millls, J., & Husle, M. J. (1974). Chemical and biological degradation of waste plastics. Nature,250, 161–163.

Cassidy, D. P., Werkema, D. D., Sauck, W. A., Atekwana, E. A., Rossbach, S., & Duris, J. (2001). The effects of LNAPL biodegradation products on electrical conductivity measurements. Journal of Environmental and Engineering Geophysics,6(1), 47–52. https://doi.org/10.4133/JEEG6.1.47.

Coates, J. (2006). Interpretation of infrared spectra, a practical approach. Encyclopedia of Analytical Chemistry. https://doi.org/10.1002/9780470027318.a5606.

Das, P. M., Santosh, D., & Jayabrata, K. (2018). Fungal-mediated deterioration and biodegradation study of low-density polyethylene (LDPE) isolated from municipal dump yard in Chennai, India. Energy, Ecology and Environment,3(4), 229–236. https://doi.org/10.1007/s40974-018-0085-z.

Devi, S. R., Rajesh Kannan, V., Nivas, D., Kannan, K., Chandru, S., & Robert Antony, A. (2015). Biodegradation of HDPE by Aspergillus spp. from marine ecosystem of Gulf of Mannar, India. Marine Pollution Bulletin,96(1–2), 32–40. https://doi.org/10.1016/j.marpolbul.2015.05.050.

Eriksson, O., & Finnveden, G. (2009). Plastic waste as a fuel—CO2-neutral or not? Energy & Environmental Science,2(9), 907. https://doi.org/10.1039/b908135f.

Esmaeili, A., Pourbabaee, A. A., Alikhani, H. A., Shabani, F., & Esmaeili, E. (2013). Biodegradation of low-density polyethylene (LDPE) by mixed culture of Lysinibacillus xylanilyticus and Aspergillus niger in soil. PLoS ONE,8(9), e71720. https://doi.org/10.1371/journal.pone.0071720.

Garaeva, S. R., Aydin, A. A., Aydin, A., Yalçin, B., Fatullaeva, P. A., & Medzhidov, A. A. (2010). Composition, properties, and application of products formed in oxidation of polyethylene by nitric acid. Russian Journal of Applied Chemistry,83(1), 97–101. https://doi.org/10.1134/S1070427210010192.

Gu, J. D. (2003). Microbiological deterioration and degradation of synthetic polymeric materials: Recent research advances. International Biodeterioration and Biodegradation,52(2), 69–91. https://doi.org/10.1016/S0964-8305(02)00177-4.

Gulmine, J. V., Janissek, P. R., Heise, H. M., & Akcelrud, L. (2002). Polyethylene characterization by FTIR. Polymer Testing,21(5), 557–563. https://doi.org/10.1016/S0142-9418(01)00124-6.

Hahladakis, J. N., Velis, C. A., Weber, R., Iacovidou, E., & Purnell, P. (2018). An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. Journal of Hazardous Materials,344, 179–199. https://doi.org/10.1016/j.jhazmat.2017.10.014.

Jeon, H. J., & Kim, M. N. (2013). Isolation of a thermophilic bacterium capable of low-molecular-weight polyethylene degradation. Biodegradation,24(1), 89–98. https://doi.org/10.1007/s10532-012-9560-y.

Kita, D. A., & Heights, J. (1957). Production of glutamic acid by Cephalosporium. US patent no-2789939 (PP. 2–3).

Koutny, M., Lemaire, J., & Delort, A. M. (2006). Biodegradation of polyethylene films with prooxidant additives. Chemosphere,64(8), 1243–1252. https://doi.org/10.1016/j.chemosphere.2005.12.060.

Kowalczyk, A., Chyc, M., & Latowski, D. (2016). Achromobacter xylosoxidans as a new microorganism strain colonizing high-density polyethylene as a key step to its biodegradation. Environmental Science and Pollution Research,23, 11349–11356. https://doi.org/10.1007/s11356-016-6563-y.

Krueger, M. C., Seiwert, B., Prager, A., Zhang, S., Abel, B., Harms, H., et al. (2017). Degradation of polystyrene and selected analogues by biological Fenton chemistry approaches: Opportunities and limitations. Chemosphere,173, 520–528. https://doi.org/10.1016/j.chemosphere.2017.01.089.

Leaversuch, R. (2002). Biodegradable polyesters: Packaging goes green. Plastics Technology, (800), 2–7. http://cat.inist.fr/?aModele=afficheN&cpsidt=13924382

Leja, K., & Lewandowicz, G. (2010). Polymer biodegradation and biodegradable polymers—A review. Polish Journal of Environmental Studies, 19, 255–266.

Morancho, J. M., Ramis, X., Fernández, X., Cadenato, A., Salla, J. M., Vallés, A., et al. (2006). Calorimetric and thermogravimetric studies of UV-irradiated polypropylene/starch-based materials aged in soil. Polymer Degradation and Stability,91(1), 44–51. https://doi.org/10.1016/j.polymdegradstab.2005.04.029.

Mukherjee, S., Roy Chowdhuri, U., & Kundu, P. P. (2016). Bio-degradation of polyethylene waste by simultaneous use of two bacteria: Bacillus licheniformis for production of bio-surfactant and Lysinibacillus fusiformis for bio-degradation. RSC Advances,6(4), 2982–2992. https://doi.org/10.1039/C5RA25128A.

Musuc, A. M., Badea-Doni, M., Jecu, L., Rusu, A., & Popa, V. T. (2013). FTIR, XRD, and DSC analysis of the rosemary extract effect on polyethylene structure and biodegradability. Journal of Thermal Analysis and Calorimetry,114(1), 169–177. https://doi.org/10.1007/s10973-012-2909-y.

Nowak, B., Pajak, J., Drozd-Bratkowicz, M., & Rymarz, G. (2011). Microorganisms participating in the biodegradation of modified polyethylene films in different soils under laboratory conditions. International Biodeterioration and Biodegradation,65(6), 757–767. https://doi.org/10.1016/j.ibiod.2011.04.007.

Ojha, N., Pradhan, N., Singh, S., Barla, A., Shrivastava, A., Khatua, P., et al. (2017). Evaluation of HDPE and LDPE degradation by fungus, implemented by statistical optimization. Scientific Reports,7(January), 39515. https://doi.org/10.1038/srep39515.

Otake, Y., Kobayashi, T., Ashabe, H., Murakami, N., & Ono, K. (1995). Biodegradation of low-density polyethylene, polystyrene, polyvinylchloride and urea- formaldehyde resin buried under soil for over 32 years. Journal of Applied Polymer Science,56, 1789–1796.

Pathak, V. M., & Navneet, (2017). Review on the current status of polymer degradation: A microbial approach. Bioresources and Bioprocessing,4(1), 15. https://doi.org/10.1186/s40643-017-0145-9.

Rajandas, H., Parimannan, S., Sathasivam, K., Ravichandran, M., & Yin, L. S. (2012). Analysis method A novel FTIR–ATR spectroscopy based technique for the estimation of low-density polyethylene biodegradation. Polymer Testing,31(8), 1094–1099. https://doi.org/10.1016/j.polymertesting.2012.07.015.

Rivard, C., Moens, L., Roberts, K., Brigham, J., & Kelley, S. (1995). Starch esters as biodegradable plastics: Effects of ester group chain length and degree of substitution on anaerobic biodegradation. Enzyme and Microbial Technology,17(9), 848–852. https://doi.org/10.1016/0141-0229(94)00120-G.

Sheik, S., Chandrashekar, K. R. R., Swaroop, K., & Somashekarappa, H. M. M. (2015). Biodegradation of gamma irradiated low density polyethylene and polypropylene by endophytic fungi. International Biodeterioration and Biodegradation,105, 21–29. https://doi.org/10.1016/j.ibiod.2015.08.006.

Skariyachan, S., Patil, A. A., Shankar, A., Manjunath, M., Bachappanavar, N., & Kiran, S. (2018). Enhanced polymer degradation of polyethylene and polypropylene by novel thermophilic consortia of Brevibacillus sps. and Aneurinibacillus sp. screened from waste management landfills and sewage treatment plants. Polymer Degradation and Stability,149, 52–68. https://doi.org/10.1016/j.polymdegradstab.2018.01.018.

Sowmya, H. V., Ramalingappa, Krishnappa, M., & Thippeswamy, B. (2015). Degradation of polyethylene by Penicillium simplicissimum isolated from local dumpsite of Shivamogga district. Environment, Development and Sustainability,17(4), 731–745. https://doi.org/10.1007/s10668-014-9571-4.

Stasinopoulos, S. J., & Seviour, R. J. (1989). Exopolysaccharide formation by isolates of Cephalosporium and Acremonium. Mycological Research,92(1), 55–60. https://doi.org/10.1016/S0953-7562(89)80096-6.

Tolinski, M. (2012). Plastics and sustainability: Towards a peaceful coexistence between bio-based and fossil fuel-based plastics. Beverly: Scrivener Publishing LLC.

Tribedi, P., & Sil, A. K. (2013). Low-density polyethylene degradation by Pseudomonas sp. AKS2 biofilm. Environmental Science and Pollution Research,20(6), 4146–4153. https://doi.org/10.1007/s11356-012-1378-y.

Wang, H., Chen, S. J., & Zhang, J. (2009). Surface treatment of LLDPE and LDPE blends by nitric acid, sulfuric acid, and chromic acid etching. Colloid and Polymer Science,287(5), 541–548. https://doi.org/10.1007/s00396-009-2000-9.

Witt, U., Einig, T., Yammoto, M., Kleeberg, I., Deckwer, W. D., & Muller, R. J. (2001). Biodegradation of aliphatic–aromatic copolyesters: Evaluation of the final biodegradability and ecotoxicological impact of degradation intermediates. Chemosphere,44, 289–299. https://doi.org/10.1016/S0045-6535(00)00162-4.

Zahra, S., Abbas, S. S., Mahsa, M. T., & Mohsen, N. (2010). Biodegradation of low-density polyethylene (LDPE) by isolated fungi in solid waste medium. Waste Management,30(3), 396–401. https://doi.org/10.1016/j.wasman.2009.09.027.

Zheng, Y., Yanful, E. K., & Bassi, A. S. (2005). A review of plastic waste biodegradation. Critical Reviews in Biotechnology,25(4), 243–250. https://doi.org/10.1080/07388550500346359.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chaudhary, A.K., Vijayakumar, R.P. Effect of chemical treatment on biological degradation of high-density polyethylene (HDPE). Environ Dev Sustain 22, 1093–1104 (2020). https://doi.org/10.1007/s10668-018-0236-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-018-0236-6