Abstract

The relationships between biomass composition, water retention value (WRV), settling volume and enzymatic glucose yield and enzyme binding is investigated in this work by employing grasses pretreated with combinations of alkaline hydrogen peroxide (AHP) delignification and liquid hot water pretreatment that result in significant alterations of cell wall properties and subsequent enzymatic hydrolysis yields. Specifically, these cell wall treatments are performed on corn stover and switchgrass to generate material with a range of lignin (6–35 %) and xylan (2–28 %) contents as well as a range of other properties such as carboxylic acid content, water binding affinity and swellability. It was determined that WRV and settling volume are predictors of glucose yield (R2 = 0.900 and 0.895 respectively) over the range of materials and treatment conditions used. It was also observed that mild AHP delignification can result in threefold increases in the WRV. Dynamic vapor sorption isotherms demonstrated that AHP-delignified corn stover exhibited an increased affinity for water sorption from the vapor phase relative to untreated corn stover. These results indicate that these water properties may be useful proxies for biomass susceptibility to enzymatic deconstruction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The majority of terrestrial carbon in the biosphere is thought to be sequestered within plant cell walls (Gilbert 2010). However, this vast resource of reduced carbon is used primarily by humans for its existing structural value, as a fuel for combustion, or as a ruminant feed rather than for the value contained in its existing chemical constituents. This is due to the recalcitrance of the cell wall to deconstruction by chemical and biological treatments which is set by features that are both structural and chemical and cut across the length scales at the molecular, macromolecular, and cellular levels (Ding et al. 2012). One route for the production of biofuels is via the biological conversion of plant cell wall polysaccharides through a pretreatment, enzymatic hydrolysis of the cell wall polysaccharides, and fermentation of these monomers to a biofuel such as ethanol (Alvira et al. 2010). The enzymatic hydrolysis of cell wall polysaccharides requires that an active cellulolytic enzyme be able to penetrate into the cell wall, bind to its substrate, and perform catalysis. Fundamentally, this can be considered as a combination of the related properties of both porosity and target glycan accessibility.

The quantification of porosity in combination with knowledge of other cell wall properties should yield important information about the enzymatic digestibility and glycan accessibility. However, compared to other properties such as bulk composition, cell wall porosity and indirect measures of glycan accessibility have received significantly less attention primarily due to the challenges relating to their accurate quantification. An important concept when considering the porosity of plant cell walls is that, as a matrix of polymers crosslinked primarily by non-covalent forces, these porous structures act as swellable hydrogels (O’Neil and York 2003), particular in unlignified or low-lignin tissues. As such, the solvent properties influence the swelling of the cell wall and hence the porosity and glycan accessibility to enzymes. A variety of techniques are available for quantifying porosity and surface area in porous materials (Papadopoulos et al. 2003), however techniques for plant cell wall porosimetry have more restrictions due to the requirement for a hydrated material to maintain pore integrity (Pönni et al. 2012). As such, common techniques such as BET or mercury intrusion are unsuitable, while methods that can be performed in the hydrated state include differential scanning calorimetry of “bound” water freezing point depression (Yu et al. 2011), solute exclusion (Thompson et al. 1992; Ishizawa et al. 2007), and 1H NMR by either cryoporosimetry (Ishizawa et al. 2007), diffusion (Topgaard and Söderman 2001), or relaxation (Andreasson et al. 2005). Complementary to these, a number of methods provide metrics for the strength of water association with plant cell walls including water retention value (WRV) (Scallan and Carles 1972; Maloney et al. 1999), settling volume (Alince and Robertson 1974; Hubbe and Heitmann 2007), “freeness” or the rate of water drainability (Helmerius et al. 2010), and water activity (Fardim et al. 2013; Selig et al. 2013).

The characterization of porosity in delignified woody plant cell walls generated by chemical pulping, cell wall swelling, and the diffusion of charged cationic or amphiphilic polyelectrolytes into pores for paper “sizing” has been covered in the literature in the context of chemical pulping and papermaking for the role these phenomena play in influencing the drainability of delignified pulps, fiber–fiber adhesion, wettability or hydrophobicity of paper, and the colloidal stability of process liquors among many others (Scallan 1983; Scallan and Tigerström 1992; Hubbe and Heitmann 2007). In the context of cellulosic biofuels, pretreated, delignified, and or mechanically refined woody biomass fibers have been characterized with respect to wet porosity (Grethlein 1985; Thompson et al. 1992; Koo et al. 2011; Yu et al. 2011; Wang et al. 2012) and water retention (Luo and Zhu 2011; Luo et al. 2011; Wang et al. 2012; Hoeger et al. 2013; Jones et al. 2013), and these properties have generally been shown to be strongly correlated to the enzymatic yield of glucose. Relative to the cell walls of woody biomass, which comprise the most industrially significant fiber source, less literature is available on the porosity and swellability of the cell walls of graminaceous monocots (grasses) that include some of the most promising feedstocks for bioenergy processes (e.g. corn stover, switchgrass, miscanthus, etc.) with several publications characterizing changes in wet-state porosity as a function of pretreatment condition for corn stover (Ishizawa et al. 2007) and sugar cane bagasse (Junior et al. 2013) while one study investigated the WRV of dilute acid-pretreated and enzymatically hydrolyzed corn stover with inconclusive results (Roche et al. 2009).

Relative to the cell walls of woody plants, the grasses have significantly different compositions and organizations at the cellular and macromolecular levels (Ding et al. 2012). For example, parenchymatous tissue comprises a significant fraction of the pith of grasses such as corn stover and sugar cane bagasse that is not present in wood (Lois-Correa 2012). These tissues are known to be low in lignin, thin-walled, and substantially more digestible by rumen microbiota (Akin et al. 1993; Wilson et al. 1993) as well as cellulolytic enzymes following a pretreatment (Zeng et al. 2012) or a chemical delignification (Ding et al. 2012) than the other cell types in grasses. These same tissues are typically removed in a “de-pithing” step when non-wood fibers such as sugar cane bagasse are used as a feedstock for chemical pulping due to their poor strength properties and extreme hygroscopicity (Zanutti 1997) which results in poor drainability of pulped fibers during papermaking. It has been shown that sugar cane bagasse is able to sorb as much as 20 times its weight in water, while depithed bagasse holds only five times (Lois-Correa 2012). Other work has shown that corn stover pith has higher equilibrium moisture contents (Igathinathane et al. 2005, 2007) than either the leaves or rinds over the entire range of relative humidities. Early work with alkaline hydrogen peroxide (AHP) delignification of wheat straw demonstrated that nearly completely delignifed wheat straw was capable of retaining three times more water than untreated wheat straw when subjected to filtration (Gould 1985).

From this it is clear that plant cell wall water swellability, lignin content, and enzymatic digestibility should be strongly correlated properties, yet these relationships have not been systematically explored, particularly for potentially important bioenergy feedstocks such as the grasses. For this work, we investigate these relationships by employing a range of pretreated grasses that include combinations of alkaline hydrogen peroxide (AHP) delignification and liquid hot water (LHW) pretreatment that result in significant alterations of cell wall properties and subsequent enzymatic hydrolysis yields. These sets of untreated and pretreated plant cell wall materials are characterized with respect to their WRV and the settling volume and correlated to enzymatic glucose yields and enzyme binding. Additionally, the impact of AHP delignification on water activity during dynamic vapor sorption will be shown for corn stover as well as significant differences in carboxylic acid contents for select materials, while FTIR is employed to yield information about compositional changes.

Materials and methods

Biomass

The biomass feedstocks used in this work included switchgrass (Panicum virgatum, cv. Cave-in-Rock) and corn stover (Zea mays L. Pioneer hybrid 36H56) as reported in our previous work (Li et al. 2012). The biomass was milled to pass a 5 mm screen (Circ-U-Flow model 18-7-300, Schutte-Buffalo Hammermill, LLC) and air-dried to a moisture content of ~5 % prior to any treatments. The composition of structural carbohydrates and lignin of all material was determined by the NREL/TP 510-42618 protocol with minor modifications as described previously (Li et al. 2012).

LHW pretreatment

Liquid hot water pretreatment of corn stover and switchgrass was performed in a 5 L M/K Systems digester (M/K Systems, Inc., Peabody, MA, USA). A total of 500 g of biomass (dry basis) was loaded into three cylinders (7 cm diameter × 35 cm height) fabricated from 200 mesh corrosion-resistant 304 stainless steel cloth (McMaster-Carr Inc., Cleveland, OH, USA), which were then placed into the digester with 4 L of water. The digester was then programmed to heat up to 160 °C at a heat rate of 0.8 °C/min, holding for 5 min, followed by cool-down for 1 h at a rate of ~1 °C/min. The pretreated biomass was washed by soaking in clean water using a large bucket while the biomass was still inside the stainless steel containers. The solids were then air-dried and composition analysis was performed prior to AHP delignification and enzymatic hydrolysis.

AHP delignification

Delignification of corn stover and switchgrass, both untreated and LHW pretreated, was performed using four different conditions of hydrogen peroxide to biomass loadings, 0, 6, 12.5 and 25 % (g H2O2/g biomass). All four conditions were performed in duplicate using 8 g of biomass (dry basis) at 15 % (w/v) which is equivalent to 12.6–13 % (w/w) depending on the H2O2 loading condition. Samples were prepared in 250 mL Erlenmeyer flasks and placed in an incubator at 30 °C with shaking at 180 rpm. The flasks were sealed with parafilm to prevent evaporation but to allow for some expansion as the pressure in the flasks increased with O2 evolution. The pH was adjusted back to 11.5 during pretreatment at 3, 6, and 9 h with aliquots of 5 M NaOH as the pH would decrease during the process for the conditions used. Delignification was stopped after 24 h by diluting the sample to 10 % (w/w) solids and adjusting the pH to approximately 4.8 using concentrated sulfuric acid in preparation for enzymatic hydrolysis.

Enzymatic hydrolysis

Hydrolysis of all corn stover and switchgrass samples was performed by diluting the AHP delignification slurries with 25 mL of water to 10 % (w/w) solids and adjusting the pH to approximately 4.8 using concentrated sulfuric acid as mentioned above. Then an aliquot of 1 M citric acid buffer was added to give a concentration of 50 mM citric acid buffer in the sample flasks. Tetracycline and cyclohexamine were added to yield concentrations of 10 mg/L each to prevent microbial growth. Next, an enzyme mixture of Accelerase 1000, Multifect Xylanase and Pectinase (Genencor, Inc., Palo Alto, CA, USA) was added in a protein mass ratio of 4.4:1.7:1, respectively, at an enzyme loading of 30 mg enzyme/g glucan; this optimized enzyme ratio was determined previously (Banerjee et al. 2011) and the protein contents of the enzymes were based on the Bradford assay. Samples were then mixed well and placed in a shaking incubator at 50 °C with 180 rpm shaking for 7 days. Sugar concentrations in the hydrolysate were determined by HPLC using the method described in the NREL/TP 510-42618 protocol and converted to glucose yields based on the solids content in the reaction vessel and glucan content in the undelignified biomass. Glucose yield is calculated as the percent monomeric glucose released following enzymatic hydrolysis per glucose in the undelignified biomass as determined by the composition analysis.

Water retention value

Water retention value was determined according to a modified version of TAPPI UM 256. For this the biomass samples were filter-washed with a fabricated Buchner funnel containing a 200 mesh stainless steel screen at the bottom as the porous base. The solids remaining after delignification were washed with approximately 700 mL of deionized water and vacuum-filtered to a moisture content of approximately 80 %. Next, approximately 2.5 g of this wet biomass was inserted into a spin-column (Handee Spin Column Cs4, Thermo Scientific) modified to have a 200 mesh stainless steel screen as the membrane directly under the biomass. The spin columns were then centrifuged at 900×g for 15 min (the TAPPI method uses 30 min.) The drained biomass was then weighed in an aluminum tray and placed in an oven at 105 °C for 3 h, and then weighed again. The WRV is the ratio of the mass of water remaining in the biomass after centrifuging divided by the mass of dry biomass. Samples were measured in triplicate and errors bars represent standard deviations.

Settling volume

The AHP delignified slurries were filter-washed on the fabricated Buchner funnel as described above. Approximately 0.5 g of the wet solids remaining were transferred to a 20 mL scintillation vial and approximately 7 mL deionized water was added to achieve a solids concentration of 6.5 % w/w accounting for the moisture content of the wet solids. The vials were vortexed for 30 s and allowed to settle for 1 h. The height of the settled solids and the height of solids and liquid slurry were measured, and the settling volume was determined as the ratio of the height of solids to the height of total slurry as reported in the literature (Riedlberger and Weuster-Botz 2012). Samples were measured in duplicate and the error bars represent the two values measured.

Enzyme binding

Alkaline hydrogen peroxide delignified corn stover slurries were filter-washed on a fabricated Buchner funnel as described above. Wet solids remaining were then air-dried for several days. Next, 0.5 g of dried biomass were placed in a 15 mL centrifuge tube for a total of 5 tubes per sample material. A combined volume of 10 mL of water, Cellic CTec2 (Novozymes, Bagsværd, DK) and 1 M citrate buffer at pH 5.5 was added to each tube for a solids concentration of 5 % (w/v). The pH of 5.5 was selected based on previous literature which demonstrated pH optima in this range for pretreated biomass (Lan et al. 2013). The enzyme loading range in the 5 tubes was 0, 5, 10, 15, and 20 mg CTec2/g biomass. The samples were then placed in a 4 °C cold room for 4 h in a rotary mixer. Following incubation, protein in the supernatant was assayed by the Bradford assay (Fischer Scientific) using BSA as a standard, and corrected for background protein from the biomass by subtracting the absorbance of the sample with no enzyme added. Unbound protein in the liquid was calculated for each tube, and the bound enzyme fraction was determined as the difference of this unbound concentration from the initial enzyme concentration. The fraction of bound enzyme for each sample material was determined by regressing total enzyme concentration with the bound enzyme concentration, where the slope of the regression line is the fraction of bound enzyme for each material.

Dynamic vapor sorption

Dynamic vapor sorption of untreated and air-dried, pretreated corn stover was performed at 25 °C using an AquaLab Vapor Sorption Analyzer (Decagon Devices, Pullman, WA, USA).

Potentiometric titration

Corn stover and switchgrass solids after AHP delignification were washed and air-dried before being milled with a Wiley mill to pass a 40 mesh screen. The method used is similar to Biliuta et al. (2011) where 200 mg milled solid samples were added to a solution consisting of 5 mL of 0.1 M KCl and HCl and 25 mL of water and the pH adjusted to 2.5. The pH was then titrated using a Brinkmann 716 DMS Titrino from 2.5 to 11 using 1 M KOH and the carboxylic acid content was determined as the mmol equivalent of KOH added per g of biomass.

FTIR-ATR

FTIR of solid biomass before and after pretreatment and delignification was performed using a Perkin Elmer Spectrum One FTIR spectrometer and the Perkin Elmer Universal ATR Sampling Accessory. Air-dried biomass samples were first milled using a Wiley mill to pass a 40 mesh screen. Samples were placed on the FTIR diamond and covered with aluminum foil and the pressure arm was adjusted to 70 bar. Spectra were collected in the transmittance mode between 650 and 4,000 cm−1 at a resolution setting of 4 cm−1 using 16 scans per sample. Individual spectra were normalized by mean-centering and scaling with respect to the spectra standard deviation (Robert et al. 2005) to better compare spectra between conditions.

Results and discussion

Biomass pretreatment and delignification

Combinations of alkaline hydrogen peroxide (AHP) delignification and liquid hot water (LHW) pretreatment of corn stover and switchgrass were performed in order to generate materials with a range of compositions, susceptibilities to enzymatic hydrolysis, as well as a diverse set of other cell wall properties such as water sorption that may allow for the correlations between these properties to be quantified. The compositions of the 20 materials generated by this combination of pretreatments and biomass feedstocks are presented in Supplemental Table S1 along with the glucose yields. These data show that AHP delignification preserves the majority of the cellulose and xylan while solubilizing lignin which has been well-established in the literature (Gould 1985). The LHW pretreatment is shown to solubilize xylan while preserving cellulose and lignin, which is also well-known from the literature whereby the improvement in digestibility can be attributed to xylan removal by autocatalyzed acid hydrolysis and lignin relocalization due to its increased mobility at elevated temperature (Selig et al. 2007). This relocalized lignin is known to occlude access to polysaccharides and has been shown to be overcome by additional, subsequent delignification (Selig et al. 2009).

Differences in macroscopic appearance of the slurries of corn stover and switchgrass subjected to AHP delignification (12.5 % w/w H2O2 loading) at 15 % (w/v) solids are presented in Fig. 1. These two materials show a striking difference in their apparent hygroscopicity with the AHP-delignified corn stover, which is substantially more digestible by fungal cellulases, showing essentially no free water while the AHP-delignified switchgrass solids are able to settle out of the slurry. A number of cell wall properties, both structural and compositional, can be hypothesized to contribute to these differences in water swelling behavior. Water is known to be associated through a number of chemico-physical phenomena with plant cell wall biopolymers and the exterior and interior surfaces of cell walls as “free” and “bound” water. Free water comprises bulk water in large pores such as the lumen, and may strongly resist removal by, for example, capillary forces. Bound water represents more thermodynamically constrained water involved in non-covalent chemical interactions with cell wall biopolymers. This bound water can consist of primary bound water or “non-freezing” water that is tightly associated with cellulose surfaces, even within cellulose crystalline regions (Matthews et al. 2006). Secondary bound water exhibits freezing point depression, but is still capable of undergoing a solid–liquid phase change. The relative abundance of these pools of water is set by the overall surface area and porosity of the cell wall matrix and its local chemical environment.

Foremost among the compositional differences are lignin content and accessible amorphous polysaccharide content. Polysaccharide-associated bound water is thought to be most abundant in association with amorphous polymers (e.g. hemicelluloses or amorphous regions of cellulose), and it is known to decrease proportionally with cellulose crystallinity (Nakamura et al. 1981; Hatakeyama et al. 2000). For lignin, both its total content and location strongly impact cell wall enzymatic digestibility (Grabber et al. 2003; Ding et al. 2012). Prior to lignification, the cell wall matrix behaves as a porous, swellable hydrogel, becoming hydrophobic and water-excluding after lignification (O’Neil and York 2003). It is well-established that delignification and hemicellulose removal can increase cell wall matrix porosity, allowing for increased water penetration and water swelling (Grethlein 1985; Akinli-Kogak 2001), and that these water-swellable, nano-scale pores are thought to exist as the voids between delaminated microfibril sheets (Fahlén and Salmén 2004). As cell wall matrix “hydrophilicity”, swellability, and porosity are clearly important properties relating to polysaccharide accessibility to cellulolytic enzymes, these water properties are the subject of further investigation in this work.

Water retention value and settling volume

Quantifiable metrics of cell wall-water association, such as WRV, incorporate many other properties such as cell wall composition and porosity, and may be a useful, simplified indicator of enzymatic digestibility. The variation in the WRV as a function of centrifugation speed was explored for untreated corn stover and switchgrass and AHP-delignified corn stover and switchgrass using the 12.5 % H2O2 loading condition. These results are presented in Fig. 2 and show a number of results of interest. The first observation is that AHP delignification more than doubles the amount of water that the biomass can hold. This substantial increase in water swelling has been identified for AHP-delignified wheat straw (Gould 1985). Figure 2 also shows that even though WRV decreases with increasing speed, the decrease is less for untreated material than for AHP-delignified material. Untreated corn stover and switchgrass decrease from approximately 1.5 to 1.2 while AHP delignified material decreases from 3.5 to 2.5. Similar results have been shown for cotton, where higher centrifuge speeds removed more water (Aggebrandt and Samuelson 1964). However, shorter centrifuge times will also reduce the amount of water removal. In fact, the SCAN-C 62:00 method for WRV uses a spin speed of 3,000×g for 15 min compared to the TAPPI UM 256 method of 900×g for 30 min.

A second notable observation from Fig. 2 is that water swelling values tend toward an asymptote as the centrifugation speed is increased for both untreated and AHP delignified corn stover and switchgrass. This is likely due to easy-to-remove free water being largely removed before some threshold centrifugation speed and the only water remaining is bound water that is more strongly associated with the biomass. A “fiber saturation point” has been proposed to represent the moisture content at which there is no free water remaining within the cell lumina, and all remaining water is contained in the cell wall, and previous work has proposed that the WRV is a good estimate of the fiber saturation point (Scallan and Carles 1972). However, certain properties of the bulk biomass material can impact water drainage suggesting that the WRV may not be such a good estimate of the fiber saturation point. For example, a higher packing density would be expected for material with a wider particle size distribution, and thus these materials would be able to trap more water in the biomass matrix. Also, the amount of small particles, or fines, can impact water drainage by blocking water flow pathways and increasing the water holding capacity; this is termed the choke-point hypothesis (Hubbe and Heitmann 2007).

A third observation from Fig. 2 is that for all centrifugation speeds, the untreated and pretreated corn stover consistently retains more water than the corresponding untreated and pretreated switchgrass. These differences are statistically significant for all but three conditions using a t test with an α of 0.05 (data not shown). These findings confirm the observations presented in Fig. 1. For the remainder of this work, the lowest centrifugation speed tested, 900×g, was employed to have more sensitivity in the measurements allowing larger differences between samples to be observed. Additionally, this is the standard centrifugation conditions for the established WRV protocols (TAPPI), albeit with a centrifugation time of 30 min rather than 15 min used in this work.

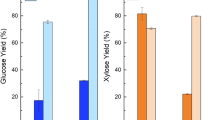

Water retention value and settling volume were next determined for corn stover and switchgrass samples that were subjected to a range of pretreatment conditions including combinations of liquid hot water (LHW) pretreatment and AHP delignification. These diverse pretreated samples showed enzymatic glucose yields after 7 days of hydrolysis ranging from 18 to 85 %. The correlations between these two metrics and enzymatic glucose yield are shown in Fig. 3. These correlations between the glucose yields settling volume and WRV both show a linear relationship, R2 of 0.895 and 0.900 respectively, regardless of biomass feedstock, pretreatment type, or pretreatment condition. This is noteworthy because correlating enzymatic digestibility to carbohydrate or even lignin content does not give a clear trend for these samples (data not shown) and is therefore inconclusive as to the relative contributions of these factors toward impacting sugar yield.

Differences in composition may be one (of many) of the factors that contributes to the differences in water swelling. Lignin has been shown to have the lowest water affinity followed by cellulose and then hemicelluloses in lignocellulosic material (Berry and Roderick 2005). However, Weber et al. (1993) have shown that cellulose does not contribute as much to WRV as hemicelluloses and lignin, and they did not observe a correlation between hemicellulose content and WRV; this may be because other properties of the hemicelluloses are also important factors that contribute to water retention (Lund et al. 2012). As factors such as porosity and surface affinity are neglected by composition-only information, the increased settling volume and WRV may provide indirect evidence for increased porosity and polysaccharide accessibility to enzymes. Previous work using bleach Kraft and sulfite pretreated/pulped hardwoods subjected to dewatering by either heat-drying (Luo and Zhu 2011) or wet-pressing (Luo et al. 2011) demonstrated a strong sigmoidal relationship between WRV and glucose hydrolysis yields. These earlier studies clearly indicated that a loss of water sorption capability as quantified by WRV due to irreversible pore collapse could be used as a proxy for changes in polysaccharide accessibility to enzymes with the porous cell wall. Settling volume has been studied extensively in the context of compaction and settling of activated sludge (Jenkins et al. 2004; Jones and Schuler 2012). For fibrous biomass, particle settling volume is an alternative quantification of the biomass bulk density which has been reported for bioenergy feedstocks such as wheat straw and switchgrass (Lam et al. 2008), with particle size, individual particle density, and particle–particle interaction being important in controlling the bulk density. The settling volume provides a metric for distinguishing differences between inter-fiber friction, and chemical treatments that increase settling volume also tend to increase dewatering rates (Hubbe and Heitmann 2007).

Enzyme adsorption

Enzyme adsorption isotherms were determined for corn stover subjected to increasing AHP delignification (Fig. 4a), with enzyme adsorption determined at 4 °C to minimize catalytic activity. The obvious trend from these data is that the substrate has a higher binding affinity for cellulases with increasing delignification. As these are not complete isotherms and only represent the portion of the curve at low enzyme loadings before the adsorption saturates, they show an approximate linear increase in enzyme adsorption with increasing loadings to which linear trendlines are fitted. The slope of this portion of the isotherm is taken as the fraction of the protein that is bound to the biomass (mass bound protein/mass total protein). These values are plotted against the WRV and enzymatic glucose yields in Fig. 4b which shows that there is a strong correlation between the bound enzyme fraction and WRV, R2 = 0.995, and the enzymatic glucose yield, R2 = 0.914. This result for increasing enzyme adsorption with increasing enzymatic hydrolyzability has been shown many times in the literature for many types of biomass and treatments for complex cellulase cocktails. As examples, strong correlations between protein adsorption and enzymatic glucose yield were found for mechanically fibrillated softwood Kraft pulps (Hoeger et al. 2013), AHP-delignified rice straw (Wei and Cheng 1985), as well as many other diverse alkaline and acid pretreatments of corn stover (Kumar and Wyman 2009; Wang et al. 2012).

It should be considered that this is a multicomponent enzyme cocktail with many proteins with strongly differing substrate affinities and even some catalytic components such as β-glucosidase that do not contain cellulose binding modules (CBMs) and would not be expected to show strong adsorption to insoluble cell wall polymers. Additionally, protein adsorption is not necessarily correlated to the sugar yields as non-specific adsorption of enzymes to lignin is known to be important, in particular to high-lignin materials such as acid-pretreated softwoods (Tu et al. 2009).

Dynamic vapor sorption

Dynamic vapor sorption (DVS) was employed as a method to investigate the impact of AHP delignification on the water affinity of surfaces within the porous cell walls, how this might relate to structural and chemical changes in the biomass, and how this could be interpreted with respect to differences in the enzymatic digestibility of these materials. A substantial literature exists for vapor sorption and its dynamics in native and modified woody biomass as reviewed by Engelund et al. (2013). However, the literature for grasses is less well-developed. For example, sorption isotherms (for adsorption only) have been reported for corn stover components (Igathinathane et al. 2005, 2007), big bluestem (Karunanithy et al. 2013), wheat straw, and reed canary grass (Nilsson et al. 2005). Adsorption–desorption hysteresis and the effect of cell wall modifications such as pretreatment on these sorption dynamics for grasses have not been reported in the literature. In this work, DVS isotherms at 25 °C were determined for untreated corn stover and AHP-delignified corn stover (12.5 % H2O2 loading) with the results presented in Fig. 5. These show changes in the moisture content of the material as a function of the relative humidity (alternatively the water activity, aw, of the sorbed water) for water adsorption (lower curves) and desorption (upper curves).

The data in Fig. 5 show at least three notable results that deserve comment. The first result is that the AHP-delignified corn stover has a lower water activity than the untreated material for any given moisture content. In other words, the water vapor adsorption–desorption isotherms are shifted to the left following delignification. This indicates that following mild delignification, more water is present at any select moisture content in a more constrained environment. This can be interpreted as indicating that more water can be adsorbed within the cell wall pores (or on fiber surfaces) and that delignification may increase the accessible sites for water to sorb by increasing intra-cell wall porosity. The oxidative delignification may additionally introduce more hydrophilic functional groups such as carboxyl groups as a consequence of oxidation reactions. Additionally, the oxidative delignification may increase the accessibility of hydroxyl groups in polysaccharides, in particular for non-crystalline hemicelluloses (Olsson and Salmen 2004). DVS of different cellulose allomorphs has shown that native allomorphs of cellulose (cellulose I) offer significantly less sorption potential than other allomorphs (Selig et al. 2013). However, alkali concentrations used for AHP delignification in this work are not at a high enough concentration to induce the formation of the cellulose II allomorph. The second notable result from Fig. 5 is that the total mass of sorbed water at 100 % relative humidity (aw of 1.0) is increased, with the equilibrium moisture content increasing from 23.7 to 25.5 % following AHP delignification, again indicating a higher affinity for water. The third notable finding is that the AHP delignified corn stover also has smaller hysteresis than the untreated material. Water sorption/desorption hysteresis in swellable, porous materials has been attributed to irreversible water phase change, irreversible absorbent swelling, and capillary condensation–evaporation processes in pores where vapor condenses in the pores and is then trapped (Boki and Ohno 1991). Small hysteresis may be the result of weakly associated fiber chains and weakly bound water for material with high swelling and sorption properties, or for smaller swelling and sorption properties the opposite is true, indicating strongly associated chains and bound water. This would make sense for AHP delignified corn stover which is more enzymatically digestible than untreated corn stover, and weaker polymer and water association would allow for easier enzyme access and subsequent hydrolysis of sugar polymers for the AHP material. However, hysteresis differences may also be explained by differences in mesopore volume (Boki and Ohno 1991) which too could explain the differences between untreated and AHP delignified corn stover, where lignin and hemicelluloses have been removed with the AHP treatment, potentially increasing pore volume and allowing, again, for more enzyme access.

Cell wall carboxylate content

Oxidizing pretreatments and pulp bleaching processes are well-known to introduce carboxylate groups to cell wall biopolymers. It is presumed that these functional groups may influence the chemical and structural environment within the cell wall matrix, for example, by increasing electrostatic repulsion between polymers, increasing the affinity for water within the cell wall, and resulting in an overall more porous cell wall when swollen with water, among others. The carboxylic acid contents of AHP-delignified corn stover and switchgrass were determined by potentiometric titration with the results presented in Fig. 6. This shows that estimated acid content is higher for corn stover (0.58–0.77 mmol COOH/g original biomass) relative to switchgrass (0.38–0.64 mmol COOH/g original biomass) for all conditions. Another result is that the carboxylic acid content passes through a maximum at an H2O2 loading of 12.5 % (w/w on biomass) after which it decreases.

Carboxylic acid groups are known to be sites for water adsorption; therefore, these data corroborate the water swelling capacities above with the exception of the 25 % condition. This may be due to the fact that lignin content has been reduced so much that cellulose chains are free to swell much less inhibited than the other conditions regardless of the amount of water adsorption sites. A similar result has been identified previously where an increase in acid groups to a maximum was observed following selective delignification by Kraft pulping, then it decreased again as progressively more lignin was removed (Scallan and Tigerström 1992). It was hypothesized that water will imbibe the cell wall due to osmotic pressure causing the cell wall to swell; swelling stops when osmotic pressure equals the elastic tension of the cell wall. Increased delignification by Kraft pulping has been shown to decrease elastic modulus which equates to increased swelling, and at some point a threshold was reached where lignin removal would no longer decrease the elastic modulus because of an increase in hydrogen bonding between cellulose fibers which counteracted the effect of lignin removal (Scallan and Tigerström 1992). Figure 6b shows the same results plotted per mass lignin with the assumption that the majority of the COOH groups are introduced onto the lignin. For this, the trend is a continuous increase in COOH/g lignin with increasing H2O2 loading showing that the introduction of COOH groups may be indicative of lignin removal. Plotting this same data against enzymatic hydrolysis yields of glucose shows similar trends (Fig. 6c, d). Specifically, the glucose hydrolysis yields show maxima (Fig. 6c) relative to a carboxylate content on a per original mass basis while a linear trend is apparent for glucose hydrolysis yields when plotted against carboxylate content on a per mass lignin basis.

FTIR-ATR

In order to understand the impact of AHP delignification and LHW pretreatment on other chemical features of corn stover and switchgrass that may contribute to water swelling, the samples were analyzed using FTIR-ATR. These results, plotted in Fig. 7a, show a select region of the FTIR spectra subtracted from the spectra of untreated material for AHP delignified corn stover over the range of H2O2 loadings used. Peaks below 0 represent decreases in transmittance intensity for that peak from untreated material, while peaks above 0 represent increases in intensity. Peak assignments to specific functional groups and properties in biomass are difficult as even in the literature there seem to be differences depending on experiments and materials. There are notable decreases in transmittance for peaks 1727, 1386, and 1235 which have been attributed to acetyl esters in xylan (Sun et al. 2004; Wrigstedt et al. 2010) as well as ferulate and p-coumarate esters (Pan et al. 1998), and therefore are indicative of saponification of these esters, which is expected considering the alkaline pH used during delignification. The decrease in peak 1517 indicates a decrease in lignin which is in agreement with the composition results after delignification (see Supplemental Table 1) (Liu et al. 2006). Ferulate and p-coumarate may contribute to this peak (Nakagame et al. 2011), which would agree with results in our lab showing an increase in ferulic and p-coumaric acid removal with increasing AHP severity (manuscript in preparation). The peak at 1640 represents water bending vibration (Lojewska et al. 2005), showing a decrease with increasing AHP severity; this makes sense as the air-dried moisture content also decreases with increasing AHP severity due to more severe hornification because of more lignin and hemicelluloses removal. The peak at 1160 is antisymmetric bridge stretching of C–O–C groups typically for the xylan backbone (Cao and Tan 2004; Wrigstedt et al. 2010) and the peak at 990 is for β-glycosidic bonds associated with cellulose (Robert et al. 2005) indicating a decrease in xylan content and an increase in cellulose content which is corroborated by composition data (Supplemental Table 1). The peak at 1710 may be due to carboxyl or aldehyde functionality (Lojewska et al. 2005) and has been attributed to carboxylic acid groups in lignin, which is in agreement with the results in Fig. 6. Figure 7b shows the same results for LHW pretreated followed by AHP delignified corn stover. There is noticeably less cellulose concentrating evinced by the smaller peak height at 990, which agrees with composition data.

Conclusions

Cell wall water swelling and particle settling volume are measurements that are impacted by and can provide indirect assessments of biomass properties such as porosity and composition which have independently been shown to correlate well with enzyme accessibility and/or enzyme binding and, therefore, enzymatic digestibility. This work has shown that for combinations of LHW pretreatment and AHP delignification of two different biomass materials, corn stover and switchgrass having a range of compositions and water sorption behavior, WRV and settling volume are strong predictors of enzyme binding and enzymatic conversion. This is reasonable as water molecular association with biomass would be constrained by the same biomass properties as limit enzymatic deconstruction of plant cell walls: polysaccharide accessibility, porosity, and surface water affinity. This work also showed that mild AHP delignification increased WRV up to threefold by removing lignin and increasing the water swellability of cell walls. It was also shown that AHP delignification increased the carboxylic acid content of corn stover and switchgrass under some oxidative delignification conditions, which may also contribute to the increased cell wall affinity for water. Dynamic vapor sorption isotherms demonstrated that AHP-delignified corn stover exhibited an increased capacity for water sorption from the vapor phase relative to untreated corn stover, with more water present at any moisture content present in a more constrained environment, indicating more water-accessible pore volume. FTIR results corroborated what was known from composition results, that AHP delignification removed lignin and xylan and consequently concentrated the composition of cellulose. Future work will investigate a greater range of pretreatment technologies and pretreatment conditions to assess the generalizability of utilizing WRV for evaluating pretreatment effectiveness. If this were to be the case, WRV, would be a very useful screening tool for identifying biomass feedstocks that would be more susceptible to chemical and enzymatic deconstruction.

References

Aggebrandt LG, Samuelson O (1964) Penetration of water-soluble polymers into cellulose fibers. J Appl Polym Sci 8(6):2801–2812

Akin DE, Rigsby LL, Hanna WW, Lyon CE (1993) In vitro digestion and textural strength of rind and pith of normal and brown midrib stems. Animal Feed Sci Technol 43(3):303–314

Akinli-Kogak S (2001) The influence of fiber swelling on paper wetting. Dissertation, The University of Maine

Alince B, Robertson AA (1974) Aggregation of microcrystalline cellulose with polyethylenimine. Colloid Polym Sci 252(11):920–927

Alvira P, Tomas-Pejo E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101(13):4851–4861

Andreasson B, Forsström J, Wågberg L (2005) Determination of fibre pore structure: influence of salt, pH and conventional wet strength resins. Cellulose 12(3):253–265

Banerjee G, Car S, Scott-Craig JS, Hodge CB, Walton JD (2011) Alkaline peroxide pretreatment of corn stover: effects of biomass, peroxide, and enzyme loading and composition on yields of glucose and xylose. Biotechnol Biofuels 4:16

Berry SL, Roderick ML (2005) Plant–water relations and the fibre saturation point. New Phytol 168(1):25–37

Biliuta G, Fras L, Harabagiu V, Coseri S (2011) Mild oxidation of cellulose fibers using dioxygen as ultimate oxidizing agent. Dig J Nanomater Biostruct 6(1):291–297

Boki K, Ohno S (1991) Moisture sorption hysteresis in kudzu starch and sweet-potato starch. J Food Sci 56(1):125–127

Cao Y, Tan HM (2004) Structural characterization of cellulose with enzymatic treatment. J Mol Struct 705(1–3):189–193

Ding S-Y, Liu Y-S, Zeng Y, Himmel ME, Baker JO, Bayer EA (2012) How does plant cell wall nanoscale architecture correlate with enzymatic digestibility? Science 338(6110):1055–1060

Engelund E, Thygesen L, Svensson S, Hill CS (2013) A critical discussion of the physics of wood–water interactions. Wood Sci Technol 47(1):141–161

Fahlén J, Salmén L (2004) Pore and matrix distribution in the fiber wall revealed by atomic force microscopy and image analysis. Biomacromolecules 6(1):433–438

Fardim P, Liebert T, Heinze T (2013) Pulp fibers for papermaking and cellulose dissolution. In: Navard P (ed) The European polysaccharide network of excellence (EPNOE). Springer, Heidelberg, pp 253–282

Gilbert HJ (2010) The biochemistry and structural biology of plant cell wall deconstruction. Plant Physiol 153(2):444–455

Gould JM (1985) Studies on the mechanism of alkaline peroxide delignification of agricultural residues. Biotechnol Bioeng 27(3):225–231

Grabber JH, Hatfield RD, Ralph J (2003) Apoplastic pH and monolignol addition rate effects on lignin formation and cell wall degradability in maize. J Agric Food Chem 51(17):4984–4989

Grethlein HE (1985) The effect of pore-size distribution on the rate of enzymatic-hydrolysis of cellulosic substrates. Nat Biotechnol 3(2):155–160

Hatakeyama T, Nakamura K, Hatakeyama H (2000) Vaporization of bound water associated with cellulose fibres. Thermochim Acta 352:233–239

Helmerius J, von Walter JV, Rova U, Berglund KA, Hodge DB (2010) Impact of hemicellulose pre-extraction for bioconversion on birch Kraft pulp properties. Bioresour Technol 101(15):5996–6005

Hoeger I, Nair S, Ragauskas A, Deng Y, Rojas O, Zhu JY (2013) Mechanical deconstruction of lignocellulose cell walls and their enzymatic saccharification. Cellulose 20(2):807–818

Hubbe MA, Heitmann JA (2007) Review of factors affecting the release of water from cellulosic fibers during paper manufacture. BioResources 2(3):500–533

Igathinathane C, Womac A, Sokhansanj S, Pordesimo L (2005) Sorption equilibrium moisture characteristics of selected corn stover components. Trans ASABE 48(4):1449–1460

Igathinathane C, Womac A, Sokhansanj S, Pordesimo L (2007) Moisture sorption thermodynamic properties of corn stover fractions. Trans ASABE 50:2151–2160

Ishizawa CI, Davis MF, Schell DF, Johnson DK (2007) Porosity and its effect on the digestibility of dilute sulfuric acid pretreated corn stover. J Agric Food Chem 55(7):2575–2581

Jenkins D, Richard MG, Daigger GT (2004) Manual on the causes and control of activated sludge bulking, foaming, and other solids separation problems. CRC Press, Boca Raton, FL

Jones P, Schuler A (2012) Role of changing biomass density in process disruptions affecting biomass settling at a full-scale domestic wastewater treatment plant. J Environ Eng 138(1):67–73

Jones BW, Venditti R, Park S, Jameel H, Koo B (2013) Enhancement in enzymatic hydrolysis by mechanical refining for pretreated hardwood lignocellulosics. Bioresour Technol 147:353–360

Junior C, Milagres A, Ferraz A, Carvalho W (2013) The effects of lignin removal and drying on the porosity and enzymatic hydrolysis of sugarcane bagasse. Cellulose 20(6):3165–3177

Karunanithy C, Muthukumarappan K, Donepudi A (2013) Moisture sorption characteristics of corn stover and big bluestem. J Renew Energy 2013:12

Koo B-W, Treasure T, Jameel H, Phillips R, Chang H-m, Park S (2011) Reduction of enzyme dosage by oxygen delignification and mechanical refining for enzymatic hydrolysis of green liquor-pretreated hardwood. Appl Biochem Biotechnol 165(3–4):832–844

Kumar R, Wyman CE (2009) Cellulase adsorption and relationship to features of corn stover solids produced by leading pretreatments. Biotechnol Bioeng 103(2):252–267

Lam P, Sokhansanj S, Bi X, Lim C, Naimi L, Hoque M, Mani S, Womac A, Narayan S, Ye X (2008) Bulk density of wet and dry wheat straw and switchgrass particles. Appl Eng Agric 24(3):351–358

Lan TQ, Lou HM, Zhu JY (2013) Enzymatic saccharification of lignocelluloses should be conducted at elevated pH 5.2–6.2. Bioenergy Res 6(2):476–485

Li M, Foster C, Pu Y, Holmes D, Saffron C, Ragauskas A, Hodge DB (2012) Structural characterization of alkaline hydrogen peroxide pretreated grasses exhibiting diverse lignin phenotypes. Biotechnol Biofuels 5(1):38

Liu CF, Xu F, Sun JX, Ren JL, Curling S, Sun RC, Fowler P, Baird MS (2006) Physicochemical characterization of cellulose from perennial ryegrass leaves (Lolium perenne). Carbohydr Res 341(16):2677–2687

Lois-Correa J (2012) Depithers for efficient preparation of sugar cane bagasse fibers in pulp and paper industry. Ing Investig Technol 13(4):417–424

Lojewska J, Miskowiec P, Lojewski T, Proniewicz LM (2005) Cellulose oxidative and hydrolytic degradation: in situ FTIR approach. Polym Degrad Stab 88(3):512–520

Lund K, Sjöström K, Brelid H (2012) Alkali extraction of Kraft pulp fibers: influence on fiber and fluff pulp properties. J Eng Fibers Fabr 7(2):30–39

Luo XL, Zhu JY (2011) Effects of drying-induced fiber hornification on enzymatic saccharification of lignocelluloses. Enzym Microb Technol 48(1):92–99

Luo XL, Zhu JY, Gleisner R, Zhan HY (2011) Effects of wet-pressing-induced fiber hornification on enzymatic saccharification of lignocelluloses. Cellulose 18(4):1055–1062

Maloney TC, Laine JE, Paulapuro H (1999) Comments on the measurement of cell wall water. Tappi J 82(9):125–127

Matthews JF, Skopec CE, Mason PE, Zuccato P, Torget RW, Sugiyama J, Himmel ME, Brady JW (2006) Computer simulation studies of microcrystalline cellulose Iβ. Carbohydr Res 341(1):138–152

Nakagame S, Chandra RP, Kadla JF, Saddler JN (2011) Enhancing the enzymatic hydrolysis of lignocellulosic biomass by increasing the carboxylic acid content of the associated lignin. Biotechnol Bioeng 108(3):538–548

Nakamura K, Hatakeyama T, Hatakeyama H (1981) Studies on bound water of cellulose by differential scanning calorimetry. Text Res J 51(9):607–613

Nilsson D, Svennerstedt B, Wretfors C (2005) Adsorption equilibrium moisture contents of flax straw, hemp stalks and reed canary grass. Biosyst Eng 91(1):35–43

Olsson AM, Salmen L (2004) The association of water to cellulose and hemicellulose in paper examined by FTIR spectroscopy. Carbohydr Res 339(4):813–818

O’Neil M, York WS (2003) The composition and structure of plant primary cell walls. In: Rose J (ed) The plant cell wall. Blackwell Pub Ltd, Oxford, pp 1–54

Pan GX, Bolton JL, Leary GJ (1998) Determination of ferulic and p-coumaric acids in wheat straw and the amounts released by mild acid and alkaline peroxide treatment. J Agric Food Chem 46(12):5283–5288

Papadopoulos AN, Hill CAS, Gkaraveli A (2003) Determination of surface area and pore volume of holocellulose and chemically modified wood flour using the nitrogen adsorption technique. Holz als Roh Werkst 61:453–456

Pönni R, Vuorinen T, Kontturi E (2012) Proposed nano-scale coalescence of cellulose in chemical pulp fibers during technical treatments. BioResources 7(4):6077–6108

Riedlberger P, Weuster-Botz D (2012) New miniature stirred-tank bioreactors for parallel study of enzymatic biomass hydrolysis. Bioresour Technol 106:138–146

Robert P, Marquis M, Barron C, Guillon F, Saulnier L (2005) FT-IR investigation of cell wall polysaccharides from cereal grains. Arabinoxylan infrared assignment. J Agric Food Chem 53(18):7014–7018

Roche CM, Dibble CJ, Knutsen JS, Stickel JJ, Liberatore MW (2009) Particle concentration and yield stress of biomass slurries during enzymatic hydrolysis at high-solids loadings. Biotechnol Bioeng 104(2):290–300

Scallan AM (1983) The effect of acidic groups on the swelling of pulps: a review. Tappi J 72(11):157–162

Scallan AM, Carles JE (1972) Correlation of water retention value with fiber saturation point. Sven Papperstid 75(17):699–703

Scallan AM, Tigerström AC (1992) Swelling and elasticity of the cell walls of pulp fibers. J Pulp Paper Sci 18(5):J188–J193

Selig MJ, Viamajala S, Decker SR, Tucker MP, Himmel ME, Vinzant TB (2007) Deposition of lignin droplets produced during dilute acid pretreatment of maize stems retards enzymatic hydrolysis of cellulose. Biotechnol Prog 23(6):1333–1339

Selig M, Vinzant T, Himmel M, Decker S (2009) The effect of lignin removal by alkaline peroxide pretreatment on the susceptibility of corn stover to purified cellulolytic and xylanolytic enzymes. Appl Biochem Biotechnol 155(1–3):94–103

Selig M, Thygesen L, Johnson D, Himmel M, Felby C, Mittal A (2013) Hydration and saccharification of cellulose Iβ, II and III at increasing dry solids loadings. Biotechnol Lett 35(10):1599–1607

Sun XF, Sun RC, Su YQ, Sun JX (2004) Comparative study of crude and purified cellulose from wheat straw. J Agric Food Chem 52(4):839–847

Thompson DN, Chen H-C, Grethlein HE (1992) Comparison of pretreatment methods on the basis of available surface area. Bioresour Technol 39(2):155–163

Topgaard D, Söderman O (2001) Diffusion of water absorbed in cellulose fibers studied with 1H-NMR. Langmuir 17(9):2694–2702

Tu M, Pan X, Saddler JN (2009) Adsorption of cellulase on cellulolytic enzyme lignin from lodgepole pine. J Agric Food Chem 57(17):7771–7778

Wang QQ, He Z, Zhu Z, Zhang YHP, Ni Y, Luo XL, Zhu JY (2012) Evaluations of cellulose accessibilities of lignocelluloses by solute exclusion and protein adsorption techniques. Biotechnol Bioeng 109(2):381–389

Weber CW, Kohlhepp EA, Idouraine A, Ochoa LJ (1993) Binding-capacity of 18 fiber sources for calcium. J Agric Food Chem 41(11):1931–1935

Wei C-J, Cheng C-Y (1985) Effect of hydrogen peroxide pretreatment on the structural features and the enzymatic hydrolysis of rice straw. Biotechnol Bioeng 27(10):1418–1426

Wilson JR, Mertens DR, Hatfield RD (1993) Isolates of cell types from sorghum stems: digestion, cell wall and anatomical characteristics. J Sci Food Agric 63(4):407–417

Wrigstedt P, Kylli P, Pitkanen L, Nousiainen P, Tenkanen M, Sipila J (2010) Synthesis and antioxidant activity of hydroxycinnamic acid xylan esters. J Agric Food Chem 58(11):6937–6943

Yu Z, Jameel H, Chang H-m, Park S (2011) The effect of delignification of forest biomass on enzymatic hydrolysis. Bioresour Technol 102(19):9083–9089

Zanutti MA (1997) Factors determining the quality of bagasse mechanical pulps. Cellul Chem Technol 31(5–6):381–390

Zeng M, Ximenes E, Ladisch MR, Mosier NS, Vermerris W, Huang C-P, Sherman DM (2012) Tissue-specific biomass recalcitrance in corn stover pretreated with liquid hot-water: enzymatic hydrolysis (part 1). Biotechnol Bioeng 109(2):390–397

Acknowledgments

This work was funded by the DOE Great Lakes Bioenergy Research Center (DOE BER Office of Science DE-FC02-07ER64494). The authors are grateful to Robert and Brady Carter at Decagon Devices (Pullman, WA, USA) for performing DVS on samples. Natasse Christides and Genevieve Gagnier provided laboratory assistance and were supported by an NSF Due Grant (#0757020).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Williams, D.L., Hodge, D.B. Impacts of delignification and hot water pretreatment on the water induced cell wall swelling behavior of grasses and its relation to cellulolytic enzyme hydrolysis and binding. Cellulose 21, 221–235 (2014). https://doi.org/10.1007/s10570-013-0149-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-0149-3