Abstract

An efficient and facile method for the synthesis of 2-arylindoles, 2-arylimidazo[1,2-a]pyridines and 2-arylquinoxalines by the reaction of various α-bromo ketones with anilines, 2-aminopyridine and 1,2-phenylenediamine, respectively, in the presence of N-methylimidazolium trifluoromethanesulfonate ionic liquid supported on nano-silica ([Hmim]OTf@nano-SiO2) as a reusable catalyst under solvent-free conditions has been developed. The bis-derivatives of these compounds were also prepared efficiently, for the first time, using this catalytic system. All products were obtained in high yields and in short reaction times.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

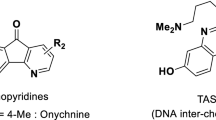

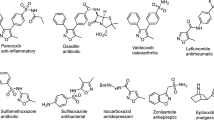

Nitrogen-containing heterocyclic compounds such as indoles, imidazo[1,2-a]pyridines and quinoxalines are of significant importance owing to their abundant existence in natural products as well as their extensive applications in the fields of pharmaceutical, medicinal, and synthetic organic chemistry [1–12]. These compounds also exhibit a wide range of biological properties, such as anti-inflammatory [13–16], antibacterial [17–20], antiprotozoal [21–24], antidepressant [25, 26], and antiviral [27–30] activities. Due to the significant applications of these heterocyclic compounds, a number of synthetic methods for their preparation have been reported in the literature [31–62]. However, some of these methods suffer from disadvantages such as long reaction times, usage of expensive and nonrecoverable catalysts, low yields of products and tedious workup. Consequently, the development of an efficient and convenient method using a reusable catalyst for the synthesis of these widely used heterocyclic compounds is highly desirable.

In the recent years, ionic liquids (ILs) have received significant attention because of their special characteristic features such as undetectable vapor pressure, non-flammability, high thermal stability, wide liquid range, and the ability to dissolve many organic and inorganic substances. These compounds have also found many applications in sensors, batteries, plasticizers, electro-chemistry, extraction, and absorption [63–69]. In addition, ionic liquids have been examined extensively in organic synthesis as reaction media or catalysts [70–73]. Despite their outstanding utilities, reactions involving homogeneous ILs suffer from drawbacks such as difficult product isolation, catalyst recovery, and the use of relatively large amounts of ILs. However, these limitations can be overcome by the immobilization of ionic liquids on solid supports, which provide the advantages of both ionic liquids and heterogeneous catalysts such as high interfacial surface area, ease of handling, separation, recycling and decreasing the amount of IL utilized in a potential process [74–77].

During the course of our studies toward the synthesis of heterocyclic compounds [78–82], herein we wish to report an efficient and convenient method for the synthesis of 2-arylindoles, 2-arylimidazo[1,2-a]pyridines and 2-arylquinoxalines and also their bis-derivatives in the presence of [Hmim]OTf@nano-SiO2 as a reusable catalyst under solvent-free conditions (Scheme 1).

Experimental section

Melting points were determined using a Stuart Scientific SMP2 apparatus. FT-IR spectra were recorded on a Nicolet-Impact 400D spectrophotometer. 1H and 13C NMR (400 and 100 MHz) spectra were recorded on a Bruker Avance 400 MHz spectrometer using CDCl3 and DMSO-d 6 as solvent. Elemental analysis was performed on a LECO, CHNS-932 analyzer.

Preparation of [Hmim]OTf@nano-SiO2

To a 50-mL round-bottomed flask containing N-methylimidazole (20 mmol, 1.64 g) at 0 °C, trifluoromethanesulfonic acid (20 mmol, 1.77 mL) was added dropwise and the mixture was stirred for 2 h. After completion of the reaction, the mixture was diluted with chloroform (20 mL) and filtered. The solid material was washed with chloroform and dried in vacuum to give N-methylimidazolium trifluoromethanesulfonate ([Hmim]OTf). Then, a mixture of nano-silica (1.0 g) and [Hmim]OTf (0.3 g) in distilled water (20 mL) was stirred for 12 h. Water was removed under reduced pressure and the catalyst was dried in vacuo to produce the [Hmim]OTf@nano-SiO2 as a white powder (30 wt % [Hmim]OTf/nano-silica).

General procedure for the synthesis 2-arylindoles, 2-arylimidazo[1,2-a]pyridines and 2-arylquinoxalines catalyzed by [Hmim]OTf@nano-SiO2

To a mixture of aniline, 2-aminopyridine or 1,2-phenylenediamine (1 mmol) and α-bromo ketone (1 mmol), was added [Hmim]OTf@nano-SiO2 (0.3 mmol). The reaction mixture was stirred at 110 °C (in the case of 1,2-phenylenediamine, the reaction was performed at room temperature) for the appropriate time according to Table 2. The progress of the reaction was monitored by TLC (eluent: ethyl acetate/petroleum ether, 1:20). After completion of the reaction, ethyl acetate (10 mL) was added and the catalyst was separated by simple filtration. Evaporation of the solvent followed by purification of the crude product by column chromatography on silica gel (eluent: ethyl acetate/petroleum ether, 1:20) afforded the pure product.

Characterization data of some representative compounds

2-(4-Cyclohexylphenyl)-1H-indole (Table 2, entry 6): Mp178–180 °C. IR (KBr): ν max 3427, 2923, 2854, 1655, 1229, 1051, 1026, 1005, 825, 763 cm−1. 1H NMR (400 MHz, DMSO-d 6 ): δ 1.26–1.48 (m, 6H), 1.70–1.82 (m, 4H), 2.50–2.51 (m, 1H), 6.83 (d, J = 1.2 Hz, 1H), 6.98 (td, J = 7.6, 0.8 Hz, 1H), 7.08 (td, J = 7.6, 0.8 Hz, 1H), 7.30 (d, J = 8.4 Hz, 2H), 7.51 (d, J = 8.4 Hz, 1H), 7.77 (d, J = 8.4 Hz, 2H), 7.88 (d, J = 8.4 Hz, 1H), 11.46 (s, 1H). 13C NMR (100 MHz, DMSO-d 6 ): δ 25.6, 26.3, 33.8, 43.5, 98.0, 111.2, 119.2, 119.8, 121.3, 124.9, 127.1, 128.4, 129.8, 137.0, 137.8, 146.9 MS: m/z (%): 276.14 ([M+1]+, 76.08), 275.08 ([M]+, 100), 232.11 (77.25), 206.09 (85.10), 193.13 (63.53), 165.12 (40.39), 128.14 (15.00), 115.13 (65.10), 90.09 (80.00), 57.17 (73.73). Anal. Calcd for C20H21N: C, 87.23; H, 7.69; N, 5.09. Found: C, 87.31; H, 7.72; N, 5.03.

2-(4-Bromophenyl)-5-chloro-1H-indole (Table 2, entry 9): Mp 147–149 °C. IR (KBr): ν max 3357, 2928, 2859, 1650, 1508, 1284, 1188, 1117, 857, 797, 751. 1H NMR (400 MHz, DMSO-d 6 ): δ 7.34 (d, J = 8.4 Hz, 2H), 7.63 (d, J = 8.4 Hz, 2H), 7.90 (dd, J = 8.8, 2.4 Hz, 1H), 8.12 (d, J = 9.2 Hz, 1H), 8.31 (d, J = 2.0 Hz, 1H), 8.63 (s, 1H), 11.12 (s, 1H). 13C NMR (100 MHz, DMSO-d 6 ): δ 99.5, 116.5, 119.0, 122.3, 123.5, 124.6, 125.3, 126.3, 129.9, 131.8, 135.2, 137.5. MS: m/z (%): 308.96 ([M+2]+, 25.32), 306.96 ([M]+, 100), 271.34 (45.32), 91.08 (26.70), 90.08 (42.23), 63.11 (43.69), 52.12 (50.00), 46.10 (93.28). Anal. Calcd for C14H9NBrCl: C, 54.85; H, 2.96; N, 4.57. Found: C, 54.94; H, 2.99; N, 4.51.

2-(4-Bromophenyl)-5-nitro-1H-indole (Table 2, entry 10): Mp 187–189 °C. IR (KBr): ν max 3369, 2951, 2854, 1651, 1594, 1331, 1280, 1160, 854, 746 cm−1. 1H NMR (400 MHz, DMSO-d 6 ): δ 7.63 (d, J = 7.2 Hz, 2H), 7.79 (d, J = 7.2 Hz, 2H), 7.97 (d, J = 2.4 Hz, 1H), 8.02 (dd, J = 8.4, 2.4 Hz, 1H), 8.08 (d, J = 7.2 Hz, 1H), 8.24 (d, J = 3.2 Hz, 1H), 11.54 (s, 1H). 13C NMR (100 MHz, DMSO-d 6 ): δ 113.4, 116.3, 119.1, 120.2, 125.0, 125.1, 126.2, 128.8, 129.1, 130.1, 135.1, 138.6. MS: m/z (%): 319.78 ([M+4]+, 14.26), 317.78 ([M+2]+, 97.31), 315.82 ([M]+, 100), 269.04 (4.32), 189.34 (5.00), 69.15 (34.78), 66.06 (76.32), 46.12 (80.70). Anal. Calcd for C14H9N2BrO2: C, 53.02; H, 2.86; N, 8.83. Found: C, 53.10; H, 2.83; N, 8.89.

2-(4-Bromophenyl)-5-methyl-1H-indole (Table 2, entry 11): Mp 103–106 °C. IR (KBr): ν max 3358, 2931, 2851, 1647, 1508, 1280, 1162, 1118, 884, 745. 1H NMR (400 MHz, DMSO-d 6 ): δ 2.60 (s, 3H), 7.57 (d, J = 8.4 Hz, 2H), 7.63 (dd, J = 8.6, 0.8 Hz, 1H), 7.68 (s, 1H), 7.77 (d, J = 8.4 Hz, 2H), 8.04 (d, J = 8.4 Hz, 1H), 8.14 (s, 1H), 11.63 (s, 1H). 13C NMR (100 MHz, DMSO-d 6 ): δ 23.8, 99.9, 110.9, 120.7, 121.6, 122.8, 125.5, 129.2, 130.2, 132.2, 136.0, 136.9, 138.0. MS: m/z (%): 289.12 ([M+4]+, 16.23), 287.11 ([M+2]+, 97.32), 285.14 ([M]+, 100), 270.02 (75.02), 77.09 (29.40), 75.04 (93.78), 63.07 (28.76), 57.12 (29.53), 50.10 (82.90). Anal. Calcd for C15H12NBr: C, 62.96; H, 4.23; N, 4.89. Found: C, 63.05; H, 4.27; N, 4.96.

2-(4-Bromophenyl)imidazo[1,2-a]pyridine (Table 2 entry 13): Mp 215–217 °C. IR (KBr): ν max 3046, 2955, 2857, 1631, 1539, 1464, 1399, 1369, 1063, 933, 824, 739 cm−1. 1H NMR (400 MHz, DMSO-d 6 ): δ 6.91 (td, J = 7.0, 1.2 Hz, 1H), 7.26 (td, J = 7.0, 1.2 Hz, 1H), 7.58 (J = 9.2 Hz, 1H), 7.64 (d, J = 8.4 Hz, 2H), 7.93 (d, J = 8.4 Hz, 2H), 8.46 (s, 1H), 8.53 (dd, J = 6.8, 1.2 Hz, 1H). 13C NMR (100 MHz, DMSO-d 6 ): δ 109.3, 114.7, 119.6, 123.3, 124.7, 125.0, 125.6, 127.3, 129.3, 129.3, 133.5. MS: m/z (%): 274.98 ([M+2]+, 49.80), 273.00 ([M]+, 64.71), 271.95 (94.90), 193.12 (84.71), 166.15 (37.65), 115.16 (50.59), 101.11 (75.69), 96.40 (100), 78.10 (98.02), 51.19 (89.41). Anal. Calcd for C13H9N2Br: C, 57.17; H, 3.32; N, 10.26. Found: C, 57.25; H, 3.37; N, 10.35.

1,4-Bis(1H-indol-2-yl)benzene (Table 3 entry 1): Mp 210–212 °C. IR (KBr): ν max 3440, 3046, 2924, 2853, 1599, 1480, 1349, 1297, 798, 742 cm−1. 1H NMR (400 MHz, CDCl3): δ 7.00 (t, J = 8.4 Hz, 2H), 7.71 (t, J = 8.4 Hz, 2H), 7.91 (s, 2H), 7.94 (d, J = 8.4 Hz, 2H), 8.03 (d, J = 8.4 Hz, 2H), 8.07 (d, J = 6.8 Hz, 2H), 8.34 (d, J = 9.6 Hz, 2H), 8.52 (s, 2H). 13C NMR (100 MHz, CDCl3): δ 98.1, 112.0, 118.2, 119.9, 122.0, 122.3, 122.4, 126.2, 127.3, 128.4, 138.5. MS: m/z (%): 310.14 ([M+2]+, 2.52), 309.13 ([M+1]+, 27.24), 308.13 ([M]+, 100), 193.09 (78.02), 116.05 (68.41), 85.15 (85.66), 71.15 (89.66), 57.15 (95.00). Anal. Calcd for C22H16N2: C, 85.69; H, 5.23; N, 9.08. Found: C, 85.77; H, 5.19; N, 9.15.

1,4-Bis(5-chloro-1H-indol-2-yl)benzene (Table 3 entry 2): Mp 215-218 °C. IR (KBr): ν max 3441, 3046, 2923, 2854, 1541, 1478, 1349, 1297, 1094, 1008, 832, 742 cm−1. 1H NMR (400 MHz, CDCl3): δ 6.80 (d, J = 8.0 Hz, 2H), 7.37 (d, J = 8.0 Hz, 2H), 7.39 (d, 7.6 Hz, 2H), 7.43 (d, J = 2.4 Hz, 2H), 7.46 (d, 7.6 Hz, 2H), 8.31 (s, 2H), 8.54 (s, 2H). 13C NMR (100 MHz, CDCl3): δ 98.0, 112.1, 118.6, 123.4, 124.1, 125.1, 127.9, 130.0, 131.3, 146.7, 151.1. MS: m/z (%): 378.06 ([M+2]+, 66.21), 377.06 ([M+1]+, 25.04), 376.05 ([M]+, 100), 341.09 (56.02), 306.13 (6514), 226.05 (78.02), 193.02 (96.00), 165.01 (84.31), 114.99 (50.20), 95.31 (98.30), 83.51 (96.08), 51.02 (85.10). Anal. Calcd for C22H14N2Cl2: C, 70.04; H, 3.74; N, 7.43. Found: C, 70.11; H, 3.77; N, 7.49.

1,4-Bis(5-bromo-1H-indol-2-yl)benzene (Table 3 entry 3): Mp 217–219 °C. IR (KBr): ν max 3420, 3046, 2923, 2854, 1540, 1480, 1351, 1297, 1094, 1008, 832, 742, 688 cm−1. 1H NMR (400 MHz, CDCl3): δ 6.90 (d, J = 8.8 Hz, 2H), 7.37 (d, J = 8.0 Hz, 2H), 7.39 (d, 7.6 Hz, 2H), 7.40–7.44 (m, 4H), 8.31 (d, J = 1.2 Hz, 2H), 8.91 (s, 2H). 13C NMR (100 MHz, CDCl3): δ 99.0, 112.4, 118.5, 123.5, 124.1, 125.1, 127.9, 129.9, 131.3, 146.6, 150.9. MS: m/z (%): 467.95 ([M+2]+, 48.91), 466.95 ([M+1]+, 51.40), 465.95 ([M]+, 100), 464.94 (45.60), 385.04 (85.01), 306.14 (78.23), 270.76 (97.00), 191.06 (78.45), 165.02 (84.10), 136.68 (48.76), 113.01 (59.19), 82.59 (82.45), 69.33 (81.95), 50.02 (93.21). Anal. Calcd for C22H14N2Br2: C, 56.68; H, 3.03; N, 6.01. Found: C, 56.78; H, 3.00; N, 6.09.

1,4-Bis(5-methyl-1H-indol-2-yl)benzene (Table 3 entry 4): Mp 185–187 °C. IR (KBr): ν max 3415, 2930, 2851, 1653, 1510, 1282, 1162, 1118, 832, 798, 742 cm−1. 1H NMR (400 MHz, CDCl3): δ 2.69 (s, 6H), 7.31 (s, 2H), 7.66 (s, 2H), 8.03 (d, J = 8.4 Hz, 2H), 8.10 (d, J = 8.4 Hz, 2H), 8.43 (d, J = 8.0 Hz, 2H), 8.52 (s, 2H), 8.74 (d, J = 10.8 Hz, 2H). 13C NMR (100 MHz, CDCl3): δ 29.7, 99.0, 112.5, 118.5, 121.6, 121.9, 125.2, 127.9, 128.9, 129.1, 130.3, 158.7. MS: m/z (%): 338.17 ([M+2]+, 3.4), 337.17 ([M+1]+, 26.17), 336.16 (100), 207.10 (91.32), 193.09 (81.54), 131.07 (68.65), 116.06 (91.36), 82.59(68.45), 69.33 (78.25), 50.02 (91.16). Anal. Calcd for C24H20N2: C, 85.68; H, 5.99; N, 8.33. Found: C, 85.75; H, 5.96; N, 8.38.

1,4-Bis(5-methoxy-1H-indol-2-yl)benzene (Table 3 entry 5): Mp 195–198 °C. IR (KBr): ν max 3431, 2923, 2851, 1650, 1505, 1250, 1051, 1005, 831, 763 cm−1. 1H NMR (400 MHz, CDCl3): δ 3.69 (s, 6H), 6.98 (d, J = 8.0 Hz, 2H), 7.43 (d, 8.0 Hz, 2H), 7.80 (s, 2H), 7.97 (d, J = 8.4 Hz, 2H), 8.07 (d, J = 8.4 Hz, 2H), 8.38 (s, 2H), 8.62 (d, J = 9.6 Hz, 2H). 13C NMR (100 MHz, CDCl3): δ 66.8, 112.4, 119.3, 112.0, 127.4, 128.7, 128.8, 129.6, 129.7, 130.3, 130.9, 158.7. MS: m/z (%): 370.16 ([M+2]+, 3.71), 369.16 ([M+1]+, 26.40), 368.15 ([M]+, 41.03), 337.14 (86.26), 307.14 (78.62), 223.17 (23.10), 191.10 (62.15), 116.06 (41.21), 93.06 (100), 77.06 (68.62), 66.07 (71.29), 57.10 (96.00). Anal. Calcd for C24H20N2O2: C, 78.24; H, 5.47; N, 7.60. Found: C, 78.19; H, 5.51; N, 7.55.

1,4-Bis(imidazo[1,2-a]pyridin-2-yl)benzene (Table 3 entry 6): Mp 159–161 °C. IR (KBr): ν max 3127, 3069, 2928, 2853, 1629, 1508, 1471, 1374, 1266, 1143, 1078, 916, 741 cm−1. 1H NMR (400 MHz, CDCl3): δ 6.90 (d, J = 6.4 Hz, 2H), 7.26 (t, J = 8.8 Hz, 2H), 7.31 (t, J = 8.4 Hz, 2H), 7.45 (d, J = 7.6 Hz, 2H), 7.54 (t, J = 8.8 Hz, 2H), 7.98 (d, J = 7.6 Hz, 2H), 8.54 (s, 2H). 13C NMR (100 MHz, CDCl3): δ 109.1, 112.3, 116.6, 124.9, 125.5, 126.9, 127.7, 128.7, 133.9, 145.0. MS: m/z (%): 312.13 ([M+2]+, 2.30), 311.13 ([M+1]+, 22.21), 310.12 ([M]+, 86.14), 194.19 (66.13), 123.13 (100), 117.05 (41.65), 78.16 (75.81), 57.20 (78.23). Anal. Calcd for C20H14N4: C, 77.40; H, 4.55; N, 18.05. Found: C, 77.48; H, 4.59; N, 17.97.

1,4-Bis(quinoxalin-2-yl)benzene (Table 3 entry 7): Mp 117–119 °C. IR (KBr): ν max 3030, 2849, 1530, 1491, 1331, 1227, 1029, 868, 774 cm−1. 1H NMR (400 MHz, CDCl3): δ 7.81–7.86 (m, 4H), 8.18–8.23 (m, 2H), 8.24 (t, J = 8.0 Hz, 2H), 8.47 (s, 4H), 9.46 (s, 2H). 13C NMR (100 MHz, CDCl3): δ 128.3, 129.2, 129.7, 129.9, 130.5, 141.8, 142.2, 143.2. MS: m/z (%): 336.13 ([M+2]+, 3.1), 335.13 ([M+1]+, 24.02), 334.12 ([M]+, 75.16), 206.16 (65.12), 179.16 (61.46), 167.12 (83.67), 149.09 (93.86), 97.19 (69.68), 71.17 (92.27), 57.16 (100). Anal. Calcd for C22H14N4: C, 79.02; H, 4.22; N, 16.76. Found: C, 79.11; H, 4.19; N, 16.80.

Results and discussion

The synthesis of the catalyst was performed in two steps, as illustrated in Scheme 2. First, an equimolar mixture of trifluoromethanesulfonic acid and N-methylimidazole was stirred at 0 °C for 2 h to afford N-methylimidazolium trifluoromethanesulfonate ([Hmim]OTf) as a white powder. Then, a mixture of nano-silica and [Hmim]OTf in distilled water was stirred at room temperature for 12 h. Water was removed in vacuum to produce the supported ionic liquid ([Hmim]OTf@nano-SiO2). The catalyst was characterized by the means of FT-IR spectroscopy and SEM.

The FT-IR spectra of nano-silica and [Hmim]OTf@nano-SiO2 are depicted in Fig. 1. The FT-IR spectra of [Hmim]OTf@nano-SiO2 (Fig. 1b) show bands at around 1589 and 1549 cm−1 which are assigned to C=N and C=C vibrations of the imidazole ring. The bands at around 3160, 2947 and 2888 cm−1 are attributed to the C–H stretching vibrations of the imidazole and alkyl moieties. Moreover, the bands related to the S=O and S–O stretching frequencies are observed at around 1166, 1030 and 641 cm−1. These characteristic bands are not observed in the FT-IR spectrum of nano-silica. For nano-silica and [Hmim]OTf@nano-SiO2, the bands due to the Si–O–Si stretching vibrations are observed at about 1103 and 810 cm−1 and a broad band belonging to the Si–OH groups and adsorbed water is seen at around 3434 cm−1 (Fig. 1a, b). These observations indicate that IL has been successfully supported on the nano-silica surface.

The scanning electron microscope (SEM) images of nano-silica and IL@nano-SiO2 revealed that the surface morphology of these two samples is different (Fig. 2). The differences in SEM images thus, illustrate that immobilization and supporting of IL on nano-SiO2 changes the morphological structure of nano-SiO2 surface considerably.

First, the reaction of α-bromo acetophenone (1 mmol) with aniline (1 mmol) was used as a model to study the catalytic activity of different ionic liquids (ILs) such as [Hmim]HSO4, [Hmim]NO3, [Hmim]BF4, [Bmim]Br, [Hmim]OTf, and supported [Hmim]OTf on the common silica (60-100 mesh) and nano-silica. The results of these studies are presented in Table 1. Among these ILs, [Hmim]OTf supported on nano-silica was found to be the most efficient catalyst for this reaction. When the reaction was carried out in the absence of the catalyst, only 5 % of the desired product was obtained (Table 1, entry 8) which shows that the presence of the catalyst is necessary for this reaction. The influence of the catalyst loading on the model reaction was then investigated using 0.2–0.4 mmol of [Hmim]OTf@nano-SiO2 and the best yield was obtained in the presence of 0.3 mmol of catalyst. Finally, the effect of temperature was evaluated for the model reaction in the range of 90–120 and 110 °C was found to be the optimum temperature.

Encouraged by the efficiency of the above reaction protocol, we then devised a novel synthesis of 2-arylindoles, 2-arylimidazo[1,2-a]pyridines and 2-arylquinoxalines under solvent-free conditions. To scrutinize the scope and generality of this protocol, we initially advocated a variety of α-bromo ketones with anilines for the synthesis of 2-arylindoles and the results are summarized in Table 2. As can be seen, the reaction of aniline and anilines bearing electron-donating as well as electron-withdrawing functionalities proceeded smoothly and cleanly with electron-withdrawing, and electron-releasing substituted α-bromo ketones under thermal conditions (110 °C) and the corresponding 2-arylindoles were obtained in high yields (Table 2, entries 1–11). With these remarkable results in hand, we then examined the preparation of 2-arylimidazo[1,2-a]pyridines in the presence of [Hmim]OTf@nano-SiO2 catalyst. As shown, 2-aminopyridine reacted efficiently with α-bromo ketones under the identical reaction conditions to generate the desired 2-arylimidazo[1,2-a]pyridines in high yields (Table 2, entries 12–15). To further expand the scope of application of this protocol, 1,2-phenylenediamine was used instead of aniline and 2-aminopyridine for the preparation of 2-arylquinoxalines. Treatment of 1,2-phenylenediamine with various α-bromo ketones under similar conditions at room temperature resulted in the formation of the corresponding 2-arylquinoxalines in excellent yields (Table 2, entries 16–19). It is noteworthy that all the reactions proceeded very efficiently and cleanly, and no undesirable side reactions were observed under these conditions.

Another outstanding feature of this catalytic system lies in the synthesis of bis-derivatives of the title compounds. As shown in Table 3, condensation of 1 mmol 1,1′-(1,4-phenylene)bis(2-bromoethanone) with 2 mmol each of anilines, 2-aminopyridine and 1,2-phenylenediamine was performed efficiently in the presence of [Hmim]OTf@nano-SiO2 under solvent-free conditions, affording the corresponding bis-2-arylindoles, bis-2-arylimidazo[1,2-a]pyridine and bis-2-arylquinoxaline in high yields. To the best of our knowledge, the present report is the first example of the use of 1,1′-(1,4-phenylene)bis(2-bromoethanone) in the synthesis of bis-derivatives of these compounds. Consequently, this new procedure is of practical importance and can be considered as a useful achievement in the synthesis of these fundamental heterocycles.

Typically, the plausible reaction mechanism for the synthesis of 2-arylquinoxaline from 1,2-phenylenediamine and α-bromo ketone is outlined in Scheme 3. Initially, activation of the carbonyl group of α-bromo ketone by the catalyst followed by condensation with one amino group of 1,2-phenylenediamine results in imine A. Then, intramolecular nucleophilic attack by the remaining NH2 in imine A leads to dehydrohalogenation and cyclization, giving dihydroquionoxaline B. Finally, oxidative aromatization of intermediate B under ambient atmosphere in the presence of the catalyst furnishes the desired 2-arylquinoxaline C and releases the catalyst for the next catalytic cycle.

Finally, the reusability of the catalyst was checked in the reaction of aniline with α-bromo acetophenone. After completion of the reaction, the mixture was cooled to room temperature and ethyl acetate (10 mL) was added. The catalyst was recovered by simple filtration, dried and reused for subsequent experiments. The results of these experiments show that the catalyst could be recycled and reused five times without notable decline in its activity (Table 4). Comparison of the FT-IR spectra of fresh and reused catalysts showed no significant changes in the characteristic bands, which indicates that the catalyst is stable during the reaction (Fig. 1b, c).

Conclusion

In conclusion, we have successfully developed a convenient and environmentally benign synthetic method to afford 2-arylindoles, 2-arylimidazo[1,2-a]pyridines and 2-arylquinoxalines and also their bis-derivatives using [Hmim]OTf@nano-SiO2 as a recyclable and reusable catalyst under solvent-free conditions. To the best of our knowledge, this is the first example of synthesizing bis-derivatives of the title compounds using this catalytic system. Short reaction times, high product yields, simplicity of the procedure, easy workup, recovery and reusability of the catalyst are the significant features of the present protocol, which make this procedure attractive and useful for the synthesis of these important heterocyclic compounds.

References

T. Kawasaki, K. Higuchi, Nat. Prod. Rep. 24, 843–868 (2007)

A. Brancale, R. Silvestri, Med. Res. Rev. 27, 209–238 (2007)

M. Somei, F. Yamada, Nat. Prod. Rep. 22, 73–103 (2005)

A.J. Kochanowska-Karamyan, M.T. Hamman, Chem. Rev. 110, 4489–4497 (2010)

F. Couty, G. Evano, in Comprehensive heterocyclic chemistry III, vol. 11, ed. by A. R. Katritzky, C. A. Ramsden, E. F. V. Scriven, R. J. K. Taylor (Elsevier, Oxford, 2008), pp 409–499

T. Okubo, R. Yoshikawa, S. Chaki, S. Okuyamac, A. Nakazato, Bioorg. Med. Chem. 12, 423–438 (2004)

C. Enguehard, F. Fauvelle, J. Debouzy, A. Peinnequin, I. Thery, V. Dabouis, A. Gueiffier, Eur. J. Pharm. Sci. 24, 219–227 (2005)

C. Enguehard-Gueiffier, A. Gueiffier, Mini-Rev. Med. Chem. 7, 888–899 (2007)

U. Sehlstedt, P. Aich, J. Bergman, H. Vallberg, B. Norden, A. Graslund, J. Mol. Biol. 278, 31–56 (1998)

A. Jaso, B. Zarranz, I. Aldana, A. Monge, J. Med. Chem. 48, 2019–2025 (2005)

A. Carta, G. Paglietti, M.E.R. Nikookar, P. Sanna, L. Sechi, S. Zanetti, Eur. J. Med. Chem. 37, 355–366 (2002)

G. Fedora, A. Francesca, D.G. Osvaldo, B. Antonella, G. Antonio, N. Nouri, Bioorg. Med. Chem. 15, 288–294 (2007)

A.S. Kalgutkar, B.C. Crews, S. Saleh, D. Prudhomme, L.J. Marnett, Bioorg. Med. Chem. 13, 6810–6822 (2005)

R.B. Lacerda, C.K. de Lima, L.L. da Silva, N.C. Romeiro, A.L. Miranda, E.J. Barreiro, C.A. Fraga, Bioorg. Med. Chem. 17, 74–84 (2009)

A. Gomtsyan, E.K. Bayburt, R.G. Schmidt, G.Z. Zheng, R.J. Perner, S. Didomenico, J.R. Koenig, S. Turner, T. Jinkerson, I. Drizin, S.M. Hannick, B.S. Macri, H.A. McDonald, P. Honore, C.T. Wismer, K.C. Marsh, J. Wetter, K.D. Stewart, T. Oie, M.F. Jarvis, C.S. Surowy, C.R. Faltynek, C.H. Lee, J. Med. Chem. 48, 744–752 (2005)

R.A. Smits, H.D. Lim, A. Hanzer, O.P. Zuiderveld, E. Guaita, M. Adami, G. Coruzzi, R. Leurs, I.J.P. de Esch, J. Med. Chem. 51, 2457–2467 (2008)

Y. Yamamoto, M. Kurazono, Bioorg. Med. Chem. Lett. 17, 1626–1628 (2007)

L.E. Seitz, W.J. Suling, R.C. Reynolds, J. Med. Chem. 45, 5604–5606 (2002)

N.M. Shukla, D.B. Salunke, E. Yoo, C.A. Mutz, R. Balakrishna, S.A. David, Bioorg. Med. Chem. 20, 5850–5863 (2012)

A.K. Parhi, Y. Zhang, K.W. Saionz, P. Pradhan, M. Kaul, K. Trivedi, D.S. Pilch, E.J. LaVoie, Bioorg. Med. Chem. Lett. 23, 4968–4974 (2013)

S.L. Colletti, C. Li, M.H. Fisher, M.J. Wyvratt, P.T. Meinke, Tetrahedron Lett. 41, 7825–7829 (2000)

G.I. Stevenson, A.L. Smith, S. Lewis, S.G. Michie, J.G. Neduvelil, S. Patel, R. Marwood, S. Patel, J.L. Castro, Bioorg. Med. Chem. Lett. 10, 2697–2699 (2000)

A. Scribner, R. Dennis, S. Lee, G. Ouvry, D. Perrey, M. Fisher, M. Wyvratt, P. Leavitt, P. Liberator, A. Gurnett, C. Brown, J. Mathew, D. Thompson, D. Schmatz, T. Biftu, Eur. J. Med. Chem. 43, 1123–1151 (2008)

M.A. Ismail, R.K. Arafa, T. Wenzler, R. Brun, F.A. Tanious, W.D. Wilson, D.W. Boykin, Bioorg. Med. Chem. 16, 683–691 (2008)

T. Heinrich, H. Bottcher, Bioorg. Med. Chem. Lett. 14, 2681–2684 (2004)

R. Sarges, H.R. Howard, R.G. Browne, L.A. Label, P.A. Seymour, B.K. Koe, J. Med. Chem. 33, 2240–2254 (1990)

K.S. Gudmundsson, B.A. Johns, Bioorg. Med. Chem. Lett. 17, 2735–2739 (2007)

G. Puerstinger, J. Paeshuyse, E. Declercq, J. Neyts, Bioorg. Med. Chem. Lett. 17, 390–393 (2007)

M. Loriga, S. Piras, P. Sanna, G. Paglietti, Farmaco 52, 157–166 (1997)

N. S. Hari Narayana Moorthy, E. Manivannan, C. Karthikeyan, P. Trivedi, Mini-Rev. Med. Chem. 13, 1415–1420 (2013)

V. Sridharan, S. Perumal, C. Avendaño, J. C. Menéndez, Synlett. 91–95 (2006)

D. Xu, W. L. Yang, S-P. Luo, B-T. Wang, J. Wu, Z-Y. Xu, Eur. J. Org. Chem. 1007–1012 (2007)

L. Ackermann, W. Song, R. Sandmann, J. Organomet. Chem. 696, 195–201 (2011)

F. Ragaini, A. Rapetti, E. Visentin, M. Monzani, A. Caselli, S. Cenini, J. Org. Chem. 71, 3748–3753 (2006)

L.T. Kaspar, L. Ackermann, Tetrahedron 61, 11311–11316 (2005)

A. Prakash, M. Dibakar, K. Selvakumar, K. Ruckmani, M. Sivakumar, Tetrahedron Lett. 52, 5625–5628 (2011)

K. Okuma, J.-I. Seto, K.-I. Sakaguchi, S. Ozaki, N. Nagahora, K. Shioji, Tetrahedron Lett. 50, 2943–2945 (2009)

A. Carpita, A. Ribecai, P. Stabile, Tetrahedron 66, 7169–7178 (2010)

L. Ackermann, A.V. Lygin, Org. Lett. 14, 764–767 (2012)

M.T. Hovey, C.T. Check, A.F. Sipher, K.A. Scheidt, Angew. Chem. Int. Ed. 53, 9603–9607 (2014)

K. Kobayashi, D. Iitsuka, S. Fukamachi, H. Konishi, Tetrahedron 65, 7523–7526 (2009)

K.C. Majumdar, S. Samanta, B. Chattopadhyay, Tetrahedron Lett. 49, 7213–7216 (2008)

T. Pei, D.M. Tellers, E.C. Streckfuss, C.Y. Chen, I.W. Davies, Tetrahedron 65, 3285–3291 (2009)

N. Chernyak, V. Gevorgyan, Angew. Chem. Int. Ed. 49, 2743–2746 (2010)

Z. Wu, Y. Pan, X. Zhou, Synthesis. 2255–2260 (2011)

M. Adib, A. Mohamadi, E. Sheikhi, S. Ansari, H. R. Bijanzadeh, Synlett. 1606–1608 (2010)

M. Bakherad, H. Nasr-Isfahani, A. Keivanloo, N. Doostmohammadi, Tetrahedron Lett. 49, 3819–3822 (2008)

S. Marhadour, M.-A. Bazin, P. Marchand, Tetrahedron Lett. 53, 297–300 (2012)

M.-A. Hiebel, Y. Fall, M.-C. Scherrmann, S. Berteina-Raboin, Eur. J. Org. Chem. 4643–4650 (2014)

H. Yan, Y. Wang, C. Pan, H. Zhang, S. Yang, X. Ren, J. Li, G. Huang, Eur. J. Org. Chem. 2754–2763 (2014)

Y. Wang, B. Frett, H.-Y. Li, Org. Lett. 16, 3016–3019 (2014)

J.-J. Cai, J.-P. Zou, X.-O. Pan, W. Zhang, Tetrahedron Lett. 49, 7386–7390 (2008)

S. Ajaikumar, A. Pandurangan, Appl. Catal. A. Gen. 357, 184–192 (2009)

M. Jafarpour, A. Rezaeifard, M. Danehchin, Appl. Catal. A. Gen. 394, 48–51 (2011)

A. Mulika, D. Chandam, P. Patil, D. Patil, S. Jagdale, M. Deshmukh, J. Mol. Liq. 179, 104–109 (2013)

G. Rezanejade Bardajee, R. Malakooti, I. Abtin, H. Atashin, Microporous Mesoporous Mater. 169, 67–74 (2013)

S. Y. Kim, K. H. Park, Y. K. Chung, Chem. Commun. 1321–1323 (2005)

C.S. Cho, W.X. Ren, J. Organomet. Chem. 694, 3215–3217 (2009)

S. Paul, B. Basu, Tetrahedron Lett. 52, 6597–6602 (2011)

B. Das, K. Venkateswarlu, K. Suneel, A. Majhi, Tetrahedron Lett. 48, 5371–5374 (2007)

A. Kumbhar, S. Kamble, M. Barge, G. Rashinkar, R. Salunkhe, Tetrahedron Lett. 53, 2756–2760 (2012)

M. Jeganathan, A. Dhakshinamoorthy, K. Pitchumani, Tetrahedron Lett. 55, 1616–1620 (2014)

H. Olivier-Bourbigou, L. Magna, D. Morvan, Appl. Catal. A. Gen. 373, 1–56 (2010)

S. Schneider, T. Hawkins, M. Rosander, G. Vaghjiani, S. Chambreau, G. Drake, Energy Fuels 22, 2871–2872 (2008)

A.I. Bhatt, A.M. Bond, D.R. MacFarlane, J. Zhang, J.L. Scott, C.R. Strauss, P.I. Iotov, S.V. Kalcheva, Green Chem. 8, 161–171 (2006)

C. Villagran, L. Aldous, M.C. Lagunas, R.G. Compton, C. Hardacre, J. Electroanal. Chem. 588, 27–31 (2006)

C.D. Hubbard, P. Illner, R. Van Eldik, Chem. Soc. Rev. 40, 272–290 (2011)

P. Forte, A. Sachse, M. Maes, A. Galarneau, D. De Vos, RSC Adv. 4, 1045–1054 (2014)

T.L. Greaves, C.J. Drummond, Chem. Rev. 108, 206–237 (2008)

N. Jain, A. Kumar, S. Chauhan, S.M.S. Chauhan, Tetrahedron 61, 1015–1060 (2005)

S. Chowdhury, R.S. Mohan, J.L. Scott, Tetrahedron 63, 2363–2389 (2007)

J. Dupont, R.F. Souza, P.A.Z. Auarez, Chem. Rev. 102, 3667–3692 (2002)

V.I. Pârvulescu, C. Hardacre, Chem. Rev. 107, 2615–2665 (2007)

Q. Zhang, S. Zhang, Y. Deng, Green Chem. 13, 2619–2637 (2011)

H. Li, P.S. Bhadury, B. Song, S. Yang, RSC Adv. 2, 12525–12551 (2012)

M. Haumann, A. Riisager, Chem. Rev. 108, 1474–1497 (2008)

A. Riisager, R. Fehrmann, M. Haumann, P. Wasserscheid, Top. Catal. 40, 91–102 (2006)

S. Pourshahrestani, I. Mohammadpoor-Baltork, M. Moghadam, S. Tangestaninejad, A. R. Khosropour, V. Mirkhani, J. Iran. Chem. Soc. 12, 573–580 (2015)

S. Safaei, I. Mohammadpoor-Baltork, A.R. Khosropour, M. Moghadam, S. Tangestaninejad, V. Mirkhani, Adv. Synth. Catal. 354, 3095–3104 (2012)

S. Safaei, I. Mohammadpoor-Baltork, A.R. Khosropour, M. Moghadam, S. Tangestaninejad, V. Mirkhani, New J. Chem. 37, 2037–2042 (2013)

M. Nasr-Esfahani, I. Mohammadpoor-Baltork, A.R. Khosropour, M. Moghadam, V. Mirkhani, S. Tangestaninejad, H. Amiri, Rudbari. J. Org. Chem. 79, 1437–1443 (2014)

S. Anvar, I. Mohammadpoor-Baltork, S. Tangestaninejad, M. Moghadam, V. Mirkhani, A.R. Khosropour, A. Landarani Isfahani, R. Kia, ACS Comb. Sci. 16, 93–100 (2014)

H. Wang, Y. Li, L. Jiang, R. Zhang, K. Jin, D. Zhao, C. Duan, Org. Biomol. Chem. 9, 4983–4986 (2011)

G.A. Kraus, H. Guo, Org. Lett. 10, 3061–3063 (2008)

H.M. Kissman, D.W. Farnsworth, B. Witkop, J. Am. Chem. Soc. 74, 3948–3949 (1952)

N.R. Deprez, D. Kalyani, A. Krause, M.S. Sanford, J. Am. Chem. Soc. 128, 4972–4973 (2006)

L. Ackermann, A.V. Lygin, Org. Lett. 13, 3332–3335 (2011)

L.J. Martin, A.L. Marzinzik, S.V. Ley, I.R. Baxendale, Org. Lett. 13, 320–323 (2011)

C.S. Cho, S.G. Oh, J. Mol. Catal. A: Chem. 276, 205–210 (2007)

Acknowledgments

The authors are grateful to the Research Council of the University of Isfahan for financial support of this work.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Soltani, M., Mohammadpoor-Baltork, I., Khosropour, A.R. et al. Efficient synthesis of 2-arylindoles, 2-arylimidazo[1,2-a]pyridines and 2-arylquinoxalines, and their bis-derivatives using [Hmim]OTf ionic liquid supported on nano-silica as a reusable catalyst. J IRAN CHEM SOC 12, 1369–1380 (2015). https://doi.org/10.1007/s13738-015-0603-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-015-0603-2