Abstract

Production of two industrially important products, xylanase and itaconic acid (IA), by Aspergillus terreus NRRL 1960 from agricultural residues was investigated within a biorefinery concept. Biological pretreatment was applied to lignocellulosic materials by using A. terreus, which produced xylanase while growing on agricultural residues. For IA production, already grown cells were transferred into a new medium. The first step provided not only the pretreatment of lignocellulosic material in order to be used as feedstock but also production of xylanase. For this purpose, cotton stalk, sunflower stalk and corn cob were used as carbon sources as lignocellulosic material. Among them, the highest xylanase production was obtained on corn cob. By application of two-step fermentation, about 70 IU/mL xylanase and 18 g/L IA production levels were achieved. This study shows the stepwise usage potential of the microorganism as a tool in a biorefinery concept.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

The Kyoto Protocol and the shortage of reserves of fossil resources (non-renewable sources) has attracted the attention of researchers toward renewable energy sources. The biorefinery concept can be defined as the usage of renewable biological or bio-based sources to convert them into added-value end-products. Various microorganisms have been used successfully in industry for the production of enzymes and secondary metabolites. For each case, the culture medium was optimized for a target product and the carbon source mainly used (glucose or sucrose) is either expensive and/or competes with the food industry. In a biorefinery, the process should be economically and ecologically sustainable (Menon and Rao 2012). Currently, strategies for the usage of lignocellulosic material are focused on individual production chains, mainly to biofuels. From an economic and environmental perspective, optimal utilization of renewable sources can be achieved by generation of multiple products in an integrated biorefinery system, in which material flows are combined or coupled so that the residue of previous processes become an input for the next one (Kamat et al. 2012).

Conversion of lignocellulosic material to its product is technically feasible, but economically it is not proved and achieved because of the complex structure of plant materials. Thus, new strategies should focus on the improvement of the cellulose accessibility (Menon and Rao 2012; Prevot et al. 2012). Based on this strategy, pretreatment methods are crucial, and each pretreatment method has different effects. One of the obstacles to cellulose accessibility is the presence of hemicelluloses; this obstacle can be overcome by using accessory enzymes such as xylanases (Van Dyk and Pletschke 2012). Degradation of xylan plays an important role in the breakdown process of plant material in nature. The main xylanolytic activities are catalyzed by endo-β-1,4-xylanases, which hydrolyze β-1,4-bonds between D-xylose residues in the main chain yielding xylo-oligosaccharides (Gawande and Kamat 1999; Kocabas et al. 2011). It can be termed biological pretreatment, which acts either partially by disruption of the hemicellulose structure or completely by removal of hemicellulose, so that the access of cellulase to cellulose is improved (Van Dyk and Pletschke 2012).

Xylan-degrading enzymes (especially cellulase-free xylanases) have a wide range of potential biotechnological applications in various industrial processes, involving the modification of cereal-based foodstuffs, and enhancing the digestibility of animal feedstocks and the delignification of paper pulp. In addition, they have roles in textile manufacture, baking, release of aroma and anti-oxidant molecules, production of biopharmaceuticals, and for bioconversion of lignocelluloses to sugar, ethanol, and other useful substances. The huge industrial usage area has encouraged increased moves to identify and obtain new xylanases with different specificities and properties (Kulkarni et al. 1999; Farinas et al. 2010; Ersayin Yasinok et al. 2010; Dhiman et al. 2011; Garg et al. 2011; Su et al. 2011).

The highest xylanase activities measured and reported in the literature from different strains of Aspergillus terreus were 35.5 IU/mL on 1 % wheat bran (Gawande and Kamat 1999), 26.9 IU/mL on 1 % oat spelt xylan (Marques et al. 2003), 16.16 IU/mL on 1 % wheat straw (Ghanem et al. 2000), 12.74 IU/mL on sugarcane bagasse residue (Kamat et al. 2012), and 4 IU/mL on 1 % xylan (Hrmova et al. 1991). Since no report on xylanase activity of this industrial strain is available in the literature and considering the possibility of IA production on agricultural residues, the production of xylanase and itaconic acid (IA) was studied.

Xylanase and IA are two products having wide application areas in industry. Xylanase is produced by wide variety of organisms and searchs continue for one having new features. IA is produced mainly by A. terreus in industry and, due to its high production cost, there is a need for improvements from an economical point of view, which will increase its application area and usage amount.

Many of the commercial production processes on organic acids are excellent examples of fungal biotechnology, such as citric, gluconic, itaconic, and lactic acids. Among fungi, Aspergilli are well known for their potential to overproduce organic acids. This ability is assumed to make them possess ecological advantages, as they can even tolerate pH values as low as 1.5 (Ruijter et al. 2002). As an example, A. niger can produce citric acid from glucose with an efficiency of 80 % (Magnuson and Lasure 2004).

IA production in A. terreus is very similar to citric acid production in A. niger, except one further step is required for IA production. In the TCA cycle, citric acid is converted to cis-aconitic acid by the enzyme aconitase, and aconitase further converts cis-aconitate to isocitrate as the continuation of the TCA cycle. Decarboxylation of cis-aconitate to IA is carried out by the unique enzyme produced in A. terreus cis-aconitate decarboxylase (Bentley and Thiessen 1995).

Commercially, IA is produced from A. terreus NRRL 1960 by using glucose or molasses as carbon sources, which creates a high production cost. Thus, it is estimated that the market volume for IA is about 80,000 tons per year and there is an expectation for a market demand increase if the selling price can be reduced (Bentley and Thiessen 1995; Willke and Vorlop 2001; Mitsuyasu et al. 2009). Decreases in production cost could be maintained by using low-cost carbon sources. Lignocellulosic residues as a renewable carbohydrate source can be a raw material for biotechnological processes, considering their widespread distribution, abundance, and low price.

The primary aim of this study was to reduce the production cost of IA by A. terreus NRRL 1960 within a biorefinery concept. In this case, the usage of renewable lignocellulosic waste materials as carbon sources and the production of another industrially important product, xylanase, by using the same cells was investigated. In this way, the production cost could be reduced and the sustainable usage of renewable agricultural residues having no commercial value could be provided. Overall, this study can grant some perspectives and point out a few potentially important issues likely to come into focus in the near future of the extensive use of biomass as a renewable feedstock in industry. Here, corn cob, cotton stalk, and sunflower stalk were used as lignocellulosic waste material for IA production. Hence, it has been shown that renewable biomass such as agricultural and forestry by-products can be used as raw materials and converted into value-added products.

To the best of our knowledge, this is the first report on the production of xylanase from A. terreus on corn cob as waste, and the highest xylanase activity within reported xylanase production among A. terreus strains.

Materials and methods

Materials

Chemicals used were analytical grade, either purchased from Sigma (NY, USA) or Merck Chemical (Deisenhofen, Germany). Commercial xylanase (Shearzyme) from A. oryzae was obtained from Novozymes (Denmark). The agricultural biomass used in production cultures as carbon source were corn cob, cotton stalk, and sunflower stalk obtained from Konya (Turkey), Sanliurfa (Turkey), and Kutahya (Turkey), sequentially. They were milled and sieved using a No. 60 sieve (2 mm) and added directly to the production culture before the autoclave process.

Microorganism and medium

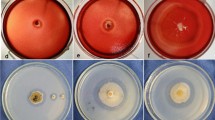

Aspergillus terreus strain NRRL 1960 was kindly provided by Dr. Leo de Graaff from Wageningen University. The organism was grown and sporulated on a solid potato dextrose agar for 4 days at 30 °C. For inoculation of liquid batch culture, stock spore suspensions were prepared in a 1 % (w/v) peptone solution. Spore concentration was determined using a haemocytometer. Spores at a concentration of 107 spores/mL were inoculated into 100 mL liquid cultures.

Enzyme productions were carried out as shake-cultures in 250-mL flasks at 37 °C at 170 rpm unless otherwise indicated. An amount of 10 mL of preculture was used to inoculate 100 mL of production medium. Medium-1 consisted of (in g/L): glucose, 100; MgSO4·7H2O, 5; peptone, 1; yeast extract, 2; NaCl, 0.4; KH2PO4, 1; CaCl2·2H2O, 1.0 (Gawande and Kamat 1999; Ghanem et al. 2000; Hrmova et al. 1991; Marques et al. 2003). Medium-2 contained (in g/L): glucose, 100; corn steep liquor, 0.5; MgSO4·7H2O, 5; NH4NO3, 3; NaCl, 0.4; ZnSO4·H2O, 0.033; KH2PO4, 0.5; CaCl2·2H2O, 1.0; CuSO4·5H2O, 0.06 (modified Cros medium) (Cros and Schneider 1993). Xylan-containing media were prepared by replacing glucose with 1 % birchwood xylan in the production culture. The pH adjustments of fermentation media to 2 were carried out by using HCl.

Analytical methods

All fermentations were carried out as biological replicates. For each tested fermentation variable, the microorganism was inoculated into two identical media and grown inat the same conditions.

Xylanase assay

Samples were collected from the production medium and centrifuged for 5 min at 15,000 g at 4–6 °C to remove cells and insoluble fragments of the medium. This clarified medium solution was used as the crude enzyme source for further studies.

Xylanase activity was determined according to Bailey et al. (1992) using 1 % birchwood xylan in 50 mM phosphate buffer at pH 7 at 40 °C ,and released reducing sugar was measured using the 3,5-dinitrosalicylic acid (DNS) method (Miller 1959) with xylose as the standard. One unit of xylanase activity (IU) is defined as the amount of enzyme necessary to produce 1 μmole of xylose equivalents per min under given reaction conditions.

Determination of itaconic acid by HPLC

HPLC analysis was performed using a Shimadzu LC-20 AD Prominence HPLC system with a Bio-Rad Aminex HPX-87H column at 30 °C. Isocratic HPLC analyses were performed using 8 mM H2SO4 as solvent at room temperature (RT) having a flow rate of 30 mL/h, and organic acids were detected at 210 nm.

Pretreatment methods

Dry and wet heat pretreatments

For dry heat pretreatment, agricultural residues were kept for 16 h in an incubator at 60 °C. For wet heat pretreatment, agricultural residues were swelled for 16 h at 60 °C after mixing with of 1:50 (w/v) distilled water. The swollen sample was filtered and dried at RT.

Alkali xylan extraction

Agricultural residues were swelled for 16 h in an oven at 60 °C after mixing with of 1:50 (w/v) distilled water. The swollen residue was filtered and stirred for 3 h at room temperature in the solution of 170 mL of 24 % KOH (w/v) and 1 % (w/v) NaBH4. After filtration, the sample was centrifuged at 7,000 g for 10 min. The supernatant was mixed with 2.5 volumes of cold ethanol:acetic acid solution (10:1). The pellet was dried at RT and used as extracted xylan (Zilliox and Debeire 1998).

Two-step fermentation

The first step was xylanase production and inoculation and growth of microorganisms on CC, as indicated above. Fermentation was carried out as 100-mL shake-cultures in 250-mL flasks at 37 °C at 170 rpm unless otherwise indicated. After optimal xylanase production was obtained, the second step was carried out either by adjusting the first fermentation medium as performing one of the followings: (1) adjustment of medium pH to 2, (2) addition of commercial xylanase at very high concentration (100 IU/mL), (3) addition of 5 % glucose, (4) addition of 10 % glucose, or (5) by transferring the organism into a new production medium with 10 % glucose. The additions and/or adjustments were performed on the 5th day of fermentation after obtaining maximum xylanase production from A. terreus.

Results and discussion

A well-known IA producer, Aspergillus terreus NRRL 1960, was selected since it is already used in industry for IA production. In addition to the IA production level, cellulase and xylanase activities were also checked under submerged fermentation conditions. For this purpose, two media were defined according to their reported inducing capacities on A. terreus for xylanase and IA production. The first medium (M1) is mentioned for xylanase production and the second medium (M2) is modified from a previously defined medium by Cros and Schneider (Cros and Schneider 1993) for IA production (Hrmova et al. 1991; Gawande and Kamat 1999; Ghanem et al. 2000; Willke and Vorlop 2001; Marques et al. 2003).

Both media were used either after adjusting their initial pHs to 2 or without any pH adjustment in which case the initial pH was about 4.5. pH adjustment was used in order to prevent the production of other organic acids (Su et al. 2011). To compare IA and xylanase production of A. terreus from agricultural wastes, two control media were used. Production culture containing glucose as sole carbon source was used as control for IA production (Fig. 1a) and medium including 1 % (w/v) birchwood xylan instead of glucose was used for xylanase production (Fig. 1b). IA level increased gradually over the incubation period showing maximum values on the 7th day, when it was about 13 g/L in M2 without initial pH adjustment. The initial pH adjustment showed a positive effect on IA production, and IA production level increased to 18 g/L in M2 (Fig. 1a). Although, the IA production amount in M1 was very low (about 2 g/L), the adjustment of initial pH to 2 increased the IA production in both media, and there was about a 30 % increase in M2.

Comparison of production media and pH adjustment in regard to their IA production and xylanase activity profiles: a IA production on 10 % glucose containing media; b xylanase production on 1 % xylan-containing media (M1 Xylanase-inducing medium without pH adjustment; M1-P Xylanase-inducing medium with pH adjustment to 2; M2 Itaconic acid inducing medium without pH adjustment; M2-P Itaconic acid inducing medium with pH adjustment to 2)

Xylanase production level was higher in M2 than M1 in all cases. The initial pH adjustment had positive effect on xylanase production in M2, Nonetheless, it changed xylanase production trend and xylanase level reached its maximum on 5th day of fermentation (Fig. 1b). The effect of initial pH adjustment on M1 was almost negligible and the xylanase production level in this medium was lower than M2. The highest xylanase activity was observed as 58 IU/mL in M2 with initial pH adjustment on the 5th day of fermentation (Fig. 1b). It is the highest xylanase production, obtained various A. terreus strains mentioned in the literature. The highest xylanase activity measured and reported in the literature from different strains of A. terreus was 35.5 IU/mL on wheat bran (Gawande and Kamat 1999). Other results have mentioned having xylanase activities of 26.9 IU/mL on 1 % oat spelt xylan (Marques et al. 2003), 16.16 IU/mL on wheat straw (Ghanem et al. 2000), 12.74 U/mL on sugarcane bagasse (Kamat et al. 2012), and 4 IU/mL on 1 % xylan (Hrmova et al. 1991). The IA production levels were also measured in xylan-containing media and the highest IA production (1.66 g/L) was also measured in the same medium having the highest xylanase production (M2-P). It is a promising result for the production of IA by using agricultural residues. Moreover, the measured cellulase activity in medium was about 0.12 FPU/mL. Low cellulase activity is consistent with other A. terreus strains mentioned in the literature (Hrmova et al. 1991; Gawande and Kamat 1999; Ghanem et al. 2000; Marques et al. 2003; Kamat et al. 2012).

Thus, since both the highest IA and xylanase productions were obtained using M2 with initial pH adjustment, M2 could be the best for production of both xylanase and IA. Therefore, the rest of the experiments were performed with this medium.

The usage of agricultural biomass as carbon source

Three agricultural waste materials, corn cob, cotton stalk, and sunflower stalk (produced in huge amount in Turkey) were used as carbon sources instead of pure xylan in the production culture. Birchwood xylan was used as control. Each agricultural residue was added at a concentration of 1 % (w/v) as a substitution of xylan in the production culture.

This experimental setup revealed the utilization of agricultural biomass by A. terreus. Utilization of biomass and xylanase production took longer on lignocellulosic materials than on pure xylan as expected, considering the complex structure of lignocellulose. Among the agricultural residues tested, corn cob showed the highest xylanase production level (36 IU/mL) after a continuous increase for 7 days corresponding to 80 % of the activity observed in the control (Fig. 2a). Xylanase production levels obtained with cotton stalk and sunflower stalk were not comparable with the one of containing corn cob, and they were very low throughout the fermentation. The reason could be either high lignin content as in the case of cotton stalk or low xylan concentration as in the case of sunflower stalk (Table 1) (Jimenez and Bonilla 1993; Tada et al. 2004; Akpinar et al. 2007).

The usage of agricultural biomass as carbon source: a effect of different agricultural residues on xylanase production (1Xn 1 % birchwood xylan; 1CC 1 % corn cob; 1SS 1 % sunflower stalk; 1CS 1 % cotton stalk); b effect of corn cob concentration on xylanase production (1 %CC containing 1 % corn cob; 3 %CC containing 3 % corn cob; 5 %CC containing 5 % corn cob; 7 %CC containing 7 % corn cob; 10 %CC containing 10 % corn cob)

None of the xylanase production levels in the agricultural residue-containing cultures reached the activity in the control (Fig. 2a). There could be different reasons. Firstly, the agricultural residues were not solely xylan. Therefore, using the same concentration of agricultural residues and birchwood xylan does not result in an equal amount of xylan concentration in the production culture. Secondly, their compositions differ in percentage of lignin, cellulose and hemicellulose content; hence, the amount of hemicellulose and chemical interactions with other materials (especially lignin) may be the barrier to reaching and hydrolyzing the hemicellulose by xylanases (Table 1) (Jimenez and Bonilla 1993; Tada et al. 2004; Akpinar et al. 2007).

Recent studies have been suggesting the usage of pretreatment methods on lignocellulosic materials in a biorefinery perspective (Kamat et al. 2012; Menon and Rao 2012; Prevot et al. 2012; Van Dyk and Pletschke 2012). Kamat et al. (2012) also used A. terreus strain for xylanase production and they indicated that usage of commercial xylan is an expensive substrate for xylanase production. Therefore, it is recommended to use cheap and renewable sources such as lignocellulosic material for large-scale production. They used sugarcane bagasse as their renewable source and tested acid pretreatment before xylanase production. The obtained xylanase production was 12.74 IU/mL and the cellulase production was 0.64 FPU/mL. Their aim was to produce xylanase, xylitol, and single cell oil by using sugarcane bagasse in a biorefinery concept. In this study, on the other hand, lignocellulosic materials were used without any pretreatment and the xylanase production process was considered as the biological pretreatment of lignocellulosic materials because xylanase disrupts and removes hemicellulose, thus it should improve cellulose accessibility (Menon and Rao 2012; Van Dyk and Pletschke 2012). Moreover, the cellulase activity (0.12 FPU/mL) of A.terreus in our study was lower than the cellulase activity (0.64 FPU/mL) of Kamat’s strain (Kamat et al. 2012). This was another advantage for xylanase production especially for industrial applications.

Since using the same concentrations of CC and pure xylan does not supply the same amount of xylan concentration in the production culture, higher concentrations of CC were tested.

Effect of concentration and pretreatment of corn cob on xylanase production

Comparative xylanase levels were obtained using 3, 5, and 7 % (w/v) CC with respect to 1 % birchwood xylan (Fig. 2b). It is clearly observable from Fig. 2b that the highest xylanase production was measured in the 7 % CC-containing culture and it was followed by the 5 %-containing culture. Although a higher xylanase production level was obtained by increasing the CC concentration up to 7 %, a decrease was observed in the 10 % CC-containing culture. This was as much as in the 3 %-containing one, which could be due to two possible reasons: high mechanical shear force applied by CC particles; and low dissolved oxygen level because of the dense culture medium. The reducing sugar concentration increased throughout the fermentation period and it was proportional to the CC concentration in the culture (data not shown).

In the case of pretreatment, the highest xylanase activity was observed with wet heat pretreated corn cob (10 % increase in xylanase production) whereas dry heat pretreatment had a little effect on xylanase production.

Overall, the results showed that the organism can utilize agricultural biomass and produce high amounts of xylanase. Since corn cob has a lignocellulosic complex structure and the organism can utilize xylan, the produced simple sugar was xylose and not enough to induce IA production. IA production needs high amounts of simple sugar (15–20 g/L glucose) (Willke and Vorlop 2001); therefore, the preliminary experimental setup was designed with the addition of commercial xylanase into the medium. By this way, xylan degradation from lignocellulosic material was increased which would result in higher simple sugar release. Increasing simple sugar concentration at a given time should increase IA production.

Effect of commercial xylanase addition on biodegradation and IA production

This setup was designed as preliminary experiment that would give information on whether the IA production could be achieved only on lignocellulosic materials. That means that if this experimental setup showed that high xylanase activity in the culture increases the degradation of agricultural residues and also increases the IA production, the organism could be modified or induced for high xylanase production.

First of all, commercial xylanase stability and activity at the cultivation temperature (37 °C) were tested. Tests were performed in the production culture without inoculation. After 24 h, the remaining activity of the commercial xylanase was 80 %. Additional 6 % activity loss was detected during the next 72 h. Hence, the addition of commercial xylanase into the production medium may provide higher amounts of reducing sugar so that it can induce IA production.

For that purpose, commercial xylanase (0.5 IU/mL) was added during the inoculation of the fermentation culture to increase the release of simple sugar from xylan (Fig. 3a). The addition of commercial xylanase during inoculation resulted in higher simple sugar concentration at the beginning of the fermentation. Nevertheless, this might not be sufficient to induce IA production. Only 0.0004 g/L IA could be obtained on the 9th day. Another effect of the addition of xylanase was a decrease in xylanase production by A. terreus (Fig. 3a). Taking these results into consideration, to keep the reducing sugar concentration constant at a high level, the amount of commercial xylanase was increased to 2.5 IU/mL. In addition, it was added 24 h before the inoculation into the cultures containing 1, 2, 4, and 8 % (w/v) birchwood xylan, in order to increase the initial reducing sugar concentration.

Effect of addition of commercial xylanase: a on xylanase production when added during inoculation of the production medium (Control grown at 37 °C at 170 rpm without addition of commercial xylanase on 1 % birchwood xylan in M2; NZ Add 0.5 IU/mL commercial xylanase was added into production culture during inoculation; NZ Add-RS and Control-RS reducing sugar concentration for the media mentioned in a); b on xylanase production when added into the production medium containing different concentration of birchwood xylan (1% containing 1 % birchwood xylan; 2% containing 2 % birchwood xylan; 4% containing 4 % birchwood xylan; 8% containing 8 % birchwood xylan in medium M2 at 37 °C at 170 rpm; c on reducing sugar concentration in the media indicated in b); 2.5 IU/mL commercial xylanase was added 24 h before inoculation

The initial reducing sugar concentrations of 1, 2, 4, and 8 % (w/v) xylan-containing cultures were 3, 7, 12, and 14 g/L, sequentially (Fig. 3b). In the first three cultures, the organism consumed most of the initial sugar in 3 days, whereas growth of the organism took more than 3 days in 8 % xylan-containing culture, probably because of its high density and viscosity. Starting with high simple sugar concentration resulted in a decrease of xylanase production by A. terreus indicating feedback inhibition on xylanase production (Fig. 3c). The highest xylanase activity (27 IU/mL) was observed in 8 % xylan-containing culture on the 6th day, and the lowest one (6 IU/mL) was observed in 1 % xylan-containing culture on the 3rd day.

Likewise for initial sugar concentration, xylan concentration affected the amount of IA production. In the cultures containing 1, 2, 4, and 8 % xylan concentration, the amount of IA production levels after the 12th day were 0.0016, 0.0028, 0.0041, and 0.0432 g/L, respectively. Based upon these data, it can be concluded that higher initial simple sugar concentration can be obtained by adding commercial xylanase to the culture. This may result in an increase in the production of IA, whereas it may lead to a decline in the xylanase production.

Addition of commercial xylanase to show the effect of high xylanase concentration in the culture and increasing xylan concentration induce IA production. Nonetheless, the degradation of the commercial enzyme in a day, and lower xylanase production by the organism at high initial simple sugar concentrations could not achieve sustainability of high simple sugar concentration in the medium. Thus, higher IA titer could not be obtained. Another reason could be a decrease in oxygen availability due to the high viscosity in high xylan concentrations. This setup showed promising results that, in a well aerated fermentor, IA production can be achieved on lignocellulosic materials. Therefore, a two-step fermentation might be better for xylanase and IA production.

Two-step fermentation for xylanase and itaconic acid production

According to results from preliminary experiments, two-step fermentation was carried out based on this idea: separate productions of xylanase and IA using the same cells. Two-step fermentation was performed firstly by production of xylanase to its maximum level on biomass and secondly applying one of these steps: (1) Low Glucose Medium (5 %): addition of low amount of glucose (5 % w/v) in the same culture medium where xylanase production was carried out; (2) High Glucose Medium (10 %): addition of high amount of glucose (10 % w/v) in the same culture medium; and (3) New Culture Medium (NG): transferring the organism to newer IA production medium with 10 % glucose (w/v).

A similar result with preliminary experiments was observed on xylanases in each media: either xylanase production decreased or completely ceased because of available simple sugar, glucose (Fig. 4a). In addition to these, IA production was observed in all cultures. Production levels of IA in 5 % and 10 % cultures were almost the same (8 g/L in 5 % and 7 g/L in 10 %) (Fig. 4b). That could be mainly because of two reasons: firstly, usage of the same production culture with previous xylanase production culture; hence, accumulation of chemicals produced during the growth of the organism and xylanase production in the medium, and secondly, the depletion of glucose. This idea was supported with the NG, as IA production level in NG medium was almost the same with the control IA production culture.

Effect of two-step fermentation on xylanase and IA production: a on xylanase production (Control grown at 37 °C at 170 rpm, adjustment and additions were performed at 5th day of fermentation) (pH pH adjusted to 2.0; NZ 100 IU/mL commercial xylanase was added; 5% 5 g/L glucose was added; 10% 10 g/L glucose was added; NG the organism transferred to new production medium containing 10 % glucose); b on itaconic acid production (5% 5 g/L glucose was added; 10% 10 g/L glucose was added; NG the organism transferred to new production medium containing 10 % glucose); c reducing sugar concentration; and d pH profiles of the media with high glucose concentration (5% 5 g/L glucose was added; 10% 10 g/L glucose was added; NG the organism transferred to new production medium containing 10 % glucose)

Another interesting result was obtained related to pH and reducing sugar concentration of the cultures (Fig. 4c, d). Glucose consumption profiles of 5 and 10 % cultures were similar and, after 4–5 days, all glucose was consumed by the organism. Moreover, when the glucose concentration came to an end, the pH of the culture started to increase and reached up to 5. Throughout these days, IA concentration started to decrease and especially in the 5 % culture most of the IA consumed. It was clearly revealed that high simple sugar concentration and lower pH value (as low as 1.8) were needed for IA production. Moreover, these results are consistent with the literature that low pH is a requirement for IA production in order to prevent the production of other acids (Ruijter et al. 2002), and medium having a C/N ratio greater than 10:1 can ensure the accumulation of secondary metabolites (Carlile et al. 1994). Willke and Vorlop (2001) claimed that 100–150 g/L glucose was required for a satisfactory production rate and amount of production of IA from A. terreus. Hence, to prevent consumption of IA by the organism, a high concentration of simple sugar should be supplied throughout the whole fermentation period.

Conclusion

Aspergillus terreus NRRL 1960 can be cultivated to produce xylanase and itaconic acid (IA) within a biorefinery concept. It can produce xylanase during cell growth by utilizing lignocellulosic materials as carbon source. Through this process, because of low cellulase activity, pretreatment of lignocellulosic material was achieved to be used in further steps in biorefinery. By transferring cells into IA production medium with high simple sugar concentration, IA production was performed. Moreover, after production of IA, the cell biomass can be used as feedstock for biodiesel. In conclusion, this study shows integrated generation of multiple products and stepwise usage of microorganism as a tool in a biorefinery concept.

References

Akpinar O, Ak O, Kavas A, Bakir U, Yilmaz L (2007) Enzymatic production of xylooligosaccharides from cotton stalks. J Agric Food Chem 55:5544–5551

Anand AAP, Sripathi K (2004) Digestion of cellulose and xylan by symbiotic bacteria in the intestine of the Indian flying fox (Pteropus giganteus). Comp Biochem Phys A 139:65–69

Bailey MJ, Biely P, Pountanen K (1992) Interlaboratory testing of methods for assay xylanase activity. Biochim Biophys Acta 1117:252–270

Bentley R, Thiessen CP (1995) cis-Aconitic Decarboxylase. Science 122:330–333

Carlile JM, Watkinson SC, Gooday GW (1994) The Fungi, 2nd edn. Academic, London

Cros P and Schneider D (1993) Microbiological production of itaconic acid. US-Patent 5 231 016 (to Rhône-. Poulenc)

Dhiman SS, Garg G, Sharma J, Mahajan R, Methoxy (2011) Characterization of statistically produced xylanase for enrichment of fruit juice clarification process. New Biotechnol 28:746–755

Ersayin Yasinok A, Biran S, Kocabas A, Bakir U (2010) Xylanase from a soil isolate, Bacillus pumilus: gene isolation, enzyme production, purification, characterization and one-step separation by aqueous-two-phase system. World J Microbiol Biotechnol 26:1641–1652

Farinas CS, Loyo MM, Junior AB, Tardioli PW, Neto VB, Couri S (2010) Finding stable cellulase and xylanase: evaluation of the synergistic effect of pH and temperature. New Biotechnol 27:810–815

Garg G, Dhiman SS, Mahajan R, Kaur A, Sharma J (2011) Bleach-boosting effect of crude xylanase from Bacillus stearothermophilus SDX on wheat straw pulp. New Biotechnol 28:58–64

Gawande PV, Kamat MY (1999) Production of Aspergillus xylanase by Lignocellulosic waste fermentation and its application. J Appl Microbiol 87:511–519

Ghanem NB, Yusef HH, Mahrouse HK (2000) Production of Aspergillus terreus xylanase in solid-state cultures: application of the Plackett-Burman experimental design to evaluate nutritional requirements. Bioresource Technol 73:113–121

Hrmova M, Petrakova E, Biely P (1991) Induction of cellulose- and xylan-degrading enzyme systems in Aspergillus terreus by homo- and heterodisaccharides composed of glucose and xylose. J Gen Microbiol 137:541–547

Jimenez L, Bonilla JL (1993) Acid hydrolysis of sunflower residue biomass. Process Biochem 28:243–247

Kamat S, Khot M, Zinjarde S, RaviKumar A, Gade WN (2012) Coupled production of single cell oil as biodiesel feedstock, xylitol and xylanase from sugarcane bagasse in a biorefinery concept using fungi from the tropical mangrove wetlands. Bioresour Technol. doi:10.1016/j.biortech.2012.11.059

Kocabas A, Sutay Kocabas D, Bakir U (2011) One-Step purification and characterization of a low molecular weight xylanase from Aspergillus terreus NRRL 1960. JABS 5:61–65

Kulkarni N, Shendye A, Rao M (1999) Molecular and biotechnological aspects of xylanases. FEMS Microbiol Rev 23:411–456

Magnuson JK, Lasure L (2004) Organic Acid Production by Filamentous Fungi. In: Lange J, Lange L (eds) Advances in Fungal Biotechnology for Industry, Agriculture, and Medicine. Kluwer/Plenum, London, pp 307–340

Marques S, Pala H, Alves L, Amaral-Collaco MT, Gama FM, Girio FM (2003) Characterization and application of glycanases secreted by Aspergillus terreus CCMI 498 and Trichoderma viride CCMI 84 for enzymatic deinking of mixed office wastepaper. J Biotechnol 100:209–219

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: Biofuels, platform chemicals and biorefinery concept. Prog Energ Combust 38:522–550

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Mitsuyasu O, Dwiarti L, Shin K, Enoch PY (2009) Biotechnological production of itaconic acid and its biosynthesis in Aspergillus terreus. Appl Microbiol Biotechnol 84:597–606

Prevot V, Lopez M, Copinet E, Duchiron F (2012) Comparative performance of commercial and laboratory enzymatic complexes from submerged or solid-state fermentation in lignocellulosic biomass hydrolysis. Bioresour Technol. doi:10.1016/j.biortech.2012.11.135

Ruijter GJG, Kubicek CP, Visser J (2002) Production of OrganicAcids by Fungi. The Mycota X Industrial Applications 10:213–230

Su Y, Zhang X, Hou Z, Zhu X, Guo X, Ling P (2011) Improvement of xylanase production by thermophilic fungus Thermomyces lanuginosus SDYKY-1 using response surface methodology. New Biotechnol 28:40–46

Tada K, Horiuchi J, Kanno T, Kobayashi M (2004) Microbial xylitol production from corn cobs using Candida magnolia. J Biosci Bioeng 98:228–230

Van Dyk JS, Pletschke BI (2012) A review of lignocellulose bioconversion using enzymatic hydrolysis and synergistic cooperation between enzymes-Factors affecting enzymes, conversion and synergy. Biotech Adv 30:1458–1480

Willke T, Vorlop KD (2001) Biotechnological Production of Itaconic Acid. Appl Microbiol Biot 56:289–295

Zilliox C, Debeire P (1998) Hydrolysis of wheat straw by a thermostable endoxylanase: Adsorbtion and kinetic studies. Enzyme Microbial Technol 22:58–63

Acknowledgements

This project was supported by the Middle East Technical University Scientific Research Found Project BAP-08-11-DPT2002K120510. The authors thank Dr. Leo de Graaff for providing the organism.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kocabas, A., Ogel, Z.B. & Bakir, U. Xylanase and itaconic acid production by Aspergillus terreus NRRL 1960 within a biorefinery concept. Ann Microbiol 64, 75–84 (2014). https://doi.org/10.1007/s13213-013-0634-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13213-013-0634-9