Abstract

This study revealed that cellulose enzymatic saccharification response curves of lignocellulosic substrates were very different from those of pure cellulosic substrates in terms of optimal pH and pH operating window. The maximal enzymatic cellulose saccharification of lignocellulosic substrates occurs at substrate suspension pH 5.2–6.2, not between pH 4.8 and 5.0 as exclusively used in literature using T. reesi cellulase. Two commercial cellulase enzyme cocktails, Celluclast 1.5L and CTec2 both from Novozymes, were evaluated over a wide range of pH. The optimal ranges of measured suspension pH of 5.2–5.7 for Celluclast 1.5L and 5.5–6.2 for CTec2 were obtained using six lignocellulosic substrates produced by dilute acid, alkaline, and two sulfite pretreatments to overcome recalcitrance of lignocelluloses (SPORL) pretreatments using both a softwood and a hardwood. Furthermore, cellulose saccharification efficiency of a SPORL-pretreated lodgepole pine substrate showed a very steep increase between pH 4.7 and 5.2. Saccharification efficiency can be increased by 80 % at cellulase loading of 11.3 FPU/g glucan, i.e., from approximately 43 to 78 % simply by increasing the substrate suspension pH from 4.7 to 5.2 (buffer solution pH from 4.8 to 5.5) using Celluclast 1.5L, or by 70 % from approximately 51 to 87 % when substrate suspension pH is increased from 4.9 to 6.2 (buffer solution pH from 5.0 to 6.5) using CTec2. The enzymatic cellulose saccharification response to pH is correlated to the degree of substrate lignin sulfonation. The difference in pH-induced lignin surface charge, and therefore surface hydrophilicity and lignin–cellulase electrostatic interactions, among different substrates with different lignin content and structure is responsible for the reported different enhancements in lignocellulose saccharification at elevated pH.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lignocelluloses are the most abundant polymeric carbohydrates in the world that could be used for sustainable biofuel production [1, 2]. The efficient bioconversion of lignocellulosic feedstock to cellulosic biofuel via the sugar platform involves three key steps: feedstock pretreatment, enzymatic saccharification, and fermentation or catalytic conversion of sugars. Enzymatic saccharification has been identified as one of the most costly steps in cellulosic biofuel production [3, 4]. Almost all reported studies on enzymatic hydrolysis of cellulose or lignocelluloses using commercial Trichoderma reesi cellulase were conducted at pH 4.8 and at 5.0 for CTec2 (a new commercial enzyme cocktail by Novozymes) with temperatures near 50 °C. These conditions were selected based on laboratory studies of enzyme activities using controlled substrates, i.e., pure cellulose (Product Sheet Celluclast 1.5L, Novozymes). Furthermore, enzyme activities were found to be maximized and fairly flat within a pH range between 4.5 and 5.0 and decrease outside of this pH range.

Limited studies were carried out on optimizing enzymatic hydrolysis conditions using lignocellulosic substrates for a given cellulase cocktail although studies on optimizing enzyme formulation for a given substrate have been reported [5, 6]. Consequently, the optimal pH based on cellulase activity measurements in the laboratories of enzyme manufacturers, using standard cellulose substrates, was used as given in almost all published studies of enzymatic hydrolysis of lignocelluloses. In fact the standard laboratory protocols developed by the US National Renewable Energy Laboratory specifically outline using pH 4.8 buffer to conduct separate and simultaneous enzymatic hydrolysis and fermentation of lignocelluloses [7, 8].

Lignocelluloses are different from pure cellulose in terms of surface hydrophobic properties, the primary driving force to bind protein or cellulase [9, 10], due to the presence of lignin. Lignin is generally considered hydrophobic to result in nonspecific (nonproductive) binding to cellulase [11, 12]. However, lignin modification by increasing acid groups on lignin surface, such as sulfonic acid, carboxylic acid, and oxidative acid groups, can reduce lignin hydrophobicity and therefore nonproductive cellulase binding to facilitate enzymatic saccharification [13–15]. It is known that pH can affect substrate surface charge through surface functional groups to alter surface hydrophobicity. The pH-induced lignin surface charge may also affect electrostatic interactions between cellulase and lignin. The degrees of pH-induced surface charge are different between lignin and cellulose due to the difference in the type and amount of surface functional groups they possess. We hypothesize that the ratio of the amount of cellulase bound productively to cellulose to the amount bound nonproductively to lignin can vary with pH as a result. For a given lignocellulose with a specific lignin structure, we further hypothesize that there is an optimal pH range within which nonspecific cellulase binding to lignin is minimized to result in a net maximal productive cellulase binding to cellulose and therefore saccharification. This pH range may well be different from the optimal pH range for a pure cellulosic substrate that does not contain lignin.

The objective of the present study is to examine the effects of pH on enzymatic saccharification of lignocelluloses produced by four different pretreatment methods from both a softwood and a hardwood to indirectly verify the above proposed hypotheses. Preliminary verification of above proposed hypotheses on pH-induced surface charge to reduce nonproductive cellulase binding to lignin was also conducted. We demonstrated that the “optimal enzymatic hydrolysis pH range” for lignocellulosic substrates is different from that for pure cellulosic substrates, i.e., Whatman paper and bleached pulp, and that obtained from laboratory enzyme activity studies using controlled pure cellulosic substrates. Two commercial cellulase cocktails were examined though most of the experiments were conducted using the commercial enzymes Celluclast 1.5L and Novozyme 188 (Novozymes) before we received Cellic® CTec2 from Novozymes in late 2011.

Materials and Methods

Materials

Commercial enzymes Celluclast 1.5L, Novozyme 188 (β-glucosidase), and Cellic® CTec2 were generously provided by Novozymes North America (Franklinton, NC, USA). The cellulase activities were Celluclast 1.5L, 60 filter paper unit (FPU)/mL; CTec2, 150 FPU/mL; and Novozyme 188, 490 cellobiose unit (CBU)/mL as calibrated using a literature method [16]. Sodium acetate, sulfuric acid, and sodium bisulfite were used as received from Sigma-Aldrich (St. Louis, MO, USA). All chemicals were ACS reagent grade. One pure cellulosic substrate sample used is Whatman filter paper (grade 3, catalogue number 1003 150, Whatman International, UK) with specified ash content is 0.06 %. A second cellulosic substrate is a loblolly pine virgin bleached Kraft pulp (BKF-LbP).

Two-lodgepole pine trees, one killed by mountain pine beetle (Dendroctonus ponderosae), with an estimated infestation age of 4 years (abbreviated BD4), and one live (abbreviated FL), were harvested from the Canyon Lakes Ranger and Sulphur Ranger District, respectively, Arapaho–Roosevelt National Forest, Colorado as described previously [17, 18]. Fresh aspen (Populus tremuloides) wood logs were obtained from northern Wisconsin, USA [19]. All wood logs were shipped to the USDA Forest Products Laboratory, Madison, WI, USA, hand-debarked and then chipped using a laboratory chipper. The wood chips were then screened to remove all particles >38 mm and <6 mm in length. The thickness of the accepted chips ranged from 1 to 5 mm. The chips were kept frozen at a temperature of about –16 °C until used.

Substrate Production

A laboratory wood pulping digester of capacity of 23 L was used to conduct cooking or pretreatment as described in our previous studies [13, 19]. Several cooking or pretreatment experiments of different reaction chemistries were conducted using both the lodgepole pine and aspen. The digester was heated by a steam jacket and rotated at 2 rpm for mixing. The oven dry (od) weight of wood chips in each pretreatment was 2 kg. The pretreatment liquid to wood ratio (L/W) was kept at 3 (v/w). The chemical charges, reaction temperature, and duration of different reactions are listed in Table 1. The pretreated wood chips remained intact and were separated from the pretreatment hydrolysate (mainly a hemicellulosic sugar stream) by a screen. The pretreated wood chips were disk milled using plates with a D2B-505 pattern at a disk plate gap of 1.00 mm and adjusted to a refiner inlet consistency of 10 % with dilution water [19]. The energy consumption for disk milling was recorded as described elsewhere [20, 21]. The size-reduced solids were directly dewatered to a solids content of approximately 30 % by vacuum pressing in a canvas bag (acting as a prewash). To reduce the effects of remaining dissolved solids, acids, and ions, three lodgepole pine substrates were separately and thoroughly washed (Table 1) using 20 folds of water at 50 °C, in addition to the prewash. The yields of solid substrate after washing were then determined from the weight and moisture contents of the collected substrate. The chemical compositions of both the solid substrates along with the untreated wood chips were analyzed. The results are listed in Table 2.

Enzymatic Hydrolysis

Enzymatic hydrolysis was conducted using commercial enzymes at 2 % (w/v) insoluble substrate solids (w/v) in 50 mL of buffer solutions on a shaker/incubator (Thermo Fisher Scientific, Model 4450, Waltham, MA, USA) at 50 °C and 200 rpm. Acetate buffer solutions with different pH were used. Different ratios of sodium acetate and acetic acid varied pH values of the buffer solutions between 4.0 and 7.0. Most enzymatic hydrolysis experiments were conducted using a mixture of Celluclast 1.5L supplemented with Novozyme 188 (β-glucosidase). The loadings of Celluclast varied between 7.5 and 15 FPU/g glucan. The ratio of Novozyme 188 loading (in CBU) to Celluclast 1.5L loading (in FPU) was maintained at 1.5 for all experiments. A relatively new commercial cellulase cocktail CTec2 was also used in selected experiments. Selected hydrolysis experiments were carried out in duplicates to ensure experimental repeatability. Hydrolysates were sampled periodically for glucose concentration analysis. Each data point is the average of two replicates. The average relative standard deviation was approximately 2 %.

Analytical Methods

The chemical compositions of the original and pretreated biomass were analyzed by the Analytical and Microscopy Laboratory of the Forest Products Laboratory as described previously [18]. All lignocellulosic samples were Wiley milled (Model No. 2, Arthur Thomas Co, Philadelphia, PA, USA). The samples were milled to 20 mesh (~1 mm) and hydrolyzed in two stages using sulfuric acid of 72 % (v/v) at 30 °C for 1 h and 3.6 % (v/v) at 120 °C for 1 h. The hydrolysate supernatants and remaining solids are then filtered through a Gooch crucible lined with a 21-mm Whatman filter paper into a volumetric flask. The supernatant was used for carbohydrate analysis using high-performance anion exchange chromatography with pulsed amperometric detection [22]. Klason lignin (acid insoluble) retained on the filter paper was quantified gravimetrically after drying. For fast analysis, glucose in the enzymatic hydrolysates were measured in duplicate using a commercial glucose analyzer (YSI 2700S, YSI Inc., Yellow Springs, OH, USA).

Sulfur Content Analysis

The sulfur contents of the substrates were analyzed using inductively coupled plasma (ICP) mass spectrometry. The solid substrate suspensions were shaken well before sampling. Aliquots of samples were digested at 145 °C for 15 min in a microwave (MDS-2000, CEM Corp., Matthews, NC, USA) with approximately 5 mL of HNO3 and 3 mL of 30 % H2O2 before ICP optical emission spectrometry analysis. The measured sulfur contents were then converted to sulfonic acid group based on the measured Klason lignin content of the substrates.

Cellulase Binding and Lignin Zeta-Potential Measurements

The amount of cellulase binding to a lignocellulosic substrate was measured using a UV-vis spectrophotometer (Model 8453, Agilent Technologies, Palo Alto, CA, USA). A spectral derivative procedure described in our previous study was employed to eliminate the interference of lignin on protein adsorption [23]. Cellualse binding was quantified by the amount of protein adsorbed on a substrate. A protein assay kit and bovine serum albumin were obtained from Bio-Rad Laboratories (Hercules, CA, USA) and used to calibrate cellulase protein concentration [24]. The protein concentration of CTec2 was 73.6 mg/mL.

The pH-induced surface charges of lignin were measured using a Zeta Potential Analyzer (Zeta Plus, Brookhaven, USA). Two sequential enzymatic hydrolysis steps were applied to SP-BD4 after excessive disk milling with overdose of CTec2 40 FPU/g substrate to produce hydrolysis lignin. The hydrolysis residue from each step was washed thoroughly using distilled water. The washed hydrolysis residue after second hydrolysis step was pretreated using excess Protease at 0.18 mg/g lignin (Pronase K 6556, 30 U/mg protein, Sigma Chemicals) in borax-CaCl2 buffer at 37 °C for 48 h to remove protein. The protease was deactivated by washing and heating in deionized water at 100 °C. The lignin is then dried and Wiley milled for use. Solutions of the final hydrolysis lignin SP-BD4 were prepared using acetate buffer of different pH between 4.5 and 6.0 at a fixed ratio of 1:3,000 (w/w). A 50-mL lignin solution was mixed on a shaker/incubator at 50 °C and 200 rpm for 120 min. After standing for another 60 min, an aliquot of the supernatant was poured into a cuvette. Each sample was analyzed twice, and each analysis was determined seven times. The average of all 14 measurements was presented. The standard deviations were used as error bars in plotting.

Results and Discussions

Comparisons Between the Measured Suspension pH and the pH of the Buffer Solutions

Because pH is a very important parameter in this study, the actual pH values of the substrate suspensions consist of the buffer solution and enzymes (either the Celluclast 1.5L + Novozymes 188 or CTec2) were measured at the beginning (0 h) and end (72 h) of enzymatic hydrolysis experiments (Table 3). Each pH value in Table 3 was average of two readings. The differences between two readings for all data were <0.05. The measured pH values of the suspensions at the beginning of enzymatic hydrolysis (0 h) were used in all data presentation to ensure the observed pH effect is real rather than artifacts. As listed in Table 3, the measured pH values in the enzymatic hydrolysis suspensions of different lignocellulosic substrates vary with the acidity or alkalinity of the substrates. pH reductions were observed in suspensions of substrates from acid based pretreatments (dilute acid and SPORL). pH increases were observed in enzymatic hydrolysis suspension of a kraft pulp (KP-FL).

Experimental Repeatability and Verification

Enzymatic hydrolysis experiments using a SPORL-pretreated lodgepople pine, SP-BD4, and a SPORL-pretreated aspen substrate, SP-AS, were conducted at different pH (buffer pH of 4.8, 5.5, and 6.5) in duplicate reactions. The measured time-dependent glucose concentrations in the enzymatic hydrolysates showed excellent repeatability (Fig. 1a–c). The measured pHs of the substrate suspensions of duplicate runs are shown in Fig. 1a–c. When a SPORL-pretreated lodgepole pine substrate, SP-BD4, was saccharified at cellulase loading of 11.3 FPU/g glucan, the terminal glucose concentration (72 h) increased approximately from 6.2 to 9.9 g/L, or by 60 %, when the measured suspension pH (0 h) was increased from approximately 4.67 to 5.13 (Fig. 1a). Similar gains in glucose concentration was also observed at cellulase loading of 15 FPU/g glucan, i.e., from 7.4 to 10.8 g/L, or by 46 % when the measured pH (0 h) was increased from 4.67 to 5.13 (Fig. 1b). When a SPORL-pretreated aspen substrate, SP-AS, was saccharified at cellulase loading of 7.5 FPU/g glucan, the gain in terminal (72 h) glucose concentration was also significant, i.e., from approximately 6.4 to 9.0 g/L, or by 40 %, when the measured pH was increased from 4.67 to 5.33 (Fig. 1c).

Experimental repeatability of time-dependent glucose concentrations in enzymatic hydrolysates of two pretreated lignocellulosic substrate using buffer solutions of different pHs. a SPORL-pretreated lodgepole pine (SP-BD4) with Celluclast 1.5L at 11.3 FPU/g glucan; b SPORL-pretreated lodgepole pine (SP-BD4) with Celluclast 1.5L at 15 FPU/g glucan; c SPORL-pretreated aspen with Celluclast 1.5L at 7.5 FPU/g glucan

To verify the validity of the experiments, enzymatic hydrolysis of a pure cellulose sample, commercial Whatman paper, was conducted using buffer solutions of different pH. The results show that the maximal substrate enzymatic digestibility (SED), defined as the percentage of glucan in the substrate enzymatically hydrolyzed to glucose, after 48 h hydrolysis, was achieved at pH 4.75 using a buffer solution pH of 4.8 (Fig. 2). This is in agreement with the Celluclast 1.5L data sheet provided by the manufacturer (Novozymes). Furthermore, the SED response curve is very flat in the range of measured suspension of pH 4.5–5.0.

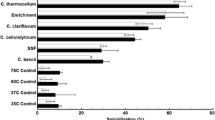

Effect of pH on Enzymatic Hydrolysis of Various Lodgepole Pine Substrates

Enzymatic hydrolysis of each of the three lodgepole pine substrates, produced from two SPORL pretreatments (SP-BD4 and SPH-FL) and one kraft pulping (KP-FL), were conducted in buffer solutions of different pH. The results clearly indicate that maximal SED at 48 h was achieved at measured pH of the suspension approximately 5.2 or higher for the three substrates rather than at 4.8 as suggested by Novozymes (Fig. 2). The optimal pH for the two lodgepole pine substrates produced by kraft pulping (KP-FL) and SPORL pretreatment using only bisulfite without acid (SPH-FL) was 5.5. More importantly, comparing the SED data of Whatman paper with those of three lodgepole pine substrates, the pH-operating windows to achieve good cellulose saccharification for the lodgepole pine substrates are broader, flatter, and shifted to a higher pH range of approximately 5.2–5.7 than 4.5–5.0 for Whatman paper. This suggests that lignin does affect optimal lignocellulosic saccharification pH operating window. One may argue the small difference in the optimal pH ranges between lignocellulosic and pure cellulosic substrates. However, the saccharification response curve to pH for a SPORL-pretreated lodgepole pine is very steep from pH 4.7 to 5.2 (Fig. 2), suggesting that a hydrolysis pH >5.2, such as 5.5, is preferred to achieve stable results. Using a commonly suggested hydrolysis pH of 4.8 can cause significant reduction in cellulose saccharification. Thus, the difference in pH between the optimal value of 5.5 and commonly used value of 4.8 is 0.7 that is quite significant. The steep response to pH explains the significant improvement in SED shown in Fig. 1a and b when pH was increased from 4.76 to 5.13.

The SED of SP-BD4, produced by SPORL with sodium bisulfite and sulfuric acid (initial pretreatment liquor pH of approximately 2.0), was increased rapidly when the pH was increased to 5.2, then decreased very slowly. The SED at 48 h was increased from 43 to 78 %, or by 80 %, when the pH was increased from 4.7 (buffer pH 4.8) to 5.2 (buffer pH 5.5). This is in agreement with the measured time-dependent glucose concentrations in the enzymatic hydrolysates (Fig. 1a, b).

For substrates KF-FL produced by kraft pulping (alkaline process) and SPH-FL produced by SPORL using sodium bisulfite alone without sulfuric acid (Table 1), the effect of increased pH on gains in SED though was less significant but important to the broad implications of the present study. The increase in SED at 48 h is approximately of 10 and 20 % for KF-FL and SPH-FL, respectively. Furthermore, the results clearly indicate that pH 4.8 is not optimal and is at the edge of the flat region of the SED response curves of these two lodgepole pine substrates (Fig. 2). Using suspension pH 5.5 is preferred to achieve a high and stable result in enzymatic saccharification for all of the three lodgepole pine substrates.

Effect of pH on Enzymatic Hydrolysis of Various Aspen Substrates

Enzymatic hydrolysis of each of the three aspen pine substrates produced from dilute acid (DA) and SPORL with and without sulfuric acid was conducted under different suspension pH. The maximal SED at 48 h was achieved at approximately at pH 5.3 for all of the aspen substrates tested (Fig. 3). Again, the results indicate the clear difference in the pH response curve and optimal pH between all aspen substrates (lignocellulose) and Whatman paper (pure cellulose). The optimal pH was shifted from 4.8 for Whatman paper to 5.3 for the Aspen substrates. At Celluclast 1.5L loading of 7.5 FPU/g glucan, SEDs were increased from approximately 44, 48, and 46 % to 55, 54, and 48 % for the SP-AS, SPH-AS, and DA-AS, respectively (Fig. 3). While the increase in SED for the dilute acid substrate is only approximately by 5 %, the implication is significant as dilute acid pretreatment is most widely studied. Furthermore, yeast fermentation is more favorable at an elevated pH of around 5.5.

Effect of pH on Enzymatic Hydrolysis of Lignocelluloses at High Cellulose Conversion Efficiencies

It is much more interesting to have the similar pH effect observed in the previous section at near complete cellulose conversion. The relative and absolute gains in SED from increased suspension pH 4.67 (buffer pH 4.8) to 5.13 (buffer pH 5.5) for a SPORL-pretreated lodgepole pine substrate, SP-BD4, were significant even at a high Celluclast 1.5L loading of 15 FPU/glucan (Fig. 4). The SED at 72 h was increased from approximately 50 to 80 % and 60 to 90 %, or by approximately 60 and 50 % at Celluclast 1.5L loadings of 11.3 and 15 FPU/glucan, respectively. Using a softwood substrate almost identical to SP-BD4 produced using the same batch of lodgepole pine wood chips under the identical pretreatment conditions, we reported a Celluclast 1.5L loading of 24 FPU/g glucan (or 15 FPU/substrate) was required to achieve SED of 90 % after 72 h enzymatic hydrolysis previously [18]. This suggests a reduction of cellulase application by approximately 40 % simply by adjusting the pH of the buffer solution from 4.8 to 5.5 for this SPORL-pretreated lodgepole pine.

Effect of pH on Enzymatic Hydrolysis of Lignocelluloses using Commercial Cellulase CTec2

CTec2 was a relatively new commercial cellulase cocktail that also contains certain amount of hemicellulase. The difference in optimal pH for enzymatic saccharification between a pure cellulosic substrate and lignocellulosic substrates presented above using Celluclast 1.5 L was also clearly observed using CTec2. The optimal measured pH of the suspension at hydrolysis temperature 50 °C was at 6.0 or higher for the three lignocellulosic substrates tested (Fig. 5), while the optimal pH for the Whatman paper is around 4.5. For the SPORL-pretreated lodgepole pine substrate (SP-BD4), SED was increased from 51 to 87 %, or by approximately 70 %, when the suspension pH was increased from 4.9 to 6.2 (buffer solution, 5.0–6.5; Table 3). To verify the difference in pH effect on enzymatic hydrolysis between cellulose and lignocelluloses, enzymatic hydrolysis of a bleached kraft pulp of loblolly pine (BKF-LbP) was also conducted under different pH. BKF-LbP has lignin content of 0.1 % with glucan content of 80 % and total hemicellulose (xylan and mannan) content of 15 % (Table 2). The hydrolysis results clearly show that the optimal suspension pH is 4.5 (Fig. 5), same as that for the Whatman paper (Fig. 5). More importantly, the pH range to achieve high and stable enzymatic saccharification of the three lignocellulosic substrates (SP-BD4, SP-AS and DA-AS) was 5.5–6.2, which is higher than the range of 4.5–5.0 for the two pure cellulosic substrates (Whatman paper, BKP-LbP). This suggests that lignin plays a role. It supports our hypothesis that pH-induced lignin surface charge via certain lignin functional groups alters the surface hydrophilicity to reduce nonproductive cellulase binding to lignin.

Novozymes determined the optimal enzymatic hydrolysis temperature and pH using CTec2 between 45 and 50 °C and 5.0 and 5.5, respectively, using a dilute acid-pretreated corn stover (Application Sheet, Cellic® CTec2 and HTec2 Enzymes, Novozymes). Novozymes suggested conducting enzymatic hydrolysis of lignocelluloses at pH 5.0, lower than that reported in this study, based on the optimization study using dilute acid-pretreated corn stover.

Lignin Functional Groups, pH-Induced Surface Charge, and Total Cellulase Binding

Lignin surface functional groups play a significant role in dictating lignin surface hydrophobicity and therefore nonproductive binding of cellulase [14, 25]. Various functional groups in differently pretreated aspen and lodgepole pine lignocelluloses can be responsible for pH-induced surface charge to affect surface hydrophobicity and perhaps electrostatic interactions between lignin and cellulase. The results presented above indicate that the observed pH effect on SED is more pronounced for the SPORL-pretreated substrates than dilute acid and alkaline pretreated substrates and more pronounced for SPORL-pretreated lodgepole pine used a higher bisulfite loading than SPORL-pretreated aspen substrate used a lower bisulfite loading (Table 1), i.e., low degree of lignin sulfonation. This suggests that sulfonic acid groups present only in the lignin fraction of SPORL substrates may play an important or dominant role affecting substrate surface charge when pH changes. Although other factors or functional groups such as carboxylic acid groups may also affect saccharification [9, 14, 15], it is prudent to examine the relations between gains in SED from increasing pH and the sulfonic acid group content of the substrates to verify the role of sulfonic acid groups on enhancing saccharification when pH changes. A linear correlation between the gains in SED from increasing buffer solution pH from 4.8 to 5.5 and the sulfonic acid group content was obtained for the six lignocellulsic substrates examined (Fig. 6).

The pH-induced lignin surface charges were measured as expressed by zeta-potential for the lignin derived from enzymatic hydrolysis of a SPORL-pretreated lodgepole pine substrate, SP-BD4. The SP-BD4 showed the most significant pH effect on enzymatic saccharification (Figs. 2, 5, and 6). Negative surface charges were increased linearly with the increase in pH (Fig. 7). This verifies our hypothesis of pH-induced lignin surface charge to result in a hydrophilic lignin surface. Cellulase adsorption measurements indicate that the total amount of cellulase binding to SP-BD4 was decreased when pH was increased from 4.5 to 5.5 (Table 4), while cellulose saccharification of SP-BD4 was increased by approximately 400 % (Fig. 5). This suggests that the reduction in CTec2 binding to SP-BD4 is predominately contributed by the reduced nonproductive binding to lignin at elevated pH due to pH-induced lignin surface charge. Similar levels of reduction in cellulase binding at elevated pH were also observed for the other five substrates (Table 4).

Discussions

The observed significantly enhanced enzymatic saccharification of SPORL-pretreated substrate at an elevated pH can be explained using the pH-induced surface charge through the lignin sulfonic acid groups to result in a hydrophilic lignin surface and reduced nonproductive cellulase binding to lignin. The pH-induced surface charge may also affect the electrostatic interactions between lignin and cellulase to reduce nonspecific binding of cellulase to lignin. It is certainly possible that other functional groups can also response to pH change to alter surface hydrophobicity. From the selected substrates with and without sulfonic acid groups studied in the present investigation, it appears however that sulfonic acid groups have a stronger response to pH change than the other functional groups, such as carboxylic acid groups, to result in enhanced saccharification of lignocelluloses. Oxidative acid groups were found to be hydrophilic and can enhance enzymatic saccharification [14]. Future studies are warranted to evaluate pH effect on enzymatic saccharification of wet oxidation-pretreated substrates that contain a significant amount of oxidative acid groups.

The required suspension pH to achieve maximal cellulose conversion for the three lignocellulosic substrates tested is between 5.5 and 6.2 using CTec 2 (Fig. 5), which is higher than 5.2–5.7 using Celluclast 1.5L (Figs. 2 and 3) when the same cellulase loadings are used for a given substrate. This reflects the differences in the composition of the two enzyme formulations between Celluclast 1.5L and CTec2. It is known that different enzymes have different isoelectric point (pI) [26–28]; therefore, pH change can also affect electrostatic interactions between cellulase and substrate component such as lignin and cellulose [25]. As a result, the optimal pH for enzymatic saccharification of lignocelluloses varies with substrates as well as enzyme formulations as observed using Celluclast 1.5L and CTec2 in the present study.

Conclusions

This study revealed that the optimal pH ranges for achieving high and stable enzymatic saccharification efficiency of lignocellulosic substrates are different from those for pure cellulosic substrates using two commercial T. reesi cellulase cocktails. For the six substrates produced by dilute acid, alkaline, and two SPORL pretreatments using both a hardwood and a softwood, the optimal pH ranges of substrate suspension solution for enzymatic saccharification of lignocellulosic substrates are 5.2–5.7 using Celluclast 1.5L and 5.5–6.2 using CTec2, higher than 4.8–5.0 as commonly suggested by cellulase manufactures and used exclusively in almost all existing literature. Furthermore, the cellulose saccharification efficiency response curve to pH for a SPORL-pretreated lodgepole pine is very steep between pH 4.7 and 5.2. Using the suggested pH of 4.8 can result in significant reduction in saccharification efficiency. Enzymatic saccharification efficiency can be improved by over 70 % when hydrolysis suspension pH was increased from 4.7 to 5.2 or from 4.9 to 6.2 when using Celluclast 1.5L or CTec2, respectively.

The pH of lignocellulose suspensions during enzymatic hydrolysis vary with substrates due to nonideal buffering. We recommend suspension pH 5.2–6.2 to conduct enzymatic hydrolysis of all types of lignocelluloses treated by different methods or untreated. This broad recommendation is based on following: (1) Enzymatic hydrolysis efficiency for alkaline and dilute acid-pretreated substrates can be improved by 10–20 % simply by increasing substrate suspension pH from 4.8 to 5.2 when using Celluclast 1.5L; and (2) an elevated pH 5.5 or higher than currently suggested is also very favorable for yeast fermentation.

The differences in enzymatic saccharification response curve to pH between pure cellulosic and lignocellulosic substrates and among lignocellulosic substrates with different lignin structures are due to the variations in pH-induced surface charge of different substrates with different surface functional groups. This surface charge variation can produce different effects on hydrophobic/hydrophilic and perhaps electrostatic interactions between cellulase and lignin in reducing cellulase nonproductive binding to lignin and therefore enhancing saccharification among different substrates.

References

Goldemberg J (2007) Ethanol for a sustainable energy future. Science 315:808–810

Somerville C, Youngs H, Taylor C, Davis SC, Long SP (2010) Feedstocks for lignocellulosic biofuels. Science 329(5993):790–792

Lynd LR, Laser MS, Bransby D, Dale BE, Davison B, Hamilton R et al (2008) How biotech can transform biofuels. Nature biotechnology. Nat Biotechnol 26:169–172

Zhu JY, Zhuang XS (2012) Conceptual net energy output for biofuel production from lignocellulosic biomass through biorefining. Prog Energy Combust Sci 38(4):583–589

Gao D, Chundawat SPS, Krishnan C, Balan V, Dale BE (2010) Mixture optimization of six core glycosyl hydrolases for maximizing saccharification of ammonia fiber expansion (AFEX) pretreated corn stover. Bioresour Technol 101(8):2770–2781

Lin Z-X, Zhang H-M, Ji X-J, Chen J-W, Huang H (2011) Hydrolytic enzyme of cellulose for complex formulation applied research. Appl Biochem Biotechnol 164(1):23–33

Selig M, Weiss N, Ji Y (2008) Enzymatic Saccharification of Lignocellulosic Biomass. Laboratory Analytical Procedure (LAP), NREL/TP-510-42629

Dowe N, McMillan J (2001) SSF experimental protocols—lignocellulosic biomass hydrolysis and fermentation. Laboratory Analytical Procedure (LAP), NREL/TP-510-42630

Nakagame S, Chandra RP, Saddler JN (2011) The influence of lignin on the enzymatic hydrolysis of pretreated biomass substrates. In: Zhu JY, Zhang X, Pan XJ (eds) Sustainable production of fuels, chemicals, and fibers from forest biomass. American Chemical Society, Washington, pp 145–167

Norde W (1986) Adsorption of proteins from solution at the solid–liquid interface. Adv Colloid Interface Sci 25(C):267–340

Mansfield SD, Mooney C, Saddler JN (1999) Substrate and enzyme characteristics that limit cellulose hydrolysis. Biotechnol Prog 15:804–816

Sewalt VJH, Glasser WG, Beauchemin KA (1997) Lignin impact on fiber degradation.3. Reversal of inhibition of enzymatic hydrolysis by chemical modification of lignin and by additives. J Agric Food Chem 45(5):1823–1828

Zhu JY, Pan XJ, Wang GS, Gleisner R (2009) Sulfite pretreatment (SPORL) for robust enzymatic saccharification of spruce and red pine. Bioresour Technol 100(8):2411–2418

Kumar L, Chandra R, Saddler JN (2011) Influence of steam pretreatment severity on post-treatments used to enhance the enzymatic hydrolysis of pretreated softwoods at low enzyme loadings. Biotechnol Bioeng 108(10):2300–2311

Nakagame S, Chandra RP, Kadla JF, Saddler JN (2011) Enhancing the enzymatic hydrolysis of lignocellulosic biomass by increasing the carboxylic acid content of the associated lignin. Biotechnol Bioeng 108(3):538–548

Wood TM, Bhat M (1988) Methods for measuring cellulase activities. In: Colowick SP, Kaplan NO (eds) Methods in enzymology, vol 160. Academic, New York, pp 87–112, Biomass(Part a, Cellulose and Hemicellulose)

Zhu JY, Luo X, Tian S, Gleisner R, Negrone J, Horn E (2011) Efficient ethanol production from beetle-killed lodgepole pine using SPORL technology and Saccharomyces cerevisiae without detoxification. TAPPI J 10(5):9–18

Luo X, Gleisner R, Tian S, Negron J, Horn E, Pan XJ et al (2010) Evaluation of mountain beetle infested lodgepole pine for cellulosic ethanol production by SPORL pretreatment. Ind Eng Chem Res 49(17):8258–8266

Zhu JY, Gleisner R, Scott CT, Luo XL, Tian S (2011) High titer ethanol production from simultaneous enzymatic saccharification and fermentation of aspen at high solids: a comparison between SPORL and dilute acid pretreatments. Bioresour Technol 102(19):8921–8929

Zhu W, Zhu JY, Gleisner R, Pan XJ (2010) On energy consumption for size-reduction and yield from subsequent enzymatic sacchrification of pretreated lodgepole pine. Bioresour Technol 101(8):2782–2792

Zhu JY, Wang GS, Pan XJ, Gleisner R (2009) Specific surface to evaluate the efficiencies of milling and pretreatment of wood for enzymatic saccharification. Chem Eng Sci 64(3):474–485

Davis MW (1998) A rapid modified method for compositional carbohydrate analysis of lignocellulosics by high pH anion-exchange chromatography with pulsed amperometric detection (HPAEC/PAD). J Wood Chem Technol 18(2):235–352

Liu H, Zhu JY, Chai XS (2011) In situ, rapid, and temporally resolved measurements of cellulase adsorption onto lignocellulosic substrates by UV-vis spectrophotometry. Langmuir 27(1):272–278

Bradford M (1976) A rapid and sensitive for the quantitation of microgram quantitites of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1–2):248–254

Nakagame S, Chandra RP, Kadla JF, Saddler JN (2011) The isolation, characterization and effect of lignin isolated from steam pretreated Douglas-fir on the enzymatic hydrolysis of cellulose. Bioresour Technol 102(6):4507–4517

Chirico WJ, Brown RD Jr (1987) Purification and characterization of a β-glucosidase from Trichoderma reesei. Eur J Biochem 165(2):333–341

Medve J, Lee D, Tjerneld F (1998) Ion-exchange chromatographic purification and quantitative analysis of Trichoderma reesei cellulases cellobiohydrolase I, II and endoglucanase II by fast protein liquid chromatography. J Chromatogr A 808(1–2):153–165

Vinzant TB, Adney WS, Decker SR, Baker JO, Kinter MT, Sherman NE et al (2001) Fingerprinting Trichoderma reesei hydrolases in a commercial cellulase preparation. Appl Biochem Biotechnol A Enzym Eng Biotechnol 91–93:99–107

Acknowledgments

This work was partially supported by a USDA Small Business Innovative Research (SBIR) Phase II project (contract number 2010-33610-21589) to Biopulping International, Inc. The financial support from this project made the visiting appointment of Lan at the US Forest Service (USFS), Forest Products Laboratory (FPL) possible. We acknowledge Fred Matt and Kolby Hirth (both USFS-FPL) for carrying out the carbohydrate and sulfur content analyses, respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was conducted while Lan and Lou are visiting scientists at the US Forest Service, Forest Products Laboratory and on official government time of Zhu.

Rights and permissions

About this article

Cite this article

Lan, T.Q., Lou, H. & Zhu, J.Y. Enzymatic Saccharification of Lignocelluloses Should be Conducted at Elevated pH 5.2–6.2. Bioenerg. Res. 6, 476–485 (2013). https://doi.org/10.1007/s12155-012-9273-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-012-9273-4