Abstract

This research presents a generic strategy to fabricate antibacterial textile through in situ synthesis of silver nanoparticles on the fabric with smart polymeric molecules. Silk fabric and polyamide network polymer (PNP) were chosen for this study. PNP which has numerous amino groups and three-dimensional structure was applied to entrap silver ions into silk fabric. The pretreated silk fabrics were heated by steam method to make silver nanoparticles synthesized in situ on them without any other reductant and linker to provide silk fabric with antibacterial properties. The results indicated that the treated silk fabrics had excellent antibacterial activity and laundering durability. The quantitative bacterial tests showed the bacterial reduction rates of Staphylococcus aureus and Escherichia coli were able to reach above 99 % with not more than 0.05 mmol/L of AgNO3. The whiteness of silk fabric only changed from 90.47 to 86.49. The antibacterial activity of the treated silk fabric was maintained at 98.86 % reduction even after being exposed to 30 consecutive home laundering conditions. In addition, the results of scanning electron microscopy, energy-dispersive X-ray spectroscopy, and X-ray photoelectron spectroscopy confirmed that silver nanoparticles had generated and dispersed well in Ag0 form on the surface of silk fibers. The understanding acquired from this work will allow one to work with the preparation of other silver nanoparticles functional textiles with excellent antibacterial activities and laundering durability through this facile, eco-friendly in situ synthesis method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microbe, fungi, virus, and yeast are present almost everywhere which affect the health of human beings. Textile is one of the daily necessities for people. In particular, natural fibers products, like cotton and silk, are highly popular for their excellent properties, such as softness, affinity to skin, high hygroscopicity, and regeneration property [1–3]. However, it provides a favorable environment for microorganisms to grow, because of its natural feature and ability to retain moisture. With increasingly awareness of consumers toward health and hygiene, demand for antibacterial textiles is now expanding. Therefore, many antibacterial agents have been applied to fabricate antibacterial textiles, such as quaternary ammonium compounds [4], chitosan [5], triclosan [6], nanoparticles of noble metals and metal oxides [7–10], and bioactive plant-based products [11–13], in which silver nanoparticle has been widely used due to its broad spectrum of antibacterial activity and low toxicity toward mammalian cells [14, 15]. To prepare antibacterial silver-loaded textiles, lots of methods have been developed, such as layer-by-layer deposition, sol–gel coating, soaking in silver colloids, adding silver nanoparticles into polymer solutions before spinning, and supercritical carbon dioxide method [16–19]. Among these methods mentioned above, simply physical adsorption often leads to unsatisfied laundering durability; some methods need cumbersome processes which are very expensive and unsuitable for commercial applications; others require harmful toxic chemicals to human body and environment. In situ synthesis of silver nanoparticles on textile hence attracted a great deal of attention recently because of their uniform distribution and stability on textile as well as its facile, efficient, eco-friendly process [20, 21].

Over the past two decades, dendrimers and hyperbranched polymers have been widely developed due to their unique chemical and physical properties together with their potential application in additives, drug and gene delivery, nanotechnology, and supramolecular science [22, 23]. With numerous interior cavities as well as inwardly and outwardly functional groups, they can be used as templates to control synthesis of nanoparticles with small size, good monodispersity, and stability [24–26]. In our previous study, an amino-terminated hyperbranched polymer (HBP-NH2) was synthesized. It was utilized to prepare silver nanoparticle colloids in aqueous solution without any other reducer and stabilizer for antibacterial finishing of cotton fabric by using an impregnation method [27]. However, this method only made the silver nanoparticles simply absorb on the surface of cotton fibers with the polymer.

To perfect the preparation of silver-treated antibacterial textile based on the previous studies, the aim of this work focus on two parts of improvement. On the one hand, the procedure of HBP-NH2 synthesis was modified to form polyamide network polymer (PNP) which has compact enclosed three-dimensional network structure and the functional groups are in the backbone of the polymer. It can control the preparation of silver nanoparticles with smaller size and better monodispersity than HBP-NH2. On the other hand, a generic strategy was developed to synthesize silver nanoparticles in situ on textile for its antibacterial finishing with the smart polymeric molecule (Fig. 1). Silk fabric was chosen as the substrate for this research. During this facile process, PNP acts as a capture agent to deliver silver ions into silk fabrics and a reducer to generate silver nanoparticles in situ on the surface of silk fibers. The prepared silver-treated silk fabrics were characterized and their antibacterial properties were measured.

Experimental

Materials

Diethylenetriamine, methyl acrylate, and silver nitrate were purchased from Sigma-Aldrich. Methanol and nitric acid (65 %) were purchased from Merck. All chemicals were used as received without any further purification or treatment. Silk fabrics were purchased from China. Staphylococcus aureus (ATCC 6538) and Escherichia coli (ATCC 8099) were obtained from College of Life Science, Soochow University (China). Nutrient broth and nutrient agar were purchased from Scas Ecoscience Technology Inc. (China). Deionized water (18 MΩ cm) was used in the preparation of all samples.

Synthesis of PNP

PNP (Fig. 2) was synthesized through modification on the method of synthesis of hyperbranched polymer as reported earlier by our group [28]. The solution of methyl acrylate (0.75 mol) in methanol (100 ml) was added dropwise into diethylene triamine (0.5 mol) with nitrogen gas protection and magnetic stirring, and cooled with ice bath. Then, the mixture was removed out of the ice bath to continue the reaction at room temperature for 4 h to form AB2 type branched monomer (A and B stand for reactive groups). Since methyl acrylate was over-dose, a handful of A2B and A3 type monomers were configurated. Then, the mixture was transferred to an eggplant-shaped flask with an automatic rotary vacuum evaporator. After removing the methanol under low pressure, the temperature was raised to 150 °C using an oil bath, and left for 4 h until the honey-like PNP was obtained. As each –NH2 could react with –OOCH3 and the ratio of the two reactive groups is 1:1, the monomer AB2, A2B, and A3 could react with each other to produce three-dimensional network structure one by one. Therefore, the PNP was shaped up with a great many of “cages.”

Preparation of silver nanoparticles in aqueous solution

PNP was dissolved in deionized water to prepare a stock solution of concentration 100 g/L. Different concentration solutions were prepared by adding different amounts of stock solution to 50 ml deionized water. Then, 0.5 ml AgNO3 solution (0.1 mol/L) was added in a dropwise manner into the solution and stirred constantly at room temperature. The mixture was then heated till it boils. Heating was stopped when the solution turned yellow in color, and the solution was left to cool. To compensate the loss of water during the boiling process, deionized water was added to maintain the initial level of solution before boiling.

During the process, the amino groups are able to entrap silver ions as well as acting as reducers. The ratio between the metal ions and the capping agents are crucial in determining the size of the metal nanoparticles [29]. In this work, the molar ratio of silver ions to nitrogen atoms of the polymer backbone was controlled to be 1:5.

In situ synthesis of silver nanoparticles on silk fabric

The solution of PNP/Ag+ hybrid was prepared as mentioned above. Then, the prepared solution was diluted to get the solutions with the concentration of silver ions at 0.05, 0.1, 0.2, and 1 mmol/L. The silk fabric was immersed in the solutions with liquor-to-fabric ratio of 50:1 (v/m) for 1 h with constant stirring. The silk fabric was then steamed for 30 min and washed with water several times to remove unreduced silver ions. The resulting silk fabric was air-dried at room temperature for subsequent characterization measurements.

Characterization of silver nanoparticles in aqueous solution and treated silk fabrics

UV spectra of silver nanoparticle colloid was measured with a Cary 50 Bio UV–Visible spectrophotometer (Varian, USA) at room temperature in a quartz cuvette of path length 1 cm. The TEM micrographs were taken from a JEOL 3010 electron microscope at an accelerating voltage of 300 kV. Samples were prepared by placing small drops of silver nanoparticles dispersion on carbon-coated copper grid, and allowing the solvent to slowly evaporate at room temperature. The size distribution of silver nanoparticles was measured with high performance particle sizer (HPPS) (Malvern instruments Ltd., UK) at 25 °C.

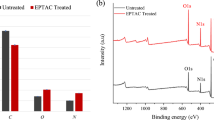

JSM-6700F scanning electron microscope (SEM) was used to observe the in situ synthesized silver nanoparticles on silk fiber. X-ray photoelectron spectroscopy (XPS) measurements were carried out on VG ESCALAB MkII with an Al Kα X-ray source. To calibrate the surface charging effects, all binding energies were referenced to the C1s hydrocarbon peak at 284.6 eV. K/S absorption spectra of treated silk fabrics were tested under D65 illuminant at 10° observer using an Ultrascan XE spectrophotometer (Hunter-Lab Co. Ltd., USA). The whiteness (WI) of silk fabric was calculated by the measured results of Ultrascan XE spectrophotometer according to the Eq. 1:

Ag content in the treated silk fabrics was measured using a Vista MPX Inductively Coupled Plasma Atomic Emission Spectrometer (ICP-AES) (Varian, USA).

Antibacterial activity testing

The antibacterial activity of treated silk fabrics was tested against E. coli and S. aureus by using a shake flask method according to GB/T 20944.3-2008 (China). The test procedure is as follows: 0.75 g sample fabric was cut into small pieces of dimensions around 0.5 × 0.5 cm2 and dipped into a flask containing 70 ml PBS (pH ≈ 7.2) and 5 ml bacterial culture which has a cell concentration of 3 × 105–4 × 105 CFU/ml. The flask was placed on a rotary shaker at 150 rpm for 18 h at 24 °C. 1 ml of solution was drawn from each sample well, diluted, and distributed into an agar plate. All plates were incubated at 37 °C for 24–48 h and the colonies were counted. The percentage reduction (R, %) was determined as follows:

where C and A are the bacterial colonies of the control and the treated silk fabrics, respectively.

The laundering durability of antibacterial activity was evaluated using a washing color fastness measuring meter according to the washing method in GB/T 20944.3-2008 (China). Samples were cut into 10 × 10 cm2 swatches and put into a stainless steel container with 150 ml of 0.2 % (w/v) AATCC WOB standard detergent solution and 10 steel balls (0.25 inch in diameter) at 40 °C for washing 45 min. This procedure was equal to five times wash cycles of home/commercial launderings. The antibacterial activity after 10, 20, and 30 washing cycles was determined.

Results and discussion

Synthesis of silver nanoparticle in aqueous solution

During the past decade, dendrimers and hyperbranched polymers have been used to control synthesis of nanoparticles due to its interior cavitary structure. In our previous work, HBP-NH2 was synthesized for the preparation of silver colloids. However, the size of silver nanoparticles synthesized by HBP-NH2 ranged from 10 to 30 nm with the average diameter of 18 nm. In addition, the silver colloids changed from light yellow to brown in 24 h [27]. This phenomenon is attributed to the aggregation of silver nanoparticles in aqueous solution. It may result from the formation of silver nanoparticles outside HBP-NH2. Masses of primary amine groups outside HBP-NH2 can capture silver ions and reduce them to silver nanoparticles, which nevertheless are liable to drop off owing to the short branches of HBP-NH2 [30]. To solve these problems, the proportion of raw materials employed to prepare HBP-NH2 was modified to synthesize PNP. Silver nanoparticles were synthesized by PNP in aqueous solution without any other reducer. The synthesized silver nanoparticle/polymer hybrids were characterized by UV–Visible spectrophotometer, transmission electron microscope (TEM), and HPPS.

Figure 3 shows the UV spectra of PNP and PNP/silver nanoparticles hybrid. The PNP solution (a) has only an absorption peak at 299 nm and exhibits no color and transparent. After adding silver ions into the solution and reduced them by PNP, the synthesized PNP/silver nanoparticles hybrid (b) exhibits a new strong absorption peak at 394 nm and turns to light yellow. These phenomena are due to the surface plasmon absorption of the silver nanoparticles which can confirm the formation of crystalline spherical silver metal nanoparticles [31]. The silver nanoparticles were further investigated by TEM and their size distributions were measured by HPPS. Figure 4 shows the TEM image and particle size distribution of silver nanoparticles synthesized by PNP. The average size and polydispersity determined by HPPS are in accordance with the results in TEM image. The average size of silver nanoparticles was about 4.34 nm with narrow size distribution upper limit of 7 nm. Furthermore, the synthesized silver nanoparticles colloids showed good stability, no color change and precipitation after a 6-month placement. The small size, narrow size distribution, and good stability of silver nanoparticles synthesized by PNP were due to the structure of PNP. It has interior sealed-in “nanocages” structure and fewer primary amino at the peripheral. Therefore, it can entrap the silver ions into the confined “nanocages,” reduce them to generate silver nanoparticles with small size and narrow size distribution and prevent them to aggregate with each other.

In situ synthesis of silver nanoparticles on silk fabrics

Usually, soaking the fabric in the silver nanoparticle colloid to prepare antibacterial textile will result in unsatisfactory laundering durability, because silver nanoparticle is difficult to fix on the fabric. Conventionally, binders were required to fix silver nanoparticles on them which may lead to undesirable effects on the properties of fabric. In situ synthesis of silver nanoparticles on fabric can fix them in uniform distribution on the fabric without any binder. According to the mechanism of silver nanoparticle synthesis by PNP in aqueous solution, PNP can be used as capture agents to deliver silver ions into textile. After heating treatment, silver ions can be reduced by the smart polymer to generate silver nanoparticles in situ on the textile (Fig. 1). In this research, antibacterial silk fabrics were prepared through this procedure. The treated silk fabrics were characterized by SEM, XPS, and Ultrascan XE spectrophotometer.

Figure 5 shows the surface morphology of the control silk fiber and the silver-treated fiber. There is an obvious difference between them in terms of surface roughness. The control silk fiber is smooth, whereas many nanoparticles can be found well dispersed on the surface of treated one. The diameters of the particles on silk fibers are around 50 nm, larger than the silver nanoparticles synthesized in aqueous solution. That may attribute to the high surface energy of silver nanoparticles on the surface of silk fibers which induce aggregation of silver nanoparticles.

To verify the nanoparticles on the silk fibers were indeed silver, elemental composition analysis were initially carried out via energy-dispersive X-ray spectroscopy (EDS). The resulting EDS spectrum (Fig. 6) shows strong carbon, oxygen, and copper peaks as expected. Carbon and oxygen arise from the silk fabric and copper arises from the substrate of sample. Three peaks of silver in the spectrum indicate the existence of silver in the silk fabric.

XPS analysis was performed to identify the chemical state of silver in silk fabric. Figure 7 shows the Ag3d spectra. The binding energies of two peaks were at 368.17 and 374.18 eV, corresponding to the Ag3d5/2 and Ag3d3/2, respectively. It presents an unambiguous proof that the nanoparticles on the silk fibers are indeed Ag0 particles [32, 33].

The K/S value reflects the depth of color. Figure 8 shows the K/S absorption spectra of control silk fabric and treated samples. The treated silk fabrics show an absorption peak at 420 nm and yellow color under light due to the surface plasma resonance of silver nanoparticles. With the increase in the concentration of AgNO3, the peaks become higher because of larger number of silver nanoparticles being formed on the surface of silver fabric. Sample 1 has a similar curve as control sample which indicates that silver fabric treated with AgNO3 at 0.05 mmol/L for antibacterial finishing exhibits significant color retention. The whiteness of the control and treated silk fabrics are listed in Table 1.

Antibacterial activity of the treated silk fabrics

The antibacterial activity and laundering durability of treated silk fabrics were evaluated by S. aureus and E. coli. Table 1 shows the silver content, whiteness, and antibacterial activity of the treated silk fabrics. Upon increasing the concentration of AgNO3 from 0.05 to 1 mmol/L, the silver content of the treated silk fabrics increases from 116.48 to 381.66 mg/kg. All the treated silk fabrics show excellent antibacterial activities. At the lowest concentration of AgNO3 of 0.05 mmol/L, the bacterial reduction rates of S. aureus and E. coli have reached above 99 % and the whiteness only decreases from 90.47 to 86.49. Compared with other treated samples, it exhibits no significant color change. The bacterial reduction rates increased slightly while the whiteness of the treated silk fabrics decreased rapidly with the increase of the silver content of the silk fabrics. Therefore, the concentration of AgNO3 at 0.05 mmol/L is chosen for antibacterial finishing on the silk fabric.

The silk fabrics treated with 0.05 mmol/L AgNO3 were then washed for 10, 20, and 30 cycles for the investigation of laundering durability on antibacterial property. The silver content and antibacterial activities of the treated silk fabrics were measured after laundering. The results are shown in Table 2. With the laundering cycles increase, the silver content and antibacterial activity of the silver-treated silk fabrics decreased slightly. After 30 washing cycles, the treated silk fabrics still exhibited bacterial reduction of 99.39 and 98.86 % for S. aureus and E. coli, respectively, which indicated excellent laundering durability of the silver-treated silk fabrics. This outstanding property is attributed to the in situ generation of silver nanoparticles on the surface of silk fibers which provided excellent fastness between silver nanoparticle and silk fiber.

Conclusions

PNP was synthesized by modification of the process of hyperbranched polymer synthesis. Due to its compact structure, it can synthesize silver nanoparticles with smaller size, more narrow size distribution, and better stability than traditional hyperbranched polymer. The average size of silver nanoparticles synthesized by PNP in aqueous solution was about 4.34 nm with narrow size distribution upper limit of 7 nm. To fabricate silver nanoparticle-treated antibacterial textiles with the smart polymer, in situ synthesis method was developed. PNP was employed as capturer to deliver silver ions into silk fabric for the preparation of silver nanoparticles in situ generated on the silk fabric. The silver-treated silk fabrics showed excellent and durable antibacterial activities against both S. aureus and E. coli. After 30 washing cycles, the treated silk fabrics still exhibited bacterial reduction above 98 %. All the results of ICP-AES, SEM, EDS, and XPS confirmed that silver nanoparticles have been fixed and well dispersed on the silk fibers at the chemical state of Ag0.

References

Van Amber RR, Niven BE, Wilson CA (2010) Text Res J 80:1557

Lu YH, Lin H, Chen YY, Wang C, Hua YR (2007) Fiber Polym 8:1

El Shafei A, Abou-Okeil A (2011) Carbohydr Polym 83:920

Sun HY, Li J, Qiu XL, Qing FL (2005) J Fluor Chem 126:1425

Ali SW, Joshi M, Rajendran S (2011) AATCC Rev 11:49

Kalyon BD, Olgun U (2001) Am J Infect Control 29:124

Ilić V, Šaponjić Z, Vodnik V, Molina R, Dimitrijević S, Jovančić P, Nedeljković J, Radetić M (2009) J Mater Sci 44. doi:10.1007/s10853-009-3547-z

Ki HY, Kim JH, Kwon SC, Jeong SH (2007) J Mater Sci 42. doi:10.1007/s10853-007-1572-3

Jeong SH, Hwang YH, Yi SC (2005) J Mater Sci 40. doi:10.1007/s10853-005-4340-2

Sójka-Ledakowicz J, Lewartowska J, Kudzin M, Leonowicz M, Jesionowski T, Siwińska-Stefańska K, Krysztafkiewicz A (2009) J Mater Sci 44. doi:10.1007/s10853-009-3522-8

Joshi M, Ali SW, Rajendran S (2007) J Appl Polym Sci 106:793

Alemdar S, Agaoglu S (2009) J Anim Vet Adv 8:99

Pinto E, Vale-Silva L, Cavaleiro C, Salgueiro L (2009) J Med Microbiol 58:1454

Gaonkar TA, Sampath LA, Modak SM (2003) Infect Control Hosp Epidemiol 24:506

Kim KJ, Sung WS, Suh BK, Moon SK, Choi JS, Kim J, Lee DG (2009) Biometals 22:235

Dubas ST, Kumlangdudsana P, Potiyaraj P (2006) Colloids Surf A 289:105

Mahltig B, Fiedler D, Bottcher H (2004) J Sol Gel Sci Technol 32:219

Falletta E, Bonini M, Fratini E, Lo Nostro A, Pesavento G, Becheri A, Lo Nostro P, Canton P, Baglioni P (2008) J Phys Chem C 112:11758

Gittard SD, Hojo D, Hyde GK, Scarel G, Narayan RJ, Parsons GN (2010) J Mater Eng Perform 19:368

Vigneshwaran N, Nachane RP, Balasubramanya RH, Varadarajan PV (2006) Carbohydr Res 341:2012

Jiang T, Liu L, Yao JM (2011) Fiber Polym 12:620

Gao C, Yan D (2004) Prog Polym Sci 29:183

Menjoge AR, Kannan RM, Tomalia DA (2010) Drug Discov Today 15:171

Castonguay A, Kakkar AK (2010) Adv Colloid Interface Sci 160:76

Kavitha M, Parida MR, Prasad E, Vijayan C, Deshmukh PC (2009) Macromol Chem Phys 210:1310

Kakati N, Mahapatra SS, Karak N (2008) J Macromol Sci A 45:658

Zhang F, Wu XL, Chen YY, Lin H (2009) Fiber Polym 10:496

Zhang F, Chen YY, Lin H, Lu YH (2007) Color Technol 123:351

Gladitz M, Reinemann S, Radusch HJ (2009) Macromol Mater Eng 294:178

Crooks RM, Zhao MQ, Sun L, Chechik V, Yeung LK (2001) Acc Chem Res 34:181

Sun YG, Xia YN (2003) Analyst 128:686

Kaspar TC, Droubay T, Chambers SA, Bagus PS (2010) J Phys Chem C 114:21562

Liao Y, Wang YQ, Feng XX, Wang WC, Xu FJ, Zhang LQ (2010) Mater Chem Phys 121:534

Acknowledgements

The authors are grateful for the financial support by The National High Technology Research and Development Program of China (No. 2012AA030313), Jiangsu Key Program for Basic Research of China (No. 08KJA540001), and Natural Science Foundation of the Jiangsu Higher Education Institutions of China (No. 11KJB540002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, D., Toh, G.W., Lin, H. et al. In situ synthesis of silver nanoparticles on silk fabric with PNP for antibacterial finishing. J Mater Sci 47, 5721–5728 (2012). https://doi.org/10.1007/s10853-012-6462-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6462-7