Abstract

Poly (β-L-malic acid) (PMLA) can be used as a prodrug or used for drug delivery system, and it has attracted industrial interest. In previous studies, we could obtain 38 g/L PMLA with 10 g/L yeast extract as a nitrogen source, but the complex broth component made it difficult to the downstream process. To decrease the pressure in the extraction process, we used inorganic nitrogen resources and growth factors to replace yeast extract. Response surface methodology (RSM) was applied to optimize the fermentation medium formulation to improve the production of poly (β-L-malic acid) (PMLA) with Aureobasidium pullulans CGMCC3337. It was confirmed that ammonium nitrate 2.06 g/L, adenine 0.02 g/L, cytosine 0.012 g/L aspartate (Asp) 0.42 g/L, histidine(His) 0.6 g/L, leucine(Leu) 0.4 g/L, and threonine(Thr) 0.28 g/L could replace the yeast extract in PMLA production. The model developed based on RSM successfully predicted PMLA productivity (R 2 = 0.9697). With the optimum medium established, 37.62 g/L PMLA was accumulated in the fermentation broth, and the impurities in the fermentation broth was reduced apparently.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Aureobasidium pullulans

- Poly (β-malic acid)

- Inorganic nitrogen

- Growth factors

- Response surface methodology (RSM)

1 Introduction

PMLA is a well-known biodegradable, bioabsorbable, and water-soluble polymer having pendant carboxylic groups, which allow further conjugation of functional groups or molecules, including drugs via chemical modification. These advantages make it important to investigate high purity and high-yield production of PMLA. For example, it is reported that a PMLA-based drug delivery system and biodegradable nanoparticles could be used for tumor targeting [1, 2]. So PMLA can be used as a prodrug or for drug delivery systems, which has attracted a great deal of interest in industries [3–5]. PMLA can be obtained by chemical synthesis or microbial fermentation. Recently, biosynthesis has been extensively investigated. Leathers [6] did significant work on PMLA production by strains of Aureobasidium pullulans. 9–11 g/L PMLA could be gained by adding yeast extract and peptone to the medium. Under optimized conditions, using sodium nitrate as the nitrogen source, 9.8 g/L PMLA was produced after nine days of fermentation in the stirred-tank reactors with an overall yield of 0.11 g PMLA/g glucose [7]. In preliminary studies, we had successfully accumulated 38.9 g/L β-PMLA with the addition of 10 g/L yeast extract, which was bad for the downstream process of β-PMLA production. The application of PMLA was vastly restricted in medicine and other industries.

Therefore, the objective of the present investigations is to optimize the cultural medium formulation with the addition of inorganic nitrogen source and amino acids, to acquire the highest possible production of PMLA, to reduce impurities in the fermentation broth, to easily investigate the metabolic flux analysis and metabonomics analysis, and to provide a kind of cheap medium components for PMLA production by the strain A. pullulans CGMCC3337.

2 Materials and Methods

2.1 Microorganism

Aureobasidium pullulans CGMCC3337 was isolated in the Key Laboratory of Industrial Microbiology, Ministry of Education, Tianjin University of Science and Technology, and stored in China General Microbiological Culture Collection Center.

2.2 Medium and Culture Method

The compositions of the inoculum medium were as follows (g/L): glucose 80.28, yeast extract 3, (NH4)2SO4 3.06, succinic acid 2, K2CO3 0.4, KH2PO4 0.1, CaCO3 27.7, ZnSO4·7H2O 5 × 10−3, MgSO4·7H2O 0.1. The medium was autoclaved for 20 min at 121 °C after the pH of the medium was adjusted to 4.5.

For the inoculums preparation, cells cultivated on potato-glucose agar inoculated to 50 ml seed medium in 500 ml baffle flasks and incubated at 25 °C, 200 rpm for 2 days on a rotary shaker. Fermentation was carried out in 500 ml baffled flasks, and each flask contains 50 ml sterile fermentation medium, which was inoculated with 5 ml of the prepared inoculum. Then the flasks were incubated for 7 days on a rotary incubator at 25 °C, 200 rpm.

2.3 Preliminary Experiments

We had developed a semisynthetic medium using yeast extract as the nitrogen source. To replace the yeast extract, we study the effect of nitrogen on PMLA production. Various inorganic salts were tested individually. Fifteen amino acids and a number of growth factors as trace elements were also evaluated for their suitability for the PMLA production. Carbon source and metal irons were kept at the initial levels. Since optimizing amino acids and growth factors involved in many parameters, only one parameter varied in the optimization process.

2.4 Experimental Design

Plackett–Burman design (PBD) was used to identify those variables that significantly influenced PMLA production. Then, experiments were performed along the steepest ascent path until the response showed no further increase. Based on the results of our preliminary experiments, the major factors were optimized by response surface methodology (RSM) design (Design-Expert 6).

2.5 Determination of Poly Malic Acid Yield

The PMLA content was determined by an HPLC method on a column of Prevail C18 after the PMLA was hydrolyzed to L-malic and was expressed as g/L [8].

3 Results and Discussion

3.1 Effects of Inorganic Nitrogen Sources to the Synthesis of PMLA

In order to replace yeast extract, inorganic nitrogen sources (NH4Cl, NaNO3, NH4NO3, Urea, NH4HSO4, (NH4)2CO3, and (NH4)2SO4) were individually evaluated for their performances in PMLA production by the strain A. pullulans CGMCC3337 (Table 58.1). To provide the optimal C/N, the addition of inorganic nitrogen source was consistent with nitrogen content in the yeast extract. Among the various inorganic nitrogen sources tested, NH4NO3 exhibited a prominent effect on the production ability of 19.86 g/L and maximum biomass is 17.92 g/L, followed by urea 16.29 g/L, 5.63 g/L, NH4Cl 10.3 g/L, 4.5 g/L, (NH4)2CO3 10.87 g/L, 2.3 g/L, respectively. NH4HSO4, (NH4)2SO4, and NaNO3 exhibited no effect on the growth ability (data not shown). The yield and biomass of inorganic nitrogen were obviously lower than those of yeast extract. This might be a result of growth factors existence in yeast extract. Therefore, the effects of growth factors on synthesis of PMLA were investigated subsequently.

3.2 Effects of Growth Factors on PMLA Production

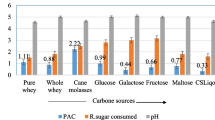

In the investigation process, adding relevant growth factors according to the content in the yeast extract, while the other nutrient contents were as follows: sugar 65, KH2PO4 0.15, MgSO4·7H2O 0.4, CaCO3 12 g/L. The concentration of PMLA increased 18.98, 7.22, 11.61, and 11.01 % compared to the original value of 19.8 g/L, with the addition of Asp (0.28), His (0.4), Leu (0.6), and Thr (0.38 g/L), as shown in Fig. 58.1a. When the fermentation medium added Ala, Glu, Ile, Met, Phe, and Ser, it had little effect on PMLA production. However, negative effects on PMLA production had been observed with Arg, Gly, Lys, Tyr, and Val. The effects of purines (Adenine, Guanine) and pyrimidines (Cytosine, Thymine) were investigated for the synthesis of PMLA. The results were shown in Fig. 58.1b. When various vitamins were added to the basic medium, the production of PMLA had no difference (data not shown). The addition of trace of growth factors almost had no effects on the biomass, respectively (data not shown). Finally, adding all the valuable factors to medium, we gained 29.8 g/L PMLA and 18.98 g/L biomass. All the results we investigated are helpful to the biomass accumulation. In order to further improve the production, RSM was used to optimize the addition of components in the medium (Table 58.2).

3.3 Screening of Significant Nutrients Using PBD

Twenty independent experiments were conducted according to the experimental design shown in Table 58.3. On the basis of the calculated coefficients, F-values and P-values (Table 58.2) X 3, X 6, X 8 were found to be the most significant variables affecting PMLA and chosen for further optimization in the next path of steepest ascent and BBD.

3.4 Method of Steepest Ascent

The method of steepest ascent was based on the zero level of the PBD and moved sequentially along the direction in which X 3, X 6 decreased and X 8 increased. The experimental design and results were shown in Table 58.4. The highest response was 34.76 with X 3 15, X 6 1.2, X 8 0.42 g/L.

3.5 Further Optimization of the Nutrients Using BBD

The design matrix of tested variables and the experimental results were represented in Table 58.5. The statistical analysis results were shown in Table 58.5, and the regression model was given as:

where Y is the predicted β-PMLA yield, X 3 is MgSO4·7H2O, X 6 is Adenine, and X 8 is initial Asp. The quadratic regression model was evaluated by ANOVA. As shown in Table 58.6, the model F-value was 24.89, and the value of “Prob > F” was 0.0002, suggesting that the model was highly significant. The “Lack of Fit F-value” of 4.10 implied the lack of fit that was not significant relative to the pure error. There was a 10.32 % chance that a “Lack of Fit F-value” of this large could occur due to the noise. The model was found to be adequate for prediction within the range of variables employed. The determination of coefficient (R 2) was 0.9697. The high R 2 values in this study indicated that the model equation could adequately predict the responses. The values of the adjusted determination coefficients (adjusted R 2) 0.9308 also indicated high significance for the model.

Three-dimensional response surface Fig. 58.2a, b, c represented regression equations to depict the relationships among the variables and to confirm these results. PMLA fermentation by A. pullulans was carried out under the optimum medium, which was improved by the RSM optimization approach. The mean value of the PMLA yield was 37.62 ± 0.21 g/L in triplicate tests, which was in agreement with the predicted value. The value also was closed to that of yeast extract (38 g/L). Yeast extract could be replaced by the complex of NH4NO3 complexing with growth factors to produce PMLA.

4 Conclusion

The present studies demonstrated that a synthetic fermentation medium would be optimized with poly (β-L-malic acid) fermentation. When the yeast extract was totally replaced by inorganic ammonium nitrate, the PMLA production was significantly increase with the addition of adenine (0.02 g/L), cytosine (0.012), Asp (0.42), His (0.6), Leu (0.4) and Thr (0.28 g/L) by response surface methodology. Finally, 37.62 ± 0.21 g/L PMLA was gained, which was closed to the value of yeast extract (10 g/L) addition. In this way, the impurities in fermentation broth were reduced apparently and the difficulty in the downstream process of PMLA production was reduced significantly. Meanwhile, PMLA produced under the condition ultimately reduced the cost of medium components. And the unclear flux of metabolic of PMLA would be much easier to be investigated in the further studies.

References

Braud C, Bunel C, Vert M (1985) Poly (β-malic acid): a new polymeric drug-carrier. Pol Bulle 13:293

Ding H, Inoue S, Ljubimov AV, Patil R, Portilla-Arias J, Hu JW, Konda B, Wawrowsky KA (2010) Inhibition of brain tumor growth by intravenous poly (β-L-malic acid) nanobioconjugate with pH-dependent drug release. Natl Acad Sci 107:18143

Ding H, Portilla-Arias J, Patil R, Black KL, Ljubimova JY (2011) The optimization of polymalic acid peptide copolymers for endosomolytic drug deliever. Biomat 32:5269

Fujita M, Lee B, Khazenzon N, Penichet M, Wawrowskyc KA, Patil R, Ding H, Eggehard Holler E, Black K (2007) Brain tumor tandem targeting using a combination of monoclonal antibodies attached to biopoly (β-l-malic acid). Control Relea 122:356

Ljubimova J, Fujita javascript:popRef(‘a1’)Mjavascript:popRef(‘a1’), Ljubimov A, Torchilin V, Black K.L, Holler E (2008) Poly(malic acid) nanoconjugates containing various antibodies and oligonucleotides for multitargeting drug delivery. Nanomedic 3:247

Manitchotpisit P, Skory CD, Peterson SW, Price NPJ, Vermillion KE (2012) Poly(-L-malic acid) production by diverse phylogenetic clades of Aureobasidium pullulans. Ind Microbio Biotechn 39:125

Yuan LL, Li YQ, Wang Y, Zhang XH, Xu YQ (2008) Optimization of critical medium components using response surface methodology for Phenazine-1-Carboxylic acid production by Pseudomonas sp M-18Q. Biosci and Bioen 105:232

Zheng YF, Zhou H, Wang LY, Wei P (2010) Determination of poly (malic acid) in fermentation broth by reversed phase high performance liquid chromatography. Food Sci Tech 35:2

Acknowledgments

This work was supported by Tianjin Higher Education Science and Technology Development Program of Tianjin Education Committee, Tianjin China (No. ZD200703) and Tianjin University of Science and Technology, scientific research funds (No. 20120118).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Qiao, C., Song, Y., Zheng, Z., Fan, X., Yu, S. (2015). Synthesis of Poly (β-L-malic Acid) by the Optimization of Inorganic Nitrogen Complexing with Growth Factors Using Aureobasidium pullulans CGMCC3337. In: Zhang, TC., Nakajima, M. (eds) Advances in Applied Biotechnology. Lecture Notes in Electrical Engineering, vol 332. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-45657-6_58

Download citation

DOI: https://doi.org/10.1007/978-3-662-45657-6_58

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-45656-9

Online ISBN: 978-3-662-45657-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)