Abstract

The combination of electrocoagulation with another process is a promising approach to enhance the removal efficiency of water pollutants. For instance, free radical-assisted electrocoagulation is a new combination showing higher performance. There are different combinations depending on the free radical source. This article reviews free radical-assisted electrocoagulation processes. We discuss electrocoagulation mechanisms; ozone-assisted electrocoagulation processes; advanced oxidation-assisted electrocoagulation processes; and ultrasound-assisted electrocoagulation. We present kinetic models used in free radical-assisted electrocoagulation, scale-up of free radical-assisted electrocoagulation and cost estimation. The major points are: most of the available studies have been done at laboratory scale with synthetic wastewater, and lack holistic and systematic approaches to consider the process complexity. The performance of the combined process is improved, and the removal efficiency is increased especially with ozone-assisted electrocoagulation, which gives a removal efficiency of more than 95%. The use of ultrasound energy with electrocoagulation is advantageous in reducing the problem of electrode passivation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the last two decades, various wastewater effluents have been treated effectively via electrocoagulation process. It was found that such methods have succeeded to remove many pollutants from water such as lignin, phenol, heavy metal ions and anionic contaminants dyes (Al-Shannag et al. 2013, 2014; Bibi et al. 2017; Butler et al. 2011; Daneshvar et al. 2006; Esfandyari et al. 2015; Murugananthan et al. 2004; Naji et al. 2017; Pulkka et al. 2014; Uğurlu et al. 2008; Wang et al. 2009). In addition, electrocoagulation (EC) processes contribute largely in reducing suspended solids (SS), total dissolved solids (TDS), chemical oxygen demand (COD) and biochemical oxygen demand (BOD) levels in wastewater effluents. In particular, many previous studies demonstrated that electrocoagulation (EC) process represents an alternative approach to remove many heavy metal ions from industrial wastewater such as chromium, copper, nickel, arsenic, zinc, manganese, mercury, cadmium, lead, silver, iron and boron (Akbal and Camcı 2011; Al-Shannag et al. 2015; Al Aji et al. 2012; Amarasinghe and Williams 2007; Bazrafshan et al. 2015; Hashim et al. 2017; Heidmann and Calmano 2008; Kartikaningsih et al. 2016; Mahmad et al. 2015; Merzouk et al. 2009; Mouedhen et al. 2009; Nanseu-Njiki et al. 2009; Singh et al. 2006; Wan et al. 2011).

Many reviews report the best achievements of electrocoagulation (EC) processes (Al-Qodah and Al-Shannag 2017; Bazrafshan et al. 2015; Hakizimana et al. 2017; Kabdaşlı et al. 2012; Khandegar and Saroha 2013; Moussa et al. 2016; Pulkka et al. 2014; Sahu et al. 2014; Verma et al. 2013; Zheng et al. 2017). Such previous reviews illustrated the many advantages of this treatment process including the simplicity of operation, low startup time, no need of chemicals to better removal efficiencies, high filterability of the produced sludge, high removal efficiency, easy and rapid controlled process (Khandegar and Saroha 2013; Siringi et al. 2012). On contrary, the major drawbacks of using electrocoagulation (EC) method as treatment process are: It depends solely on the electrical energy produced from non-renewable resources which can be overcome by using renewable energy resources such as solar energy (Dominguez-Ramos et al. 2010) and biogas produced from waste materials (Fernandes et al. 2015), the consumption of sacrificial as a result of its oxidation wastewater solution medium, the generation of oxide film on the cathode which reduces electrocoagulation (EC) efficiency, the electrocoagulation medium requires minimum electrical conductivity of the wastewater, and the creation of new materials in the generated sludge from the electrocoagulation reactor that may be harmful to the environment.

In addition, the literature does not have sufficient information for scaling up this process from laboratory/batch to industrial/continuous scale or even to pilot plant scale (Calvo et al. 2003; Den and Huang 2006; Feng et al. 2003; Holt et al. 2005; Zolotukhin 1989). Therefore, the use of electrocoagulation process together with other treatment processes might improve its performance. The review of Barrera-Díaz et al. (2014) discussed the electrocoagulation process combined with the following treatment processes: electrocoagulation–ultrasound, electrocoagulation–ozone, electrocoagulation–pulses and electrocoagulation–adsorption processes.

This review represents the first attempt to focus on the performance of free radical-assisted electrocoagulation processes. Free radical-assisted electrocoagulation includes processes using ozone, advanced oxidation materials or devises in addition to ultrasound energy. The common feature in these processes is the formation of free radicals that attack the pollutants found in the wastewater. In addition to the mechanism and performance of these processes, the kinetics, scale-up approach, and cost analysis will be discussed and analyzed.

Electrocoagulation mechanism

In the electrocoagulation (EC) complex process, ionic coagulants are generated by the oxidation of consumable metallic anodes (Salameh et al. 2015). The generated ionic species diffuse throughout the solution, destabilize the emulsion and then enhance the formation of complex flocculants from the dissolved suspended, or emulsified pollutants (Fernandes et al. 2015). The physical and chemical changes that usually occur in any electrocoagulation process can be summarized into the following successive steps (Cañizares et al. 2007; Fernandes et al. 2015; Salameh et al. 2015; Zhao et al. 2016):

-

(i)

Oxidation of the anode to form the positive ionic coagulants.

-

(ii)

Reduction in water molecules on the cathode to form hydroxyl ions (OH−) and some oxygen and hydrogen gas bubbles.

-

(iii)

Movement of the formed ions to the oppositely charged electrodes. This movement leads to destabilization of the pollutants and then breaks down the emulsion.

-

(iv)

Intimate interaction between the positive ions and the negative hydroxyl ions to form metallic hydroxides of high adsorption properties. The metallic hydroxide molecules aggregate to form polymeric structure that sweep in solution.

-

(v)

Pollutants are adsorbed into the polymeric structures to form larger aggregates.

-

(vi)

Pollutants could be converted to less toxic forms by possible redox reactions.

-

(vii)

Removal of aggregates by flotation of hydrogen and oxygen bubbles which move upwards in the liquid phase or get precipitated if they have relatively high density compared to the solution medium.

On the other hand, it should be noted that there is a wide variety of perspective views in the literature about the exact mechanism of the electrocoagulation processes. For this reason, a systematic approach is required to fully understand the electrocoagulation (EC) mechanism and its controlling variables. This will enable the design of an optimum process and a prior prediction of the treatment of any pollutant (Holt 2002).

The oxidation reactions that take place on the sacrificial electrodes depend on the anode material. Many previous electrocoagulation investigations utilized anodes that are made of iron (Fe) and stainless steel (SS) and aluminum (Al) or aluminum alloy (Fekete et al. 2016; Lin et al. 2005; Vasudevan et al. 2011). Other electrocoagulation researches utilized copper (Ali et al. 2013; Prajapati et al. 2016), zinc (Ali et al. 2013; Vasudevan et al. 2011), and magnesium or magnesium-based alloy anode (Oumar et al. 2016; Vasudevan and Lakshmi 2012).

For iron (Fe) or stainless steel (SS) electrodes with alkaline conditions, the following oxidation/reduction reactions could take place (Al-Shannag et al. 2012; Pulkka et al. 2014; Salameh et al. 2015):

At acidic conditions, the following reactions may occur:

For aluminum electrode systems in basic conditions, the redox reactions can be summarized as follows (Pulkka et al. 2014):

At acidic conditions, the following reactions occur:

According to the above equations, as aluminum ions (Al3+) are generated from the anode, they react with hydroxyls ions (OH−) generated from the cathode to form Al(OH) +2 at low pH. Then, with increasing pH, Al(OH)3 is initially produced and finally polymerization takes place to form Aln(OH)3n.

Ozone-assisted electrocoagulation processes

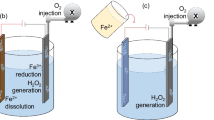

Ozone (O3) is as a strong oxidizing agent (Al-Momani et al. 2008; Song et al. 2008). It can oxidize various organic and inorganic compounds in two different mechanisms: direct oxidation by ozone molecule and/or indirect by the formation of free radicals such as the hydroxyl radical (OH·) (Asaithambi et al. 2012; Hernández-Ortega et al. 2010; Lafi et al. 2009). The action of ozone in the production of hydroxyl radical (OH·) which acts as strong, effective and non-selective oxidizing agent can be expressed by the following set of equations:

If ozone is bubbled into the electrocoagulation (EC) aqueous solution, redox reactions take place in which ozone decomposes after its reaction with Fe2+ ions to form the intermediate ion (FeO2+) which consequently reacts with water to form hydroxyl radical (OH·) and Fe3+ ions as follows (Bernal-Martínez et al. 2010; Sauleda and Brillas 2001):

After the formation of the hydroxyl radical, it oxidizes the organic compounds present in the medium by three different mechanisms including: radical addition to the compound, abstraction of hydrogen atom and electron transfer (Huang et al. 1993).

It is clear from Eqs. (24)–(26) that there is a mutual activation between ozone and Fe2+. On the one hand, the presence of Fe2+ in the electrocoagulation medium enhances ozone decomposition to hydroxyl radical. On the other hand, the presence of ozone bubbles in the coagulation system, with Fe2+, forms the catalytic O3/Fe2+ system that forms the intermediate FeO2+, a species that reacts with water to evolve hydroxyl radical, HO· and Fe3+ ions. These mutual activation products could accelerate the decomposition of the organic pollutants and consequently enhance the process efficiency (Piera et al. 2000; Sauleda and Brillas 2001). Accordingly, many researchers have combined ozonation with electrocoagulation treatment process especially in the case of organic pollutants. The first cited contribution was that of He et al. (2007) who used electrocoagulation enhanced with ozone to decolorize aqueous solutions containing C.I. Reactive Yellow 84. They reported that the rate of dye decay increased with increasing ozone flow rate and the total organic carbon (TOC) removal reached 85% where 97% of color decay was achieved in the first 10 min of the process. Song et al. (2008) repeated the same process to decolorize aqueous solutions containing C.I. Reactive Blue. They used a flow rate of ozone of 20 mL/min and found that total organic carbon (TOC) removal reached 80 and 97% of color decay was achieved in the first 10 min of the process.

Subsequently, several researchers used the same ozone-assisted electrocoagulation (OEC) process combination with some differences in the values of the operational parameters. In most of these researches, the experimental setup of the electrocoagulation process is similar to that of Asaithambi et al. (2016a) shown in Fig. 1.

Experimental setup of ozone-assisted electrocoagulation. It consists of a batch reactor equipped with the suitable electrodes. The required ozone is usually generated from dry air by electric discharge and was continuously bubbled into the electrochemical reactor with air or as pure ozone (Asaithambi et al. 2016a); Elsevier license number 4236550321997

The main results obtained by previous researches are summarized in Table 1. It is clear from Table 1 that all of the applications of combined ozone-assisted electrocoagulation (OEC) processes were used to decolorize colored wastewater in addition to remove total organic carbon (TOC) removal and/or chemical oxygen demand (COD) (Asaithambi et al. 2012, 2016a; Behin et al. 2015; Daghrir et al. 2016; García-García et al. 2014; He et al. 2007; Hernández-Ortega et al. 2010; Hsing et al. 2007; Orescanin et al. 2011; Roa-Morales et al. 2014; Song et al. 2007, 2008; Wu et al. 2008). The maximum removal efficiencies of color, chemical oxygen demand (COD), total organic carbon (TOC) and turbidity were 100 (Asaithambi et al. 2016a; Behin et al. 2015; Wu et al. 2008), 99.3 (Daghrir et al. 2016), 85 (He et al. 2007) and 90% (Hernández-Ortega et al. 2010), respectively. García-García et al. (2014) successfully used it to reduce or eliminate the microorganism population in the treated water prior storage. However, very limited number of publications has showed the impact of ozone on the electrocoagulation process. Asaithambi et al. (2016a) applied three different processes for the treatment of real distillery industrial effluents. These processes were ozonation, electrocoagulation (EC) and ozone-assisted electrocoagulation (OEC). The removal efficiencies of color and chemical oxygen demand (COD) in these three processes are compared in Fig. 2.

Comparison of ozonation, electrocoagulation (EC) and combined ozone-assisted electrocoagulation (OEC) processes (current density: 3 A/dm2; effluent chemical oxygen demand (COD) concentration: 3000 ppm, effluent pH: 7; Inter-electrode distance: 1.8 cm; electrolysis time: 5 h and ozone flow rate: 15 L/min and concentration: 2 g/h). The removal efficiencies of the combined process were 100% for color and 97.50% of chemical oxygen demand (COD). On the other hand, the removal efficiency of the single ozonation process was 18% of color and 21% of chemical oxygen demand (COD) and that of single electrocoagulation (EC) process was 92% of color and 78% of chemical oxygen demand (COD). (Asaithambi et al. 2012); Elsevier license number 4236630471733

As can be seen in Fig. 2, the combination of combined ozone-assisted electrocoagulation (OEC) processes process resulted in a very effective and efficient treatment process. As mentioned above, this enhancement is referred to the effect of ozonation on the formation of the hydroxyl radical (OH·). The interaction between ozone and Fe2+ ions produced from iron electrode oxidation expressed by Eq. 23 through Eq. 25 produces the generated in situ active radicals that attack and oxidize the organic compound. Consequently, both color and chemical oxygen demand (COD) were remarkably reduced. Similar results were obtained by Asaithambi et al. (2012) for the removal of color and chemical oxygen demand (COD) from the distillery effluent as shown in Fig. 3.

Comparison of ozonation, electrocoagulation and combined ozone-assisted electrocoagulation (OEC) for the removal of color and chemical oxygen demand (COD) from the distillery effluent (condition: initial chemical oxygen demand (COD) concentration: 2500 ppm, current density: 3 A/dm2, initial pH: 6, ozone flow rate: 15 L/min). The maximum chemical oxygen demand (COD) removal efficiency of the combined process was only 83% compared with 97.5% obtained by Asaithambi et al. (2016a) (Asaithambi et al. 2012); Elsevier license number 4236551000535

It is clear from Fig. 3 that ozone-assisted electrocoagulation (OEC) process was more efficient than EC or ozonation process alone. It should be noted that the removal efficiencies of both color and chemical oxygen demand (COD) using ozonation only were relatively low compared to those achieved using electrocoagulation (EC) or combined ozone-assisted electrocoagulation (OEC). The reason could be attributed to the poor mass transfer of ozone O3 from the gaseous to the liquid phase containing the organic pollutants.

Behin et al. (2015) applied a combined ozone-assisted electrocoagulation (OEC) process to decolorize the acid dye, AB214 using a rectangular internal loop airlift reactor. This reactor which is shown in Fig. 4 was used to enhance ozone (O3) transfer between the gaseous and liquid phases. They reported that the decolorization efficiencies of AB214 obtained at 30-min treatment period in Fig. 5. This result confirms that if ozone (O3) mass transfer to the liquid phase is improved using suitable reactors such as the air lift reactor, it will result in a good decolorization efficiency.

Schematic of experimental combined ozone-assisted electrocoagulation (OEC) setup. Intensive mixing between the phases takes place due to the induced liquid recirculation between the riser and the down comer of the reactor (Behin et al. 2015); Elsevier License number 4236551295750

Decolorization efficiency of AB214 by ozonation, electrocoagulation (EC) and ozone-assisted electrocoagulation (OEC) (initial dye concentration: 50 mg/L, current density: 15 mA/cm2, initial pH 9.5, superficial gas velocity: 0.45 cm/s, salt concentration: 3 g/L). The decolorization by ozonation, electrocoagulation (EC) and combined ozone-assisted electrocoagulation (OEC) was 82.88, 45.72 and 100.00%, respectively. (Behin et al. 2015); Elsevier License number 4236631162790

According to the above results, combined ozone-assisted electrocoagulation (OEC) process has an improved performance compared to both ozone and electrocoagulation (EC) processes and permits high removal efficiencies of organic pollutants. However, this process still faces many challenges that limit its large-scale application. The first challenge is the poor mass transfer of ozone gas to the liquid phase in the combined ozone-assisted electrocoagulation (OEC) reactor. This problem becomes more serious in large-scale reactors. Consequently, this fact suggests the search for a suitable design of the combined ozone-assisted electrocoagulation (OEC) reactor is able to facilitate intensive mass transfer rates of ozone to the liquid phase. The air lift reactor of a square cross section used by Behin et al. (2015) represents a good attempt to achieve a suitable reactor design. However, the use of circular cross section of the reactor could give more encouraging results since mixing between the phases will be more efficient than that in square cross section. The second challenge for this combined ozone-assisted electrocoagulation (OEC) application is the absence of any scale-up attempt since all the published experiments are laboratory scale. Since the combined ozone-assisted electrocoagulation (OEC) reactor usually contains different phases including the gas phase, the design of this reactor plays a critical role in improving the overall performance of the process. Another challenge is the large-scale production of ozone by a cost-effective process. This could be achieved by using simultaneous anodic oxidation, taking advantage of the possibilities of electrochemical technology to produce oxidants (Cañizares et al. 2009).

Advanced oxidation-assisted electrocoagulation processes

Advanced oxidation processes are considered as a suitable alternative approaches for dye decolorizing and for reducing organic wastewater loads produced from textile companies (Wu et al. 2008). These processes include the use of ozone (O3) as discussed in the previous section, TiO2 (Xu 2001), ultra violet radiation (UV) (Lafi et al. 2010; So et al. 2002) or a combination of these processes. In the different advanced oxidation-assisted electrocoagulation (AOEC) processes, not only the hydroxyl radical (OH*), as very powerful and non-selective oxidizing agent, is formed and acts to destroy hazardous pollutants. Other radicals are formed as will be shown in the following mechanisms expressing the advanced oxidation-assisted electrocoagulation (AOEC) processes performance. For this reason, these processes were combined with electrocoagulation process to enhance the overall treatment process (Xu 2001).

The combination of advanced oxidation-assisted electrocoagulation (AOEC) processes could affect the mechanism of the free radicals formation. For example, the combination of ozone with ultraviolet (UV) leads to the formation of the hydroxyl radicals by the direct and indirect after the decomposition of ozone and after the formation of hydrogen peroxide (H2O2) formation, respectively, as expressed in the following equation (Peyton and Glaze 1985):

It is clear from Eqs. (26)–(29) that ultraviolet (UV) radiation enhances ozone decomposition, yielding more free hydroxyl radicals and thereby increasing the decolorization rate. Various studies have also established that ultraviolet (UV) promotes ozone decolorization (Peyton and Glaze 1985; Tezcanli-Güyer and Ince 2004).

Several authors suggested mechanisms for the enhancement effect of ultraviolet (UV) irradiation on TiO2. Konstantinou and Albanis (2004) proposed a mechanism for the degradation of dye in ultraviolet/titanium oxide, (UV)/(TiO2), system as shown the following set of equations:

On the other hand, Qu et al. (1998) previously had suggested that the mechanism of UV/TiO2 could have the following additional reactions:

Subsequently, Chen et al. (2001) added two possible reactions as a part of the mechanism of ultraviolet/titanium oxide system:

The above set of equations showed that in addition to hydroxyl radicals, OH*, there are other radicals such as superoxide radical anions, O ·−2 , hydrodioxyl radicals, HO ·2 and photo-generated holes hVB+, hydrogen peroxide (H2O2) formed as the primary oxidizing species in the UV/TiO2 system (Ganzenko et al. 2017). In addition, and as mentioned above, Fe2+ and Fe3+ are usually generated in the electrocoagulation system. Accordingly, so combining ultraviolet/titanium oxide with electrocoagulation could produce a Fenton or Fenton-like reaction that enhances the decolorization.

Several researches have been published since 2008 dealing with the coupling of one or more advanced oxidation-assisted electrocoagulation processes (AOEC) with electrocoagulation (EC) process. Wu et al. (2008) investigated the decolorization efficiency of Procion Red MX-5B in electrocoagulation assessed by ultraviolet/titanium oxide and ozone-related systems. They reported that the decolorization rate constants of these combined processes fitted pseudo-first-order kinetics and the rate constants increased as the total power input increased. In addition, it was found that decolorization efficiency was enhanced by combining ultraviolet with electrocoagulation, electrocoagulation with ultraviolet/titanium oxide and electrocoagulation with ultraviolet/titanium oxide as shown in Fig. 6.

Decolorization efficiency of electrocoagulation, ultraviolet/electrocoagulation, ultraviolet/titanium oxide and ultraviolet/titanium oxide/electrocoagulation systems (Procion Red MX-5B = 20 ppm, ultraviolet = 8 W, titanium oxide = 0.5 g/L, EC = 0.2 A, current density = 1.5 mA/cm2 and T = 25 °C. Decolorization % and the reaction rate constants, k of the systems ultraviolet/titanium oxide/electrocoagulation, ultraviolet/titanium oxide, ultraviolet/electrocoagulation and electrocoagulation were 80, 0.89; 50, 0.35; 40, 0.26 and 35%, 0.22 h-1, respectively, (Wu et al. 2008); Elsevier License number 4236640139733

Recently, Akyol et al. (2015) investigated the synergetic effect of combined electrocoagulation (EC), electrocoagulation (EC) and photochemical oxidation (PCO), electrocoagulation-photochemical oxidation (EC-PCO) process for the removal of hydroquinone (HQ) from aqueous solution. The experimental setup is shown in Fig. 7. They suggested the following two reactions for the formation of necessary free radicals that attack the hydroquinone (HQ) and convert it to p-benzoquinone (BQ) which was removed by the subsequent electrocoagulation (EC) process:

The experimental setup of photochemical oxidation-assisted electrocoagulation, the electro-coagulator was made of Plexiglas equipped with four aluminum anodes and of three stainless steel cathodes (Akyol et al. 2015); Elsevier License number 4236600045316

For the experimental setup shown in Fig. 7, the electrodes were connected to a digital direct-current (DC) power supply at monopolar parallel mode. They used a tubular quartz photoreactor which as surrounded by six ultraviolet (UV) lamps which predominantly emit homogenous radiation field inside the reactor at 365 nm. Air was bubbled blown into the photoreactor through a diffuser in order to maintain the solution saturated with oxygen during the course of the experiment. They used several combinations of treatment processes of hydroquinone (HQ) by the separate and combined electrocoagulation and photochemical oxidation (EC-PCO) processes in the presence or the absence of the air supply.

The results of Akyol et al. (2015) are shown in Fig. 8. It is evident from Fig. 8 that the complete remove of hydroquinone (HQ) is not achievable by any combination of the treatment processes. However, the lowest hydroquinone (HQ) removal efficiency was achieved when photochemical oxidation (PCO) was applied alone. On the other hand, hydroquinone (HQ) removal efficiency was maximum by combining both electrocoagulation (EC) and photochemical oxidation (PCO) methods with constant air supply, which indicates that oxygen plays an important role in the oxidation of hydroquinone (HQ). The photochemical oxidation process converts hydroquinone (HQ) in the presence of oxygen to p-benzoquinone (BQ) which was subsequently removed by the electrocoagulation (EC) process.

Effect of ultraviolet (UV) light power on the hydroquinone (HQ) removal efficiency. The removal efficiency of hydroquinone (HQ) was 9 and 91.5% for photochemical oxidation (PCO) and combining both electrocoagulation (EC) and photochemical oxidation (PCO), respectively. (Akyol et al. 2015); Elsevier License number 4236640605105

Jaafarzadeh et al. (2016) applied an electrocoagulation process, electrocoagulation followed by ultraviolet oxidant system for the removal of organic compounds from pulp and paper wastewater. Since the pulp and paper wastewater usually contain high load of pollutants characterized by dense color and high-level turbidity, the performance of the ultraviolet (UV)-based processes will be very limited as the pollutants absorb ultraviolet (UV) irradiation and prevent the activation of the oxidant. Therefore, electrocoagulation (EC) process is applied as pre-treatment process in this application to reduce the color and turbidity necessary for effective performance of ultraviolet (UV)-based processes for the treatment such as wastewater. The ultraviolet oxidant system was ultraviolet/persulfate (UV/PP) at pH = 8.2 and ultraviolet/peroxi-mono-sulfate (UV/PMS) at pH = 4.0. At these conditions, ultraviolet irradiation enhances the formation of the following free radicals (Li et al. 2013a):

Jaafarzadeh et al. (2016) used an efficient parameter as a partial oxidation efficiency (µpartox) in order to evaluate the mineralization capacity of oxidative processes of ultraviolet/peroxi-mono-sulfate (UV/PMS) and ultraviolet/persulfate (UV/PS). This parameter was evaluated using the following two equations (Mantzavinos et al. 2000; Papastefanakis et al. 2010):

The values of µpartox are between 0 and 1. µpartox is 0 for total oxidation and 1 for ideal condition or partial oxidation only. The results of Jaafarzadeh et al. (2016) showed the variation of values of µpartox with photolysis time in ultraviolet/persulfate (UV/PS) and ultraviolet/peroxi-mono-sulfate (UV/PMS) systems. As can be seen, the values of µpartox were 0.72 and 0.56 for UV/PS and UV/PMS, respectively, after 30 min. This indicates the occurrence of partial oxidation to the organic pollutants. After 120 min of the oxidation time, µpartox values for both UV/PS and UV/PMS systems decreased and reached 0.44 and 0.30, respectively. This indicates that the chemical oxygen demand (COD) reduction changed from partial to total oxidation due to higher chance of organic compounds for mineralization by free radicals produced through photo-activation of peroxi-mono-sulfate and persulfate. The results of biodegradability index, biological oxygen demand/chemical oxygen demand (BOD5/COD) demonstrated that the electrocoagulation (EC) process was not able to increase BOD5/COD ratio but decreases 0.26–0.21 because electrocoagulation is a nondestructive process. On the other hand, BOD5/COD ratio was remarkably increased to 0.44 and 0.46 by electrocoagulation–ultraviolet/persulfate (EC-UV/PS) and electrocoagulation–ultraviolet/peroxi-mono-sulfate (EC-UV/PMS) processes, respectively.

Finally, Asaithambi et al. (2017) developed several process combinations including electrocoagulation (EC), photo-electrocoagulation (PhEC), peroxi-electrocoagulation (PEC) and peroxi-photo-electrocoagulation (PPhEC) for the removal of chemical oxygen demand (COD) from distillery industrial effluent and compared their performance in terms of color and COD removal in addition to electrical energy consumption. Asaithambi et al. (2017) summarized the mechanism of hydrogen peroxide (H2O2) action in the electrocoagulation (EC) process as:

Normally, Fe2+ consumption is more rapidly than their formation. However, if the hydroxyl radical concentration becomes high, the following reaction could take place:

Accordingly, more ferrous ion dosage is needed to maintain hydroxyl free radicals production in a moderate amount. Otherwise, a large amount of ferric hydroxide sludge will be produced during neutralization stage of Fenton process, which needs disposal management.

Part of Asaithambi et al. (2017) results summarized the chemical oxygen demand (COD) removal percentage by electrocoagulation (EC), photo-electrocoagulation (PhEC), peroxi-electrocoagulation (PEC) and peroxi-photo-electrocoagulation (PPhEC) processes was 72, 78, 85 and 82%, respectively after 4 h of continuous treatment. It seems that the use of hydrogen peroxide (H2O2) has more enhancement effect on the chemical oxygen demand (COD) removal than the ultraviolet (UV) source. In addition, the use of hydrogen peroxide showed the lowest electrical energy consumption. The minimum electrical energy consumption of 1.2 kWh/m3 was required for a removal of 85% chemical oxygen demand (COD) in the peroxi-electrocoagulation (PEC) process.

Table 2 summarizes the main parameters of the advanced oxidation processes discussed in this section. It is evident from the data in Table 2 that the combination of advanced oxidation with (AO) electrocoagulation (EC) enhanced the removal of high percentage of the pollutants especially from highly polluted wastewater. However, the arrangement of the AOPs process in the combined system or whether advanced oxidation (AO) process is pre or post the electrocoagulation (EC) process is a very important parameter that determines the success of this combination. As an example and in the case of highly polluted pulp and paper wastewater, the ultraviolet (UV) irradiation step should be after the electrocoagulation (EC) process in order to remove the highest percent of the colored materials and turbidity by electrocoagulation (EC) then ultraviolet (UV) will be able to treat the residual pollutants (Jaafarzadeh et al. 2016).

Ultrasound-assisted electrocoagulation processes

It is expected that the ultrasound irradiation-assisted treatment electrocoagulation (EC) cell wastewater will considerably enhance the kinetics and the performance of the electrocoagulation processes (Kovatcheva and Parlapanski 1999). Kovatcheva and Parlapanski (1999) who were the first to investigate the influence of low-frequency ultrasound upon electrocoagulation process of colloidal iron oxides wastewater. They reported that this combination improves the process and increases the removal efficiency of iron hydroxides. They attributed this performance to several positive impacts of ultrasound (US) energy on the electrocoagulation process:

-

The destruction of the solid layer deposited on the electrode surfaces from the products of redox reactions.

-

The reduction in the diffuse part thickness of the electrical double layer found at the electrode surface.

-

The direct activation of the ions found in the electrodes reaction zone.

-

The activation of the electrodes by defects generation on their surfaces.

-

The friction between the liquid and the surfaces causes local augmentation of the temperature at the electrode surfaces.

On the other hand, the ultrasound waves used may cause some negative effects directly related to the purification process, such as the following (Barrera-Díaz et al. 2014; Kovatcheva and Parlapanski 1999):

-

The destruction effect of the ultrasonic waves on the obtained colloidal hydroxides. This causes diminution of the solid phase used by in the adsorption step and a consequent diminution of the removal efficiency of the pollutants.

-

The destruction effect on the formed adsorption layer at the colloidal particles surface and the possible desorption of the adsorbed ions.

-

The disorganization of the ions migration processes in the medium.

The mechanism of free radical formation by the ultrasonic (acoustic) waves and free radicals combination can be expressed by the following equations (Al-Qodah et al. 2014; Farooq et al. 2002; Vianney and Muthukumar 2015):

It is clear from Eqs. (53)–(58) that the radicals: OH·, H· and HO ·2 are formed by the ultrasound energy then some of these radicals recombine again. These radical are responsible about the degradation of the organic pollutants found in the wastewater.

As mentioned above, Kovatcheva and Parlapanski (1999) were the first to apply ultrasound-assisted electrocoagulation and reported that US energy enhanced removal efficiency of iron hydroxide. Kathiravan and Muthukumar (2011) applied ultrasound on a sludge obtained from pharmaceutical wastewater as a post-treatment process after electrocoagulation (EC) to reduce Cr(VI) to Cr(III). The reduction rate was found to be higher its value in achieved by EC alone. Chu et al. (2012) used a combined electrocoagulation-ultrasound technique to reduce the water consumption and pollution in car-washing wastewater. They compared the removal efficiency as a function of time for different treatment processes. They demonstrated that the degradation of pollutants occurs mainly in the first 20 min of operation. These meet the water reuse requirements. On the other hand, the removal efficiency of both chemical oxygen demand (COD) and turbidity for single treatment processes was very low.

More promising results were obtained by Li et al. (2013b) for the removal of phosphorus found in fine chemical industry using electrocoagulation (EC) coupled with ultrasound (US) energy. They found that the concentration of total phosphorus (TP) decreased from 86 to about 0.4 mg/L in 10 min, with a removal efficiency of 99.5%. On the other hand, the total phosphorus (TP) removal efficiency using electrocoagulation (EC) only was 81.3% and that using ultrasound only was very low. This indicates the high synergy between electrocoagulation (EC) and US to effectively remediate high-phosphorus wastewater.

Subsequently, Lakshmi and Sivashanmugam (2013) investigated the influence of ultrasound and hybrid electrode on chemical oxygen demand (COD) removal from oil tanning effluent by electrocoagulation (EC) process. They reported that under optimal operating conditions of 20 mA/cm2 current density, using Fe/Fe electrodes, The estimated %COD removal, energy consumption and operating cost were 89.65%, 1.279 kWh/m3 and 6.28 US $/m3, respectively. On the other hand, EC removal efficiency was 90% indicating that EC is a better than ultrasound (US)-assisted electrocoagulation (EC) for the treatment. However, ultrasound was found able to overcome electrode passivation since the sludge produced by the ultrasound (US)-assisted electrocoagulation was doubled from 0.49 to 0.9 kg/m3. This is attributed to the fact that ultrasound energy reduces diffusional resistance thickness at the electrode surface. Consequently, the current efficiency is improved along the process time. This will lead to generation of more metal ions and thereby enhancing metal hydroxide formation.

Recently, three researches have applied ultrasound-assisted electrocoagulation treatment (USEC) processes (Asaithambi et al. 2016b; Asgharian et al. 2017; He et al. 2016). Asaithambi et al. (2016b) compared the efficiency of the US, EC and USEC process for treatment of the pulp and paper industrial effluents. The results of comparison for the removal of color and COD are shown in Fig. 9. This means that the individual US process and the EC process were not able to achieve significant removal of color and COD. On the other hand, the compelled USEC process yielded significant color and COD removals. The authors attributed this enhancement to the regeneration of additional electrode surface by cavitation and/or the formation of micro-streaming effect as a result of the sonication energy (Wang et al. 2009).

Comparison of sonication, electrocoagulation and sono-electrocoagulation process for the removal of a color and b COD of the pulp and paper effluent (condition: current density, 4 A/dm2; effluent pH, 7; COD concentration, 3000 mg/L; electrode combination, Fe/Fe; interelectrode distance, 1 cm; electrolyte concentration, 4 g/L; ultrasound frequency, 40 kHz; and reaction time, 4 h). The color and COD removals were about 4.87, 93, 100 and 2.35, 76, 95% for the US, EC and USEC processes, respectively. (Asaithambi et al. 2016b); Springer license number 4236650096575

He et al. (2016) applied ultrasonic energy to remove the passive film that formed on electrode surface during the electrocoagulation process used for the removal of Reactive Blue 19 from synthetic wastewater. Their experimental setup which was operated in three modes of operation: electrocoagulation with an intermittent ultrasonic process (ECIU), and electrocoagulation with a continuous ultrasonic process (ECCU) and electrocoagulation (EC) alone. In electrocoagulation with an intermittent ultrasonic process (ECIU), the ultrasound was applied 1 min in every 10 min. In electrocoagulation with a continuous ultrasonic process (ECCU), ultrasound is applied throughout the electrocoagulation process. The experimental setup of He et al. (2016) had two reactor types. The single electrocoagulation reactor denoted as S-EC is used when the ultrasound energy is used to break the passive film forms on the electrodes whereas the double electrocoagulation reactors denoted as D-EC is used when the ultrasonic process is used to break the flocs in the solution into separate flocs. Part of He et al. (2016) results is shown in Fig. 10. Figure 10 gives the removal efficiencies of RB19 by different processes with or without ultrasound and in single or in double reactors.

Removal of RB19 by various processes in different reactors (Co = 100 mg/L, I = 10 mA/cm2, pH = 7, U = 150 W, T = 20 °C). The removal efficiencies of RB19 removal by US, S-EC, S-ECIU and S-ECCU in 60 min of continuous operation were 3, 43, 49 and 55%, respectively. (He et al. 2016); Elsevier License number 4236650584752

This indicates that ultrasound energy helps in breaking down the passive film from the sacrificial anodes which were then able to provide more coagulate matter. In addition, S-ECCU has relatively higher removal efficiency than S-ECIU or S-EC. He et al. (2016) explained this behavior by the fact that the continuous ultrasonic process was able to provide sufficient energy that causes cavitation in the solution. This cavitation enhances the production of OH* radicals, which degrade RB19. On the other hand, the removal efficiencies of the double reactor systems: D-EC, D-ECIU and D-ECCU after 60 min of continuous operation were 49, 59 and 56%, respectively. In the double reactor, the back flue may have inhibited the ultrasound’s provision of enough energy to cause cavitation, which produces OH radicals. Moreover, it seems that the intermittent ultrasonic process broke fewer flocs than the continuous ultrasonic process. Accordingly, the D-ECIU process showed higher removal efficiency than D-ECCU.

The final study on ultrasound-assisted electrocoagulation was conducted by Asgharian et al. (2017) for the removal of humic acid (HA) from wastewater. They used five combinations of platinum, graphite and aluminum electrodes and found that the combination of Pt (anode)/Al (cathode) at neutral pH, 10 V Voltage, 0.02 M concentration of electrolyte support and temperature of 25 °C had the maximum removal efficiency as 96.5% of HA at 15 min by Pt/Al and without ultrasonic wave. Finally, they reported that when they used ultrasonic energy simultaneously with electrocoagulation, the removal efficiency fall drastically. It was clear from their results that the ultrasound (US)-assisted electrocoagulation and ultrasound processes indicated a high HA absorbance compared to electrocoagulation process alone. This indicates a low removal efficiency of ultrasound-assisted electrocoagulation and ultrasound (US) processes as compared to electrocoagulation alone. This is attributed to the fact that EC process produces clusters of HA and ultrasound (US) waves seem to destroy it and the coagulated HA dissolves again and returns to the solution. Moreover, the ultrasound frequency used in this study was low frequency of 24 kHz. This value is not sufficient to cause the formation of hydroxyl radicals. For this reason, the amount of HA degraded was negligible.

A summary of the results using ultrasound-assisted electrocoagulation is presented in Table 3. It is clear from the results in Table 3 that in most cases the use combination of ultrasound (US) with electrocoagulation enhances the pollutants removal efficiencies because ultrasound enhances the formation of hydroxyl free radicals. These radicals attack the pollutants and degrade them in a faster rate. In addition, the ultrasound waves act in the cleaning of the electrodes from the deposited solids that reduce the rate of electrolysis reactions. Moreover, it was reported that the electrocoagulation intermittent ultrasonic process (ECIU) enhances the removal efficiency more than electrocoagulation continuous ultrasonic process (ECCU) (He et al. 2016). On the other hand, the removal efficiency decreased with the application of ultrasound-assisted electrocoagulation compared with electrocoagulation alone in one research (Asgharian et al. 2017). This phenomenon was attributed to the low ultrasound frequency of 24 kHz, which was not able to degrade humic acid.

Kinetic models of free radical-assisted electrocoagulation

(Al-Qodah 1998; Al-Shawabkah et al. 2015) Several kinetic models have been used to describe the kinetics of the adsorption step in the electrocoagulation process for the removal of pollutants. These models include the first-order, second-order, pseudo-first-order, pseudo-second-order and Elovich model (Al-Shannag et al. 2015; Kamaraj et al. 2013; Wang et al. 2009; Zalloum et al. 2008). On the other hand, only few attempts have been cited to model free radical-assisted electrocoagulation process. Asaithambi et al. (2012) applied the pseudo-first-order kinetic to describe chemical oxygen demand (COD) removal from real distillery wastewater using ozone-assisted electrocoagulation. Then they derived a mathematical equation based on the experimental results. They assumed that the rate constant, kobs, is affected by chemical oxygen demand (COD) initial concentration and the current density. Consequently, they used the following empirical formula to express the relation:

where CA is chemical oxygen demand (COD) initial concentration, CD is the current density, m, a, b are constants, which can be evaluated from a plot between time versus concentration and time versus current. Based on the experimental results, the previous equation was written as:

On the other hand, they calculated the theoretical chemical oxygen demand (COD) removal using the following equation:

Farooq et al. (2002) investigated the effect of sonicated field on the percentage removal of copper ions from EC cell using mesh cathode and two platinized titanium anodes. They plotted the difference of electrolysis rate constants (k) with and without ultrasonic field using two concentrations as log C versus time t as shown in Fig. 11.

Effect of ultrasound on the electrolytic removal of copper. Copper concentration decreases under the effect of sonicated field in a first-order kinetics. The value of k in 100 mg/L solution is larger than in 500 mg/L solution (Farooq et al. 2002); Elsevier License number 4236650988758

Accordingly, Farooq et al. (2002) concluded that the electrolysis with ultrasonic technology is more effective in lower concentrated solution than in higher concentrated solution.

Qiu et al. (2010) studied the removal of phosphorus by ultrasound-assisted EC process. They reported that phosphorus removal in this combined process was found to fit zero-order kinetics. Recently, Vianney and Muthukumar (2015) studied the removal of some azo dyes including: Congo red (CR), Methyl red (MR) and Eriochrome black (EB) from aqueous solutions by ultrasound-assisted electrocoagulation (USEC). The results of Vianney and Muthukumar (2015) demonstrated that the dye removal fits pseudo-first-order mechanism expressed by the following equation:

The rate constants values are shown in Table 4. It is evident from Table 2 that the rate constants values when the aluminum (Al) electrodes are used are much higher than that of stainless steel (SS) electrodes. In addition, CR was found to be easily decolorized as compared to EB and MR dyes.

The first-order kinetics of an ultrasound-assisted electrocoagulation USEC was confirmed by Asaithambi et al. (2016b) for the removal of COD from pulp and paper industry effluents. According to their results, the rate constant k for COD removal was 0.013 min−1. On the other hand, He et al. (2016) used the variable-order kinetics previously presented by Zheng et al. (2017) for the removal of fluoride ions by electrocoagulation (EC) process using aluminum electrodes. This model which was derived from Langmuir equation as described by the following equation to express the coagulation of different materials in an ultrasound-assisted electrocoagulation (USEC) process for the removal of Reactive Blue (RB19):

where ɛAl is the efficiency of formation of hydro-RB19-aluminum; ɛC represents the current efficiency; n is the number of cells; I is the current (A); Z is the valence of the metal of the electrode; F is the Faraday constant, 96,487 C mole−1; V is the volume of the solution; Γmax is the maximum value of C, which represents the amount in moles of RB19 removed per mole of AI(III) ions at a given equilibrium, and k is the Langmuir constant. If 1/k » [RB19], Eq. (63), becomes first-order kinetics and when [RB19] » 1/k, it becomes zero-order kinetics. Since the concentration of a reactant is variable, the kinetic is consequently a variable-order kinetic. The results were evaluated to fit the first-order and variable-order kinetics as shown in Table 5.

Table 5 shows that the pseudo-first-order kinetics fits the experimental data more than the variable-order kinetics for a wide range operational parameters values with relatively high R2. However, the variable-order kinetics is the only model that considers a wider range of coagulated matter. Consequently, it is more accurate and more suitable the pseudo-first-order kinetic model. It should be noted that all the above studies used zero-order, first-order or variable-order kinetics and used the simple kinetic equation with concentration only as the variable with time. However, only one study considers the effect of other operational parameters rather than the coagulate concentration. It is mentioned above that Asaithambi et al. (2012) introduces the current density (CD) as a variable in the kinetic model.

Scale-up of free radical-assisted electrocoagulation

Scale-up of chemical processes is an essential step to transfer the initial laboratory-scale processes to final production plant. The production of a commercial product requires process optimization, scale-up from the laboratory to a pilot plant and finally from the pilot to the full industrial scale process (Den and Huang 2006). Orescanin et al. (2011) reported a pilot plant study that dealt with ozone-assisted electrocoagulation (EC) treatment process using SS and Al electrodes. Since they had found that this process had demonstrated the best results in the removal of heavy metals and organic matter on laboratory scale, they used the same experimental setup in a pilot plant scale. They found that the treatment of 90 L of wastewater by EC/ozonation generated a mean waste mud volume of 5.1 L containing only 217.3 g of dry sludge. Orescanin et al. (2011) found that the concentrations of Cu, Fe and Zn were highly enriched in the mud; however, all measured parameters in the leachate were lower than the upper permissible limit for inert waste.

Cost estimation

Fixed and operating costs are fundamental parameters that should be considered in the selection of any treatment process to decide whether it is feasible or not in large-scale processes (Al-Shannag et al. 2015; Lin et al. 2005). Since, there are many alternative treatment processes for the removal of pollutants from wastewater, any combined treatment process with electrocoagulation should be a cost-effective and easily applied (Butler et al. 2011). Actually, unstable energy prices could represent a serious drawback that could limit the large-scale application of EC processes alone since it uses of electric current as an operating parameter (Moussa et al. 2016). For this reason, the search for a combined treatment process that could reduce the power consumption in addition to the necessary of optimization of the overall treatment process is a an important to prove its cost effectiveness before its large-scale application. Actually, very limited research attempts have been cited that consider process optimization and cost effectiveness of electrocoagulation (EC) combined treatment processes. However, despite the tremendous number of publications on electrocoagulation (EC) processes, systematic studies dealing with are very limited.

Lakshmi and Sivashanmugam (2013) investigated the treatment of oil tanning effluent by ultrasound-assisted electrocoagulation, ultrasound-assisted electrocoagulation (USEC) process. In their cost analysis of the process, they considered the following elements that contribute in the operating cost of a treatment plant: material and electrical energy costs as well as labor, maintenance, sludge dewatering, transportation and disposal costs. The operating cost based on electrode material was calculated using the following equation:

where ENC = energy consumed (kW h/m3), ELC = electrode consumed (kg/m3) and CC = chemical consumed (kg/m3) (Sridhar et al. 2011). Lakshmi and Sivashanmugam (2013) found that under optimum condition the energy, electrode and electrolyte consumptions were found to be 1.279 kW h/m3, 0.287 and 1 kg/m3, respectively. On the other hand, the operating cost in the same optimum condition was found to be 6.28 US $/m3.

Recently, Jaafarzadeh et al. (2016) applied a combined electrocoagulation and UV-based sulfate radical oxidation processes for the treatment of pulp and paper wastewater. They used the following equation to calculate the electrical energy consumption, EEC for both EC and UV processes:

where I is the applied current, A; t is the time, h; U is the applied voltage, V; P is the power of the UV lamp, W; V is the volume of the wastewater, L. They found that the electrical energy consumption by EC, UV/PS and UV/PMS was 2.98, 160 and 160 kWh/m3, respectively. On the other hand, the current efficiency in EC process was 100%. They concluded that the UV/oxidant process was not cost-effective.

He et al. (2016) investigated electrical energy consumption as an important economical parameter of the sono-EC process. They considered the energy consumed per milligram of RB19 removed by the different processes. He et al. (2016) found that the intermittent sono-EC process is more economically efficient than continuous sono-EC process, since it coasted only one tenth that of the continuous sono-EC process. Moreover, intermittent sono-EC showed better solid/liquid separation efficiency because the size of flocs in was higher than that of continuous sono-EC process.

It should be noted that the above studies are still limited and not sufficient to make a suitable judgment whether the combined processes are more or less cost-effective compared to electrocoagulation (EC) process alone. In addition, the removal efficiency is another critical factor that contributes in the decision-making process whether to use a combined process or to use electrocoagulation (EC) process alone.

Conclusion

In this review, the performance of free radical-assisted electrocoagulation processes is discussed and compared. The following are the main concluding remarks and perspectives that could benefits researchers in their future work:

-

I.

The main advantage of free radical-assisted electrocoagulation processes is the enhanced pollutants removal efficiency especially in the case of ozone-assisted electrocoagulation.

-

II.

The number of studies on free radical-assisted electrocoagulation processes is limited. Consequently, more extensive researches are required in the fields of process optimization, modeling and scale-up in order to prove the reliability of this technology for efficient large-scale wastewater treatment.

-

III.

Most of the performed studies used synthetic rather than real wastewater. For this reason, most of the results are ideal since the interference of real mater matrix in the results is excluded. For this reason, research extension to use real wastewater is essential in order to investigate the actual process performance (Pulkka et al. 2014).

-

IV.

Only one study tried to scale up the free radical-assisted electrocoagulation processes since most of the published work deals with single pollutant batch laboratory-scale level. Despite that, these studies might provide important guidelines for larger scale processes. Additional systematic studies to scale up electrocoagulation (EC) processes using continuous operation and real wastewater must be performed in order to introduce this process as an efficient and reliable technology for wastewater treatment (Orescanin et al. 2011).

-

V.

The free radical-assisted electrocoagulation processes depend solely on the electrical energy produced from non-renewable resources. This could lead to two major drawbacks, the high operating cost and the indirect pollution caused by the combustion of fossil fuel to produce electricity. This necessitates the use of sustainable renewable energy resources such as wind or tidal energy or photovoltaic modules (Pulkka et al. 2014). Another energy option is the use of biogas produced from anaerobic fermentation of waste materials (Dominguez-Ramos et al. 2010).

-

VI.

Additional reviews are required to discuss and compare the performance of other assisted treatment processes with electrocoagulation (EC) process such as chemical coagulation, biological treatment and adsorption (Fernandes et al. 2015).

References

Akbal F, Camcı S (2011) Copper, chromium and nickel removal from metal plating wastewater by electrocoagulation. Desalination 269:214–222. https://doi.org/10.1016/j.desal.2010.11.001

Akyol A, Can OT, Bayramoglu M (2015) Treatment of hydroquinone by photochemical oxidation and electrocoagulation combined process. J Water Process Eng 8:45–54. https://doi.org/10.1016/j.jwpe.2015.09.001

Al Aji B, Yavuz Y, Koparal AS (2012) Electrocoagulation of heavy metals containing model wastewater using monopolar iron electrodes. Sep Purif Technol 86:248–254. https://doi.org/10.1016/j.seppur.2011.11.011

Ali I, Asim M, Khan T (2013) Arsenite removal from water by electro-coagulation on zinc–zinc and copper–copper electrodes. Int J Environ Sci Technol 10:377–384. https://doi.org/10.1007/s13762-012-0113-z

Al-Momani F, Shawaqfah MA, Shawaqfeh A, Al-Shannag M (2008) Impact of Fenton and ozone on oxidation of wastewater containing nitroaromatic compounds. J Environ Sci 20:675–682. https://doi.org/10.1016/S1001-0742(08)62112-9

Al-Qodah Z (1998) Adsorption of methylene blue with diatomite. J Eng Technol 17:128–137

Al-Qodah Z, Al-Bsoul A, Assirey E, Al-Shannag M (2014) Combined ultrasonic irradiation and aerobic biodegradation treatment for olive mills wastewaters. Environ Eng Manag J 13:2109–2118

Al-Qodah Z, Al-Shannag M (2017) Heavy metal ions removal from wastewater using electrocoagulation processes: a comprehensive review. Sep Sci Technol 17:2649–2676. https://doi.org/10.1080/01496395.2017.1373677

Al-Shannag M, Lafi W, Bani-Melhem K, Gharagheer F, Dhaimat O (2012) Reduction of COD and TSS from paper industries wastewater using electro-coagulation and chemical coagulation. Sep Sci Technol 47:700–708. https://doi.org/10.1080/01496395.2011.634474

Al-Shannag M, Bani-Melhem K, Al-Anber Z, Al-Qodah Z (2013) Enhancement of COD-nutrients removals and filterability of secondary clarifier municipal wastewater influent using electrocoagulation technique. Sep Sci Technol 48:673–680. https://doi.org/10.1080/01496395.2012.707729

Al-Shannag M, Al-Qodah Z, Alananbeh K, Bouqellah N, Assirey E, Bani-Melhem K (2014) COD reduction of baker’s yeast wastewater using batch electrocoagulation. Environ Eng Manag J 13:3153–3160

Al-Shannag M, Al-Qodah Z, Bani-Melhem K, Qtaishat MR, Alkasrawi M (2015) Heavy metal ions removal from metal plating wastewater using electrocoagulation: kinetic study and process performance. Chem Eng J 260:749–756. https://doi.org/10.1016/j.cej.2014.09.035

Al-Shawabkah R, Al-Qodah Z, Al-Bsoul A (2015) Bio-adsorption of triadimenol pesticide from aqueous solutions using activated sludge of dairy plants. Desalin Water Treat 53:2555–2564. https://doi.org/10.1080/19443994.2013.865565

Amarasinghe B, Williams R (2007) Tea waste as a low cost adsorbent for the removal of Cu and Pb from wastewater. Chem Eng J 132:299–309. https://doi.org/10.1016/j.cej.2007.01.016

Asaithambi P, Susree M, Saravanathamizhan R, Matheswaran M (2012) Ozone assisted electrocoagulation for the treatment of distillery effluent. Desalination 297:1–7. https://doi.org/10.1016/j.desal.2012.04.011

Asaithambi P, Aziz ARA, Daud WMABW (2016a) Integrated ozone—electrocoagulation process for the removal of pollutant from industrial effluent: optimization through response surface methodology. Chem Eng Process 105:92–102. https://doi.org/10.1016/j.cep.2016.03.013

Asaithambi P, Sajjadi B, Aziz ARA, Daud WMABW (2016b) Performance evaluation of hybrid electrocoagulation process parameters for the treatment of distillery industrial effluent. Process Saf Environ Prot 104:406–412. https://doi.org/10.1016/j.psep.2016.09.023

Asaithambi P, Aziz ARA, Sajjadi B, Daud WMABW (2017) Sono assisted electrocoagulation process for the removal of pollutant from pulp and paper industry effluent. Environ Sci Pollut Res 24:5168–5178. https://doi.org/10.1007/s11356-016-6909-5

Asgharian F, Khosravi-Nikou M, Anvaripour B, Danaee I (2017) Electrocoagulation and ultrasonic removal of humic acid from wastewater. Environ Progress Sustain Energy 36:822–829. https://doi.org/10.1002/ep.12512

Asha A, Muthukrishnaraj A, Balasubramanian N (2014) Improvement of biodegradability index through electrocoagulation and advanced oxidation process. Int J Ind Chem 5:4. https://doi.org/10.1007/s40090-014-0004-x

Aziz ARA, Asaithambi P, Daud WMABW (2016) Combination of electrocoagulation with advanced oxidation processes for the treatment of distillery industrial effluent. Process Saf Environ Prot 99:227–235. https://doi.org/10.1016/j.psep.2015.11.010

Barrera-Díaz CE, Roa-Morales G, Hernández PB, Fernandez-Marchante CM, Rodrigo MA (2014) Enhanced electrocoagulation: new approaches to improve the electrochemical process. J Electrochem Sci Eng 4:285–296. https://doi.org/10.5599/jese.2014.0060

Bazrafshan E, Mohammadi L, Ansari-Moghaddam A, Mahvi AH (2015) Heavy metals removal from aqueous environments by electrocoagulation process—a systematic review. J Environ Health Sci Eng 13:74. https://doi.org/10.1186/s40201-015-0233-8

Behin J, Farhadian N, Ahmadi M, Parvizi M (2015) Ozone assisted electrocoagulation in a rectangular internal-loop airlift reactor: application to decolorization of acid dye. J Water Process Eng 8:171–178. https://doi.org/10.1016/j.jwpe.2015.10.003

Bernal-Martínez LA, Barrera-Díaz C, Solís-Morelos C, Natividad R (2010) Synergy of electrochemical and ozonation processes in industrial wastewater treatment. Chem Eng J 165:71–77. https://doi.org/10.1016/j.cej.2010.08.062

Bibi S, Kamran MA, Sultana J, Farooqi A (2017) Occurrence and methods to remove arsenic and fluoride contamination in water. Environ Chem Lett 15:125–149. https://doi.org/10.1007/s10311-016-0590-2

Boroski M, Rodrigues AC, Garcia JC, Gerola AP, Nozaki J, Hioka N (2008) The effect of operational parameters on electrocoagulation–flotation process followed by photocatalysis applied to the decontamination of water effluents from cellulose and paper factories. J Hazard Mater 160:135–141. https://doi.org/10.1016/j.jhazmat.2008.02.094

Boroski M, Rodrigues AC, Garcia JC, Sampaio LC, Nozaki J, Hioka N (2009) Combined electrocoagulation and TiO2 photoassisted treatment applied to wastewater effluents from pharmaceutical and cosmetic industries. J Hazard Mater 162:448–454. https://doi.org/10.1016/j.jhazmat.2008.05.062

Butler E, Hung Y-T, Yeh RY-L, Suleiman Al Ahmad M (2011) Electrocoagulation in wastewater treatment. Water 3:495–525. https://doi.org/10.3390/w3020495

Calvo LS, Leclerc JP, Tanguy G, Cames M, Paternotte G, Valentin G, Rostan A, Lapicque F (2003) An electrocoagulation unit for the purification of soluble oil wastes of high COD. Environ Prog 22:57–65. https://doi.org/10.1002/ep.670220117

Cañizares P, Louhichi B, Gadri A, Nasr B, Paz R, Rodrigo M, Saez C (2007) Electrochemical treatment of the pollutants generated in an ink-manufacturing process. J Hazard Mater 146:552–557. https://doi.org/10.1016/j.jhazmat.2007.04.085

Cañizares P, Sáez C, Sánchez-Carretero A, Rodrigo M (2009) Synthesis of novel oxidants by electrochemical technology. J Appl Electrochem 39:2143. https://doi.org/10.1007/s10800-009-9792-7

Chen Y, Sun Z, Yang Y, Ke Q (2001) Heterogeneous photocatalytic oxidation of polyvinyl alcohol in water. J Photochem Photobiol A Chem 142:85–89. https://doi.org/10.1016/S1010-6030(01)00477-4

Chu JY, Li YR, Li N, Huang WH (2012) Treatment of car-washing wastewater by electrocoagulation-ultrasound technique for reuse. Adv Mater Res 433:227–232. https://doi.org/10.4028/www.scientific.net/AMR.433-440.227

Daghrir R, Gherrou A, Noel I, Seyhi B (2016) Hybrid process combining electrocoagulation, electroreduction, and ozonation processes for the treatment of grey wastewater in batch mode. J Environ Eng 142:04016008. https://doi.org/10.1061/(ASCE)EE.1943-7870.0001071

Daneshvar N, Oladegaragoze A, Djafarzadeh N (2006) Decolorization of basic dye solutions by electrocoagulation: an investigation of the effect of operational parameters. J Hazard Mater 129:116–122. https://doi.org/10.1016/j.jhazmat.2005.08.033

Den W, Huang C (2006) Electrocoagulation of silica nanoparticles in wafer polishing wastewater by a multichannel flow reactor: a kinetic study. J Environ Eng 132:1651–1658. https://doi.org/10.1061/(ASCE)0733-9372(2006)132:12(1651)

Dominguez-Ramos A, Aldaco R, Irabien A (2010) Photovoltaic solar electrochemical oxidation (PSEO) for treatment of lignosulfonate wastewater. J Chem Technol Biotechnol 85:821–830. https://doi.org/10.1002/jctb.2370

Esfandyari Y, Mahdavi Y, Seyedsalehi M, Hoseini M, Safari GH, Ghozikali MG, Kamani H, Jaafari J (2015) Degradation and biodegradability improvement of the olive mill wastewater by peroxi-electrocoagulation/electrooxidation-electroflotation process with bipolar aluminum electrodes. Environ Sci Pollut Res 22:6288–6297. https://doi.org/10.1007/s11356-014-3832-5

Farooq R, Wang Y, Lin F, Shaukat S, Donaldson J, Chouhdary A (2002) Effect of ultrasound on the removal of copper from the model solutions for copper electrolysis process. Water Res 36:3165–3169. https://doi.org/10.1016/S0043-1354(01)00546-2

Fekete E, Lengyel B, Cserfalvi T, Pajkossy T (2016) Electrochemical dissolution of aluminium in electrocoagulation experiments. J Solid State Electrochem 20:3107–3114. https://doi.org/10.1007/s10008-016-3195-6

Feng C, Sugiura N, Shimada S, Maekawa T (2003) Development of a high performance electrochemical wastewater treatment system. J Hazard Mater 103:65–78. https://doi.org/10.1016/S0304-3894(03)00222-X

Fernandes A, Pacheco M, Ciríaco L, Lopes A (2015) Review on the electrochemical processes for the treatment of sanitary landfill leachates: present and future. Appl Catal B 176:183–200. https://doi.org/10.1016/j.apcatb.2015.03.052

Ganzenko O, Oturan N, Sirés I, Huguenot D, van Hullebusch ED, Esposito G, Oturan MA (2017) Fast and complete removal of the 5-fluorouracil drug from water by electro-Fenton oxidation. Environ Chem Lett. https://doi.org/10.1007/s10311-017-0659-6

García-García P, Arroyo-López FN, Rodríguez-Gómez F (2014) Partial purification of iron solutions from ripe table olive processing using ozone and electro-coagulation. Sep Purif Technol 133:227–235. https://doi.org/10.1016/j.seppur.2014.06.011

Hakizimana JN, Gourich B, Chafi M, Stiriba Y, Vial C, Drogui P, Naja J (2017) Electrocoagulation process in water treatment: a review of electrocoagulation modeling approaches. Desalination 404:1–21. https://doi.org/10.1016/j.desal.2016.10.011

Hashim KS, Shaw A, Al Khaddar R, Pedrola MO, Phipps D (2017) Iron removal, energy consumption and operating cost of electrocoagulation of drinking water using a new flow column reactor. J Environ Manage 189:98–108. https://doi.org/10.1016/j.jenvman.2016.12.035

He Z, Song S, Qiu J, Yao J, Cao X, Hu Y, Chen J (2007) Decolorization of CI Reactive Yellow 84 in aqueous solution by electrocoagulation enhanced with ozone: influence of operating conditions. Environ Technol 28:1257–1263. https://doi.org/10.1080/09593332808618884

He C-C, Hu C-Y, Lo S-L (2016) Evaluation of sono-electrocoagulation for the removal of Reactive Blue 19 passive film removed by ultrasound. Sep Purif Technol 165:107–113. https://doi.org/10.1016/j.seppur.2016.03.047

Heidmann I, Calmano W (2008) Removal of Zn(II), Cu(II), Ni(II), Ag(I) and Cr(VI) present in aqueous solutions by aluminium electrocoagulation. J Hazard Mater 152:934–941. https://doi.org/10.1016/j.jhazmat.2007.07.068

Hernández-Ortega M, Ponziak T, Barrera-Díaz C, Rodrigo M, Roa-Morales G, Bilyeu B (2010) Use of a combined electrocoagulation—ozone process as a pre-treatment for industrial wastewater. Desalination 250:144–149. https://doi.org/10.1016/j.desal.2008.11.021

Holt PK (2002) Electrocoagulation: unravelling and synthesising the mechanisms behind a water treatment process. Master’s thesis, The University of Sydney

Holt PK, Barton GW, Mitchell CA (2005) The future for electrocoagulation as a localised water treatment technology. Chemosphere 59:355–367. https://doi.org/10.1016/j.chemosphere.2004.10.023

Hsing H-J, Chiang P-C, Chang E-E, Chen M-Y (2007) The decolorization and mineralization of Acid Orange 6 azo dye in aqueous solution by advanced oxidation processes: a comparative study. J Hazard Mater 141:8–16. https://doi.org/10.1016/j.jhazmat.2006.05.122

Huang C, Dong C, Tang Z (1993) Advanced chemical oxidation: its present role and potential future in hazardous waste treatment. Waste Manag 13:361–377. https://doi.org/10.1016/0956-053X(93)90070-D

Jaafarzadeh N, Omidinasab M, Ghanbari F (2016) Combined electrocoagulation and UV-based sulfate radical oxidation processes for treatment of pulp and paper wastewater. Process Saf Environ Prot 102:462–472

JiaYan Q (2012) Research on the treatment of chlorpyrifos wastewater by ultrasound-assisted electro-coagulation, Master’s thesis, Nanjing University of Aeronautics and Astronautics

Kabdaşlı I, Arslan-Alaton I, Ölmez-Hancı T, Tünay O (2012) Electrocoagulation applications for industrial wastewaters: a critical review. Environ Technol Rev 1:2–45. https://doi.org/10.1080/21622515.2012.715390

Kamaraj R, Ganesan P, Lakshmi J, Vasudevan S (2013) Removal of copper from water by electrocoagulation process—effect of alternating current (AC) and direct current (DC). Environ Sci Pollut Res 20:399–412. https://doi.org/10.1007/s11356-012-0855-7

Kartikaningsih D, Shih Y-J, Huang Y-H (2016) Boron removal from boric acid wastewater by electrocoagulation using aluminum as sacrificial anode. Sustain Environ Res 26:150–155. https://doi.org/10.1016/j.serj.2015.10.004

Kathiravan MN, Muthukumar K (2011) Ultrasound mediated reduction of Cr(VI) using sludge obtained during electrocoagulation. Environ Technol 32:1523–1531. https://doi.org/10.1080/09593330.2010.543928

Khandegar V, Saroha AK (2013) Electrocoagulation for the treatment of textile industry effluent—a review. J Environ Manage 128:949–963. https://doi.org/10.1016/j.jenvman.2013.06.043

Konstantinou IK, Albanis TA (2004) TiO 2-assisted photocatalytic degradation of azo dyes in aqueous solution: kinetic and mechanistic investigations: a review. Appl Catal B 49:1–14. https://doi.org/10.1016/j.apcatb.2003.11.010

Kovatcheva VK, Parlapanski MD (1999) Sono-electrocoagulation of iron hydroxides. Colloids Surf A 149:603–608. https://doi.org/10.1016/S0927-7757(98)00414-2

Lafi WK, Shannak B, Al-Shannag M, Al-Anber Z, Al-Hasan M (2009) Treatment of olive mill wastewater by combined advanced oxidation and biodegradation. Sep Purif Technol 70:141–146. https://doi.org/10.1016/j.seppur.2009.09.008

Lafi WK, Al-Anber M, Al-Anber ZA, Al-shannag M, Khalil A (2010) Coagulation and advanced oxidation processes in the treatment of olive mill wastewater (OMW). Desalin Water Treat 24:251–256. https://doi.org/10.5004/dwt.2010.1567

Lakshmi PM, Sivashanmugam P (2013) Treatment of oil tanning effluent by electrocoagulation: influence of ultrasound and hybrid electrode on COD removal. Sep Purif Technol 116:378–384. https://doi.org/10.1016/j.seppur.2013.05.026

Li H, Gong Y, Huang Q, Zhang H (2013a) Degradation of orange II by UV-assisted advanced Fenton process: response surface approach, degradation pathway, and biodegradability. Ind Eng Chem Res 52:15560–15567. https://doi.org/10.1021/ie401503u

Li J, Song C, Su Y, Long H, Huang T, Yeabah TO, Wu W (2013b) A study on influential factors of high-phosphorus wastewater treated by electrocoagulation–ultrasound. Environ Sci Pollut Res 20:5397–5404. https://doi.org/10.1007/s11356-013-1537-9

Lin C-J, Lo S-L, Kuo C-Y, Wu C-H (2005) Pilot-scale electrocoagulation with bipolar aluminum electrodes for on-site domestic greywater reuse. J Environ Eng 131:491–495. https://doi.org/10.1061/(ASCE)0733-9372(2005)131:3(491)

Mahmad MKN, Rozainy MR, Abustan I, Baharun N (2015) Removal of iron and total chromium contaminations in landfill Leachate by using electrocoagulation process. Key Eng Mater 660:279–283. https://doi.org/10.4028/www.scientific.net/KEM.660.279

Mantzavinos D, Lauer E, Sahibzada M, Livingston AG, Metcalfe IS (2000) Assessment of partial treatment of polyethylene glycol wastewaters by wet air oxidation. Water Res 34:1620–1628. https://doi.org/10.1016/S0043-1354(99)00320-6

Merzouk B, Gourich B, Sekki A, Madani K, Chibane M (2009) Removal turbidity and separation of heavy metals using electrocoagulation–electroflotation technique: a case study. J Hazard Mater 164:215–222. https://doi.org/10.1016/j.jhazmat.2008.07.144

Mouedhen G, Feki M, De Petris-Wery M, Ayedi H (2009) Electrochemical removal of Cr(VI) from aqueous media using iron and aluminum as electrode materials: towards a better understanding of the involved phenomena. J Hazard Mater 168:983–991. https://doi.org/10.1016/j.jhazmat.2008.07.144

Moussa DT, El-Naas MH, Nasser M, Al-Marri MJ (2016) A comprehensive review of electrocoagulation for water treatment: potentials and challenges. J Environ Manag 186:24–41. https://doi.org/10.1016/j.jenvman.2016.10.032

Murugananthan M, Raju GB, Prabhakar S (2004) Removal of sulfide, sulfate and sulfite ions by electro coagulation. J Hazard Mater 109:37–44. https://doi.org/10.1016/j.jhazmat.2003.12.009

Naji T, Dirany A, Carabin A, Drogui P (2017) Large-scale disinfection of real swimming pool water by electro-oxidation. Environ Chem Lett. https://doi.org/10.1007/s10311-017-0687-2

Nanseu-Njiki CP, Tchamango SR, Ngom PC, Darchen A, Ngameni E (2009) Mercury (II) removal from water by electrocoagulation using aluminium and iron electrodes. J Hazard Mater 168:1430–1436. https://doi.org/10.1016/j.jhazmat.2009.03.042

Orescanin V, Kollar R, Nad K (2011) The application of the ozonation/electrocoagulation treatment process of the boat pressure washing wastewater. J Environ Sci Health Part A 46:1338–1345. https://doi.org/10.1080/10934529.2011.606423

Oumar D, Patrick D, Gerardo B, Rino D, Ihsen BS (2016) Coupling biofiltration process and electrocoagulation using magnesium-based anode for the treatment of landfill leachate. J Environ Manage 181:477–483. https://doi.org/10.1016/j.jenvman.2016.06.067

Papastefanakis N, Mantzavinos D, Katsaounis A (2010) DSA electrochemical treatment of olive mill wastewater on Ti/RuO2 anode. J Appl Electrochem 40:729–737. https://doi.org/10.1007/s10800-009-0050-9

Peyton G, Glaze W (1985) The mechanism of photolytic ozonation. Abstracts of papers of the American chemical society. AMER Chemical Soc 1155 16TH ST, NW, Washington, DC 20036, pp 5-GEOC

Piera E, Calpe JC, Brillas E, Domènech X, Peral J (2000) 2,4-Dichlorophenoxyacetic acid degradation by catalyzed ozonation: TiO2/UVA/O3 and Fe(II)/UVA/O3 systems. Appl Catal B 27:169–177. https://doi.org/10.1016/S0926-3373(00)00149-1

Prajapati AK, Chaudhari PK, Pal D, Chandrakar A, Choudhary R (2016) Electrocoagulation treatment of rice grain based distillery effluent using copper electrode. J Water Process Eng 11:1–7. https://doi.org/10.1016/j.jwpe.2016.03.008

Pulkka S, Martikainen M, Bhatnagar A, Sillanpää M (2014) Electrochemical methods for the removal of anionic contaminants from water—a review. Sep Purif Technol 132:252–271. https://doi.org/10.1016/j.seppur.2014.05.021

Qing Y, Hang Y, Xuelei L, Hui W, Shu X (2016) Combined electrocoagulation, electrolysis and photocatalysis technologies applied to ship sewage treatment. Int J Environ Sci Dev 7:248

Qiu M, Wang L, Xue J (2010) Kinetics of the removal of phosphorus by ultrasound-assisted electro-coagulation. Acta Sci Circunstantiae 30:519–523

Qu P, Zhao J, Shen T, Hidaka H (1998) TiO 2-assisted photodegradation of dyes: a study of two competitive primary processes in the degradation of RB in an aqueous TiO2 colloidal solution. J Mol Catal A Chem 129:257–268. https://doi.org/10.1016/S1381-1169(97)00185-4

Roa-Morales G, Barrera-Díaz C, Balderas-Hernández P, Zaldumbide-Ortiz F, Reyes Perez H, Bilyeu B (2014) Removal of color and chemical oxygen demand using a coupled coagulation-electrocoagulation-ozone treatment of industrial wastewater that contains offset printing dyes. J Mex Chem Soc 58:362–368

Sahu O, Mazumdar B, Chaudhari P (2014) Treatment of wastewater by electrocoagulation: a review. Environ Sci Pollut Res 21:2397–2413. https://doi.org/10.1007/s11356-013-2208-6

Salameh WKB, Ahmad H, Al-Shannag M (2015) Treatment of olive mill wastewater by electrocoagulation processes and water resources management. World Acad Sci Eng Technol Int J Environ Chem Ecol Geol Geophys Eng 9:288–292

Sauleda R, Brillas E (2001) Mineralization of aniline and 4-chlorophenol in acidic solution by ozonation catalyzed with Fe2+ and UVA light. Appl Catal B 29:135–145. https://doi.org/10.1016/S0926-3373(00)00197-1

Singh K, Singh A, Hasan S (2006) Low cost bio-sorbent ‘wheat bran’ for the removal of cadmium from wastewater: kinetic and equilibrium studies. Biores Technol 97:994–1001. https://doi.org/10.1016/j.biortech.2005.04.043

Siringi DO, Home P, Chacha JS, Koehn E (2012) Is electrocoagulation (EC) a solution to the treatment of wastewater and providing clean water for daily use. ARPN J Eng Appl Sci 7:197–204

Sister V, Kirshankova E (2005) Ultrasonic techniques in removing surfactants from effluents by electrocoagulation. Chem Pet Eng 41:553–556. https://doi.org/10.1007/s10556-006-0017-1

So C, Cheng MY, Yu J, Wong P (2002) Degradation of azo dye Procion Red MX-5B by photocatalytic oxidation. Chemosphere 46:905–912. https://doi.org/10.1016/S0045-6535(01)00153-9

Song S, He Z, Qiu J, Xu L, Chen J (2007) Ozone assisted electrocoagulation for decolorization of CI Reactive Black 5 in aqueous solution: an investigation of the effect of operational parameters. Sep Purif Technol 55:238–245. https://doi.org/10.1016/j.seppur.2006.12.013

Song S, Yao J, He Z, Qiu J, Chen J (2008) Effect of operational parameters on the decolorization of CI Reactive Blue 19 in aqueous solution by ozone-enhanced electrocoagulation. J Hazard Mater 152:204–210. https://doi.org/10.1016/j.jhazmat.2007.06.104

Sridhar R, Sivakumar V, Immanuel VP, Maran JP (2011) Treatment of pulp and paper industry bleaching effluent by electrocoagulant process. J Hazard Mater 186:1495–1502. https://doi.org/10.1016/j.jhazmat.2010.12.028

Tezcanli-Güyer G, Ince N (2004) Individual and combined effects of ultrasound, ozone and UV irradiation: a case study with textile dyes. Ultrasonics 42:603–609. https://doi.org/10.1016/j.ultras.2004.01.096

Thiam A, Zhou M, Brillas E, Sirés I (2014) A first pre-pilot system for the combined treatment of dye pollutants by electrocoagulation/EAOPs. J Chem Technol Biotechnol 89:1136–1144. https://doi.org/10.1002/jctb.4358

Uğurlu M, Gürses A, Doğar Ç, Yalçın M (2008) The removal of lignin and phenol from paper mill effluents by electrocoagulation. J Environ Manage 87:420–428. https://doi.org/10.1016/j.jenvman.2007.01.007

Vasudevan S, Lakshmi J (2012) Electrochemical removal of boron from water: adsorption and thermodynamic studies. Can J Chem Eng 90:1017–1026. https://doi.org/10.1002/cjce.20585