Abstract

Nano-SiO2 efficiently catalyzed the synthesis of β-enaminones using direct condensation of various (cyclic and acyclic) β-diketones with aromatic and aliphatic amines under solvent-free conditions. This eco-friendly catalyst can be recovered and reused without significant loss of activity. This methodology provides a simple synthetic route to enaminones in excellent yields at room temperature.

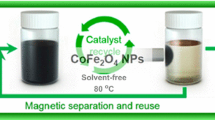

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

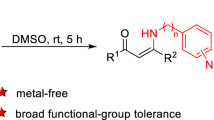

Enaminones are versatile, readily obtainable reagents and their chemistry has received considerable attention in recent years [1, 2]. β-Enaminones are useful synthones for the synthesis of various pharmaceuticals and bioactive heterocycles [3], including anticonvulsant, anti-inflammatory, and antitumor agents. The conventional method for the synthesis of enaminones is the azeotropic removal of water by refluxing an amine with 1,3-diketones in aromatic solvents [4]. Recently, some other methods applied various catalysts such as NaAuCl4 [5], SiO2/NaHSO4 [3], PPA-SiO2 [6], zirconium(IV) chloride [7], Bi(TFA)3 [8], Cu-np [9], H3PW12O40 [10], (bromodimethyl)sulfonium bromide [11], silica supported Fe(HSO4)3 [12], trichloroacetic acid [13], AlPO4 [14], VO(acac)2 [2], silica-supported sulfuric acid [15], and SiO2/HClO4 [16]. Despite efficiency of the published methods, some of these procedures suffer from disadvantages such as long reaction times, use of toxic organic solvent, use of expensive and non-reusable catalyst and high temperature reaction. Therefore, there is much room for the development of new protocols to overcome these problems. Use of heterogeneous solid catalysts in organic synthesis and industrial reactions is interesting due to their selectivity, recyclability, operational simplicity, and minimal waste disposal [17]. Recently, nano-SiO2 has been found to be an efficient, cheap, noncorrosive and reusable solid catalyst for a variety of organic synthesis like preparation of 2-aryloxazines, 2-aryltetrahydropyrimidines [18], α-aminophosphonates [19], and oxidation of alcohols [20].

Herein, we report a simple and convenient method for the synthesis of β-enaminones by condensation of various amines with β-dicarbonyls in the presence of catalytic amounts nano-SiO2 as a reusable and eco-friendly catalyst at room temperature under solvent free conditions (Scheme 1).

Results and discussion

In this work, we initially showed the effect of the catalyst for the preparation of 4-(phenylamino)-pent-3-en-2-one. Acetylacetone (1 mmol) was treated with aniline (1 mmol) in the absence and presence of different amounts of nano-SiO2 at room temperature for 60 min under solvent-free conditions (Table 1). As it is clear from this table, the best result was obtained when the reaction was carried out in the presence of 10 mol% of nano-SiO2 (Table 1, entry 3). Use of higher amount of catalyst (20–30 mol%) neither improves the yield nor the reaction time further.

To explore the scope and limitation of this reaction, we synthesized different substituted β-enaminones using condensation of β-dicarbonyls with various amines (aliphatic and aromatic) in the presence of nano-SiO2 under solvent-free conditions at room temperature (Table 2). As indicated in this table, the reactions of aniline with cyclic and acyclic β-diketones under optimal reaction conditions afforded β-enaminones in excellent yields (Table 2, entries 1–4). Similarly anilines possessing both electron-donating and electron-withdrawing groups reacted with various β-dicarbonyls to afford excellent yields of the desired β-enaminones (Table 2, entries 5–11). In the same conditions, cyclic and acyclic aliphatic amines such as morpholine and benzylamine successfully condensed with β-dicarbonyls to produce the corresponding β-enaminones in excellent yields and short reaction times (Table 2, entries 12–17). In the case of ethylenediamine when 2 mmol of β-dicarbonyls was used the expected products were produced in excellent yields (Table 2, entries 18, 19).

The recyclability of the catalyst was also studied for the reaction of acetyl acetone with aniline. After the completion of the reaction, the catalyst was filtered off, washed with ethyl acetate, dried, and reused as such for subsequent experiments under the same reaction conditions. The results in Table 3 clearly established the recyclability and reusability of the catalyst without significant loss of activity.

Mechanistically, it is well established that the activation of the carbonyl groups of the diketones with the silanol groups of the nano-SiO2 can facilitate the nucleophilic attack of the amine to generate the imine intermediate [9]. Subsequent tautomerisation of resulting imine forms the corresponding β-enaminones as shown in Scheme 2.

To show the advantages and limitation of the present method the synthesis of 3-(p-tolylamino)-5,5-dimethylcyclohex-2-enone was compared with some of those reported in the literature using other solid catalysts (Table 4).

As it is evident from Table 4, nano-SiO2 is an effective, reusable, and commercially available this purpose, leading to β-enaminone at ambient temperature with high yield and low catalyst loading.

Conclusion

We have demonstrated a green protocol for the preparation of β-enaminones using commercially available nano-SiO2 as a heterogeneous catalyst. The major advantages of our method are solvent-free conditions, easy recovery and reuse of catalyst, short reaction time, excellent yield, easy work up, cost-effective use of cheap and commercially available catalyst.

Experimental

Nano-SiO2 was purchased from Plasmachem Company. The structure of the products was characterized by spectral data (1H NMR and 13C NMR) and physical properties and comparison with authentic samples.

General procedure for the preparation of β-enaminones using nano-SiO2

A mixture of β-dicarbonyl (1 mmol), amine (1 mmol), and 0.006 g nano-SiO2 (10 mol%) was stirred at room temperature without solvent. The progress of the reaction was monitored by TLC. After completion of the reaction, 10 cm3 ethyl acetate was added to the mixture and filtered off. The residue was washed with ethyl acetate and catalyst was recovered. The filtrate was evaporated and product was collected. In the case of ethylenediamine, under optimal reaction conditions two equivalents of β-diketone was used (Table 2, entries 18, 19).

Recycling of the catalysts

To a mixture of acetyl acetone (30 mmol) and aniline (30 mmol), 0.18 g nano-SiO2 was added in one lot and the resulting mixture was stirred at room temperature for 60 min. After completion of the reaction, ethyl acetate was added to the mixture and the catalyst was filtered off, washed with ethyl acetate, dried, and reused as such for subsequent experiments under same reaction conditions (Table 3).

References

Elassar AZA, Khair AA (2003) Tetrahedron 59:8463

Laskar RA, Begum NA, Hedayetullah M, Alic S, Khan AT (2013) Tetrahedron Lett 45:436

Sapkal SB, Shelke KF, Bapurao SB, Shingare MS (2010) J Korean Chem Soc 54:723

Martin DF, Janusonis GA, Martin BB (1961) J Am Chem Soc 83:73

Arcadi A, Bianchi G, Giuseppe S, Marinelli F (2003) Green Chem 5:64

Nisar M, Ali I, Shah MR, Qayum M, Zia-Ul-Haq M, Rashid U, Islam MS (2013) Molecules 18:15182

Lin J, Zhang LF (2007) Monatsh Chem 138:77

Khosropour AR, Khodaei MM, Kookhazadeh M (2004) Tetrahedron Lett 45:1725

Kidwai M, Bhardwaj S, Mishra NK, Bansal V, Kumar A, Mozumdar S (2009) Catal Commun 10:1514

Chen X, She J, Shang Z, Wu J, Wu H, Zhang P (2008) Synthesis 21: 3478

Das B, Kanth BS, Majhi A, Reddy KR (2008) Heteroat Chem 19:630

Eshghi H, Seyedi SM, Safaei E, Vakili M, Farhadipour A, Mokhtari BM (2012) J Mol Catal A Chem 430:363

Karimi JZ, Takmilifard Z (2013) Eur Chem Bull 4:211

Harrad MA, Boualy B (2013) J Mater Environ Sci 4:566

Chen X, She J, Shang Z, Wu J, Zhang P (2009) Synth Commun 39:947

Das B, Venkateswarlu K, Majhi A, Reddy MR, Reddy KN, Rao YK, Ravikumar K, Sridhar B (2005) J Mol Catal A Chem 246:276

Zareyee D, Ghandali SM, Khalilzadeh MA (2011) Catal Lett 141:1521

Mohammadpoor B, Moghadam M, Tangestaninejad S, Mirkhani V, Eskandari Z, Salavati H (2011) J Iran Chem Soc 8:17

Nasseri MA, Sadeghzadeh M (2013) J Chem Sci 125:537

Bamoharram F, Heravi M, Teymouri H, Zebarjad M, Ahmadpour A (2011) Synth React Inorg Met Org Chem Nan Met Chem 41:1221

Epifano F, Genovese S, Curini M (2007) Tetrahedron Lett 48:2717

Hasaninejad A, Zare A, Mohammadizadeh MR, Shekouhy MS, Zare ARM (2010) J Mol Catal 7:1546

Suryakant BS, Kiran FS, Bapurao BS, Murlidhar SS (2010) J Korean Chem Soc 54:723

Zhang ZH, Ma ZC, Ma LP (2007) Ind J Chem 43:535

Acknowledgments

Financial support of this work from the Research Council of University of Mazandaran gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Alinezhad, H., Tajbakhsh, M., Sarkati, M.N. et al. Nano-SiO2 catalyzed synthesis of β-enaminones under solvent free conditions. Monatsh Chem 147, 1591–1596 (2016). https://doi.org/10.1007/s00706-016-1654-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-016-1654-5