Abstract

Submerged fermentation (SmF) is an attractive biotechnological option for waste treatment, generating fungal bioprotein from food industry by-products. Using different Rhizopus sp. strains as fermentation agents, this paper describes a global strategy to identify interactions between cultivation parameters (pH 4.75–7.75, 7.5–82.5 g/l glucose, 0.75–3.75 g/l nitrogen, incubation time up to 5 days) for valorization of food industry by-products. Selected parameters and/or their interactions are critical for most of the proposed resulting values, giving the opportunity to optimize the process depending on the objective and making an “in silico” pre-evaluation of the process conditions. SmF of orange molasses leads to a high biomass and protein yield (11.9 g biomass/l and 4.0 g protein/l), with 43.1 ± 0.1% of essential amino acids and chemical oxygen demand (COD) reduction of almost 50%. Experiments with cheese whey result in 76.3 ± 1.1% of glucose consumption and a biomass production of 5.6 ± 2.2 g/l with 48.9 ± 5.1% of essential amino acids. SmF of orange molasses and cheese whey could contribute to promoting a sustainable feed industry while reducing by-product treatment.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Food processing industries produce billions of tons of organic by-products and wastewater each year, which become, in a significant proportion, organic-rich waste streams. EU directive 2018/851 [1] establishes that food wastes cannot be disposed of in a landfill without a previous valorization, due to environmental and economic concerns. Significant efforts have been made to use these organic pollutants as valuable resources for microbial bioconversion, removing organic material and generating valuable end products [2]. In this context, by-products from the dairy industry (mainly cheese whey) and from the fruit industry (molasses generated during juice production) are very relevant, both quantitatively and qualitatively. Cheese whey (CW) is the liquid by-product portion produced by casein coagulation during the cheese-making process. The current total worldwide production of whey is estimated at about 180–190 million tons/year, and only half of this by-product is used for food and feed production [3]. CW generates important environmental problems due to its large volume of production (9 l of whey per kg of cheese) [4] and high chemical oxygen demand (COD), approximately between 50 and 102 g/l [5]. Therefore, proper management, with treatment or reuse, is mandatory before its elimination. The same problem is observed in the fruit industry. Worldwide production of citrus fruits in 2016 was close to 124 million tons, of which almost 70 million tons corresponded to oranges [6]. More than 18 million tons of those oranges were required for processing and over 50% are discarded as organic waste [7], including the orange molasses (OMs). OMs are generated after product extraction from solid by-products by skin and pulp maceration process with calcium carbonate, which breaks down the vegetable matrix. Considering the potential environmental problems caused by this huge quantity of organic material, an efficient waste treatment is vital for food industries sustainability.

Several organisms can use these products as carbon and nutrient sources, generating high-value products and reducing their waste potential. This has been applied to several by-products and with diverse organisms including yeast, bacteria, fungi or insect [8, 9]. Compared to yeast or bacteria, fungi are easy to be harvested, have low nucleic acid and high protein proportion [10]. Fungal fermentation reduces COD of pollutant to significant levels, [11, 12], produces fungal biomass which can be used as a source of animal feed and, potentially, in human diets, and also presents diversity in high-value end products [13,14,15,16,17]. When the by-product is liquid, the use of Rhizopus oryzae, a filamentous fungus, is an attractive option to treat high-strength wastewater. This genus can use pentoses and hexoses, components of agricultural wastes, as the carbon source for the production of high-value products from food by-products, including organic acids (lactic acid and fumaric acid) [18,19,20], enzymes [21,22,23,24], and volatile compounds [25]. The main biopolymer of Rhizopus is chitosan, a polysaccharide composed of β-(1-4) d-glucosamine and N-acetyl-d-glucosamine with high value due to its technological uses [26]. This biopolymer is usually obtained from the crustacea, but R. oryzae has overcome the industrial feasible source in the last years [27, 28]. Other authors have considered Rhizopus sp. as a bioconversion agent to transform large volumes of liquid wastes into fungal bioprotein (FBP), an alternative source of protein to animal protein or other vegetable ingredients commonly used in feed for livestock and aquaculture diets, such as soybeans, wheat, corn and fish meal [17, 29,30,31,32,33]. The main components of the resulting biomass are proteins, carbohydrates, fatty acids, components of the cell wall, nucleic acids and vitamins, and their relative proportion and nutritional value must be analyzed case by case due to the dependence of the selected substrate [34].

The EFFPA (European Former Foodstuff Processor Association) states that 5 million tons of food products are used in animal feed [35], and that there is an upward trend to 7 million tons by 2025. The sustainability of feed production systems is being challenged due to factors such as scarcity of land, soil and water, competition between food and fuel, climate change, together with increased competition for arable land and non-renewable resources. One of the keys to sustainable livestock development is the efficient use of available resources, including the reduction of food waste and the application of new resources for animal feed that do not compete with human food. Cereals and oilseeds are the fundamental components of livestock feed, but their impact on prices is very high and manufacturers need a continuous and guaranteed supply that allows them to cover the needs of livestock feed. The EU is totally dependent on imports to supply the internal market with protein intended for animal feed (mainly soya), therefore, new alternative sources of protein are urgently needed. Harvesting fish species that are used for fishmeal production has reached its maximum capacity, increasing the fish meal price. Considering the current fishmeal production and aquaculture growth, an alternative protein source is needed [36]. Alternative protein sources must have lower or similar prices to actual protein sources (soybean, fish meal), must be produced in a sustainable manner, not exposed to fluctuations in the market and not dependent on geographical factors and climate variability. The price of soybeans varied between 295 and 435 euros per ton in 2016 [37], so the production of Rhizopus biomass should not exceed these amounts to be competitive in price and attractive to feed manufacturers. Therefore, the use of fungal biomass as an alternative protein for feed manufacturers could be an exceptional example of resource efficiency in the circular economy of the EU.

When fungal fermentation is considered for by-product treatments, carbon consumption (COD reduction) and biomass production are critical parameters. To maximize them, the effects of several process variables like substrate composition, substrate concentration, medium pH, inoculation, nutrient addition, incubation time and temperature have been previously studied by many researchers [38,39,40], but optimization failed to evaluate multiple parameters at a time. This multiparametric strategy has been considered by other authors to maximize enzyme production during Rhizopus growth, including the Plackett–Burman design [41] and response surface methodology (RSM) [42].

In this paper, we consider R. oryzae to optimize industry waste treatment (organic carbon consumption) and high-value product generation (mainly biomass, fungal protein, pure chitosan and fumaric acid) with a global strategy that would identify interactions between cultivation parameters. Based on our preliminary results, central composite rotary design (CCRD) and RSM were used to study the effect of nitrogen and glucose concentration, medium pH and culture time. Results obtained using synthetic medium were evaluated using real agro-industrial by-products, CW and OM, as substrate and the obtained biomasses’ amino acid (AA) and fatty acid (FA) profiles were analyzed for using them as potential animal feed.

Materials and methods

Microorganism and culture media

Top cultures (Belgium) provided commercial R. oryzae culture (internal code ROR001). The inoculum was received as a powder and stored at 4 °C until use. The specification sheet claims, at least, 8 × 106 spores per gram of starter when it was packaged. Two food-derived Rhizopus sp. strains isolated and characterized in our laboratory (ROR003 and ROR004) [43] were used to validate the model and to compare the potential uses of our own strains for the development of biotechnological strategies.

Potato dextrose agar and buffered peptone water (both from Oxoid, Basingstoke, Hampshire, England) were used for fungal propagation, count and dilution when required. Tween 80 (Merck, Darmstadt, Germany) was used for inoculum preparation. All media were prepared as recommended by the producer and sterilized at 121 °C for 15 min. Plates for total fungal counts (active cell and/or spores) were incubated at 30 °C for 48 h.

Analytical determinations

Culture was filtered through the 300 µm sterile metal filter and retentate was considered as the fungal mycelium. Fungal mycelium was washed with distilled water (1:2 w/w). Dry matter (DM) was calculated by drying the sample at 60 °C for 24 h, until constant weight [44]. Protein content of the substrates and the mycelia during CCRD development was determined by Kjeldahl [45]. Mycelia protein content during model validation and CW and OM fermentation was determined by the Biuret method as proposed by Satari et al. [39] due to its simplicity after a comparison with the Kjeldahl method as done before by Ferreira et al. [46]. Briefly, approximately 100 mg of sample was mixed with 3 mL of 1 M NaOH (Fischer Scientific, Loughborough, UK) and boiled for 10 min. After immediate cooling in an ice bath, required dilutions were prepared with 1 M NaOH, CuSO4 × 5H2O (2.5% w/v) (Merck, Darmstadt, Germany) and added to the test tubes (25% v/v final volume) and then mixed gently for 5 min. The clear supernatant was collected after centrifuging (6714 g, 5 min), and the absorbance was read at 555 nm. Different concentrations of bovine serum albumin (BSA, Sigma-Aldrich, Steinheim, Germany) dissolved in 1 M NaOH were used as standard.

Total fat was determined as described previously [47]. Briefly, biomass (500–1000 mg) was mixed with 3 ml of methanol, 1.5 ml of chloroform (both from Fischer Scientific, Loughborough, UK) and 1.2 ml of water and homogenized for 1 min. In addition, 1.5 ml of chloroform and 1.2 ml of water were added, homogenized again and centrifuged (1450 g, 15 min). Aqueous and protein phases were removed and the lipid phase (at the bottom of the tube) in chloroform was determined. Moisture and impurities were removed by passing through Na2SO4 (Fischer Scientific, Loughborough, UK). The solvent was evaporated under nitrogen flush.

Total glucose and reducing sugars were determined by dinitrosalicylic (DNS) acid reagent method [48] adjusted to microplate (Thermo Fisher Scientific, Roskilde, Denmark) assay procedure. DNS acid reagent was prepared by dissolving 8 g of NaOH in 100 ml of distilled water. Then, 5 g of DNS (Fischer Scientific, Loughborough, UK), 250 ml of distilled water and 150 g of potassium sodium tartrate tetrahydrate (Sigma-Aldrich, Steinheim, Germany) were added and made up to volume (500 ml). 25 µl of sample, blank or standard (different concentrations of d-glucose, Fischer Scientific, Loughborough UK) and 25 µl of DNS reagent were added to each well and incubated for 10 min at 100 °C. The microplate was rapidly cooled in an ice bath and 250 µl of distilled water was added to each well. Absorbance was read at 540 nm.

Fumaric acid was determined by the Fumarate Assay Kit (Sigma-Aldrich, St. Louis, USA) as described in the microplate assay procedure. The pH of the culture was determined using a potentiometer (Crison micropH 200, Hach Lange Spain S.L.U., Spain).

COD was determined using the COD spectroquant cell test (Merck, Darmstadt, Germany).

Extraction and precipitation of chitosan were done as described previously by Zamani et al. [44]. Briefly, wet mycelium of Rhizopus was treated with 0.5 M NaOH (30 ml of sodium hydroxide per gram of mycelium dry weight) at 90 °C for 2 h. Alkali-insoluble material (AIM) was separated by centrifugation (4000g, 10 min), washed four times with distilled water, and stored at 4 °C until use. The yield of AIM from biomass was measured after drying it at 60 °C until constant weight. Sulfuric acid (1% v/v) (Fischer Scientific, Loughborough, UK) was mixed with AIM (100 ml/g), the mixture was heated at 121 °C for 20 min, followed by hot filtration (> 90 °C) and chitosan was precipitated in an ice bath for 2 h. The bottom phase was centrifuged (4000g, 10 min) and the pellet was dried until constant weight.

The AA profile was determined as done before [43]. Protein quality was evaluated by the essential amino acid index (EAAI) as described before [49]. EAAI is based on the content of essential amino acids (EAA) compared to a reference protein or specific requirements for human nutrition [50] and it is used as a rapid method to evaluate and optimize the AA content of food and feed formulations. The EAAI equation is described as follows:

n is the number of EAA referenced.

FA acid profile was determined by adding 5 ml of sodium methoxide (Fischer Scientific, Loughborough, UK, 0.2% w/v in methanol) to previously extracted lipid fraction and boiling for 10 min in a reflux system. Samples were cooled by introducing them into ice. After that, they were neutralized by adding HCL (5% v/v) (Fischer Scientific, Loughborough, UK) in methanol and again boiled for 10 min, cooled in ice and mixed with 5 ml of n-hexane (Fischer Scientific, Loughborough, UK). Saturated sodium chloride (Fischer Scientific, Loughborough, UK) was added forcing the separation of the hexane from the inorganic part. At that point, the methyl esters were dissolved in the hexane part, dried and dissolved in C19 methyl ester (internal standard). GC-FID analysis was fitted with a DB-23 column of Agilent Technologies (60 m × 0.25 mm). The program was 150 °C for 1 min, a 5 °C/min gradient up to 200 °C, a second gradient of 2 °C/min up to 230 °C and 20 min at 230 °C. Fatty acid methyl esters were identified by comparing the retention times with standard and were expressed as percentages of total fatty acid methyl esters.

Parameters optimization via central composite rotary design (CCRD) and statistical analysis

An optimization of fermentation conditions was done to maximize biomass production (g/l), protein production (% DM), glucose consumption (%), biomass yield (gram of biomass DM/gram of consumed glucose), chitosan production (% biomass DM) and fumaric acid production (g/l).

Optimization was done in synthetic culture medium, which includes (g/l): 7.5–82.5 glucose, 3.0 KH2PO4 (Panreac Química SA, Barcelona, Spain), 0.5 MgSO4 × 7H2O, 0.5 FeSO4 (both from Sigma-Aldrich, Steinheim, Germany) and 0.5 KCl (Merck, Darmstadt, Germany). Nitrogen was 0.75–3.75 g/l (Proteose peptone, Oxoid, Basingstoke, Hampshire, England) and 1 ml of olive oil was added as the antifoaming agent. Culture initial pH was adjusted with sterile 1 M NaOH and 1 M HCl. Submerged fermentation (SmF) was carried out on sterile 1 l pirex bottles (500 ml medium) with sterile air flux 2.0 v/v per minute, incubated at 30 °C, inoculated with 0.1% of spore suspension in dark conditions and without shaking. Inoculum spore suspension was prepared as described before [43] and adjusted to 107 cfu/ml just before inoculation.

Based on preliminary experiences (not shown), a CCRD was carried out, which contained 27 experimental trials (Supplementary material Table S.1). Five levels of the varying four factors (glucose, nitrogen, pH and incubation time) were used in the central composite design (Table 1). Considered runs included 24 factorial design (16 runs), star points (8 runs) and central points (3 runs). Results were expressed as a second-order equation, formally presented as Eq. (2):

where Y is the response parameter, X1, X2, X3 and X4 are the coded independent variables, A, B, C and D are linear coefficients, AA, BB, CC and DD are quadratic coefficients and AB, AC, AD, BC, BD and CD are the interactive coefficients. ANOVA (analysis of variance) models were used for statistical analysis (Statgraphics Centurion XVI software package) of the model. Factors were considered significant when their probability (p value) was lower than 0.05.

Model validation

Model validation comprised two steps. First, independent runs were carried out using synthetic medium (SM) to compare the obtained values with the model. Different experimental conditions were carried out with the SM (Table 2, ROR001 (n = 3), ROR003 (n = 1) and ROR004 (n = 2) in conditions 1–9).

Later, the model was validated at optimal conditions for protein and biomass production (SM, 3.75 g/l nitrogen, 32 g/l glucose, 5 incubation days and 6.12 initial pH, Table 2, condition 10) with a food-derived strain (ROR004). Twelve independent experiments (n = 12) were run and compared with the predicted values.

Finally, CW and OM were used as food industry-derived by-products for the model validation in different fermentation conditions (Table 2, conditions 11–16). Bovine CW samples were obtained fresh from a commercial cheese factory (Vascolac S.L. Zamudio, Spain) and heated at 110 °C for 1 min to remove the precipitated proteins. Extra nitrogen (proteose peptone 0.25 g/l), glucose (9.96 g/l) and micronutrients (KH2PO4 4 g/l, KCL 0.5 g/l, MgSO4 × 7H2O 0.5 g/l, FeSO4 0.5 g/l and olive oil 0.8% v/v as antifoaming) were added. Each experimental condition included a different percentage of partially deproteinized CW and SM (Table 2, conditions 11–13). Whey and nutrients were sterilized (121 °C 15 min) separately and mixed in sterile conditions and inoculated with the original strain (ROR001, n = 2). Commercial OM was obtained from a fruit-processing factory during the production of orange juice (Indulleida S.A. Vilanova de Segrià, Spain). Original pH of the substrate was adjusted with NaOH 4 M before autoclaving (121 °C 15 min) and the final substrate pH was 5.4 ± 0.1. When required, medium was supplemented up to 2 g/l nitrogen with (NH4)2SO4 (Fischer Scientific, Loughborough, UK) (Table 2, conditions 14 and 15) before autoclaving. Samples were inoculated with a food-isolated Rhizopus sp. strain (ROR004).

Statistical analysis

Differences between fungal samples were determined by one-way ANOVA statistics analyzed using the software package SPSS (IBM Corp. V 24.0, New York, USA). When equal variances were not assumed (Levene test), Welch statistic was used to compare samples. The level of significance was set at p < 0.05.

Results and discussion

Influence of the studied variables on the considered products

Preliminary characterization of selected by-products shows that reducing sugars are 21.5 ± 2.6 and 22.6 ± 0.7 g/l in CW and OM, respectively, the nitrogen content is higher in CW (1.3 ± 0.1 g/l) and, as expected, quite lower in OM (0.20 g/l). Original pH is 6.1 ± 0.1 in CW and pH 4.7 ± 0.1 in OM.

CCRD was selected to predict selected variables in such high different by-products. Based on the preliminary characterization, the substrate conditions used for model development range were selected. These parameters include a wide pH range (4.75–7.75), glucose concentration (7.5–82.5 g/l), nitrogen concentration (0.75–3.75 g/l) and the usual incubation time (1–5 days) (Table 1). Nitrogen’s minimum concentration is higher than present in OM, but preliminary experiments (not shown) and published results [12, 51] suggested that OM would require nitrogen supplementation to maximize biomass production. This point was confirmed in later experiments (see Table 2, condition 14 and related results).

As described later, the statistical analysis of the results obtained after CCRD runs demonstrate that only few factor interactions have a significant effect on the results. To simplify the number of parameters and their interactions for the prediction of the variable, those interactions with a p value higher than 0.7 have been removed from the model and not considered in further analysis as recommended by Anderson, Whitcomb [52]. The obtained and predicted results during model generation are shown in supplementary material (Table S.2). Statistical analysis of the results obtained after this purge shows that the proposed model is significant for almost all the response factors considered (Table 3). The F test is used to analyze the statistical significance of proposed equations for each interesting parameter (Eq. 2) and the analysis of variance (ANOVA) was used for the response surface quadratic model. As an overview, equations derived from the considered variables can predict positively biomass, biomass yield, protein concentration, fumaric acid and consumed glucose (p values lower than 0.05, Table 3). The percentage of variation (R2 value) that can be attributed to the dependent variables indicates that those selected variables explain between 70 and 95% of the final values (75.69, 81.96, 76.99, 94.55 and 70.64 for biomass, biomass yield, protein, fumaric acid and glucose consumption, respectively). However, the proposed variables do not predict chitosan concentration in a significant way (p value of 0.3208 and R2 value of 52.53) (Table 3), therefore, it is excluded from further analysis. Other authors found that chitosan production depends on different factors like dimorphism, obtaining higher productions when fungi are grown in filamentous form [40] and longer incubation periods [53]. Although our experimental conditions lead to filamentous growth form (results not shown) and some conditions include long incubation periods, the obtained chitosan yields are lower than published results [39], obtaining concentrations between 1 and 3% of total fungal biomass (Table S.2).

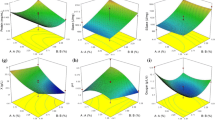

Results demonstrate that nitrogen, glucose and incubation time are significant factors (p < 0.05) for biomass production (Fig. 1a). When nitrogen is high in the medium, but glucose is low (C/N ≤ 4), or when nitrogen is low, and glucose is high (C/N ≥ 16), biomass production decreases, especially when fermentation time is 2 days or lower, which reinforces the idea that the carbon:nitrogen ratio should be balanced (C/N ratios around 8, Table S.2) for maximal production (Fig. 2a). Incubation period has also a positive impact on produced biomass (Fig. 1a) and high biomass is also harvested in low (C/N ≤ 4) ratios. We observe fungal growth up to 4 days in most cases with maximum production of 9.3 g/l (Table S.2), in agreement with the published results [46, 54].

Glucose and the interaction between glucose × time and glucose2 are significant factors (p < 0.05) for biomass yield (biomass produced per glucose consumed) (Fig. 1b). When glucose is poor, the biomass yield parameter is dependent on the interaction of glucose × time, resulting in higher productivity when the incubation time is longer. As explained in the paragraph above, biomass production (g DM/l) is highly dependent on longer incubation periods when glucose is at a low concentration (15 g/l) in the medium, which leads to a higher biomass yield. In contrast, when the medium is rich in glucose, the higher incubation period does not lead to higher productivity (Fig. 2b). The increase in C/N ratio could lead to a reduction in the formation of biomass, thereby redirecting the pyruvate flow to fumarate production [55]. Our results show that the lowest yields (< 0.16 g/g) are always obtained at a high glucose concentration (> 60 g/l), and highest yields (> 0.33 g/g) in contrast, at low glucose concentrations (< 15 g/l) (Table S.2).

Nitrogen, glucose and the interaction between nitrogen × glucose and nitrogen × time are significant factors (p < 0.05) for protein concentration (Fig. 1c). Protein concentration is a vital parameter in obtaining a high-value biomass for feed application [34]. The highest protein proportion is obtained when the medium is rich in nitrogen and poor in glucose (Fig. 2c), this condition provides a C/N ratio of 10:1 or less, which ensures a high protein content [56]. Our results show that C/N ratios ≤ 4 lead to higher protein production (> 35%) than the values obtained at higher C/N ratios (Table S.2).

Fumaric acid production is not considered for model validation due to the low production in the studied conditions. Results confirm that high biomass production conditions do not match with high fumaric acid production conditions as reported previously [57]. Rhizopus strains tend to form cotton-like mycelia, which limits the mass transfer of oxygen and nutrients onto the microorganisms and the release of the produced organic acids into bulk solutions. These conditions lead to low yield and productivity of organic acids during fermentation which could be alleviated by growing fungi in pellet form [57].

The obtained results report maximal yield of 0.08 g fumaric acid per gram of consumed glucose (0.12 mol/mol) (Table S.2), which is much lower than the maximal theoretical yield in a nongrowth situation of 2 mol of fumaric acid per mole of consumed glucose [58]. This effect can be because the CCRD conditions were not optimized for fumaric acid production, where C/N ratios ranging from 120:1 to 150:1 are suggested [59] and the highest C/N ratio was 20:1. Adding a neutralizing agent like CaCO3 or developing simultaneous fermentation–separation process that avoids the use of neutralizing agents while preventing product inhibition and maintaining a high level of dissolved oxygen in the fermentation broth are also possible strategies for improving fumaric acid yield [60, 61]. Results confirm that it is not possible to maximize the co-production of fumaric acid and biomass in a single-step fermentation process.

As expected, lower initial glucose concentration always leads to a higher proportional glucose consumption and when glucose concentration is high, longer incubation periods are required to obtain maximal glucose consumptions (Fig. 2d). Nitrogen concentration is critical (has a rather high coefficient) in the glucose consumption equation (Fig. 1d), resulting in a relative high nitrogen proportion becoming necessary for high glucose consumption and confirming the idea that C/N ratio is critical for this fungus metabolism. For glucose consumption, the considered significant factors are glucose and time (Fig. 1d).

Multiparameter optimization and RSM analysis allow finding the optimal compromise to obtain a combination of high-value products and a COD reduction, related to reducing sugars consumption, as result of the by-product treatment. In this case, food and feed production strategy would require identifying the optimal conditions for the highest biomass production with the highest protein concentration, as well as identifying the highest sugar consumption in the case of by-product treatment. The resulting conditions are medium glucose concentration (32 g/l), high nitrogen (3.75 g/l) in a slight acid medium (6.12) and being incubated for long time (5 days). In these conditions, SM fermented with ROR004 (condition 10, Table 2) arrives up to 8.1 ± 1.9 g biomass DM/l. 52.4 ± 12.2% protein and consumes 99.6 ± 0.1% of total sugars and leads the expected values in most of the parameters (Fig. 3, condition 10).

Comparison between predicted and obtained values for biomass production (a), protein concentration (b), biomass yield (c) and reducing sugars consumption (d). Experimental conditions are described in Table 2. Error bars represent SD

Model validation

A comparison was done between Kjeldahl and Biuret methods for protein determination which is summarized in Table 4. The Biuret method determines peptide bonds, while the Kjeldahl method determines total nitrogen and in general a conversion factor of 6.25 is used for protein calculation, which could lead to an overestimation. Results show that the Kjeldahl method results in 1.2 ± 0.2 times higher values compared to the Biuret method (Table 4). Ferreira et al. [46] also found a similar relation (0.15 g/g higher values) between Kjeldahl- and Biuret-based methods. However, both methods show the same trend, and as expected with higher nitrogen in the medium higher Kjeldahl nitrogen values are obtained. The Biuret results for model validation have been adjusted to the Kjeldahl values using a conversion factor of 1.2.

Sixteen independent assays were performed to test the proposed model’s accuracy (Table 2). Three SM compositions were selected (Table 2, conditions 1–9) and incubated in independent experiments with three fungal strains ROR001 (n = 3), ROR003 (n = 1) and ROR004 (n = 2) for model validation. The obtained results are in accordance with predictions for most cases, although the ROR004 strain produces a higher protein proportion when more nitrogen is available in the medium compared to ROR001 and ROR004 (conditions 1–6) (Fig. 3b) and biomass production is slightly higher in ROR003 and ROR004 also in nitrogen-rich conditions (1–6) (Fig. 3a). The parameter “reducing sugar consumption” is lower than the predicted results for two non-commercial Rhizopus sp. strains in low nitrogen fermentation condition (condition 8 and 9) (Fig. 3d), although other parameters, such as biomass production, protein and biomass yield are not affected for predictions by lower nitrogen content (Fig. 3a–c). ROR004 seems to be the strain which produces higher biomass and accumulates higher protein proportion in nitrogen-rich medium (≥ 2.25 g/l).

Twelve (n = 12) extra runs were done with SM and optimal conditions to maximize biomass production and protein concentration (Table 2, condition 10). Obtained values (Fig. 3, condition 10) demonstrate a good correlation (R2 = 0.983) between the observed and predicted values in a rather repetitive manner (small SD). As described by the model, long incubation time and high nitrogen would have a positive impact on the biomass and protein production, 8.1 ± 1.9 g/l and 52.4 ± 12.2% DM, respectively.

When the highest studied proportion of CW is used as substrate (40%), obtained results match with expected biomass yield variables but do not match with biomass, protein and reducing sugar consumption (Fig. 3, condition 11). However, when medium CW proportion (18%) is used, all the studied variables are well adjusted (Fig. 3, condition 12). Concentrations higher than 40% (whey:medium) resulted in low fungal growth, confirming previous observations (not shown) and pointing that cheese derived whey has to be diluted to support the growth of this fungi. Other authors have reported growth in deproteinized whey, up to 6 g dry mycelia/l after 3 days [62] that would agree with our predictions for pH 6.0, t = 4 days, reducing sugars 18.6 g/l, nitrogen 0.78 g/l (6.6 g biomass DM/l, Fig. 3 a, condition 11). Differences in whey preparation protocol would explain the difference, especially our short thermal process and the long process proposed by Chatterjee et al. [62]. Lactoferrin and derived peptides have a relatively high concentration in bovine whey (> 1 g/l of whey) [63] which could be the cause of inhibition, but further research is required to clarify this effect.

Results obtained with OM are shown in Fig. 3, conditions 14–16. As predicted, a longer incubation period leads to higher biomass production (up to 9–11.9 g/l, 120 h) and, although the nitrogen is ten times lower in experimental condition 14 compared to condition 16 (Table 2), biomass production is 1.8 times higher in the first one due to the longer incubation period. Reducing sugars consumption and protein production are higher than predicted in the lowest nitrogen concentration, (Fig. 3b, d, condition 14); since the model was created with higher nitrogen concentration range, it cannot predict accurately reducing sugars consumption and biomass yield in these low nitrogen concentration cases. Obtained equations are valid for supplemented OM fermentation with the added value that a second strain is used in the test, demonstrating that proposed equations are valid to predict the growth parameters of different Rhizopus sp. strains. Final biomass production is 11.9 g DM/l when incubation time is 5 days, which is a higher value than the obtained one at optimal conditions in SM (Table 2, condition 10), although protein production is lower (39.6%, Fig. 3b) due to lower nitrogen content in the medium.

In addition, it is interesting to note that the model can be “forced out” from the range of variables. Nitrogen concentrations in conditions 12, 13 and 14 are lower than the model—α value for this variable, but the equations are able to predict biomass and protein (Fig. 3a, b). In any case, the authors recommend maintaining the values in the range of the model to have stronger predictions.

Obtained biomass (g biomass/l) and protein yield (g protein/l) in SM, 8.1 and 4.3, respectively, are in accordance or are even higher than previously reported [10, 51]. Other authors found higher biomass production (up to 38.7 ± 3.7 g/l), but in consequence a lower protein proportion was obtained leading to similar protein yields (g/l) [32, 33]. The biomass obtained in the studied by-products achieves a lower protein concentration (Fig. 3b), but higher protein yield in the optimal conditions for OM (4.7 g/l OM Table 2, condition 15). Other studied conditions lead to lower protein yield (2.9 g/l OM Table 2, condition 14 and 1.4 g/l in CW Table 2, condition 12). Reducing initial sugars and increasing nitrogen in the medium, by supplementation or by combining with higher nitrogen by-products, will result in the final C/N ratio becoming lower, which could lead to a higher protein concentration [56]. Other authors [39] reported lower protein yield in citrus wastes’ free sugars without supplementation than obtained hereby.

The model could be used for a preliminary selection of the process conditions, simulating the effects of variable modifications (nitrogen supplementation or longer fermentation periods) on determinant end products, such as biomass and protein yield, and evaluate if the resulting process could be cost effective, or even selecting the best process regarding obtained profits and generated costs. Fermentation reduces the COD of the treated by-products. COD reduction values are around 50% for OM and CW fermentation after 120 h and lower in shorter incubation time. Other authors found higher COD reductions when initial COD was much lower than in this case [10, 12] and lower when initial COD was higher [51]. Total reducing sugars dropped below 5 g/l in initial 48 h and below 3.5 g/l after 120 h of fermentation (Table 5).

Biomass characterization

The nutritional value and utility of fungal biomass depends on the nutrient content and composition. Thus, biomasses obtained with Rhizopus sp. in optimal SM, CW and OM (Table 2 conditions 10, 12 and 15), have been characterized for AA and FA profile.

Obtained proteins profiles are dominated by Glu, Ala, Asp, Leu, Arg and Lys (Table 6) and result in high-quality protein, both in SM and in industrial by-products. The percentage of total EAA is 40.9 ± 2.5, 43.0 ± 0.1 and 48.9 ± 5.1% in SM, OM and CW biomasses, respectively. Obtained EAAI for human consumption is 1.4 for SM and OM and 1.6 for CW, which means that profiles fulfill human consumption requirements determined by FAO standards [50]. There are no significant differences (p < 0.05) between AA profiles of the obtained biomasses, thus, the beneficial AA profile will be guaranteed within medium modifications. The overall EAA (mg/g fungal biomass) is 214.4 ± 13.0, 170.2 ± 0.2 and 121.3 ± 12.6 mg/g fungal biomass in SM, OM and CW, respectively (Table 6). Biomass grown in CW is the poorest biomass in EAA, with significantly lower Phe, Ile, Leu, Pro and Ala concentrations. Although the EAA profile (% EAA of total AA) does not differ significantly within biomasses, lower protein concentration in CW biomass leads to lower EAA content. Lower protein concentration in this biomass could be related to medium inhibition, which ends in lower biomass and protein production and higher fat accumulation.

Fish meal and soybean meal are the most used protein sources in animal feeding [64], and the fungal biomasses obtained in the selected conditions are compared to these commercial meals in terms of protein, fat and AA and FA profile. AA concentration of biomasses grown in OM and CW are in general lower than fish meal, and only the biomass grown in SM reaches its great profile (Table 6). EAA concentration of biomass grown in OM is quite similar to soybean meal, but the biomass grown in CW, however, does not reach the EAA concentration required to use it as high-quality alternative protein source. In all the fungal biomasses, sulfur AA is lower than the required concentration, and previous studies also showed that the production of sulfur AA is limited in zygomycetes biomass, and therefore, feed should be supplemented in those AA [12, 65]. Lysine is considered the most critical AA in fish feed and often the most limiting one in feed ingredients [12]. Lysine content of fungal biomasses is lower than in fish meal (Table 6), but biomasses from SM and OM have higher and similar lysine and protein content compared to soybean meal (3.0 and 47.5%, respectively) (Table 6).

Protein recommendations for fresh monogastric and ruminants feed are between 12 and 18% [66, 67]; in aquaculture, the protein needs are higher, as most herbivorous and omnivorous fish required 25–35% of protein in their diet, while carnivores required higher levels ranging from 40 to 55% in their diet [68]. Fungal biomass through fermentation of SM and OM would meet these required protein levels which makes them interesting alternative protein sources and could contribute greatly towards protecting the surrounding environment and promoting a sustainable feed industry.

Lipids provide palatability and energy value to the formulation of feed. Comparing the FA composition, there are differences regarding the fermented substrate. Biomass of CW leads to a higher fat fraction (31.1 ± 10.6%) than in SM (6.6 ± 0.4%) and OM (4.2 ± 0.4%) (Table 7) and OM leads to significantly higher polyunsaturated fatty acids (PUFA) and lower monounsaturated fatty acids (MUFA) proportion (Table 7). Main FA of the biomasses are oleic (C18:1), palmitic (C16:0), linoleic (C18:2n-6) and stearic acid (C18:0) in agreement with results reported previously [43, 51, 69]. Several medium and long FA (14:1, 15:1, 17:0, 17:1, 20:5n-3, 22:1, 22:5n-3 and 22:6n-3) are below the detection limit in all the biomasses. The higher fat fraction and MUFA composition of the CW biomass could be related to the higher proportion of olive oil used as the antifoaming agent in CW fermentation due to higher foam production or with the possible adsorption of whey–FA in the fungal biomass [46]. In this condition, fat fraction is five and seven times higher than in SM and OM, respectively, and C18:1 increases up to 75.7 ± 3.8%. Biomass obtained through the fermentation of OM otherwise, is 2.9 and 4 times richer in PUFA than the biomasses obtained in SM and CW which were almost twice richer in MUFA (Table 7). It should be mentioned that gamma-linolenic acid (GLA C18: 3n-6) increases up to 8.6% of the profile of biomass grown in OM. This FA of the ω-6 series is the precursor of DGLA (dihomo-gamma-linolenic acid C20:3n-6) [70], which produces short-lived second messengers, including prostaglandins of series 1 (PGE1) and thromboxane A1 (TxA1), with anti-inflammatory, vasodilatory and anti-aggregatory actions [71]. Other authors have described that stress conditions during microorganism cultivation would lead to desaturation of membrane FA, which enhanced membrane fluidity, related to this fact [72]. The slightly more acidic pH of OM could lead to a higher accumulation of PUFA in fungal cells, however, further experiments are required to determine if the differences in FA profile of Rhizopus sp. biomass are related to the cultivation conditions or to the Rhizopus strain used as reported previously [73]. Compared to soybean meal, obtained biomasses have higher total lipids; compared to fish meal however, biomasses through fermentation of OM and SM show lower total lipids (Table 7). FA profiles are also quite different, while biomasses have higher C18:1 and lower C18:2 than soybean meal, the biomasses have higher C18:1, C18:2 and C18:3 as well as a lower proportion of FA higher than C20 (represent the 47.1% of total fish meal lipids) than fish meal. In general, obtained biomasses could add a higher nutritional value regarding lipid content and FA profile compared to soybean meal, but FA profile is not as good as fish meal profile regarding essential highly unsaturated fatty acids (HUFA).

Freshwater fish can convert C18 PUFA to C20 or C22 HUFA by elongation and desaturation reactions, thus, their essential fatty acids (EFA) requirements are met by PUFA (18:3n-3 and 18:2n-6) [74]. Marine fish otherwise cannot perform [75] or have limited capability [76] for such conversion, therefore they have requirements for n-3 HUFA (20:5n-3 and/or 22:6n-3), so fungal biomass should be added with other feed which includes those FA.

Rhizopus biomass has already been tested as fish meal substitute in fish feed [77,78,79], always without total substitution, where similar responses and good growth rates have been obtained compared to fish meal-based feed. Therefore, the Rhizopus biomass could present as an alternative to the large quantities of fish meal necessary for aquaculture.

Nutritional requirements regarding FA profile for cattle, dairy, swine and poultry are not specific, and just a minimum amount of C18:2n-6, > 0.1% in swine and around 1.1% in poultry is required due to its benefits in clutch size and egg mass [66, 80]. Obtained biomasses provide 0.5, 0.8 and 1.8% in fungal biomass grown in SM, OM and CW. To the best of our knowledge, no farm trail has been done with Rhizopus biomasses in these species.

For any industrial process, the price of the substrate and the produced valuable end products has a huge impact on the economic feasibility of the proposed scenario. By-product treatments, OM and CW treatments in this case, are costly processes due to investment and operating costs, even so, the results presented here reinforced the idea that fungal treatment of food industry by-products is a promising technology for alternative protein source production, contributing to the income of the plants. In the proposed scenario, the fermentation process should be installed near the by-product generating industries and would be focused on producing mainly fungal biomass for animal or human consumption. The model described and validated in this paper is a necessary milestone, but the collaboration between engineers, specialist in Rhizopus metabolism and animal nutritionist would be required to confirm that this technology is feasible, scalable and cost effective.

Conclusions

Optimization of fermentation parameters for simultaneous production of fungal biomass, protein and glucose consumption result in a multiparametric model with significant interactions between considered parameters (mainly nitrogen and carbon concentration and fermentation time). These models can be used to optimize the fermentation with a defined objective. In synthetic medium, best conditions lead to total consumption of glucose and maximizing biomass yield and protein production up to 8.1 g/l with a 52.4% DM, respectively. When applied to real food industry by-products, this paper confirms OM as a promising organic by-product for fungal fermentation due to high COD reduction, high biomass production, high protein yield, even without nitrogen addition and micronutrient supplementation, and high nutritional value of the obtained biomass (EAA and omega-6 FA proportion), comparable or even better than soybean meal. Fungal biomass obtained by fermentation of OM is, therefore, a very promising alternative protein source in animal feed. CW requires to be diluted (consuming clean water and increasing final waste volume) and needs to be supplemented to assure fungal growth. In addition, obtained COD reduction and biomass production are lower than with OM.

References

Diario Oficial de la Unión Europea. Directiva (UE) (2018) 2018/851 del Parlamento Europeo y del Consejo de 30 de mayo de 2018 por la que se modifica la Directiva 2008/98/CE sobre los residuos

Angenent LT, Karim K, Al-Dahhan MH, Wrenn BA, Domíguez-Espinosa R (2004) Production of bioenergy and biochemicals from industrial and agricultural wastewater. Trends Biotechnol 22(9):477–485. https://doi.org/10.1016/j.tibtech.2004.07.001

Mollea C, Marmo L, Bosco F (2013) Valorisation of cheese whey, a by-product from the dairy industry. In: Mazzalupo I (ed) Food industry. InTECH, London. https://doi.org/10.5772/53159

Turner TL, Kim E, Hwang C, Zhang GC, Liu JJ, Jin YS (2017) Short communication: conversion of lactose and whey into lactic acid by engineered yeast. J Dairy Sci 100(1):124–128. https://doi.org/10.3168/jds.2016-11784

Carvalho F, Prazeres AR, Rivas J (2013) Cheese whey wastewater: characterization and treatment. Sci Total Environ 445–446:385–396. https://doi.org/10.1016/j.scitotenv.2012.12.038

FAO (2017) Citrus fruit—fresh and processed statistical bulletin 2016. Trade and Market Division, Rome

Rezzadori K, Benedetti S, Amante ER (2012) Proposals for the residues recovery: orange waste as raw material for new products. Food Bioprod Process 90(4):606–614. https://doi.org/10.1016/j.fbp.2012.06.002

Brar SK, Dhillon GS, Soccol CR (2014) Biotransformation of waste biomass into high value biochemicals. Springer, New York. https://doi.org/10.1007/978-1-4614-8005-1

Sadh PK, Duhan S, Duhan JS (2018) Agro-industrial wastes and their utilization using solid state fermentation: a review. Bioresour Bioproces. https://doi.org/10.1186/s40643-017-0187-z

Jin B, Yu Q, van Leeuwen JH, Hung Y-T (2010) An integrated biotechnological process for fungal biomass protein production and wastewater reclamation. In: Wang LK, Tay J-H, Tay STL, Hung Y-T (eds) Environmental bioengineering, vol 11. Humana Press, Totowa, pp 699–721. https://doi.org/10.1007/978-1-60327-031-1_20

Zhang Z, Liu D, Feng F, Li J, Li M, Pang Q, Chen K (2013) Optimization of the nutrition for biodegradation of vinasse by Aspergillus oryzae using response surface methodology. Water Sci Technol 67(4):772–779. https://doi.org/10.2166/wst.2012.631

Nitayavardhana S, Issarapayup K, Pavasant P, Khanal SK (2013) Production of protein-rich fungal biomass in an airlift bioreactor using vinasse as substrate. Bioresour Technol 133:301–306. https://doi.org/10.1016/j.biortech.2013.01.073

Mahboubi A, Ferreira J, Taherzadeh M, Lennartsson P (2017) Production of fungal biomass for feed, fatty acids, and glycerol by Aspergillus oryzae from fat-rich dairy substrates. Fermentation 3(4):48. https://doi.org/10.3390/fermentation3040048

Souza Filho PF, Nair RB, Andersson D, Lennartsson PR, Taherzadeh MJ (2018) Vegan-mycoprotein concentrate from pea-processing industry byproduct using edible filamentous fungi. Fungal Biol Biotechnol 5:5. https://doi.org/10.1186/s40694-018-0050-9

Nair RB, Kabir MM, Lennartsson PR, Taherzadeh MJ, Horvath IS (2018) Integrated process for ethanol, biogas, and edible filamentous fungi-based animal feed production from dilute phosphoric acid-pretreated wheat straw. Appl Biochem Biotechnol 184(1):48–62. https://doi.org/10.1007/s12010-017-2525-1

Kantifedaki A, Kachrimanidou V, Mallouchos A, Papanikolaou S, Koutinas AA (2018) Orange processing waste valorisation for the production of bio-based pigments using the fungal strains Monascus purpureus and Penicillium purpurogenum. J Clean Prod 185:882–890. https://doi.org/10.1016/j.jclepro.2018.03.032

Ferreira JA, Mahboubi A, Lennartsson PR, Taherzadeh MJ (2016) Waste biorefineries using filamentous ascomycetes fungi: present status and future prospects. Bioresour Technol 215:334–345. https://doi.org/10.1016/j.biortech.2016.03.018

Papadaki A, Papapostolou H, Alexandri M, Kopsahelis N, Papanikolaou S, de Castro AM, Freire DMG, Koutinas AA (2018) Fumaric acid production using renewable resources from biodiesel and cane sugar production processes. Environ Sci Pollut Res Int. https://doi.org/10.1007/s11356-018-1791-y

Li X, Zhou J, Ouyang S, Ouyang J, Yong Q (2017) Fumaric acid production from alkali-pretreated corncob by fed-batch simultaneous saccharification and fermentation combined with separated hydrolysis and fermentation at high solids loading. Appl Biochem Biotechnol 181(2):573–583. https://doi.org/10.1007/s12010-016-2232-3

Zheng Y, Wang Y, Zhang J, Pan J (2016) Using tobacco waste extract in pre-culture medium to improve xylose utilization for l-lactic acid production from cellulosic waste by Rhizopus oryzae. Bioresour Technol. https://doi.org/10.1016/j.biortech.2016.06.071

Battaglia E, Benoit I, van den Brink J, Wiebenga A, Coutinho PM, Henrissat B, de Vries RP (2011) Carbohydrate-active enzymes from the zygomycete fungus Rhizopus oryzae: a highly specialized approach to carbohydrate degradation depicted at genome level. BMC Genom 12:38. https://doi.org/10.1186/1471-2164-12-38

Benoit I, Coutinho PM, Schols HA, Gerlach JP, Henrissat B, de Vries RP (2012) Degradation of different pectins by fungi: correlations and contrasts between the pectinolytic enzyme sets identified in genomes and the growth on pectins of different origin. BMC Genom 13:321. https://doi.org/10.1186/1471-2164-13-321

Kupski L, de Carvalho Silvello MA, Fontes MRV, Lima TS, Treichel H, Badiale Furlong E (2015) Rhizopus oryzae cellulases: a new approach to degrading lignocellulosic material. J Food Biochem 39(2):129–138. https://doi.org/10.1111/jfbc.12097

Vaseghi Z, Najafpour GD, Mohseni S, Mahjoub S (2013) Production of active lipase by Rhizopus oryzae from sugarcane bagasse: solid state fermentation in a tray bioreactor. Int J Food Sci Technol 48(2):283–289. https://doi.org/10.1111/j.1365-2621.2012.03185.x

Christen P, Bramorski A, Revah S, Soccol CR (2000) Characterization of volatile compounds produced by Rhizopus strains grown on agro-industrial solid wastes. Bioresour Technol 71(3):211–215. https://doi.org/10.1016/s0960-8524(99)00084-x

Thadathil N, Velappan SP (2014) Recent developments in chitosanase research and its biotechnological applications: a review. Food Chem 150:392–399. https://doi.org/10.1016/j.foodchem.2013.10.083

Ghormade V, Pathan EK, Deshpande MV (2017) Can fungi compete with marine sources for chitosan production? Int J Biol Macromol 104:1415–1421. https://doi.org/10.1016/j.ijbiomac.2017.01.112

Tai C, Li S, Xu Q, Ying H, Huang H, Ouyang P (2010) Chitosan production from hemicellulose hydrolysate of corn straw: impact of degradation products on Rhizopus oryzae growth and chitosan fermentation. Lett Appl Microbiol 51(3):278–284. https://doi.org/10.1111/j.1472-765X.2010.02893.x

Upadhyaya S, Tiwari S, Arora N, Singh DP (2016) Microbial protein: a valuable component for future food security. In: Singh JS, Singh DP (eds) Microbes and environmental management. Studium press, Delhi. https://doi.org/10.13140/rg.2.1.1775.8801

Yadav JSS, Yan S, Ajila CM, Bezawada J, Tyagi RD, Surampalli RY (2016) Food-grade single-cell protein production, characterization and ultrafiltration recovery of residual fermented whey proteins from whey. Food Bioprod Process 99:156–165. https://doi.org/10.1016/j.fbp.2016.04.012

Ferreira JA, Lennartsson PR, Edebo L, Taherzadeh MJ (2013) Zygomycetes-based biorefinery: present status and future prospects. Bioresour Technol 135:523–532. https://doi.org/10.1016/j.biortech.2012.09.064

Souza Filho PF, Zamani A, Taherzadeh MJ (2017) Production of edible fungi from potato protein liquor (PPL) in airlift bioreactor. Fermentation. https://doi.org/10.3390/fermentation3010012

Souza Filho PF, Zamani A, Taherzadeh MJ (2018) Edible protein production by filamentous fungi using starch plant wastewater. Waste Biomass Valoriz. https://doi.org/10.1007/s12649-018-0265-2

Anupama Ravindra P (2000) Value-added food: single cell protein. Biotechnol Adv 18(6):459–479. https://doi.org/10.1016/S0734-9750(00)00045-8

EFFPA (European Former Foodstuff Processor Association). Reducing food waste. https://www.effpa.eu/reducing-food-waste/. Accessed 10 Mar 2018

Karimi S, Soofiani NM, Mahboubi A, Taherzadeh MJ (2018) Use of organic wastes and industrial by-products to produce filamentous fungi with potential as aqua-feed ingredients. Sustainability 10(9):1–19. https://doi.org/10.3390/su10093296

Ministerio de Agricultura, Alimentación y Medio Ambiente. Estimación de precios de piensos: Mayo 2016 (Semanas 18 a 21) (2016). Gobierno de España

Büyükkileci AO (2007) Investigation of sugar metabolism in Rhizopus oryzae. Middle East technical University, Ankara

Satari B, Karimi K, Taherzadeh MJ, Zamani A (2016) Co-production of fungal biomass derived constituents and ethanol from citrus wastes free sugars without auxiliary nutrients in airlift bioreactor. Int J Mol Sci 17(3):302. https://doi.org/10.3390/ijms17030302

Lennartsson PR (2012) Zygomycetes and cellulose residuals: hydrolysis, cultivation and applications. Chalmers University of Technology, Göteborg

Gajdhane SB, Bhagwat PK, Dandge PB (2016) Statistical media optimization for enhanced production of α-galactosidase by a novel Rhizopus oryzae strain SUK. Biocatal Agric Biotechnol 8:301–309. https://doi.org/10.1016/j.bcab.2016.08.016

Karmakar M, Ray RR (2011) A statistical approach for optimization of simultaneous production of beta-glucosidase and endoglucanase by Rhizopus oryzae from solid-state fermentation of water hyacinth using central composite design. Biotechnol Res Int 2011:574–983. https://doi.org/10.4061/2011/574983

Ibarruri J, Hernández I (2018) Rhizopus oryzae as fermentation agent in food derived sub-products. Waste Biomass Valoriz 9(11):2107–2115. https://doi.org/10.1007/s12649-017-0017-8

Zamani A, Edebo L, Sjostrom B, Taherzadeh MJ (2007) Extraction and precipitation of chitosan from cell wall of zygomycetes fungi by dilute sulfuric acid. Biomacromol 8(12):3786–3790. https://doi.org/10.1021/bm700701w

Centro de Investigación y Control de la Calidad (1985) Análisis de alimentos: métodos oficiales y recomendados por el Centro de Investigación y Control de la Calidad. Ministerio de Sanidad y Consumo, Spain

Ferreira JA, Lennartsson PR, Niklasson C, Lundin M, Edebo L, Taherzadeh MJ (2012) Spent sulphite liquor for cultivation of an edible Rhizopus sp. Bioresources 7(1):173–188

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37(8):911–917. https://doi.org/10.1139/o59-099

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428. https://doi.org/10.1021/ac60147a030

Waghmare AG, Salve MK, LeBlanc JG, Arya SS (2016) Concentration and characterization of microalgae proteins from Chlorella pyrenoidosa. Bioresour Bioprocess. https://doi.org/10.1186/s40643-016-0094-8

FAO/WHO/UNU Expert Consultation (2007) Protein and amino acid requirements in human nutrition, WHO Technical Report Series, vol 935. Geneva

Asadollahzadeh M, Ghasemian A, Saraeian A, Resalati H, Taherzadeh M (2018) Production of fungal biomass protein by filamentous fungi cultivation on liquid waste streams from pulping process. Bioresources 13(1):5013–5031. https://doi.org/10.15376/biores.13.3.5013-5031

Anderson JM, Whitcomb JP (2004) RSM simplified: optimizing processes using response surface methods for design of experiments. Taylor & Francis Group, New York. https://doi.org/10.4324/9781482293777

Chatterjee S, Guha AK (2014) A study on biochemical changes during cultivation of Rhizopus oryzae in deproteinized whey medium in relation to chitosan production. Lett Appl Microbiol 59(2):155–160. https://doi.org/10.1111/lam.12259

Das RK, Brar SK, Verma M (2015) A fermentative approach towards optimizing directed biosynthesis of fumaric acid by Rhizopus oryzae 1526 utilizing apple industry waste biomass. Fungal Biol 119(12):1279–1290. https://doi.org/10.1016/j.funbio.2015.10.001

Meussen BJ, de Graaff LH, Sanders JP, Weusthuis RA (2012) Metabolic engineering of Rhizopus oryzae for the production of platform chemicals. Appl Microbiol Biotechnol 94(4):875–886. https://doi.org/10.1007/s00253-012-4033-0

van Leeuwen J, Rasmussen ML, Sankaran S, Koza CR, Erickson DT, Mitra D, Jin B (2012) Fungal treatment of crop processing wastewaters with value-added co-products. In: Gopalakrishnan K, van Leeuwen J, Brown R (eds) Sustainable bioenergy and bioproducts. Green energy and technology. Springer, London, pp 13–44. https://doi.org/10.1007/978-1-4471-2324-8_2

Liu Y, Liao W, Chen S (2008) Co-production of lactic acid and chitin using a pelletized filamentous fungus Rhizopus oryzae cultured on cull potatoes and glucose. J Appl Microbiol 105(5):1521–1528. https://doi.org/10.1111/j.1365-2672.2008.03913.x

Roa Engel CA, Straathof AJJ, Zijlmans TW, van Gulik WM, van der Wielen LAM (2008) Fumaric acid production by fermentation. Appl Microbiol Biotechnol 78(3):379–389. https://doi.org/10.1007/s00253-007-1341-x

Magnuson JK, Lasure LL (2004) Organic acid production by filamentous fungi. In: Tkacz JS, Lange L (eds) Advances in fungal biotechnology for industry, agriculture, and medicine. Springer, Boston, pp 307–340. https://doi.org/10.1007/978-1-4419-8859-1_12

Foster JW, Carson SF, Anthony DS, Davis JB, Jefferson WE, Long MV (1949) Aerobic formation of fumaric acid in the mold Rhizopus nigricans-synthesis by direct C-2 condensation. Proc Natl Acad Sci USA 35(12):663–672. https://doi.org/10.1073/pnas.35.12.663

Zhang K (2012) Fumaric acid fermentation by Rhizopus oryzae with integrated separation technologies. The Ohio State University, Columbus

Chatterjee S, Chatterjee BP, Guha AK (2008) Enhancement of growth and chitosan production by Rhizopus oryzae in whey medium by plant growth hormones. Int J Biol Macromol 42(2):120–126. https://doi.org/10.1016/j.ijbiomac.2007.10.006

Ye X, Yoshida S, Ng TB (2000) Isolation of lactoperoxidase, lactoferrin, α-lactalbumin, β-lactoglobulin B and β-lactoglobulin A from bovine rennet whey using ion exchange chromatography. Int J Biochem Cell Biol 32(11):1143–1150. https://doi.org/10.1016/S1357-2725(00)00063-7

Miles RD, Chapman FA (2006) The benefits of fish meal in aquaculture diets. Institute of Food and Agricultural Sciences, University of Florida, Florida

Nitayavardhana S, Khanal SK (2010) Innovative biorefinery concept for sugar-based ethanol industries: production of protein-rich fungal biomass on vinasse as an aquaculture feed ingredient. Bioresour Technol 101(23):9078–9085. https://doi.org/10.1016/j.biortech.2010.07.048

de Blas C, Mateos GG (2013) Necesidades nutricionales para ganado porcino. FEDNA (Fundación Española para el Desarrollo de la Nutrición Animal)

Ferret A, Calsamiglia S, Bach A, Devant M, Fernández C, García-Rebollar P (2008) Necesidades nutricionales para rumiantes de cebo. FEDNA (Fundación Española para el Desarrollo de la Nutrición Animal)

Lall SP, Tibbetts SM (2009) Nutrition, feeding, and behavior of fish. Vet Clin N Am Exot Anim Pract 12(2):361–372. https://doi.org/10.1016/j.cvex.2009.01.005

Yunoki K, Musa R, Kinoshita M, Oda Y, Ohnishi M (2004) Determinations of triacylglycerol and fatty acid esters in potato pulp fermented with lactic acid-producing fungus. J Oil Chem Soc Jpn 53(11):565–569. https://doi.org/10.5650/jos.53.565

Innes JK, Calder PC (2018) Omega-6 fatty acids and inflammation. Prostaglandins Leukot Essent Fatty Acids 132:41–48. https://doi.org/10.1016/j.plefa.2018.03.004

Kapoor R, Huang YS (2006) Gamma linolenic acid: an antiinflammatory omega-6 fatty acid. Curr Pharm Biotechnol 7(6):531–534

Guerzoni ME, Lanciotti R, Cocconcelli PS (2001) Alteration in cellular fatty acid composition as a response to salt, acid, oxidative and thermal stresses in Lactobacillus helveticus. Microbiology (UK) 147:2255–2264. https://doi.org/10.1099/00221287-147-8-2255

Oda Y, Yajima Y, Kinoshita M, Ohnishi M (2003) Differences of Rhizopus oryzae strains in organic acid synthesis and fatty acid composition. Food Microbiol 20(3):371–375. https://doi.org/10.1016/s0740-0020(02)00131-4

Oliva-Teles A (2012) Nutrition and health of aquaculture fish. J Fish Dis 35(2):83–108. https://doi.org/10.1111/j.1365-2761.2011.01333.x

Mourente G, Tocher DR (1993) Incorporation and metabolism of 14C-labelled polyunsaturated fatty acids in juvenile gilthead sea bream Sparus aurata L. in vivo. Fish Physiol Biochem 10(6):443–453. https://doi.org/10.1007/bf00004599

Ghioni C, Tocher DR, Bell MV, Dick JR, Sargent JR (1999) Low C18 to C20 fatty acid elongase activity and limited conversion of stearidonic acid, 18:4(n–3), to eicosapentaenoic acid, 20:5(n–3), in a cell line from the turbot, Scophthalmus maximus. Biochimica et Biophysica Acta (BBA) Mol Cell Biol Lipids 1437(2):170–181. https://doi.org/10.1016/s1388-1981(99)00010-4

Bankefors J, Kaszowska M, Schlechtriem C, Pickova J, Brännäs E, Edebo L, Kiessling A, Sandström C (2011) A comparison of the metabolic profile on intact tissue and extracts of muscle and liver of juvenile Atlantic salmon (Salmo salar L.)—application to a short feeding study. Food Chem 129(4):1397–1405. https://doi.org/10.1016/j.foodchem.2011.05.081

Abro R, Moazzami AA, Lindberg JE, Lundh T (2014) Metabolic insights in Arctic charr (Salvelinus alpinus) fed with Zygomycetes and fish meal diets as assessed in liver using nuclear magnetic resonance (NMR) spectroscopy. Int Aquat Res. https://doi.org/10.1007/s40071-014-0063-9

Edebo L (2009) Zygomycetes for fish feed. EE.UU. Patent no 20090136617

Lázaro R, Mateos GG (2008) Necesidades nutricionales para avicultura: pollos de carne y aves de puesta. FEDNA (Fundación Española para el Desarrollo de la Nutrición Animal)

National Research Council (1998) Composition of feed ingredients. In: Nutrient requirements of swine. The National Academy Press, Washington DC, pp 124–142. https://doi.org/10.17226/6016

FEDNA. Tablas de ingredientes para piensos: harina de pescado 70/9/13. http://fundacionfedna.org/ingredientes_para_piensos/harina-de-pescado-70913. Accessed 18 Nov 2018

FEDNA. Tablas de ingredientes para piensos: Harina de soja 44% PB. http://fundacionfedna.org/ingredientes_para_piensos/harina-de-soja-44-pb. Accessed 18 Nov 2018

Acknowledgements

Authors thank Vascolac S.L, and Indulleida S.A. for providing the food industry by-products. This work was funded by the Basque Government (Department of economic development and competitiveness and infrastructure development, agriculture, fisheries and food policy). This paper is contribution no 909 from AZTI (Food Research).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ibarruri, J., Hernández, I. Valorization of cheese whey and orange molasses for fungal biomass production by submerged fermentation with Rhizopus sp.. Bioprocess Biosyst Eng 42, 1285–1300 (2019). https://doi.org/10.1007/s00449-019-02127-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-019-02127-4