Abstract

Recent experimental studies indicate that Young’s modulus of carbon nanotubes increases steeply with tube diameter decreasing. The consideration of this effect is of great importance for the fabrication and exploitation of nano-electromechanical devices. Nevertheless, the rapid stiffness enhancement effect noticed from experimental observation maybe unable to be predicted by using size-dependent elasticity models available in literatures. It is strongly necessary to further shed light on the size-dependent mechanical mechanism and characterize the rapid strengthening effect of stiffness for nano-sized materials. To achieve this goal, the nonlocal second-order strain gradient elasticity model is established by introducing the second-order strain gradient field with nonlocal effect into the stored energy function of nonlocal first-order strain gradient elasticity theory. With the aids of the laws of thermodynamics, the constitutive relations are obtained. The Hamilton principle is used to derive the governing equations of equilibrium and boundary conditions. The proposed model is applied to investigate the problem of wave propagating in carbon nanotubes. The new dispersion relations derived are presented for evaluating the influences of size-dependent parameters on the characteristics of wave propagation. The results show that present model can predict the rapid increasing effect of carbon nanotubes with the decrease of tube size.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The small-scale effect is referred to the changes in the dimensions of an internal feature (structure) or in the external physical dimensions of nano-sized materials lead to the changes of material mechanical, electrical, optical and magnetic properties. The consideration of this effect in the experimental and theoretical analysis of the new and multifunctional nanomaterials is of great importance for the fabrication and exploitation of nano-electromechanical devices, such as nanorod (Bahrami 2017a, b), nanobeams (Bahrami and Teimourian 2015, 2016), functionally graded nanobeam (Rahmani and Pedram 2014), thin rectangular and circular annular nano-plates (Ilkhani et al. 2016; Bahrami and Teimourian 2017), nanocomposites (Bi et al. 2017) and nano-electromechanical resonator (Bouchaala 2018). Nowadays, carbon nanotubes (CNTs) have been used as one of the most promising functional materials in nanodevices (Liew and Wang 2007; Chen et al. 2013) due to their excellent performance in thermal, chemical, mechanical and electrical properties (Yu et al. 2005; Dupuis 2005; Lipomi et al. 2011; Lekawa-Raus et al. 2014; Goya et al. 2017). Ever since the discovery of CNTs (Iijima 1991), a large number of experimental and theoretical attempts on this topic have been made in order to provide a thorough and comprehensive understanding on the material characteristics of CNTs. As a matter of fact, CNTs share the remarkable features of low weight, high aspect ratios, higher stiffness and axial strength and so on (Thostenson et al. 2001). The great advantages of CNTs in mechanical aspects motivate their widespread application in nanotechnology. For example, CNTs can be used as super-strong reinforcement fibers in strong and lightweight nanocomposites (Tjong 2013). In the current studies, it has been experimentally reported that the Young’s modulus of CNTs increases steeply with decreasing tube diameter (Treacy et al. 1996). It was also found that the change in external dimension affects their stiffness, namely, the Young’s modulus of CNTs increases significantly (slightly) with decreasing tube diameter (helicity) (Yao and Lordi 1998). However, most of theoretical models in available literatures may fail to characterize the rapid strengthening effect of stiffness of CNTs. It is strongly necessary to establish a new model to illustrate this phenomenon and give more accurate predictions. This is expected to be helpful for the theoretical modeling of nanomechanics and may be beneficial to the analysis and design of CNTs.

Although experimental investigations on CNTs are very difficult to achieve, numerous theoretical attempts have been carried out. Among them, molecular dynamic (MD) method is used as a powerful tool to predict physical properties of CNTs based on the following assumptions: (i) the atom in CNTs is treated as a discrete mass point and (ii) the bonding forces between each pair in long range distance satisfies the Newton’s laws of motion. Until now, MD simulations available in literatures are mainly devoted on the studies of mechanical characteristics of CNTs (Liew et al. 2004; Fang et al. 2016; Liu et al. 2017). One of the topics of primary interest on this topical issue is focused on the studies of its Young’s modulus (Hsieh et al. 2006; Agrawal et al. 2006). In mechanical sense, the Young’s modulus (i.e. the elastic modulus) is a measurement of the stiffness of a solid material. It represents the factor of proportionality in Hooke’s law. The Young’s modulus is available to be used to calculate the change in the dimension of a bar made of an isotropic elastic material under tensile/compressive loads. At micro scale, the classical elasticity theory is valid to some extent. However, its applicability is questionable at micro/nano scale (Eringen 1983). The classical continuum mechanics and couple-stress models can be used to investigate the mechanical problems of CNTs (Liew and Wang 2007; Ke and Wang 2011). However, the rapid stiffness enhancement effect of CNTs noticed from experimental observation maybe unable to be predicted by using size-dependent elasticity models available in literatures due to the absence of the material constants related to structural scale parameters in the constitutive relations (Srinivasa and Reddy 2013; Reddy and Srinivasa 2014). The key issue is that the microstructure of materials (e.g. the lattice spacing between atoms) becomes more and more important and the material discrete structure cannot be homogenized into a continuum at small length scale (Govindjee and Sackman 1999). Although MD method is feasible to predict mechanical behavior of CNTs, it is always computationally intensive and prohibitively expensive. Even if the solutions can be found, they should be compared with ones obtained experimentally. On the other hand, while MD models are conceptually valid for small length scales, they are difficult to formulate accurately and only applicable to nano-systems with limited number of molecules/atoms. To compensate for the aforementioned defects of MD approach, nonlocal continuum elastic stress field theory is a possible solution (Eringen and Edelen 1972; Eringen 1983, 2002). This theoretical framework involves information regarding the behavior of material microstructure. Due to the introduction of internal length scale parameter, the information about the long range forces between atoms is inherently incorporated in it.

The nonlocal elastic stress field model plays a vital role in exploring the size-effects on mechanical properties of CNTs. It has been suggested that nonlocal continuum mechanics is a powerful tool in analysis related to nanotechnology applications (Peddieson et al. 2003). With the aids of a positive distance-decaying kernel function, the nonlocal integral constitutive relation of Eringen’s model (Eringen and Edelen 1972) states that the stress field at a reference point is interrelated to the strain filed at all points within a continuous domain. Nevertheless, this integral-type non-local formulation is difficult to be solved. To deal with the problem, a nonlocal differential model was put forward based on the fact that the kernel function of the nonlocal integral constitutive equation can be transformed into a differential one with the exact same properties (Eringen 1983). It is one of the most widely used in the literatures to evaluate size-dependent effect of CNTs. The recent progress in the development of nonlocal models can be found in the review article (Arash and Wang 2012). In the latest work, a unified integro-differential nonlocal elastic model is illustrated, of which the novelty is depicted by two-phase integro-differential form of Eringen nonlocal elasticity theory (Khodabakhshi and Reddy 2015). In the past several decades, application of differential nonlocal elastic stress field model can be found in the studies of size effect on mechanical properties of CNTs is an important area of interest. This model was also introduced to account for the size effect of the problems of buckling analysis (Sudak 2003; Golmakani and Vahabi 2017), wave propagation (Narendara et al. 2011) and vibration control (Behera and Chakraverty 2017) in Euler–Bernoulli/Timoshenko nanobeams (Reddy 2007; Thai 2012). Also, application of nonlocal elastic stress field model can be found in various material systems (Li et al. 2016b, 2017, 2018).

The description of the mechanical behavior of nano-sized materials is not limited to the relations between stress and strain. Higher-order theories of elasticity, which include contributions from strain gradients, have been developed (Toupin 1963; Mindlin 1964, 1965). In terms of the deformation metrics used, higher-order theories can be classified into general strain gradient theories and couple stress theories. The strain gradient elasticity theories can be treated as extensions of classical elasticity with additional higher-order strain gradient terms. They were put forward based on the assumption that the materials should be viewed as atoms with higher-order deformation mechanism at micro/nano-scale. Within the theoretical framework of couple stress theories, the higher-order rotation gradients are included as the deformation metrics. To further explore the practical applications of physical phenomenon of interest, the simple models with one additional material length scale parameter (Aifantis 1992; Yang et al. 2002) and thermodynamically-based gradient theories (Srinivasa and Reddy 2013) were also proposed. In the context strain gradient theories, most of studies have been conducted to investigate the static and dynamic problems and the predicted results present a pronounced stiffness enhancement effect with increasing gradient coefficients (Ma et al. 2008; Reddy 2011). The stiffness strengthening effect has been verified from experimental tests. However, Eringen’s differential nonlocal model is limited to its capability of predicting softening stiffness of CNTs, namely, the Young’s modulus reduces with increasing nonlocal scale parameter. In order to predict the softening and strengthening stiffness of CNTs, the nonlocal first-order strain gradient elasticity theory is established by introducing the first-order strain gradient into the classical nonlocal elasticity theory based on thermodynamic framework (Lim et al. 2015). This theory builds a bridge between the internal structure (nonlocal elastic model) and external geometry (strain gradient models) of nanomaterials. It provides a feasible approach to the theoretical modeling of nanomechanics. The new dispersion relation between frequency and wave number formulated by the constitutive model of the nonlocal first-order strain gradient elasticity theory can be used to study the problems of wave propagating in CNTs (Li et al. 2016a; Tang et al. 2016).

The nonlocal first-order strain gradient elasticity theory has achieved great success in evaluating size-dependent mechanical behavior of nanomaterials. Nevertheless, Treacy et al. (1996) found that CNTs share exceptionally mechanical properties (i.e. high stiffness and axial strength). The rapid strengthening effect of stiffness of CNTs noticed from experimental observations may be not fully presented by using the existing theories of size-dependent elasticity due to the lack of higher-order deformation mechanism. It is strongly necessary to further perfect nonlocal first-order strain gradient elasticity theory and make it possible to characterize the feature of rapid strengthening stiffness of CNTs. It is noted that there exist numerous applications and extensions of gradient elasticity theories (Ma et al. 2008; Akgöz and Civalek 2011; Simsek and Reddy 2013; Dehrouyeh-Semnani and Bahrami 2016). The most typical one of strain gradient theories is the second-order strain gradient theory (Mindlin 1965). This general higher-order stress theory was initially put forward by introducing second-order deformation gradients (first-order strain gradients) as additional deformation metrics into the strain energy density function of classical elasticity theory. Many related research works have been performed to investigate the size-dependent mechanical problems of nanomaterials based on second-order strain gradient theory and all the results indicate an obvious stiffness enhancement effect with an increase of the gradient coefficients. As a recent study made reference to the fact that the second strain gradient theory with higher-order material constants is highly capable to evaluate small-scale effects (Karparvarfard et al. 2015). Furthermore, a modified version of second-order strain gradient theory can be found in the work of Lam et al. (2003). It is worth mentioning that Lazar et al. (2006) developed a more simplified but straightforward version of second strain gradient theory to investigate a screw dislocation and an edge dislocation. In follow-up studies, it has been applied to investigate surface effects, dislocations and disclinations and so on (Deng et al. 2007; Polizzotto 2014). A recent work was devoted to provide analytical formulation of material length scale parameters associated with second strain gradient theory for face-centered-cubic materials and evaluate the size-dependent static behavior of a cantilever beam (Shodja et al. 2012). It can be concluded that second order strain gradient theory and its extensions play an important role in predicting size-dependent effect of nanomaterials.

The existing theories of size-dependent elasticity are mainly divided into three classes: (i) the non-gradient nonlocal elastic stress field theory; (ii) the high-order theories (strain gradient theories and couple stress theories) and (iii) the nonlocal first-order strain gradient elasticity theory. Although these theories are available to characterize the size-dependent mechanical behavior of solids at micro/nano-scales with additional structural scale parameters, they are limited to predicting softening/strengthening effect of stiffness. The rapid stiffness enhancement effect noticed from experimental observation may be not fully presented by them. Enlightened by the superiorities of second-order strain gradient theory, the main objective of this paper is to establish the nonlocal second-order strain gradient elasticity theory by introducing the second-order strain gradient field into the stored energy function of nonlocal first-order strain gradient elasticity theory. This may be significant important in the fabrication and exploitation of nano-electromechanical devices. The constitutive relations are obtained via the thermodynamic framework. Hamilton principle is used to derive the governing equations of equilibrium and boundary conditions. The proposed model is applied to investigate the wave propagating in CNTs. The new dispersion relations derived are presented for evaluating the effects of size-dependent on the characteristics of wave propagation. Finally, some conclusions are reached.

2 Theoretical framework of nonlocal second-order strain gradient elasticity

The main goal of this section is to establish the theoretical framework of nonlocal second-order strain gradient elasticity.

2.1 Constitutive relations

Within the non-gradient nonlocal elastic stress field theory, the authors assume that the nonlocal stress field and local strain field satisfy the following integral type constitutive relationship (Eringen and Edelen 1972):

where \({\varvec{\upsigma}}({\mathbf{x}}) = \{ \sigma_{ij} \}\) is the nonlocal stress tensor at point \({\mathbf{x}}\), \({\varvec{\upvarepsilon}}({\mathbf{x^{\prime}}}) = \{ \varepsilon^{\prime}_{ij} \}\) is the strain tensor at point \({\mathbf{x^{\prime}}}\), \({\mathbf{c}} = \{ c_{ijkl} \}\) is the elastic modulus tensor. The positive distance-decaying kernel function \(\alpha_{0} ({\mathbf{x}} ,\,{\mathbf{x^{\prime}}} ,\,e_{0} a)\) is used to characterize the dependence of stress field at each point on the strain field at all the points of the elastic body at the nanoscale. The information of the long range forces between atoms is involved by introducing nonlocal internal energy density potential \(U({\varvec{\upvarepsilon}}({\mathbf{x}}) ,\,{\varvec{\upvarepsilon}}({\mathbf{x^{\prime}}}),\,e_{0} a)\) as:

where \(a\) is the internal characteristic length, \(e_{0}\) is the nonlocal material constant, \({\varvec{\upvarepsilon}}({\mathbf{x}}) = \{ \varepsilon_{ij} \}\) is the strain tensor at point \({\mathbf{x^{\prime}}}\). The nonlocal scale parameter \(e_{0} a\) can be treated as the measurement of the internal structure feature of nano-sized materials. It has been found that the nonlocal differential constitutive relation can be used to replace the specific class of kernel functions in the nonlocal integral form with the exact same properties (Eringen 1983). However, its capability of predicting size-dependent stiffness is limited to characterize the softening stiffness behavior by using the dispersive relation between frequency and wave number. The stiffness enhancement effect verified from experimental tests is not involved. In order to deal with the problem, the kernel function \(\alpha ({\mathbf{x}} ,\,{\mathbf{x^{\prime}}} ,\,e_{1} a)\) is introduced to the non-gradient nonlocal elastic stress field model to describe the nonlocal effect of first-order strain gradient field (Lim et al. 2015). Nevertheless, numerous experimental studies indicate that the strength of materials increases rapidly with decreasing sample size. To better capture the size-dependence feature of stiffness strengthening effect, the nonlocal internal energy density potential function in the theoretical framework of nonlocal first-order strain gradient elasticity (Lim et al. 2015) is further extended as:

where \(\nabla {\varvec{\upvarepsilon}}({\mathbf{x}}) = \{ \varepsilon_{ij,k} \}\) and \(\nabla {\varvec{\upvarepsilon}}({\mathbf{x^{\prime}}}) = \{ \varepsilon^{\prime}_{ij,k} \}\) are the first-order strain gradient at point \({\mathbf{x}}\) and point \({\mathbf{x^{\prime}}}\), \(\nabla \nabla {\varvec{\upvarepsilon}}({\mathbf{x}}) = \{ \varepsilon_{ij,km} \}\) and \(\nabla \nabla {\varvec{\upvarepsilon}}({\mathbf{x^{\prime}}}) = \{ \varepsilon^{\prime}_{ij,km} \}\) are the second-order strain gradient at point \({\mathbf{x}}\) and point \({\mathbf{x^{\prime}}}\), \(e_{1}\) and \(e_{2}\) are the related material constants. The material length scale \(l\) is used to evaluate the influences of higher-order strain gradient fields and the additional kernel function \(\alpha_{2} ({\mathbf{x}} ,\,{\mathbf{x^{\prime}}} ,\,e_{2} a)\) is introduced to the nonlocal effect of second-order strain gradient field. With the aids of principles of thermodynamics, the constitutive relations of nonlocal second-order strain gradient elasticity can be derived. According to the first law of thermodynamics, one can obtain:

where \(\rho\) is the mass density, \(s_{1}\) is the heat source density, \({\mathbf{q}}\) is the heat flux vector, \({\varvec{\upsigma}}^{{({\mathbf{1}})}} = \{ \sigma_{ij,k} \}\) is the gradient of stress tensor, \({\varvec{\upsigma}}^{{({\mathbf{2}})}} = \{ \sigma_{ij,km} \}\) is the gradient of the gradient of stress tensor. The superposed dot represents the time rate of the field quantities. The local (or point-wise) form of Eq. (4) can be written as:

where the nonlocal energy residual \({\text{E}}_{{\text{nonlocal}}}\) satisfies the condition:

Within the framework of classical continuum mechanics, the second law of thermodynamics states that the time rate of internal entropy production \(\dot{s}_{\text{int}}\) maintains the non-negativity at each points within the domain for all thermo-mechanical deformation processes, i.e.:

The global form of relation (7) can be expressed as:

where \(s\) and \(\theta\) are the entropy density and the absolute temperature, respectively. By using the Reynolds transport theorem, the above Eq. (8) can be written as:

and its local form is given as:

where \(\varPsi_{\text{nonlocal}}\) is nonlocal entropy residual. Through the Legendre transform, the Helmholtz free energy potential \(\psi\) can be defined as:

and then eliminating \(U\) from Eqs. (5) and (9) has the form:

which can be further expressed as:

For a thermo-mechanical deformation process under uniform temperature, Eq. (13) has the form:

In terms of the internal energy density potential function (3), the Helmholtz free energy potential involving nonlocal effects of non-gradient field, first-order strain gradient and second-order gradient is given by:

where \(\varphi\) is assumed to be a symmetric function of its arguments (Eringen 2002):

and its time rate is:

Based on the symmetric characteristic of \(\varphi\), Eq. (17) is rearranged as:

where

which is not a nonlocal energy. Due to the symmetric feature of \(\varphi\), it is obtained:

Using the above relation (20) and then substitution of Eq. (18) into Eq. (14) yields

For arbitrary choices of fields \({\dot{\mathbf{\varepsilon }}}\), \({\mathbf{\nabla \dot{\varepsilon }}}\) and \({\mathbf{\nabla \nabla \dot{\varepsilon }}}\), the inequality (21) must hold for all thermo-mechanical processes. This implies the following state equations:

Thus far, the constitutive relations of nonlocal second-order strain gradient elasticity are established and elaborated.

2.2 Governing equations of equilibrium and boundary conditions

To derive the governing equations of equilibrium and boundary conditions of nonlocal second-order strain gradient elasticity theory, Hamilton’s principle is applied.

2.2.1 Hamilton’s principle

Based on Hamilton’s principle, the energy function is given as:

which can be further represented as:

The energy conservation law for nonlocal second-order strain gradient elasticity theory is introduced as:

where \({\mathbf{f}}\) is the body forces per unit mass, \({\varvec{\uptau}}^{{\left( {\mathbf{0}} \right)}}\) and \({\varvec{\uptau}}^{{\left( {\mathbf{1}} \right)}}\) (\({\varvec{\uptau}}^{{\left( {\mathbf{2}} \right)}}\)) are the classical traction and couple vector per unit surface area, respectively. The normal gradient operator \({\text{D}}\) is defined as:

where \({\mathbf{n}}\) is defined as the unit outward vector normal to the surface of the body. Noting that the free energy potential containing nonlocal effects of non-gradient strain field and first and second order strain gradient fields has the form:

Substitution of Eq. (28) into Eqs. (22) and (23) yields:

The variational statements of the external work, kinetic energy and nonlocal strain energy in (25) are listed as follows:

-

1.

The variational form of the external work.

The first variation of the integral of the external work over a period from \(t_{1}\) to \(t_{2}\) reads as:

-

2.

The variational form of the kinetic energy

The first variation of the integral of the kinetic energy over a period from \(t_{1}\) to \(t_{2}\) reads as:

$$\begin{aligned} \delta \int_{{t_{1} }}^{{t_{2} }} {\rm T} {\text{d}}t & = \delta \int_{{t_{1} }}^{{t_{2} }} {\int_{\upsilon } {\frac{\rho }{2}({\dot{\mathbf{u}}} \cdot {\dot{\mathbf{u}}})} } \,{\text{d}}\upsilon {\text{d}}t \\ & = \int_{\upsilon } {\int_{{t_{1} }}^{{t_{2} }} \rho } ({\dot{\mathbf{u}}} \cdot \delta {\dot{\mathbf{u}}})\,{\text{d}}t{\text{d}}\upsilon \\ & = \int_{\upsilon } {\rho \left[ {({\dot{\mathbf{u}}} \cdot \delta {\mathbf{u}})\left| {_{{t_{1} }}^{{t_{2} }} - \int_{{t_{1} }}^{{t_{1} }} {({\ddot{\mathbf{u}}} \cdot \delta {\mathbf{u}})} \,{\text{d}}t} \right.} \right]} {\text{ d}}\upsilon \\ & = - \int_{\upsilon } {\int_{{t_{1} }}^{{t_{2} }} {\rho ({\ddot{\mathbf{u}}} \cdot \delta {\mathbf{u}})} } \,{\text{d}}t{\text{d}}\upsilon \\ & = - \int_{{t_{1} }}^{{t_{2} }} {\int_{\upsilon } {\rho ({\ddot{\mathbf{u}}} \cdot \delta {\mathbf{u}})} } \,{\text{d}}\upsilon {\text{d}}t \\ \end{aligned}$$(33)when it is assumed that \(\delta {\mathbf{u}}(t_{1} ) = \delta {\mathbf{u}}(t_{2} ) = 0\).

-

3.

The variational form of the nonlocal strain energy

Substituting Eq. (28) into the nonlocal strain energy and taking the first variation yields:

$$\delta U = \int_{\upsilon } {\left( {{\mathbf{\sigma :\nabla }}\delta {\mathbf{u}} + {\varvec{\upsigma}}^{{\left( {\mathbf{1}} \right)}} {\mathbf{ \vdots \nabla \nabla }}\delta {\mathbf{u}} + {\varvec{\upsigma}}^{{\left( {\mathbf{2}} \right)}} {\mathbf{::\nabla \nabla \nabla }}\delta {\mathbf{u}}} \right)\,} {\text{d}}\upsilon$$(34)

By means of the corollaries of divergence theorems for double-dot/triple-dot/quadruple-dot product of two tensors and higher-dimensional integration by parts, the volume integral in the right-hand side of Eq. (34) is converted into the sum of a volume integral and three surface integrals as:

The second and the third surface integrals in Eq. (35) are rewritten as (Mindlin 1965):

where the operator \({\mathbf{L}}\) and the surface gradient operator \(\mathop {\mathbf{\nabla }}\limits^{\text{S}}\) are respectively defined as (Mindlin 1965):

where the normal gradient operator \({\mathbf{\nabla }}\) and \(\mathop {\mathbf{\nabla }}\limits^{\text{S}}\) satisfy the following relationship:

where \(\delta_{ij}\) is the Kronecker delta, \({\mathbf{i}}_{i}\) and \({\mathbf{i}}_{j}\) are the unit base vectors. Then, Eq. (35) is further expressed as:

The first variation of the integral of the nonlocal strain energy over a period from \(t_{1}\) to \(t_{2}\) reads as:

Substitution of Eqs. (32), (33) and (41) into Eq. (25) yields:

2.2.2 Derivation of governing equations

Using the Hamilton’s principle (25), the governing equations of equilibrium and boundary conditions of nonlocal second-order strain gradient elasticity theory are derived:

Field equilibrium equation:

Surface boundary conditions:

Boundary conditions:

where the constitutive relation of the total stress tensor \({\mathbf{t}}\) is given by:

where \(S_{u}\) and \(S_{t}\) are the surface conditions for geometric boundary conditions and natural boundary conditions.

3 Application

Using the model proposed in Sect. 2, wave propagation in CNTs is investigated based on Euler–Bernoulli beam model. The nonlocal strain energy function of Euler–Bernoulli beam is represented as:

where \(E\) is the Young’s modulus. The classical stress \(\sigma_{xx}\), the first-order stress \(\sigma_{xx}^{\left( 1 \right)}\), the second-order stress \(\sigma_{xx}^{\left( 2 \right)}\) and the total stress \(t_{xx}\) are:

where the first-order strain gradient \(\varepsilon_{xx,x}\) and second-order strain gradient \(\varepsilon_{xx,xx}\) denote as \({{{\text{d}}\varepsilon_{xx} } \mathord{\left/ {\vphantom {{{\text{d}}\varepsilon_{xx} } {{\text{d}}x}}} \right. \kern-0pt} {{\text{d}}x}}\) and \({{{\text{d}}^{2} \varepsilon_{xx} } \mathord{\left/ {\vphantom {{{\text{d}}^{2} \varepsilon_{xx} } {{\text{d}}x^{2} }}} \right. \kern-0pt} {{\text{d}}x^{2} }}\), respectively. It is further assumed that the nonlocal attenuation functions \(\alpha_{0} ({\mathbf{x}},\;{\mathbf{x^{\prime}}},\;e_{0} a)\), \(\alpha_{1} ({\mathbf{x}},\;{\mathbf{x^{\prime}}},\;e_{1} a)\) and \(\alpha_{2} ({\mathbf{x}},\;{\mathbf{x^{\prime}}},\;e_{2} a)\) satisfy the conditions in (Eringen 1983). Hence, the nonlocal integral constitutive relations (52) to (54) can be transformed into the nonlocal differential forms:

By performing the linear nonlocal differential operator:

to both sides of Eq. (55), it is obtained:

where \(\nabla^{2} = {{{\text{d}}^{2} } \mathord{\left/ {\vphantom {{{\text{d}}^{2} } {{\text{d}}x^{2} }}} \right. \kern-0pt} {{\text{d}}x^{2} }}\) and \(\nabla^{4} = {{{\text{d}}^{4} } \mathord{\left/ {\vphantom {{{\text{d}}^{4} } {{\text{d}}x^{4} }}} \right. \kern-0pt} {{\text{d}}x^{4} }}\) are defined as one-dimensional differential operators. The Eq. (60) presents the constitutive relation for the Euler–Bernoulli beam model based on the nonlocal second-order strain gradient elasticity theory. Noting that four length scale parameters are involved in relation (60), namely, three of them represent the nonlocal effect of lower and higher order stress fields and the fourth one is the nonlocal effect of higher-order strain gradients. The nonlocal second-order strain gradient constitutive relation (60) can degenerate into the limiting cases as follows:

-

(a)

The nonlocal first-order strain gradient model (Lim et al. 2015):

$$\begin{aligned} & \left[ {1 - (e_{0} a)^{2} \nabla^{2} } \right]\left[ {1 - (e_{1} a)^{2} \nabla^{2} } \right]t_{xx} \\ & \quad = E\left[ {1 - (e_{1} a)^{2} \nabla^{2} } \right]\varepsilon_{xx} - El^{2} \left[ {1 - (e_{0} a)^{2} \nabla^{2} } \right]\nabla^{2} \varepsilon_{xx} \\ \end{aligned}$$(61)is obtained when the nonlocal effect of second-order strain gradient is ignored.

-

(b)

The second-order strain gradient model (Mindlin 1965):

$$t_{xx} = E(1 - l^{2} \nabla^{2} + l^{4} \nabla^{4} )\varepsilon_{xx}$$(62)is obtained when the nonlocal effect of stress field is ignored.

-

(c)

The non-gradient nonlocal elastic stress field model (Eringen 1983):

$$\left[ {1 - (e_{0} a)^{2} \nabla^{2} } \right]t_{xx} = E\varepsilon_{xx}$$(63)is obtained when the nonlocal effects of first and second order strain gradients are both ignored.

The nonlocal second-order strain gradient model of Euler–Bernoulli beam can be further simplified as:

when assuming \(e_{0} = e_{1} = e_{2} = e\) by retaining terms of order \(O(\nabla^{2} )\) and \(O(\nabla^{4} )\). For Euler–Bernoulli beam, the dynamic equilibrium equations are:

where \(\rho\) is the material mass density, \(A\) is the cross-sectional area, \(x\) is the lengthwise coordinate, \(Q(x,t)\) is the shear force, \(M(x,t)\) is the bending moment, \(w(x,t)\) is the flexural deflection of the beam. The bending moment and the strain read as:

where \(z\) is the transverse coordinate. By integrating over the cross-section of the beam on both sides of Eq. (64), it is obtained:

Using the differential operator:

on both sides of Eq. (65) and substituting Eq. (66) into the equation, then Eq. (69) is further expressed as:

where \(I\) is the second moment of area of the cross-section about the y-axis. To investigate the wave propagation in CNTs, the solution can be assumed as:

where \(k\) is the wave number, \(\omega\) is the wave frequency, \(W\) is the wave amplitude. Substitution of Eq. (71) into Eq. (70) and applying the dimensionless quantities \(\bar{\omega } = \omega T\) and \(\bar{k} = kL\) yields:

where \(\tau_{l} = {l \mathord{\left/ {\vphantom {l L}} \right. \kern-0pt} L}\), \(\tau = {{ea} \mathord{\left/ {\vphantom {{ea} L}} \right. \kern-0pt} L}\), \(\bar{c}_{0} = {T \mathord{\left/ {\vphantom {T {L^{2} }}} \right. \kern-0pt} {L^{2} }}\sqrt {{{EI} \mathord{\left/ {\vphantom {{EI} {\rho A}}} \right. \kern-0pt} {\rho A}}}\),\(L\) is the external length scale parameter, \(T\) is the characteristic time, \(\bar{c} = {{\bar{\omega }} \mathord{\left/ {\vphantom {{\bar{\omega }} {\bar{k}}}} \right. \kern-0pt} {\bar{k}}}\) is the dimensionless wave phase velocity for Euler–Bernoulli beam. The relation (72) indicates that the simplified nonlocal second-order strain gradient model of Euler–Bernoulli beam can degenerate into the nonlocal stress field model (Eringen 1983) (\(\tau_{l} \to 0\)) and classical strain gradient model (Aifantis 1992) (\(\tau \to 0\)). Following the similar approach, the dispersion relation of nonlocal second-order strain gradient model based on Euler–Bernoulli beam (60) has the form as:

where \(\tau_{0} = {{e_{0} a} \mathord{\left/ {\vphantom {{e_{0} a} L}} \right. \kern-0pt} L}\), \(\tau_{1} = {{e_{1} a} \mathord{\left/ {\vphantom {{e_{1} a} L}} \right. \kern-0pt} L}\) and \(\tau_{2} = {{e_{2} a} \mathord{\left/ {\vphantom {{e_{2} a} L}} \right. \kern-0pt} L}\).

4 Numerical results and discussions

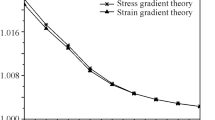

In Eq. (73), it is clear that four size-dependent parameters, i.e., \(\tau_{0}\), \(\tau_{1}\), \(\tau_{2}\) and \(\tau_{l}\) are involved in the dispersion relation between the dimensionless quantity \({{\bar{c}} \mathord{\left/ {\vphantom {{\bar{c}} {\bar{c}_{0} }}} \right. \kern-0pt} {\bar{c}_{0} }}\) and dimensionless wave number \(\bar{k}\). The dimensionless coefficients \(\tau_{0}\), \(\tau_{1}\) and \(\tau_{2}\) can be treated as the nonlocal parameters to characterize the internal feature of nano-sized materials and the dimensionless coefficient \(\tau_{l}\) represents the influences of first and second strain gradients on the size-dependent mechanical behavior. Using the simplified relation (72), comparison studies are performed for present model, nonlocal elastic stress field model (Eringen 1983) and nonlocal first-order strain gradient elasticity model (Lim et al. 2015). For numerical calculation, three cases are discussed: (a) \(\tau_{l} = 0.20\) and \(\tau = 0.05\) in the presence of second-order strain gradient; (b) \(\tau_{l} = 0.2\) and \(\tau = 0.05\) in the absence of second-order strain gradient and (c) \(\tau_{l} = 0.00\) and \(\tau = 0.05\). From Fig. 1, it is observed that the magnitudes of dimensionless quantity \({{\bar{c}} \mathord{\left/ {\vphantom {{\bar{c}} {\bar{c}_{0} }}} \right. \kern-0pt} {\bar{c}_{0} }}\) increases continuously with increasing dimensionless wave number \(\bar{k}\) for the three cases. It is noted that the results of \({{\bar{c}} \mathord{\left/ {\vphantom {{\bar{c}} {\bar{c}_{0} }}} \right. \kern-0pt} {\bar{c}_{0} }}\) predicted by the present model is considerably higher than that from nonlocal first-order strain gradient elasticity theory and nonlocal elastic stress field theory. For example, when the dimensionless wave number is fixed (\(\bar{k} = 7\)), the value of \({{\bar{c}} \mathord{\left/ {\vphantom {{\bar{c}} {\bar{c}_{0} }}} \right. \kern-0pt} {\bar{c}_{0} }}\) calculated from present model is \(\sim 51.6\,\%\) larger than that from nonlocal first-order strain gradient elasticity theory and \(\sim 161\,\%\) larger than that form nonlocal elastic stress field theory. However, the value of \({{\bar{c}} \mathord{\left/ {\vphantom {{\bar{c}} {\bar{c}_{0} }}} \right. \kern-0pt} {\bar{c}_{0} }}\) calculated from nonlocal first-order strain gradient elasticity theory is only \(\sim 72\,\%\) larger than that form nonlocal elastic stress field theory. This implies that the dimensionless frequency of wave propagating in CNTs increases steeply in the presence of second-order strain gradient. The experimental measurements of neutron scattering in germanium (Mindlin 1964) verified the stiffness strengthening effect for long wavelength limit for two low frequency approximations. This enhanced effect of static stiffness was also checked in the latest work by introducing an additional material length scale parameter (Lim et al. 2015). The authors concluded that the enhancement effect of stiffness for very larger wave length can be predicted by the size-dependent parameter \(\tau_{l}\). It means that the larger \(\tau_{l}\) is, the larger the stiffness. However, the remarkably strengthening effect of stiffness cannot be well predicted by using nonlocal first-order strain gradient elasticity model. In a pioneering experiment work, Treacy et al. (1996) found that the “bamboo-like” Young’s modulus (i.e. the exceptionally high Young’s modulus) of CNTs and presented this finding through the bright-field TEM micrographs. As shown in Fig. 1, the high frequency can be predicted in the presence of second-order strain gradient field. This indicates that present model can characterize the rapid strengthening effect of stiffness of CNTs.

Dispersion relations based on present model, nonlocal stress field model and nonlocal first-order strain gradient model (Lim et al. 2015)

To weigh the influences of size-dependent parameters on the wave propagating in CNTs, the following two cases are discussed in detail:

-

(a)

Case 1, the material length scale used to evaluate the influence of higher-order strain gradient fields is dominant, i.e., \(\tau_{l} > \tau_{0} > \tau_{1} > \tau_{2}\) (\(\tau_{l} > \tau_{0} > \tau_{2} > \tau_{1}\)), \(\tau_{l} > \tau_{1} > \tau_{2} > \tau_{0}\) (\(\tau_{l} > \tau_{1} > \tau_{0} > \tau_{2}\)) and \(\tau_{l} > \tau_{2} > \tau_{1} > \tau_{0}\) (\(\tau_{l} > \tau_{2} > \tau_{0} > \tau_{1}\)).

-

(b)

Case 2, the material length scale used to evaluate the influence of internal structure is dominant, i.e., \(\tau_{0} > \tau_{l} > \tau_{1} > \tau_{2}\) (\(\tau_{0} > \tau_{l} > \tau_{2} > \tau_{1}\)),\(\tau_{0} > \tau_{1} > \tau_{2} > \tau_{l}\) (\(\tau_{0} > \tau_{1} > \tau_{l} > \tau_{2}\)),\(\tau_{0} > \tau_{2} > \tau_{1} > \tau_{l}\) (\(\tau_{0} > \tau_{2} > \tau_{l} > \tau_{1}\)).

By using the dispersion relation (73), the numerical results are obtained. In the calculation, the parameters \(\tau_{l}\) and \(\tau_{0}\) are chosen as fixed values for the both two cases. Figures 2 and 3 display the dispersion relations based on present model for Case 1 and Case 2, respectively. From Fig. 2, it is seen that the magnitudes of \({{\bar{c}} \mathord{\left/ {\vphantom {{\bar{c}} {\bar{c}_{0} }}} \right. \kern-0pt} {\bar{c}_{0} }}\) in the cases of \(\tau_{l} > \tau_{0} > \tau_{1} > \tau_{2}\), \(\tau_{l} > \tau_{1} > \tau_{2} > \tau_{0}\) and \(\tau_{l} > \tau_{2} > \tau_{0} > \tau_{1}\) are significantly greater than that in the case of classical solutions. This suggests that the influence of gradient coefficient \(\tau_{l}\) is superior to \(\tau_{0}\) in determining the stiffness of CNTs. Although the value of \(\tau_{0}\) is assumed to be larger than \(\tau_{l}\) in Case 2, Fig. 3 shows that the magnitude of \({{\bar{c}} \mathord{\left/ {\vphantom {{\bar{c}} {\bar{c}_{0} }}} \right. \kern-0pt} {\bar{c}_{0} }}\) from classical solutions is less than that from the cases of \(\tau_{0} > \tau_{l} > \tau_{1} > \tau_{2}\), \(\tau_{0} > \tau_{1} > \tau_{2} > \tau_{l}\) and \(\tau_{0} > \tau_{2} > \tau_{1} > \tau_{l}\). And again, it is indicated that the gradient coefficient \(\tau_{l}\) plays a leading role in predicting the size-dependent mechanical behavior of CNTs.

To further explore the effects of size-dependent parameters on the wave propagating in CNTs, Figs. 4 and 5 illustrate dispersion relations from the proposed model for different values of \(\tau_{l}\) and \(\tau_{0}\). The calculation is carried out when parameters \(\tau_{1}\) and \(\tau_{2}\) are assumed to be constants (i.e. \(\tau_{1} = 0.20\) and \(\tau_{2} = 0.30\)). Figure 4 indicates that the magnitude of \({{\bar{c}} \mathord{\left/ {\vphantom {{\bar{c}} {\bar{c}_{0} }}} \right. \kern-0pt} {\bar{c}_{0} }}\) increases significantly with the increase of \(\tau_{l}\). It is clear that the special-scale of the CNTs is even smaller when \(\tau_{l}\) is larger. Therefore, it can be concluded that the strengthening effect of stiffness is more apparent for the smaller CNTs. Figure 5 shows that the curves of dispersion relations in the cases of \(\tau_{l} = 0\) and \(\tau_{l} = 0.001\). It means that the influence of gradient coefficient can be ignored when \(\tau_{l}\) approaches to zero. As shown in Fig. 5, it is observed that the larger the \(\tau_{0}\) is, the smaller the magnitude of \({{\bar{c}} \mathord{\left/ {\vphantom {{\bar{c}} {\bar{c}_{0} }}} \right. \kern-0pt} {\bar{c}_{0} }}\). It can be deduced that the stiffness of CNTs is decreasing for the smaller CNTs. From above discussions, it is obtained that present model can be used to predict the rapid strengthening effect and softening effect of stiffness of CNTs.

5 Conclusions

To compensate for the defect in the existing size-dependent elasticity theories, this work aims to establish a nonlocal second-order strain gradient theory by introducing the second-order strain gradient tensor involving nonlocal effect into the stored energy function of nonlocal first-order strain gradient elasticity theory. The theory proposed in this paper is expected to bridge the gap between experimentation (i.e. rapid stiffness enhancement effect noticed from experimental observation) and available computational size-dependent elasticity models. On the other hand, the new governing equations of equilibrium and boundary conditions are also obtained via Hamilton principle. The new dispersion relations between frequency and wave number are derived from present model and then used to investigate wave propagating problem in CNTs. Unlike the prevalent size-dependent elasticity models, the results indicate that present model can predict the rapid increasing effect of stiffness of nanobeams. This work may be helpful for theoretical modeling of nanomechanics.

References

Agrawal PM, Sudalayandi BS, Raff LM, Komanduri R (2006) A comparison of different methods of Young’s modulus determination for single-wall carbon nanotubes (SWCNT) using molecular dynamics (MD) simulations. Comput Mater Sci 38:271–281

Aifantis EC (1992) On the role of gradients in the localization of deformation and fracture. Int J Eng Sci 30:1279–1299

Akgöz B, Civalek O (2011) Strain gradient elasticity and modified couple stress models for buckling analysis of axially loaded micro-scaled beams. Int J Eng Sci 49:1268–1280

Arash B, Wang Q (2012) A review on the application of nonlocal elastic models in modeling of carbon nanotubes and graphenes. Comput Mater Sci 51:303–313

Bahrami A (2017a) A wave-based computational method for free vibration, wave power transmission and reflection in multi-cracked nanobeams. Compos B Eng 120:168–181

Bahrami A (2017b) Free vibration, wave power transmission and reflection in multi-cracked nanorods. Compos B Eng 127:53–62

Bahrami A, Teimourian A (2015) Nonlocal scale effects on buckling, vibration and wave reflection in nanotubes via wave propagation approach. Compos Struct 134:1061–1075

Bahrami A, Teimourian A (2016) Study on the effect of small scale on the wave reflection in carbon nanotubes using nonlocal Timoshenko beam theory and wave propagation approach. Compos B Eng 91:492–504

Bahrami A, Teimourian A (2017) Small scale effect on vibration and wave power reflection in circular annular nanoplates. Compos B Eng 109:214–226

Behera L, Chakraverty S (2017) Recent researches on nonlocal elasticity theory in the vibration of carbon nanotubes using beam models: a review. Arch Comput Method Eng 24:481–494

Bi MH, Hao YA, Zhang JM, Lei M, Bi K (2017) Particle size effect of BaTiO3 nanofillers on the energy storage performance of polymer nanocomposites. Nanoscale 9:16386–16395

Bouchaala AMS (2018) Size effect of a uniformly distributed added mass on a nanoelectromechanical resonator. Microsyst Technol 24:2765–2774

Chen P, Xiao TY, Qian YH, Li SS, Yu SH (2013) A nitrogen-doped graphene/carbon nanotube nanocomposite with synergistically enhanced electrochemical activity. Adv Mater 25:3192–3196

Dehrouyeh-Semnani AM, Bahrami A (2016) On size-dependent Timoshenko beam element based on modified couple stress theory. Int J Eng Sci 107:134–148

Deng SC, Liu JX, Liang NG (2007) Wedge and twist disclinations in second strain gradient elasticity. Int J Solids Struct 44:3646–3665

Dupuis AC (2005) The catalyst in the CCVD of carbon nanotubes—a review. Prog Mater Sci 50:929–961

Eringen AC (1983) On differential equations of nonlocal elasticity and solutions of screw dislocation and surface waves. J Appl Phys 54:4703–4710

Eringen AC (2002) Nonlocal continuum filed theories. Springer, New York

Eringen AC, Edelen DBG (1972) On nonlocal elasticity. Int J Eng Sci 10:233–248

Fang TH, Chang WJ, Feng YL (2016) Mechanical characteristics of graphene nanoribbons encapsulated single-walled carbon nanotubes using molecular dynamics simulations. Appl Surf Sci 356:221–225

Golmakani ME, Vahabi H (2017) Nonlocal buckling analysis of functionally graded annular nanoplates in an elastic medium with various boundary conditions. Microsyst Technol 23:3613–3628

Govindjee S, Sackman JL (1999) On the use of continuum mechanics to estimate the properties of nanotubes. Solid State Commun 110:227–230

Goya K, Fuchiwaki Y, Tanaka M, Addinall R, Ooie T, Sugino T, Asaka K (2017) A micropipette system based on low driving voltage carbon nanotube actuator. Microsyst Technol 23:2657–2661

Hsieh JY, Lu JM, Huang MY, Hwang CC (2006) Theoretical variations in the Young’s modulus of single-walled carbon nanotubes with tube radius and temperature: a molecular dynamics study. Nanotechnology 17:3920–3924

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Ilkhani MR, Bahrami A, Hosseini-Hashemi SH (2016) Free vibration of thin rectangular nano-plates using wave propagation approach. Appl Math Model 40:1287–1299

Karparvarfard SMH, Asghari M, Vatankhah R (2015) A geometrically nonlinear beam model based on the second strain gradient theory. Int J Eng Sci 91:63–75

Ke LL, Wang YS (2011) Flow-induced vibration and instability of embedded double-walled carbon nanotubes based on a modified couple stress theory. Phys E 43:1031–1039

Khodabakhshi P, Reddy JN (2015) A unified integro-differential nonlocal model. Int J Eng Sci 95:60–75

Lam DCC, Yang F, Chong ACM, Wang J, Tong P (2003) Experiments and theory in strain gradient elasticity. J Mech Phys Solids 51:1477–1508

Lazar M, Maugin GA, Aifantis EC (2006) Dislocations in second strain gradient elasticity. Int J Solids Struct 43:1787–1817

Lekawa-Raus A, Patmore J, Kurzepa L, Bulmer J, Koziol K (2014) Electrical properties of carbon nanotube based fibers and their future use in electrical wiring. Adv Funct Mater 24:3661–3682

Li L, Hu YJ, Ling L (2016a) Wave propagation in viscoelastic single-walled carbon nanotubes with surface effect under magnetic field based on nonlocal strain gradient theory. Phys E 75:118–124

Li CL, Guo HL, Tian XG (2016b) A size-dependent generalized thermoelastic diffusion theory and its application. J Therm Stress 40:603–626

Li CL, Guo HL, Tian XG (2017) Shock-induced thermal wave propagation and response analysis of a viscoelastic thin plate under transient heating loads. Wave Random Complex 28:270–286

Li CL, Guo HL, Tian XG (2018) Size-dependent effect on thermo-electro-mechanical responses of heated nano-sized piezoelectric plate. Wave Random Complex. https://doi.org/10.1080/17455030.2018.1450539

Liew KM, Wang Q (2007) Analysis of wave propagation in carbon nanotubes via elastic shell theories. Int J Eng Sci 45:227–241

Liew KM, He XQ, Wong CH (2004) On the study of elastic and plastic properties of multi-walled carbon nanotubes under axial tension using molecular dynamics simulation. Acta Mater 52:2521–2527

Lim CW, Zhang G, Reddy JN (2015) A higher-order nonlocal elasticity and strain gradient theory and its applications in wave propagation. J Mech Phys Solids 78:298–313

Lipomi DJ, Vosgueritchian M, Tee BCK, Hellstrom SL, Lee JA, Fox CH, Bao ZN (2011) Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat Nanotechnol 6:788–792

Liu X, Yang QS, Liew KM, He XQ (2017) Superstretchability and stability of helical structures of carbon nanotube/polymer composite fibers: coarse-grained molecular dynamics modeling and simulation. Carbon 115:220–228

Ma HM, Gao XL, Reddy N (2008) A microstructure-dependent Timoshenko beam model based on a modified couple stress theory. J Mech Phys Solids 56:3379–3391

Mindlin RD (1964) Micro-structure in linear elasticity. Arch Ration Mech Anal 16:51–78

Mindlin RD (1965) Second gradient of strain and surface-tension in linear elasticity. Int J Solids Struct 1:414–438

Narendara S, Mahapatra DR, Gopalakrishnan S (2011) Prediction of nonlocal scaling parameter for armchair and zigzag single-walled carbon nanotubes based on molecular structural mechanics, nonlocal elasticity and wave propagation. Int J Eng Sci 49:509–522

Peddieson J, Buchanan GR, McNitt RP (2003) Application of nonlocal continuum models to nanotechnology. Int J Eng Sci 41:305–312

Polizzotto C (2014) Surface effects, boundary conditions and evolution laws within second strain gradient plasticity. Int J Plast 60:197–216

Rahmani O, Pedram O (2014) Analysis and modeling the size effect on vibration of functionally graded nanobeams based on nonlocal Timoshenko beam theory. Int J Eng Sci 77:55–70

Reddy JN (2007) Nonlocal theories for bending, buckling and vibration of beams. Int J Eng Sci 45:288–307

Reddy JN (2011) Microstructure-dependent couple stress theories of functionally graded beams. J Mech Phys Solids 59:2382–2399

Reddy JN, Srinivasa AR (2014) Non-linear theories of beams and plates accounting for moderate rotations and material length scales. Int J Nonlinear Mech 66:43–53

Shodja HM, Ahmadpoor F, Tehranchi A (2012) Calculation of the additional constants for fcc materials in second strain gradient elasticity: behavior of a nano-sized Bernoulli–Euler beam with surface effects. J Appl Mech 79:021008

Simsek M, Reddy JN (2013) Bending and vibration of functionally graded microbeams using a new higher order beam theory and the modified couple stress theory. Int J Eng Sci 64:37–53

Srinivasa AR, Reddy JN (2013) A model for a constrained, finitely deforming, elastic solid with rotation gradient dependent strain energy, and its specialization to von Kármán plates and beams. J Mech Phys Solids 61:873–885

Sudak LJ (2003) Column buckling of multiwalled carbon nanotubes using nonlocal continuum mechanics. J Appl Phys 94:7281–7287

Tang YG, Liu Y, Zhao D (2016) Viscoelastic wave propagation in the viscoelastic single walled carbon nanotubes based on nonlocal strain gradient theory. Phys E 84:202–208

Thai HT (2012) A nonlocal beam theory for bending, buckling, and vibration of nanobeams. Int J Eng Sci 52:56–64

Thostenson ET, Ren ZF, Chou TW (2001) Advances in the science and technology of carbon nanotubes and their composites: a review. Compos Sci Technol 61:1899–1912

Tjong SC (2013) Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater Sci Eng R 74:281–350

Toupin RA (1963) Elastic materials with couple-stresses. Arch Ration Mech Anal 11:385–414

Treacy MMJ, Ebbesen TW, Gibson JM (1996) Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 381:678–680

Yang F, Chong ACM, Lam DCC, Tong P (2002) Couple stress based strain gradient theory of elasticity. Int J Solids Struct 39:2731–2743

Yao N, Lordi V (1998) Young’s modulus of single-walled carbon nanotubes. J Appl Phys 64:1939–1943

Yu CH, Shi L, Yao Z, Li DY, Majumdar A (2005) Thermal conductance and thermopower of an individual single-wall carbon nanotube. Nano Lett 5:1842–1846

Acknowledgements

This work is supported National Natural Science Foundation of China (11572237, 11732007) and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, C., Guo, H. & Tian, X. Nonlocal second-order strain gradient elasticity model and its application in wave propagating in carbon nanotubes. Microsyst Technol 25, 2215–2227 (2019). https://doi.org/10.1007/s00542-018-4085-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-4085-x