Abstract

Thermophilic fungi are potential sources of thermostable enzymes and other value added products. Present study has focused on optimization of different physicochemical parameters for production of thermostable cellulases and xylanase by Thermoascus aurantiacus RCKK under SSF. Enzyme production was supported maximally on wheat bran fed with 20 % inoculum, at initial pH 5, temperature 45 °C and moisture ratio 1:3. The supplementation of wheat bran with yeast extract, Tween-80 and glycine further improved enzyme titres (CMCase 88 IU/g, FPase 15.8 IU/g, β-glucosidase 25.3 IU/g and xylanase 6,543 IU/g). The crude enzymes hydrolyzed phosphoric acid-swollen wheat straw, avicel and untreated xylan up to 74, 71 and 90 %, respectively. In addition, T. aurantiacus RCKK produced antioxidants as fermentation by-products with significant %DPPH∙ scavenging, FRAP and in vivo antioxidant capacity against H2O2-treated Saccharomyces cerevisiae. These capabilities show that it holds potential to exploit crop by-products for providing various commodities.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Continuous depletion in non-renewable energy resources has attracted researchers to exploit renewable energy resources, especially secondary agriculture resources such as lignocellulosic biomass, which have potential to be converted to various valuable products [1]. Lignocellulose is the most abundantly available and sustainable raw material, it consists of cellulose, a homopolymer of glucose; hemicellulose, a heteropolymer of pentoses and hexoses; and lignin, an amorphous polymer of phenyl propanoid units [2]. Enzymatic release of monosaccharides from cellulose and hemicelluloses is mediated by glycoside hydrolases (cellulases and xylanases mostly). Cellulases and xylanases selectively catalyze reactions that produce smaller carbohydrate (monosaccharides) units from polysaccharides which eventually could be converted to various products [3].

Among glycoside hydrolases, cellulases hold more potential in deconstruction of cellulose to hexose sugars, which in turn can easily be converted to ethanol. Cellulase is a family of at least three groups of enzymes: first endoglucanases (EC 3.2.1.4) which act randomly on soluble and insoluble cellulose chains; second exoglucanases (cellobiohydrolases EC 3.2.1.91) that act to liberate cellobiose from the reducing and non-reducing ends of cellulose chains and finally, β-glucosidases (EC 3.2.1.21) which liberate glucose from cellobiose. Similarly, Xylanases (EC. 3.2.1.8) act on xylan, present in wood biomass and release pentose sugars.

Majority of cellulases and xylanases known are from mesophilic microorganisms and act optimally in mesophilic range, i.e., 40–50 °C. However, for efficient utilization of lignocellulose, thermostable enzymes possess certain advantages, such as more compatible with pretreatment strategies [4], increased flexibility for process parameters [5], reduced risk of contamination, easy storage and transportation, and finally higher stability allows extended hydrolysis time which subsequently reduces the enzyme requirement and cost [5]. These advantages are significant because approximately one-half of the projected process costs in biomass conversions are estimated to be associated with enzyme production, and all these benefits attributed to thermostable enzymes, will result in an improvement to the overall economy of the process [6].

Currently, strategies for the usage of lignocellulosic material are focused on individual production chains, mainly its conversion to biofuels. However, for an economic and environmental perspective, optimal utilization of renewable sources can be achieved by generating multiple products following an integrated biorefinery strategy, in which material flows are combined or coupled so that the residues of the previous processes become an input for the next one [7]. Thus, following a biorefinery approach some industrially important enzymes and bioactive compounds can be produced together in a single process, and this in turn can help in improving economic viability of the process.

The filamentous fungi are reported to synthesize secondary metabolites in addition to industrially important glycosyl hydrolases [8]. Among thermophilic fungi, an ascomycetous fungus Thermoascus aurantiacus, isolated first time by Hugo Miehe in 1907 from self heating hay, was reported to produce cellulases and xylanases but has not been exploited to its fullest potential. Keeping this in view, T. aurantiacus RCKK isolated from Aravali forest area of University of Delhi South Campus, New Delhi was studied for hyper production of cellulase and xylanase. In addition, the fungus was also observed to produce bioactive compounds (antioxidants) in medium during preparation of fungal inocula for enzyme production. The crude fungal enzymes were also evaluated for their potential in hydrolysis of cellulose and hemicellulose. This is a first report of its kind, in which cheaper production of cellulase, xylanase and bioactive compounds in a single process has been done and further their utility has also been evaluated. Here we report an economic method for production of cellulase, xylanase and bioactive compounds in a single process and their application has been evaluated.

Materials and methods

Raw materials

Avicel, carboxy methyl cellulose (CMC), birchwood xylan, oat spelt xylan 2,2′-diphenyl-1-picryl-hydrazyl (DPPH), 2,4,6-tri(2-pyridyl)-triazine (TPTZ), phenolic acid standards such as gallic acid, protocatechuic acid, caffeic acid, 4-hydroxy benzoic acid, 4-hydroxy 3-methoxy benzoic acid, trans-cinnamic acid and ferulic acid were procured from Sigma-Aldrich (USA), while cellulose powder was obtained from Hi-Media laboratories (India). MGYP (malt glucose yeast extract and peptone media) was prepared in the lab using HI-Media laboratories’ media components (malt extract 3 g/L, glucose 20 g/L, yeast extract 3 g/L, peptone 5 g/L). DMSO (dimethylsulfoxide) is of cell culture grade (Fishers). Phosphoric acid-swollen cellulose (PASC) and phosphoric acid-swollen wheat straw was prepared by treating avicel and wheat straw with phosphoric acid as reported elsewhere [9] and used directly. All other chemicals were of analytical grade.

Organism and culture conditions

The fungal isolate RCKK was isolated from Aravali forest area of University of Delhi South Campus, New Delhi and maintained by periodical subculturing on potato dextrose agar (PDA) at 45 °C and stored at 4 °C.

Identification of the fungal isolate

Genomic DNA isolation

Fungal isolate was grown in potato dextrose broth at 45 °C under liquid static condition for 72 h. The mycelium was harvested and processed as described by Kuhad et al. [10]. Further, mycelium was crushed with liquid nitrogen and processed for genomic DNA isolation as per manufacture’s protocol using mdi genomic DNA isolation Kit (mdi Corporation, India).

Phylogenetic studies of the fungus

ITS sequence of fungal isolate RCKK was amplified by PCR using pITS-1 (5′-TCCGTAGGTGAACCTGCGG-3′) and pITS-4 (5′-TCCTCC GCTTATTGATATGC-3′) primer pair. Following PCR program composed of an initial denaturation at 94 °C (4 min), followed by 30 cycles of denaturation at 94 °C (1 min), primer annealing at 58 °C (30 s) and elongation at 68 °C (1 min). A final elongation time of 10 min was provided at 68 °C for end filling. The PCR product was eluted using gel extraction kit (mdi Corporation, India) and sequenced. Sequence obtained was compared with ITS sequences available in Gen Bank, by BLAST analysis and deposited to Gen Bank. Further dendrogram was constructed using MEGA-5 [11] program to establish the taxonomic rank of the fungus.

Enzyme production under solid-state fermentation

Solid-state fermentation was carried out in 250 mL Erlenmeyer flasks, each having 5.0 g of dry wheat bran moistened with mineral salt solution (g/L:Ca(NO3)2.4H2O 0.5; KH2PO4 0.5; MgSO4.7H2O 0.5 and pH 7) to attain final substrate-to-moisture ratio of 1:3. The flasks were sterilized by autoclaving at 121 °C (15 psi), and thereafter cooled to room temperature and inoculated with 5 % (v/w) fungal biomass. The contents of the flasks were mixed well with sterilized glass rod to distribute the inocula throughout the substrate and incubated at 45 °C. Fermented wheat bran (mycobran) was aseptically removed from flasks after an appropriate interval, harvested in 50 mL sodium citrate buffer (50 mM, pH 4.8) and shaken gently for 45 min. The mycobran was squeezed through muslin cloth for maximizing the enzyme extraction and enzyme extract centrifuged at 10,000g at 4 °C for 10 min. The enzyme solution thus obtained was assayed for cellulase and xylanase activities.

Preparation of inocula

Different types of inocula such as fungal disc (4 × 8 mm diameter), spore suspension (5 % v/w), crushed mat (5 % v/w) were applied for enzyme production. Fungal discs were cut with a borer from a 48-h-grown culture plate. A spore suspension was prepared from fully grown fungal culture slants by adding 5 mL 0.1 % (v/v) Tween-80 to each slant. To produce crushed mat inoculum, each Erlenmeyer flask (250 mL) containing 50 mL of potato dextrose broth (PDB) was inoculated with four mycelial discs (0.8 cm diameter each) and incubated at 45 °C under static cultivation conditions for 48 h. The inoculum mat thus obtained was homogenized with pestle and mortar under sterile conditions and used as inoculum.

Optimization of cellulase and xylanase production

The cellulases and xylanase production by the fungus was optimized following one factor at a time (OFAT) method. The effect of various factors such as initial pH (3.0–10.0), incubation temperature (40–55 °C), substrate-to-moisture ratio (1:1–1:4), carbon and nitrogen sources, surfactants, amino acids, inoculum size and inoculum age on cellulase and xylanase production was studied.

Thermostability of crude enzyme

The concentrated crude enzyme extract obtained from SSF was kept at higher temperature range (50–80 °C) for 6 h and then kept on ice for 10 min. Thereafter, it was centrifuged at 10,000g at 4 °C and the supernatant was run on SDS PAGE.

Extraction of bioactive compounds

The PDB medium after separation of the fungal mat was processed to isolate the bioactive compounds by extraction with ethyl acetate. The upper organic phase was collected and evaporated. The dried material was dissolved in DMSO/methanol as per required assay. Its antioxidant activity was evaluated using DPPH and FRAP assay.

In vivo antioxidant capacity using S. cerevisiae

Primary culture of S. cerevisiae was prepared by inoculating single colony in 50 mL of MGYP and incubated at 30 °C for 24 h at 150 rpm. The primary culture was inoculated (1 % final concentration) in culture tubes containing 5 mL of MGYP media and incubated at 30 °C and 150 rpm. After 6 h of incubation, 100 µL of ascorbic acid (10 mg/mL) as positive control and fungal extract (26 mg/mL) dissolved in DMSO were added. Then 10 µL of hydrogen peroxide (H2O2) as oxidant was added in each tube. Growth of the yeast was monitored measuring absorbance at 600 nm at the end of 20 h. Effect of phenolic extracts in the presence of oxidants on the net growth of yeast cells was determined according to the following equation [12].

where A yeast growth = net growth of H2O2-induced yeast cells after treatment with fungal extract, A control = absorbance of yeast cells in presence of H2O2, A test sample = absorbance of yeast cells in presence of H2O2 and fungal extracts.

TLC analysis

The fungal extract was filtered through 0.45 μm Supor®-450 membrane disc filters (Pall Gelman Laboratory, USA) and analyzed by thin layer chromatography (TLC). Choloroform:methanol:formic acid (85:15:1; v/v/v) was used as mobile phase. Mixture of different phenolics (1 mg/mL) was used as standard (gallic acid, protocatecheuic acid, 4-hydroxybenzoic acid; 4-hydroxy-3-methoxybenzoic acid, caffeic acid, ferulic acid, trans-cinnamic acid).

Enzymatic hydrolysis

The crude enzyme preparation was tested for its saccharification efficiency at 3 % substrate consistency using avicel, carboxymethyl cellulose (CMC), cellulose power, phosphoric acid-swollen avicel (PASC) and phosphoric acid-treated wheat straw. While xylan hydrolysis ability was tested at 4 % substrate consistency of birchwood and oat spelt xylan. 10 IU/g FPase and 1,000 IU/g of xylanase were used for the hydrolysis of cellulose and xylan, respectively. The reaction was carried out in Na-citrate buffer (pH 5) at 60 °C. The saccharification efficiency of crude enzyme preparation was calculated as reported elsewhere [13].

Analytical methods

The total cellulase (filter paper cellulase, FPase), carboxymethyl cellulase (CMCase) activities were determined in accordance with the International Union of Pure and Applied Chemistry procedures as reported by Ghose [14]. While, β-glucosidase and xylanase activities were measured using methods used by Wood and Bhat [15] and Kapoor et al. [16], respectively. All enzyme assays were carried out at 60 °C. One unit of enzyme activity was defined as the amount of enzyme required to liberate 1 µmol of glucose, xylose or p-nitrophenol, from the appropriate substrate, per mL per min under the assay conditions. Reducing sugar content was measured following DNSA method of Miller [17].

The free radical scavenging activity of different fractions was measured by the DPPH radical scavenging method according to Brand-Williams et al. [18]. DPPH solution (0.1 mM) in methanol was added to 0.5 mL of properly diluted phenolic extracts. The change in absorbance at 515 nm was measured after 30 min of incubation. The DPPH radical scavenging activity of fungal extract was calculated according to the following equation.

where, AbC denotes absorbance of control and AbS stands for absorbance in the presence of the test compound.

FRAP was estimated by the method of Wong et al. [19] with slight modifications. Extract (100 μL) at different concentrations (0.13–2.6 mg/mL) was mixed with 1.5 mL of FRAP reagent (10 parts of 300 mM sodium acetate buffer at pH 3.6, 1 part of 10 mM TPTZ solution and 1 part of 20 mM FeCl3.6H2O solution and incubated at 37 °C in a water bath for 30 min. Increase in absorbance was measured at 593 nm. FRAP values were expressed in terms of mM ascorbic acid equivalent (AAE)/mg using l-ascorbic acid as standard.

Results and discussion

Identification of the fungal isolate

The fungal isolate RCKK was identified based on the sequence variation present in internal transcribing spacer (ITS) region. The sequence was analyzed using blast (NCBI), which showed that it has 100 % similarity with T. aurantiacus. Phylogenetic analysis also confirmed the maximum closeness of the isolate with T. aurantiacus (supplementary data). Thus, the fungal isolate was identified as T. aurantiacus and named as T. aurantiacus RCKK. The sequence had been deposited in NCBI Genbank database with accession number: JN676149.

Time course of cellulase and xylanase production

T. aurantiacus RCKK grown under SSF started producing cellulases and xylanase after 48 h of incubation (Fig. 1a). However, the maximum production of all three cellulases and xylanase peaked at 72 h of incubation (8.3 IU/g of FPase, 45.3 IU/g of CMCase IU/g, 14.3 IU/g of β-glucosidase and 4,000 IU/g of xylanase). Further increase in incubation caused drying of the medium and brought down enzyme production. The comparison of cellulase production by different strains of T. aurantiacus and other fungi from earlier reports (Table 1) revealed that the enzyme production by T. aurantiacus RCKK is much higher. However, the exact comparison of cellulase and xylanase production with other reports could be different possibly because of difference in assay procedures and conditions followed by different laboratories. Moreover, in the present study the spent broth also has been used for the extraction of antioxidant compounds along with enzyme production. This signifies the use of whole fermentation broth for dual applications and thus fungus could be used for the production of multiple useful products.

a Time course of cellulase and xylanase production using T. aurantiacus RCKK under SSF. b Effect of pH on cellulase and xylanase production using T. aurantiacus RCKK under SSF. c Effect of different lignocellulosic substrate on cellulase and xylanase production using T. aurantiacus RCKK under SSF. WB wheat bran, CS cotton stocks, CSP cotton stem part, RS rice straw, SB sugar cane bagasse

Preparation of different types of inocula

Different types of inocula such as fungal disc, spore suspension, crushed mat were used for cellulase production. The use of crushed fungal mat as inoculums resulted in higher fungal growth and enzyme titers as compared to procedures using spore suspension and fungal discs (Table 2). Deswal et al. [20] have also reported maximum production of cellulase under SSF when wheat bran was inoculated with fungal mat. The choice of inocula has been reported to influence the minimal temperature of growth of thermophilic fungi [21] and in turn might be affecting enzyme production.

Effect of physiological and nutritional parameters on cellulase and xylanase production

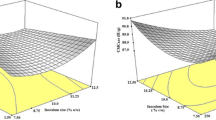

Temperature is one of the most important physical variables affecting solid-state fermentation [22]. The optimization of incubation temperature for production of cellulases from T. aurantiacus RCKK under SSF conditions revealed that the enzyme production gradually increased from 40 to 45 °C (Table 2) and maximum production of all the four enzymes viz. CMCase (60.3 IU/g), FPase (10.4 IU/g), β-glucosidase (20.3 IU/g) and xylanase (3,954 IU/g) was achieved at 45 °C, thereafter the production declined. This may be attributed to the release of more proteases from dead cells and folding deformity while translation of the protein [23]. Kalogeris et al. [24] also reported the decrease in enzyme production on increasing the temperature beyond 50 °C.

The pH of the medium is one of the most critical environmental parameters affecting the mycelial growth, enzyme production and transport of various components across the cell membrane [20, 25]. The enzyme production by T. aurantiacus RCKK was also tested at different pH ranging from 3.0 to 9.0. Fungus produced maximum CMCase (70.1 IU/g), FPase (11.8 IU/g), β-glucosidase (20.5 IU/g) and xylanase (4,163 IU/g) at initial medium pH 5.0 (Fig. 1b). Increasing the initial pH of the medium from 5.0 to 7.0 slightly decreased the enzyme production and on further increase in pH caused almost 60 % reduction in enzyme production. Kalogeris et al. [24] and Narra et al. [26] have also observed the effect of initial medium pH on the production of cellulases under SSF.

The moisture level at which free liquid occurs shows a discrepancy among substrates depending on their water holding/binding characteristics [27]. Low moisture may reduce the solubility of lignin and swelling capacity of substrate causing high water stress, and consequently decrease the growth and enzyme production [28]. This study has shown that an increase in the initial moisture ratio from 1:1 to 1:3 greatly influenced the enzyme production (Table 2), However, any further increase in moisture level in SSF lowered the same. This may be attributed to particles sticking, limited gas exchange and higher vulnerability to bacterial contamination, while low moisture leads to reduced solubility of nutrients and substrate swelling [29]. Pal and Khanum [30] have reported maximum production of xylanase at 70 % moisture ratio and either low or high initial moisture significantly decreased the enzyme production.

The inoculum size and age also play pivotal role in fungal growth and enzyme production. On one hand lower amount of inoculum is not sufficient for optimal fungal growth and on other hand a higher level may cause competitive inhibition [31]. 20 % v/w of 72-h old inoculum was found optimum for cellulase and xylanase production (Table 2).

Extracellular enzyme production largely depends on the constituents of the medium. Solid substrate provides maximum necessary nutrients to the growing microorganism for optimal function [32].Various lignocellulosic substrates were tested as carbon source for their effect on production of hydrolases. Among carbon sources tested, wheat bran was observed to induce maximum production of CMCase (71.2 IU/g), FPase (12.3 IU/g), β-glucosidase (22.4 IU/g) and xylanase (4,562 IU/g) (Fig. 1c). According to Sun et al. [33] wheat bran has all nutrients required and probably some oligosaccharides which stimulate the production of biomass hydrolyzing enzymes. The unsuitability of the other lignocellulosic substrates to support enzyme production under SSF might be because of their inappropriate physical properties like particle size, geometry and compactness of the substrate [22].

Different nitrogen sources differently affected cellulase production by T. aurantiacus RCKK (Table 3). Among organic nitrogen sources, yeast extract stimulated maximum enzyme production (CMCase 74.2 IU/g, FPase 13.4 IU/g, β-glucosidase 23.2 IU/g and xylanase 6,245 IU/g). Yeast extract is a complex nitrogen source, which has growth factors, blend of amino acids, peptides, water soluble vitamins which affect fungal growth and enzyme production [34]. Recently similar observations have also been made by Gautam et al. and Mridula et al. [35, 36] in case of cellulase production by Trichoderma virdae and Aspergillus niger, respectively.

Surfactants probably act by increasing the permeability of the cell membrane, allowing more rapid secretion of enzymes [20, 37]. Moreover, this increase may be attributed to the release of non-specific, unproductive enzyme adsorption on the solid substrate used under SSF [38]. In present study, Tween-80 maximally enhanced CMCase (82.1 IU/g), FPase (14.3 IU/g), β-glucosidase (24.3 IU/g) and xylanase (6,545 IU/g) followed by Triton X-100 and Tween-20 (Table 3). Some of the surfactants did not support the enzyme production positively, which might be due to instability of various proteins in the presence of these surfactants.

Among various amino acids and their analogs tested, the maximum enzyme production was obtained in the presence of glycine (CMCase 88 IU/g, FPase 15.8 IU/g, β-glucosidase 25.3 IU/g and xylanase 6,543 IU/g) (Table 3). Our results are in accordance with an earlier report on cellulase production [20] where increase in cellulase production has been observed in presence of glycine. Dhawan and Kuhad [39] also found similar effect of glycine in case of laccase production by Cythus bulleri under SSF. Changes in the membrane permeability in presence of glycine had been responsible for release of enzymes extracellularly [39].

In comparison to the enzyme production under unoptimised medium (FPase 54.24 %, CMCase 51.47 %, β-glucosidase 56.52 % and xylanase 61 %) more than 50 % increase in the enzyme production has been achieved after optimization of enzyme production by T. aurantiacus RCKK following OFAT method.

Thermostability of the hydrolases secreted by T. aurantiacus RCKK

The hydrolytic enzymes produced by T. aurantiacus RCKK under SSF were found stable at 70 °C up to 6 h (supplementary data). However, after 6 h at 80 °C, degradation of the proteins was noticed. This is well in agreement with earlier reports [40].

Antioxidant activity of the bioactive compounds extracted from spent medium

T. aurantiacus RCKK was grown in PDB for inocula production. The spent broth after separating fungal mass, when analyzed was found to contain some metabolites produced by fungus after 72 h. The culture-free ethyl acetate extract was found to possess antioxidant properties when tested using DPPH∙ scavenging properties and FRAP, the two most commonly used assays.

The %DPPH∙ scavenging activities of colored compounds produced by T. aurantiacus RCKK at different concentrations are depicted in Fig. 2a. Increasing the concentration of bioactive compound (5.2–20.8 mg/mL) the %DPPH∙ scavenging activity enhanced from 14.37 to 51.8 % (Fig. 2a). It exhibited an IC50 value of 17.9 mg/mL, which indicated that it had 50 %DPPH∙ scavenging activity at 17.9 mg/mL concentration. The fungal extract showed maximum 0.51 mM AAE FRAP at the 2.6 mg/mL concentration (Fig. 2b) which revealed that fungal extract had reducing power as well as electron donor capability that increased (0.03–0.51 mM AAE) with the increase in concentration from 0.13 to 2.6 mg/mL.

The fungal extract was also evaluated for its in vivo antioxidant activity against H2O2 in yeast cells. Figure 3 shows that the fungal extract (26 mg/mL) showed almost similar % yeast cell survival as ascorbic acid standard (ascorbic acid C; 10 mg/mL). Thin layer chromatogram of the filtered fungal extract revealed the presence of two clear and distinct bands when observed under UV light (Fig. 4). However, it did not match with any of the phenolic acid standards ran on TLC but it might be polymer of phenolic compounds, but further it needs to be identified.

TLC profile of fungal extract under UV light (1) Phenolic standards 1 mg/mL (2) fungal extract (GA gallic acid, PCA protocatecheuic acid, HBA 4-hydroxybenzoic acid; HMBA 4-hydroxy-3-methoxybenzoic acid, CA caffeic acid, FA ferulic acid, TCA trans-cinnamic acid, SU unknown compound in short wave UV, LU unknown compound in long wave UV)

Application of cellulase and xylanase in hydrolysis of cellulose and xylan

The crude enzyme preparation from T. aurantiacus RCKK hydrolyzed Phosphoric acid-treated wheat straw maximally (74 %) in 24 h and PASC up to 71 % followed by CMC, cellulose power and avicel up to 22, 8 and 4 %, respectively, in 36 h (Table 4). It showed that the crude enzyme solution was quite efficient in hydrolysis of phosphoric acid-treated wheat straw (feedstock) as well as amorphous form of avicel. This could be because of phosphoric acid treatment, which might have resulted in generation of more reducing ends in wheat straw and PASC, Thus, making available more attackable sites for the exoglucanase [41]. Moreover, efficient hydrolysis of pretreated wheat straw also suggests that the enzymes system is resilient to pretreatment degradation products as well. Interestingly the crude enzyme solution containing cellulases and xylanases from T. aurantiacus RCKK hydrolyzed both the xylans by almost 90 % in 48 h (Table 4). The results demonstrate the efficiency of the crude enzyme preparation and could be used for hydrolysis of crop residues to fermentable sugars.

Conclusion

In the present study, T. aurantiacus RCKK turns out to be a potential fungus with the ability to produce all the three thermostable cellulases and xylanase, which could be used for exploiting crop residues for biofuel production. Moreover, the fungus was also observed to produce some antioxidant compounds as byproduct of its inoculum preparation process. However, the enzyme production may be enhanced using statistical approaches and modern molecular biology techniques.

References

Kocabas A, Ogel Z-B, Bakir U (2014) Xylanase and itaconic acid production by Aspergillus terreus NRRL 1960 within a biorefinery concept. Ann Microbiol 64:75–84

Kuhad R-C, Singh A, Eriksson K-E (1997) Microorganisms and enzymes involved in the degradation of plant fiber cell walls. Adv Biochem Eng Biotechnol 57:45–125

Olofsson K, Wiman M, Lidén G (2010) Controlled feeding of cellulases improves conversion of xylose in simultaneous saccharification and co-fermentation for bioethanol production. J Biotechnol 145:168–175

Szijártó N, Siika-aho M, Tenkanen M, Alapuranen M, Vehmaanperä J, Réczey K, Viikari L (2008) Hydrolysis of amorphous and crystalline cellulose by heterologously produced cellulases of Melanocarpus albomyces. J Biotechnol 136:140–147

Viikari L, Alapuranen M, Puranen T, Vehmaanperä J, Siika-Aho M (2007) Thermostable enzymes in lignocellulose hydrolysis. Advances Biochem Eng Biotechnol 108:121–145

Haki G-D, Rakshit S-K (2003) Developments in industrially important thermostable enzymes: a review. Bioresour Technol 89:17–34

Kamat S, Khot M, Zinjarde S, Ravikumar A, Namdeo W (2013) Coupled production of single cell oil as biodiesel feedstock, xylitol and xylanase from sugarcane bagasse in a biorefinery concept using fungi from the tropical mangrove wetlands. Bioresour Technol 135:246–253

Yu H-J, Keller N (2005) Regulation of secondary metabolism in filamentous fungi. Ann Rev Phytopathol 43:437–458

Zhang J, Zhang J, Lin L, Chen T, Zhang J, Liu S, Li Z, Ouyang P (2009) Dissolution of microcrystalline cellulose in phosphoric acid—molecular changes and kinetics. Molecules 14:5027–5041

Kuhad R-C, Kapoor R-K, Lal R (2004) Improving the yield and quality of DNA isolated from white-rot fungi. Folia Microbiol 49:112–116

Tamura K, Peterson D, Peterson N, Stecher G, Nei M, Kumar S (2011) MEGA5: molecular evolutionary genetics analysis using maximum likelihood, evolutionary distance, and maximum parsimony methods research resource. Mol Bio Evol 28:2731–2739

Zhang L, Sundar K-R, Sang J-C, Narsimha R, Paul S-T, Ananthanc R, Longvahc T (2012) Antioxidant and immunomodulatory activities of polysaccharides from the roots of Sanguisorba officinalis. Int J Biological Macromol 51:1057–1062

Kuhad R-C, Gupta R, Khasa Y-P, Singh A (2010) Bioethanol production from Lantana camara (red sage): pretreatment, saccharification and fermentation. Bioresour Technol 101:8348–8354

Ghose T-K (1987) Measurements of cellulase activities. Methods Enzymol 59:257–268

Wood TM, Bhat MK (1988) Methods for measuring cellulase activities. In: Wood WA, Kellogg ST (Eds) Methods in Enzymology, vol. 160. Academic Press Inc., London, UK, pp 87–112

Kapoor M, Nair L-M, Kuhad R-C (2008) Cost-effective xylanase production from free and immobilized Bacillus pumilus strain MK001 and its application in saccharification of Prosopis juliflora. Biochem Eng J 38:88–97

Miller L-G (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426

Brand-Williams W, Cuvelier M-E, Berset C (1995) Use of free radical method to evaluate antioxidant activity. Lebensm Wiss Technol 28:25–30

Wong C, Li H, Cheng K, Chen F (2006) A systematic survey of antioxidant activity of 30 Chinese medicinal plants using the ferric reducing antioxidant power assay. Food Chem 97:705–711

Deswal D, Khasa Y-P, Kuhad R-C (2011) Optimization of cellulase production by a brown rot fungus Fomitopsis sp. RCK2010 under solid state fermentation. Bioresour Technol 102:6065–6072

Maheshwari R, Bharadwaj G, Bhat M-K (2000) Thermophilic fungi: their physiology and enzymes. Microbiol Mol Biol Rev 64:461–488

Krishna C (2005) Solid-state fermentation systems—an overview. Crit Rev Biotechnol 25:1–30

Hong F, Meinander N-Q, Jo L-J (2002) Fermentation strategies for improved heterologous expression of laccase in Pichia pastoris. Biotechnol Bioeng 79(4):438–449

Kalogeris E, Christakopoulos P, Katapodis P, Alexiou A, Vlachou S, Kekos D, Macris B-J (2003) Production and characterization of cellulolytic enzymes from the thermophilic fungus Thermoascus aurantiacus under solid state cultivation of agricultural wastes. Process Biochem 38:1099–1104

Mohana S, Shah A, Divecha J, Madamwar D (2008) Xylanase production by Burkholderia sp. DMAX strain under solid state fermentation using distillery spent wash. Bioresour Technol 99:7553–7564

Narra M, Dixit G, Divecha J, Madamwar D, Shah A-R (2012) Production of cellulases by solid state fermentation with Aspergillus terreus and enzymatic hydrolysis of mild alkali-treated rice straw. Bioresour Technol 121:355–361

Shah A-R, Madamwar D (2005) Xylanase production under solid-state fermentation and its characterization by an isolated strain of Aspergillus foetidus in India. Bioresour Technol 21:233–243

Poorna C-A, Prema P (2007) Production of cellulase-free endoxylanase from novel alkalophilic thermotolerant Bacillus pumilus by solid-state fermentation and its application in wastepaper recycling. Bioresour Technol 98:485–490

Hamidi-esfahani Z, Shojaosadati S-A, Rinzema A (2004) Modelling of simultaneous effect of moisture and temperature on A. niger growth in solid-state fermentation. Biochem Eng J 21:265–272

Pal A, Khanum F (2010) Production and extraction optimization of xylanase from Aspergillus niger DFR-5 through solid-state-fermentation. Bioresour Technol 101:7563–7569

Sabu A, Shegal K, Pandey G (2005) Purification and characterization of tannin acyl hydrolase from Aspergillus niger ATCC 16620. Food Technol Biotechnol 43(2):133–138

Soni R, Nazir A, Chadha B-S (2010) Optimization of cellulase production by a versatile Aspergillus fumigatus fresenius strain (AMA) capable of efficient deinking and enzymatic hydrolysis of Solka Floc and bagasse. Ind Crop Prod 31:277–283

Sun X, Liu Z, Qu Y, Li X (2008) The effects of wheat bran composition on the production of biomass-hydrolyzing enzymes by Penicillium decumbens. Appl Biochem Biotechnol 146:119–128

Gupta G, Sahai V, Gupta R-V (2013) Optimization of xylanase production from Melanocarpous albomyces using wheat straw extract and its scale up in stirred tank bioreactor. Ind J Chem Technol 20:282–289

Gautam S-P, Bundela P-S, Pandey AK, Awasthi M-K (2010) Optimization of the medium for the production of cellulase by the Trichoderma viride using submerged fermentation. Int J Environ Sci 1:656–665

Mridula S, Murugamml R (2011) Production of cellulase by Aspergillus niger under submerged and solid state fermentation using coir waste as a substrate, Brazilian. J Microbiol 42:1119–1127

Ahamed A, Vermette P (2010) Effect of mechanical agitation on the production of cellulases by Trichoderma reesei RUT-C30 in a draft-tube airlift bioreactor. Biochem Eng J 49:379–387

Seo J-D, Fujita H, Sakoda A (2011) Effects of non ionic surfactant, Tween-20 on adsorption/desorption of saccharification enzymes onto/from lignocelluloses and saccharification rate. Adsorption 17:813–822

Dhawan S, Kuhad R-C (2002) Effect of amino acids and vitamins on laccase production by the bird’ s nest fungus Cyathus bulleri. Bioresour Technol 84:35–38

Gomes I, Gomes J, Gomes D-J (2000) Simultaneous production of high activities of thermostable endoglucanase and β-glucosidase by the wild thermophilic fungus Thermoascus aurantiacus. Appl Microbiol Biotechnol 53(4):461–468

Anderson W-F, Akin D-E (2008) Structural and chemical properties of grass lignocelluloses related to conversion for biofuels. J Ind Microbiol Biotechnol 355–366

Badhan A-K, Chadha B-S, Kaur J, Saini H-S, Bhat M-K (2007) Production of multiple xylanolytic and cellulolytic enzymes by thermophilic fungus Myceliophthora sp. IMI 387099. Bioresour Technol 98:504–510

Membrillo I, Meneses M, Favela E, Loera O, Sa C (2008) Effect of substrate particle size and additional nitrogen source on production of lignocellulolytic enzymes by Pleurotus ostreatus strains. Bioresour Technol 99:7842–7847

Silva R, Lago E-S, Merheb C-W, Macchione M-M, Park Y-K, Gomes E (2005) Production of xylanase and CMCase on solid state fermentation in different residues by Thermoascus aurantiacus Miehe. Braz J Microbiol 36:235–241

Chandra M-S, Viswanath B, Reddy B-R (2007) Cellulolytic enzymes on lignocellulosic substrates in solid state fermentation by Aspergillus niger. Indian J Microbiol 255760:323–328

Singhania R-R, Sukumaran R-K (2007) Improved cellulase production by Trichoderma reesei RUT C30 under SSF through process optimization. App Biochem Biotechnol 60–70

Acknowledgments

The authors gratefully acknowledge financial support under major research project grant [F.2-2/2011 (SAP-II)] from University Grants Commission (UGC) and University of Delhi. KKJ also thanks CSIR for senior research fellowship during the course of this study.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jain, K.K., Bhanja Dey, T., Kumar, S. et al. Production of thermostable hydrolases (cellulases and xylanase) from Thermoascus aurantiacus RCKK: a potential fungus. Bioprocess Biosyst Eng 38, 787–796 (2015). https://doi.org/10.1007/s00449-014-1320-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1320-4