Abstract

A one-pot synthesis of 1,4-disubstituted 1,2,3-triazoles via Huisgen 1,3-dipolar cycloaddition reaction between terminal alkynes, benzyl/allyl/alkyl halides, and NaN3 in water at room temperature using silica-supported copper(I) oxide (SiO2–Cu2O) has been developed. Various supported copper(I) oxide catalysts have been tested for this reaction where silica-supported copper(I) oxide works well in this reaction. The catalyst being heterogeneous can be easily recovered at the end of reaction and can be reused making the process completely economical. A single crystal X-ray analysis of 1-benzyl-4-phenyl-1H-1,2,3-triazole has revealed that the compound crystallizes in the monoclinic space group P21.

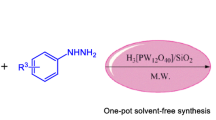

Graphical abstract

.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The introduction of Cu(I) catalysis in 2001 for the Huisgen 1,3-dipolar cycloaddition reaction of organic azides and alkynes [1] has gained much attention in recent years [2]. This catalytic species further improves both the rate and regioselectivity of the reaction due to its quantitative, very robust, general, and insensitive nature [3]. Various copper species were used as a copper source for this azide/alkyne-“click”-reaction or CuAAC-reaction such as Cu(0)/oxidizing agent, Cu(0) on charcoal, Cu(0) nano particles [3], Cu(0) catalyst [4], Cu(II)-TD@nSiO2 [5], Cu(I)/auxiliary ligand [3], and the use of Cu(I) species alone [3].

Although various catalytic systems, both homogenous as well as heterogeneous, have been explored heterogeneous catalysis in organic reactions is of great interest to organic chemists because of their synthetic utility [6], easy isolation of product, simple work-up procedure, recovery and reusability of the catalyst, thus making the process green and economical [7]. The use of silica as a support for heterogeneous catalyst takes the advantage due to its excellent stability (both chemical and thermal), high surface area, good accessibility, and also because organic groups can be robustly anchored to the surface [8–15]. Further, water provides an excellent medium for this CuAAC-reaction due to its non-toxic, non-flammable, abundant, inexpensive nature, and rate enhancement property. Further, silica supported heterogeneous catalysts have been successfully used in the aqueous medium [16, 17].

The multicomponent reaction of alkynes and azides yielding 1,2,3-triazoles is a powerful one-pot three-component click reaction as the afforded triazoles show anti-allergical [18], anti-infective [19], anti-malarial [20], anti-HIV [21], and anti-bacterial biological activities[22]. The low-molecular-weight organic azides are difficult to handle due to their explosive nature. Therefore, a method which involves the in situ formation of organic azides from the starting materials in the reaction medium will be advantageous. Further, avoiding the use of any base makes the process more useful.

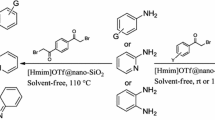

Herein, we report a silica-supported copper(I) oxide catalysed one-pot synthesis of 1,4-disubstituted 1,2,3-triazoles from terminal alkynes, benzyl/allyl/alkyl halides, and NaN3 in water at room temperature (Scheme 1). The catalyst is easy to prepare, inexpensive, and can be reused for five times without significant loss of catalytic activity. Use of additional base for this CuAAC reaction is avoided.

Results and discussion

Preparation and characterization of SiO2–Cu2O

All the supported copper(I) oxide catalysts such as SiO2–Cu2O (1), HAP/Cu2O (2), basic Al2O3/Cu2O (3), and cellulose/Cu2O (4) have been prepared following the earlier reported procedure [23] as shown in Scheme 2. Among the various supported copper(I) oxide catalysts, SiO2–Cu2O was found to be most active and was further characterized by FTIR, thermogravimetric analysis (TGA), X-ray diffractometry (XRD), X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and atomic absorption spectroscopic analysis (AAS). Complete characterization of the catalyst has been reported [23] (see Supplementary Material).

Catalyst testing for the azide/alkyne-“click”-reaction or CuAAC-reaction

To optimise the reaction conditions for this CuACC reaction, phenylacetylene, benzyl chloride, and sodium azide were selected as a test substrate to examine the catalytic effect of supported copper(I) oxide.

To select the most appropriate heterogeneous solid supported copper(I) oxide catalyst, Huisgen 1,3-dipolar cycloaddition reaction was carried out using different supported copper(I) oxide catalysts (1–4) at room temperature in aqueous medium. The results are summarised in Table 1. It has been seen that silica-supported copper(I) oxide gave good yields whereas for basic alumina supported copper(I) oxide, yield is quite low. After carrying out series of reactions, 5 mol% of Cu in SiO2–Cu2O was found to be sufficient to carry out the reaction in good to excellent yields. Further, the use of different solvents (water, ethanol, acetonitrile) has been investigated using the test substrates (phenylacetylene, benzyl chloride, and sodium azide). The results are evaluated through TLC (Table 2). It has been assumed that water proves to be an activator for Cu2O catalyst. The product, i.e. 1-benzyl-4-phenyl-1H-1,2,3-triazole obtained from the reaction has been subjected to single crystal X-ray studies. It is important to note that the reaction proceeds under neat conditions but the yield is very poor, i.e. 60 % in 20 h at room temperature. To study the generality of the developed protocol, various benzyl/allyl/alkyl halides with phenylacetylene or propargyl alcohol were chosen and results are presented in Table 3. It has been observed that benzyl halides provide the best results, whereas alkyl halides take much time for the reaction to proceed to completion.

Crystal and molecular structure of 3b

An ORTEP view of the title compound with atomic labelling is shown in Fig. 1 [24]. The geometry of the molecule was calculated using PLATON [25] and PARST [26] software. The selected bond lengths and bond angles are given in Table 4.

The title molecule comprises of a triazole ring and two phenyl rings (Fig. 1). Bond lengths and angles of the title molecules are within normal ranges [27]. Triazole ring (N1/N2/N3/C4/C5) makes a dihedral angle of 79.02(7)° and 9.63(7)° with phenyl rings (C7–C12) and (C13–C18), respectively. Dihedral angle between the phenyl rings is 77.67(7)°. Packing view of the molecules in the unit cell viewed down the b axis is shown in Fig. 2.

Recyclability of SiO2–Cu2O for CuAAC-reaction

For heterogeneous catalyst, recyclability is an important factor which made the process cost effective and greener. A series of five consecutive runs were carried out in case of compound 3b. It was found that there is almost no change in the activity of catalyst up to fifth use: yields were 96, 95, 94, 94, and 92 %, respectively (Fig. 3). The catalyst after fifth use showed the presence of Cu(II), as indicated by magnetic moment measurements.

Conclusion

In conclusion, we have presented a simple, efficient, and greener method for the synthesis of 1,4-disubstituted 1,2,3-triazoles via azide/alkyne-“click”-reaction or CuAAC-reaction using recyclable SiO2–Cu2O. This simple procedure afforded the products in good to excellent yields. The catalyst is selective and heterogeneous and therefore its practical use in this reaction makes the process more advantageous. Further, the reaction proceeds in the absence of any ligand and base. The use of water as a solvent in the reaction makes the process environment-friendly.

Experimental

Silica gel was purchased from ACROSS Organics and all other chemicals were purchased from Merck and Sigma Aldrich and were used without further purification. IR spectra of the catalyst and the synthesized compounds were recorded in the range of 4,000–300 cm−1 on a Shimadzu Prestige-21 spectrophotometer. TGA of the catalyst was obtained on a Linesis Thermal Analyser. X-ray diffractograms were recorded in 2θ range of 10°–80° on a Panalyticals X’pert Pro X-ray diffraction spectrometer using CuKα radiation. XPS spectra of the catalyst were recorded on KRATOS ESCA model AXIS 165 (Resolution). SEM was recorded on JSM-6100 (JEOL) and TEM was recorded on Hitachi (H-7500) 120 kV with CCD camera. The atomic absorption spectrometric analysis (AAS) was done on Avanta-M atomic absorption spectrometer. 1H NMR and 13C NMR of the compounds were obtained on Bruker Avance III (400 MHz) spectrometer. Mass spectra of the products were obtained on a Bruker Daltonics Esquire 3000 spectrometer.

General procedure for azide/alkyne-“click”-reaction or CuAAC-reaction using SiO2–Cu2O

In a round-bottom flask (25 cm3), a mixture of alkyne 1 (1.2 mmol), halide 2 (1 mmol), NaN3 (1 mmol), and 0.2 g SiO2–Cu2O (5 mol% Cu) in 5 cm3 water was stirred at room temperature for an appropriate time. On completion (monitored by TLC), the reaction was cooled to room temperature and filtered. The residue was washed with water followed by EtOAc (3 × 10 cm3). The product was obtained after the removal of solvent under reduced pressure followed by crystallization from petroleum ether or EtOAc: petroleum ether or passing through column of silica and elution with EtOAc: petroleum ether.

Crystal structure determination and refinement

X-ray intensity data of 21,166 reflections (of which 2,427 unique) were collected on X’calibur CCD area-detector diffractometer equipped with graphite monochromated MoKα radiation (λ = 0.71073 Å). The crystal used for data collection was of dimensions 0.30 × 0.20 × 0.20 mm. The cell dimensions were determined by least-squares fit of angular settings of 8,109 reflections in the θ range 3.53°–29.10°. The intensities were measured by ω scan mode for θ ranges 3.60°–26.00°. 1,891 reflections were treated as observed (I > 2σ(I)). Data were corrected for Lorentz, polarization, and absorption factors. The structure was solved by direct methods using SHELXS97 [28]. All non-hydrogen atoms of the molecule were located in the best E-map. All the hydrogen atoms were geometrically fixed and allowed to ride on the corresponding non-hydrogen atoms with C–H = 0.93–0.97 Å. Full-matrix least-squares refinement was carried out using SHELXL97 [28]. The final refinement cycles converged to an R = 0.0429 and wR(F 2) = 0.0843 for the observed data. Residual electron densities ranged from −0.133 to 0.099 eÅ−3. Atomic scattering factors were taken from International Tables for X-ray Crystallography (1992, Vol. C, Tables 4.2.6.8 and 6.1.1.4). The crystallographic data are summarized in Table 5.

CCDC-940362 contains the supplementary crystallographic data for this paper. These data can be obtained free of charge from The Cambridge Crystallographic Data Centre via www.ccdc.cam.ac.uk/data_request/cif.

References

Huisgen R (1989) Pure Appl Chem 61:613

Tornoe CW, Meldal M (2001) Peptidotriazoles: copper(I)-catalyzed 1,3-dipolar cycloadditions on solid-phase. Peptides 2001, San Diego, p 263

Meldal M, Tornoe CW (2008) Chem Rev 108:2952

Chen Y, Zhao ZJ, Cui DM, Zhang C (2014) J Organomet Chem 749:215

Esfahani MN, Baltork IM, Khosropour AR, Moghadam M, Mirkhani V, Tangestaninejad S, Rudbari HA (2014) J Org Chem 79:1437

Hiddesh H (1995) Chem Rev 95:537

Kale S, Kahandal S, Disale S, Jayaram R (2012) Curr Chem Lett 1:69

Reddy BM, Reddy GK, Rao KN, Khan A, Ganesh I (2007) J Mol Catal A: Chem 265:276

Cho YS, Park JC, Lee B, Kim Y, Yi J (2002) Catal Lett 81:89

Fey T, Fischer H, Bachmann S, Albert K, Bolm C (2001) J Org Chem 66:8154

Polshettiwar V, Len C, Fihri A (2009) Coord Chem Rev 253:2599

Paul S, Clark JH (2004) J Mol Catal A: Chem 215:107

Choudhary D, Paul S, Gupta R, Clark JH (2006) Green Chem 9:479

Shamim T, Gupta M, Paul S (2009) J Mol Catal A: Chem 302:15

Shamim T, Choudhary D, Mahajan S, Gupta R, Paul S (2009) Catal Commun 10:1931

Minakata S, Komatsu M (2009) Chem Rev 109:711

Gu Y, Karam A, Jerome F, Barrault J (2007) Org Lett 9:3145

Buckle DR, Rockell CJ, Smith H, Spicer BA (1983) J Med Chem 26:251

Damodiran M, Muralidharan D, Paramasivan T (2009) Bioorg Med Chem Lett 19:3611

Sahu K, Ganguly S, Kaushik A (2013) Chin J Nat Med 11:456

Alvarez R, Velazquez S, Felix AS, Aquaro S, Clercq ED, Perno CF, Karlsson A, Balzarini J, Camarasa MJ (1994) J Med Chem 37:4185

Genin MJ, Allwine DA, Anderson DJ, Barbachyn MR, Emmert DE, Garmon SA, Graber DR, Grega KC, Hester JB, Hutchinson DK, Morris J, Reischer RJ, Zurenko GE, Hamel JC, Schadt RD, Stapert D, Yagi BH (2000) J Med Chem 43:953

Gupta M, Paul S, Gupta R (2014) Chin J Catal 35:444

Farrugia LJ (2012) J Appl Cryst 45:849

Spek AL (2009) Acta Cryst D65:148

Naedelli M (1995) J Appl Cryst 28:659

Allen FH, Kennard O, Watson DG, Brammer L, Orpen AG, Taylor R (1987) J Chem Soc Perkin Trans 2:S1

Sheldrick GM (2008) Acta Cryst A64:112

Gonda Z, Novak Z (2010) Dalton Trans 39:726

Naeimi H, Dadashzadeh S, Moradian M (2013) Res Chem Intermed. doi:10.1007/s11164-013-1379-6

Shamim T, Paul S (2010) Catal Lett 136:260

Mathew P, Neels A, Albrecht M (2008) J Am Chem Soc 130:13534

Girard C, Onen E, Aufort M, Beauviere S, Samson E, Herscovici J (2006) Org Lett 8:1689

Acknowledgments

We are grateful to Director, SAIF, Punjab University, Chandigarh, for SEM, TEM, and XRD. We also extend our sincere thanks to UGC, New Delhi, for financial support to purchase FTIR and for awarding Major Research Project (F 41‐281/2012 (SR)), and Prof. R. K. Bamezai, Department of Chemistry, University of Jammu, for recording TGA. We are also thankful to Prof. Rajni Kant for the single crystal X-ray diffractometer sanctioned as a National Facility under project No. SR/S2/CMP-47/2003 by Department of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gupta, M., Gupta, M., Paul, S. et al. One-pot synthesis of 1,4-disubstituted 1,2,3-triazoles via Huisgen 1,3-dipolar cycloaddition catalysed by SiO2–Cu(I) oxide and single crystal X-ray analysis of 1-benzyl-4-phenyl-1H-1,2,3-triazole. Monatsh Chem 146, 143–148 (2015). https://doi.org/10.1007/s00706-014-1285-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-014-1285-7