Abstract

We disclose synthesis of a novel dicationic 1,3-bis(1-methyl-1H-imidazol-3-ium) propane copper(I) dibromate [Bis-(MIM)](CuBr2)] and explored its potential as a heterogeneous catalyst in 1,3-dipolar cycloaddition for regioselective synthesis of 1, 4-disubstituted-1,2,3- triazoles in excellent yields in ethanol: water (60:40%) system at 80°C. The noteworthy feature of the protocol includes in situ generation of aryl azides by azotisation of aryl as well as alkyl halides with sodium azide thereby enduring facile 1,3-dipolar cycloaddition with terminal alkynes.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Designing of sustainable synthetic methodologies to reduce the waste and hazards associated with the conventional synthetic procedures is the main motive of green chemistry [1, 2]. The use of efficient and reusable catalysts has always remained a tool of choice for organic synthesis [3–7]. In this regards metal incorporated heterogeneous catalysts have attracted immense attention due to their plethora of applications to realize green aspects such as high efficiency, reusability, low catalyst loading and ease of separation [8–11].

In the last decade, use of aqueous media in transition-metal catalyzed reactions became popular due to credentials such as nontoxicity, non-flammability, easy availability, safety and inexpensive nature [12–15]. However, scanty solubility of precursors in water avoids its utility in organic transformations. Hence to overcome this problem, aqueous mixed solvent system has been found to be more effective for promoting organic reactions.

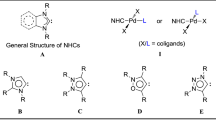

1,2,3-Triazoles have a wide range of applications in medicinal and pharmaceutical chemistry. They exhibit activities such as anti-HIV [16], antibacterial [17], anticancer [18], antiviral [19], Histone deacetylase inhibitor, antifungal [20, 21], antiepileptic [22, 23], anti-allergic [24], antimicrobial against gram positive bacteria and β3-adrenergic receptor agonist [25–27]. The wide applications of 1,2,3-Triazoles have stimulated development of new methods for their synthesis as well as their derivatives. Amongst several methods available for the synthesis of triazoles [28–34], 1,3-dipolar cycloaddition is one of the most admired protocols for the synthesis of 1,2,3-triazole framework [35–43]. The maiden report on 1,3-dipolar cycloaddition of azides with alkynes was put forward by Huisgen et. al [44]. They carried out reactions without using any metal catalyst however, even after long reaction time obtained mixture of 1,4 and 1,5-isomers of 1,2,3-Triazole at high temperature. Later on Meldal [45] and Sharpless [46] introduced the term Click chemistry by employing Cu(I) salts for the reaction of azide with terminal alkynes to afford 1,4-disubstituted products [47, 48]. Now a days, numerous methods are available for 1,3-dipolar cycloaddition employing homogeneous/heterogeneous Cu complex as catalyst [49–53]. Though, copper salts act as a homogeneous catalyst, they suffer from drawbacks such as difficult separation, reusability of the catalyst, cytotoxicity and environmental pollution issues. Furthermore, it is difficult to remove trace amount of catalyst from the final product as metal contamination is highly regulated in the pharmaceutical industry [54–56].

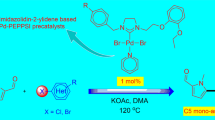

The green chemistry legislations insist to employ eco-benign synthetic procedures but unfortunately most of the reported methods involve explosive and difficult to handle azides as starting materials, organic solvents as reaction media, prolong heating, non-reusable catalytic system and tedious experimental procedures used for separation of catalyst [13, 57–69]. Thus, a truly green method for 1,3-dipolar cycloaddition is highly warranted which could avoid direct use of hazardous organic azides and get catalyzed by eco-friendly heterogeneous copper catalyst which we achieved by in situ generated azides from aryl/ alkyl halides using [bis-(MIM)](CuBr2)] as a reusable, eco-friendly heterogeneous catalyst in ethanol: water system (Scheme 1).

2 Results and Discussion

Initially, we focused our attention towards design and synthesis of copper containing reusable and heterogeneous catalyst viz 1,3-bis(1-methyl-1H-imidazol-3-ium) propane copper(I) dibromate [bis-(MIM)](CuBr2)]. The synthesis of [bis-(MIM)](CuBr2)] is carried out in two steps. In the first step, reaction of 1-methyl imidazole and 1,3-dibromopropane in toluene at 80 °C for 24 h resulted into 83% of dicationic 1,3-bis(1-methyl-1H-imidazol-3-ium) propane dibromide [bis-(MIM)](Br2)]. In the second step the resultant dicationic ionic liquid (IL) was refluxed at 60 °C with CuBr in methanol for 4 h to afford desired amorphous powder of [bis-(MIM)](CuBr2)] (4.56 g, 97%) (Scheme 2). Analysis of synthesized catalyst was done by IR, NMR, SEM, EDS and XPS techniques. Figure 1 displays the overlay FTIR spectra of CuBr(a), [bis-(MIM)](Br2)](b) and [bis-(MIM)](CuBr2)] (c). The absorption bands at 3069 and 3010 cm−1 shows presence of saturated C–H stretching vibrations. The characteristic absorption bands at 1560 and 1466 cm− 1 attributed to C–N stretching vibrations of the imidazole ring [70]. The disappearance of absorption band at 3438 cm−1 in [bis-(MIM)](CuBr2)](c) indicates the formation of desired catalyst.

The SEM analysis (Fig. 2) of the catalyst, before (a) and after use (b) exhibits no significant change in its morphology. The thermal stability of the catalyst was studied by using the thermogravimetric analysis (TGA) and differential thermogravimetry (DTG) analysis in the range of 25–800 °C in an air atmosphere at 10 °C /min. The TGA analysis of the catalyst is depicted in Fig. 3. The TGA profile reflects that the catalyst is highly thermo stable. At the beginning, the catalyst showed a slight weight loss due to the physically adsorbed water molecules upto 200 °C, and had a weight loss of 4.403% at 294.82 °C [70]. The further weight loss in the range of 264.82–385.79 °C is attributed to loss and decomposition of copper(I) dibromate anion. The largest weight loss 48.41% is due to decomposition of cation and formation of metal oxides at 632.68 °C. The total residual weight (24.5%) after thermal degradation of catalyst is in accordance with the theoretical residual weight of the CuO. The presence of copper in [bis-(MIM)](CuBr2)] catalyst is supported by its EDS analysis (Fig. 4) which illustrates incorporation of copper with [bis-(MIM)](Br2)] during reaction.

To investigate the oxidation state of copper in catalyst, XPS analysis was carried out (Fig. 5). The values of binding energy (Fig. 5c) at 932.93 and 953.32 eV correspond to the Cu2p3/2 and Cu2p1/2, respectively. The Auger spectra (Fig. 5d) of catalyst exhibits a characteristic peak at 570.65 eV, which is close to the reported value of 569.9 eV and 570.0 eV for Cu2O [71–73]. The data of binding energy is in good agreement with the literature value of binding energy of Cu(I) [74, 75] revealing that copper integrated in the catalyst is in the form of Cu(I).

In Huisgen 1,3-dipolar cycloaddition, aromatic azides are generally used as precursors. These organic azides are stable against most reaction conditions but their low molecular weight derivatives are explosive and high temperature lead to the decomposition [46]. Recently, scientists explored in situ generation of aryl azides and thus put forward a remedy to overcome drawbacks caused by the direct use of aryl azides [47, 48]. In this perspective, we have initially reacted aryl/alkyl halides with sodium azides for in situ generation of the corresponding azides.

Initially, model reaction for the 1,3-dipolar cycloaddition of benzyl chloride, sodium azide and phenyl acetylene was carried out in presence of catalytic amount of [bis-(MIM)](CuBr2)] at room temperature using ethanol as a solvent, however no progress was observed. Hence, the model reaction was carried out at reflux condition. Pleasurably, the corresponding 1,2,3-triazole was obtained in good yield within short time. The formation of 1,4-disubstituted 1,2,3-triazole instead of 1,5-disubstituted 1,2,3-triazole was confirmed on the basis of spectral data of product in the literature [58, 76, 77].

In order to optimize the reaction conditions for 1,3-dipolar cycloaddition, initially screening of catalyst was carried out for the model reaction (Table 1, entry 1–7). The product was obtained in excellent yield with 5 mol% (0.032 g) of catalyst at 80 °C in ethanol (Table 1, entry 3). No significant change in reaction time and yield of product was observed even though increasing catalyst loading up to 10 mol% (0.064 g) (Table 1, Entry 4). However, when the catalyst loading was reduced to 4 mol% (0.025 g) and 2 mol% (0.012 g), increase in time for completion of reaction and decrease in yield of product was observed (Table 1, entries 1 and 2). To investigate the effect of copper in the catalyst, model reaction was performed in presence of 5 mol% [bis-(MIM)](Br2)] but, no progress in the reaction was observed (Table 1, entry 5). When the same reaction was carried out in the presence of 5 and 10 mol% of CuBr, afforded lower yield of product with increased reaction time (Table 1, entries 6 and 7) as compared to [bis-(MIM)](CuBr2)]. Afterwards, in order to investigate combinatorial effect of both the subparts of catalyst, the model reaction was carried out utilizing CuBr in combination with [bis-(MIM)](Br2)] 5 mol% each (Table 1, entry 8) then there was no significant change in the yield and reaction time.

After screening of the catalyst, we investigated the solvent effect for model reaction. In light of the principles of green chemistry, initially model reaction was carried out in water; however, no product formation was observed (Table 2, entry 1). From our earlier experience in mixed solvent system, we envisaged that mixed solvent system may reinforce the reaction towards completion [78]. Hence, we focused our attention towards screening of ethanol: water system for model reaction (Table 2, entries 2–10). Satisfyingly, we observed the formation of desired product in excellent yield [91%] with 60% ethanol (Table 2, entry 7).

With the optimized reaction conditions in hand, the generality of protocol was evaluated by reactions of various halides with terminal alkynes and NaN3 under optimized reaction conditions and observed that all reactions proceed smoothly furnishing desired product in good yields (Table 3, entries 1–13).

The reusability of catalyst is a prominent feature in case of heterogeneous catalysts. The recovery and reusability of catalyst was performed with model reaction of benzyl bromide, sodium azide and phenyl acetylene. Due to heterogeneous nature, catalyst was separated just by filtration. The filtrate was analyzed using atomic absorption spectroscopy (AAS) and satisfyingly, no copper metal was detected in filtrate which is in support of ionic liquid binds with copper to minimize deterioration and metal leaching results into efficient catalyst recycling. The filtered catalyst was washed with ethyl acetate and chloroform, dried and reused for new reaction. Noticeably, the recovered catalyst was successfully used for four cycles without any remarkable loss in efficiency in terms of time and the yield of desired 1,4-disubstituted 1,2,3-triazole (Fig. 6).

Table 4 encompassed comparison of catalytic system and highlights merits as well as demerits of the literature methods. It is noteworthy that the use of 1,3-bis(1-methyl-1H-imidazol-3-ium) propane copper(I) dibromate [bis-(MIM)](CuBr2)] as new heterogeneous and reusable catalyst for 1,3-dipolar cycloaddition has a comparable/ excellent activity as compared to reported copper catalytic systems. The use of water: ethanol as solvent system, low cost, easy isolation of product from the reaction mixture, operational simplicity, and re-usability are the merits of present method.

3 Conclusion

We have synthesized [bis-(MIM)](CuBr2)] as a novel efficient heterogeneous catalyst in 1,3-dipolar cycloaddition for one-pot multicomponent synthesis of 1,4-disubstituted 1,2,3-triazoles in ethanol: water mixed system at 80 °C. Noticeable advantages of this protocol include operational simplicity, reusability of catalyst, mild reaction conditions along with ambient temperature, regioselectivity and wide substrate scope.

4 Experimental

4.1 General

Various Halides (Sigma Aldrich/Alfa Aesar), Alkynes (Sigma Aldrich/Alfa Aesar), sodium azide (Spectrochem, Mumbai), N-Methyl imidazole (Spectrochem, Mumbai), 1,3-Dibromopropane (Spectrochem, Mumbai) and copper(I) Bromide (Spectrochem, Mumbai) were used as received. All reactions were carried out in aerobic conditions. Melting points were recorded using open capillary method. Infrared spectra were measured with an Agilent Cary (IR-630) spectrophotometer. 1H NMR and 13C NMR spectra were recorded on a Brucker AC spectrometer (300 MHz for 1H NMR and 75 MHz for 13C NMR), using CDCl3 and DMSO-D6 as solvent and tetramethylsilane (TMS) as an internal standard. Chemical shifts (δ) are expressed in parts per million (ppm) and coupling constants are expressed in hertz (Hz). Mass spectra were recorded on a Shimadzu QP2010 GCMS and GC-HRMS from SAIF, IIT Bombay. The morphology of [bis-(MIM)](CuBr2)] was assessed by scanning electron microscope (SEM) (JEON-6360 Japan), operated at an accelerating voltage of 20 kV. EDS were determined using Energy Dispersive X-ray analysis (EDX) was done using ‘Bruker 129 ev’ with ‘Espirit software. X-ray photoelectron (XPS) was measured using monochromatic Al Kα (1486.6 eV) source.

4.2 Typical Procedure for Preparation of Dicationic 1,3-Bis(1-methyl-1H-imidazol-3-ium) Propane Copper(I) Dibromate Catalyst [Bis-(MIM)](CuBr2)

4.2.1 Preparation of Dicationic 1,3-Bis(1-methyl-1H-imidazol-3-ium) Propane Dibromide [Bis-(MIM)](Br2)

In a 100 mL round-bottom flask, 1-methylimidazole (1) (5.0 g, 60.90 mmol) was mixed with 1,3-dibromopropane (6.14 g, 30.45 mmol) in toluene at 80 °C for 12h. After the completion of reaction, the reaction mixture was cooled to room temperature and filtered. The obtained residue was then washed with toluene (10 mL), ethyl acetate (20 mL) and diethyl ether (20 mL) to remove traces of starting materials. Further it was dried under reduced pressure to afford white crystals of dicationic 1,3-bis(1-methyl-1H-imidazol-3-ium) propane dibromide [bis-(MIM)](Br2)] with 83% yield.

4.2.2 Preparation of Dicationic 1,3-Bis(1-methyl-1H-imidazol-3-ium) Propane Copper(I) Dibromate Catalyst [Bis-(MIM)](CuBr2)

The 100 mL round bottom flask is charged with dicationic 1,3-bis(1-methyl-1H-imidazol-3-ium) propane dibromide [bis-(MIM)](Br2) (3.0 g, 7.34 mmol) in methanol (20 mL). Then powdered CuBr (2.109 g, 14.69 mmol) was added in it with constant stirring. The mixture was then stirred at 40 °C for 4h. On completion, the reaction mixture was filtered and washed with MeOH (10 mL × 5) and diethyl ether (20 mL) sequentially dried under reduced pressure to afford 95% amorphous powder of dicationic 1,3-bis(1-methyl-1H-imidazol-3-ium) propane copper(I) dibromate catalyst [bis-(MIM)](CuBr2) .

4.3 General Procedure for Synthesis of 1,4-Disubstituted 1,2,3-triazoles

25 mL of round bottom flask was charged with Aryl/alkyl halides (1 mmol), NaN3 (1.2 mmol), and terminal alkyne (1 mmol) in ethanol: water (60: 40%) (5mL). Then [bis-(MIM)](CuBr2)] (5 mol%) was added to the above solution. The reaction mixture was stirred at 80 °C for time mentioned in Table 3. The completion of reaction was monitored by TLC. Work-up of reaction is done by adding ice water. The solid obtained was extracted with ethyl acetate over anhydrous sodium sulphate. The structure of the product was confirmed by using IR, 1H NMR, 13C NMR and MS (EI) analysis.

References

United States Environmental Protection Agency. http://www.epa.gov/ Accessed Mar 2009

Paul A, Nicolas E (2010) ChemSoc Rev 39:301.

Walsh PJ, Lia H, de Parrodi CA (2007) Chem Rev 107(6):2503

Zaera F (2013) Chem Soc Rev 42:2746

Madhavan N, Jones CW, Weck M (2008) Acc Chem Res 41:1153

Schatz A, Grass RN, Stark WJ, Reiser O (2008) Chem Eur J 14:8262

Bhadra S, Sreedhar B, Ranu BC (2009) Adv Synth Catal 351:2369

Pitchaimani V, Murugesan V Kuang-Lieh L, Seenivasan R (2011) Catal Sci Technol 1:1512

Ali P, Mahmood T, Maryam F, Seyed HH (2015) New J Chem 39:4591

Kantama ML, Jaya VS, Sreedhar B, Rao MM, Choudary BM (2006) J Mol Catal 256:273

Baig RN, Vaddula BR, ‡a Nadagouda MN, Varma RS (2015) Green Chem 17:1243.

Xiong X, Cai L, Jiang Y, Han Q (2014) ACS Sustain Chem Eng 2:765

Movassagh B, Rezaei N (2014) Tetrahedron 70:8885

Tajbakhsh M, Farhang M, Baghbanian SM, Hosseinzadeh R, Tajbakhsha M (2015) New J Chem 39:1827

Shintaku H, Nakajima K, Kitano M, Ichikuni N, Hara M (2014) ACS Catal 14:1198.

Ouellet M, Mercier S, Pelletier I, Bounou S, Roy J, Hirabayashi J, Sato S, Tremblay MJ (2005) J Immunol 174:4120

Velazquez S, Alvarez R, Perez C, Gago F, De Clercq E, Balzarini J, Camarasa MJ (1998) Antiviral Chem Chemother 9:481.

Dabak K, Sezer O, Akar A, Anac O (2003) Eur J Med Chem 38215

Shanmugavelan P, Nagarajan S, Sathishkumar M, Ponnusamy A, Yogeeswari P, Sriram D (2011) Bioorg Med Chem Lett 21:7273.

Agalave SG, Maujan SR, Pore VS (2011) Chem Asian J 6:2696

Genin MJ, Allwine DA, Anderson DJ, Barbachyn MR, Emmert DE, Garmon SA, Graber DR, Grega KC, Hester JB, Hutchinson DK, Morris J, Reischer RJ, Ford CW, Zurenco GE, Hamel JC, Schaadt RD, Stapert D, Yagi BH (2000) J Med Chem 43:953

Buckle DR, Rockell CJM, Smith H, Spicer BA (1986) J Med Chem 29:2262

Haider S, Alam MS, Hamid H (2014) Inflamm Cell Signal 1:10

Brockunier LL, Parmee ER, Ok HO, Candelore MR, Cascieri MA, Colwell LF, Deng L, Feeney WP, Forrest MJ, Hom GJ, MacIntyre DE, Tota L, Wyvratt MJ, Fisher MH, Weber AE (2000) Bioorg Med Chem Lett 10:2111.

Pagliai F, Pirali T, Grosso ED, Brisco RD, Tron GC, Sorba G, Genazzani AA (2006) J Med Chem 49:467

Bakunov SA, Bakunova SM, Wenzler T, GhebruM, Werbovetz KA, Brun R, Tidwell RR (2010) J Med Chem 53:254

Banday AH, Shameem SA, Gupta BD, Sampath Kumar HM (2010) Steroids 75:801

Haldόn E, Álvarez E, Nicasio MC, Pérez PJ 2014 Chem Commun 50:8978

Liu X, Li J, Chen B (2013) New J Chem 37:965

Patil JD, Pore DM (2014) RSC Adv 4:14314

Pore DM, Hegade PG, Mane MM, Patil JD (2013) RSC Adv 3:25723

Ueda S, Nagasawa H (2009) J Am Chem Soc 131:15080

Batchelor DV, BealDM, Brown TB, Ellis D, Gordon DW, Johnson PS, Mason HJ, Ralph MJ, Underwood TJ, Wheeler S (2008) Synlett 16:2421

Yin P, Ma WB, Chen Y, Huang WC, Deng Y, He L (2009) Org Lett 11:5482

Brittain WDG, Buckley BR, Fossey JS (2016) ACS Catal 6:3629

Ladomenou K, Nikolaou V, Charalambidis G, Coutsolelos AG (2016) Coordinat Chem Rev 306:1

Bock VD, Hiemstra H, van Maarseveen JH (2006) Eur J Org Chem 2006:51

Dervaux B, Du Prez FE, (2012) Chem Sci 3:959

Kappe CO, der Eycken EV, (2010) Chem Soc Rev 39:1280.

Amblard F, Cho JH, Schinazi RF (2009) Chem Rev 109:4207

Dedola S, Nepogodiev SA, Field RA (2007) Org Biomol Chem 5:1006

Sletten EM, Bertozzi CR 2011 Acc Chem Res 44:666

Ganesh V, Sudhir VS, Kundu T, Chandrasekaran S (2011) Chem Asian J 6:2670.

Huisgen R, Knorr R, Mobius L, Szeimies G (1965) Chem Ber 98:4014

Tornøe CW, Christensen C, Meldal M (2002) J Org Chem 67:3057

Kolb HC, Finn MG, Sharpless KB (2001) Angew Chem Int Ed 40:2004

Rostovtsev VV, Green LG, Forkin VV, Sharpless KB (2002) Angew Chem Int Ed 41:2596

Alonso F, Moglie Y, Radivoy G (2015) Acc Chem Res 48:2516

Patil JD, Patil SA, Pore DM (2015) RSC Adv 5:21396

Matlack AS (2001) Introduction to green chemistry, Marcel Dekker, New York

Lachlan S, Campbell -V, SzymańskiW, Postema CP, Dierckx RA, Elsinga PH, Janssen DB, Feringa BL (2010) Chem Commun 46:898

Senwar KR, Sharma P, NekkantiS, SathishM, Kamal A, Sridhar B, Shankaraiahet N (2015) New J Chem 39:3973

CaiY-B, Liang L, Zhang J, Sun H-L, Zhang J-L (2013) Dalton Trans 42:5390

Baig RN, Varma RS (2012) Green Chem 14:625

Dervauxa B, Du Prez FE (2012) Chem Sci 3:959

Megia-Fernandez A, Ortega-Mun˜oz M, Lopez-Jaramillo J, Hernandez-Mateo F, Santoyo-Gonzalez F (2010) Adv Synth Catal 352:3306

Roy S, Chatterjee T, Islam SKM (2013) Green Chem 15:2532

Alonso F, Moglie Y, Radivoy G, Yus M (2011) Org Biomol Chem 9:6385

Mohammed S, Padala AK, Dar BA, Singh B, Sreedhar B, Vishwakarma RA, Bharate SB (2012) Tetrahedron 68:8156

Johansson JR, Lincoln P, Nordén B, Kann N, (2011) J Org Chem 76:2355.

Pitchaimani V, MurugesanV, Lu K-L, Rajagopal S (2011) Catal Sci Technol 1:1512

Bénéteau V, Olmos A, Boningari T, Sommer J, Pale P (2010) Tetrahedron Lett 51:3673

Abdulkin P, Moglie Y, Knappett BR, Jefferson DA, Yus M, Alonso F, Wheatley AEH (2013) Nanoscale 5:342

Alonso F, Moglie Y, Radivoy G, Yus M, (2012) Syn Lett 23:2179

Zhang C, Huang B, Chen Y, Cui D-M (2013) New J Chem 37:2606

Huang L, Liu W, Wu J, Fu Y, Wang K, Huo C, Du Z (2014) Tetrahedron Lett 55:2312

Tasca E, Sorella GL, Sperni L, Strukul G, Scarso A (2015) Green Chem 17:1414

Albadi J, eshavarz MK, Abedini M, Vafaie-nezhad M, (2012) Chin Chem Lett 23:797

Chen Y, Zhuo Z-J, Cui D-M, Zhang C (2014) J Organomet Chem 749:215.

Ren Q, Zuo T, Pan J, Chen C, Li W (2014) Materials 7:8012.

Diaz-Droguett DE, Espinoza R, Fuenzalida VM (2011) App Surf Sci 257:4597

Park J-Y, Jung Y-S, Cho J, Choi W-K (2006) Appl Surf Sci 252:5877

Zhou JC, Soto CM, Chen M–S, Bruckman MA, Moore MH, Barry E, Ratna BR, Pehrsson PE, Spies BR, Confer TS (2012) J Nanobiotechnol 10:18

Laffineur F, Mekhalif Z, Tristani L, Delhalle J (2005) Mater J Chem 15:5054

Gelves GA, Murakami ZTM, Krantz MJ, Haber JA (2006) J Mater Chem 16:3075.

Esfahani MN, -Baltork IM, Khosropour AR, Moghadam M, Mirkhani V, Tangestaninejad S, Rudbari HA (2014) J Org Chem 79:1437

Campbell-Verduyn LS, Mirfeizi L, Dierckx RA, Elsinga PH, Feringa BL (2009) Chem Commun 16:2139.

Dige NC, Pore DM (2015) Synth Commun 45:2498.

Acknowledgements

One of the authors NCD is grateful to the University Grants Commission (UGC), New Delhi for providing financial assistance in the form of UGC-BSR-SAP fellowship (F.25- 1/2014-15(BSR)/7-183/2009(BSR) – 5 November 2015). We are also grateful to the Department of Science and Technology (DST), New Delhi for providing funds under FIST-Level-II program for infrastructure improvement and University Grants Commission (UGC), New Delhi for financial support through DRS-Phase-II program to the Department of Chemistry, Shivaji University, Kolhapur.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Dige, N.C., Patil, J.D. & Pore, D.M. Dicationic 1,3-Bis(1-methyl-1H-imidazol-3-ium) Propane Copper(I) Dibromate : Novel Heterogeneous Catalyst for 1,3-Dipolar Cycloaddition. Catal Lett 147, 301–309 (2017). https://doi.org/10.1007/s10562-016-1942-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-016-1942-z