Abstract

Fibrous poly(styrene-b-glycidylmethacrylate) brushes were grafted on poly(styrene–divinylbenzene) (P(S–DVB)) beads using surface-initiated atom transfer radical polymerization. Tetraethyldiethylenetriamine (TEDETA) ligand was incorporated on P(GMA) block. The ligand attached beads were used for reversible immobilization of lipase. The influences of pH, ionic strength, and initial lipase concentration on the immobilization capacities of the beads have been investigated. Lipase adsorption capacity of the beads was about 78.1 mg/g beads at pH 6.0. The K m value for immobilized lipase was about 2.1-fold higher than that of free enzyme. The thermal, and storage stability of the immobilized lipase also was increased compared to the native lipase. It was observed that the same support enzyme could be repeatedly used for immobilization of lipase after regeneration without significant loss in adsorption capacity or enzyme activity. A lipase from Mucor miehei immobilized on styrene–divinylbenzene copolymer was used to catalyze the direct esterification of butyl alcohol and butyric acid.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lipase (triacylglycerol acylhydrolase, EC 3.1.1.3) is an enzyme possessing an intrinsic capacity to catalyze the cleavage of carboxy ester bonds in tri-, di-, and monoacylglycerols to glycerol and fatty acids. Lipases from different sources are currently used in various biochemical reactions including triacylglycerols hydrolysis, esterification of fatty acids with various alcohols [1–3]. Esters of carboxylic acids are important components of natural aromas, contributing to the flavor in most fruits and many other foods. The lipase-catalyzed synthesis of several flavoring esters has been described to date [3–5] and in principle, the reaction can be carried out in a mixture of alcohol and carboxylic acid with or without solvents, resulting in very high productivities and yields [6, 7]. However, like many other enzymes, lipases have limited use in industrial applications due to their short life-times. For this reason, the improvement of the stability of lipases is crucial for their use in large-scale biotechnological processes. The stability of lipases can be improved by immobilization to insoluble supports. Several methods, namely, adsorption, cross-linking and covalent attachment have been employed for the immobilization of lipase [8–11]. Among the different immobilization techniques, the adsorption technique for immobilization of enzyme might be a good option, due to simplicity and avoidance of the tedious work-up. Although bonding by a physical adsorption is a weak interaction in general, this provides a reversible immobilization of the enzyme. However, to avoid the enzyme loss while processing or washing, a relatively strong Van-der Waals interaction between the enzyme and support is essential. Multi-modal ligand functionalized polymers may provide very strong hydrophobic and electrostatic interactions between enzyme and supports to preclude the enzyme leakage [12–18]. Additional advantage of the reversible immobilization is recovery of the support by easy removal of the inactivated enzyme and it may reuse in further cycles, which makes the process cost effective.

Specially designed functional hairy brushes tethered to solid surfaces are promising materials for immobilization of enzymes due to their intrinsically high surface areas, providing the quantity and better accessibility of the binding sites for high immobilization capacity [19, 20]. Epoxy functional polymer brushes such as poly(glycidyl methacrylate) can be created on an insoluble polymeric support via surface-initiated atom transfer radical polymerization methodology [21]. In this hybrid polymer system, ligand attached polymer brush layers will effectively involve in high capacity-enzyme binding and could increase the enzymatic reaction rates [21–23].

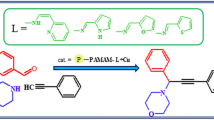

In this study, P(S–DVB) beads were prepared by suspension polymerization and modified with poly(styrene-b-glycidylmethacrylate) brushes using surface-initiated atom transfer radical polymerization aiming to decorate the beads surface with a fibrous polymer. A multi-modal ligand (i.e., TEDETA) was incorporated to the P(GMA) block via epoxy-amine reaction. The resulting polymer was employed as adsorbing material for a fungal lipase (from Mucor miehei). The adsorption parameters (i.e., initial lipase concentration, pH, and ionic strength) were investigated and nature of the lipase binding mechanism was studied. Finally, the immobilized lipase was then, used successfully to esterify n-butanol with butyric acid yielding butyl butyrate which is a pleasant aroma having extensive use in creating sweet fruity flavors.

Materials and methods

Materials

Lipase from Mucor miehei (lyophilized powder, ≥4,000 Units/mg solid (using olive oil), p-nitrophenyl palmitate (p-NPP), CuBr, dibenzoyl peroxide and Gum Arabic were supplied by the Sigma-Aldrich Chemical Co. (St. Louis, MO, USA) and used as received. Styrene and divinyl benzene (DVB) were obtained from Merck AG (Darmstadt, Germany), and inhibitor was rendered by washing with NaOH solution (3%, w/w) prior to use. Dibenzoyl peroxide was recrystallized from ethanol. All substrates were dehydrated before use, with 0.32-cm molecular sieves (aluminum sodium silicate, type 13×, BHD Chemicals). CuBr was freshly prepared by the procedure as described in the literature [25]. The ATRP ligand, H-TETA (1,1,4,7,10,10-hexakis [hexyl 1,4,7,10-tetraazadecane]) was prepared by alkylation of triethylenetetramine with 1-bromohexane as described previously [19]. N,N,N′,N′-Tetraethyldiethylenetriamine (TEDETA) and glycidyl methacrylate were distilled before use, and were obtained from Merck Chemical Co (Darmstadt, Germany). n-Butanol, butyric acid and all other chemicals were of analytical grade products and were purchased from Merck AG (Darmstadt, Germany).

Preparation of 2-bromoacetyl bromide modified P(S–DVB) beads

P(S–DVB) beads were prepared by cross-linking copolymerization of styrene–divinyl benzene mixture (with 9/1 M ratio) in aqueous suspension using Gum Arabic as stabilizer, according to the method given in the literature [4]. The beads were dried, sieved, and 210–422 μm size of fraction was used for acetoxy mercuration reaction. The acetoxymercurated beads were subjected to chlorine exchange reaction in saturated NaCl solution for 24 h at room temperature, and the chloromercurated beads were obtained after the chlorine exchange reaction. Then, the beads were reacted with 2-bromoacetyl bromide (Fig. 1). Grafting of 2-bromoacetyl bromide modified P(S–DVB) beads with P(S) and P(GMA) were carried out in a glass reactor as described previously. Briefly, the 2-bromoacetyl bromide modified P(S–DVB) beads were charged to the reactor and swelled in dry toluene for 2 h. After this period, styrene, H-TETA and CuBr were transferred into the reactor under nitrogen atmosphere. The grafting reaction was carried out at 90 °C for 6.0 h under continuous stirring. After reaction period, the beads were filtered and dried under reduced pressure at 60 °C for 24 h (Fig. 1). The P(GMA) was also grafted as a functional second block on the P(S–DVB)-g-P(S) beads using SI-ATRP method. For this grafting procedure, P(S–DVB)-g-P(S) beads, toluene and GMA were transferred in a three-necked round bottom flask. The medium left in contact for 1.0 h to swell. Then, H-TETA and CuBr were added under nitrogen atmosphere. The grafting reaction was carried out at 60 °C for 4.0 h under continuous stirring. The beads were washed with THF to eliminate residuals. The product was dried under reduced pressure at room temperature for 24 h (Fig. 1). Attachment of multimodal tetraethyldiethylenetriamine ligand on the P(GMA) block of the beads was carried out in a reactor (100 mL). It was equipped with a reflux condenser and a dropping funnel, and P(GMA) grafted beads (5 g) and THF (20 mL) was transferred in the flask. The TEDETA ligand (5 g) in distilled water was added to this mixture, and was stirred for 24 h at room temperature and then heated to 60 °C for 4 h. The ligand attached beads were collected by suction and washed with excess water. The product was cleaned with THF and dried under vacuum at 45 °C for 24 h (Fig. 1).

Immobilization studies

Immobilization of lipase on the TEDETA ligand attached beads (0.5 g) via adsorption was studied at various pH, in either acetate (50 mM, pH 3.0–5.5) or in phosphate buffer (50 mM, pH 6.0–8.0). The initial concentration of lipase was kept at 2.0 mg/mL in each corresponding buffer solution (30 mL). The effect of initial lipase concentration on the immobilization efficiency was studied at different initial lipase concentrations in the range of 0.2–2.0 mg/mL and at pH 6.0. The immobilization experiments were conducted at 25 °C for 2 h with continuous shaking. After the immobilization was done as described above, the beads were separated from the enzyme solution and washed with respective buffer solutions. The amount of immobilized lipase was obtained by using the following equation:

where Q is the amount of lipase immobilized onto beads (mg/g); C o and C are the concentrations of the lipase in the initial and final solutions (after combining wash solution), before and after immobilization, respectively (mg/mL); V is the volume of the aqueous solution (mL); m is the mass of the P(S–DVB)-g-P(S–GMA)–TEDETA beads (g). The amount of protein in medium and wash solutions was determined by the Bradford method [24]. A calibration curve was prepared using lipase as a standard (0.1–2.0 mg/mL). All the above experiments were performed in triplicates. For each set of data present, standard statistical methods were used to determine the mean values and standard deviations. Confidence intervals of 95% were calculated for each set of samples in order to determine the margin of error. The enzyme leakage from TEDATA ligand attached beads was studied in the different enzyme operation conditions as described above. Any measurable enzyme leakage was not observed under all these studied conditions.

Activity assays of free and immobilized lipase

The reaction rate of the free and adsorbed lipase preparations was determined as described previously [15]. A 100-mL reaction mixture was prepared by mixing with 50 mL ethanol containing 15 mM p-NPP and 50 mL buffer solution (50 mM) in a flask. The reaction was started by the addition of 0.1 mL free enzyme (or 20 mg immobilized enzyme) into 4 mL reaction mixture. The artificial substrate p-NPP hydrolysis was carried out at 35 °C for 5.0 min in a shaking water-bath at 150 rpm. After 5 min, the reaction was terminated by the addition of Na2CO3 (0.25 M, 2.0 mL). After removing the enzyme immobilized beads by filtration, the reaction mixture (0.5 mL) was diluted tenfold with purified water. The absorbance was measured at 410 nm using UV–vis spectrophotometer (PG Instrument Ltd., Model T80+; PRC). One enzyme unit was the amount of biocatalyst liberating 1.0 mmol of p-NPP per minute under given experimental conditions. These activity assays were carried out over the pH range 4.0–9.0 and temperature range 20–60 °C to determine the pH and temperature profiles for the free and the immobilized enzymes. The results of pH and temperature are presented in a normalized form with the highest value of each set being assigned the value of 100% activity.

Determination of the kinetic parameters of the free and immobilized enzyme

The kinetic constants were determined using tributyrin as substrate (in the concentrations range (5–50 mM) using free and immobilized lipase and titrating the butyric acids produced with 50 mM NaOH as described previously [15]. The experiments were conducted under the optimized assay conditions. The apparent K m and V max values for the free and immobilized lipase were calculated from Lineweaver–Burk plots by using the initial rate of the enzymatic reaction data:

where [S] was the concentration of substrate, v and V max represented the initial and maximum rate of reaction, respectively. K m was the Michaels constant. One lipase unit corresponded to release of 1 μmol fatty acid per minute under assay conditions. The specific activity is the number of lipase units per mg protein.

Thermal and storage stability of lipase preparations

The activity of free and immobilized lipase after storage in phosphate buffer (50 mM, pH 6.0 at 4 °C was measured for 8 weeks in a batch-mode as given above. The tests for the determination of the thermal stability of free and immobilized lipase were carried out by measuring the residual activity of the enzyme, exposed to two different temperatures (55 and 65 °C) in phosphate buffer (50 mM, pH 6.0) for 120 min. A predetermined time interval, a sample was removed and assayed for enzymatic activity as described above.

Reusability of the lipase immobilized P(S–DVB)-g-P(S–GMA)–TEDETA beads

In order to determine the reusability of the lipase immobilized P(S–DVB)-g-P(S–GMA)–TEDETA beads, enzyme adsorption and desorption cycle was repeated six times. Desorption experiments were carried out in alkaline solution (1.0 M NaOH). Lipase immobilized P(S–DVB)-g-P(S–GMA)–TEDETA beads was placed in the desorption medium for 2 h with a stirring rate at 150 rpm, and at 25 °C. The beads were washed several times with phosphate buffer (50 mM, pH 6.0), and were then reused in lipase immobilization. Lipase concentration within the desorption medium was determined as described above.

Esterification studies

Esterification activity of free and immobilized lipase was estimated through a model esterification reaction of butyric acid and butyl alcohol. A typical esterification reaction was as follows: free lipase solution (0.1 mL) or enzyme immobilized beads (0.1 g) was added to a 100 mL round bottomed flask containing a mixture of butyric acid (200 mM) and butyl alcohol (200 mM) in n-heptane (20 mL). The flask was placed on a controlled temperature shaker at 30 °C and was shaken with an agitation speed of 100 rpm. The reaction was stopped after 24 h by removing the enzyme immobilized beads. The remaining butyric acid was determined by titration with 0.1 M NaOH and using phenolphthalein as indicator. The total acid content before reaction was determined by titration of a blank sample, without enzyme. The esterification yield was calculated from the decrease in butyric acid concentration after 24 h of reaction. All of the experiments were carried out in triplicate. The control experiments (no enzyme) were performed and it was observed that ester yield is less than 1.7%.

These ester synthesis reactions were carried out at four different temperatures (i.e., 20, 30, 40, and 50 °C) and with different percent water content (between 0.5 and 3.0%) to determine optimum esterification conditions for the immobilized enzyme.

Operational stability of the immobilized enzyme during of butyl butyrate synthesis was studied using the same enzyme immobilized beads (0.1 g). Reaction conditions were the same as described above. After each batch, the enzyme immobilized beads was removed from the reaction medium and washed with phosphate buffer (50 mM, pH 6.5). After air drying of enzyme immobilized beads, the enzyme immobilized beads were reintroduced into a fresh medium containing a mixture of 200 mM butyl alcohol and 200 mM butyric acid in n-heptane. The reaction was repeated up to six cycles for ester synthesis.

Characterization of beads

The bromide content of the beads was determined by simple titration. For this purpose, 0.2 g of the bromoacetylated polymer was mixed with 10 mL methanolic NaOH solution (5 M) in a 50 mL flask and refluxed for 4 h. The mixture was filtered and washed with distilled water and the filtrate was transferred into a volumetric flask and diluted to 250 mL with distilled water. The NaBr content of the solution was assayed calorimetrically by mercuric thiocyanate method [25]. This analysis gave 0.84 mmol bromine per gram of the polymer. Determination of the amine content of the P(S–DVB)-g-P(S–GMA)–TEDETA beads was carried out by potentiometric titration. Briefly, the beads sample (1.0 g) was mixed with HCl acid (15 mL, 1.0 M) in a flask and stirred for overnight. The mixture was filtered and 2 mL of the filtrate was titrated with NaOH (0.1 M) in the presence of phenolphthalein. NaOH consumption was determined as 18.6 mL. These results revealed that P(S–DVB)-g-P(S–GMA)–TEDETA beads has 1.05 mmol amine group or else 0.35 mmol chelating units per gram of the polymer.

The specific surface area of the P(S–DVB)-g-P(S–GMA)–TEDETA beads was measured by a surface area apparatus and calculated using the Brunauer, Emmett, and Teller (BET) method.

The Fourier transform infrared (FTIR) spectra were carried on a spectrophotometer (Shimadzu, FTIR 8000, Japan) at room temperature and the samples were prepared in pellet form using spectroscopic grade KBr. The P(S–DVB) and modified counterpart beads (0.01 g) and KBr (0.1 g) were thoroughly mixed and the mixture was pressed to form a tablet, and the spectrum was recorded.

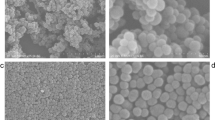

The surface morphology of the P(S–DVB)-g-P(S–GMA)–TEDETA beads was observed by scanning electron microscopy (SEM). The dried beads were coated with gold under reduced pressure and their electron micrographs were obtained using a scanning electron microscope (JEOL, JSM 5600, Japan).

Results and discussion

Properties of the support

Using surface-initiated atom transfer radical polymerization (SI-ATRP) technique, fibrous polymer chains on the polymeric beads surface can be created to produce uniform and flexible surface layer. In this study, P(S–DVB) bead surfaces were sequentially grafted with PS and P(GMA) via SI-ATRP (Fig. 1). The functional epoxy groups of the grafted fibrous polymer were further modified by attachment of a tri-dentate ligand, TEDETA serving multi-mode interaction for adsorption of proteins as illustrated in Fig. 2.

The synthesis of the beaded support and chemical transformations in each step were followed by monitoring characteristic bands in FT-IR spectra of the products (Fig. 3a). In the spectrum of P(S–DVB) bearing bromoacetyl groups, typical stretching vibration band of the carbonyl (C=O) group is observed at 1719 cm−1 as a weak band. And also a weak band associated with C–Br vibration is observable at 795 cm−1 (Fig. 3a). This band becomes almost invisible after grafting with PS due to its consumption by utilization in the grafting. Similarly, the carbonyl band vibration at 1719 cm−1 disappears because of its decreasing concentration of this group (Fig. 3b). After followed grafting with GMA, typical methacrylate ester vibrations associated with stretching vibrations of carbonyl, CO–O and COO–C bonds are observed at 1725, 1255, and 1150 cm−1, respectively. However, the typical bands of the epoxy group are not observed around 1000 cm−1, because these are obscured by the other bands in the same region. The shoulder around 1170 cm−1 might be ascribed to C–O–C stretching vibration of the epoxy group. Intensity of this band decreases after modification with TEDETA and the broad band emerged at 3100–3500 cm−1 range indicates O–H vibration band due to opening of the epoxy ring (Fig. 3c). FT-IR spectrum of P(S–DVB)-g-P(S-d-GMA) beads modified with TEDETA (Fig. 3d) shows a weak band around 970 cm−1 that can be assigned to C–N bond formed by reaction of NH group of TEDETA with the epoxy unit.

Scanning electron microscopy (SEM) micrographs in Fig. 4 exhibits a smooth surface texture of the P(S–DVB)-g-P(S–GMA)–TEDETA beads, which indicates retaining of the bead shapes after the modifications.

BET measurements revealed a specific surface area of 14.6 m2/g for the P(S–DVB)-g-P(S–GMA)–TEDETA beads. The epoxy group content of the P(S–DVB)-g-P(S–GMA) beads was determined to be 0.18 mmol per gram. The ligand content of the P(S–DVB)-g-P(S–GMA)–TEDETA beads were determined simply by acid titration method. The result showed an amine content of 1.05 mmol g−1 amine group which corresponds to a 0.35 mmol of the ligand units per gram of the polymer.

Immobilization of lipase on the P(S–DVB)-g-P(S–GMA)–TEDETA beads

Activity retention on the support is one of the most important aspects in the enzyme immobilization process. Any chemical modification or the physical adsorption in the procedure of immobilization will affect their activity to some extent. Adsorption through multi-mode interactions might be relatively a mild protein immobilization method, since the multi-modal ligand attached adsorbents have been applied in several protein separation and refolding processes [26–28]. The enzyme lipase contains several interactive amino acid residues on the surface. The presence of these amino acid residues on the surface of lipase can be interacted with mixed mode upon contacting with a support carrying multi-modal ligand. The pH of the adsorption medium influences the ionization state of the amino acid residues. The effect of pH on the adsorption of lipase onto TEDETA ligand attached beads is shown in Fig. 5. The maximum amount of lipase adsorption on the support was observed at pH 6.0. TEDETA is a multi-modal ligand, the optimal adsorption with multi-modal ligand was generally obtained at around the pI value of the target protein. Since the pI value of lipase is around 6.2, and as expected the maximum lipase adsorption was obtained at pH 6.0. Similar observations are reported in the literature for various multi-modal ligands [4, 29]. For a multi-modal ligand, a mixed type interaction is observed between ligand and target protein such as electrostatic and hydrophobic binding interactions. The TEDETA multi-modal ligand possessing three tertiary amine and four hydrophobic ethyl groups that can interact with the target molecule (i.e., lipase) in different ways, thus, a mixed mode interaction can be obtained. In addition, the polystyrene segment of the fibrous polymer has several aromatic rings for hydrophobic interaction with the target enzyme molecules. Thus, these interactions between lipase and TEDETA-functionalized beads at pH 6.0 may result from both the conformational state of the functional groups on the grafted polymer chains and amino acid side chains of the lipase molecule. In addition, during the epoxy ring opening reaction a hydroxyl group was formed in the proximity of the TEDETA ligand. Thus, the relative position of the hydroxyl groups on the ligand incorporated polymer chains could also provide an additional hydrogen bonding sites for the target biomolecules. Thus, a created specific binding side could also improve the adsorption capacity of lipase. As medium pH rises, the TEDETA ligand incorporated polymer chains are closely packed, limiting the interaction of lipase with functional groups, thus, a decrease in adsorption capacity will be observed for TEDETA-incorporated beads.

As shown in Fig. 6, the adsorption capacity increased with increasing initial lipase concentration in the medium. As expected, an increase in the adsorption capacity of the TEDETA ligand attached beads was observed for lipase [30–32]. The maximum adsorption capacity of lipase on the multi-modal beads was 78.1 mg/g dry beads. As seen in figure, the experimental lipase adsorption isotherm is very steep at low lipase concentration and reached a plateau about 1.0 mg/mL initial lipase concentration due to the saturation of binding sides of the immobilized ligand molecules.

Effect of pH and temperature on activity

The effect of pH on the activity of free and immobilized lipase in p-NPP hydrolysis was carried out in the pH range 4.0–9.0 and the results are presented in Fig. 7. The maximum activity for free enzyme was observed at pH 6.5. The optimum pH value of the immobilized lipase was shifted 0.5 units to acidic region. The shift could depend on the method of immobilization as well as the functional groups of the support. It may be a result of the basic nature of the TEDETA ligand attached beads, the amino groups on the beads surface could prevent the uniform distribution of hydrogen ions between the surface and the bulk solution. In other similar research, the optimum pH value of the immobilized lipase was shifted toward acidic or alkaline regions [33, 34]. It should be noted that the pH profile of the immobilized lipase is broader than that of the free enzyme, which means that the immobilization methods preserved the enzyme activity in a wider pH range. These results could probably be attributed to the stabilization of lipase molecules resulting from multipoint interactions with the TEDETA ligand.

The effect of temperature on the activity of free and immobilized lipases for p-NPP hydrolysis at pH 6.5 and 6.0, respectively, in the temperature range of 20–60 °C is presented in Fig. 8. As seen in this figure, the maximum activity for the free and immobilized lipase was observed at 35 °C. Whereas the profile of temperature effect on immobilized enzyme is a slightly broader than that of free enzyme [35, 36]. The improvement in the temperature profile can be caused by the changing physical properties of the lipase upon immobilization. The immobilization of lipase might also reduce the conformational flexibility via non-covalent interactions and may provide a higher stability for the immobilized enzyme in the tested temperature ranges compared to free lipase. In a previous study, Rhizomucor miehei lipase was covalently immobilized on the P(S–DVB)-g-P(S–GMA) beads, and stabilizations in pH and temperature profiles of immobilized lipase was observed compared to free counterpart [4].

Kinetic parameters for free and immobilized lipase

The initial reaction rates of the hydrolysis of the substrate (tributyrin) were measured at different substrate concentrations (i.e., 5–50 mM) with the free and adsorbed lipase. The kinetic data for hydrolysis of tributyrin was fitted to the Michaelis–Menten equation. The Lineweaver–Burk plot of 1/v vs. 1/S, Michaelis constant (K m) and the maximum reaction velocity (V max) of the free and the immobilized enzymes were calculated. For the free lipase the K m value was found to be 22.5 mM, and the V max was calculated to be 3810 U/mg enzymes. K m value was found to be 48.2 mM for the immobilized enzyme. The apparent K m for the immobilized enzyme was increased by about 2.1-fold compared to the free enzyme. The V max value of immobilized enzyme was calculated as 2420 U/mg enzymes. The V max value of the immobilized enzyme decreased about 1.6-fold compared to the free enzyme. The reason for activity loss of the adsorbed lipase could be extensive interaction of the surface amino acid residues with the ligand. Further, aggregation of fibrous polymer chains with each other could be another reason. In this case, adsorbed lipase on the ligand attached fibrous polymer chains could cause protein/protein interaction and could become large aggregated enzyme/fibrous polymer layers. Thus, the diffusion of substrate and product from fibrous polymer layers could become limiting-step and lead to decline in total activity of the adsorbed lipase.

The efficiency factor η can be calculated from the maximum reaction rates of the adsorbed enzyme over that of the free counterpart:

where v immobilized was the reaction rate of the adsorbed enzyme and v free that of the free enzyme. From this calculation, TEDETA ligand–enzyme system provided an efficiency factor of 0.635 for the adsorbed lipase. The ratio V max/K m defines a measure of the catalytic efficiency of an enzyme-substrate pair. In this study, the catalytic efficiencies (V max/ K m) of the free and adsorbed lipase were found to be 169 and 50, respectively. The catalytic efficiency of lipase was decreased about 3.4-fold upon immobilization.

Thermal and storage stability of the enzyme preparations

Thermal stability experiments were carried out with the free and the immobilized enzymes, which were incubated in the absence of substrate at various temperatures (data not shown). The thermal inactivation rate of the adsorbed lipase was smaller than that of the free counterpart. At 55 °C, the free enzyme retained 71% of its initial activity after a 120 min of heat treatment while the adsorbed enzyme showed significant resistance to thermal inactivation (retaining about 86% of its initial activity after the same period). At 65 °C, the free enzyme retained 19% of its initial activity after a 120 min of heat treatment, on the other hand, the immobilized form was inactivated at a much slower rate than the native form. These results suggest that the thermostability of adsorbed lipase becomes significantly higher at higher temperature [37, 38].

The free and immobilized enzymes were stored in phosphate buffer (50 mM, pH 6.0) at 4 °C and activity measurements carried out for a period of 8 weeks (data not shown). The free enzyme lost its all-initial activity within 6 weeks. The immobilized lipase preserved its initial activity more than 71% at the end of 8 weeks storage period (data no shown). Thus, the immobilization of lipase via adsorption on the beads definitely appears to hold the enzyme in a stable position in comparison to the free counterpart [39].

Synthesis of butyl butyrate by free and immobilized lipases

The capacity of the free and immobilized lipases to catalyze butyl butyrate synthesis in n-heptane medium was investigated. Butyl butyrate is a short chain ester widely used in food industry due to its pleasant pineapple flavor [40, 41]. The butyl butyrate synthesis experiments were carried out under 1:1 acid/alcohol molar ratio and present of about 1.5% water. The immobilized enzyme was a higher catalytic activity about 1.7-fold in the esterification of n-butyl alcohol and n-butyric acid compared to the free enzyme. The amount of synthesized butyl butyrate was 72.4 and 42.6% for the free and the immobilized enzyme in the n-heptane. Similar results related to the increment in the amount of ester synthesized after immobilization of lipases were reported in earlier studies [42, 43].

These ester synthesis reactions were carried out in the temperature ranges 20–50 °C. As reported previously, a high temperature value results in the decrease of ester synthesis in organic medium. In this study, the ester production decreased up to 34% when the temperature level raised from 30 to 50 °C in n-heptane medium. On the other hand, an opposite trend was observed for increase temperature from 20 to 30 °C, and in this case, the increase reaction temperature significantly increased the esterification yield and an optimum reaction temperature was obtained at 30 °C (Fig. 9). Similar observations were reported by several researchers [3, 6].

The amount water in the organic media plays a critical role in enzymes structure and function. A small amount of water is essential for the enzymatic activity during ester synthesis reaction and excess water leads to a lower reaction rate as reported earlier. The necessary amount of water for the optimal esterification activity of lipases in organic media depends on the origin of lipase, the surface properties of supports and the polarity of organic solvents [44, 45]. In this study, the effect of water content on the esterification activity of immobilized lipase for synthesis of butyl butyrate from butyric acid and butyl alcohol was carried out in n-heptane medium by addition of different amount of water. As seen in Fig. 10, the immobilized enzyme activity increased significantly as the water content increased up to 1.5% (v/v) water content. It should be noted that the immobilized lipase on the beads had a higher esterification rate at the reaction system containing 1.5% (v/v) water content than that of the pure n-heptane medium. As reported previously, the excess amount of water can attacks the polar site of the immobilized lipase causing reduction in esterification activity. Thus, the hydrophilicity of the support material could play an important role in deciding the extent esterification activity lost [44]. A low esterification yield was observed for the adsorbed lipase when the water content was higher than 1.5% may be a result of accumulation of water molecules surrounding of the immobilized enzyme, which led to a diffusional barrier between enzyme and substrates.

Operational stability of lipase in butyl butyrate synthesis

Lipase is an industrial enzyme, and its repetitive use in the immobilized form is very important as far as the economy of the process is concerned. The operational stability and multiple uses of immobilized lipase can make the process more viable over its free counterpart. Operational stability of the immobilized lipase was determined for six successive batch operations at 30 °C in n-heptane and results are presented in Fig. 11. The residual conversion is given as percentage of initial conversion of butyric acid (first cycle of synthesis) under standard conditions. As seen in Fig. 11, the retained activity of immobilized lipase was around 92% after the third cycle of ester synthesis reaction. After third operation cycle, a steady decrease in ester synthesis capability of the immobilized lipase was observed, and this loss reached to about 73% after six cycles of batch operation. This result showed that the operational stability of immobilized lipase was improved by adsorption on the multi-modal ligand attached beads. In this immobilization system, the active conformation of enzymes might be more stable due to the multi point electrostatic and strong hydrophobic interactions between lipase and the multi-modal ligand. In addition, hydrophilic/hydrophobic functionality of the beaded support could also provide a proper microenvironment for the immobilized enzyme by preventing the accumulation of excess of water around enzyme molecules during the long-time ester synthesis reaction.

Regeneration of the support for reuse in enzyme immobilization

Regeneration is a crucial step for reversible enzyme immobilization techniques. It was thus necessary to evaluate the regeneration efficiency of the TEDETA ligand attached beads after inactivation of the adsorbed enzyme upon use. In order to show the reusability of the beads, adsorption–desorption cycle of lipase was repeated six times by using the same beads. In this system, the lipase adsorbed on the TEDETA ligand attached beads was placed within the cleaning medium containing 1.0 M NaOH. The adsorption–desorption cycle of lipase was repeated five times by using the same beads. The immobilization capacity of the affinity beads did not change significantly after five times use in the repeated use of the support after regeneration of the beads in cleaning medium for 2 h (data not shown). The sixth adsorption–desorption cycle of lipase, the amount of immobilized enzyme (72.8 mg/g beads) was about 5% lower than that of the first use (78.1 mg protein/g beads). It should be noted that the immobilized enzyme activity was not changed during these reversible immobilization cycles of lipase on the same support. The activity performance of the immobilized enzyme was also same on the support as the first load at the end of the six cycles. This indicates that the prepared TEDETA attached beads were of high stability in repeated enzyme loading.

Conclusion

In this study, the P(S-b-GMA) grafted and TEDETA ligand attached to P(S–DVB) beads were used for the immobilization of Mucor miehei lipase via physical adsorption. The adsorption behavior of the lipase onto the nanofibrous polymer coated and multi-modal-ligand attached beads was investigated in various reaction conditions. It was observed that pH and initial concentration of enzyme greatly effects on the adsorption equilibrium. Notably, the optimum pH and temperature profiles of the immobilized enzyme did not differ so much from those of the free enzyme. The V max and K m values for the immobilized enzyme were lower and higher compared to free counterpart, respectively. The thermal and storage stability of the lipase was shown to increase upon immobilization. These results show that fibrous polymer grafted and ligand attached beads are promising supports in the reversible enzyme immobilization technology for industrial applications. Finally, the immobilized lipase showed enhanced activity for butyl butyrate synthesis compared to the free counterpart and exhibited a good operational stability for the esterification reaction in n-heptane medium. The overall results showed that, the supported-enzyme system presented is suitable biocatalyst which is useful in the synthesis of different flavors for pharmaceutical and food industries.

References

Gaur R, Gupta GN, Vamsikrishnan M, Khare SK (2008) Protein-coated microcrystals of Pseudomonas aeruginosa PseA lipase. Appl Biochem Biotechnol 151:160–166

Raghavendra T, Sayania D, Madamwar D (2010) Synthesis of the ‘green apple ester’ ethyl valerate in organic solvents by Candida rugosa lipase immobilized in MBGs in organic solvents: effects of immobilization and reaction parameters. J Mol Catal B Enzym 63:31–38

Dwiarti L, Ali E, Park EY (2010) Enhancement of lipase catalyzed-fatty acid methyl esters production from waste activated bleaching earth by nullification of lipase inhibitors. Bioresour Technol 101:14–20

Karagoz B, Bayramoglu G, Altintas B, Bicak N, Arica MY (2010) Poly(glycidyl methacrylate)–polystyrene diblocks copolymer grafted nanocomposite microspheres from surface-initiated atom transfer radical polymerization for lipase immobilization: application in flavor ester synthesis. Ind Eng Chem Res 49:9655–9665

Bayramoglu G, Altintas B, Arica MY (2011) Reversible immobilization of uricase on conductive polyaniline brushes grafted on polyacrylonitrile film. Bioprocess Biosyst Eng (in press)

Torres S, Baigori MD, Swathy SL, Pandey A, Castro GR (2009) Enzymatic synthesis of banana flavour (isoamyl acetate) by Bacillus licheniformis S-86 esterase. Food Res Int 42:454–460

Serri NA, Kamaruddin AH, Long WS (2006) Studies of reaction parameters on synthesis of Citronellyl laurate ester via immobilized Candida rugosa lipase in organic media. Bioprocess Biosyst Eng 29:253–260

Yang J, Ma X, Zhang Z, Chen B, Li S, Wang G (2010) Lipase immobilized by modification-coupled and adsorption–cross-linking methods: a comparative study. Biotechnol Adv 28:644–650

Milasinovic N, Milosavljevic N, Filipovic J, Knezevic-Jugovic Z, Krusic MK (2010) Synthesis, characterization and application of poly(N-isopropylacrylamide-co-itaconic acid) hydrogels as supports for lipase immobilization. React Funct Polym 70:807–814

Bayramoglu G, Kacar Y, Arica MY (2002) Covalent immobilization of lipase onto hydophobic group incorporated poly(hydroxyethyl-methacrylate) based membrane matrix. J Food Eng 52:367–374

Arica MY, Soydogan H, Bayramoglu G (2010) Reversible immobilization of Candida rugosa lipase on fibrous polymer grafted and sulfonated p(HEMA/EGDMA) beads. Bioprocess Biosyst Eng 33:227–236

Bayramoglu G, Senel AU, Yilmaz M, Arica MY (2008) Preparation of nanofibrous polymer grafted magnetic poly(GMA-MMA)-g-MAA beads for immobilization of trypsin via adsorption. Biochem Eng J 40:262–274

Arica MY, Bayramoglu G (2006) Invertase reversibly immobilized onto polyethylenimine-grafted poly(GMA-MMA) beads for sucrose hydrolysis. J Mol Catal B Enzym 38:131–138

Arica MY, Bayramoglu G (2004) Reversible immobilization of tyrosinase onto polyethyleneimine-grafted and Cu(II) chelated poly(HEMA-co-GMA) reactive membranes. J Mol Catal B Enzym 27:255–265

Bayramoglu G, Arica MY (2010) Reversible immobilization of lipase on fibrous polymer grafted and metal chelated chitosan membrane. J Mol Catal B Enzym 62:297–304

Yavuz E, Bayramoglu G, Senkal BF, Arica MY (2009) Poly(glycidylmethacrylate) brushes generated on poly(VBC) beads by SI-ATRP technique: hydrazine and amino groups functionalized for invertase adsorption and purification. J Chromatogr B 877:1479–1486

Costa L, Brissos V, Lemos F, Ribeiro RF, Cabral JMS (2009) Enhancing the thermal stability of lipases through mutagenesis and immobilization on zeolites. Bioprocess Biosyst Eng 32:53–61

Li Y, Gao F, Wei W, Qu J-B, Ma G-H, Zhou W-Q (2010) Pore size of macroporous polystyrene microspheres affects lipase immobilization. J Mol Catal B Enzym 66:182–189

Acar MH, Bicak N (2003) Synthesis of hexylated triethylenetetramine. A new ligand for homogeneous atom transfer radical polymerization. J Polym Sci A Polym Chem 41:1677–1680

Cullen SP, Liu XS, Mandel IC, Himpsel FJ, Gopalan P (2008) Polymeric brushes as functional templates for immobilizing ribonuclease A: study of binding kinetics and activity. Langmuir 24:913–920

Sun L, Dai JH, Baker GL, Bruening ML (2006) High-capacity, protein-binding membranes based on polymer brushes grown in porous substrates. Chem Mater 18:4033–4039

Bicak N, Gazi M, Galli G, Chiellini E (2006) Polystyrene microspheres having epoxy functional dangling chains linked by hydrolytically stable bonds via ATRP. J Polym Sci A Polym Chem 44:6708–6716

Jain P, Vyas MK, Geiger JH, Baker GL, Bruening ML (2010) Protein purification with polymeric affinity membranes containing functionalized poly(acid) brushes. Biomacromolecules 11:1019–1026

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein–dye binding. Anal Biochem 72:248–254

Furniss BH, Hannaford AJ, Rogers V, Smith PWG, Tatchell AR (eds) (1978) Vogel’s textbook of practical organic chemistry, 4th edn. Longman Inc, New York, p 287

Johansson BL, Belew M, Eriksson S, Glad G, Lind O, Maloisel JL, Norrman N (2003) Preparation and characterization of prototypes for multi-modal separation media aimed for capture of negatively charged biomolecules at high salt conditions. J Chromatogr A 1016:21–33

Chang Y-K, Chou S-Y, Liu J-L, Tasi J-C (2007) Characterization of BSA adsorption on mixed mode adsorbent I. Equilibrium study in a well-agitated contactor. Biochem Eng J 35:56–65

Yang T, Malmquist G, Johansson B-L, Maloisel J-L, Cramer S (2007) Evaluation of multi-modal high salt binding ion exchange materials. J Chromatogr A 1157:171–177

Yavuz E, Bayramoglu G, Senkal BF, Arica MY (2009) Poly(vinylbenzylchloride) beads grafted with polymer brushes carrying hydrazine ligand for reversible enzyme immobilization. J Appl Polym Sci 113:2661–2669

Garcia-Diego C, Cuellar J (2008) Preparation and characterization of a dye–ligand adsorbent for lysozyme adsorption. Chem Eng J 143:337–348

Bayramoglu G, Yilmaz M, Arica MY (2010) Reversible immobilization of laccase to poly(4-vinylpyridine) grafted and Cu(II) chelated magnetic beads: biodegradation of reactive dyes. Bioresour Technol 101:6615–6621

Arıca MY, Bayramoglu G (2004) Polyethyleneimine grafted poly(hydroxyethyl methacrylate-co-glycidyl methacrylate) membranes for glucose oxidase immobilization. Biochem Eng J 20:73–77

Bayramoglu G, Yalın E, Arıca MY (2005) Immobilization of urease via adsorption onto l-histidine-Ni(II) complexed poly(HEMA-MAH) microspheres: preparation and characterization. Process Biochem 40:3505–3513

Arica MY (2000) Immobilization of polyphenol oxidase on carboxymethylcellulose hydrogel beads: preparation and characterization. Polym Int 49:775–781

Arica MY, Tunalı Y, Bayramoglu G (2007) Immobilization of β-galactosidase onto magnetic poly(GMA–MMA) beads for hydrolysis of lactose in bed reactor. Catal Commun 8:1094–1101

Bayramoglu G, Arica MY (2008) Enzymatic removal of phenol and p-chlorophenol in enzyme reactor: horseradish peroxidase immobilized on magnetic beads. J Hazard Mater 156:148–155

Kartal F, Akkaya A, Kilinc A (2009) Immobilization of porcine pancreatic lipase on glycidyl methacrylate grafted poly vinyl alcohol. J Mol Catal B 57:55–61

de Oliveira PC, Alves GM, de Castro HF (2000) Immobilisation studies and catalytic properties of microbial lipase onto styrene–divinylbenzene copolymer. Biochem Eng J 5:63–71

Ozmen EY, Sezgin M, Yilmaz M (2009) Synthesis and characterization of cyclodextrin-based polymers as a support for immobilization of Candida rugosa lipase. J Mol Catal B 57:109–114

Dandavate V, Keharia H, Madamwar D (2009) Ethyl isovalerate synthesis using Candida rugosa lipase immobilized on silica nanoparticles prepared in nonionic reverse micelles. Process Biochem 44:349–352

Pires-Cabral P, da Fonseca MMR, Ferreira-Dias S (2010) Esterification activity and operational stability of Candida rugosa lipase immobilized in polyurethane foams in the production of ethyl butyrate. Biochem Eng J 48:246–252

Bayramoglu G, Hazer B, Altıntas B, Arica MY (2011) Covalent immobilization of lipase onto amine functionalized polypropylene membrane and its application in green apple flavor (ethyl valerate) synthesis. Process Biochem 46:372–378

Kumari A, Mahapatra P, Kumar GV, Banerjee R (2008) Comparative study of thermostability and ester synthesis ability of free and immobilized lipases on cross linked silica gel. Bioprocess Biosyst Eng 31:291–298

Santos JC, de Castro HF (2006) Optimization of lipase-catalysed synthesis of butyl butyrate using a factorial design. World J Microbiol Biotechnol 22:1007–1011

Su G-D, Huang D-F, Han S-Y, Zheng S-P, Lin Y (2010) Display of Candida antarctica lipase B on Pichia pastoris and its application to flavor ester synthesis. Appl Microbiol Biotechnol 86:1493–1501

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Bayramoglu, G., Karagoz, B., Altintas, B. et al. Poly(styrene–divinylbenzene) beads surface functionalized with di-block polymer grafting and multi-modal ligand attachment: performance of reversibly immobilized lipase in ester synthesis. Bioprocess Biosyst Eng 34, 735–746 (2011). https://doi.org/10.1007/s00449-011-0523-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-011-0523-1