Abstract

Silica functionalized Cu(I) is reported as a green and recyclable heterogeneous catalyst for the regioselective synthesis of 1,4-disubstituted-1,2,3-triazoles via Huisgen 1,3-dipolar cycloaddition reaction between terminal alkynes, benzyl/allyl/alkyl halides and NaN3 in water at room temperature. The azide intermediate do not need to be isolated, which make this procedure highly economical. Further, silica functionalized Cu(I) could be recovered by simple filtration and recycled up to 7 consecutive runs without loss of significant activity. The catalyst is characterized by FTIR, thermal analysis, SEM, TEM and AAS.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Owing to increasing concern about environmental impact, tremendous efforts have been made towards the development of new processes that minimize pollution in chemical synthesis. For this reason and others (catalyst removal, recovery and recycling), heterogeneous catalysis is clearly on the rise, including in industry [1, 2]. Among various heterogeneous catalysts developed over the past decades, metallic species supported on silica take the lead, since silica displays many advantageous properties––excellent stability (both chemical and thermal), high surface area, good accessibility, and organic groups can be robustly anchored to the surface, to provide catalytic centres [3–10]. Recently, water has been found to be a promising medium for heterogenised homogeneous catalysis. Catalysts heterogenised through covalent or non-covalent attachment to either inorganic or organic materials, particularly, silica have been successfully employed in aqueous media [11–14].

Huisgen 1,3-dipolar cycloaddition of azides and alkynes [15–18] to afford 1,2,3-triazole ring system via ‘click chemistry’ has been attracting great attention in recent times. The enormous attention recently gained by this reaction began with the pivotal discovery by the groups of Meldal [19] and Sharpless [20], in which copper(I) catalysis was found to dramatically accelerate the reaction under mild conditions at the same time that a high regioselectivity was achieved towards the 1,4-regioisomer of the triazole product. Recently, copper-free Huisgen 1,3-dipolar cycloadditions have been reported, but reactions are usually slow and the regioselectivity is unpredictable [21, 22]. Therefore, copper catalyzed processes are still being preferred. The sources of copper(I) include: (a) copper(I) salts, normally in the presence of a base and/or a ligand, (b) insitu reduction of copper(II) salts and (c) comproportionation of copper (0) and copper(II), generally limited to special applications (e.g., biological systems) [23, 24].

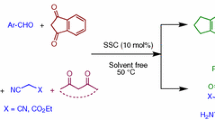

Although organic azides are generally safe compounds, but low molecular weight can be unstable and therefore, difficult to handle [25]. Thus, a method that avoids isolation of organic azides is desirable. In situ generation of organic azides from suitable precursors followed by addition of alkyne in one-pot, to form the corresponding 1,2,3-triazole would avoid the difficulties associated with the explosive nature of azides. Recently, copper catalyzed one-pot synthesis of 1,2,3-triazoles from aryl/alkyl halides, alkynes and sodium azides have been reported [26]. However, these homogeneous processes suffer from one or more disadvantages like, difficulty in separation of the product from the reaction medium, catalysts are generally non-recyclable, low regioselectivity and long reaction times. In order to address these problems, recently, heterogeneous copper(I) catalysts based on silica [27, 28], polymer [29, 30], montmorillonite [31], copper nanoparticles [32, 33], zeolites [34], Cu in charcoal [35] have been developed. These catalysts possess increased advantages over their homogeneous counter parts, however, a heterogeneous catalytic system which could be used under aqueous conditions and yield products in minutes at room temperature is still required to be developed. In this paper, we wish to report a silica functionalized Cu(I) catalyzed one-pot synthesis of 1,2,3-triazoles from terminal alkynes, benzyl/allyl/alkyl halides and sodium azide in water at room temperature (Scheme 1).

2 Experimental

2.1 General Remarks

2.1.1 General

Silica gel (K100, 0.063–0.200 mm) was purchased from Merck (Germany) and 3-aminopropyl(trimethoxy) silane and 2-acetyl pyridine from Aldrich Chemical Company. All melting points were determined on a Perfit melting point apparatus and are uncorrected. 1H NMR spectra were registered on a Bruker DPX-300 NMR spectrometer (300 MHz) in CDCl3 + DMSO-d 6 using tetramethylsilane as an internal standard. The IR spectra were recorded using KBr disc on Perkin-Elmer FTIR spectrophotometer. Mass spectral data were recorded on Esquire 3000 (ESI). Thermal analysis was carried out on DTG-60 Shimadzu make thermal analyzer with heating rate of 10 °C/min. SEM was recorded using Jeol make T-300 Scanning Electron Microscope and Transmission Electron Microscope (TEM) on H7500 Hitachi. The amount of copper in SiO2–CuI was determined on double beam Atomic Absorption Spectrophotometer (AAS), GBC 932 AB manufactured in Australia. The catalyst was stirred in dil. HCl for 10 h and then subjected to AAS analysis.

2.2 Preparation of Silica Functionalized Cu(I) Catalyst [SiO2–CuI]

Silica (K100, 0.063–0.200 mm) was activated by refluxing in a mixture of conc. HCl and distilled water (1:1) for 24 h and then washed thoroughly with distilled water and dried at 110 °C for 12 h. Activated silica (10 g) was added to a solution of 3-aminopropyl(trimethoxy) silane (1.79 g, 10 mmol) in dry toluene and refluxed for 24 h. The 3-aminopropyl silica (AMPS) was filtered off, washed with hot toluene and dried at 110 °C for 5 h to give the surface bound amino groups (AMPS). The oven dried aminopropyl silica (AMPS, 5 g) was added to sodium dried toluene (50 mL) in a round-bottom flask (100 mL) followed by 2-acetylpyridine (0.605 g, 5 mmol). The reaction mixture was refluxed at 120 °C and water formed during the reaction was removed using dean-stark apparatus. The ligand-grafted silica (imine) was filtered at the reaction temperature and washed with hot toluene thoroughly to remove unreacted 2-acetylpyridine. It was dried in an oven at 100 °C for 10 h.

The mixture of ligand-grafted silica (imine, 4 g) and CuI (1.528 g, 2 mmol/g) was stirred in acetonitrile (60 mL) at room temperature for 18 h. The solid was filtered off at pump and washed with acetonitrile till washings were colourless. It was dried in an oven at 95 °C for 5 h and then conditioned for a total of 8 h (2 × 2 h each refluxing in acetonitrile and toluene). The conditioned catalyst was dried under vacuum for 5 h before use.

2.3 General Procedure for The Synthesis of 1,4-Disubstituted-1,2,3-triazoles

To a mixture of alkyne 1 (1 mmol), halide 2 (1 mmol), NaN3 (1 mmol) and SiO2–CuI (0.1 g, 5 mol% Cu) in a round-bottom flask (25 mL), deionized water (5 mL) was added. The reaction mixture was then stirred at room temperature for an appropriate time (Table 2). After completion of the reaction (monitored by TLC), the reaction mixture was triturated with EtOAc (20 mL) and the SiO2–CuI was filtered off. The product was obtained after removal of the solvent under reduced pressure followed by column chromatography. The SiO2–CuI was washed with distilled water (200 mL) followed by methylene chloride (3 × 15 mL) and dried at 110 °C for 2 h. It was used further for carrying out the reaction (Fig. 3).

The structures of the products were confirmed by IR, 1H & 13C NMR, mass spectral data and comparison with authentic samples prepared according to the literature methods.

2.4 Characterization Data

2.4.1 1-Benzyl-4-phenyl-1H-1,2,3-triazole

M. pt. 128–130 °C (Lit. 128–129 °C) [36]. IR (νmax in cm−1, KBr): 3087, 2956, 1494, 1469, 1450, 1361, 1224, 1140, 1076, 1046, 972, 807, 769, 739; 1H NMR (CDCl3, 300 MHz): δ 5.58 (s, 2H), 7.42–7.75 (m, 8H), 7.67 (s, 1H), 7.82 (d, J = 7.1 Hz, 2H); 13C NMR (75 MHz, CDCl3): δ 53.66, 119.10, 124.74, 125.47, 126.08, 129.97, 134.17, 147.64; m/z (%): 235 (M+).

2.4.2 1-(4-Iodobenzyl)-4-phenyl-1H-1,2,3-triazole

M. pt. 153–155 °C (Lit. 154–156 °C) [36]. IR (νmax in cm−1, KBr): 3142, 3029, 1497, 1468, 1449, 1360, 1221, 1139, 1077, 971, 806, 769, 732; 1H NMR (CDCl3, 300 MHz): δ 5.62 (s, 2H), 7.17 (d, 2H, J = 8.25 Hz), 7.37 (d, 1H, J = 7.25 Hz), 7.43 (t, 2H, J = 7.25 Hz), 7.77 (d, 2H, J = 8.25 Hz), 7.86 (d, 2H, J = 7.5 Hz), 8.63 (s, 1H); 13C NMR (75 MHz, CDCl3): δ 52.4, 94.4, 121.5, 125.1, 127.9, 128.8, 130.1, 130.5, 135.7, 137.5, 146.6; m/z (%) = 361 (M+).

2.4.3 1-(4-Bromobenzyl)-4-phenyl-1H-1,2,3-triazole

M. pt. 150–151 °C (Lit. 150–152 °C) [36]. IR (νmax in cm−1, KBr): 3138, 3016, 1495, 1465, 1447, 1358, 1223, 1137, 1075, 969, 804, 765, 726; 1H NMR (CDCl3, 300 MHz): δ = 5.64 (s, 2H), 7.35–7.30 (m, 3H), 7.43 (t, 2H, J = 7.25 Hz), 7.61 (d, 2H, J = 8.25 Hz), 7.87 (d, 2H, J = 7.5 Hz), 8.65 (s, 1H); 13C NMR (75 MHz, CDCl3): δ 52.5, 121.3, 121.5, 125.0, 127.8, 128.8, 130.0, 140.5, 131.6, 135.3, 146.5; m/z (%) = 314 (M+).

2.4.4 1-Butyl-4-phenyl-1H-1,2,3-triazole

M. pt. 46–48 °C (Lit. 46–47 °C) [36]. IR (νmax in cm−1, KBr): 3040, 2954, 2918, 2847, 1493, 1467, 1360, 1216, 1137, 1079, 762, 696; 1H NMR (CDCl3, 300 MHz): δ 0.99 (t, J = 7.4 Hz, 3H), 1.34–1.41 (m, 2H), 1.87–1.96 (m, 2H), 4.40 (t, J = 6.5 Hz, 2H), 7.26–7.34 (m, 1H), 7.39–7.44 (m, 2H), 7.75 (s, 1H), 7.82 (d, J = 3.6 Hz, 2H); 13C NMR (75 MHz, CDCl3): δ 13.39, 19.24, 31.80, 49.78, 119.08, 125.56, 127.97, 128.59, 128.72, 130.63, 147.59; m/z (%) = 198 (M+).

2.4.5 1-Allyl-4-phenyl-1H-1,2,3-triazole

M. pt. 40–42 °C. IR (νmax in cm−1, KBr): 3122, 3080, 2926, 1640, 1483, 1465, 1453, 1360, 1150, 1077, 1050, 980, 817, 765, 730; 1H NMR (CDCl3, 300 MHz): δ 5.45 (d, 2H), 5.52 (d, 2H), 6.21–6.43 (m, 1H), 7.24–7.40 (m, 3H), 7.68 (s, 1H), 7.81 (d, 2H, J = 6.75 Hz); 13C NMR (75 MHz, CDCl3): δ 56.1, 114.2, 128.1, 129.2, 129.7, 132.2, 133.2, 135.3; m/z (%) = 185 (M+).

2.4.6 (1-Allyl-1H-1,2,3-triazol-4-yl)methanol

M. pt. 43–45 °C. IR (νmax in cm−1, KBr): 3266, 3139, 3088, 1820, 1650, 1498, 1467, 1450, 1365, 1222, 1138, 1010, 972, 813, 770, 700; 1H NMR (CDCl3, 300 MHz): δ 3.12 (br s, 1H), 4.68 (s, 2H), 5.42 (d, 2H), 6.21–6.42 (m, 1H), 7.28–7.45 (m, 3H), 7.61 (s, 1H), 7.80 (d, 2H, J = 6.74 Hz); 13C NMR (75 MHz, CDCl3): δ 55.6, 62.3, 106.5, 130.3, 131.5, 147.2; m/z (%) = 139 (M+).

2.4.7 (1-Benzyl-1H-1,2,3-triazol-4-yl)methanol

M. pt. 77–78 °C (Lit. 76–77 °C) [30]. IR (νmax in cm−1, KBr): 3266, 3139, 3088, 1497, 1468, 1450, 1365, 1222, 1138, 1076, 1046, 972, 813, 770, 730; 1H NMR (CDCl3, 300 MHz): δ 3.10 (br s, 1H), 4.71 (s, 2H), 5.46 (s, 2H), 7.20–7.39 (m, 6H); 13C NMR (75 MHz, CDCl3): δ 57.2, 61.5, 125.6, 128.2, 129.1, 133.2, 137.7, 146.5; m/z (%) = 189 (M+).

3 Results and Discussion

The preparation procedure followed to obtain silica functionalized Cu(I) [SiO2–CuI] is outlined in Scheme 2. It consists of building up a suitable ligand structure on the surface of commercial silica gel (K100) followed by complexation with copper iodide. To make the process completely heterogeneous, SiO2–CuI was conditioned for 8 h by refluxing each in acetonitrile (2 × 2 h) and toluene (2 × 2 h) so as to remove the physisorbed copper iodide. The characterization of SiO2–CuI was done on the basis of thermal analysis (TGA), FTIR, Atomic Absorption Spectroscopy (AAS), Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM).

Thermal analysis curve of SiO2–CuI showed an initial weight loss up to 100 °C (attributed to the residual solvent and water) and then from 175 to 400 °C was due to loss of organic functionality. Thus, the catalyst is stable up to 175 °C. The FTIR of 3-aminopropylsilica displays CH2 stretching bands at 2933 and 2860 cm−1 and aliphatic deformation bands at 1470 and 1445 cm−1. The FTIR of chemically modified silica (imine) shows a sharp peak at 1640 cm−1 due to C=N bond, which on complexation with copper disappears and appear as a band at 1635 cm−1. The lowering in frequency of the C=N peak is indicative of the formation of the metal–ligand bond [37]. The amount of the copper loaded on the surface of silica gel was determined by AAS. The catalyst was stirred in dil. HCl and the solution was then subjected to AAS analysis. SiO2–CuI was found to contain 0.0335 g of Cu per gram of the catalyst. However, the amount of copper before conditioning was found to be 0.1082 g per gram of the catalyst. SiO2–CuI was also examined by Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM). SEM image shown in Fig. 1 indicate that catalyst is homogeneous powder with porous structure. TEM image (Fig. 2) shows the distribution of copper onto silica. Copper is uniformly distributed with average diameter of about 2.25 nm.

To optimize the reaction conditions, phenyl acetylene, benzyl bromide and NaN3 for the synthesis of 1-benzyl-4-phenyl-1,2,3-traizole were selected as the test substrates to examine the effects of SiO2–CuI (5–20 mol%), at room temperatures with different solvents (acetonitrile, methylene chloride, ethanol and water). The results were evaluated qualitatively through TLC (Table 1). The best conditions employ 0.05:1:1:1 mol ratios of SiO2–CuI, phenyl acetylene, benzyl bromide and NaN3 at room temperature for 15 min using water as solvent.

Using these optimized conditions, the reaction of various terminal acetylenes (phenyl acetylene, propargyl alcohol), halides (benzyl, allyl and alkyl halides) and NaN3 was investigated (Scheme 1). It was found that all the reactions proceeded smoothly to give the corresponding 1,4-disubstituted-1,2,3-triazoles in high yields (Table 2), which clearly indicates the generality and scope of the reaction with respect to various terminal alkynes and halides. The reaction was also carried out using bromobenzene as halide but unfortunately very low conversion was observed on TLC.

In order to find the role of SiO2–CuI for the Huisgen 1,3-dipolar cycloaddition reaction, we have carried out the reaction in case of entry 1 (Table 2) with activated silica, ligand grafted silica (imine) and in the absence of SiO2–CuI under the similar conditions as applied for SiO2–CuI. The results are summarized in Table 3. Thus, it was concluded that SiO2–CuI catalyzes the reaction and the corresponding triazole was obtained in high yield and regioselectivity. It is pertinent to mention that reaction did take place without any catalyst but regioselectivity is very poor (65% yield in 30 h at room temperature).

When using a heterogeneous catalyst, the important point is the deactivation and recyclability of the catalyst. To test this, a series of 7 consecutive runs in case of entry 1 (Table 2) under the selected conditions were carried out with the same catalyst. The results are shown in Fig. 3. They demonstrate that there is no significant change in the activity of the catalyst. Further, there is no change in the TGA of the fresh and the catalyst after 7th use, which indicates that no loss of any organic functionality has taken place during repeated chemical reactions. Moreover, no leaching of copper has been indicated by AAS analysis of the supernatant. Thus, this makes the process still more cost-effective.

4 Conclusion

In conclusion, we have developed a mild, simple, cost-effective and green procedure for the one-pot regiospecific synthesis of 1,4-disubstituted-1,2,3-triazoles via Huisgen 1,3-dipolar cycloaddition reaction between terminal alkynes, halides and NaN3 in the presence of recyclable SiO2–CuI using water as reaction medium at room temperature. Moreover, the mild reaction conditions, high yield of products, ease of work-up, and the ecologically clean procedure, will make the present method a useful and important addition to the present methodologies for the synthesis of 1,4-disubstituted-1,2,3-triazoles.

References

Thomas JM, Thomas WJ (1997) In principles and practice of heterogeneous catalysis. VCH, Weinheim

Blaser HU, Baiker A, Prins R (1997) In heterogeneous catalysis and fine chemicals IV. Elsevier, Netherlands

Reddy BM, Reddy GK, Rao KN, Khan A, Ganesh I (2007) J Mol Catal A Chem 265:276

Cho YS, Park JC, Lee B, Kim Y, Yi J (2002) Catal Lett 81:89

Fey T, Fischer H, Bachmann S, Albert K, Bolm C (2001) J Org Chem 66:8154

Polshettiwar V, Len C, Fihri A (2009) Co-ord Chem Rev 253:2599

Paul S, Clark JH (2004) J Mol Catal A Chem 215:107

Choudhary D, Paul S, Gupta R, Clark JH (2006) Green Chem 9:431

Shamim T, Gupta M, Paul S (2009) J Mol Catal A Chem 302:15

Shamim T, Choudhary D, Mahajan S, Gupta R, Paul S (2009) Catal Commun 10:1931

Minakata S, Komatsu M (2009) Chem Rev 109:711

Gu Y, Karam A, Jerome F, Barrault J (2007) Org Lett 9:3145

Isobe K, Hoshi T, Suzuki T, Hagiwara H (2005) Mol Divers 9:317

Gu Y, Ogawa C, Kobayashi J, Mori Y, Kobayashi S (2006) Angew Chem 118:7375

Huisgen R, Szeimies G, Moebius L (1967) Chem Ber 100:2494

Huisgen R (1984) In: Padwa A (ed) 1, 3-diplar cycloaddition chemistry. Wiley, New York

Huisgen R (1989) Pure Appl Chem 61:613

Gil MV, Arevalo MJ, Lopez O (2007) Synthesis 1589

Tornoe CW, Christensen C, Meldal M (2002) J Org Chem 67:3057

Rostovtsev VV, Green LG, Fokin VV, Sharpless KB (2002) Angew Chem Int Ed 41:2596

Li P, Wang L (2007) Lett Org Chem 4:23

Lutz J-F (2008) Angew Chem Int Ed 47:2182

Bock VD, Hiemstra H, Van Maarseveen JH (2006) Eur J Org Chem 51

Meldal M, Tornoe CW (2008) Chem Rev 108:2952

Scriven EFV, Turnbull K (1988) Chem Rev 88:297

Maksikova AV, Serebryakova ES, Tikhonova LG, Vereshchagin LI (1980) Chem Heterocycl Comp 1284

Miao T, Wang L (2008) Synthesis 363

Li P, Wang L, Zhang Y (2008) Tetrahedron 64:10825

Sirion U, Bae YJ, Lee BS, Chi DY (2008) Synlett 2326

Girard C, Onen E, Aufort M, Beauviere S, Samson E, Herscovici J (2006) Org Lett 8:1689

Jlalia I, Elamari H, Meganem F, Herscovici J, Girarad C (2008) Tetrahedron Lett 49:6756

Alonso F, Moglie Y, Radivoy G, Yus M (2009) Tetrahedron Lett 50:2358

Raul D, Wankhede K, Vaidya V, Bhilare S, Darwatkar N, Deorukhkar A, Trivedi G, Salunkhe M (2009) Catal Commun 10:1240

Chassaing S, Kumarraja M, Sido ASS, Pale P, Sommer J (2007) Org Lett 9:883

Lee C-T, Huang S, Lipshutz BH (2009) Adv Synth Catal 351:3139

Gonda Z, Novak Z (2010) Dalton Trans 39:726

Mobofu EB, Clark JH, Macquarrie DJ (2001) Green Chem 3:23

Mathew P (2008) J Am Chem Soc 130:13534

Tsypin GI (1975) Zhur Org Khimii 11:1395

Kacprzak K (2005) Synlett 943

Acknowledgement

We are grateful to SAIF, Punjab University, Chandigarh for SEM and TEM; Head, Institute Instrumentation Centre, Indian Institute of Technology, Roorkee for TGA; and SAIF, Nagpur University, Nagpur for AAS analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shamim, T., Paul, S. Silica Functionalized Cu(I) as a Green and Recyclable Heterogeneous Catalyst for the Huisgen 1,3-Dipolar Cycloaddition in Water at Room Temperature. Catal Lett 136, 260–265 (2010). https://doi.org/10.1007/s10562-010-0330-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-010-0330-3