Abstract

The present work investigated the feasibility to develop of a new microstructure of a material from date palm sawdust in order to improve its adsorption properties. The preparation of the material consists of mechanical grinding of fibers, sieving of sawdust, extractibles extraction and then pretreatment with activating agent sulfuric acid at 1% and 40%. It was then followed by chemical treatment using urea by grafting reaction. The phases change due to chemical modification on sawdust particles was examined using Fourier Transform Infrared (FTIR), spectroscopy Scanning Electron Microscopy (SEM), X-ray diffraction analysis (XRD) and BET method. The hydrolysis at 40% has an effect on the increase of the material crystallinity, higher than the hydrolysis at 1%. An increase in the size of crystallites was also observed by XRD measurements. These results were related to the reduction of the amorphous fractions of wood, and, consequently, to the enrichment of the relative crystalline content. Indeed, the degradation of hemicellulose was observed, by FT-IR analysis, for treated samples. The treated sawdust at 40% acid has the better adsorption characters due to high surface area of 135 m2/g as compared to 44.4 m2/g for treated sawdut (1% acid), this is well supported by SEM micrographs wich also suggest has greater number of pores. Based on preliminary satisfactory results, the sawdust date palm provides a valuable addition to the existing conventional processes to better optimize the adsorption capacity along with low-cost potential application in wastewater treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The use of natural materials, as adsorbents, provides a promising alternative to the process of wastewaters purification and could enable to manage both, solid residues and the wastewater, by decreasing the environmental impacts.

Among natural materials, the date palm fibers Phoenix dactylifera L., whose properties as composite materials have been subject to previous studies (Abu-Sharkh and Hamid 2004; Al-Kaabi et al. 2005; Kaddami et al. 2006), and have been used as adsorbents, continues to be developed. The date palm-tree Phoenix dactylifera L., synonymous to live in desert, is the most wide-spread fruit tree in arid, tropical and sub-tropical regions of the world, in particular those of Northern Africa and Middle East (Achoura and Belhamra 2010). Moreover, the date palm tree (Phoenix dactylifera L) is consired one of sources of natural fibers (Elseify et al. 2019). Nowadays, the world production, the utilization and industrialization of dates is increasing, as recorded by some major producers of dates such as Egypt, Saudi Arabia, United Arab Emirates and Algeria.

Algeria is the world fifth producer of date fruits with a production of 710 000 tons in an area of 170,000 hectares (FAO 2013). The wealth of the Algerian date palm cultivation shows the necessity of projects on the valorization of date palm and the management of wastes coming out of this activity. Indeed, the date palm cultivation generates enormous solid wastes whose elimination is a major problem, but which can be valorized as clean and natural adsorbent material. The valorization of vegetal fibers of date palm is motivated by its low cost, its origin from a renewable source and its abundance in nature which enables to integrate it in a rational way in the field of wastewaters treatment.

Recent studies on the adsorption properties of materials prepared from dates or residuals of date palm cultivation have been reported (Arshad et al. 2014; Ahmad et al. 2012; El Nemr et al. 2008; Riahi et al. 2009a, b; Houache et al. 2009). It appears that the capacity of adsorption of this natural material is the most promising for the elimination of various pollutants in water.

In this context, we quote some works on residuals of date palm used as adsorbents. For example the nucleus of dates considered as a cheap source of active charcoal, have been used in the elimination of heavy metals (copper, hexavalent chromium and iron) contained in industrial waste waters of a tannery and galvano plasty factory (Arshad et al. 2014).

Other works (Ahmad et al. 2012) have proved the role of date palm fibers as adsorbents in the elimination of undesirable matter such as the acid and basic colorants, heavy metals and phenolic compounds. On the other hand, a new activated charcoal developed from grains of date palm by dehydration using concentrated sulfuric acid, has been utilized as adsorbent in the elimination of chromium (El Nemr et al. 2008). The fibers of date palm are also potentially interesting for the elimination of phosphates from aqueous solution (Riahi et al. 2009a, b). However, the valorization of natural fibers as filtering support or adsorbent in the purification of waste waters requires knowledge of structure and texture of material (Cases et al. 2000; Arias Arias et al. 2017; Tursi et al. 2018a, b; Tursi et al. 2019; De Vietro et al. 2019; Tursi 2019; Rodríguez-Restrepo and Orrego 2020).

Furthermore, the date palm belongs to a class of monocotyledons and does not possess any cambium (a thin layer located between the wood and the bark), and consequently presenting a structure and properties different from those of other trees (Trouy-Triboulot and Triboulot 2001). It is characterized by a fibrous structure, possessing four types of fiber. The natural fiber consists of an external layer called primary wall which surrounds another layer which is the secondary wall. The secondary wall consists of three layers, s1, s2, s3, the latter bind the secondary wall to lumen. Each wall consists of crystalline microfibrils based on cellulose reunited between themselves by lignin and the hemicellulose which are amorphous (John and Anandjiwala 2008; Tursi 2019; Rodríguez-Restrepo and Orrego 2020). These structural properties are of interest in the treatment of waste waters, by fixation of various undesirable elements on the material borders. The capacity of the sawdust to fix adsorbents such as pollutants can be improved greatly by subjecting it to chemical treatment (Tursi 2019).

The objective of this treatment is to activate the functional sites of adsorption as well as the increase of the fixation capacity of material with respect to the adsorbents to be eliminated. This objective can be reached by several ways: by lowering the lignin and hemicellulose content of solid substrate to be treated, by increasing the specific surface. The modification of wood can be done using various chemical products such as H2SO4 or H3PO4 acids or enzymes. However, the behavior of lignocellulosic material varies from specie to another. Hence, the mastering of modifications undergone by the material during the chemical treatment requires a good understanding of the microstructure evolution as function of different steps of the chemical activation. This is to limit the formation of inhibiting products and to avoid the loss or the degradation of sugars.

In this context, owing to the economical and environmental importance of the valorization of biomass waste in wastewaters treatment, we are therefore primordially interested in studying the effect of the chemical modification on the wood microstructure of date palm, with the aim to formulate in future adsorbent lignocellulosic materials.

Therefore, the major novelty of this work is the elaboration of a new microstructure of a material, without prior active carbon preparation, with improved adsorption properties from modified date palm sawdust by chemical activation.

Methodology

Sample collection and preparation

The semi hardwood used for this study was collected from date palm (Algerian Ghars variety). The samples were collected from fibers at the level of peduncle (fruit bunches) (Fig. 1a). The stalks represent cellulosic wastes of date palm produced abundantly in Algeria that we have recuperated at the city of Ghardaïa (southern Algeria). The stalks of bunches of palm date have been cleaned, cut in small pieces (Fig. 1b), then mechanically grinded to obtain the sawdust (Fig. 1c). The date palm sawdust appears under the initial form of cuttings of clear yellow color, which once chemically modified becomes brown without ever being calcinated (Fig. 1d).

A granulometric analysis has been performed on the initial wood sawdust, so to separate with a sieving the fine particles characterized by a diameter of 0.5 mm. The specific surface area is increased as the particle size becomes small, which allows a better adsorption capacity of the material (Crini et al. 2009; Nwufo et al. 2014). The physicochemical characterization has enabled to determine the following parameters: the moisture, the pH, the apparent density, the elementary composition (by EDS analysis), the specific surface (SBET) and a quantification of different proportions of primary constituents of wood has been performed according to standard method described by Technical Association of the Pulp and Paper Industry (TAPPI 1992, 2003, 2006, 2007).

Treatment conditions

Physical pretreatment

According to the protocols reported in previous works (Anirudhan et al. 2009; Benyoucef and Harrache 2015), the raw sawdust was repeatedly washed, with distilled water at 60 °C and dried in an oven at 80 °C during 24 h in order to remove water-soluble particles that adheres to the surface.

Chemical treatment

At the second stage, the samples undergo chemical treatment in order to activate the functional adsorption sites and consequently to improve the ability of the sawdust to fix adsorbates. Chemical treatments were done: extractables extraction and chemical pretreatment using sulfuric acid H2SO4 followed by chemical treatment using urea.

Soxhlet extraction

The extractables which risk inhibiting the prehydrolysis of the sawdust are the only fraction which can be isolated without degrading nor modifying the other main wood constituents. The solvents render soluble the extractables contained in the biomass. The choice of solvents is done so to extract the biggest quantity of extractables. These extractables are eliminated and are finally concentrated in the recuperation ball, by extraction using Soxhlet (Mellouk 2007). The extraction has been done according to the protocols reported in previous works (Mellouk 2007; Schultz and Nicholas 2000; Pohjamo et al. 2003; Benyoucef and Harrache 2015). A mass of 11 g of wood sawdust weighed in a cartridge of cellulosis and placed in the Soxhlet apparatus, is dipped in 300 ml of organic solvent mixture: ethanol/toluene (1/2, v/v) of a volume v of 100 ml during 7 h. The extraction has been performed at 1 to 4 cycles (dipping/washing) per hour. Finally, the saw dust has been dried in a drying-room at 80 °C during 5 h.

Chemical pretreatment using sulfuric acid H2SO4 at (1% and 40%)

Dilute acid pretreatment is able to convert hemicellulose contained in biomass to soluble sugars and is a method alternative to enzymatic hydrolysis of cellulose (Ballerini and Alazard-Toux 2006; Xu 2015. In order to compare the effect of acidity on the performance of the hydrolysis, the date palm sawdust undergoes a pre-treatment using sulfuric acid H2SO4, by opting to two types of acid pre-hydrolysis: The first at 1% realized with a ratio liquid/solid equal to 10:1, at temperature of 100 °C during 4 h, according to the protocols reported in previous works (Soom et al. 2009; Benyoucef and Harrache 2015); the second with 40% of a ratio liquid/solid equal to 6.25/1, at 60 °C and during 4 h, according to the protocol of (Hameed et al. 2007; Singh et al. 2011a, b; Benyoucef and Harrache 2015). After filtering, we wash using distilled water until a pH of washing water equal to 7 is reached, so to eliminate any traces of acid and hydrolyzed sugar. The modified sawdusts as such have been dried in a drying-room at 100 °C, during 24 h.

Chemical treatment using urea by grafting reaction

The urea (CO (NH2)2) appears interesting for improving the sorption properties, by grafting of amine functions (NH2) on the cellulosic backbone and lignin of sawdust (Abduazimov and Saipov 1973; Benyoucef and Harrache 2015). The principle is to create new centers of sorption (such as amine groups) on the surface of lignocellulosic material by reaction of polycondensation between groups of C=O of lignin. According to the protocol of previous studies (Pokhrel and Viraraghavan 2006; Benyoucef and Harrache 2015), to each sample of sawdust previously hydrolysed at 1% and 40% (mass of 10 g) was added 50 g of urea, and then stirred (140 rpm) for 24 h at room temperature. After filtration, the grafted sawdust was washed with water and then dried at 80° C during 24 h.

Physicochemical characterization of palm date sawdust

Analysis by Fourier Transform Infrared spectroscopy (FTIR)

Infrared spectroscopy has been widely used to analyze biomass structure and to study the modifications resulting from chemical treatment (Lupo et al. 2014). Samples of palm date sawdust, before and after chemical modification, were analyzed without any prior preparation, by FTIR with a « Bruker Alpha FT-IR Spectrometer».

Estimation of the crystallinity index (CrI %) by X-rays diffraction (XRD)

X-ray diffraction (XRD) patterns of the raw and treated samples were examined using a BRUKER type D8 Advance, using a source of monochromatic radiation CuKα (λ = 0,154 nm) at 45 kV and a current of 40 mA in a continuous scanning mode. The technique of sampling used is the one of diffuse reflectivity. The powdered samples have been scanned along the diffraction angles 2θ range 0–50°. The effect of chemical treatment on cellulosic crystallinity was determined by comparing the crystallinity index (CrI) of sawdust samples before and after chemical modification (Park et al. 2010; Wang et al. 2008). The crystallinity index CrI(%) was calculated respecting the nomenclature (diffraction peak labels) for the cellulose allomorphs that must conform to the conventions used in French (2014). The highest peak (200), and the Iam should be defined as the minimum (not a peak) in the intensity near 18° (French and Santiago Cintrón 2013; French 2014, 2020).

Analysis by scanning electron microscopy (SEM)

The morphology of wood sawdust samples was studied via Scanning Electron Microscopy (JEOL JSM-6320F), it enables to work in a mode by detection of secondary and backscattered electrons. The non conducting samples of wood sawdust must be covered by a conducting film, of the order of 5–30 µm, this is achieved by cathodic pulverization (the pulverization electrode is made of a gold sheet). This operation enables to avoid the surface charges, to reduce the thermal effect due to electronic beam and to improve the efficiency of secondary electrons. The sample is put on a double face adhesive band cut to the dimension of sample holder and fixed on it. The sample surface is covered with a gold layer whose thickness depends on the exposition time and the current intensity of the enclosure (90 s under a current intensity of 50 mA).

Results and discussion

Characterization of material

The results of physical analysis are presented in Table 1 and show that the untreated palm date sawdust contains 4.5% of moisture and apparent density is 0.2286 g/cm3. The low pH (5.82) of the biomass showed an acidity nature.

While the elementary composition (analyzed by EDS) (Fig. 2), gives the most of this elements is Carbon (61.60%), followed by Oxygen (38.28%).

The chemical analysis of primary constituents of untreated sawdust, according to TAPPI standards, reveals (Table 2) that it is essentially composed of 42.28% (± 0.02) of cellulose, followed by hemicelluloses with a rate of 28.9% (± 0,01), determined by the difference between the rate of holocellulose and the rate of cellulose, then the lignin (27.55% ± 0,01).

The content of ashes has been estimated at 0.19% (± 0.01), and the content of extractable matter is 1.37% (± 0.01). The holocellulose, mixture of cellulosic and hemicellulosic constituents, is present at 71.18% (± 0.01). These results are in agreement with previous findings (Nasser et al. 2016) that date palm residues (fruit stalks) are essentially composed by 43.05% of cellulose, followed by hemicelluloses with a rate of 27.5%.

Measurement of specific surface area

The specific surface areas were determined by the B.E.T method, using ASAP 2010 Micromeritics. The results show that the surface area of the untreated sawdust is about 1.36 m2/g, whereas that of the sawdust treated with 1% and 40% acid is respectively 44.4 m2/g and 135 m2/g. Our results are promising since the increase of the specific surface area is significant. This increase in specific surface indicates the presence of significant number of micropores which provides the greater adsorption capacity material. The increase in specific surface area is much more pronounced for the material undergoing hydrolysis with a concentrated acid (40%), in favor of highly microporous structure and very promising textural properties which can provides the greater adsorption capacity material compared to sawdust treated at 1%.

Our results are in agreement with previous findings (Benyoucef et al. 2015) that specific surface area of activated scots pine sawdust increased after modification of material, in particular the case of treated sawdust after pre hydrolysis at 40%. The values of the specific surface are 2.79, 13.4 and 32.6 m2/g for untreated sample, treated sawdust (1%) and treated sawdust (40%), respectively. However, our results show that the specific surface area value for the date palm sawdust is higher than that in scots pine sawdust.

Besides, according to the results reported by Hameed et al. (2007), the specific surface area of activated palm ash were 5.356 m2/g using 40% pretreatment, relatively less than that found by us using date palm sawdust.

Analysis by fourier transform infrared spectroscopy (FTIR)

The FTIR spectra of untreated and treated sawdust presented a great similarity and exhibited various bands that show the presence of some functional groups present in the macromolecular constituents of wood (lignin, cellulose and hemicellulose) ( Fig. 3).

A broad band was observed around 3400 cm−1 in the three spectra, attributed to O–H stretching vibrations of aromatic and aliphatic group of lignin and cellulose. After treatment, this band increased for sawdust treated with 40% acid. There are also present signals at 2917 and 2852 cm−1 assigned to the asymmetric and symmetric stretching vibrations of the C–H bond of the aliphatic group of cellulose, respectively (Heredia-Guerrero et al. 2014).

A band near 1732 cm−1 related to the stretching vibration of (C=O) was present in the lignin and hemicelluloses (Guo and Lua 2003; O’Sullivan 1997). However, the relative intensity of this peak of the carbonyl vibration decreased after treatment in H2SO4 and depends on the concentration of the acid, suggesting that the removal of hemicelluloses is enhanced in the presence of diluted acid.

The characteristic bands of the lignin observed in the spectra of untreated sawdust do not seem to vary in the spectra of treated sawdust and thus bands corresponding to the vibration O–H of aromatic structures (cellulose and lignin) and characteristic lignin bands are observed similarly in all three spectra. Vibrations at 1509 cm−1 and 1613 cm−1, attributed to the deformation (C=C) of aromatic cycles of the lignin (Zghari et al. 2017), and the observed bands at 1372 cm−1 and at 1325 cm−1,assigned to the (C–O) vibration of lignin methoxy groups (Benyoucef and Harrache 2015) confirm that the lignin has not been degraded and that the decrease, even the disappearance, of carbonyl compounds correspond to the elimination of hemicelluloses. According with the decrease of hemicellulose bands, the relative intensity peak of cellulose increase as compared with those of spectra of untreated samples. So, it increases the peak at 1509 cm−1, in the spectrum of chemically treated sawdust and the band at 1430 cm−1 increases only in the spectrum of the sample treated with 40% acid. According to Ciolacu et al. (2001) an increase in the intensity of this band, called the crystallinity band, reflects an increase in the degree of crystallinity of the sample. As a reference band, the band at 1160 cm−1, characteristic of the glycosidic bond, was found in all the spectra, but its relative intensity increased after chemical modification of the biomass, in particular after 40% acid treatment, thus evidencing that cellulose was not degraded during the treatment.

Other characteristic vibrations of cellulose are observed in the three spectra: The peaks at 1028 cm−1 and 1033.68 cm−1 indicate C–O and C–O–C stretching vibration of cellulose (Brum et al. 2012; Alemdar and Sain 2008). The peak at 898 cm−1 and other bands appearing at the frequency between 718 and 400 cm−1 are characteristic of the C–H group in cellulose (Rana et al. 1997; Alemdar and Sain 2008).

In other respects, the FTIR analysis enabled to confirm the grafting of grouping amino on cellulose since the shoulder at around 3555 cm−1, attributed to the valence vibration symmetric to the bond N–H, has been observed in the case of modified sawdust particularly in the case of acid prehydrolysis at 1%. A shoulder at 1655 cm−1 and 1644 cm−1, observed uniquely in the spectrum of chemically treated wood sawdust ( pre-hydrolysis at 1% and 40%) respectively and attributed to the vibration of deformation out of the bond plane (N–H).

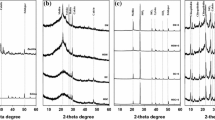

Crystallinity index by X-ray diffraction

The X-ray diffraction patterns of palm date sawdust before and after chemical modification are illustrated in Fig. 4. Two main peaks and a broad amorphous background band were observed due to presence of native cellulose of lignocellulosic materials, with a neat domination of the allomorph I beta (Segal et al. 1959; Fengel and Wegener 1984; Marcovich et al. 1996).

The intensity of diffraction, observed at the diffraction peaks located about 2θ = 16.1°, 22.5° and 34.5°, increased after modification of sawdust, particularly in the case of treated sawdust after pre hydrolysis at 40%. The values of crystallinity index CrI are 49%, 57% and 64% for untreated sample, treated sawdust (1%) and treated sawdust (40%) respectively.

These results obtained from XRD show an increase of the crystallinity index after chemical treatment applied to palm date sawdust which implies an improvement of the crystallites order. The degree of crystallinity of the cellulose is higher in the treated samples than in the raw sawdust, because of the partial elimination of hemicelluloses during treatment. These observations on the increase of the index after chemical modification are in agreement with previous work (Alemdar and Sain 2008; Benyoucef and Harrache 2015).

Morphology by scanning electron microscope (SEM)

The images acquired following the analysis of the surface morphology of the samples by Scanning Electron Microscopy (SEM) are displayed in Fig. 5a–c (before chemical treatment) and Fig. 5d–f (after chemical treatment).

At first sight, the differences of fiber morphology have been observed after chemical treatment of sawdust. The image magnification to 250× (Fig. 5a), reveals an irregular external surface and having heterogeneous structure whose aspect is of orientated sheets along the longitudinal direction, observed in the sample of untreated sawdust.

The micrograph magnified to 700 × of the sample before treatment reveals the presence of tracheids having on their surface numerous bordered punctuations honeycomb shaped (Fig. 5b).

The magnified micrographs at 250 × and 750 × of the surface morphology of the treated samples, shown in Fig. 5d and e respectively, reveal clearly a rearrangement of tracheids having the scalariform punctuations in scale form and uniform structure oriented perpendicular to the direction of the sheets.

This rearrangement of the structure results from the effect of the acid hydrolysis undergone by the material. The porous structure is apparent on the surface, exposed in the longitudinal cavity walls (Fig. 5f) and proves the degradation of hemicelluloses and the elimination of extractible matters, after the chemical modification of cellulosic material.

The elimination of hemicelluloses is known to have an increasing effect on pores volume (Segal et al. 1959). Consequently, this porous appearance on the surface facilitates the adsorption of pollutants. This porous structure is not observed in the case of the untreated saw dust, even at magnification of 3500x (Fig. 5c).

Conclusion

The characterization of cellulose materials, prepared from sawdust of palm date, using physicochemical methods of analysis (SEM, FTIR and XRD), has provided interesting data on the effect of chemical modification on its microstructure.

Indeed, the technique of acidic chemical modification of sawdust material, used in this study, has induced the elimination of hemicellulose and extractable matter, which implied the apparition of new microstructures characterized by an increase of the degree of crystallinity of the cellulose. This effect on the microstructure of modified material increase on increasing the concentration of the acid used in the pre-hydrolysis. It implies a rearrangement of the structure, by the apparition of tracheids having scalariform punctuations with scale form and with a uniform and porous structure. This porous structure is not observed in the case of the untreated sawdust. Furthermore, we note the significant increase of the specific surface from 1.360 m2/g of the untreated sawdust at 44.4 m2/g and 135 m2/g respectively of the material undergoing hydrolysis with 1% and 40% acid. Moreover, Infrared spectroscopy shows that elimination of hemicelluloses is favorable after chemical modification of the material. So, whatever the concentration of the acid used in the hydrolysis, this new microstructure considerably improves the absorption capacity of this developed material. We can conclude that sawdust modified date palm in this way could provide a significant economy and environmental potential, which should contribute to the valorization of this abundant biomass that can have a potential application in the adsorption of pollutants in the field of wastewater treatment.

References

Abduazimov KA, Saipov ZK (1973) Preparation of a nitrogen-containing derivative of lignin. Chem Nat Compd 4:548–549. https://doi.org/10.1007/BF00568668

Abu-Sharkh BF, Hamid H (2004) Degradation study of date palm fibre/polypropylene composites in natural and artificial weathering: mechanical and thermal analysis. Polym Degrad Stab 73:85–967. https://doi.org/10.1016/j.polymdegradstab.2003.10.022

Achoura A, Belhamra M (2010) Aperçu sur la faune arthropodologique des palmeraies d’El-Kantara. Courrier du Savoir 10:93–101

Ahmad T, Danish M, Rafatullah M, Ghazali A, Sulaiman O, Hashim R, Ibrahim MNM (2012) The use of date palm as a potential adsorbent for wastewater treatment. Environ Sci Pollut Res 19:1464–1484. https://doi.org/10.1007/s11356-011-0709-8

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues-Wheat straw and soy hulls. Bioresour Technol 99:1664–1671. https://doi.org/10.1016/j.biortech.2007.04.029

Al-Kaabi K, Al-Ahanbashi A, Hammami A (2005) Date palm fibers as polymeric matrix reinforcement: DPF/polyester composite properties. Polym Compos 26:604–613. https://doi.org/10.1002/pc.20130

Anirudhan TS, Divya L, Suchithra PS (2009) Kinetic and equilibrium characterization of uranium (VI) adsorption onto carboxylate functionalized poly (hydroxyethylmethacrylate)-grafted lignocellulosics. J Environ Manage 90:549–560. https://doi.org/10.1016/j.jenvman.2007.12.010

Arias Arias FE, Beneduci A, Chidichimo F, Furia E, Straface S (2017) Study of the adsorption of mercury (II) on lignocellulosic materials under static and dynamic conditions. Chemosphere 180:11–23. https://doi.org/10.1016/j.chemosphere.2017.03.137

Arshad IE, Minerva EM, Hisham AH, Farouk MA (2014) Adsorption of heavy metals from industrial wastewater using Palm Date pits as low cost adsorbent. Int J Eng Adv Technol 3:71–76

Ballerini D, Alazard-Toux N (2006) Les biocarburants. Etat des lieux, perspectives et enjeux du développement. Technip. Paris, p 348.

Benyoucef S, Harrache D (2015) Microstructure characterization of scots pine "Pinus sylvestris" sawdust. J Mater Environ Sci 6:765–772

Brum SS, De Oliveira LCA, Bianchi ML, Guerreiro De Oliveira LK, Carvalho KTG (2012) Synthesis of cellulose acetate from the bean straw using N-bromosuccinimide (NBS) as catalyst. Polímeros 22:447–452. https://doi.org/10.1590/S0104-14282012005000061

Cases JM, Villiéras F, Michot L (2000) Les phénomènes d’adsorption, d’échange ou de rétention à l’interface solide-solution aqueuse. 1. Connaissance des propriétés structurales, texturales et superficielles des solides, Académie des Sciences., Paris. Sciences de la Terre et des Planètes / Earth and Planetary Sciences 331:763–773

Ciolacu D, Ciolacu F, Popa VI (2001) Amorphus cellulose-structure and characterization. Cellulose Chem. Technol 45(1–2):13–21

Crini G, Badot PM, Guibal E (2009) Chitine et chitosane: du biopolymère à l’application. Presse Univ, Franche-Comté., p 303

De Vietro N, Tursi A, Beneduci A, Chidichimo F, Milella A, Fracassi F, Chatzisymeon E, Chidichimo G (2019) Photocatalytic inactivation of Escherichia coli bacteria in water using low pressure plasma deposited TiO2 cellulose fabric. Photochem Photobiol Sci 18(9):2248–2258. https://doi.org/10.1039/C9PP00050J

El Nemr A, Azza K, Ola A, El-Sikaily A (2008) Treatment of wastewater containing toxic chromium using new activated carbon developed from date palm seed. J Hazard Mater 152:263–275. https://doi.org/10.1016/j.jhazmat.2007.06.091

Elseify LA, Midani M, Shihata LA (2019) Review on cellulosic fibers extracted from date palms (Phoenix Dactylifera L.) and their applications. Cellulose 26:2209–2232. https://doi.org/10.1007/s10570-019-02259-6

FAO: Food and Agriculture Organization (2013) Statistical databases. Accessed 20.01.2013. www.FAO.org

Fengel D, Wegener G (1984) Ultrastructure and reactions Walter de Gruyter. Springer, Berlin, p 613

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the segal crystallinity index. Cellulose 20:583–588. https://doi.org/10.1007/s10570-012-9833-y

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

French AD (2020) Increment in evolution of cellulose crystallinity analysis. Cellulose. https://doi.org/10.1007/s10570-020-03172-z

Guo J, Lua AC (2003) Surface functional groups on oil-palm-shell adsorbents prepared by H3PO4 and KOH activation and their effects on adsorptive capacity. Chem Eng Res Des 81:585–590. https://doi.org/10.1205/026387603765444537

Hameed BH, Ahmad AA, Aziz N (2007) Isotherms, kinetics and thermodynamics of acid dye adsorption on activated palm ash. Chem Eng J 1333:195–203. https://doi.org/10.1016/j.cej.2007.01.032

Houache O, Al-Maamari R, Al-Rashidi B, Jibril B (2009) Study of date palm stem as raw material in preparation of activated carbon. J Eng Res 6(2): 47–51. https://doi.org/10.24200/tjer.vol5iss1pp47-54

John MJ, Anandjiwala RD (2008) Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym Compos 29:187–207. https://doi.org/10.1002/pc.20461

Heredia-Guerrero JA, Benítez JJ, Domínguez E, Bayer IS, Cingolani R, Athanassiou A, Heredia A (2014) Infrared and Raman spectroscopic features of plant cuticles: a review. Front Plant Sci 5:305. https://doi.org/10.3389/fpls.2014.00305

Kaddami H, Dufresne A, Khelifi B, Bendahou A, Taourirte M, Raihane M, Issartel N, Sautereau H, Gérard JF, Sami N (2006) Short palm tree fibers-thermoset matrices composites. Compos A Appl Sci Manuf 37:1413–1422. https://doi.org/10.1016/j.compositesa.2005.06.020

Lupo SJ, Singh S, Simmons BA, Henry RJ (2014) Assessment of lignocellulosic biomass using analytical spectroscopy: an evolution to high-throughput techniques. Bioenergy Res 7(1):1–23. https://doi.org/10.1007/s12155-013-9352-1

Marcovich NE, Reboredo MM, Aranguren MI (1996) Composites from sawdust and unsaturated polyster. J Appl Polym Sci 61:119–124. https://doi.org/10.1002/(SICI)1097-4628(19960705)61:1<119:AID-APP13>3.0.CO;2-2

Mellouk H (2007) Extraction des volatiles à partir du bois par détente instantanée contrôlée (DIC): Valorisation industrielle des extraits et des résidus solide, Thèse de doctorat. Université de la Rochelle. France. https://tel.archives-ouvertes.fr/tel-00397799

Nasser RA, Salem MZM, Hiziroglu S, Al-Mefarrej HA, Mohareb AS, Alam M, Aref IM (2016) Chemical analysis of different parts of date palm (Phoenix dactylifera L.) using ultimate, proximate and thermo-gravimetric techniques for energy production. Energies 9(5): 374. https://doi.org/10.3390/en9050374

Nwufo BT, Isaac ND, Onche EU (2014) Preparation and characterization of sawdust as an adsorbent for oil pollution remediation. Int J Natl Sci Res 6:97–102

O’Sullivan AC (1997) Cellulose: the structure slowly unravels. Cellulose 4:173–207. https://doi.org/10.1023/A:1018431705579

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DA (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulose performance. Biotechnol Biofuels 3:10. https://doi.org/10.1186/1754-6834-3-10

Pohjamo SP, Hemming JE, Willfor SM, Reunanen MHT, Holmbom BR (2003) Phenolic extractives in Salix caprea wood and knots. Phytochemistry 63:165–169. https://doi.org/10.1016/s0031-9422(03)00050-5

Pokhrel D, Viraraghavan T (2006) Arsenic removal from an aqueous solution by a modified fungal biomass. Water Res 3:549–552. https://doi.org/10.1016/j.watres.2005.11.040

Rana AK, Basak RK, Mitra BC, Lawther M, Banerjee AN (1997) Study of acetylation of jute using simplified procedure and its characterization. J Appl Polym Sci 64:1517–1523. https://doi.org/10.1002/(SICI)1097-4628(19970523)64

Riahi K, BenThayer B, BenMammou A, BenAmmar A, Jaafoura MH (2009) Biosorption characteristics of phosphates from aqueous solution onto Phoenix dactylifera L date palm fibers. J Hazard Mater 170(2–3):511–519. https://doi.org/10.1016/j.jhazmat.2009.05.004

Riahi K, Mammou AB, Thayer BB (2009) Date-palm fibers media filters as a potential technology for tertiary domestic wastewater treatment. J Hazard Mater 161(2–3):608–613. https://doi.org/10.1016/j.jhazmat.2008.04.013

Rodríguez-Restrepo YA, Orrego CE (2020) Immobilization of enzymes and cells on lignocellulosic materials. Environ Chem Lett 18:787–806. https://doi.org/10.1007/s10311-020-00988-w

Schultz TP, Nicholas DD (2000) Naturally durable heartwood: evidence for a proposed dual defensive function of the extractives. Phytochemistry 54(1):47–52. https://doi.org/10.1016/S0031-9422(99)00622-6

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of cristallinity of native cellulose using the x-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Singh J, Mishra NS, Sharma U, Sharma YC (2011) Comparative studies of physical characteristics of raw and modified sawdust for their use as an adsorbent for removal of acid dye. BioResource 6(3):2732–2743

Singh J, Sharma U, Banerjee S, Gusain D, Sharma YC (2011) Equilibrium modelling and thermodynamics of removal of orange g from its aqueous solutions. J Appl Sci Environ Sanit 6(3):317–326

TAPPI (1992) Tappi test methods: solvent extractives of wood and pulp, (T-204 om-88). Tappi Press, Atlanta, GA

TAPPI (2003) Ash in wood and pulp, (T 211 cm-86). Tappi Press, Atlanta, GA

TAPPI (2006) Acid-insoluble lignin in wood and pulp, (T 222 om-06). Tappi Press, Atlanta, GA

TAPPI (2007) Solvent extractives of wood and pulp, (T 204 cm-97). Tappi Press, Atlanta, GA

Tursi A (2019). A review on biomass: importance, chemistry, classification, and conversion. Biofuel Research Journal 22:962–979. https://doi.org/10.18331/BRJ2019.6.2.3

Tursi A, Beneduci A, Chidichimo F, De Vietro F, Chidichimo G (2018) Remediation of hydrocarbons polluted water by hydrophobic functionalized cellulose. Chemosphere 201:530–539. https://doi.org/10.1016/j.chemosphere.2018.03.044

Tursi A, Chatzisymeon E, Chidichimo F, Beneduci A, Chidichimo G (2018) Removal of endocrine disrupting chemicals from water: adsorption of bisphenol-A by biobased hydrophobic functionalized cellulose. Int J Environ Res Public Health 15(11):2419. https://doi.org/10.3390/ijerph15112419

Tursi A, De Vietro N, Beneducia A, Milella A, Chidichimo F, Fracassib F, Chidichimo G (2019) Low pressure plasma functionalized cellulose fiber for the remediation of petroleum hydrocarbons polluted water. J Hazard Mater 373:773–782. https://doi.org/10.1016/j.jhazmat.2019.04.022

Trouy-Triboulot MC, Triboulot P (2001) Matériau bois: structure et caractéristiques. Techniques Ingénieur. Construction. C 925:1–26. https://www.techniques-ingenieur.fr/

Wang W, Zhao Y, Deng Y (2008) Effect of enzymatic treatment on cotton fiber dissolution in NaOH/urea solution at cold temperature. Carbohydr Polym 72:178–184. https://doi.org/10.1016/j.carbpol.2007.08.003

Wise LE, Murphy M, D’Addieco AA (1946) Chlorite holocellulose: its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Pap. Trade. J 122:35–43

Xu J (2015) Microwave pretreatment. Pretreat Biomass. https://doi.org/10.1016/B978-0-12-800080-9.00009-8

Zghari B, Doumenq P, Romane A, Boukir A (2017) GC-MS, FTIR and 1H, 13C NMR Structural analysis and identification of phenolic compounds in olive mill wastewater extracted from oued Oussefrou effluent (Beni Mellal-Morocco). J. Mater. Environ Sci 8:4496–4509. https://doi.org/10.26872/jmes.2017.8.12.475.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Benyoucef, S., Harrache, D., Djaroud, S. et al. Preparation and characterization of novel microstructure cellulosic sawdust material: application as potential adsorbent for wastewater treatment. Cellulose 27, 8169–8180 (2020). https://doi.org/10.1007/s10570-020-03349-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03349-6