Abstract

β-Poly(malic acid) (PMLA) has attracted industrial interest because this polyester can be used as a prodrug or for drug delivery systems. In PMLA production by Aureobasidium pullulans ipe-1, it was found that PLMA production was associated with cell growth in the early exponential growth phase and dissociated from cell growth in the late exponential growth phase. To enhance PMLA production in the late phase, different fermentation modes and strategies for controlling culture redox potential (CRP) were studied. The results showed that high concentrations of produced PMLA (above 40 g/l) not only inhibited PMLA production, but also was detrimental to cell growth. Moreover, when CRP increased from 57 to 100 mV in the late exponential growth phase, the lack of reducing power in the broth also decreased PMLA productivity. PMLA productivity could be enhanced by repeated-batch culture to maintain cell growth in the exponential growth phase, or by cell-recycle culture with membrane to remove the produced PMLA, or by maintaining CRP below 70 mV no matter which kind of fermentation mode was adopted. Repeated-batch culture afforded a high PMLA concentration (up to 63.2 g/l) with a productivity of 1.15 g l−1 h−1. Cell-recycle culture also confirmed that PMLA production by the strain ipe-1 was associated with cell growth.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

β-Poly(malic acid) (PMLA) has attracted industrial interest because this polyester can be used as a prodrug or for drug delivery system [2, 4, 5]. PMLA can be produced by either chemical synthesis [10] or microbial fermentation [17]; the latter approach has been extensively investigated. Leathers et al. [17] did significant work on PMLA production by strains of Aureobasidium pullulans representing genetically diverse phylogenetic clades, some of which included strains produced relatively high levels of PMLA. Zhang et al. [24] also reported a new strain, characterized as the candidate of A. pullulans on the basis of the morphology and phylogenetic analyses of internal transcribed spacer sequences; this strain was isolated from fresh plants samples and gave a high PMLA productivity of 0.35 g l−1 h−1 in a 10-l bioreactor. However, there are discrepancies regarding the relationship between cell growth and PMLA production in the literature. Nakajima-Kambe et al. [18] reported the highest PMLA production (80 g/l) by the non-growing cells of Aureobasidium in flasks with a long cultivation time up to 12 days, and found that PMLA production was dissociated from cell growth. Lee and Holler [11] also reported the dissociation between cell growth and PMLA production by Physarum polycephalum in flasks, showing that cell growth was minimal in culture medium devoid of nitrogen source, while PMLA was produced at a substantial rate. In their studies, the cells could be regarded as a whole-cell enzyme system for catalyzing the synthesis of PMLA, wherein the cultivation in the early phase afforded cells with high catalytic activity for subsequent PMLA production. On the other hand, some confusing phenomena relating to cell growth and PMLA production have been reported to occur in bioreactors. Zhang et al. [24] found the cell growth of A. pullulans and PMLA concentration in a 10-l bioreactor rapidly increased during the exponential and stationary phases, whereas Liu and Steinbüchel [15] reported that PMLA production was almost unrelated to cell growth and PMLA was largely yielded in the late exponential growth phase when A. pullulans CBS 591.75 was cultivated in a 1-l fermenter. Unfortunately, no detailed explanation was presented in their work. Therefore, there is a need to identify the main factors affecting PMLA production in the late exponential growth phase so as to further promote PMLA production.

Doig et al. [6] and Zambianchi et al. [25] found that the whole cells could be used as biocatalysts for the biosynthesis of metabolites, whereas the catalytic activity [22] was highly affected by the culture redox potential (CRP), which expresses the sum of all oxidoreduction processes in a fermentation, especially for the metabolic processes in cells. CRP was determined by reversible oxidoreduction couples and irreversible reducing agents coupled with the action of free oxygen and hydrogen. For example, with addition of potassium ferrocyanide, CRP could be maintained between 280 and 80 mV [1] to obtain a high citric acid productivity in Aspergillus niger fermentation. In addition, CRP played an important role in the cellular physiology of microorganisms such as growth capacity [12, 14, 16] and thermal resistance [8, 20]. However, there was no literature about the effects of CRP on the production of biopolymers, such as ε-polylysine, poly(γ-d-glutamic acid), and PMLA. Since CRP could be artificially controlled by adding a reducing agent to affect the oxidoreduction couples in cells [13, 19], this may be an effective way to examine the effect of CRP on the dissociation between PMLA production and cell growth in the late exponential growth phase.

The present work is a part of our ongoing project aimed at developing a practical approach for the biotechnological production of PMLA by A. pullulans ipe-1. The objectives of this work were to identify the relationship between cell growth and PMLA production by the strain ipe-1 in the late exponential growth phase and then to develop a strategy to enhance PMLA production in this phase. Different fermentation modes, namely fed-batch culture, repeated-batch culture, and cell-recycle culture with membrane, were examined, with a focus on the role of CRP in PMLA production. To our knowledge, this is the first reported use of CRP as a controlling parameter in the production of biopolymers.

Materials and methods

Microorganism

Aureobasidium pullulans ipe-1(CGMCC no. 3337) used throughout this study was stored in the China General Microbiological Culture Collection (CGMCC), Institute of Microbiology, Chinese Academy of Sciences. The strain was maintained on potato-glucose agar slant at 4°C.

Culture medium

The seed culture medium contained (w/v) 8% glucose, 0.2% NaNO3, 0.01% KH2PO4, 0.02% MgSO4·7H2O, 0.05% KCl, and 0.1% tryptone (Oxoid LP0042) in deionized water. For the production of PMLA in the bioreactor (BioFio®110), the following medium was used (w/v): 19% glucose, 1.5% tryptone, 0.6% NaNO3, 0.5% yeast extract (Oxoid LP0021), 0.05% KH2PO4, 0.02% MgSO4·7H2O, 0.05% KCl, and 5 ppm ZnSO4·7H2O in deionized water.

Culture method

In all fermentation experiments, the seed culture of strain ipe-1 was prepared by inoculating cells grown on potato-glucose agar into 500-ml Erlenmeyer flasks containing 100 ml of seed culture medium, followed by incubation at 25°C for 2 days on a rotary shaker. The seed culture broth (400 ml) was transferred to a 7.5-l bioreactor (BioFio®110) containing 4 l of the fermentation culture medium. The temperature, aeration rate, and pH in the bioreactor were kept at 25°C, 0.25–2.5 vvm, and 6.0, respectively; the pH was kept constant automatically by adding 2 M Na2CO3 or 1 M H2SO4. Dissolved oxygen (DO) was controlled by agitation and detected by a DO electrode. When DO dropped to the set value of 70%, the agitation rate was automatically increased on the basis of the value of DO concentration. Each experiment was performed at least twice, and the data reported are the average value with a standard deviation within ±10%.

For chemostat experiments with a working volume typically around 4 l, this equipment was completed by a permanent volume measurement of both the filled bioreactor and the feed bottle. This kind of level control allowed dilution rates to be respectively controlled very accurately at 0.03, 0.04, and 0.05 h−1. Fed solution had the same composition as the fermentation medium, with the exception of 7 g/l yeast extract and 21 g/l tryptone.

For repeated-batch fermentation, when initial batch fermentation arrived at the end of exponential growth, 3 l of the broth was removed, and 3 l of the fresh medium was fed into the bioreactor. The fermentation was restarted under the same conditions as the batch fermentation.

For cell-recycle fermentation, a CéRAM INSIDE (UF) tubular ceramic module membrane was coupled to the bioreactor. The molecular weight cutoff (MWCO) of the membranes was 300 kDa, and the effective surface area of the membrane was 0.16 m2. After 48-h cultivation in batch fermentation at 25°C, the broth was pumped into the membrane module to recycle the cells and remove the filtrate at the same time. Once 2 l filtrate had been removed by membrane filtration in cross-flow mode also at 25°C, the cells were washed with 2 l sterile water. In the washing process, the broth with the added sterile water (2 l) was filtered through the membrane module also in cross-flow mode for 40 min till 2 l filtrate was pooled. The cells were washed three times and 6 l sterile water in total was used. The whole washing process lasted for 2 h. After the cell were washed, 2 l of the fresh medium, having the same composition of the initial 4-l fermentation medium, was fed into the bioreactor and then the fermentation was restarted under the same operating conditions as the batch fermentation.

Analytical methods

The culture broth (8 ml) was centrifuged at 10,000×g for 8 min and the resulting supernatants used for the measurement of PMLA and glucose. For the measurement of biomass content, the cells were washed three times with 8 ml distilled water, then dried to constant weight at 90°C. To measure the amount of PMLA, 1-ml samples of supernatants were incubated with 1 ml 2 M H2SO4 for 12 h at 90°C. After neutralization of the solution, l-malic acid concentration was measured by an HPLC apparatus (Shimadzu LC20AT) equipped with an SPR-H column. Glucose concentrations of the supernatants were measured using a biosensor with glucose oxide electrodes (SBA-40C, Institute of Biology, Shandong Academy of Science, China). CRP was measured by a platinum electrode and controlled by exogenous addition of Na2S whenever required.

Results and discussion

Time profiles of PMLA production in a 7.5-l jar bioreactor

Time profiles of PMLA production by A. pullulans ipe-1, cultivated in a 7.5-l bioreactor, are shown in Fig. 1. In the early exponential growth phase, PMLA production was associated with cell growth, whereas the dissociation between the PMLA production and cell growth appeared after 48 h of cultivation. The dissociation between PMLA production and cell growth in the late exponential growth phase was reported by Nakajima-Kambe et al. [18], Liu and Steinbüchel [15], and Zhang et al. [24]. However, Nakajima-Kambe et al. [18] found that PMLA was mainly produced in the late exponential and stationary phases when PMLA was produced by Aureobasidium sp. A-91 in flasks; Liu and Steinbüchel [15] reported PMLA production by A. pullulans CBS 591.75 in a 1-l bioreactor was almost unrelated to cell growth, and production of large amounts of PMLA started only in the late exponential growth phase; whereas Zhang et al. [24] found that PMLA concentration in a 10-l bioreactor rapidly increased during the exponential and stationary phases in batch fermentation with A. pullulans ZD-3d. These differences could be caused by the different strains and experimental conditions used by different investigators. By summarizing previous literature, Zhang et al. [24] also showed that the production levels of PMLA varied a lot among the strains previously used, i.e., P. polycephalum, Aureobasidium sp. A-91, A. pullulans CBS 591.75, and A. pullulans ZD-3d.

The results of kinetic analysis for PMLA production (Fig. 2) show that the productivity of PMLA and biomass and the glucose consumption rate increased with increasing fermentation time up to 36 h, but thereafter they began to decrease sharply. Three reasons could possibly result in such a decrease. Firstly, the produced PMLA could be a factor involved in the feedback inhibition of PMLA production. Secondly, the remaining glucose concentration might be too low for PMLA production. Thirdly, CRP played an important role in PMLA production. As can be seen from Fig. 1, when PMLA began to be largely produced after 12 h, CRP decreased significantly from above 120 to 57 mV at 36 h, and then it started to increase till the end of fermentation, whereas after culture for 48 h, PMLA production almost ceased. Different experiments were therefore performed to identify the main reasons for the decrease of PMLA productivity.

Effects of continuous fermentation on PMLA production

As shown in Fig. 1, about 15 g/l PMLA was produced from 36 to 48 h, whereas the PMLA productivity decreased as fermentation went on. In order to relieve the feedback inhibition of the newly produced PMLA on the production process, thus maintaining the high PMLA productivity, continuous fermentation with dilution rates of 0.03, 0.04, and 0.05 h−1 was carried out. The fed solution had the same composition as the fermentation medium, with the exception of 7 g/l yeast extract and 21 g/l tryptone added. The experimental results are shown in Fig. 3. At the dilution rate of 0.04 h−1 (Fig. 3a), average PMLA concentration in the bioreactor was lower than that in the removed broth, whereas the remaining concentration of biomass and glucose in the bioreactor showed a reverse trend, suggesting that the capacity of PMLA production by the remaining cells was declining. However, the average concentration of PMLA in the bioreactor was almost equal to that in the removed broth at the dilution rate of 0.03 h−1 (Fig. 3b) and 0.05 h−1 (Fig. 3c). It can also be seen that the concentration of PMLA was the highest at the dilution rate of 0.03 h−1 and increased gradually, whereas the concentration of PMLA decreased as continuous fermentation went on at the dilution rates of 0.04 and 0.05 h−1. Compared with the batch culture, the final quantity of produced PMLA increased by 56.8, 49.6, and 37.5%, respectively, at the dilution rates of 0.03, 0.04, and 0.05 h−1 after 72-h cultivation. Given the fact that the concentration of cells was higher at the dilution rate at 0.04 h−1 than that at 0.03 h−1 and the concentration of PMLA produced was higher at the latter rate, this suggested that the cells should be incubated with the substrate for a certain time to synthesize PMLA. High concentrations of PMLA (above 40 g/l) in the broth inhibited cell growth, thus decreasing PMLA productivity in batch culture, whereas the PMLA productivity could be enhanced by removing the newly produced PMLA in continuous-mode fermentation. The results indicated that the dissociation of the cell growth and PMLA production did exist in the late exponential growth phase.

Effect of dilution rate on PMLA production. The continuous fermentation started at 36 h. The time courses refer to a dilution rate of a 0.04 h−1, b 0.03 h−1, and c 0.05 h−1. Parameters in the bioreactor: PMLA (filled circles), biomass (filled squares), glucose (filled triangles). Parameters in the removed broth: PMLA (open circles), biomass (open squares), glucose (open triangles)

Effects of repeated-batch culture on PMLA production

It could be seen that PMLA production was associated with the cell growth in batch culture in the early exponential growth phase, and the dissociation between the cell growth and PMLA production occurred after 48 h in the late exponential growth phase (Fig. 1). To further examine the relations between cell growth and PMLA production, repeated-batch culture was performed to maintain cells in the exponential growth phase by supplying fresh medium at 48 h after about 75% of the fermented broth drained. Repeated-batch culture of A. pullulans ipe-1 was implemented for five cycles (Fig. 4). The glucose concentration was consumed steadily with increasing time throughout the fermentation, and cells of the strain ipe-1 continued to produce PMLA from glucose in the exponential growth phase, with much shorter lag period and higher volumetric productivity than in the batch fermentation. With cell growing, PMLA could be synthesized with no dissociation between cell growth and PMLA production during the period even if the concentration of PMLA was high (up to 63.2 g/l) with a PMLA productivity of 1.15 g l−1 h−1 in the broth. For comparison, the highest level of PMLA productivity in the available literature was reported recently to be only 0.35 g l−1 h−1 [24]. In the five-cycle fermentation, PMLA and biomass produced per unit glucose also had no significant difference, demonstrating that PMLA production increased with cell growth in the exponential growth phase. However, Liu and Steinbüchel [15] reported that PMLA was mainly produced in the late exponential growth phase, whereas Zhang et al. [24] found the cell growth of A. pullulans and PMLA concentration could also be increased in the stationary phase of cells. Therefore, fed-batch fermentation was further carried out to examine whether nutrition supply could be the main factor affecting the synthesis of PMLA by the strain ipe-1 in the late exponential growth phase.

Effects of fed-batch fermentation on PMLA production

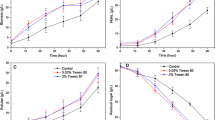

Fed-batch fermentations were performed to examine whether the medium composition was sufficient or not for the cells to synthesize PMLA in the late exponential growth phase. Additional fed solution was continuously supplied from 36 h to keep the concentration of residual sugar constant and offer other medium components required for cell growth. The fed solution had the same composition as the fermentation medium, with the exception of 500 g/l glucose. As shown in Fig. 5a, the final PMLA and biomass concentrations were almost the same as those in the batch culture, indicating that the dissociation between PMLA production and cell growth was not due to the deficiency of culture compositions. If one compares Figs. 4 and 5a, the dissociation could be caused by the high concentration of produced PMLA (above 40 g/l) in the broth, which not only inhibited its production, but also was detrimental to cell growth. By comparing the batch culture (Fig. 1) and the fed-batch culture (Fig. 5a), the CRP in fed-batch culture was just a little lower than that in the batch culture, but they varied similarly, suggesting that the CRP could not be controlled by the added glucose solution. It can also be seen from Fig. 5 that the metabolic state changed to PMLA production when CRP dropped to a characteristic value lower than about 70 mV, and PMLA production increased with cell growth. In the late exponential growth phase, the CRP increased gradually above 100 mV till the end of fermentation, whereas PMLA production almost ceased during the period. These results implied that CRP could be used to monitor and optimize PMLA production. Since fed-glucose solution could neither control the CRP nor increase PMLA productivity (Fig. 5a), another fed-batch culture was carried out with exogenous addition of Na2S to maintain CRP lower than 70 mV in the late exponential growth phase (Fig. 5b). Compared with the fed-batch culture without CRP control (Fig. 5a), PMLA production and cell growth increased by 21.2 and 11.7%, respectively, in the CRP-controlled fed-batch culture (Fig. 5b), indicating that the dissociation between PMLA production and cell growth partially resulted from the lack of reducing power in the broth. The results were not consistent with the work by Liu and Steinbüchel [15] and Nakajima-Kambe et al. [18], as they found that PMLA was mainly produced in the late exponential and stationary phases. Again, this could be attributed to the different strains and experimental conditions used.

PMLA production in fed-batch culture. Fresh medium was continuously added in the broth from 36 h. The fed solution had the same composition as the fermentation medium, with the exception of 7 g/l yeast extract and 21 g/l tryptone. About 1.06 l of the fed solution was added to the broth at 72 h. The time courses refer to a without CRP control and b with CRP maintained below 70 mV. PMLA (filled squares), biomass (open squares), glucose (filled triangles), CRP (open circles)

Effects of membrane cell-recycle on PMLA production

Nakajima-Kambe et al. [18] reported that the highest PMLA production (80 g/l) could be produced by the non-growing cells of Aureobasidium sp. in flasks, whereas our results discussed above in the present work showed that cell growth was necessary for PMLA production, and high concentration of PMLA was detrimental to cell growth. In order to validate the relationship between cell growth and PMLA production, a cell-recycle experiment with membrane was carried out (Fig. 6) to maintain the high concentration of cells and remove the produced PMLA. In Fig. 6a, about 95% of the fresh cells were recycled in the bioreactor, and just 4 g/l PMLA remained in the broth at the beginning of cell-cycle culture phase. In the fermentation phase using the recycled cells (Fig. 6a), biomass and PMLA increased similarly to those in the repeated-batch culture but differently from those in fed-batch culture. Glucose was consumed in the subsequent 48 h, during which time 87 g/l biomass and 51.3 g/l PMLA were newly produced. Three parameters—PMLA produced per unit glucose, the concentration of newly produced PMLA, and the variation of CRP—were almost the same as those in the batch culture (Fig. 1), whereas biomass produced per unit glucose increased by 10%. It is noteworthy that it was difficult to control the fermentation process because the final concentration of cells was too high, up to 150 g/l, and exogenous supply of pure O2 was required to maintain the DO value.

PMLA production in repeated-batch cultures with cell-recycle. Cell-recycle culture stared after the first 48 h of batch culture time. The added fresh medium had the same composition as the batch culture in a, with the exception of organic nitrogen sources in b and with addition of Na2S to maintain CRP below 70 mV in c. PMLA (filled squares), biomass (open squares), glucose (filled triangles), CRP (open circles)

To lower cell growth rate, organic nitrogen was added in the fresh medium in the cell-recycle culture (Fig. 6b). Compared with those in Fig. 6a, PMLA and biomass produced per unit glucose decreased by 26.8 and 31.3%, respectively, and the PMLA productivity decreased even up to 54.1%, whereas CRP maintained above 100 mV during the period of cell-recycle culture. To further identify whether the high CRP led to the decrease, the cell-recycle experiment was performed under conditions in which CRP was maintained below 70 mV by extraneous addition of Na2S during the period of cell-recycle fermentation (Fig. 6c). Compared with those in Fig. 6b, PMLA produced per unit glucose and PMLA productivity increased by 33.2 and 15.6%, respectively, whereas biomass yielded per unit glucose decreased by 15.9%. The results in Fig. 6 suggested that the PMLA was produced by the growing cells even in the cell-recycle phase. Though the concentration of the biomass in cell-recycle phase was about twice that in batch culture, the PMLA productivity did not increase, and the produced PMLA was only associated with the newly increased biomass. From Figs. 5a and 6, it was concluded that high concentration of PMLA (above 40 g/l) could inhibit cell growth because the cells could continue to grow quickly after removing the produced high concentration of PMLA. Shimada et al. [21] also showed that PMLA was a naturally occurring protease inhibitor; therefore, high concentrations of PMLA would inhibit the assimilation of nitrogen be cells. This could be the reason why cell growth rate decreased in the late growth phase, and why there was no difference in PMLA production between batch culture and fed-batch culture without CRP control. In the late exponential growth phase, PMLA production could be effectively improved by maintaining CRP below 70 mV, and the addition of the reducing agent Na2S could offer additional reducing power in the broth. In an ongoing study in our laboratory, it was found that PMLA biosynthesis was related to a reducing pathway involving phosphoenolpyruvate formation via oxaloacetate catalyzed by PEP carboxylase. Therefore, it was an effective way to promote PMLA production by maintaining CRP below 70 mV no matter which kind of fermentation mode was adopted.

Similar results were also reported by Holler et al. [9] in batch culture of P. polycephalum, showing that the plasmodia had a maximum intracellular level of PMLA when they grew at maximum rate, and synthesis of PMLA was typical for growing plasmodia [3, 7]. The dissociation between PMLA production and cell growth of P. polycephalum, as reported by Lee and Holler [11], only appeared under extreme conditions such as addition of metabolic intermediates or omission of hematin or a nitrogen source. The reasons may be that the added intermediates participated in the biosynthesis pathway for PMLA or the cells could not grow well because of the lack of nitrogen. In addition, by investigating PMLA synthesis in vivo with plasmodia employing the microinjection of l-[14C]malate and various inhibitors of the enzymes involved in the synthesis, Willibald et al. [23] found that PMLA was synthesized by an enzyme complex reminiscent of nonribosomal peptide synthetase, harboring malyl-AMP ligase and malyl-transferase (polymerase) activity, and PMLA was synthesized only during cell growth and the synthesis was disrupted immediately upon cell injury. For Aureobasidium pullulans, the synthesis of PMLA may follow the same mechanism. The dissociation could only be detected in the late exponential growth phase because of the inhibition by the high concentration of PMLA and the lack of reducing power in the broth. The findings in the present study could offer an effective strategy to intensify PMLA production in the late exponential growth phase and provide a good reference for process development and optimization for PMLA production.

Conclusion

In β-poly(l-malic acid) production by Aureobasidium pullulans ipe-1, the dissociation between the cell growth and PMLA production in the late exponential growth phase could be attributed to the high concentration of produced PMLA (above 40 g/l) and lack of reducing power in the broth. High concentration of PMLA (above 40 g/l) not only inhibited its production, but also was detrimental to cell growth, and lack of reducing power in the broth also decreased the PMLA productivity. PMLA productivity could be enhanced by repeated-batch culture to maintain cell growth in the exponential growth phase, or by cell-recycle culture with membrane to remove the produced PMLA, or by maintaining CRP below 70 mV no matter which kind of fermentation mode was adopted. With repeated-batch culture, PMLA concentration was high (up to 63.2 g/l) with a productivity of 1.15 g l−1 h−1. When CRP was adjusted to below 70 mV in the late exponential growth phase, PMLA production and cell growth in the fed-batch culture were increased by 21.2 and 11.7%, respectively. Under cell-recycle culture with membrane and CRP-controlled conditions, PMLA produced per unit glucose increased by 33.2%.

References

Berovi M (1999) Scale-up of citric acid fermentation by redox potential control. Biotechnol Bioeng 64:552–557

Braud C, Bunel C, Vert M (1985) Poly(β-malic acid): a new polymeric drug-carrier. Polym Bull 13:293–299

Daniel JW, Kelley J, Rusch HP (1962) Hematin requiring plasmodial myxomycete. J Bacteriol 84:1104–1110

Ding H, Inoue S, Ljubimov AV, Patil R, Portilla-Arias J, Hu J, Konda B, Wawrowsky KA, Fujita M, Karabalin N (2010) Inhibition of brain tumor growth by intravenous poly(β-l-malic acid) nanobioconjugate with pH-dependent drug release. PNAS 107:18143–18148. doi:10.1073/pnas.1003919107

Ding H, Portilla-Arias J, Patil R, Black KL, Ljubimova JY, Holler E (2011) The optimization of polymalic acid peptide copolymers for endosomolytic drug delivery. Biomaterials 32:5269–5278

Doig SD, Simpson H, Alphand V, Furstoss R, Woodley JM (2003) Characterization of a recombinant Escherichia coli TOP10 [pQR239] whole-cell biocatalyst for stereoselective Baeyer-Villiger oxidations. Enzyme Microb Technol 32:347–355

Fischer H, Erdmann S, Holler E (1989) An unusual polyanion from Physarum polycephalum that inhibits homologous DNA polymerase alpha in vitro. Biochemistry 28:5219–5226

George S, Richardson L, Pol I, Peck M (1998) Effect of oxygen concentration and redox potential on recovery of sublethally heat-damaged cells of Escherichia coli O157: H7, Salmonella enteritidis and Listeria monocytogenes. J Appl Microbiol 84:903–909

Holler E, Angerer B, Achhammer G, Miller S, Windisch C (1992) Biological and biosynthetic properties of poly-l-malate. FEMS Microbiol Rev 103:109–118

Kajiyama T, Kobayashi H, Taguchi T, Saito H, Kamatsu Y, Kataoka K, Tanaka J (2004) Synthesis of activated poly(α,β-malic acid) using N-hydroxysuccinimide and its gelation with collagen as biomaterials. Mater Sci Eng, C 24:815–819

Lee B, Holler E (2000) β-Poly(l-malate) production by non-growing microplasmodia of Physarum polycephalum: effects of metabolic intermediates and inhibitors. FEMS Microbiol Lett 193:69–74

Lin YH, Chien WS, Duan KJ (2010) Correlations between reduction-oxidation potential profiles and growth patterns of Saccharomyces cerevisiae during very-high-gravity fermentation. Process Biochem 45:765–770

Liu CG, Lin YH, Bai FW (2011) A kinetic growth model for Saccharomyces cerevisiae grown under redox potential-controlled very-high-gravity environment. Biochem Eng J 56:63–68

Liu CG, Lin YH, Bai FW (2011) Development of redox potential-controlled schemes for very-high-gravity ethanol fermentation. J Biotechnol 153:42–47

Liu S, Steinbüchel A (1996) Investigation of poly(β-l-malic acid) production by strains of Aureobasidium pullulans. Appl Microbiol Biotechnol 46:273–278

Lund B, Wyatt G (1984) The effect of redox potential, and its interaction with sodium chloride concentration, on the probability of growth of Clostridium botulinum type E from spore inocula. Food Microbiol 1:49–65

Manitchotpisit P, Skory CD, Peterson SW, Price NPJ, Vermillion KE, Leathers TD (2011) Poly(β-l-malic acid) production by diverse phylogenetic clades of Aureobasidium pullulans. J Ind Microbiol Biotechnol 39:125–132

Nakajima-Kambe T, Hirotani N, Nakahara T (1996) Poly(β-malic acid) production by the non-growing cells of Aureobasidium sp. strain A-91. J Ferment Bioeng 82:411–413

Pei J, Zhou Q, Jing Q, Li L, Dai C, Li H, Wiegel J, Shao W (2011) The mechanism for regulating ethanol fermentation by redox levels in Thermoanaerobacter ethanolicus. Metab Eng 13:186–193

Riondet C, Cachon R, Wache Y, Alcaraz G, Divies C (2000) Extracellular oxidoreduction potential modifies carbon and electron flow in Escherichia coli. J Bacteriol 182:620–626

Shimada K, Matsushima K, Fukumoto J, Yamamoto T (1969) Poly-(l)-malic acid: a new protease inhibitor from Penicillium cyclopium. Biochem Biophys Res Commun 35:619–624

Unden G, Trageser M, Duchene A (1990) Effect of positive redox potentials (>+400 mV) on the expression of anaerobic respiratory enzymes in Escherichia coli. Mol Microbiol 4:315–319

Willibald B, Bildl W, Lee B, Holler E (1999) Is β-poly(l-malate) synthesis catalysed by a combination of β-l-malyl-AMP-ligase and PMLA polymerase? Eur J Biochem 265:1085–1090

Zhang H, Cai J, Dong J, Zhang D, Huang L, Xu Z, Cen P (2011) High-level production of poly(β-l-malic acid) with a new isolated Aureobasidium pullulans strain. Appl Microbiol Biotechnol 92:295–303

Zambianchi F, Raimondi S, Pasta P, Carrea G, Gaggero N, Woodley JM (2004) Comparison of cyclohexanone monooxygenase as an isolated enzyme and whole cell biocatalyst for the enantioselective oxidation of 1,3-dithiane. J Mol Catal B Enzym 31:165–171

Acknowledgments

The authors thank the Chinese Academy of Sciences’ Knowledge Innovation Program for the financial support (grant no. KSCX2-EW-G-3).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cao, W., Luo, J., Zhao, J. et al. Intensification of β-poly(l-malic acid) production by Aureobasidium pullulans ipe-1 in the late exponential growth phase. J Ind Microbiol Biotechnol 39, 1073–1080 (2012). https://doi.org/10.1007/s10295-012-1111-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-012-1111-3