Abstract

A novel quaternarized N-halamine precursor (3-chloro-2-hydroxypropyl)-(5, 5-dimethylhydantoinyl-1-ylmethyl)-dimethylammonium chloride (CDDAC), has been synthesized by a very facile two-step reaction. The two-step synthesis of CDDAC occurred at room temperature with common reactors, so the production of CDDAC could be easily enlarged to an industrial scale. Without any work-up, the final reaction solution which contained CDDAC could be directly used as grafting solution. CDDAC could be effectively grafted onto the surface of cellulose by a dehydrochlorination reaction. CDDAC grafted on cellulose was converted to N-halamine structure which showed powerful antimicrobial property by a chlorination reaction in the diluted NaClO solution. The antimicrobial tests showed that the chlorinated cellulose grafted with CDDAC was capable of 5-log inactivation of S. aureus and E. coli within 5 min. Also, the washing durability and storage stability of chlorinated cellulose grafted with CDDAC were investigated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Textile materials provide ideal media for kinds of microorganisms to grow and spread, and some bacteria can survive in polymer materials as long as 90 days (Slaughter et al. 1996). Contamination of textile materials by microorganisms can cause extensive transmission of infections and damage of the textile (Omar 2010). As the awareness of healthcare increasing and the global infectious disease events frequently happening, a wide range of research has been done to gain antibacterial textiles which could not only avoid discoloration and degradation of textiles by microorganisms (Phugare et al. 2011; Glenn and Gold 1983), but also effectively prevent the propagation of bacteria in textiles (Pi 2012; Zhang et al. 2012; Yeo et al. 2003).

A variety of functional groups such as metal ion metal oxide, quaternary ammonium salt, quaternary phosphonium salt, and N-halamine have been employed for biocidal purpose over the years. As a kind of traditional germicides, quarternary ammonium salts have been widely used to produce biocidal materials (Hazziza-Laskar et al. 1993; Yang et al. 2011; Jia et al. 2001; Korotkii et al. 2011; Weng et al. 2011). In the previous studies, much attention was paid to produce antibacterial textiles by using quarternary ammonium salts (Jung et al. 1998; Kotek et al. 2001). However, the antimicrobial efficacy of quarternary ammonium salts was relatively mild and the antimicrobial capability would reduce as the working time went on (Kim and Sun 2001).

Compared with some other germicides, N-halamine has been demonstrated to possess higher antimicrobial efficacy. N-halamines are useful biocidal treatment materials which have been applied to a variety of surfaces such as cellulose (Sun et al. 2001; Qian and Sun 2003; Liang et al. 2007; Ren et al. 2008), silica gel (Liang et al. 2006), paint (Cao and Sun 2009; Kocer et al. 2001), polystyrene (Worley and Chen 2005), polyethylene (Badrossamay and Sun 2009), and polyurethane (Tan and Obendorf 2007). The N-halamine precursors with reactive groups can be covalently bonded to the surface of cellulose since cellulose has abundant active hydroxyl groups on its surface. A kind of N-halamine precursor, hydantoinyl siloxane, was successfully grafted onto cellulose (Barnes et al. 2007), but the grafting solution contained organic solvent, ethanol. To avoid the use of organic solvents in grafting process, water-soluble N-halamine precursors are desirable. A water-soluble hydantoinyl epoxide, 3-glycidyl-5,5-dimethylhydantoin, was reported to prepare antimicrobial cotton fabrics (Liang et al. 2007), but the hydrophobicity on the surface of cotton fabrics might increase to cause the decrease of softness, which would limit its applications.

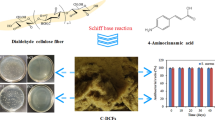

In this study, 1-(hydroxymethyl)-5,5-dimethylhydantoin was used as starting material to react with dimethylamine in 2-propanol and then epichlorohydrin in diluted HCl solution under room temperature to produce a novel water-soluble N-halamine precursor with quaternary ammonium salt group, (3-chloro-2-hydroxypropyl)-(5, 5-dimethylhydantoinyl-1-ylmehyl)-dimethylammonium chloride (CDDAC). The final reaction water solution was directly used to graft CDDAC onto the cellulose. After a convenient chlorination process, CDDAC grafted on cellulose was converted to N-halamine structure. The whole procedure was shown in Fig. 1. Apparently, the synthetic route is eco-friendly and energy-saved. More importantly, the two-step synthetic reaction happened at room temperature, so it could be easily enlarged for industrial application. It is reasonably thought that the coexistence of quaternary ammonium salt group and N-halamine group should lead to an enhancement of antimicrobial efficacy.

Experimental

Chemicals and reagents

The fabrics used were bleached 100 % Cotton Print Cloth (Shanghai Luyang Window Decoration Co., Ltd.). The bacteria employed were Staphylococcus aureus ATCC 6,538P (S. aureus) and Escherichia coli O157:H7 ATCC 11,229 (E. coli) which were obtained from Shanghai Institute of Materia Medica. The Trypticase soy agar used was purchased from Sinophram Chemical Reagent Co., Ltd. 1-(Hydroxymethyl)-5,5-dimethylhydantoin was purchased from Tokyo Chemical Indusry Co., Ltd. 33 % dimethylamine water solution was purchased from Shanghai SSS Reagent Co., Ltd. Epichlorohydrin was purchased from Shanghai Zhanyun Chemical Co., Ltd. Other chemicals were obtained from Shanghai Lingfeng Chemical Reagent Co., Ltd.

Instruments

The NMR spectra were obtained using Bruker Avance 400. The IR spectra were obtained using Mattson PK-60,000 infrared spectrometer. Elementary analysis was performed on Elementar Vario El III elementalanalyser. The MS spectra were obtained using Triple Quad LC/MS 6410B from Agilent.

Synthesis of (5,5-dimethylhydantoinyl-1-ylmethyl)-dimethylamine (DHDA)

15.82 g of 1-hydroxymethyl-5,5-dimethylhydantoin (0.10 mol) was added to 200 mL of 2-propanol in a 250 mL flask and stirred until completely dissolved and then 16.39 g of 33 % dimethylamine water solution (0.12 mol) was added. The mixture was kept stirring at 25 °C for 4 h. After the removal of 2-propanol, water, and unreacted dimethylamine, 18.44 g of crude DHDA product was gained. Yield was 98.24 %, calculated from the mass percentage of DHDA in the crude product obtained by using acid-base titration method. For characterization of DHDA, 2.00 g of crude DHDA product was dissolved in anhydrous acetone and anhydrous HCl gas was imported to precipitate DHDA hydrochloride. After filtration and drying, 2.32 g of white DHDA hydrochloride crystal was obtained, which exhibited the following properties: elemental analysis: found (calc) C8H1602N3Cl: C% 44.19 (43.34); H% 7.23 (7.27); N% 19.19 (18.95). IR (KBr): 3492, 3212, 2976, 1785, 1716, 1432, 1106, 776 cm−1. M/Z (MH+): 186.1; 1H-NMR (D2O-d2), δ: 1.40 (6H, -CH3), 2.70 (6H, N-CH3), 4.87 (2H, N-CH2-N).

Synthesis of (3-chloro-2-hydroxypropyl)-(5,5-dimethylhydantoinyl-1-ylmehyl)-dimethylammonium chloride (CDDAC)

18.52 g of crude DHDA product was added to 200 mL of 0.05 N HCl solution, then 9.25 g of epichlorohydrin (0.10 mol) was added after the solid was dissolved. The mixture was stirred at 25 °C for 6 h. Yield was 87.32 %, calculated from the moles of CDDAC in the reaction solution obtained by silver nitrate titration. The reaction solution can be directly used for grafting. After the removal of water, white oil crude CDDAC product was obtained. The CDDAC crystal was gained by dissolving crude CDDAC product in ethanol and then adding ether. The obtained CDDAC crystal exhibited the following properties: elemental analysis: found (calc) C11H2103N3Cl2: N% 13.26(13.37); C% 41.52(42.05); H% 6.91 (6.74). IR (KBr): 3095, 1784, 1720, 1487, 1297, 773,716 cm−1. M/Z: 278.1; 1H-NMR (D2O-d2): δ: 1.48 (6H, –CH3), 3.19 (6H, N-CH3), 3.60 (2H, N–CH2–C), 3.68 (2H, –CH2–Cl), 4.64 (1H, –CH–OH), 5.06 (2H, N–CH2–N).

Grafting procedures

The reaction solution of CDDAC was directly used for grafting. The original concentration of CDDAC in the reaction solution can be gained by the titration method. Water was added to adjust the concentration of CDDAC to 2.50 %. 10.00 g of cotton fabrics was soaked into 200 mL of 2.50 % CDDAC water solution for 15 min. The wet cotton fabrics were dried at 95 °C for 1 h, and further cured at 155 °C for 10 min. After the curing process, the fabrics were soaked in 0.5 % detergent solution for 15 min, washed with water, and dried at 70 °C in an oven for 2 h.

Chlorination and titration

10.00 g of the grafted cotton fabric was immersed in 200 mL of 0.10 % NaClO aqueous solution with pH adjusted to 7.50 for about 20 min. The chlorinated cotton fabrics were then rinsed 3 times in distilled water to remove unreacted free chlorine and then dried at 45 °C for 2 h. Regeneration of the antimicrobial function of the washed fabric samples was performed under the same conditions.

The percentage of oxidative chlorine (Cl+), which is covalently bonded to the imide nitrogen of CDDAC on the grafted cotton fabrics, was determined by a standard iodometric/thiosulfate titration procedure. A small cotton sample (about 0.40 g) was suspended in 50 mL of a 0.04 N sulfuric acid solution. After addition of 0.30 g of KI, and 0.40 mL of 0.50 % of starch water solution as an indicator, the solution was titrated with 0.01 N of sodium thiosulfate solution until the blue color disappeared at the end point. The percentage of oxidative chlorine in the cotton fabrics could then be calculated using the following equation

where N and V are the normality (eqv/L) and volume (L), respectively, of the Na2S2O3 consumed in the titration, and W is the weight in grams of the chlorinated cotton fabric sample.

Assessment of antimicrobial efficacy

The cotton fabrics were challenged with S. aureus and E. coli using a modified AATCC 100-199 Test Method (Ren et al. 2008). 25 μL of the bacterial suspensions (107 CFU/mL) buffered at pH = 7 were added to the center of two pieces of square cotton fabrics (0.3 g of untreated control, unchlorinated control, chlorinated cotton samples) which were held in place by sterile weights. After the contact time of 5 and 10 min, the various cotton samples were placed in sterile conical centrifuge tubes, each containing 9.50 mL of sterile phosphate buffer and 0.50 mL of sterile 0.05 M sodium thiosulfate to quench any oxidative free chlorine which might have been present, and vortexed for 250 s. Plates with serial dilutions of the vortexed quenched solutions on Trypticase soy agar were incubated at 37 °C for 24 h, and viable bacterial colonies were counted for biocidal efficacy analysis.

Washing durability and stability testing

For washing durability testing, 10.00 g of the cotton fabrics grafted with CDDAC was chlorinated and the initial oxidative chlorine (Cl+) percentage of the chlorinated cotton fabrics was measured by a standard iodometric/thiosulfate titration procedure. The chlorinated cotton fabrics were soaked in 0.50 % detergent solution for 15 min, rinsed five times with distilled water, and then dried at 45 °C for 2 h. The above washing process was repeated for 7 times. After each washing cycle, one small piece of chlorinated cotton fabrics was used to measure its Cl+ % and other small one was used to measure its Cl+ % after rechlorination.

For stability testing, the chlorinated cotton fabric grafted with CDDAC was stored at room temperature for a period of time to assess its oxidative chlorine (Cl+) stability.

Results and discussions

Synthesis of CDDAC

1-(Hydroxymethyl)-5,5-dimethylhydantoin is a commercially available N-halamine precursor with reactive hydroxymethyl group, which can react with dimethylamine to produce DHDA under room temperature (Thomas and Olivier 2006). It was found that 2-propanol was suitable solvent for this reaction. After the reaction was over, the solvent could be collected by evaporation for reuse. An acid–base titration method was used to determine the content of DHDA in the crude product. Under optimized conditions, the yield was up to 98 %. To get the chemical structure of DHDA, the crude DHDA product was dissolved in anhydrous acetone and anhydrous HCl gas was imported to precipitate pure DHDA hydrochloride. The structure of DHDA hydrochloride was confirmed by its mass spectrum, 1H NMR, and elementary analysis. Epichlorohydrin is a kind of common chemical reagent, which can react with tertiary amine to form quarternary ammonium salt (Mo 2010) and hydrochloric acid can open the epoxide ring to form chloro- and hydroxyl- substituted moieties (Sharif and Ahmad 2000; Deavenport and Lopez 1995). In this paper, a novel water-soluble quarternarized N-halamine precursor, CDDAC, was synthesized by a reaction between DHDA and epichlorohydrin in diluted HCl solution. The crude DHDA product was used without further purification due to its high yield. The moles of HCl participated in the reaction were the same as those of epichlorohydrin. After the reaction was over, pH value of reaction solution was close to 7 since all HCl was consumed. The yield of CDDAC could be achieved by silver nitrate titration method and was found to be very high (>85 %). For industrial applications, the final reaction water solution can be directly used without any work-up, so the cost of production is dramatically reduced. The synthetic route is facile, green, and energy-saved. After the removal of water, oil-like CDDAC crude product was obtained. As the oil-like CDDAC crude product was dissolved in ethanol and then ether was added, CDDAC crystals precipitated out. The structure of CDDAC was confirmed by its 1H-NMR spectrum, shown in Fig. 2.

Grafting CDDAC onto cotton fabrics

CDDAC can be covalently grafted onto the surface of cellulose by a dehydrochlorination reaction under heating. In order to prove this assumption, we adopted oxygen flask combustion method (Sakla and Abu-Taleb 1973) to measure the covalent chlorine content on the cotton fabric after grafted. The determination results showed that after grafted cotton fabric was rinsed with 0.50 % detergent solution, 0.001 mol/L NaOH, and then deionized water to remove any unreacted CDDAC and free chlorine ions, the covalent chlorine content of rinsed cotton grafted with CDDAC was zero. It means that the covalent chlorine of CDDAC reacted with the active hydroxyl group of cotton fabric to form HCl which went into air under heating or was washed off after grafting. In this paper, we adopted immersion-dry-cure process to covalently graft CDDAC onto the surface of cotton fabrics. Cotton fabrics were immersed in 2.50 % CDDAC water solution diluted from the final reaction solution of CDDAC. For grafting cellulose, the key parameter is curing temperature. After immersed for 15 min, the wet cotton fabrics were dried at 95 °C for 1 h, and further cured at different temperatures for 10 min.

After curing, 0.10 % NaClO aqueous solution was used to chlorinate the treated cotton fabrics to form antimicrobial quarternarized N-halamine on cellulose. The mass-on of CDDAC grafted onto cellulose can be estimated from the oxidative chlorine percentage (Cl+ %) on the cotton fabrics. Higher Cl+ % indicate more CDDAC grafted on the cotton fabrics. Figure 3 shows the effect of curing temperature on Cl+ % on the cotton fabrics. It is obvious that higher curing temperature leads to a higher Cl+ % on the cotton fabrics. However, too high curing temperature may lead to deterioration of cotton fabrics. Considering this factor, we chose 155 °C as optimized curing temperature. In fact, the Cl+ % of the grafted cellulose prepared from the curing temperature of 155 °C reached 0.23 %, which was enough to quickly kill harmful microorganisms. At 155 °C, the effect of curing time on Cl+ % on the cotton fabrics was tested, as shown in Fig. 4. It was found that the Cl+ % increased by approximately 60 %, from 0.13 to 0.21 %, when curing time changed from 5 to 10 min, whereas no obvious Cl+ % change occurred when the curing time was longer than 10 min.

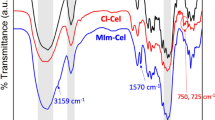

The effective grafting of CDDAC onto cellulose was also verified by FTIR spectra, as shown in Fig. 5. Compared to untreated cotton fabric, the treated one had new peaks at 1,712 and 1,783 cm−1 which were related to the C=O stretching vibration on the hydantoinyl ring of CDDAC (Sun et al. 2001; Cerkez et al. 2012). It clearly demonstrated that CDDAC was covalently bonded onto cellulose because unreacted water-soluble CDDAC could be easily washed off.

Antimicrobial efficacy evaluation

The antimicrobial efficacies for chlorinated cotton fabrics grafted with CDDAC against Gram-positive S. aureus and Gram-negative E. coli are presented in Table 1. As can be seen from Table 1, the chlorinated fabrics provided about 6 log reduction of both S. aureus and E. coli within a contact time of 5 min. The untreated fabrics provided only less than 0.5 log reduction of both S. aureus and E. coli, probably due to the adhesion of bacteria to them. For unchlorinated grafted fabrics, the log reductions of S. aureus and E. coli within 5 min were 1.00 and 0.61, respectively. It means that quarternary ammonium salt functional groups existed in unchlorinated grafted fabrics have much weaker antimicrobial efficacy than N-halamine functional groups. However, the coexistence of quarternary ammonium salt functional groups and N-halamine functional groups in the CDDAC grafted cotton fabrics can make the fabric surfaces easy to hold bacteria and then kill them due to the negative charges of the bacteria surface.

Washing durability and stability

As antimicrobial textiles, the washing durability and stability of their biocidal moieties are crucial for their commercial applications. For antimicrobial textiles grafted with N-halamines, the washing stability of N-halamine moieties can be tested by measuring the Cl+ % on the textiles. The decrease of Cl+ % on the textiles during washing is caused by reduction of N–Cl group in the N-halamine moieties and departure of the whole N-halamine moieties from textiles due to the disconnection of covalent bonds between N-halamine moieties and textiles. Interestingly, the loss of Cl+ due to reduction of N–Cl group can be easily regained by rechlorination. In this study, we simulated the laundry conditions to test the washing durability of chlorinated cotton fabrics grafted with CDDAC and the results were shown in Fig. 6.

The data in Fig. 6 show that the Cl+ % of chlorinated cotton fabrics decreased by about 30 % from initial 0.23 to 0.16 % after 8 washing cycles, but the lost Cl+ could be almost regained by rechlorination, which means that the loss of Cl+ is mainly caused by reduction of N–Cl groups and covalent bonds between N-halamine moieties and textiles are very stable and resistant to washing.

N-halamines are relatively active and their oxidative chlorine content (Cl+ %) may decrease during storage due to their interaction with microorganisms, moistures, etc. Figure 7 shows the stability testing results of the as-prepared chlorinated cotton fabrics grafted with CDDAC. After 25 days storage in the air under room temperature, the Cl+ % of chlorinated cotton fabrics decreased by about 50 % from initial 0.26 to 0.13 % which is still high enough to quickly kill bacteria. Normally, even several hundreds ppm of Cl+ on the N-halamine textiles can effectively kill bacteria due to their powerful antimicrobial efficacy (Badrossamay and Sun 2009). Also, as mentioned above, the lost Cl+ during storage can be easily regained by rechlorination. In fact, most textiles need regular washing and the diluted bleach solution (NaClO solution) can be added to washing machine to run in-situ rechlorination for N-halamine textiles after a period of time.

Conclusions

We developed a facile two-step method to synthesize a new water-soluble quaternarized N-halamine precursor, CDDAC. Commercially available 1-(hydroxymethyl)-5,5-dimethyl-hydantoin can react easily with dimethylamine to form a N-halamine precursor with tertiary amino group, DHDA, under room temperature with a high yield. DHDA can react with commercially available epichlorohydrin to form CDDAC in water. Very interestingly, the crude CDDAC water solution can be directly used as grafting solution after diluted, avoiding the addition of organic solvents in grafting process and reducing the production cost. CDDAC and cellulose can undergo a dehydrochlorination reaction under heating to form CDDAC grafted cellulose which can become efficient quaternarized N-halamine antimicrobial cellulose after a facile chlorination. The as-prepared antimicrobial cellulose exhibits powerful antibacterial properties against S. aureus and E. coli and will have potential commercial applications, especially in the antimicrobial treatment of textiles.

References

Badrossamay MR, Sun G (2009) A study on melt grafting of N-halamine moieties onto polyethylene and their antibacterial activities. Macromolecules 42:1948–1954

Barnes K, Liang J, Worley SD, Lee J, Broughton RM, Huang TS (2007) Modification of silica gel, cellulose, and polyurethane with a sterically hindered N-halamine moiety to produce antimicrobial activity. J Appl Polym Sci 105:2306–2313

Cao ZB, Sun YY (2009) Polymeric N-halamine latex emulsions for use in antimicrobial paints. ACS Appl Mater Interfaces 1:494–504

Cerkez I, Kocer HB, Worley SD, Broughton RM, Huang TS (2012) Epoxide tethering of polymeric N-halamine moieties. Cellulose 19:959–966

Deavenport JL, Lopez BI (1995) Process for preparation of (halohydroxypropyl) trialkylammonium halides by quaternization of trialkylamines with epihalohydrins.US 5463127

Glenn JK, Gold MH (1983) Decolorization of several polymeric dyes by the ligniN-degrading basidiomycete phanerochaete chrysosporium. Appl Environ Microbiol 45:1741–1747

Hazziza-Laskar JN, Helary G, Sauvet G (1993) Biocidal polymers active by contact. I. Synthesis of polybutadiene with pendant quaternary ammonium groups. J Appl Polym Sci 50:651–662

Jia ZS, Shen DF, Xu WL (2001) Synthesis and antibacterial activities of quaternary ammonium salt of chitosan. Carbohydr Res 333:1–6

Jung N, Han JS, Yeun SH, Chen XH (1998) Process for preparation of quaternary ammoniate containing organosilane group. KR 142146 B1

Kim YH, Sun G (2001) Durable antimicrobial finishing of nylon fabrics with acid dyes and a quaternary ammonium salt. Text Res J 71:318–323

Kocer HB, Cerkez I, Worley SD, Broughton RM, Huang TS (2011) N-Halamine copolymers for use in antimicrobial paints. Appl Mater Interfaces 3:3189–3194

Korotkii YV, Vrynchanu NA, Maksimov YN, Lozinskii MO (2011) Synthesis and antimicrobial and antifungal activities of quaternary salt of adamantine-containing alkoxydialkylaminopropanols. Pharm Chem J 45:19–21

Kotek R, Ola SMAE, White WC, Hauser P (2001) Polymerization of silane quaternary ammonium salts on fibers. Polym Prepr 42:106–107

Liang J, Owens JR, Huang TS, Worley SD (2006) Biocidal hydantoinylsiloxane polymers IV. N-halamine siloxane functionalized silica gel. J Appl Polym Sci 101:3448–3454

Liang J, Chen YJ, Ren XH, Wu R, Barnes K, Worley SD (2007) Fabric treated with antimicrobial N-halamine epoxides. Ind Eng Chem Res 46:6425–6429

Mo ZL (2010) Synthesis method of epoxypropyltrimethylammonium chloride. CN101648927

Omar AK (2010) Evaluating the combined efficacy of polymers with fungicides for protection of museum textiles against fungal deterioration in Egypt. Pol J Microbiol 59:271–280

Phugare SS, Kagalkar AN, Govindwar SP, Jadhav JP (2011) A study on significant microbial interaction leading to decolorization and degradation of textile dye Rubine 3GP. J Basic Microbiol 51:499–514

Pi ZB (2012) Environmentally-friendly antibacterial textile especially suitable suitable for next-to-skin clothing. CN 102433736 A

Qian L, Sun G (2003) Durable and regenerable antimicrobial t extiles: synthesis and applications of 3-ethylol-2,2,5,5-tetramethylimidazolidiN-1-one (TMIO) J]. J Appl Polym Sci 89:2418–2425

Ren XH, Kou L, Liang J, Worley SD, Tzou YM, Huang TS (2008) Antimicrobial efficacy and light stability of N-halamine siloxanes bound to cotton. Cellulose 15:593–598

Sakla AB, Abu-Taleb SA (1973) Individual microdetermination of chlorine, bromine and iodine in halogenated organic compounds by the oxygeN-flask method. Talanta 20:1332–1334

Sharif S, Ahmad S (2008) Synthesis and spectroscopic characterisation of 2,3-epoxy/3-chloro-2-hydroxy propyl derivatives of quaternary ammonium salts: useful cationic fixing agents. Chin J Chem 26:553–559

Slaughter S, Hayden MK, Nathan C, Hu TC, Rice T, Van VJ, Matushek M, Franklin C, Weinstein RA (1996) A comparison of the effect of universal use of gloves and gowns with that of glove use alone on acquisition of vancomyci N-resistant enterococci in a medical intensive care unit. Ann Intern Med 125:448

Sun G, Xu XJ, Bickett JR, Williams JF (2001) Durable and regenerable antibacterial finishing of fabrics with a new hydantoin derivative. Ind Eng Chem Res 40:1016–1021

Tan KT, Obendorf SK (2007) Development of an antimicrobial microporous polyurethane membrane. J Membr Sci 289:199–209

Thomas R, Olivier L (2006) General and environmentally friendly synthesis of heterocyclic multidentate molecules based on microwave-assisted heating protocol. Tetrahedron 62:155–159

Weng YM, Guo X, Gregory RL, Xie D (2011) Preparation and evaluation of an antibacterial dental cement containing quaternary ammonium salts. J Appl Polym Sci 122:2542–2551

Worley SD, Chen YJ (2005) Preparation of biocidal crosslinked polystyrene particles containing hydantoin groups. US6852312 B2

Yang HF, Ren RS, Li ZF (2011) Preparation and antibacterial properties of nano-hydroxyapatite/quaternary ammonium sait composite material. Appl Mech Mater 71–78:830–832

Yeo SY, Lee HJ, Jeong SH (2003) Preparation of nanocomposite fibers for permanent antibacterial effect. J Mater Sci 38:2143–2147

Zhang DS, Toh GW, Lin H, Chen YY (2012) In situ synthesis of silver nanoparticles on silk fabric with PNP for antibacterial finishing. J Mater Sci 47:5721–5728

Acknowledgments

The authors would like to acknowledge the financial support from the Shanghai Natural Science Foundation (10ZR1407700), Shanghai Pujiang Talent Project (11PJ1407600), the Research and Innovation Project of Municipal Education Commission of Shanghai (12YZ085).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, ZZ., Zhang, B., Jiao, YC. et al. High-efficacy antimicrobial cellulose grafted by a novel quaternarized N-halamine. Cellulose 20, 885–893 (2013). https://doi.org/10.1007/s10570-012-9848-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9848-4