Abstract

Phenol, an important bulk organic compound, has diverse applications encompassing both industry and society. Commercially, it is produced through energy intensive three-step cumene process operating at relatively low yield with the co-production of acetone. Several attempts were made for producing phenol through challenging one-step direct hydroxylation of benzene using different oxidants like O2, N2O and H2O2. Liquid phase hydroxylation of benzene using H2O2 found to be more attractive due to its low reaction temperature and environmentally friendly nature (as water is only formed as by-product). The hydroxylation reaction occurs through Fenton’s mechanism; however along with phenol several other products are also formed due to higher reactivity of phenol compared to benzene. Our research group has been working on this reaction for nearly a decade using layered double hydroxides (LDHs) and their derived forms as heterogeneous selective oxidation catalyst. Screening of different LDHs having different metal ions in the layers revealed the necessity of copper for hydroxylation in pyridine. Addition of co-bivalent metal ion along with copper was made in an endeavour to improve the activity that revealed the promising results for CuZnAl LDHs. Efforts were then made to shift from pyridine to environmentally benign solvent, water, for this reaction that showed reasonably good yields with very high selectivity of phenol. Addition of small amount of sulfolane as a co-solvent increased the selectivity for phenol further. The reusability difficulty faced while using as-synthesized LDHs was overcome when calcined LDHs were used. Structure–property-activity relationships were deduced to understand the results observed. The present review besides covering our work also provides the state-of-art on this reaction using different oxidants with emphasis on H2O2.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Phenol is the common name of hydroxy benzene (C6H5OH) that belongs to the class of compounds containing one or more hydroxyl groups attached to an aromatic ring. Phenol has also been called as carbolic acid, phenolic acid, phenylic acid or oxybenzene. Being an important intermediate in the chemical industry, it is extensively used in the production of phenolic resins, bisphenol-A, caprolactam, adipic acid and plasticisers. Worldwide production of phenol was more than 5.5 megatons in 2000 and 7.2 megatons in 2006 and it is continuously growing. The history of phenol goes back to 1834, when it was first isolated from coal tar and named as carbolic acid [1]. Until the advent of synthetic phenol production, just before World War-1, coal tar remained as the only source of phenol. In the early years of the 20th century, Belgian chemist entrepreneur Leo Baekeland created the world’s first completely synthetic plastic. Baekeland mixed phenol and formaldehyde, subjected them to heat, pressure and produced a sticky, amber-colored resin and named as Bakelite [2]. Due to this finding, requirement of phenol increased and forced its synthetic production from other petroleum fraction. Several industrial applications have been developed during last century based on phenol and their derivatives. Demand for phenol and its derivatives has been the driving force to discover new technologies and several commercial processes were developed.

2 Commercialized Processes

2.1 Sulfonation Process

The first synthetic phenol was produced by sulfonation of benzene and hydrolysis of sulfonate (Scheme 1, BASF-1899).

Even though this process involves corrosive sulphuric acid and produce large amounts of sodium sulphite waste, this process was used for about 80 years [3].

2.2 Chlorination Process

In 1924, a new chlorination process was put in operation by Dow Chemicals in the USA.

Chlorination of benzene was done using iron catalyst to obtain chlorobenzene which on reaction with NaOH at high temperature and pressure produces phenol and sodium chloride (Scheme 2).

2.3 Toluene-Benzoic Acid Process

Dow-Canada Ltd. first introduced the toluene benzoic acid process in 1961 (Scheme 3). The three chemical reactions in the toluene-benzoic acid process are oxidation of toluene to form benzoic acid, oxidation of thus formed benzoic acid to benzoyl salicylic acid and hydrolysis of the latter to form phenol [4]. A typical process consists of two steps; in the first step, the oxidation of toluene to benzoic acid is achieved with air and cobalt salt catalyst in the temperature range 394–450 K, the reactor operated at 206 kPa and the catalyst concentration is between 0.1 and 0.3 %, the reactor effluent is distilled and the purified benzoic acid is collected. The overall yield of this process is believed to be about 68 mol% of toluene.

In the second processing step, benzoic acid is oxidized and hydrolyzed to phenol; the formation of phenol is the net result of several reactions that occur simultaneously in the system. In the first reactor, the benzoic acid is oxidized to benzoyl salicylic acid in presence of air and a catalyst mixture of copper and magnesium salts. The reactor is operated at 513 K and 147 kPa. The benzoyl salicylic acid is then hydrolyzed with steam in the second reactor to yield phenol and CO2. The overall yield of phenol from benzoic acid is around 88 mol %. All commercial plants based on this process were closed in 2006 and currently there is no commercial production of phenol from toluene [5].

2.4 Cumene Process

The cumene process was developed and first realized in the former Soviet Union (Scheme 4); 95 % of phenol produced today is through this method. The route was discovered in 1942 by a group of chemists P. G. Sergeev, R. Yu. Udris and B. D. Kruzhalov, and in 1949, the first industrial plant was put in operation in Dzerzhinsk [3]. There are several licensed processes to produce phenol, which are based on cumene. Benzene on reaction with propene to give cumene, which is oxidized with air to form cumene hydroperoxide and cumene hydroperoxide is cleaved to yield phenol and acetone. In this process, approximately 0.46 kg of acetone and 0.75 kg of phenol are produced per kg of cumene feedstock.

Oxidation of cumene to cumene hydroperoxide is usually achieved in three to four oxidizers in series, where the fractional conversion is about the same for each reactor. Fresh cumene and recycled cumene are fed to the first reactor. Air is bubbled in at the bottom of the reactor and leaves at the top of each reactor. The oxidizers are operated at low to moderate pressure. Due to the exothermic nature of the oxidation reaction, heat generated must be removed by external cooling. A portion of cumene reacts to form dimethyl benzyl alcohol and acetophenone. Methanol is formed in the acetophenone reaction and is further oxidized to formaldehyde and formic acid. A small amount of water is also formed by various reactions. The selectivity of this oxidation reaction is influenced by temperature, conversion level, residence time and oxygen partial pressure. Typical commercial yield of cumene hydroperoxide is about 95 mol % in the oxidizers. The reaction effluent is striped off for un-reacted cumene, which is then recycled as feedstock. Spent air from the oxidizers is treated to recover 99.99 % of the cumene and other volatile organic compounds. Due to environmental consideration, many phenol plants are equipped with a special water treatment facility where acetone and phenol are recovered from the wastewater effluent stream. Even though this process is commercially very successful, it has multiple steps and acetone formed as co-product whose market is volatile (like its chemical nature!) and hence there is an intense effort to develop a one-step production of phenol directly from benzene.

3 Direct Hydroxylation of Benzene

The market growth is quite different for phenol and acetone produced from cumene process, and hence effort is currently being devoted to decouple their production. In addition, the day-to-day increasing demand of phenol leads researchers to find new cost-effective and environmentally friendly processes. The practical development of the one-step production of phenol will have advantages in cost reduction and energy saving. To achieve direct hydroxylation of aromatic compounds, a neutral oxygen or radical oxygen such as HO. or HOO., might work as the active species. The efficient production of active oxygen species on a catalyst surface remains difficult that can be obtained through three different sources namely:

-

Molecular oxygen (O2) in presence of different reducing agents like H2, NH3, CO, dithioalcohols, ascorbic acid etc.

-

Nitrous oxide (N2O)

-

Hydrogen peroxide (H2O2)

To be best of our knowledge no extensive review is available on one-step production of benzene to phenol using different oxidizing agents. This article reviews the hydroxylation of benzene by different oxidizing agents with special emphasis on hydrogen peroxide followed by the recent advancements made by our group using copper containing layered double hydroxides catalysed benzene hydroxylation.

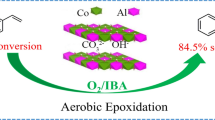

3.1 Molecular Oxygen

Benzene hydroxylation using molecular oxygen requires the activation of C–H bonds in the aromatic ring and the subsequent insertion of oxygen. Most heterogeneous catalysts that contain transition metals can generate an active oxygen species, such as O−, O2 − and O2− which cause oxidation of benzene [6]. More than 100 years ago, Friedel and Crafts examined the conversion of benzene to phenol using oxygen in the gas phase in the presence of aluminium chloride [7]. Later studies include molybdenum, tungsten, copper, uranium, and vanadium oxides as catalysts [8–10]. The selectivity of phenol obtained was very low and hence they were of no importance with regard to practical applications. Investigations on liquid phase oxidation in the presence of CuCl [11], iron or palladium in heteropoly acids [12, 13] or palladium acetate [14] also gave only low selectivity. Table 1 shows literature compilation of benzene hydroxylation using O2 as oxidant giving phenol yield and selectivity. Tsuruya et al. worked diversely on this reaction using O2 as oxidizing agent and ascorbic acid as reducing agent at >0.5 Mpa and at different temperatures. They examined and patented both vanadium and copper supported materials like V/SiO2, CuO–Al2O3, CuHZSM-5, V/Al2O3, V-HPAs and Cu/Ti/H-ZSM-5 as catalysts and among them vanadium supported catalysts showed higher phenol yield as compared to copper [15]. Both V and Cu substituted materials showed leaching of active metals in different quantities in all studies. Several other materials like titanium silicate, microporous SBA-15 containing Mo or V heteropolyacid and organo-transition metal incorporated on solid matrix were also patented for phenol production [16–18].

Kubacka et al. achieved phenol yield of 10 % using Cu-ZSM-5 catalyst using both O2 and O2/H2 mixtures as oxidant. Followed by them, Gu et al. showed highest phenol yield of 27 % using VOx/Cu-SBA-15 catalyst [45], however with leaching of active metal ions from the catalyst. Similar leaching of active metal ion was commonly observed when ascorbic acid was used as sacrificial reductant that leads to catalyst deactivation [57]. Rhenium supported metal oxide was also reported for this reaction using ammonia as reducing agent [58] and vanadium complex encapsulated zeolite as catalyst and saccharides as reducing agents was also used for the synthesis of phenol in aqueous acetic acid as solvent [59].

Pioneering work on hydroxylation using palladium membrane was done in 2002. Mizukami et al. [24] from Japan used Pd/porous alumina membranes for the continuous production of phenol from benzene using H2/O2 mixture. Since H2 and O2 were not mixed simultaneously it has the advantage of low probability of causing detonating gas reaction and phenol yield of 1.5 Kg per Kg of catalyst per hour at 423 K was achieved. Followed by them Itoh et al. [27] used 4 μm thick palladium film formed on a porous alumina tube as membrane and showed appropriate H2/O2 ratio renders larger benzene yield (Fig 1).

Palladium membrane reactor [Reprinted from ref [24] with permission from Elsevier, Amsterdam, The Netherlands]

This novel idea improved the phenol yield up to 20 % at 473 K. Several other works are also reported on palladium membranes for benzene hydroxylation; however the stability of the Pd membrane is still a challenge for longer operations [6]. Guo et al. prepared Pd membranes of excellent stability and flux with multi-legged anchors by electroless plating of Pd on a porous support modified by a zeolite barrier layer containing Pd seeds [47].

Ye et al. improved the stability of the membrane by using a Pd membrane made by chemical vapour decomposition (CVD) or a Pd–Ag membrane instead of the Pd membrane made by sputtering in the Pd membrane micro reactor [46]. Recently Shu et al. observed that, the surface area of the dense palladium membrane is low, and it cannot be sufficiently utilized because of the hydrogen combustion and concluded that the membrane concept is not effective for the one step hydroxylation of benzene to phenol with hydrogen and oxygen [60].

Bortolotto et al. used novel microstructured membrane reactor with distributed dosing of hydrogen and oxygen with palladium-coated Pd/Cu foil membrane. The highest phenol selectivity obtained at 423 K was 9.6 % with carbon dioxide being the dominant product [61].

Recently several modified Pd membranes are used for the direct hydroxylation on benzene with maximum phenol formation rate [62, 63]. To summarize:

3.1.1 Advantages

-

Low cost.

-

Environmentally friendly.

3.1.2 Disadvantages

-

Usage of reducing agents like CO, NH3 and ascorbic acid are industrially not attractive.

-

Oxygen-hydrogen mixture in a large-scale synthesis is not preferred (safety reasons).

-

Low selectivity—over oxidation to maleic acid and CO2.

3.2 Nitrous Oxide

N2O is one of the best mono oxygen donors used in the literature as the O− ion formed by surface decomposition of N2O [64, 65] can efficiently oxidize hydrocarbons than by using O2. Pioneering work on benzene hydroxylation using N2O was done by Iwamoto et al. [66] in 1983, where they showed N2O oxidation selectively forms phenol while O2 oxidation leads to the cleavage of C–C bond to maleic acid or maleic anhydride (Scheme 5). They used V2O5/SiO2 as catalyst at 823 K and showed 11 % conversion of benzene with 45 % phenol selectivity.

In 1988, three groups of researchers: Suzuki et al. [67] from Japan (Tokyo Institute of Technology), Gubelmann et al. [68, 69] from France (Rhone Poulenc Co.), and Panov et al. [70–73] from Boreskov Institute of Catalysis (BIC) independently discovered that ZSM-5 zeolites are the best catalysts for this reaction. In ZSM-5 zeolites, reaction proceeded at much lower temperature and more importantly, with selectivity approaching 100 % [3]. Fe-ZSM-5 with 0.055 wt% of Fe showed 27 % benzene conversion with 98 % phenol selectivity at 623 K [74]. In subsequent years several patents published in nitrous oxide hydroxylation of benzene [75–80] using several catalysts.

In Fe-ZSM-5, ‘α-sites’ were found to be the active centres and minimum concentration of Fe atoms was needed for its generation. The mechanism of formation of active oxygen species, their interaction with the catalyst and the mechanism of phenol formation using N2O are well reviewed by G. I. Panov [3]. Solutia Inc., a USA chemical company was one of the major world producers of adipic acid, an intermediate for Nylon 6,6, and BIC jointly made a process called AlphOx (after the name of α-oxygen). They used waste nitrous oxide from adipic acid plant for the oxidation of benzene to phenol, incorporating this reaction as a key stage in a new modified adipic acid production (Scheme 6).

The reaction was performed in a simple adiabatic reactor, an essential feature of this process in view of economics and also has environmental attractiveness. Instead of spending efforts and cost on N2O neutralization, the new phenol process used N2O as a raw material, and thus demonstrated the waste-to-wealth strategy.

Followed by these findings, several other materials like Fe/Mo/DBH (partially deboronated borosilicate) synthesized through chemical vapor deposition method [81], unsupported and supported FePO4 [82], Fe β-zeolites (where coke formation was higher), iron-exchanged ferrierite [83], copper–calcium–phosphates [84], tetrahedrally coordinated iron in framework substituted microporous AlPO-5 (gave less selectivity) [85] and iron-functionalized Al-SBA-15 [86] were studied. However, they failed to give either good conversion or selectivity compared to Fe-ZSM-5 under similar operating conditions.

To further improve this process, ZSM-5 coated on stainless steel grids [87], Fe-ZSM-5 coated stainless-steel supports [88], (NH4)2SiF6-modified iron exchanged ZSM-5 [89], Fe/ZSM-5 prepared by chemical vapor deposition [90], Fe-ZSM-5 sintered metal fibers composites as catalytic beds [91], hierarchical Fe/ZSM-5 [92], wet milled H-ZSM-5 zeolite [93] and Fe-ZSM-5 under microwave radiation [94] were used and obtained improved conversions and selectivity. Meloni et al. [95] showed that the addition of steam to the feed increased to the benzene conversion over Fe-ZSM-5 catalyst with improved selectivity and durability.

Several works were done to find out mechanism and the nature of active sites for benzene hydroxylation using N2O. Nature of the active sites in H-ZSM-5 with Fe concentration was studied [96] and showed that there was no direct correlation between the concentrations of Bronsted and Lewis acid sites. The Fe ions with complex oxo structure were found to be the active sites. Hensen et al. [97] showed extra framework Fe–Al–O species occluded in MFI zeolite as the active species for benzene hydroxylation and observed negligible conversion in the absence of aluminum. Yuranov et al. [98] observed three types of Fe(II) active sites in the zeolites upon activation and which could be assigned to Fe(II) sites in mononuclear species, oligonuclear species with at least two oxygen-bridged Fe(II) sites, and Fe(II) sites within Fe2O3 nanoparticles and amount of different sites were measured by the transient response of CO2 during CO oxidation. Only mononuclear and oligonuclear Fe(II) sites were active and Fe2O3 nanoparticles were inactive. Fe(II) ions present in Fe2O3 nanoparticles (inactive in hydroxylation) were probably irreversibly reoxidized by N2O to Fe(III), which are known to be responsible for the total oxidation of benzene. Sun et al. [99] studied the mechanism of this reaction using Fe-ZSM-5 catalyst obtained through solid state ion exchange process and proved by spectroscopic studies that oligonuclear and binuclear iron sites appeared most favorable for nitrous oxide decomposition, whereas the mononuclear iron sites were active for benzene hydroxylation to phenol. Recently, Pirutko et al. [100] studied the kinetics and mechanism of nitrous oxide decomposition over Fe-ZSM-5 and showed that both N2O decomposition and benzene hydroxylation were shown to have kindred mechanisms, which can be described by two main steps (Scheme 7). The first step includes oxidation of the α-site of Fe-ZSM-5 by N2O.

The second step involves the removal of α-oxygen by the interaction with benzene that leads to phenol.

Fellah et al. [101] have done density functional theory calculations for the oxidation of benzene to phenol by N2O on a model (FeO)1+-ZSM-5 cluster and [(SiH3)4AlO4(FeO)] cluster. They suggested that the experimentally observed preference of Fe2+ sites over (FeO)1+ on ZSM-5 for benzene oxidation to phenol by N2O was due to the reduced formation of adsorbed phenolate, which was possibly an intermediate for deactivation. Rana et al. [102] synthesized hierarchically mesoporous Fe-ZSM-5 zeolite with catalytically active surface Fe species by introduction of Fe3+ in the synthesis gel of mesoporous ZSM-5 with varying Fe content and porosity. Samples with very high surface area, strong acidity, low zeolitic wall crystallinity and 0.93 wt% Fe content showed 1.3 times higher phenol formation rate than a steamed H-ZSM-5 sample. Following this work, hierarchically structured Fe/ZSM-5 synthesized by templating desilication showed higher rate of phenol formation and displayed slower deactivation than conventional Fe/ZSM-5 [103]. To summarise:

3.2.1 Advantages

-

Low capital expenses.

-

No by-product.

-

No highly reactive intermediates.

3.2.2 Disadvantages

-

Applicable only where N2O is available cheaply such as adipic acid plants.

3.3 Hydrogen Peroxide

Next to air or O2, hydrogen peroxide (H2O2) is the most environmentally friendly oxidizing agent for oxidation reactions as water alone is formed as the by-product. Phenol is more reactive towards oxidation than benzene and hence subsequent formation of over-oxidized by-products (catechol, hydroquinone, benzoquinones, and tars) usually occurs [104, 105] when hydrogen peroxide is used resulting generally in its low selectivity for this reaction. As hydrogen peroxide is expensive (compared to air or oxygen) and auto-catalytic decomposition of H2O2 is also a competing reaction during hydroxylation of benzene, this method will be economically attractive only when H2O2 selectivity for the desired product, here phenol, is high.

Hydroxylation of benzene to phenol was studied initially in the literature in a view to understand the biological processes and to comprehend Fenton’s mechanism which showed that formation of biphenyl occurs through cyclohexadienyl radical [106, 107]. It was also reported that presence of copper in the Fenton’s system reduces the formation of biphenyl [108, 109]. After the synthesis of titanium silicates [110], Perego et al. [111] first reported the synthesis of phenol using titanium silicate and followed by them Thangaraj et al. [112, 113] reported the titanium silicate catalyzed phenol synthesis from benzene using H2O2 as oxidant. Balducci et al. [114, 115] patented the synthesis of phenol using spherical silica/zeolite composite materials with submicronic dispersion of titanium silicate. Amorphous microporous mixed oxides containing transition metals and copper containing molecular sieves were also found to be active for this reaction with 15–35 % yield of phenol with 100 % selectivity [116, 117]. Table 2 shows literature compilation of benzene hydroxylation using H2O2 as oxidant. H2O2 selectivity was calculated from the reported conversion values wherever it was necessary.

Bhaumik et al. used triphasic catalysis using TS-1 as catalyst and showed 28.8 % conversion with 95 % phenol selectivity and 90 % H2O2 selectivity [120]. Several other reports on Ti or V containing MCM-41 were reported however showed poor H2O2 selectivity [119, 121, 124, 125]. Bianchi et al. used homogeneous catalysis using Fe2+ co-ordinated with different bidentate ligands with (N,N) (N,O) and (O,O) co-ordination and among them (N,N) ligand was nearly inactive, (O,O) ligand showed good activity but poor selectivity and (N,O) gave good activity as well as good selectivity. 5-Carboxy-2-methylpyrazine-N-Oxide gave highest H2O2 conversion of 94 %, 78 % H2O2 selectivity and 85 % benzene conversion whereas FeSO4 pyrazine-3-carboxylic acid N-oxide gave 8.1 % benzene conversion with 80 % H2O2 selectivity and 95 % phenol selectivity [122, 126]. Bianchi et al. [127, 186] showed for the first time heterogeneously catalyzed reaction with 8.6 % conversion with 80.5 % H2O2 selectivity and 94 % phenol selectivity using TS-1 as catalyst. They used sulfolane as solvent for the first time for this reaction and the complex formation of sulfolane with phenol increased the phenol selectivity. Several other attempts were made to improve the benzene conversion using VO2+ functionalized (APTS)/MCM-41, LaMn-MCM-41, Co (V, Nb, La)-MCM-41 and Fe/activated carbon as catalyst and achieved conversion of benzene from 50–65 % whereas H2O2 selectivity of 17–50 % [129, 135, 136, 138]. Recent patents claim the catalytic application of different materials like vanadyl pyrophosphate, vanadium phthalocyanine complex, vanadium loaded SBA-16 and vanadium containing aluminum phosphate molecular sieves for this reaction [187–190].

Peng et al. [132] used biphasic hydroxylation using 1-n-octyl-3-methylimidazolium-tetrafluoroborate (OMImBF4) ionic liquid as solvent and ferric tri(dodecanesulfonate) (Fe(DS)3) as catalyst. They screened different ionic liquids and found that length of alkyl chains on the 1-alkyl-3-methylimidazolium cations and the anions had some effect on the conversion and selectivity; however, detailed mechanism is still not clear [132]. After the reaction, oxidation products and un-reacted substrate were extracted from the aqueous and ionic liquid phase with ether at the end of each reaction and aqueous–ionic liquid catalyst system was reused.

Liu et al. [139] recently reported novel micro-emulsion system made of water, benzene, acetic acid, sodium dodecylbenzene sulfonate as a surfactant and ferric dodecane sulfonate as catalyst. They achieved a maximum conversion of 21.9 % with 93.1 % H2O2 selectivity, 92.9 % phenol selectivity and the system is reusable for several times. Bianchi et al. [153] used modified titanium silicate (TS-1B) obtained by the post-synthesis treatment of TS-1 with NH4HF2 and H2O2, as catalyst and obtained 8.6 % benzene conversion with 78.4 % H2O2 selectivity and 91 % phenol selectivity. Several other reports are available using both vanadium and copper containing materials; however many of them failed to give good H2O2 selectivity or benzene conversion; further research is needed in order to make this process commercially attractive.

Recently, Barbera et al. [191] studied the effect of solvent and crystallite size of TS-1 for benzene hydroxylation in both biphasic and triphasic conditions and also in presence of co-solvent sulfolane. Small-sized TS-1 crystallites produced the highest primary selectivity to phenol and different titanium environments and defective hydroxyls population was evaluated by means of diffuse reflectance UV–Vis and IR spectroscopy. Mesoporous aluminium oxide containing transition metals were also found to be active for this reaction under mild reaction conditions [192]. Attempts were also very recently made to improve the phenol and H2O2 selectivity using membrane contactor [193, 194]. To summarize:

3.3.1 Advantages

-

Environmentally friendly oxidant.

-

Only water formed as by-product.

3.3.2 Disadvantages

-

More expensive than oxygen.

-

H2O2 selectivity is generally low.

-

Inability to control over-oxidation and subsequent separation problems.

Molinari and Poerio have recently reviewed the direct production of phenol in conventional and membrane reactors. Attention was devoted to phenol production processes using various configurations of membrane reactors (MRs) and a photocatalytic membrane reactor (PMR). They classified the oxidation according to oxidants such as N2O, O2, and H2O2 and each of them ascertained that direct oxidation of benzene to phenol is a difficult task and concluded that further efforts are needed to search and replace the three-step traditional process of converting benzene into phenol with a process that involves direct oxidation [195]. We have studied this challenging one step hydroxylation reaction using H2O2 as oxidant and transition metal containing layered double hydroxides as heterogeneous redox catalysts and the results are summarized in the following sections.

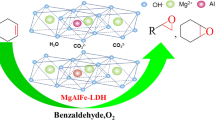

4 Liquid Phase Hydroxylation of Benzene Over Copper Containing Ternary Hydrotalcites

Layered double hydroxide (LDH) otherwise called as hydrotalcite-like (HT-like) compounds are a class of two dimensional materials that are scarcely found in nature. The basic units of LDHs are M(OH)6 octahedra similar to brucite (Mg(OH)2) that are edge shared to form sheets (Fig. 2). Such sheets stack on top of one another to produce two-dimensional layered structure. If some of the M2+ (Mg2+in brucite) ions are substituted by a trivalent cation, having a similar ionic radius, like Al3+ (in hydrotalcite) the positive charge density of the sheets increases. This excess positive charge is charge neutralized by anions that occupy in between the sheets (in the interlayers) along with water molecules.

LDHs have the general formula [M(II)1−xM(III)x(OH)2]x+[A n−x/n ].yH2O where M(II) is divalent metal ion, M(III) is the trivalent metal ion and An− is interlayer anion. The composition of LDHs are limitless; the divalent metal ions can be Ni2+, Mg2+, Co2+, Zn2+ etc. while trivalent metal ions may be Al3+, Cr3+, Fe3+, Co3+, Ga3+ etc. [196]. Different binary and ternary LDHs were synthesized and studied for the direct hydroxylation of benzene to phenol in liquid phase using pyridine as solvent and H2O2 as an oxidant [140].

4.1 Catalyst Screening and Benzene Hydroxylation Activity

Binary hydrotalcite of general formula M(II)Al–HT (M(II)/Al atomic ratio of 3.0), where M(II) = Mg, Co, Ni, Cu or Zn were synthesized by co-precipitation as reported [197, 198]. Benzene hydroxylation was carried out in a custom designed temperature controlled stainless steel closed reactor (70 ml). Typically, 5 g of benzene and desired amount of catalyst were added in 15 ml of pyridine. The hydrogen peroxide (molar ratio of benzene: H2O2 = 3:1) was added slowly to the reaction mixture, however, all at once and the reactor was subjected to desired temperatures in a controlled pre-temperature set oil bath. Among the binary hydrotalcite screened (Table 3), only CuAl-HT, showed around 1.6 % conversion of benzene. All other HTs are found to be inactive under the reaction conditions; this shows the necessity of copper in mediating the hydroxylation reaction.

The observed conversion for CuAl-HT was less with only 4.8 % selectivity of H2O2. To improve the activity, several copper containing ternary LDHs were synthesized in presence of different co-bivalent ions like Co, Ni, Mg or Zn and trivalent ion Al. Cu/M(II) atomic ratio was also varied from 75 to 17 % and the materials were characterized by various physiochemical techniques [199–201]. The materials are represented as CuM(II)Alxy-HT where M(II) is co-bivalent metal ion and xy stands for Cu:M(II) atomic ratio. Powder X-ray diffraction of the catalysts studied in this work have showed a single phase whose pattern resembles that of hydrotalcite (HT; JCPDS: 41-1428) [202]. Hydroxylation activities of these ternary hydrotalcites were studied under similar reaction conditions. All catalysts yielded phenol with 100 % selectivity without forming any dihydroxybenzenes (Table 4) which is one of the advantages of these materials.

All ternary hydrotalcites showed higher conversion than binary CuAl-HT and the activity was significantly influenced by the nature of bivalent metal ions in the HT-like lattice. The conversion decreased with a decrease in the concentration of copper irrespective of the co-bivalant metal ion, suggests its direct dependence. This indicates that although copper ions are the active centres involved in the reaction, the overall activity is varied by the nature and concentration of co-bivalent metal ions present in the hydrotalcite lattice. The results observed here have advantages over some of the copper supported systems such as Al–MCM-41 where the maximum yield of phenol was around 0.5–1.2 % with 97 % selectivity, however, varied depending on the type of support [203, 204]. Among the materials, CuNiAl31-HT and CuCoAl31-HT showed highest conversion of 4.8 and 4.7 % respectively.

To find the influence of trivalent metal ion Al3+ was replaced by Fe3+ and Cr3+ for the active Co and Ni co-bivalent ions and studied for benzene hydroxylation (Table 5). For both systems, the other trivalent ions showed lesser conversion than Al3+. Time variation studies revealed that the maximum conversion was obtained within 6 h while no significant change with a further increase in time up to 48 h. Variation of reaction temperature showed that the conversion of benzene increased up to 338 K while a further increase decreased the conversion. This may be due to the thermal decomposition of H2O2 at higher temperatures; this behaviour is similar to other Cu-based microporous and mesoporous materials like Cu–NaY and Cu–MCM-41 catalysts [205]. Solvent variation studies showed that only pyridine is active among various solvents (acetonitrile, acetone, THF, DMF, and chloroform) at 3:1 benzene:H2O2 molar ratio. This may be due to ionic nature coupled with basic character of this solvent which can hold phenol more strongly than non-ionic solvents. Further, it is also known on the promotional influences of such bases in oxidation of organic substrates [206]. However, it should be mentioned here that no catalytic activity was found in the absence of catalyst in pyridine solvent.

4.2 Parametric Variation Studies

The effect of substrate:catalyst mass ratio indicated a decreasing trend in the activity with a decrease in the ratio (Fig. 3a). This may be due to the spontaneous formation of coke (as the reaction mixture turned dark black) which probably blocks the active sites of the catalysts. The influence of the weight of the benzene as plotted in Fig. 3b) indicated that the conversion of benzene increased continuously with an increase in its weight. This is due to the higher heat capacity of benzene which avoids an uncontrolled heating of the system thereby decreases the occurrence of undesired consecutive reactions [207]. The weight of the substrate was optimized at 5 g for further studies.

Influence of a substrate:catalyst mass ratio b weight of benzene c volume of solvent and d substrate:oxidant mole ratio on the catalytic hydroxylation of benzene over CuNiAl31-HT and CuCoAl31-HT (time: 24 h; temperature: 338 K) [Reprinted from ref [140] with permission from Elsevier, Amsterdam, The Netherlands]

Changing the volume of the solvent (Fig. 3c) indicated that the conversion of benzene increased up to 15 ml and decreased with a further increase in the volume of the solvent. This may be due to variations in the local heat balance and/or a decrease in the number of active sites per unit volume of the reaction mixture. The influence of the substrate:oxidant ratio, given in Fig. 3d, indicated an increasing trend with an increase in H2O2 concentration up to 3:1 benzene:H2O2 mol ratio but became nearly constant with a further increase in the H2O2 concentration. This may be due to the high exothermic nature of the reaction wherein at higher concentration of H2O2, the reaction temperature shoots up leading to decomposition and in turn undesired consumption of H2O2.

To discern whether the reaction is heterogeneously catalysed, CuNiAl31–HT was suspended (under stirring) in H2O2 and pyridine for 24 h at 338 K, and the catalyst was removed and the solvent was tested for a fresh reaction under similar experimental conditions. No conversion of benzene was observed augments the reaction is heterogeneous. Reusability studies showed that the conversion decreased to 3 % after three cycles for both active catalysts (Ni and Co), probably due to changes in the crystallinity of the samples. Active catalysts (CuNiAl31–HT and CuCoAl31–HT) were calcined at different temperatures and studied for this reaction; irrespective of calcination temperature, the conversion was lesser than the fresh (uncalcined) samples. The structural loss of the hydrotalcite phase at higher temperature in addition to the loss in the specific surface area is probably the reasons for lesser conversion. These results are similar to our earlier observation over these catalysts for phenol hydroxylation [197].

In order to explain mechanism of this reaction, two different experiments were performed by taking into the consideration of induction time (30 min) observed in this reaction. In one of the experiments, benzene and catalyst were mixed under stirring for 30 min and in another experiment the catalyst was suspended in H2O2 for 30 min. Subsequently, H2O2 was added to the former while benzene was added to the later experiment and monitored the reaction. The results indicated that no induction time was observed for the later experiment while similar induction time was noted for the first case. This suggests the hydroxyl radicals were produced by the interaction of H2O2 with the catalyst and confirms the Fenton’s mechanism. Addition of radical quenchers like ethanol during the reaction also decreased the conversion augments their participation.

5 Benzene Hydroxylation Over Low Copper Containing Ternary Hydrotalcites

By understanding the interaction of copper in HT with other metal ions is one of the ways by which one can improve the phenol yield. Further such interactions may have stronger bearing if the concentration of the active metal ions is low. To discern such interactions between the copper and other bivalent ion, copper containing hydrotalcites with very low copper concentration (Cu/M(II) ratio is 1/9; samples are denoted as CuM(II)Al19-HT) along with different co-bivalent ions M(II) such as Co, Ni, Mg or Zn with Al as trivalent cation were synthesized. The samples were synthesized by co-precipitation under low supersaturation with (Cu + M(II))/Al atomic ratio of 3.0 and characterized. The materials were then studied for benzene oxidation in various solvents including pyridine under different reaction conditions.

5.1 Structural and Textural Properties of Catalysts

PXRD patterns of the as-synthesized materials are shown in Fig. 4; for comparison, diffraction patterns of as-synthesized binary MgAl-HT and ZnAl-HT are also included. Irrespective of the co-bivalent ion, all samples showed patterns similar to the HT-like structure with no observable peaks from crystalline impurity phases.

The samples showed sharp and symmetric reflections at low diffraction angles (peaks close to 2θ = 11, 24 and 35o; ascribed to diffraction by basal planes (003), (006), and (009) respectively) and broad asymmetric reflections at higher angles (peaks close to 2θ = 38, 46, and 60o; ascribed to diffraction by (105), (108) and (110) planes). These diffraction features are characteristic of hydrotalcite (JCPDS: 41-1428). Among the co-bivalent metal ions studied, zinc showed highest crystallinity followed by Mg, Ni, and Co respectively. This is probably a consequence of the similarity of the octahedral ionic radii of Zn2+ and Cu2+ (Zn2+ = 0.74 Å; Cu2+ = 0.73 Å; Mg2+ = 0.72 Å; Ni2+ = 0.69 Å; Co2+ = 0.65 Å) [208]. Further, no significant variation in the crystallinity was noted upon substitution of 10 atom% of Cu2+ as evidenced by PXRD profiles of binary and ternary LDHs (see Fig. 4c, f or d, e). The d-spacing values calculated from (003) diffraction peaks for all materials are in between 7.6 and 7.8 Å, which was consistent with interlayer gallery height of 2.8–3.0 Å, allowing 4.8 Å for the thickness of the brucite-like sheets. This gallery height was in accordance with the presence of carbonate anion [209]. FT-IR spectra of the as-synthesized materials, shown in Fig. 5, support the presence of carbonate ions exhibiting sharp and intense band around 1,350–1,380 cm−1 attributed to the ν3 asymmetric stretching vibration of carbonate, probably present in D3h symmetry.

CuZnAl19-HT alone exhibited an additional shoulder band around 1,490–1,510 cm−1, which might be due to symmetry lowering of free carbonate (to C2v or C3v symmetry) and/or to partial co-ordination of the carbonate ion with Cu2+ in the cationic layer, owing to Jahn–Teller distortion of the Cu2+ coordination environment. Such a symmetry change for the carbonate anion was known for HTs on mild heating [202]. The TGA/DTGA curves of the samples recorded in a flow of nitrogen are shown in Fig. 6. They showed two transitions; the first one, which is reversible, endothermic, and occurs at lower temperature, corresponds to the loss of interlayer water molecules.

The second one, which is endothermic, occurs at higher temperature and is due to the loss of hydroxyl groups (as H2O) from the brucite-like layers as well as decomposition of the carbonate anions (as CO2). The higher second transition temperatures for Mg- and Ni-containing samples (around 623 K) confirm the presence of strongly held hydroxyl groups. However, for CuZnAl19-HT, high temperature transitions around 833 and 1,038 K were also observed. These transitions are probably due to the release of strongly bound carbonate anions, as substantiated by FT-IR spectroscopy. Table 6 summarizes the elemental compositions and the calculated formulae of the as-synthesized samples. The carbonate content was computed from the M(II)/Al atomic ratio and the water content was calculated from the TG analysis. Here we have assumed carbonate is the only charge compensating interlayer anion as excess Na2CO3 was used in the synthesis.

This assumption was substantiated by PXRD and FT-IR measurements. BET specific surface area measurements showed the highest surface area for CuNiAl19-HT and the lowest for CuZnAl19-HT.

5.2 Catalytic Studies

These copper containing HTs were studied for the benzene hydroxylation in pyridine solvent with benzene:oxidant mole ratio of 1:1. It is worth mentioning here that copper containing HTs with high copper concentration gave higher conversion using benzene:oxidant mole ratio of 3:1 while those with low copper concentration showed high conversion at 1:1 (Table 7).

Maximum conversion of 6.7 % was observed for CuZnAl19-HT while CuMgAl19-HT and CuNiAl19-HT showed ~5.8 % conversion; CuCoAl19-HT showed very low conversion of 2.2 %. This reveals that copper and cobalt containing HT is found to be active only at high copper concentration whereas copper and zinc containing HTs are active even at low copper content. High activity of zinc containing HT is probably due to the extra stability of copper as supported form the FT-IR and TGA measurements. In addition, the variation in the redox chemistry of Cu2+ by the presence of the co-bivalent metal ion is also critical. To qualify this, X-ray photoelectron spectroscopic (XPS) measurements were done. Figure 7 shows the Cu 2p3/2 core level XPS spectra of CuZnAl19-HT and CuCoAl19-HT. The main line observed at 933.4 eV in both CuZnAl19-HT and CuCoAl19-HT corresponds to Cu2+.

Cu 2p core level X-ray photoelectron spectra of a CuZnAl19-HT, b CuCoAl19-HT. [Reprinted from ref [198] with permission from Elsevier, Amsterdam, The Netherlands]

An additional peak could be discerned at 932.1 eV for CuZnAl19-HT (missing for CuCoAl19-HT) arising from Cu+ species [210]. Since the zinc content of the material is very large (in comparison with copper), it masks the Cu-LMM Auger signal. It has been reported that Cu+ is the active intermediate for the hydroxylation of phenol using H2O2 [211], a reaction that follows Fenton’s mechanism. From these observations, one can conclude that the formation Cu+, which is an active intermediate in benzene hydroxylation, is regulated by the nature of the co-bivalent metal ion. Among the metal ions studied, Zn2+ evidently facilitates the formation of Cu+ species. The presence of Cu+ species reported earlier for thermally treated CuZnAl19-HT by XPS measurements corroborates our findings [212, 213].

From the above results, a reaction mechanism is proposed for the benzene hydroxylation over copper containing hydrotalcites (Scheme 8). Solvent variation studies were done for the active CuZnAl19-HT in view of replacing the hazardous pyridine (Table 8).

As the benzene : oxidant molar ratio is high, the possibility of decomposition of formed phenol is higher and hence weight loss calculations were done by quantifying the amount of benzene remained in the reaction mixture. Negative weight loss observed for low boiling solvents is probably due to the evaporative loss of the solvents. Acetonitrile showed 3.9 % conversion (which is 60 % as that of pyridine), is highly active solvent next to pyridine, supporting the results reported in literature. Daniele Bianchi expressed [122] that in acetonitrile there is an effective formation of bilayer which drives the reaction towards the high yields without forming side products. Gif chemistry results are also in good agreement with our results wherein hydrocarbon oxidation is viable in pyridine and can also is replaced by acetonitrile [214, 215]. We have also attempted to use other nitrogen containing solvents like triethylamine and diethylamine; however, no conversion was noted under the experimental conditions. Product analysis in pyridine solvent showed very small formation of pyridine N-oxide (GC–MS), and irrespective of the conversion very small quantity of pyridine N-oxide is present in all samples. It was earlier reported that pyridine N-oxides can also acts as a hydrocarbon oxidizing agent via in situ generated H2O2 [216]. To delineate this, oxidation in pyridine N-oxide was carried out. No conversion was noted under these conditions suggest its non-influence. Since pyridine and acetonitrile are found to be highly active, substrate:oxidant molar ratio variation studies were done (Table 9) for both solvents.

Pyridine showed higher conversion in 1:1 substrate to oxidant ratio; at higher amount of oxidant coke formed (black colored reaction mixture or char-like material along with the catalyst). The reason for poor conversion at higher oxidant amount might be due to non- productive decomposition of hydrogen peroxide in presence of catalyst. In acetonitrile 1:1.5 substrate to oxidant mole ratio showed highest conversion; at higher oxidant amounts (1:2) coke formation was observed, and the selectivity decreased due to the formation of catechol and hydroquinone.

Table 10 shows a substrate:catalyst weight ratio of 500:1 is the best for obtaining high yields of phenol. At higher catalyst amount, acetonitrile showed higher conversion which in turn showed greater weight loss of benzene that suggests the coke formation. In pyridine also coke formation at higher catalytic amount was observed and color of the reaction mixture turned dark black with poor selectivity of H2O2.

5.3 Mixed Solvent Studies

To understand the influence of pyridine and to improve the yields of phenol, benzene hydroxylation was carried out using mixed solvents from the optimized solvents namely, pyridine-acetonitrile and pyridine-acetone mixture and the results are given in Tables 11 and 12.

From the results, it is clear that up to 5 ml of pyridine the conversion increases in presence of acetonitrile, but a further increase decreased the conversion. In acetone-pyridine mixture conversion increased up to 8.4 % for 50 % acetone in pyridine; however, a significant decrease in the selectivity was noted. Acetone favors the oxidation of phenol to the further hydroxylated products such as catechol or hydroquinone. CuZnAl19-HT after the reaction was collected, washed, dried and tested for reusability under similar reaction conditions. A conversion of 0.1 and 1.7 % was observed in acetonitrile and pyridine respectively suggests the inability of the catalyst for its reuse similar to Cu-containing HTs with high copper contents. In other words, both low and high Cu-containing samples were inefficient for their reuse for hydroxylation of benzene. The catalyst deactivation might be due to the formation of coke during the reaction that may block the active centers and thereby not allowing the access of reactant molecules. The color of the catalyst after its first use was black supports the formation of coke. Albeit reasonable conversion obtained with selective formation of phenol, the conditions and the results are still not suitable due to non-reusability of the catalyst and the use of environmentally unfriendly solvent.

6 Benzene Hydroxylation Using Water Solvent: Triphasic Catalysis

As pyridine is not an environmentally benign solvent, we have opted water as solvent for further studies. Benzene hydroxylation in water is a triphasic reaction wherein benzene and solvent forms different phases and the catalyst in solid phase. H2O2 reacts vigorously in water and hence greater possibility for occurrence of side reactions which must be avoided. To reduce the reaction rate, benzene:oxidant molar ratio was taken very low as 1:10 and low copper containing HTs (Cu/M(II) ratio is 1/9) that were used in Sect. 5 were taken. Since, fresh HTs failed for their reuse in water as solvent, all catalysts were calcined at 973 K for 5 h in air and named as CuM(II)Al19-CHT-973.

6.1 Structure, Textural Properties and Catalysis

PXRD profiles of calcined copper containing HTs are given in Fig. 8. All materials showed reflections of the oxide phase typical of the co-bivalent metal ion namely, ZnO, MgO, NiO and Co3O4. It should be noted that no discrete reflections of CuO were seen for these samples suggests CuO is well dispersed in the host oxide. Benzene oxidation in water was done in a two-neck 50 ml glass reactor by taking 5 g (64.1 mmol) of benzene, calculated amount of catalyst and 15 ml of solvent. The reactor was placed in a pre-heated oil bath at 338 K. As soon as the solution reached 338 K, 0.7 ml (6.2 mmol) of H2O2 (30 % W/V) was added through a septum at once, and the reaction mixture was kept for 6 h with stirring at 800 rpm. Immediately after the reaction, 5 ml of ethylacetoacetate and 5 ml of water were added, mixed well, and the aqueous and organic layers were collected separately. The yields of phenol and other hydroxylated aromatics (given here as total hydroxylated products) were determined in both the organic and aqueous layers by gas chromatography (Varian 450-GC with a Factor Four VF-1 ms capillary column) by injecting 0.25 μl of sample [198]. Catalytic activity of calcined HTs and their surface properties are given in Table 13.

PXRD of a CuZnAl19-CHT-973, b CuMgAl19-CHT-973, c CuNiAl19-CHT-973, d CuCoAl19-CHT-973 * Co3O4 (JCPDS-43-1003), @ NiO (JCPDS-22-1189), # MgO (JCPDS-01-1235), + ZnO (JCPDS-36-1415).[Reprinted from ref [198] with permission from Elsevier, Amsterdam, The Netherlands]

The surface areas and pore volumes of the calcined materials follow the same trend as those of the as-synthesized materials (Table 6). Here again, CuZnAl19-CHT showed the highest activity while CuCoAl19-CHT showed the lowest, similar to the trend that was seen for as-synthesized hydrotalcites in pyridine solvent. To find out the influence of calcination temperature on the activity, CuZnAl19-HT was calcined at different temperatures and tested for hydroxylation.

Figure 9A shows the PXRD of materials calcined at different temperatures namely 723, 973 and 1173 K. The temperatures were deduced based on the thermogravimetric profiles. CuZnAl19-CHT calcined at 723 and 973 K showed mixed oxide phases without any discrete reflections of CuO. However, when the temperature was increased to 1,173 K, the calcined material showed the reflections of a discrete CuO phase along with ZnO and ZnAl2O4.

A PXRD of a CuZnAl19-CHT-723, b CuZnAl19-CHT-973, c CuZnAl19-CHT-1173—* ZnO (JCPDS-36-1415), # ZnAl2O4 (JCPDS-01-1146), @ CuO (JCPDS-05-0661); B Catalytic activity of CuZnAl-CHT calcined at different temperatures (Benzene: 5 g; catalyst: 20 mg; benzene/H2O2 mol ratio: 10; water: 15 ml; temperature: 323 K; time: 6 h.) [Reprinted from ref [198] with permission from Elsevier, Amsterdam, The Netherlands]

Activity studies revealed (Fig. 9B) nearly similar activity for the samples calcined at 973 and 1,173 K. Since it is known from our earlier experiments that the discrete CuO phase may facilitate the formation of further oxidation products and pose difficulty for reuse, further studies were done with the sample calcined at 973 K (CuZnAl19-CHT-973).

In anticipation of increasing the yield of phenol, substrate:catalyst mass ratio variation studies were done and found 250:1 ratio gave high yield of phenol and used for further studies. Temperature variation studies were done over CuZnAl-CHT-973 and the results are given in Fig. 10.

Though high yield of phenol was observed at high temperature (>338 K) the formation of coke also increased at higher temperature. In other words, reactions at high temperatures favored over oxidation products. This is evidenced by the darker color of the reaction mixture at higher temperatures, and under these conditions it was difficult to recover the catalyst from the reaction mixture. Hence, further studies were carried out at 338 K.

Attempts were then made to increase the yield of phenol by varying solvents whose results are given in Table 14. Interestingly, among the solvents screened, water showed the highest yield, but with lower selectivity for phenol. The high activity using water as solvent under triphasic conditions is advantageous from an environmental perspective. The addition of co-solvents was attempted in order to discern the effect of co-solvents on the selectivity of the reaction. Sulfolane is one of the interesting solvents reported in literature for the hydroxylation of benzene because it controls the further oxidation of easily oxidizable (relative to benzene) phenol to dihydroxy benzenes [217, 153].

The reaction using sulfolane alone as the solvent over CuZnAl-CHT-973 failed to give high product yields under the reaction conditions. Hence, attempts were made to add sulfolane as a co-solvent along with water, and the results are also given in Table 14. The addition of larger amounts (33.3 vol.% and 6.7 vol.%) of sulfolane decreased the conversion of benzene whereas the addition of small amounts (0.6 vol.% to 4.1 vol.%) gave nearly equivalent conversion of benzene with 100 % phenol selectivity. Under equivalent conditions, water alone gave slightly higher conversion but with only about 80 % selectivity. It is clear that the addition of suflolane enhance the selectivity for phenol as reported in literature; however the quantity also has an effect on the activity, probably due to change in the polarity of the medium. Due to its high dielectric constant (43.26), sulfolane has the peculiar property of forming complexes with phenolic compounds [217], and this sterically hindered complex does not allow further hydroxylation of phenol, and thus improving the selectivity. Time variation study was done under optimized conditions in the hope of improving the yield of phenol; a maximum yield of 1.95 % was obtained with 95 % selectivity in 24 h.

The reusability of the CuZnAl-CHT-973 was assessed as follows. Immediately after the reaction, the catalyst was separated by centrifugation, washed with water and calcined at 973 K to remove the adsorbed organics and then reused. Figure 11B shows the activity of the recycled catalysts (referred here as cycle 2 and cycle 3) along with PXRD profiles (Fig. 11A) of the correspondingly used catalysts. Activity studies indicated that the catalyst could be reused for up to three cycles without important changes in the yield of phenol. However, PXRD showed an interesting observation wherein immediately after the first use, specific removal of zinc oxide was noted. This is evident from the absence of characteristic reflections at 2θ = 34.6°, 36.4°, 47.7°, 56.7° and 63.0° for zinc oxide (JCPDS: 36-1415). However, on further recycling, no change in the phase was observed, which showed characteristic reflections of ZnAl2O4 (JCPDS: 1-1146). Similar activity even after removal of ZnO suggests the retention of nature of active copper species and its dispersion. Further, no discrete CuO domains could be seen even after repetitive calcination.

A Powder X-ray diffraction patterns of used catalysts a CuZnAl19-CHT-973, b CuZnAl19-CHT-973-cycle 2, c CuZnA19l-CHT-973-cycle 3; B Recycle studies for CuZnAl19-CHT-973 (Reaction conditions as given in Fig. 11, except solvent; water (15 ml) and sulfolane (180 μl)). [Reprinted from ref [198] with permission from Elsevier, Amsterdam, The Netherlands]

To confirm the absence of leaching of copper during the reaction and also to find the morphological changes that were anticipated upon removal of ZnO, TEM-STEM-EDAX analysis was done (carbon coated gold grids were used) and the results are shown in Fig. 12. Significant changes in the morphology of the catalyst were found after the reaction. Large irregular platelets (~200–300 nm) with nano-sized punctures were seen (due to decarbonation and dehydroxylation of the layered lattice) for the calcined catalyst before the reaction, whereas oblong condensed particles of smaller size (~20–50 nm) were seen after the reaction.

STEM-EDAX analysis of a CuZnAl19-CHT-973 b CuZnAl19-CHT-973-cycle 3. [Reprinted from ref [198] with permission from Elsevier, Amsterdam, The Netherlands]

7 Conclusions and Future Directions

Direct hydroxylation of benzene to phenol using H2O2 as oxidant was carried out using as-synthesized hydrotalcites as heterogeneous selective oxidation catalysts. Among the bivalent metal ions studied, copper is found to be inevitable to enable this reaction. The conversion enhanced when a co-bivalent metal ion (such as Co, Ni or Zn) is present along with copper in pyridine as solvent. A direct dependence on the activity with the concentration of copper was observed and more importantly these materials showed nearly 100 % selectivity towards phenol. To understand the role of copper better, hydrotalcites with low copper content were synthesized and studied for this reaction under similar conditions. XPS analysis revealed a facile formation Cu+ for the sample with zinc as co-bivalent metal ion (CuZnAl19-HT) that showed high conversion and a reaction pathway is proposed based on Fenton’s mechanism. Mixed solvent studies in view of partially replacing pyridine did not render encouraging results wherein high conversion with 100 % phenol selectivity was obtained only in pyridine. In addition, the as-synthesized hydrotalcites were also not reusable. To make the process more environmentally benign and to develop reusable catalysts, the as-synthesized hydrotalcites were calcined and tested under the similar reaction conditions in water as solvent however using low substrate:oxidant mole ratio. CuZnAl19-CHT-973 was found to be highly active and also reusable. Addition of small amounts of sulfolane increased the selectivity of phenol (to nearly 100 %). The retention of good dispersion of copper as confirmed by STEM-EDAX measurements is the likely reason for the recyclability of the catalyst. Although the catalysts reported in the study show lesser yields of phenol, it has the advantage of avoiding environmentally unfriendly catalysts/reagents and dangerous intermediates. Further research is needed to improve the yields without compromising on the selectivity in order to make this process commercially attractive.

An analysis on the published content (covering only journal articles) on this challenging reaction gave (Fig. 13) interesting observations. Though direct oxidation of benzene to phenol started at different times, till 2000 all the three oxidants (O2, H2O2 and N2O) were explored to similar extent. The discovery of Panov and coworkers [3] and consequently proposed commercial process for the production of phenol using N2O as oxidant from adipic acid plants accelerated the research on N2O based oxidation as evident from the number of research output reported between 2000 and 2005. The bottleneck, however, is the cheap availability of N2O and thus the use of membrane reactors using both O2 and H2O2 as oxidants was introduced and explored till 2010. The challenges that however need to overcome for these reactors are the stability and cost. Although the results based on H2O2 proposed initially by Ratnasamy and coworkers in early 1990s have taken a way forward where some of the catalysts show very high conversion and nearly 100 % selectivity of phenol (for example,VO(acac)2]-grafted periodic mesoporous organosilica (PMO) showed 27 % conversion of benzene with 100 % phenol selectivity) the selectivity of H2O2 is on the downside and taking its cost into account, significant developments are necessary to address this issue [218]. Very recently, a contrasting approach is reported by Hibino and coworkers using electrochemical vapor phase hydroxylation of benzene using V2O5 anode that found to be highly selective for producing phenol [219]. Further, the yield of the phenol by this approach improved up to 2 times by using alternating current electrolysis instead of direct current [220]. However, the bottleneck is the scale up issues as the phenol yield at present is low owing to the small area of the electrode used. A clear understanding on the mechanism of this reaction would be beneficial in the design and development of new catalysts independent of methodology (batch/continuous) or approach (homogeneous/heterogeneous/electrochemical/membrane). Efforts have been made through both spectroscopic and theoretical studies [221–223]. The role of solvent, active metal centres and their dispersion, the nature of reaction intermediates, deactivation centers that promote undesired product formation are some of the issues that could be unravelled if sound mechanistic investigations are in place. There are also recent discoveries on the in situ generation of hydrogen peroxide using hydrogen and oxygen and the use of such mixture for direct hydroxylation of benzene [24, 224]. The other important limiting factor is very few scale-up operations (pilot scale) and long-term stability/selectivity studies were carried out for this reaction irrespective of the oxidant. It is pertinent now that chemical engineering inputs have to be incorporated in scaling up some of the promising studies to really understand the difficulties and challenges to overcome. Synergy between combinations of multitude approaches mentioned above with a rationale understanding on the catalytic material would sure to design and develop commercially demonstrable process for this challenging reaction in future.

Literature overview on the use of different oxidants for the selective oxidation of benzene to phenol. (Obtained from ISI web of knowledge (v5.8) using keywords, Topic = (Hydroxylation OR Oxidation) AND Topic = (Benzene) AND Topic = (Phenol) as on 16th October 2012; further, articles are individually analyzed for the relevance pertaining to ‘one-step selective oxidation form benzene to phenol’ and categorized for plotting. ‘Others’ represents the articles using oxidants other than O2, H2O2 and N2O like water, CO and other peroxide oxidants)

References

Weber M, Weber M, Kleine-Boymann M (2004) Phenol. Ullmann’s Encyclopaedia Ind Chem. doi:10.1002/14356007.a19_299.pub2

American chemical society in age of plastic dawns with bakelite, http://acswebcontent.acs.org/landmarks/newproducts_t.html#bakelite

Panov GI (2000) CATTECH 4 18:18

Brownstain AM (1994) CHEMTECH, September 58

Weber M, Weber M, Pilato L (eds) (2010) Phenolic Resins: a century of progress. Springer, Berlin, Heidelberg

Sato K, Hanaoka T, Niwa S, Stefan C, Namba T, Mizukami F (2005) Catal Today 104:260

Friedel C, Crafts JM (1888) Ann Chim (Paris) 14:935

Farben IG (1927) DE Patent 501:467

Socony-Vacuum Oil Co. (1948) US Patent 2,456,597

Chem Abstr (1949) 1805

Ito S, Kunai A, Okada H, Sasaki K (1988) J Org Chem 53:296

Passoni LC, Cruz AT, Buffon R, Schuchardt U (1997) J Mol Catal A: Chem 120:117

Seo YJ, Mukai Y, Tagawa T, Goto S (1997) J Mol Catal A: Chem 120:149

Schuchardt U, Cruz AT, Collins CH, Passoni LC (1994) Stud Surf Sci Catal 82:551

Tsuruya S, Hyogo-ken K (2000) EP Patent 1(024):129

Lin M, Luo Y, Mu X, Ru Y, Shi C, Shu X, Wang X, Zhu B (2009) CN Patent 101(434):515

Dan Y, Gu Y, Hou Y, Meng J (2009) CN Patent 101(440):021

Paul R, Robert R (2009) IN Patent 193:301

Ishida M, Masumoto Y, Hamada R, Nishiyama S, Tsuruya S, Masaic M (1999) J Chem Soc Perkin Trans 2:847

Miyahara T, Kanzaki H, Hamada R, Kuroiwa S, Nishiyama S, Tsuruya S (2001) J Mol Catal A: Chem 176:141

Laufer W, Hoelderich WF (2002) Chem Commun 1684

Masumoto Y, Hamada R, Yokota K, Nishiyama S, Tsuruya S (2002) J Mol Catal A: Chem 184:215

Yamanaka H, Hamada R, Nibuta H, Nishiyama S, Tsuruya S (2002) J Mol Catal A: Chem 178:89

Niwa S, Eswaramoorthy M, Nair J, Raj A, Itoh N, Shoji H, Namba T, Mizukami F (2002) Science 29:125

Battistel E, Tassinari R, Fornaroli M, Bonoldi L (2003) J Mol Catal A: Chem 202:107

Hamada R, Shibata Y, Nishiyama S, Tsuruya S (2003) Phys Chem Chem Phys 5:956

Itoh N, Niwa S, Mizukami F, Inoue T, Igarashi A, Namba T (2003) Catal Commun 4:243

Lee D, Lee J, Chun B, Lee K (2003) Plasma Chem Plasma Process 23:519

Remias JE, Pavlosky TA, Sen A (2003) J Mol Catal A: Chem 203:179

Bahidsky M, Hronec M (2004) Catal Today 91–92:13

Kanzaki H, Kitamura T, Hamada R, Nishiyama S, Tsuruya S (2004) J Mol Catal A: Chem 208:203

Kusakari T, Sasaki T, Iwasawa Y (2004) Chem Commun 992

Liptakova B, Bahidsky M, Hronec M (2004) Appl Catal A Gen 263:33

Castagnola NB, Kropf AJ, Marshall CL (2005) Appl Catal A Gen 290:110

Kuznetsova NI, Kuznetsova LI, Likholobov VA, Pez GP (2005) Catal Today 99:193

Liu Y, Murata K, Inaba M (2005) Catal Commun 6:679

Murata K, Yanyong R, Inaba M (2005) Catal Lett 102:143

Shibata Y, Hamada R, Ueda T, Ichihashi Y, Nishiyama S, Tsuruya S (2005) Ind Eng Chem Res 44:8765

Yamaguchi S, Sumimoto S, Ichihashi Y, Nishiyama S, Tsuruya S (2005) Ind Eng Chem Res 44:1

Gao X, Xu J (2006) Catal Lett 111:203

Liu Y, Murata K, Inaba M (2006) J Mol Catal A: Chem 256:247

Sumimoto S, Tanaka C, Yamaguchi S, Ichihashi Y, Nishiyama S, Tsuruya S (2006) Ind Eng Chem Res 45:7444

Tada M, Bal R, Iwasawa Y (2006) Catal Today 117:141

Kubacka A, Wang Z, Sulikowski B, Corberan VC (2007) J Catal 250:184

Gu Y, Zhao X, Zhang G, Ding H, Shan Y (2007) Appl Catal A Gen 328:150

Ye S, Hamakawa S, Tanaka S, Sato K, Esashi M, Mizukami F (2009) Chem Eng J 155:829

Guo Y, Zhang X, Zou H, Liu H, Wanga J, Yeung KL (2009) Chem Commun 5898

Qing GH, Yan L, Min ZF, Rui PJ, Jiang ZC, Jun W (2009) Sci China Ser B: Chem 52:1264

Tanarungsun G, Yamada H, Tagawa T, Kiatkittipong W, Praserthdam P, Assabumrungrat S (2010) Chem Eng Comm 197:1140

Zhou C, Wang J, Leng Y, Ge H (2010) Catal Lett 135:120

Ichihashi Y, Kamizaki Y, Terai N, Taniya K, Tsuruya S, Nishiyama S (2010) Catal Lett 134:324

Changjiang Z, Hanqing G, Yan L, Jun W (2010) Chin J Catal 31:623

Gao X, Lv X, Xu J (2010) Kinet Catal 51:394

Gimeno MP, Soler J, Herguido J, Menendez M (2010) Ind Eng Chem Res 49:6810

Jiaqi C, Shuang G, Jun L, Ying L (2011) Chin J Catal 32:1446

Yang H, Chen J, Li J, Lv Y, Gao S (2012) Appl Catal A Gen 415–416:22

Takata K, Yamaguchi S, Nishiyama S, Tsuruya S (2005) J Mol Catal A: Chem 225:125

Iwasawa Y, Oikawa T, Wang L S, Yui M (2009) JP Patent 2,009,249,332

Ichihashi Y, Ikeda K, Nishiyama S (2010) JP Patent 2,010,126,466

Shu S, Huang Y, Hu X, Fan Y, Xu N (2009) J Phys Chem C 113:19618

Bortolotto L, Dittmeyer R (2010) Sep Purif Technol 73:51

Wang X, Guo Y, Zhang X, Wang Y, Liu H, Wang J, Qiu J, Yeung KL (2010) Catal Today 156:288

Dittmeyera R, Bortolotto L (2011) Appl Catal A Gen 391:311

Lunsford JH (1973) Catal Rev Sci Eng 8:135

Clark A (1970) The theory of adsorption and catalysis. Academic Press, New York 344

Iwamoto M, Hlrata J, Matsukami K, Kagawa S (1983) J Phys Chem 87:903

Suzuki E, Makashiro K, Ono Y (1988) Chem Soc Jap Chem Commun 953

Gubelmann MH, Tirel PJ (1988) FR2630735

Gubelmann M, Tirel PJ (1991) US5001280

Kharitonov AS, Aleksandrova TN, Vostrikova LA, Sobolev VI, Ione KG, Panov GI (1988) USSR Patent 1(805):127

Kharitonov AS, Panov GI, Ione KG, Romannikov VN, Sheveleva GA, Vostrikova LA, Sobolev VI (1992) US Patent 5(110):995

Kharitonov AS, Panov GI, Sheveleva GA, Pirutko LV, Voskresenskaya TP, Sobolev VI (1997) US Patent 5(672):777

Panov GI, Kharitonov AS, Sheveleva GA (1998) US Patent 5(756):861

Panov GI, Kharitonov AS, Sobolev VI (1993) Appl Catal A Gen 98:1

Reitzmann A, Emig G, Klemm E, Kowalak S, Nowinska K (2000) DE Patent 19(829):515

Hamilton DM (2001) US Patent 20,010,044,559

Jaehnisch K, Ehrich H, Lohse U, Lemke K, Luecke B, Baerns M (2002) DE Patent 10(123):121

Korchak VN, Udalova OV, Shibanova MD, Seleznev VA, Kuli-Zade AMO, Silchenkova ON, Korchak VN (2002) RU Patent 2(184):722

Tanger U, Tillaart JVD (2003) US Patent 20,030,040,646

Kuhnle A, Duda M, Seelbach K, Hasenzahl S, Tanger U, Jost C, Klemm E, Reitzmann A (2004) US Patent 20,040,063,568

Yoo JS (1998) Catal Today 41:409

Ren T, Yan L, Zhang X, Suo J (2003) Appl Catal A Gen 244:11

Kachurovskaya NA, Zhidomirov GM, van Santen RA (2004) J Phys Chem B 108:5944

Bahidsky M, Hronec M (2005) Catal Today 99:187

Shiju NR, Fiddy S, Sonntag O, Stockenhuber M, Sankar G (2006) Chem Commun 4955

Li Y, Xia H, Fan F, Feng Z, van Santen RA, Hensen EJM, Li C (2008) Chem Commun 774

Louis B, Kiwi-Minsker L, Reuse P, Renken A (2001) Ind Eng Chem Res 40:1454

Hiemer U, Klemm E, Scheffler F, Selvam T, Schwieger W, Emig G (2004) Chem Eng J 101:17

Kollmer F, Hausmann H, Hoelderich WF (2004) J Catal 227:408

Zhu Q, van Teeffelen RM, van Santen RA, Hensen EJM (2004) J Catal 221:575

Yuranov I, Renken A, Kiwi-Minsker L (2005) Appl Catal A Gen 281:55

Xin H, Koekkoek A, Yang Q, van Santen R, Li C, Hensen EJM (2009) Chem Commun 7590

Gopalakrishnan S, Yada S, Muench J, Selvam T, Schwieger W, Sommer M, Peukert W (2007) Appl Catal A Gen 327:132

Gopalakrishnan S, Munch J, Herrmann R, Schwieger W (2006) Chem Eng J 120:99

Meloni D, Monaci R, Solinas V, Berlier G, Bordiga S, Rossetti I, Oliva C, Forni L (2003) J Catal 214:169

Kubanek P, Wichterlova B, Sobalik Z (2002) J Catal 211:109

Hensen EJM, Zhu Q, van Santen RA (2003) J Catal 220:260

Yuranov I, Bulushev DA, Renken A, Kiwi-Minsker L (2004) J Catal 227:138

Sun K, Xia H, Feng Z, van Santen R, Hensen E, Li C (2008) J Catal 254:383

Pirutko LV, Chernyavsky VS, Starokon EV, Ivanov AA, Kharitonov AS, Panov GI (2009) Appl Catal B Environ 91:174

Fellah MF, Onal I, van Santen RA (2010) J Phys Chem C 114:12580

Rana BS, Singh B, Kumar R, Verma D, Bhunia MK, Bhaumik A, Sinha AK (2010) J Mater Chem 20:8575

Koekkoek AJJ, Xin H, Yang Q, Li C, Hensen EJM (2011) Microporous Mesoporous Mater 145:172

Sheldon RA, Kochi JK (1981) Metal-catalyzed oxidations of organic compounds. Academic Press, New York p 329

Goor G, Strukul G (eds) (1992) Catalytic oxidations with hydrogen peroxide as oxidant. Kluver, Dordrecht, p 29

Smith JRL, Norman ROC (1963) J Chem Soc 2897

Uri (1952) Chem Rev 50:375

Baxendale JH, Magee J (1955) Trans Faraday Soc 51:205

Walling C, Kato S (1971) J Am Chem Soc 93:4275

Taramasso M, Perego G, Notari B (1983) US Patent 4(410):501

Perego G, Bellussi G, Corno C, Taramasso M, Buonomo F, Esposito A (1986) Stud Surf Sci Catal 28:129

Thangaraj A, Kumar R, Ratnasamy P (1990) Appl Catal 57:L1

Keshavaraja A, Ramasamy AV, Ratnasamy P (1998) US Patent 5(811):599

Balducci L, Ungarelli F, Tonini C (1999) US Patent 5(965):476

Maruzen Petrochem Co. Ltd. (1995) JP Patent 7,206,736

Notheis U, Konietzni F, Maier WF, Stockmann M (2000) DE Patent 19(853):491

Jeng S, Jou H (2003) TW Patent 503:234

Dongare MK, Singh P, Moghe PP, Ratnasamy P (1991) Zeolites 11:690

Tanev PT, Chibwe M, Pinnavaia TJ (1994) Nature 368:321

Bhaumik A, Mukherjee P, Kumar R (1998) J Catal 178:101

Chen Y, Lu Y (1999) Ind Eng Chem Res 38:1893

Bianchi D, Bortolo R, Tassinari R, Ricci M, Vignola R (2000) Angew Chem Int Ed 39:4321

Chou B, Tsai J, Cheng S (2001) Microporous Mesoporous Mater 48:309

Chen Y, Lin H (2002) J Porous Mater 9:175

Jing H, Guo Z, Ma H, Evans DG, Duan X (2002) J Catal 212:22

Bianchi D, Bertoli M, Tassinari R, Ricci M, Vignol R (2003) J Mol Catal A: Chem 204–205:419

Balducci L, Bianchi D, Bortolo R, Aloisio RD, Ricci M, Tassinari R, Ungarelli R (2003) Angew Chem Int Ed 42:4937

Dumitriu D, Barjega R, Frunza L, Macovei D, Hu T, Xie Y, Parvulescu VI, Kaliaguine S (2003) J Catal 219:337

Lee C, Lin T, Mou C (2003) J Phys Chem B 107:2543

Lemke K, Ehrich H, Lohse U, Berndt H, Jahnisch K (2003) Appl Catal A Gen 243:41

Parvulescu V, Constantin C, Su BL (2003) J Mol Catal A: Chem 202:171

Peng J, Shi F, Gu Y, Deng Y (2003) Green Chem 5:224

Li L, Shi J, Yan J, Zhao X, Chen H (2004) Appl Catal A Gen 263:213

Monfared HH, Amouei Z (2004) J Mol Catal A: Chem 217:161

Parvulescu V, Anastasescua C, Sub BL (2004) J Mol Catal A: Chem 211:143

Parvulescu V, Tablet Cr, Anastasescu C, Sub BL (2004) J Mol Catal A Chem 208:253

Choi J, Kim T, Choo K, Sung J, Saisutta MB, Song S, Rhee Y (2005) J Porous Mater 12:301

Choi J, Kimb T, Choo K, Sung J, Saidutta MB, Ryu S, Song S, Ramachandra B, Rhee Y (2005) Appl Catal A Gen 290:1

Liu H, Fu Z, Yin D, Yin D, Liao H (2005) Catal Commun 6:638

Dubey A, Kannan S (2005) Catal Commun 6:394

Zhanga J, Tang Y, Lia G, Hu C (2005) Appl Catal A Gen 278:251

Gao X, Xu J (2006) Appl Clay Sci 33:1

Jian M, Zhu L, Wang J, Zhang J, Li G, Hu C (2006) J Mol Catal A: Chem 253:1

Molinari R, Poerio T, Argurio P (2006) Catal Today 118:52

Molinari R, Poerio T, Argurio P (2006) Desalination 200:673

Tang Y, Zhang J (2006) Transition Met Chem 31:299

Rudakova NI, Klyuev MV, Erykalov YG, Ramazanov DN (2006) Russ J Gen Chem 76:1407

Nur H, Hamid H, Endud S, Hamdan H, Ramli Z (2006) Mater Chem Phys 96:337

Rudakova NI, Klyuev MV, Erykalov YG, Ramazanov DN (2007) Russ J Gen Chem 77:911

Peng G, Fu Z, Yin D, Zhong S, Yang Y, Yu N, Yin D (2007) Catal Lett 118:270

Fumin Z, Maiping G, Hanqing G, Jun W (2007) Chin J Chem Eng 15:895

Zhong Y, Li G, Zhu L, Yan Y, Wu G, Hu C (2007) J Mol Catal A: Chem 272:169

Bianchi D, Balducci L, Bortolo R, D’Aloisio R, Ricci M, Span G, Tassinari R, Tonini C, Ungarellia R (2007) Adv Synth Catal 349:979

Burri DR, Shaikh IR, Choi K, Park S (2007) Catal Commun 8:731

Dimitrova R, Spassova M (2007) Catal Commun 8:693

Tanarungsun G, Kiatkittipong W, Assabumrungrat S, Yamada H, Tagawa T, Praserthdam P (2007) J Ind Eng Chem 13:1

Parida KM, Rath D (2007) Appl Catal A Gen 321:101

Chen J, Gao S, Xu J (2008) Catal Commun 9:728

Tanarungsun G, Kiatkittipong W, Praserthdam P, Yamadac H, Tagawac T, Assabumrungrat S (2008) Catal Commun 9:1886

Shulpin GB, Muratov DV, Shulpina LS, Kudinov AR, Strelkova TV, Petrovskiy PV (2008) Appl Organometal Chem 22:684

Tanarungsun G, Kiatkittipong W, Praserthdam P, Yamada H, Tagawac T, Assabumrungrat S (2008) J Ind Eng Chem 14:596

Leng Y, Ge H, Zhou C, Wang J (2008) Chem Eng J 145:335

Chammingkwan P, Hoelderich WF, Mongkhonsi T, Kanchanawanichakul P (2009) Appl Catal A Gen 352:1

Todorova S, Parvulescu V, Kadinov G, Tenchev K, Somacescu S, Su BL (2008) Microporous Mesoporous Mater 113:22

Joseph JK, Singhal S, Jain SL, Sivakumaran R, Kumar B, Sain B (2009) Catal Today 141:211

Arichi J, Eternot M, Louis B (2008) Catal Today 138:117

Thibon A, Bartoli J, Guillot R, Saintona J, Martinho M, Mansuy D, Banse F (2008) J Mol Catal A: Chem 287:115

Pan J, Wang C, Guo S, Li J, Yang Z (2008) Catal Commun 9:176

Qi X, Li J, Ji T, Wang Y, Feng L, Zhu Y, Fan X, Zhang C (2009) Microporous Mesoporous Mater 122:36

Shijina AV, Renuka NK (2009) React Kinet Catal Lett 98:139

Feng S, Pei S, Yue B, Ye L, Qian L, He H (2009) Catal Lett 131:458

Sirotin SV, Moskovskaya IF (2009) Pet Chem 49:99

Renuka NK (2010) J Mol Catal A: Chem 316:126

Song S, Yang H, Rao R, Liu H, Zhang A (2010) Catal Commun 11:783

Song S, Yang H, Rao R, Liu H, Zhang A (2010) Appl Catal A Gen 375:265

Zhua Y, Donga Y, Zhaoa L, Yuana F (2010) J Mol Catal A: Chem 315:205

Zhang T, Gao C, Yang H, Zhao Y (2010) J Porous Mater 17:643

Wu G, Tan X, Li G, Hu C (2010) J Alloys Compd 504:371

Molinari R, Poerio T, Granato T, Katovic A (2010) Microporous Mesoporous Mater 129:136

Tong L, Xianyong W, Jianjun Z, Hengsen X, Taotao W, Zhimin Z (2010) Min Sci Tech 20:93

Adam F, Thankappan R (2010) Chem Eng J 160:249

Arab P, Badiei A, Koolivand A, Ziarani GM (2011) Chin J Catal 32:258

Hu X, Zhu L, Wang X, Guo B, Xu J, Li G, Hu C (2011) J Mol Catal A: Chem 342–343:41

Tan X, Zhao Y, Li G, Hu C (2011) Appl Surf Sci 257:6256

Kharat AN, Moosavikia S, Jahromi BT, Badiei A (2011) J Mol Catal A: Chem 348:14

Bianchi D, Bortolo R, Buzzoni R, Cesana A, Dalloro L, D’Aloisio R (2004) EP Patent 1424320

Arunabha D, Sakthivel S, Kumar SJ (2008) US Patent 20,080,234,524

Jain SL, Joseph JK, Singhal S, Sain B, Sivakumaram R, Kumar B (2009) US Patent 20,090,192,337

Dong Y, Fu H, Yuan F, Zhu Y (2009) CN Patent 101(362):098

Chen J, Gao S, Zhang Y (2010) CN Patent 101(612):586

Barbera D, Cavani F, D’Alessandro T, Fornasari G, Guidetti S, Aloise A, Giordano G, Piumetti M, Bonelli B, Zanzottera C (2010) J Catal 275:158

Li Z, Zhang S, Zhao Y, Zhao Z (2010) CN Patent 101(659):598

Molinari R, Poerio T (2011) Appl Catal A Gen 393:340

Molinari R, Lavorato C, Poerio T (2012) Appl Catal A Gen 417–418:87

Molinari R, Poerio T (2010) Asia-Pac J Chem Eng 5:191

Cavani F, Trifiro F, Vaccari A (1991) Catal Today 11:173

Dubey A, Rives V, Kannan S (2002) J Mol Catal A: Chem 181:151

Antonyraj CA, Kannan S (2011) Appl Clay Sci 53:297

Kannan S, Rives V (2000) J Mater Chem 10:489

Rives V, Dubey A, Kannan S (2001) Phys Chem Chem Phys 3:4826

Dubey A, Velu S, Suzuki S, Kannan S (2003) Appl Catal A Gen 238:319

Kannan S, Rives V, Knozinger H (2004) J Solid State Chem 177:319

Ohtani T, Nishiyama S, Tsuruya S, Masai M, J Catal155 (1995) 158

Ohtani T, Nishiyama S, Tsuruya S, Masai M, in Guczi L, Solymosi F, Tetenyi P (eds) (1992) Proceedings of the 10th International Congress on Catalysis, Budapest. Elsevier, Amsterdam, p.1999

Okamura J, Nishiyama S, Tsuruya S, Masai M (1998) J Mol Catal A: Chem 135:133

Sawyer DT, Sobkowiak A, Matsushita T (1996) Acc Chem Res 29:409

Waclaw A, Nowinska K, Schwieger W (2004) Appl Catal A Gen 270:151

Shannon RD, Mitchell CT (1969) Acta Crystallogr Sect B: Struct Sci 25:925

Rives V, Ulibarri MA (1999) Coord Chem Rev 181:61