Abstract

Pretreatment of corn stover with alkaline peroxide (AP) at pH 11.5 resulted in reduction of lignin content in the residual solids as a function of increasing batch temperature. Scanning electron microscopy of these materials revealed notably more textured surfaces on the plant cell walls as a result of the delignifying pretreatment. As expected, digestion of the delignified samples with commercial cellulase preparations showed an inverse relationship between the content of lignin present in the residual solids after pretreatment and the extent of both glucan and xylan conversion achievable. Digestions with purified enzymes revealed that decreased lignin content in the pretreated solids did not significantly impact the extent of glucan conversion achievable by cellulases alone. Not until purified xylanolytic activities were included with the cellulases were significant improvements in glucan conversion realized. In addition, an inverse relationship was observed between lignin content after pretreatment and the extent of xylan conversion achievable in a 24-h period with the xylanolytic enzymes in the absence of the cellulases. This observation, coupled with the direct relationship between enzymatic xylan and glucan conversion observed in a number of cases, suggests that the presence of lignins may not directly occlude cellulose present in lignocelluloses but rather impact cellulase action indirectly by its association with xylan.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Increased demand worldwide for alternative biomass-derived fuels to reduce nations’ dependence on the currently volatile petroleum market has created renewed scientific enthusiasm over plant cell wall structure and investigation into the most efficient manner by which sugars can be extracted for fermentation processes. An emerging fundamental aspect of this conversion process is the need for a strong understanding of plant cell wall complexity; a major component in the natural recalcitrance of biomass. Lignin and xylan components of the cell wall matrix are key targets for removal in order to improve the accessibility of the cellulosic fraction to cellulase enzymes [1]. Commercially available fungal cellulase preparations, often used in research today, typically contain a number of cellulolytic, xylanolytic, and other hemicellulolytic enzyme activities working in concert [2]; this can make it difficult to determine how the removal of a specific cell wall fraction alters the saccharification of the residual structural carbohydrates. A number of different pretreatment chemistries have been studied to target these key cell wall components prior to enzymatic hydrolysis. Traditionally, xylan has been targeted with high temperature and neutral to acidic chemistries, whereas alkaline chemistries have often been utilized to remove lignin present in cell wall substrates [3].

Among pretreatments, alkaline peroxide (AP) has long been used as an environmentally favorable method for paper pulp bleaching. Used in conjunction with stabilizers, this chemistry effectively bleaches pulps without removing lignins. Without these stabilizers, hydrogen peroxide dissociates into the highly reactive oxygen species, superoxide and hydroxyl radical (Eqs. 1 and 2); the reactions are shown below as previously described by Gould and co-workers [4, 5].

The oxidative action of the H2O2-derived radicals is thought to contribute to the depolymerization of lignin by attacking lignin side chains and fragmenting the lignin macrostructure into a number of low-molecular-weight compounds [5, 6]. Sun and co-workers have noted that a number of chemical changes occur in biomass as a result of such pretreatment; these include the reduction of esterified acetic, ferulic, and ρ-coumaric acids as well as significant cleavage of ether linkages between ferulic acid and lignin. They found that the hemicelluloses in alkaline-peroxide-pretreated samples were relatively unassociated with lignin, whereas the “macromolecular” structure of the hemicellulose itself remained relatively unchanged [7, 8]. In addition, Gould and co-workers [5] concluded that an increase in water absorbency in wheat straw following AP treatment suggests a decrease in the proportion of crystalline cellulose present; in contrast, later work by Sun and co-workers [8] concluded that AP treatment “did not cause any significant changes in the macromolecular structure of the cellulose”.

In this study, we have utilized purified cell wall hydrolyzing enzymes to investigate the role of lignin removal in improving enzyme access to the lignocellulosic matrix. Using individual and combinations of specific enzyme activities, we have investigated the effect of lignin removal by AP treatment on the ability of individual cellulases and xylanases to hydrolyze their respective target substrates. In taking this simplified approach, we were able to identify which activities are most affected by the removal of lignin. The goal is to better understand how the presence of this specific cell wall polymer is linked to the effectiveness of traditional fungal cellulase preparations.

Materials and Methods

Corn Stover

Whole corn stover was harvested in the fall of 2004 at the Kramer farm in Wray, CO, USA. All stover used in this study was milled to a one-fourth-inch screen size in a Thomas-Wiley (Thomas Scientific, Swedesboro, NJ, USA) cutting mill.

Pretreatments

AP pretreatments of corn stover were carried out in 1,000-mL glass bottles at 4% dry matter. Pretreatment was initiated by adding 30% (w/w) hydrogen peroxide to achieve a 1% (w/w) solution and the pH was then adjusted to pH 11.5 with 10 M sodium hydroxide. All treatments were run for 3 h with constant agitation via orbital shaking. Pretreatments were carried out at 25, 37, 50, and 65 °C under the same conditions in order to obtain a series of samples with progressively lower lignin contents in the residual solids. Following pretreatment, the solids were thoroughly washed with distilled water.

Analysis of Pretreated Materials

All pretreated samples were analyzed for structural carbohydrates, lignin, and ash by two-stage sulfuric acid hydrolysis according to the National Renewable Energy Laboratory’s Laboratory Analytical Procedure for Determination of structural carbohydrates and lignin in biomass [9].

Enzymes

Spezyme CP from Genencor International (a Danisco Division, Copenhagen, Denmark) was used as the commercial Trichoderma reesei cellulase preparation, which was augmented with an additional cellobiase (CB) preparation, Novozyme 188 (Aspergillus niger), from Novozymes A/S (Bagsværd, Denmark) to reduce cellulase end product inhibition by cellobiose. The purified enzyme activities utilized in this study include a cellobiohydrolase, Cel7A, from T. reesei; a cellobiose-specific β-glucosidase from A. niger; an endoglucanase, Cel5A, from Acidothermus cellulolyticus; an endoxylanase, XynA, from Thermomyces lanuginosus; and a beta-xylosidase, XlnD, from A. niger. The Cel7A, XynA, and cellobiase activities were purified from commercial enzyme preparations as previously described [10, 11]. The beta-xylosidase was expressed in Aspergillus awamori according to methods described by Adney and co-workers [12] and then purified from the fermentation broth as previously described [13]. The endoxylanase was expressed in Streptomyces lividans and then purified as previously described [14]. All purified proteins were stored at −80 °C in 20 mM sodium acetate buffer at pH 5.0 with 100 mM NaCl.

Enzyme Digestions

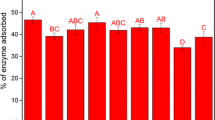

Enzymatic digestions in this study were run for 24 or 120 h at 50 °C in 50 mM citrate buffer at pH 4.8. All pretreated substrates were initially digested with Spezyme CP loaded at 15 mg/g cellulose plus 5 mg/g cellulose of Novozyme 188. Digestions with the cellobiohydrolase, Cel7A, were carried out at protein loadings of 15 and 35 mg/g cellulose. Purified endoglucanase (Cel5A) and cellobiase were loaded at 2.5 mg/g cellulose when included. Digestions with purified endoxylanase (XynA) and beta-xylosidase (XlnD) were loaded at 5 mg protein per gram of xylan for each protein included. To determine accurate protein loadings, the protein contents of each enzyme preparation were determine by the Pierce BCA protein assay protocol using bovine serum albumin as the standard; all commercial protein preparations were desalted into an appropriate buffer prior to analysis. Digestions focused on monitoring cellulose conversion were run at solids loadings that equated to a 1% (w/v) glucan concentration, whereas those digestions monitoring xylan conversion were run at solids loadings that equated to a 0.5% (w/v) xylan concentration. All digestions were run with a total reaction volume of 1 mL in 1.5-mL Eppendorf tubes mixed by continuous inversion on a horizontal rotator. Triplicate digestions were run for all conditions.

HPLC Analysis

All digestion samples were filtered through a 0.45-μm syringe filter prior to analysis for simple sugars by high-performance liquid chromatography (HPLC). Sugar analysis was performed on a Jasco HPLC (Tokyo, Japan) utilizing a lead-based sugar analysis column (model SP0810) from Shodex (Kawasaki, Japan) operated at 80 °C. Ultrapure water was used as the eluent at a flow rate of 0.6 mL/min.

SEM Imaging

All scanning electron micrographs were acquired on a FEI (Hillsboro, OR, USA) Quanta 400 FEG instrument operated under high vacuum with an Everhart-Thornley Detector and a solid-state backscatter detector. Treated corn stover samples were prepared by lyophilization to eliminate potential structural distortion caused by the surface tension of liquid water during evaporation at atmospheric conditions. Lyophilized samples were mounted on aluminum stubs using carbon tape and sputter-coated with gold to a thickness of 20 nm using a Cressington (Watford, England) model 203 sputter coater. Imaging was performed at beam accelerating voltages ranging from 12.5 to 25 kV. Approximately 40 images from eight randomly selected regions on representative samples of both untreated and AP-treated corn stover were taken; from these sets, representative images were chosen at both ×5,000 and ×20,000 magnifications.

Results and Discussion

Alkaline Peroxide Pretreatments

Treatment with AP at pH 11.5 resulted in progressively reduced lignin and ash content of the residual corn stover solids as batch pretreatment temperature was increased (Table 1). At the highest pretreatment temperature tested (65 °C), the final lignin content dropped to 5.4% of the residual dry solids, indicating that a significant fraction of the lignin was removed. For the 25, 37, 50, and 65 °C pretreatments, the total solids recovery was 75.9%, 73.2%, 68.6%, and 62.8%, respectively; based on these data, the lignin values in Table 1 translate to respective lignin losses of 34.6%, 41.1%, 56.3%, and 78.6%. The relatively constant ratio of xylan in the residual solids shown in Table 1 also suggests that a small, although increasing, quantity (up to 17.6% at 65 °C) of xylan was removed from the corn stover as the pretreatment temperature increased; based on mass spectroscopy analysis of liquid fractions from similar pretreatments, we know that the xylan fraction released remains in a high molecular weight and highly branched oligomeric state (data not shown). In addition, a small fraction (∼10% or less) of the total glucose available in the untreated biomass was released in the form of glucose and small gluco-oligomers; whether these are from cellulose, xyloglucan, or residual starch is unclear. Despite these minor levels of glucan and xylan solubilization, it is apparent that the primary cell wall component affected by the AP pretreatment is lignin.

Scanning electron micrographs (Fig. 1) of the corn stem vascular bundles (removed from the bulk corn stover) before and after AP treatment at 50 °C show a rougher and generally more textured cell wall surface after the delignifying pretreatment. This observation is in agreement with that of Kristensen and co-workers who have shown that a similar change in surface texture occurs when lignocellulosic fibers from wheat straw are delignified by a sodium chlorite bleaching process following hydrothermal pretreatment [15]. From these images, one could speculate that the removal of lignin from the cell wall surface works to expose the structural carbohydrates that remain in the residual solid material after pretreatment, although further microscopy work is warranted.

Enzymatic Saccharification of Delignified Corn Stover

Hydrolysis of untreated and AP-treated corn stover samples with a commercial cellulase showed an inverse relationship between the starting lignin content prior to enzymatic hydrolysis and the final extent of both glucan and xylan conversion (Fig. 2). The extent of conversion describes the fraction of total glucan or xylan converted in that an extent of 1.0 indicates 100% conversion; extents were calculated based on the release of monomer glucose and xylose in all cases except for digestions using only cellobiohydrolase enzyme which were based on cellobiose release. This relationship between conversion and lignin content was relatively linear between the four AP-pretreated substrates (compared to the entire set including the untreated corn stover data points at 0.158 g/g biomass on the x-axis) and was observed at 120 h (data not shown) in addition to that shown for 24 h in Fig. 2. This result was expected and was in accordance with literature reports regarding lignin removal and its effect on the digestibility of lignocellulosic substrates. In particular, Yang and Wyman [16] made similar observations regarding the removal of lignin from corn stover using hot water and dilute acid pretreatment in a flow-through reactor.

Extent of glucan conversion in untreated and AP-pretreated corn stover after 24-h digestion at 50 °C, pH 4.8 with a 15 mg/g cellulose loading of Spezyme CP and a 5 mg/g cellulose loading of Novo 188. Values are plotted against the starting lignin content of the material prior to enzymatic digestion. Error bars represent the standard deviation between triplicate digestions

To properly understand how the removal of lignin results in the improvements in enzymatic hydrolysis shown in Fig. 2, similar digestions were run using purified cell-wall-hydrolyzing enzymes. At first, digestions were conducted with a purified cellobiohydrolase, Cel7A, the primary component of commercial T. reesei cellulase preparations, at the same protein loading that was used for the commercial enzyme preparation (15 mg/g cellulose) as well as a higher loading (35 mg/g cellulose). Figure 3 shows that the decreasing lignin content of the pretreated material had little impact on the capacity for the cellobiohydrolase to convert glucan present in the substrates, which is in contrast to what was observed with the whole fungal cellulase preparation. Furthermore, controls run with the addition of a purified cellobiase to prevent end product inhibition showed an identical result, indicating that this observation was not an effect of end product inhibition on the cellobiohydrolase (data not shown).

Extent of glucan conversion in untreated and AP-pretreated corn stover after 24-h digestion with two loadings of Cel7A at 50 °C, pH 4.8. Values are plotted against the starting lignin content of the material prior to enzymatic digestion. Error bars represent the standard deviation between triplicate digestions

Digestions with the addition of Cel5A and cellobiase to the lower loading of Cel7A are plotted in Fig. 4a. Despite conversion being slightly higher than the Cel7A only experiments, digestion with the more complete enzyme mixture resulted in similarly mild, and diminishing, improvements in the extent of glucan conversion in accordance with lignin content reduction. Not until purified xylanolytic enzymes were added to the digestion mix were considerable improvements in glucan conversion observed. This observation is in agreement with previous work where we have shown that the addition of xylanolytic enzymes generally enhances the performance of cellobiohydrolases on pretreated lignocellulosic biomass [10, 13]. Additionally, it should be noted from Fig. 4a that, whereas the effects of lignin removal taper off when the material is digested with the simplified cellulase mix (described above), the improvement in conversion with respect to decreasing starting lignin content is more pronounced when the xylanolytic enzymes are present.

a Extent of glucan conversion in untreated and AP-pretreated corn stover after 24-h digestion at 50 °C, pH 4.8 with a 15 mg/g cellulose loading of Cel7A in addition to smaller loadings of purified Cel5A and cellobiase. Twenty-four digestion with this mix in addition to loadings of XynA and XlnD is also plotted. b Extent of xylan conversion in untreated and AP-pretreated corn stover after 24-h digestion at 50 °C, pH 4.8 with 5 mg/g xylan loadings of the purified xylanolytic enzymes by themselves and in addition to purified cellulase enzymes. All data points represent the conversion of glucan or xylan present in the untreated and residual pretreated solids and are plotted against the starting lignin content of the material prior to enzymatic digestion. Error bars represent the standard deviation between triplicate digestions

When delignified corn stover samples were digested solely with purified endoxylanase and beta-xylosidase, a dramatic improvement in the extent of xylan conversion was observed as the starting lignin content of the substrates was decreased. As shown in Fig. 4b, a strong inverse relationship exists between the extent of xylan hydrolysis achievable in 24 h and the lignin content of the corn stover prior to enzymatic digestion, improving from approximately 5% with the unpretreated material to almost 50% conversion with the most delignified corn stover sample. These data provide strong evidence that lignin in biomass directly occludes the xylan component in the cell wall from enzymatic hydrolysis.

The digestion data described above suggest that lignin removal has a direct impact on enzymatic xylan hydrolysis with subsequent xylan removal affecting cellulase accessibility to the cellulose. Minimal levels (e.g., no more than 17%) of glucan conversion were achieved by the cellulase-only mixes even when the lignin content of the material had been significantly reduced. Although in some cases there were diminishing improvements in glucan conversion with respect to reduced lignin content, it is difficult to say whether those improvements were related to the reduction in lignin content or related to the small amounts of xylan also removed during the varied pretreatments. The considerable increase in glucan conversion observed by addition of xylanolytic enzymes to the purified cellulase mix gives us an indication that the xylan in cell walls more directly limits enzymatic access to the cellulose than lignins do.

Plotting the extent of glucan conversion against the extent of xylan conversion achieved by the cellulase/xylanase mix on the alkaline-treated substrates clearly demonstrates a linear relationship (Fig. 5). A linear correlation can also be shown for glucan and xylan conversions achieved by the commercial cellulase preparation, although the slope of the relationship is different. The difference in these slopes may be associated with the types of xylan and/or glucan that can be hydrolyzed with the simplified enzyme mix versus that hydrolyzable by a more complete enzymatic system. Additionally, we reported a similar relationship in our previous work with hot-water-pretreated corn stover [10]. This line of evidence, along with the observation that the xylan component in the AP-treated corn stover is much more easily hydrolyzed by xylanolytic enzymes independent of cellulase enzyme than the cellulose is by cellulases independent of xylanolytic enzymes, is a strong indication that the xylan fraction more directly occludes the cellulose. Moreover, it could be stated that the lignin in such substrates only has an indirect impact on cellulose accessibility as a consequence of its more direct association with the xylan present in the plant cell wall.

Extent of glucan conversion in AP-pretreated corn stover plotted against the extent of xylan conversion after 24-h digestion at 50 °C, pH 4.8 with the Spezyme CP/Novo 188 mix and the mix of purified cellulase/xylanase enzymes. Values represent conversions of glucan and xylan present in the residual pretreated solids. Error bars represent the standard deviation between triplicate digestions

Summary

Running identical AP pretreatments at varying temperatures resulted in a series of progressively delignified corn stover samples. The effect of the alkaline treatment appears to expose the mesh of macrofibers on the cell wall surface and in doing so improves the overall extent to which the structural carbohydrates in the corn stover can be converted to simple sugars by a commercial cellulase preparation. Whereas the removal of lignin directly correlated to improved conversions by a “whole” commercial cellulase preparation, a similar trend was not observed when the material was digested with individually purified cellulase enzymes. These data suggest that the removal of lignin does not directly reveal the bulk of the cellulose present in the corn stover. Rather, the occlusion of cellulose by lignin appears to be more of an indirect effect linked to what was observed to be a direct association between the xylan and lignin components in the plant cell wall. It could further be hypothesized that as chemical treatments remove and/or relocate lignins in biomass, as we have previously suggested [17], the xylan becomes more readily accessible to enzymatic or chemical attacks which can work to expose the occluded cellulose surface.

References

Kohlmann, K. L., et al. (1996). Advances in Space Research, 18, 251–265. doi:10.1016/0273-1177(95)00815-V.

Zhang, Y. H., & Lynd, L. R. (2006). Biotechnology and Bioengineering, 94, 888–898. doi:10.1002/bit.20906.

Wyman, C. E., et al. (2005). Bioresource Technology, 96, 2026–2032. doi:10.1016/j.biortech.2005.01.018.

Gould, J. M. (1984). Biotechnology and Bioengineering, 26, 46–52. doi:10.1002/bit.260260110.

Gould, J. M. (1985). Biotechnology and Bioengineering, 27, 225–231. doi:10.1002/bit.260270303.

Lachenal, D., & Papadopoulos, J. (1988). Cellulose Chemistry and Technology, 22, 537–546.

Sun, J. X., et al. (2004). Journal of Wood Chemistry and Technology, 24, 239–262. doi:10.1081/WCT-200038170.

Sun, R. C., et al. (2001). Journal of Applied Polymer Science, 79, 719–732. doi:10.1002/1097-4628(20010124)79:4<719::AID-APP170>3.0.CO;2-3.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., & Templeton, D. (2004) Determination of structural carbohydrates and lignin in biomass. DOE, National Renewable Energy Laboratory.

Selig, M. J., et al. (2008). Bioresource Technology, 99, 4997–5005. doi:10.1016/j.biortech.2007.09.064.

Himmel, M. E., et al. (1993). Applied Biochemistry and Biotechnology, 39, 213–225. doi:10.1007/BF02918991.

Adney, W. S., et al. (2003). Applications of enzymes to lignocellulosics, (pp. 403–437). Washington: American Chemical Society.

Selig, M. J., et al. (2008). Applied Biochemistry and Biotechnology, 146, 57–68. doi:10.1007/s12010-007-8069-z.

Sakon, J., et al. (1996). Biochemistry, 35, 10648–10660. doi:10.1021/bi9604439.

Kristensen, J. B., et al. (2008). Biotechnology for Biofuels, 1, 1–9. doi:10.1186/1754-6834-1-5.

Yang, B., & Wyman, C. E. (2004). Biotechnology and Bioengineering, 86, 88–95. doi:10.1002/bit.20043.

Selig, M. J., et al. (2007). Biotechnology Progress, 23, 1333–1339. doi:10.1021/bp0702018.

Acknowledgment

This work was supported by the DOE Office of the Biomass Program. This work was supported by the US Department of Energy under contract no. DE-AC36-99GO10337 with the National Renewable Energy Laboratory.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Selig, M.J., Vinzant, T.B., Himmel, M.E. et al. The Effect of Lignin Removal by Alkaline Peroxide Pretreatment on the Susceptibility of Corn Stover to Purified Cellulolytic and Xylanolytic Enzymes. Appl Biochem Biotechnol 155, 94–103 (2009). https://doi.org/10.1007/s12010-008-8511-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8511-x