Abstract

Grafting is one of the best method for the modification of physicochemical properties of the cellulose. The –OH groups present at C2, C3, and C6 atoms of each β-d-glucopyranose units of cellulose chains are the most susceptible active sites for the grafting of many monomer units or polymers for the formation of a variety of cellulose-based graft copolymers with advanced properties and potential applications as compared to the bare cellulose. In this review article, a brief introduction to get an insight into the structural features of cellulose is given. After that, the potential applications and recent advancements of various cellulose graft copolymers made in fields of controlled drug delivery, adsorption of harmful, toxic and non-biodegradable dyes from industrial effluents, sorption of heavy metal ions from aqueous medium, modification of electrolyte, electrodes and separators of the modern age Lithium ion batteries, and fabrication of smart and innovative food packaging materials are reviewed.

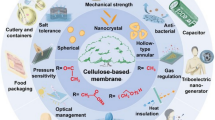

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural biopolymers have received an appreciable attention of the researcher throughout the world because of their remarkable properties and potential applications in innumerable fields. Among the various listed biopolymers, cellulose is a versatile, renewable, inexpensive, abundant, and extensively studied bio-based polymer, whose contents in the various lignocellulosic biomass vary from few percent to even 98% [1]. It is commonly used for making paper, paperboard, cellophane membranes, fabrics, water-soluble adhesives, and binders. In spite of these traditional applications, a large fraction of this biopolymer, in particular from agro-waste, remains un-utilized and is either usually burnt or allowed to decompose naturally, causing serious environmental and ecological issues. The potential scope of this renewable biopolymer is further limited owing to its insoluble nature in common solvents. However, recent progress in polymer chemistry has triggered and introduced new pathways of utilizing the cellulose for the synthesis of varieties of bio-based cellulose derivatives, composites, and copolymers with improved functionalities, as potential candidates for advanced applications. Chemical modifications of the cellulose not only improve the chemical, physical, mechanical, and thermal properties, but also increase the hydrophilicity to different extents depending upon the mode of modification and nature of modifying agents. These modified cellulose-based materials are further advantageous over synthetic polymers due to their biodegradability and recyclability.

Regardless of its source, cellulose is a chiral, hydrophobic, linear polymer of β-d-anhydroglucopyranose units which are linked through C1–C4 covalent β-glycosidic linkages. Each β-d-glucopyranose unit carries three free hydroxyls (–OH) groups at C2, C3, and C6 atoms [2]. Hydrolytic studies conducted in the past reveal the formation of cellobiose units which confirms the fact that cellulose is, in fact, a polymer of cellobiose units [3] (Fig. 1).

Due to the presence of electronegative O atoms and –OH groups on β-d-glucopyranose units, equatorial conformations, neighboring cellulose chains, are held together by strong inter- as well as intramolecular hydrogen bonding resulting in the formation of microfibrils with physical and chemical stabilities and high tensile strength [4, 5]. The active sites in the form of –OH groups present at C2, C3, and C6 atoms of each β-d-glucopyranose units of cellulose chains can be easily attacked for the grafting of a variety of monomer units or polymers for the formation of grafted cellulosic polymers with advanced properties and potential applications as compared to virgin cellulose. In general, there are three basic techniques, i.e., grafting to (polymer-to-polymer grafting), grafting from (monomer-to-polymer grafting), and grafting through (copolymerization), reported in the literature for the synthesis of grafted copolymers of cellulose [6]. Among these, the grafting-from technique is preferred over other techniques due to faster rates of grafting reactions [7]. Considering the physicochemical properties required for a particular type of application of grafted cellulosic materials, the concentration of the monomeric units, the degree of the polymerization, graft distribution, and polydispersity, different grafting methods initiated through chemicals, radiations, plasma radiations, enzymes, and radiations are employed. Various types and subtypes of these grafting methods are schematically represented in Scheme 1 and have been well elaborated elsewhere [8,9,10,11,12].

The main focus of this review article is to elaborate some of the potential and crucial applications of the grafted cellulosic copolymers in the fields of controlled drug release, adsorption of harmful, toxic and non-biodegradable dyes from industrial effluents, sorption of heavy metal ions from aqueous medium, modification of electrolyte, electrodes, and separators of the modern Lithium ion batteries, and fabrication of smart and innovative food packaging materials along with the discussion about some important factors which affect the candidature of cellulose-based materials for these applications.

Applications of cellulose graft copolymers

Controlled drug release

Many biodegradable and biocompatible polymers such as polysaccharides (starch and cellulose), carrageenan, chitosan, alginate, and their derivatives are explored as stimuli-responsive polymers for controlled delivery of a variety of drugs including antibiotics, anti-inflammatory agents, antipyretics, analgesics, enzymes, steroids, hormones, immune-suppressants, and contraceptives [13,14,15]. As compared to the conventional methods, the controlled drug delivery systems offer advantages in terms of refined efficacy, minimized toxicity, drug delivery over an extended period of time (temporal control), and at a particular site of activity (distribution control) and convenience [16,17,18,19,20]. Three basic mechanisms for temporal control have been reviewed in the literature, namely, delay drug dissolution, diffusion-controlled release, and drug solution flow control. For distribution control, the polymer matrix is stuffed with a site-specific targeting moiety called space molecules [13,14,15,16,17,18]. Cellulose graft copolymers are one of the potential and suitable candidates as a drug carrier [15,16,17,18,19,20,21,22,23,24,25,26] (Table 1). In addition to the nature of the cellulose backbone, grafted polymer, the functional groups present in the grafted copolymer, presence of cross-linkers in the cellulose graft copolymer matrix, other stimuli including pH, ionic strength, temperature, nature of the solvent, and drug to be loaded greatly influence the loading efficiency (LE), encapsulation efficiency (EE), and cumulative percentage drug release [21,22,23,24,25,26] (Eqs. 1–3). However, to maintain human body compatibility, all the drug release experiments are performed at the physiological pH of 7.4 and at 37 °C:

The nature of the drug carrier, its hydrophilicity, and hydrophobicity, pH, the extent of cross-linking, composition of the cellulose-based drug carrier, micellization behavior of carriers, drug solubility, temperature, and interactions between the drug and drug carrier moieties are the most critical factors which affect the LE and EE. The various drug–carrier physical interactions involved are van der Waals forces, interlocking, electrostatic, and capillary force, whereas chemical interactions involve chemisorption and reversible chemical reactions between the functional groups of the drugs and carrier molecules which are susceptible to hydrolyze during the release process [27]. Wang et al. [15] synthesized EC-g-PDEAEMA copolymers assisted through ATPR polymerization and studied the pH-responsive behavior of EC-g-PDEAEMA copolymers for controlled release of sparingly water-soluble RIF drug. A micellar aqueous solution of EC-g-PDEAEMA was prepared by adding EC-g-PDEAEMA solution in THF into an aqueous medium having pH of 3.2 dropwise and with continuous stirring followed by dialysis. It was suggested that in EC-g-PDEAEMA copolymers, the hydrophobic and hydrophilic nature of ethyl cellulose backbone and grafted side chain PDEAEMA results in the micellization of the copolymer in selective solvents and the critical micelle concentration of the EC-g-PDEAEMA copolymers was found to decrease with increase in the graft PDEAEMA chain length and graft density. Due to the interactions between the N atoms of the PDEAEMA grafted chains and the hydroxyl groups of the RIF, LE was increased for a higher dose of the drug. Similarly, Amin et al. [16] also reported BC-g-PAA as pH-sensitive carries, particularly for protein-based gastric drugs such as BSA, which can survive from very strong acidic (pH 1.2) conditions owing to their lesser extent of BC-g-PAA swelling under these conditions.

For EC-g-PolyPEGMA copolymers, a lower release rate for pyrene was reported for shorter PolyPEGMA side chains of the EC-g-PolyPEGMA copolymer and a higher EC-g-PolyPEGMA–pyrene ratio [17].

In addition to graft cellulosic copolymers, cellulose-based hydrogels are also reported in the literature with potential controlled drug release applications. For such biomedical applications, the stability and swelling properties of the cellulose-based hydrogels play a key role. Sodium CMC and cellulose were cross-linked using ECH as cross-linker in the NaOH/urea aqueous system for the fabrication of novel cellulose-based superabsorbent hydrogels [18]. It was observed that the presence of cellulose in the hydrogel was necessary for the stability as the author did not report hydrogel prepared without cellulose. It was proposed that the –OH groups of the cellulose present at C2, C3, and C6 atoms of each β-d-glucopyranose units of cellulose chains were cross-linked to the –OH groups of the CMC. Because of the mechanical strength and stiffness of the cellulose chains, they act as a strong backbone to maintain the stability of the hydrogel. However, cellulose contents in the hydrogel inversely affected the swelling properties. Figure 2 represents the swollen states of sodium CMC–cellulose cross-linked super adsorbent hydrogel under different conditions are represented.

[Reprinted with permission from Ref. [18], © 2009 Elsevier Ltd.]

a Original hydrogel synthesized. b Distilled water-swollen hydrogel. c Completely vacuum-dried hydrogel and d hydrogel swollen in 0.1 M aqueous NaCl solution to an equilibrium state.

A high degree of rigidity due to extensive cross-linking also decreases the cumulative release percent of the drugs. Cross-linked copolymers of cellulose pose extra mechanical stability as compared to either pure homopolymers or cellulosic copolymers synthesized without using any cross-linkers. Homopolymer polyacrylamide-based hydrogels prepared without using MBA cross-linker were reported to be unstable, flimsy, delicate, and translucid, while polyacrylamide-cellulose acetate hydrogels were quite strong, hard, and opaque. In contrast, polyacrylamide-cellulose acetate hydrogels prepared using MBA cross-linker were transparent [28].

In addition to the optimization of copolymer–drug ratio, the amount of cross-linker during grafting polymerization is a crucial factor [19,20,21]. The optimization of the copolymer–drug ratio is important for the homogeneous distribution of the drug particles at the active sites present on the surface of the cellulose-based copolymer. Very low contents of the drug will leave some of the active sites of the copolymer vacant, thereby reducing efficiency and effective drug release at the target. In contrast, very high drug loadings could lead to the formation of some segregated agglomerates of drug molecules due to drug–drug adhesion [29].

The drug release behavior of the cellulose-based copolymers is also affected by the influence of the presence of different electromagnetic radiations. According to Fomina et al. [14] wavelengths and intensities of UV, visible, and near-infrared radiation can be easily tuned for controlled drug release without disturbing the physiological changes. A light-sensitive EC-g-PHEMA-g-PSPMA copolymer was successfully prepared [22] through ATRP. Due to the presence of light-responsive SPMA monomer, the grafted hydrophobic chains of PSPMA switch to hydrophilic nature under the UV light irradiation with squeezed micelle diameter.

In addition to radiation-responsive drug release carriers, recent studies are also focusing on the synthesis and development of some thermo-sensitive cellulose-based drug carriers. Nanofibrous blends of hydrophilic PNIPAAm and hydrophobic EC prepared through electrospinning technique were recently reported to exhibit excellent thermo-sensitive sustained in vitro release of KET in PBS of physiological pH 7.4. A faster release of KET was observed at 25 °C in contrast to at 35 °C temperature. PNIPAAm is a thermo-sensitive polymer and undergoes a faster phase transition from linear (hydrophilic) to globular (hydrophobic) at LCST of 32 °C (Fig. 3) [30].

Hydrophilic carriers show a faster rate of drug release as compared to a hydrophobic carrier [31]. At lower temperature of 25 °C, hydrophilic nature of PNIPAAm in the nanofibrous blends is responsible for faster KET release which lowers at higher (>32 °C) 37 °C due to its switching over to hydrophobic nature. It was further concluded that a higher contents of temperature-sensitive PNIPAAm in the EC nanofibrous blends favor the faster drug release at lower 25 °C but opposes drug release at a higher temperature of 37 °C [30]. Thus, cellulose graft copolymers may be one of the revolutionary, smart, and stimuli-responsive materials of future for controlled drug release applications.

Lithium ion batteries

Lithium ion batteries, due to their excellent energy storage capacity, are the major power sources of almost every portable and non-portable modern electronic gadget. Continuous research is going on around the globe to modify the electrodes, spacers/separators and electrolytes of these electrochemical devices to make them safer, flexible, electrochemically, thermally and mechanically more stable, environmental friendly with improved energy density. For devices such as smart cards, displays and many embeddable and implantable medical devices, the flexibility of the battery is the major requisite. Photo-cured quasi-solid polymer membrane derived from acrylic acid and methacrylic acid gel polymer electrolytes shows remarkable electrochemical behavior [32]. To enhance the mechanical strength of these membranes, cellulose and cellulose-based materials are, nowadays, considered to be good reinforcing agents for gel/solid polymer electrolytes, in making or modifying electrode materials and spacers owing to their excellent wettability, low cost, high porosity, remarkable mechanical properties, and light weight [32, 33]. UV-induced in situ grafting of PEGMA polymer network in the presence of GA on to the surface of the cellulose fiber sheet was also studied [34]. The polymer membranes thus formed exhibited high elastic modulus, tensile resistance with high flexibility, high ionic conductivity, and excellent electrochemical conductivity. Cellulose-based BEMA and PEGMA copolymer membranes without GA (Fig. 4a) and GA laden (Fig. 4b) prepared using 2-hydroxy-2-methyl-1-phenyl-1-propanone free radical initiator degraded much faster. In contrast, cellulose paper grafted with PEGMA polymer network either in the presence of GA (Fig. 4c) or radical/cationic photoinitiators (Fig. 4d) maintained its mechanical characteristics even after 2 h of swelling in standard liquid electrolyte solution consisting of lithium bistrifluoromethane sulfonimide (CF3SO2NLiSO2CF3) salt dissolved in EC–DEC.

[Reprinted with permission from Ref [34], © The Royal Society of Chemistry 2014]

a Cellulose–BEMA–PEGMA copolymer membranes without GA after 5 min of swelling. b Cellulose–BEMA–PEGMA copolymer membranes with GA after 1 h of swelling. c Cellulose–BEMA–PEGMA copolymer membranes with GA and using radical/cationic photoinitiator after 2 h of swelling and d cellulose–BEMA–PEGMA copolymer membranes with GA, using radical/cationic photoinitiator and EC–DEC after 2 h of swelling in Lithium bistrifluoromethane sulfonimide.

To ascertain the chemical bonding between the cellulose sheet and the polymer gel electrolyte, the addition of inorganic fillers such as alumina nanoparticles is also proposed in the literature [34, 35]. The presence of alumina in the matrix did not affect the mechanical and thermal properties of the gel polymer electrolytes but led to a noticeable increase in the ionic conductivity (Fig. 5a).

[Reprinted with permission from Ref [35], ©2014 Elsevier Ltd]

a Variations of conductivity as a function of temperature and b comparison of tensile strength and Young’s modulus for cellulose paper grafted with BEMA and PEGMA in the absence of benzophenone (PCE), in the presence of benzophenone as initiator (PCE–BP), and the alumina-modified (PCE–BP–Al).

The tensile strength values and Young’s modulus for cellulose paper grafted with BEMA and PEGMA in the absence of benzophenone (PCE), in the presence of benzophenone as initiator (PCE–BP), and the alumina-modified (PCE–BP–Al) cellulose paper are represented in Fig. 5b. When soaked in Lithium bistrifluoromethane sulfonimide salt dissolved in EC–DEC for 15 min, PCE–BP, and PCE–BP–Al maintain their integrity while grafting was detached from the cellulose paper for PEC. The results confirmed that the use of initiators such as benzophenone is essential for successful grafting of the polymers matrix onto the cellulosic materials [35].

Chelmecki et al. [36] grafted oligo(ethylene oxide) branches through ether cross-linkages onto the 2-HPC to improve its mechanical properties. The cross-linked stable film exhibited a storage modulus and conductivity of 105 Pa at 100 °C and 2.5 × 10−4 S cm−1 at room temperature, respectively. The PEO–HPC/lithium bistrifluoromethane sulfonimide blends as separators were also tested in by constructing a rechargeable cell with a maximum cell voltage of 3.65 V, comparable to a commercial Li-ion battery. Paracha et al. [37] synthesized grafted lithium salt of AASO3H onto the EC initiated through ABCN as a free radical initiator and DAA as a solvent, followed by co-grafting of MMA with the help of ethylene glycol dimethacrylate as cross-linker. It was concluded that the mechanical strength, as well as conductivity of the gel polymer electrolyte, was influenced by the concentration of EC and MMA.

Cellulose-grafted materials are also studied as binders for high-capacity anodic electrodes like Si with very low discharge potential and extremely high charge capacity as compared to graphite anodes [38, 39]. Usually, Si anodes are reported to undergo a large anisotropic volume change during the charging–discharging cycles resulting into pulverization, degradation and thus a substantial loss in its charge storage capacity [40]. NaPAA-g-CMC copolymer prepared via free radical polymerization of CMC and sodium acrylic acid was used as a binder material for Si anode in lithium ion batteries [41], which enhanced the cell cycle stability with coulombic efficiencies. It was proposed that the as-fabricated NaPAA-g-CMC copolymer not only acts as a binder for Si anode through its multi-point interactions with Si particles but also helps in the building of solid electrolyte interfaces onto the Si surface. As compared to bare, linear structured NaPAA and CMC, highly branched copolymer NaPAA-g-CMC offers more interactions with the Si as well as Cu particles, resulting in better binding capacity. Peeling tests performed for the said binders showed that the Si–Cu anodic surface coated with NaPAA-g-CMC remains intact, whereas a major portion of the PAA and CMC binders was peeled off. The results demonstrate that NaPAA-g-CMC, as binder imparts higher mechanical stability to the Si anode as compared to PAA and CMC binders.

In addition to the electrolyte and the electrodes of Li-ion batteries, the third most crucial component is the separator, which plays a significant role in electrical isolation of anode and cathode to avoid any electric short circuits [42]. The permeability of the separators allows the rapid transportation of the charge carriers across it to complete the circuit [43]. A separator must have thermal, chemical, and electrochemical stabilities, proper thickness and porosity, permeability, wettability, and thermal shutdown. The most commonly used separators may constitute membrane sheets made up of PE, PP, PTFE, PVC, some nonwoven fibers of cotton, nylons, polyesters, etc. To improve the above-mentioned properties of the separators for high-capacity and longer life Li-ion batteries, many attempts have been made and reported in the literature [44,45,46,47,48,49]. One of the approaches involves the incorporation or coating of inorganic nanomaterials such as Al2O3 [44, 45], SnO2 [46], and SiO2 [47,48,49] into the polymer matrix. These nanomaterials, though improve the mechanical and thermal stabilities of the polymer separators, have no remarkable effect on the wettability, permeability, and ionic conductivity of the separator membranes. Grafted copolymers based upon cellulosic materials are nowadays studied to address all the related properties of the Li-ion battery separators. Polymer electrolyte, PVDF-HPF was nonwoven with cellulose acetate via an electrospinning technique [50]. For this cellulose/PVDF-HFP composite membrane, electrolyte wettability—a crucial parameter for cycle performance—was found to be superior to polypropylene (PP) and cellulose nonwoven sheets (Fig. 6a), which may be attributed to the hydrophobic nature and low surface energy of the latter materials. Rapid and large-scale wettability further improves the electrolyte uptake and ionic conductivity of the cellulose/PVDF-HFP composite membrane.

Photograph representing a electrolyte wettability b before heat treatment. c After heat treatment at 200 °C for 0.5 h. [Reprinted with permission from Ref. [50] © 2012 American Chemical Society] Thermal stabilities of PP separator and cellulose/PSA composite membranes d before and e after exposure to 200 °C for 0.5 h [Reprinted with permission from Ref. [51], © 2013 American Chemical Society]

In addition, the thermal tolerance studies also proved the better thermal stability of the cellulose/PVDF-HFP membranes when treated at 200 °C for 0.5 h (Fig. 6b, c). Negligible dimensional changes were observed for cellulose/PVDF-HFP composite nonwoven. In contrast, PP separator was melted and curled even at a low temperature of 165 °C which may lead to thermal shrinkage at elevated temperatures resulting in internal short circuits. Excellent thermal stability of the cellulose/PVDF-HFP composite thus could efficiently avoid the electrical short circuits in the batteries even at elevated temperatures.

Xu et al. [51] reported a simple, cost-effective, and facile papermaking process to fabricate cellulose/polysulfonamide (cellulose/PSA) composite membrane as Li-ion battery separator with enhanced mechanical and thermal stabilities, low interfacial resistance, better rate capability, and cell cycle performances. As-fabricated cellulose/PSA composite membrane does not undergo any thermal damage at an even elevated temperature of 200 °C and maintained its original dimensions, while the PP membrane separator was unable to do so (Fig. 6d, e). Further, liquid electrolyte (1 M LiPF6 in EC/DMC)-soaked cellulose/PSA composite membrane exhibited a superior ionic conductivity of 1.2 × 10−3 S cm−1 because of the synergism between the electrolyte and cellulose/PSA material.

Dye adsorption

With the fast industrialization in the modern era, environmental pollution is at its alarming rate. Effluent released from textile, dyeing, printing, and paint industries contains highly toxic and non-biodegradable dyes. These dyes are generally accumulated in the water bodies making the water unfit for aquatic life and domestic use. Additionally, due to the strong visible light-absorbing capacity of these dyes, aquatic plants do not receive sufficient sunlight for photosynthesis directly thereby increasing the BOD as well as COD [52]. The removal of these harmful dyes from industrial effluent before its discharge into water bodies is thus an important issue. The techniques such as adsorption, flocculation, reduction, electrochemical oxidation, chemical precipitation, and electrolysis are most widely used [53]. Recently, many un-doped or doped p-type or n-type metal oxide semiconductor materials are used as photocatalyst for the degradation of organic dyes under UV or visible light irradiation. However, large-scale industrial implementation of this method is still under investigation [54]. Among the various dye removal techniques, flocculation and adsorption are two, low-cost, simple, viable and facile techniques. Natural polymers in either pure or modified form are not only nontoxic, biodegradable, easily available, recyclable, mechanically and thermally stable and cheap but are also highly efficient green adsorbents and flocculants. One of the most abundant natural biopolymers is cellulose. In spite of having free hydroxyl groups (–OH) groups, cellulose is water insoluble and chemically nonreactive. Chemical modifications and grafting of cellulose are the two main approaches applied to overcome these limitations. The extent of dye adsorption is directly influenced by the physical and chemical properties, nature, and the amount of functionalities present on the adsorbent and adsorbates [55,56,57,58,59,60,61,62,63,64,65,66,67,68]. Modification of cellulose to CMC by the introduction of the negatively charged carboxyl groups improves the electrostatic attractions selectively with cationic/basic dyes such MB and CV [57,58,59, 62, 63, 67].

Roy et al. [55] modified the cellulosic contents of jute fiber with polyphenolic tannin in aqueous medium facilitated through epoxy activation for adsorption of CR dye from an aqueous solution. The adsorption capacity of the modified jute fiber was reported to be much higher that of the unmodified jute fibers. N atoms of –N=N– and –NH2 group, and S and O atoms of –SO3 – group of CR dye form intermolecular hydrogen bonding with either –OH groups of the cellulose chain or phenolic –OH groups of the tannin (Fig. 7).

[Reprinted with permission from Ref [55], © 2013 American Chemical Society]

Pictorial representation showing H-bonding between –OH groups of the cellulose backbone or phenolic –OH groups of the tannin with N, S, and O atoms of CR dye molecules.

Cellulose-based grafted copolymers with enhanced functionalities also act as excellent adsorbents for dyes from wastewater. Lee et al. [56] reported PAA-grafted cellulose as excellent adsorbents along with very high flocculation efficiency. Table 2 represents some recently modified and grafted cellulosic adsorbents along with optimized conditions for the adsorption of different dyes.

Grafting of cellulose through different polymers is reported to improve the physicochemical and thermal stability, increase the surface area, porosity and the density of adsorption sites for better sorption applications [59]. Different research groups have expressed the dye adsorption efficiencies differently (Eqs. 4, 5) [57, 58]:

where C o and C is the initial and equilibrium dye concentrations in the solution, V is the volume of the solution and m mass of adsorbent used.

In addition to the nature of adsorbent and adsorbate, the factors such as pH of the dye solution, temperature, initial dye concentration, contact time, the amount of the adsorbent also affect the rate and extent of adsorption of the dye [55, 68]. The presence of some additives such as surfactants and electrolytes, largely used in textile and dyeing industries, also influences the adsorption parameters [62]. At optimized temperature, mobility of the dye molecules is increased, strong interaction operate between the functional groups of the dye molecules and the adsorption sites of the grafted cellulosic adsorbents and swelling is induced with modification of the internal structure of the bio-adsorbent thereby influencing the penetration power of the dye molecules deep into the adsorbent matrix [63, 69].

The introduction of aldehydic (–CHO) functional groups by the oxidation of cellulosic –OH groups also provides active sites for the chemisorption of dye through the formation of Schiff bases. Kumari et al. [61] cross linked cellulose fibers extracted from pine needles of Pinus wallichiana using epichlorohydrin as cross-linker. The cross-linked polymer was oxidized by NaIO4 to form CCDA. Schiff base was proposed to be formed between the two primary amino groups of the CR dye with the –CHO groups of the CCDA (Fig. 8).

[Reprinted with permission from Ref. [61], © 2016 Elsevier Ltd.]

Pictorial representation of the formation of Schiff’s base between CR dye and oxidized cross-linked cellulose chains.

Anionic functional groups such as carboxylate (–COO–) and sulfonates (–SO3 –) of grafted cellulosic adsorbents are easily protonated in the acidic medium. This reduced the adsorbing capacity of the grafted cellulosic adsorbents to adsorb cationic dyes in particular. However, in alkaline medium, such dyes are strongly attracted toward these functional groups of the grafted cellulose-based bio-adsorbents due to deprotonation [62, 70]. Thus, cationic dyes are efficiently removed from the dye solution at high pH, whereas anionic dye prefers low-pH conditions. This differential behavior can be utilized to remove cationic or anionic dyes preferentially from a mixture solution. Lin et al. [31] observed 98.76% removal of cationic MB dye at pH 10, whereas, for anionic OR-II dye, 71.73% of removal was observed at pH 2 at room temperature from the mixture solution of two dyes.

A proper ratio of the dosages of grafted cellulose material as adsorbent and dye as adsorbate is also necessary to achieve maximum adsorbed per unit mass and percent dye removal efficiency. A high adsorbent to adsorbate ratio, no doubt increases the percent dye removal efficiency but decreases the adsorption capacity per unit mass of adsorbent due to the unsaturation of the active sites, whereas at a low adsorbent to adsorbate ratio, the dye removal percentage decreases due to non-availability of the active sites for adsorption [57, 71]. To investigate the adsorption equilibrium of dyes, various adsorption isotherms such as Langmuir, Freundlich, Temkin, Dubinin–Radushkevich, Redlich–Peterson are reported in the literature and the corresponding linear equations are given below (Eqs. 6–12) [61, 63, 64, 67, 68].

This model assumes a monolayer adsorption at a fixed number of identical localized sites sterically independent of each other [72]. Another dimensionless factor called separation factor, R L, is used to describe the shape and favorability of the Langmuir adsorption isotherm, where

For linear and irreversible Langmuir adsorption isotherm R L = 1 and 0, respectively. For favorable fitting, R L = 0 → 1, whereas for unfavorable fitting R L > 1.

For favorable fitting, \( 0 < \frac{1}{n} < 1. \)

In contrast to Langmuir isotherm model, it assumes a multilayer adsorption, with non-uniform distribution of heat of adsorption over the heterogeneous adsorbent surface [67, 68].

Temkin isotherm model considers a linear decrease in the heat of adsorption and binding energy between dye molecules and functional groups of the grafted cellulose adsorbent as a function of covered surface area [61,62,63, 67].

The factor, K DR, in this is a temperature-dependent model used to calculate the adsorption mean free energy

In the above expressions,

-

C o, C e is the initial and equilibrium dye concentrations, respectively, in mg L−1,

-

q e is the amount of dye adsorbed on the adsorbent at equilibrium (mg g−1),

-

q m is the monolayer saturation adsorption (saturation capacity of adsorbent in mg.g−1),

-

K L, K F is the Langmuir and Freundlich isotherm constants, respectively,

-

n is the heterogeneity factor that defines the adsorption intensity of the adsorbent,

-

R is the gas constant (8.314 J mol−1 K−1), T is the absolute temperature (K),

-

A T (mL mg−1), b T (J mol−1) is the isotherm and Temkin–Pyzhev constants, respectively.

Various studies conducted have revealed that the experimental data better fit into Langmuir isotherm model as compared to the Freundlich model with few exceptions [61,62,63, 67]. These results thus confirm the fact that chemisorption is mainly responsible for adsorption of the dye molecules onto the surface of the grafted cellulose-based adsorbents as compared to physisorption.

Kinetic studies of the dye adsorption process are evaluated using pseudo-first-order, pseudo-second order, and Elovich kinetic models (Eqs. 13–16):

or

where q e and q t are adsorption capacities in mg g−1 at equilibrium and at time ‘t’, respectively. k 1 is the pseudo-first order rate constant (min−1).

where k 2 is the pseudo-second-order rate constant (g mg−1 min−1).

where α (mg g−1 min−1) is the initial adsorption rate and β (g mg−1) is related to the activation energy and extent of the surface covered during adsorption.

Most of the kinetic studies carried out for dye adsorption on grafted cellulose adsorbents suggest pseudo-second-order kinetics fit best with a correlation coefficient value (R 2) close to unity [61,62,63, 67, 68].

Metal ion sorption

The functional groups present on the grafted cellulose are not only suitable active sites for the adsorption of the harmful organic dyes but can also effectively adsorb toxic heavy and non-heavy metal ions from wastewater. These metal ions include Cd2+, Pd2+, Hg2+, Cu2+, Ni2+, Fe2+, Fe3+, Co2+, Co3+, Zn2+, Mn2+, As3+, Mo2+, V3+, Cr6+, Al3+, Sb3+ released from various chemical, electrochemical, leather, metalliferous mining, electronics, metal finishing, metallurgical operations, paint and dying industry, etc., which are accumulated in water bodies and terrestrial environment. As these metal ions cannot be degraded or destroyed, they pose serious health relate issues. The toxic effects of these metal ions on terrestrial and aquatic life are discussed in detail elsewhere [73]. For the removal of these toxic metal ions from wastewater many strategies such as chemical precipitation, carbon adsorption, co-precipitation, coagulation–flocculation, flotation, membrane separation, electrolytic reduction to neutral form, ion exchange, electrochemical treatment, hydroxide, and sulfide precipitation, ultrafiltration, electrodialysis, and adsorption are reported in the literature [74]. Biosorption of heavy metal ions from wastewater using biodegradable, natural, stable and reusable biomaterials is now becoming a promising technique for the removal of toxic metal ions. Low-cost, high adsorption capacity, minimized biochemical sludge, recovery and regeneration of sorbent material, and easy desorption of metal ions for their possible recovery are some of the major advantages of this technique [75]. The most abundant agro-based biomaterial cellulose can be chemically modified or grafted to improve its adsorption capacity toward toxic metal ions. Owing to the insoluble behavior of modified or grafted forms of cellulose, it can be easily separated from the aqueous medium after the adsorption process. Grafting of vinyl and other monomers onto cellulose backbone introduces grafted side chains with multi-functional groups. These grafted copolymers formed through various physical attractions such as van der Waals forces, hydrophobicity, hydrogen bonds, polarity and steric interaction, and dipole-induced dipole interaction adsorb the different metal ions onto their surfaces very easily. Recently, Hokkanen et al. [76] reviewed the various adsorption mechanisms, which mainly involve chemisorption complexation—formation of complexes between the metal ions and the anionic functional groups of the cellulose graft copolymer and ion exchange—replacement of cationic counterparts (–COOH, –SO3H, –COONa, –SO3Na) of the functional groups of the grafted side chains with those of the metal ions from the effluent.

Many monomeric species such as GMA [77], AA [78], AAm [79], AN [80], 4-vinylpyridine [81], AASO3H [82], and HEMA [83] are used for the synthesis of cellulose graft copolymers and binary copolymers. These monomers usually contain acidic –COOH, –SO3H, –COONa, –SO3Na and basic –NH2 functional group moieties. Divalent metal ions can very easily chelate with the lone pair of electrons present in O atoms of functional groups.

The adsorption amount “q” of the metal ions adsorbed on the surface of the grafted cellulosic materials is expressed according to the following equation:

where C o, C e is the initial and equilibrium metal ion concentrations, respectively. V is the volume of the sample solution and W is the weight of the adsorbent taken.

Protonation–deprotonation of the functional groups that affect the adsorption capacity of the grafted cellulose is controlled by the pH of the solution. The density of surface charges and degree of ionization of the cellulose-based grafted adsorbent is directly influenced by the initial pH of the sample solution. At low pH value, a high concentration of the H+ ions favors the protonation, which ultimately lowers the adsorption capacity of the metal ions due to electrostatic repulsions. A very high pH of the solution may convert metal ions into their soluble or insoluble hydroxides [84]. However, anionic pollutants and contaminates such as \( {\text{F}}^{ - } \), \( {\text{SO}}_{4}^{2 - } \), \( {\text{CrO}}_{4}^{2 - } \), \( {\text{Cr}}_{2} {\text{O}}_{7}^{2 - } \), \( {\text{MnO}}_{4}^{ - } \), \( {\text{PO}}_{4}^{3 - } \), \( {\text{S}}_{2} {\text{O}}_{3}^{2 - } \), \( {\text{AsO}}_{4}^{3 - } \), and \( {\text{AsO}}_{2}^{ - } \) are preferably adsorbed on protonated amine groups [85]. Some other factors such as temperature, amount of the adsorbate, the concentration of the metal ions in the solution, contact time also affect the adsorption capacity and percentage removal [78,79,80,81]. Further, the kinetic and adsorption isotherm studies reveal the best fit for pseudo-second-order kinetics and Langmuir isotherm model, respectively [70,71,72, 74,75,76,77,78,79].

Food packaging materials

To preserve the organoleptic food qualities such as appearance, taste and texture, improve the shelf life, to prevent the deterioration and contamination, and protect from physical, chemical and biological factors different food materials are packed in different packaging materials such as metal foils, laminated metallized films, and synthetic polymer-based packaging materials [86]. Such packaging materials are non-biodegradable in nature and thus have serious and concerned environmental and health-related issues. In contrast, paper and paperboards are lightweight, natural, and biodegradable packaging materials but suffer from some other serious drawbacks and limitations. Packaging for a longer duration of time is not feasible with these materials as they have poor mechanical strength, more wettability, inferior heat insulating, and barrier properties. To overcome these limitations and to further improve the protective properties such as strength of primary packaging paper, coating, lamination and impregnation of the paper with waxes, resins, or lacquers is carried out [86,87,88,89,90,91]. The growth of microbial agents such as bacteria, viruses, fungi and contamination of food materials are some other critical problems, which are also of utmost importance to control the various infectious diseases. Chemical preservatives or additives—harmful in higher doses—are generally added to the food materials during their manufacturing. The recent, innovative, smart, intelligent and interactive food packaging involves the coating or grafting of chemical/biochemical preservatives to the packaging materials. It is more advantageous as compared to traditional method as a lesser amount of preservatives is required and the extent of direct contact of food with this chemical is also minimized. The undesired growth of the microbial agents, like bacteria, is the major cause of food deterioration. To retard or inhibit the growth of such disease-causing agents, antimicrobial agents are applied to packaging materials [87]. Poly(hexamethyleneguanidine hydrochloride)-derivatized beeswax latex particle-coated paper exhibited excellent antimicrobial activity against pathogenic Gram-negative Escherichia coli bacterial strain [88]. The guanidine present is poly(hexamethyleneguanidine hydrochloride) is a reported antimicrobial agent [89]. MFC with lateral dimensions of 10–100 nm and length in the micrometer range consist of hydrophilic hydroxyl groups (–OH) which are modified to ensure their physicochemical interactions with polymeric antimicrobial agents. These MFC with covalently grafted ODDMAC exhibited 99% effective killing of Escherichia coli and Staphylococcus aureus bacterial strains [90]. Many other antimicrobial agents such as octadecyl isocyanate, acetic anhydride, butyric anhydride, hexanoic anhydride, and amino-propyl trimethoxysilane granted either on MFC or NFC are reported in the literature [91,92,93]. Isothiocyanate derivatives of naturally occurring glucosinolate–sulfur-containing chemicals present in cruciferous vegetables including broccoli, brussels sprouts, watercress, cabbage, horseradish, papaya seeds and mustard with antimicrobial and anti-carcinogenic activities are preferred over other chemically derived, toxic and non-permissive agents for grafting onto cellulose-based packaging materials [94]. Saini et al. [95] through n-butyltindilauratein catalyzed a chemical reaction, immobilized aromatic phenyl isothiocyanate on the surface of MFC through a thiocarbamate bond in a non-swelling solution. As grafted MFC were studied for their antibacterial activities against Gram-positive Staphylococcus aureus and Bacillus subtilis bacterial strains. Additionally, metallic silver, particularly in nanoregime, is also an effective antibacterial/antifungal agent in biotechnology and bioengineering. These nanoparticles can be adsorbed on the surface of the food packaging materials. In this regard, Tankhiwale and Bajpai [96] incorporated Ag nanoparticles on the surface of cellulose-based filter paper grafted with polyacrylamide using CAN and MBA as initiator and cross-linker, respectively. Ag nanoparticles can interact with the cell wall of Gram-positive as well Gram-negative bacterial cell through various physical interactions which may lead to cell wall rupturing, cellular internalization or mechanical damage. It has been observed that the mechanical strength is generally compromised by grafting of paper sheets using different polymers. This drawback, however, can be minimized by hydroxypropylation of cellulose fibers which increases the elongation, transparency, low water retention, and hydrophobicity of the cellulose-based paper sheets [97].

Recent studies are now focusing on the preparation of smart packaging materials of completely biological origin. In this regard, Wu et al. [98] demonstrated the grafting of chitosan—a linear polysaccharide comprising randomly distributed β-(1-4)-linked d-glucosamine and N-acetyl-d-glucosamine units, onto the oxidized cellulose films. Chitosan is a well-known bio-pesticide and novel antibacterial agent. Through Schiff base reaction, the active amino (–NH2) groups of chitosan can be linked to aldehyde group (–CHO) of the oxidized cellulose. The microstructural properties were altered which leads to the low mechanical strength of the chitosan-grafted cellulose films as compared to bare cellulose films. However, the oxygen barrier properties of the cellulose films were enhanced after grafting of chitosan. As fabricated chitosan-grafted cellulose films exhibited 99% antimicrobial activities against Escherichia coli and Staphylococcus aureus bacteria, shelf life of sausage was extended at least to 6 more days.

Phenolic compounds such as p-hydroxybenzoic acid, gallic acid, caffeic acid, dopamine, eugenol, isoeugenol, and thymol are considered to be potential antimicrobial agents and are grafted onto the unbleached kraft-liner fibers with the aid of laccase—a blue copper oxidase enzyme [99].

Recent literature reveals still another modified approach of controlled release of these antimicrobial agents to the food articles from the surface of packaging materials, which potentially extends the shelf life and prevents microbial growth [100]. Dong et al. [101] grafted β-CD—a cyclic oligosaccharide composed of d-glucopyranose units linked through α-1, 4-glucosidic linkages—to the cellulose fibers using citric acid as a cross-linking agent. For antimicrobial modification, CipHCl—an antibiotic—was introduced to the grafted matrix to form an inclusion complex. In a similar study, Lavoine et al. [102] incorporated Carvacrol—an antibacterial molecule—into the cavity of β-CD, grafted onto MFC through impregnation. A prolonged and delayed release of CipHCl and carvacrol from the grafted β-CD-cellulose was reported with excellent antibacterial activities against Escherichia coli, Staphylococcus aureus, and Bacillus subtilis as compared to virgin sample packaging materials. Certain antimicrobial proteins such as lysozyme and lactoferrin are also incorporated into carboxymethyl cellulose-based films through a non-covalent binding of the positively charged proteins to the cellulose matrix [103].

Thus, the incorporation of safe, reliable, low-dose, biocompatible and bio-based antimicrobial agents onto the surface of the bio-based packaging materials with controlled release while maintaining the mechanical strength and improved heat insulating properties is of great interest and probably the future and next area of research in packaging technology.

Conclusion and future scope

A number of recent studies clearly report the use of grafted cellulose-based copolymers as a potential candidate for effective drug release, but practical applications are still to be practiced. The effective translation of cellulosic copolymeric drug delivery platforms to actual biomedical applications still needs testing, validation, precision, optimization, spatiotemporal release and much more. Proper choice of polymeric species to be grafted on the cellulosic backbone, the mechanisms of drug loading, and the nature of interactions between the drug and the carrier are still to be established. The need of the hour is to fabricate biocompatible, biodegradable, economic, stimulus-responsive and nontoxic drug carries of total biological origin.

Cellulose-based copolymerized reinforced polymers provide extra mechanical, thermal and electrochemical stabilities, durability and wettability for better ionic conductivity for Li-ion battery separators. In addition, copolymerized cellulose materials are also reported to be excellent binder materials for Li-ion electrodes and stiffener materials for the formation of gel–polymer electrolytes. Li-ion batteries with such modification are supposed to be safe, low cost and environment friendly. The future studies should focus on the assembly of electrochemical devices with the entire cell components based on cellulose or graft/modified cellulose-based materials with auspicious electrochemical performances.

The active sites in the form of functional groups present on grafted cellulose are excellent binding sites for a variety of cationic as well as anionic, harmful, toxic and non-biodegradable dyes, many toxic heavy metal ions and anionic species. The density of these binding sites on a cellulose backbone depends on the nature of the grafted polymer and the techniques applied for grafting. Thus, a proper choice of monomer and grafting technique can drastically change the adsorption behavior of the cellulosic adsorbent. Regeneration and desorption of the adsorbates are other issues which still need improvements. Thus, the synthesis of cellulosic super-adsorbents with capabilities to adsorb undesirable materials from acidic, basic, as well as neutral aqueous medium and excellent adsorption–desorption characteristics, is desired. Future research in this field will definitely help the humanity with an adequate supply of pure and drinkable water throughout the world.

Innovative, smart and interactive food packaging involves the coating or grafting of chemical/biochemical preservatives and antimicrobial agents to the packaging materials, in particular cellulose with biocompatible nature and mechanical and thermal stabilities to preserve the organoleptic food qualities and to prevent the deterioration and contamination of the foods from various physical, chemical and biological agents. The exact mechanism and the factors which affect the loading of the antimicrobial agents and their controlled release from the grafted cellulose-based polymer materials should be the focus of the future research so that these aspects can be optimized and controlled to fulfill the basic requirements of the smart food packaging materials.

Abbreviations

- AA:

-

Acrylic acid

- AA-g-CLCF:

-

Acrylic acid-g-cellulosic Luffa cylindrical fiber

- AAm:

-

Acrylamide

- AAm-g-HEC:

-

Acrylamide-g-hydroxyethylcellulose

- AASO3H:

-

2-Acrylamido-2-methylpropane sulfonic acid

- AB-93:

-

Acid blue-93

- ABCN:

-

Azobiscyclohexanecarbonitrile

- AN:

-

Acrylonitrile

- ASA:

-

Aminosalicylic acid

- ATPR:

-

Atom transfer radical polymerization

- BC-g-PAA:

-

Bacterial cellulose-g-poly(acrylic acid)

- BEMA:

-

Bisphenol A ethoxylate (15 EO/phenol) dimethacrylate

- BF:

-

Basic fuchsine

- BGE-g-HEC:

-

Butyl glycidyl ether-g-hydroxyethyl cellulose

- BOD:

-

Biological oxygen demand

- BSA:

-

Bovine serum albumin

- CAN:

-

Ceric ammonium nitrate

- CCDA:

-

Cross-linked cellulose dialdehyde

- CD:

-

Cyclodextrin

- Cell-g-PAA-co-AM:

-

Cellulose-g-poly(acrylic acid-co-acrylamide)

- Cell-g-PAm/HBH:

-

Cellulose-g-polyacrylamide/hydroxyapatite biocomposite hydrogel

- CipHCl:

-

Ciprofloxacin hydrochloride

- CMC:

-

Carboxy methyl cellulose

- CMC-g-HPAM:

-

Hydrolyzed polyacrylamide-g-carboxymethyl cellulose

- CMC-g-PAAm:

-

Carboxymethyl cellulose-g-polyacrylamide

- CMC-g-PDMAEMA:

-

Carboxymethyl cellulose-g-poly(dimethylaminoethyl methacrylate)

- CMC-g-PDMAEMA:

-

Carboxymethylcellulose-g-poly(2-(dimethylamino) ethylmethacrylate)

- CMC-g-PHEA:

-

Carboxymethyl cellulose-g-poly(hydroxyethyl acrylate)

- COD:

-

Chemical oxygen demand

- CR:

-

Congo red

- CRP:

-

Controlled radical polymerization

- CV:

-

Crystal violet

- DAA:

-

N,N-Dimethylacetamide

- EC:

-

Ethyl cellulose

- EC–DEC:

-

Ethylene carbonate–diethyl carbonate

- EC-g-PDEAEMA:

-

Ethyl cellulose-g-poly(2-(diethylamino) ethyl methacrylate)

- EC-g-PHEMA-g-PSPMA:

-

Ethylcellulose-g-poly(2-hydroxyethyl methacrylate)-g-poly(spiropyran ether methacrylate)

- EC-g-PPEGMA:

-

Ethyl cellulose-g-poly(poly(ethylene glycol) methyl ether methacrylate)

- ECH:

-

Epichlorohydrin

- EE:

-

Encapsulation efficiency

- GA:

-

Glycidyl acrylate

- GMA:

-

Glycidyl methacrylate

- GMA/DTPA-g-cellulose:

-

Glycidyl methacrylate/diethylenetriamine pentaacetic acid-g-cellulose

- HEC-g-LANM:

-

Hydroxyethylcellulose-g-linoleic acid nano micelles

- HEMA:

-

2-Hydroxy methacrylate

- HPC:

-

Hydroxypropylcellulose

- HPMC-g-PAM:

-

Hydroxypropyl methyl cellulose-g-polyacrylamide

- KET:

-

Ketoprofen

- LCST:

-

Lower critical solution temperature

- LE:

-

Loading efficiency

- MA/Aam-g-LCF:

-

Methyl acrylate/acrylamide-g-Luffa cylindrical fiber

- MB:

-

Methylene blue

- MBA:

-

N,N′-Methylene bisacrylamide

- MCA-E0.7/CMC-g-PDMDAAC:

-

Monochloroacetic acid-modified epichlorohydrin cross-linked carboxymethyl cellulose-g-dimethyl diallyl ammonium chloride

- MC-g-A/GM:

-

Methyl cellulose-g-acrylamide/gelatin microspheres

- MFC:

-

Microfibrillated cellulose

- MG:

-

Malachite green

- MMA:

-

Methyl methacrylate

- MO:

-

Methyl orange

- NaPAA-g-CMC:

-

Poly(acrylic acid sodium)-g-carboxymethyl cellulose

- NFC:

-

Nanofibrillated cellulose

- NFD:

-

Nifedipine

- NMP:

-

Nitroxide-mediated polymerization

- NR:

-

Nile red

- ODDMAC:

-

Octadecyldimethyl (3-trimethoxysilylpropyl) ammonium chloride

- OR-II:

-

Orange red-II

- PAA:

-

Poly(acrylic acid sodium)

- PAM:

-

Polyacrylamide

- PBS:

-

Phosphate buffer solution

- PDEAEMA:

-

Poly(2-(diethylamino) ethyl methacrylate)

- PE:

-

Polyethylene

- PEGMA:

-

Poly(ethylene glycol) methyl ether methacrylate)

- PNIPAAm:

-

Poly(N-isopropylacrylamide)

- PP:

-

Polypropylene

- PSPMA:

-

Poly(spiropyran ether methacrylate)

- PTFE:

-

Poly(tetrafluoroethylene)

- PVC:

-

Polyvinyl chloride

- PVDF-HPF:

-

Poly(vinylidene fluoride-co-hexafluoropropylene)

- RAFT:

-

Reversible addition fragmentation chain transfer

- RB-2:

-

Reactive blue-2

- RIF:

-

Rifampicin

- ROP:

-

Ring-opening polymerization

- SET-LRP:

-

Single-electron transfer living radical polymerization

- SPMA:

-

Spiropyran ether methacrylate

- THA:

-

Theophylline

- THF:

-

Tetrahydrofuran

References

Anwar Z, Gulfraz M, Irshad M (2014) Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: a brief review. J Radiat Res Appl Sci 7:163–173. doi:10.1016/j.jrras.2014.02.003

Bali G, Meng X, Deneff JI, Sun Q, Ragauskas AJ (2015) The effect of alkaline pretreatment methods on cellulose structure and accessibility. Chemsuschem 8:275–279. doi:10.1002/cssc.201402752

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479–3500. doi:10.1021/cr900339w

Koh J (2011) Dyeing of cellulosic fibres. In: Clark M (ed) Handbook of Textile and industrial dyeing. Woodhead Publishing Limited, Sawston, pp 129–146

Oehme DP, Downton MT, Doblin MS, Wagner J, Gidley MJ, Bacic A (2015) Unique aspects of the structure and dynamics of elementary iβ cellulose microfibrils revealed by computational simulations. Plant Physiol 168:3–17. doi:10.1104/pp.114.254664

Hansson S, Trouillet V, Tischer T, Goldmann AS, Carlmark A, Barner-Kowollik C, Malmström E (2013) Grafting efficiency of synthetic polymers onto biomaterials: a comparative study of grafting- from versus grafting- to. Biomacromolecules 14:64–74. doi:10.1021/bm3013132

Carlmark A (2013) Tailoring cellulose surfaces by controlled polymerization methods. Macromol Chem Phys 214:1539–1544. doi:10.1002/macp.201300272

Roy D, Semsarilar M, Guthrie JT, Perrier S (2009) Cellulose modification by polymer grafting: a review. Chem Soc Rev 38:2046–2064. doi:10.1039/b808639g

Bertoldo M, Zampano G, La Terra F, Villari V, Castelvetro V (2011) Amphiphilic amylose-g-poly(meth)acrylate copolymers through “click” onto grafting method. Biomacromolecules 12:388–398. doi:10.1021/bm101143q

Kang H, Liu R, Huang Y (2015) Graft modification of cellulose: methods, properties and applications. Polymer (United Kingdom) 70:A1–A16. doi:10.1016/j.polymer.2015.05.041

Deng J, Wang L, Liu L, Yang W (2009) Developments and new applications of UV-induced surface graft polymerizations. Prog Polym Sci 34:156–193. doi:10.1016/j.progpolymsci.2008.06.002

Bhattacharya A, Misra BN (2004) Grafting: a versatile means to modify polymers: techniques, factors and applications. Prog Polym Sci 29:767–814. doi:10.1016/j.progpolymsci.2004.05.002

Uhrich KE, Cannizzaro SM, Langer RS, Shakesheff KM (1999) Polymeric systems for controlled drug release. Chem Rev 99:3181–3198. doi:10.1021/cr940351u

Fomina N, Sankaranarayanan J, Almutairi A (2012) Photochemical mechanisms of light-triggered release from nanocarriers. Adv Drug Deliv Rev 64:1005–1020. doi:10.1016/j.addr.2012.02.006

Wang D, Tan J, Kang H, Ma L, Jin X, Liu R, Huang Y (2011) Synthesis, self-assembly and drug release behaviors of pH-responsive copolymers ethyl cellulose-graft-PDEAEMA through ATRP. Carbohydr Polym 84:195–202. doi:10.1016/j.carbpol.2010.11.023

Mohd Amin MCI, Ahmad N, Halib N, Ahmad I (2012) Synthesis and characterization of thermo- and pH-responsive bacterial cellulose/acrylic acid hydrogels for drug delivery. Carbohydr Polym 88:465–473. doi:10.1016/j.carbpol.2011.12.022

Tan J, Li Y, Liu R, Kang H, Wang D, Ma L, Liu W, Wu M, Huang Y (2010) Micellization and sustained drug release behavior of EC-g-PPEGMA amphiphilic copolymers. Carbohydr Polym 81:213–218. doi:10.1016/j.carbpol.2010.02.017

Chang C, Duan B, Cai J, Zhang L (2010) Superabsorbent hydrogels based on cellulose for smart swelling and controllable delivery. Eur Polym J 46:92–100. doi:10.1016/j.eurpolymj.2009.04.033

Kajjari PB, Manjeshwar LS, Aminabhavi TM (2011) Semi-interpenetrating polymer network hydrogel blend microspheres of gelatin and hydroxyethyl cellulose for controlled release of theophylline. Ind Eng Chem Res 50:7833–7840. doi:10.1021/ie200516k

Babu VR, Kanth VR, Mukund JM, Aminabhavi TM (2010) Novel methyl cellulose-grafted-acrylamide/gelatin microspheres for controlled release of nifedipine. J Appl Polym Sci 115:3542–3549. doi:10.1002/app.30480

Al-Kahtani AA, Sherigara BS (2014) Controlled release of diclofenac sodium through acrylamide grafted hydroxyethyl cellulose and sodium alginate. Carbohydr Polym 104:151–157. doi:10.1016/j.carbpol.2014.01.018

Wang B, Chen K, Yang R, Yang F, Liu J (2014) Stimulus-responsive polymeric micelles for the light-triggered release of drugs. Carbohydr Polym 103:510–519. doi:10.1016/j.carbpol.2013.12.062

Moghaddam PN, Avval ME, Fareghi AR (2014) Modification of cellulose by graft polymerization for use in drug delivery systems. Colloid Polym Sci 292:77–84

Salama A, El-Sakhawy M, Kamel S (2016) polymer. Int J Biol Macromol 93:1647–1652. doi:10.1016/j.ijbiomac.2016.04.029

Yang Y, Guo Y, Sun R, Wang X (2016) Self-assembly and β-carotene loading capacity of hydroxyethyl cellulose-graft-linoleic acid nanomicelles. Carbohydr Polym 145:56–63

Das R, Pal S (2013) Hydroxypropyl methyl cellulose grafted with polyacrylamide: application in controlled release of 5-amino salicylic acid. Colloids Surf B Biointerfaces 110:236–241. doi:10.1016/j.colsurfb.2013.04.033

Singh DJ, Jain RR, Soni PS, Abdul S, Darshana H, Gaikwad RV, Menon MD (2015) Preparation and evaluation of surface modified lactose particles for improved performance of fluticasone propionate dry powder inhaler. J Aerosol Med Pulm Drug Deliv 28:254–267. doi:10.1089/jamp.2014.1146

Muñoz-García RO, Hernández ME, Ortiz GG, Fernández VV, Arellano MR, Sánchez-Díaz JC (2015) A novel polyacrylamide-based hydrogel crosslinked with cellulose acetate and prepared by precipitation polymerization. Quim Nova 38:1031–1036

Young PM, Wood O, Ooi J, Traini D (2011) The influence of drug loading on formulation structure and aerosol performance in carrier based dry powder inhalers. Int J Pharm 416:129–135. doi:10.1016/j.ijpharm.2011.06.020

Hu J, Li HY, Williams GR, Yang HH, Tao L, Zhu LM (2016) Electrospun poly(N-isopropylacrylamide)/ethyl cellulose nanofibers as thermoresponsive drug delivery systems. J Pharm Sci 105:1104–1112. doi:10.1016/S0022-3549(15)00191-4

Lin X, Tang D, Cui W, Cheng Y (2012) Controllable drug release of electrospun thermoresponsive poly(N-isopropylacrylamide)/poly(2-acrylamido-2-methylpropanesulfonic acid) nanofibers. J Biomed Mater Res Part A 100A:1839–1845. doi:10.1002/jbm.a.34142

Jabbour L, Gerbaldi C, Chaussy D, Zeno E, Bodoardo S, Beneventi D (2010) Microfibrillated cellulose–graphite nanocomposites for highly flexible paper-like Li-ion battery electrodes. J Mater Chem 20:7344. doi:10.1039/c0jm01219j

Jabbour L, Bongiovanni R, Chaussy D, Gerbaldi C, Beneventi D (2013) Cellulose-based Li-ion batteries: a review. Cellulose 20:1523–1545. doi:10.1007/s10570-013-9973-8

Chiappone A, Nair J, Gerbaldi C, Zeno E, Bongiovanni R (2014) Flexible and high performing polymer electrolytes obtained by UV-induced polymer–cellulose grafting. RSC Adv 4:40873–40881. doi:10.1039/C4RA07299E

Chiappone A, Nair JR, Gerbaldi C, Zeno E, Bongiovanni R (2014) Cellulose/acrylate membranes for flexible lithium batteries electrolytes: balancing improved interfacial integrity and ionic conductivity. Eur Polym J 57:22–29. doi:10.1016/j.eurpolymj.2014.05.004

Chelmecki M, Meyer WH, Wegner G (2007) Effect of crosslinking on polymer electrolytes based on cellulose. J Appl Polym Sci 105:25–29

Paracha RN, Ray S, Easteal AJ (2012) Grafting of LiAMPS on ethyl cellulose: a route to the fabrication of superior quality polyelectrolyte gels for rechargeable lithium ion batteries. J Mater Sci 47:3698–3705

Mazouzi D, Karkar Z, Hernandez CR, Manero PJ, Guyomard D, Roué L, Lestriez B (2015) Critical roles of binders and formulation at multiscales of silicon-based composite electrodes. J Power Sources 280:533–549. doi:10.1016/j.jpowsour.2015.01.140

Koo B, Kim H, Cho Y, Lee KT, Choi NS, Cho J (2012) A highly cross-linked polymeric binder for high-performance silicon negative electrodes in lithium ion batteries. Angew Chemie Int Ed 51:8762–8767. doi:10.1002/anie.201201568

Ryou MH, Kim J, Lee I, Kim S, Jeong YK, Hong S, Ryu JH, Kim TS, Park JK, Lee H, Choi JW (2013) Mussel-inspired adhesive binders for high-performance silicon nanoparticle anodes in lithium-ion batteries. Adv Mater 25:1571–1576. doi:10.1002/adma.201203981

Wei L, Chen C, Hou Z, Wei H (2016) Poly(acrylic acid sodium) grafted carboxymethyl cellulose as a high performance polymer binder for silicon anode in lithium ion batteries. Sci Rep 6:19583. doi:10.1038/srep19583

Arora P, Zhang Z (2004) Battery separators. Chem Rev 104:4419–4462. doi:10.1021/cr020738u

Zhang SS (2007) A review on the separators of liquid electrolyte Li-ion batteries. J Power Sources 164:351–364. doi:10.1016/j.jpowsour.2006.10.065

Kim M, Han GY, Yoon KJ, Park JH (2010) Preparation of a trilayer separator and its application to lithium-ion batteries. J Power Sources 195:8302–8305. doi:10.1016/j.jpowsour.2010.07.016

Choi J-A, Kim SH, Kim D-W (2010) Enhancement of thermal stability and cycling performance in lithium-ion cells through the use of ceramic-coated separators. J Power Sources 195:6192–6196. doi:10.1016/j.jpowsour.2009.11.020

Zaccaria M, Gualandi C, Fabiani D, Focarete ML, Croce F (2012) Effect of oxide nanoparticles on thermal and mechanical properties of electrospun separators for lithium-ion batteries. J Nanomater. doi:10.1155/2012/216012

Hsu C-H, Chien L-H, Kuo P-L (2016) High thermal and electrochemical stability of a SiO2 nanoparticle hybird-polyether cross-linked membrane for safety reinforced lithium-ion batteries. RSC Adv 6:18089–18095. doi:10.1039/C5RA26694G

Choudhury S, Mangal R, Agrawal A, Archer LA (2015) A highly reversible room-temperature lithium metal battery based on crosslinked hairy nanoparticles. Nat Commun 6:10101. doi:10.1038/ncomms10101

Jeong HS, Lee SY (2011) Closely packed SiO2 nanoparticles/poly(vinylidene fluoride-hexafluoropropylene) layers-coated polyethylene separators for lithium-ion batteries. J Power Sources 196:6716–6722. doi:10.1016/j.jpowsour.2010.11.037

Zhang J, Liu Z, Kong Q, Zhang C, Pang S, Yue L, Wang X, Yao J, Cui G (2013) Renewable and superior thermal-resistant cellulose-based composite nonwoven as lithium-ion battery separator. ACS Appl Mater Interfaces 5:128–134. doi:10.1021/am302290n

Xu Q, Kong Q, Liu Z, Wang X, Liu R, Zhang J, Yue L, Duan Y, Cui G (2014) Cellulose/polysulfonamide composite membrane as a high performance lithium-ion battery separator. ACS Sustain Chem Eng 2:194–199. doi:10.1021/sc400370h

Zahrim AY, Tizaoui C, Hilal N (2011) Coagulation with polymers for nanofiltration pre-treatment of highly concentrated dyes: a review. Desalination 266:1–16. doi:10.1016/j.desal.2010.08.012

Wojnárovits L, Földváry CM, Takács E (2010) Radiation-induced grafting of cellulose for adsorption of hazardous water pollutants: a review. Radiat Phys Chem 79:848–862. doi:10.1016/j.radphyschem.2010.02.006

Kumar R, Kumar G, Umar A (2014) Zinc oxide nanomaterials for photocatalytic degradation of methyl orange: a review. Nanosci Nanotechnol Lett 6:631–650. doi:10.1166/nnl.2014.1879

Roy A, Adhikari B, Majumder SB (2013) Equilibrium, kinetic, and thermodynamic studies of azo dye adsorption from aqueous solution by chemically modified lignocellulosic jute fiber. Ind Eng Chem Res 52:6502–6512

Lee KE, Teng TT, Morad N, Poh BT, Mahalingam M (2011) Flocculation activity of novel ferric chloride-polyacrylamide (FeCl3-PAM) hybrid polymer. Desalination 266:108–113. doi:10.1016/j.desal.2010.08.009

Batmaz R, Mohammed N, Zaman M, Minhas G, Berry RM, Tam KC (2014) Cellulose nanocrystals as promising adsorbents for the removal of cationic dyes. Cellulose 21:1655–1665

Cai T, Yang Z, Li H, Yang H, Li A, Cheng R (2013) Effect of hydrolysis degree of hydrolyzed polyacrylamide grafted carboxymethyl cellulose on dye removal efficiency. Cellulose 20:2605–2614

Gupta VK, Agarwal S, Singh P, Pathania D (2013) Acrylic acid grafted cellulosic Luffa cylindrical fiber for the removal of dye and metal ions. Carbohydr Polym 98:1214–1221. doi:10.1016/j.carbpol.2013.07.019

Gupta VK, Pathania D, Agarwal S, Sharma S (2014) Amputation of congo red dye from waste water using microwave induced grafted Luffa cylindrical cellulosic fiber. Carbohydr Polym 111:556–566. doi:10.1016/j.carbpol.2014.04.032

Kumari S, Mankotia D, Chauhan GS (2016) Crosslinked cellulose dialdehyde for Congo red removal from its aqueous solutions. J Environ Chem Eng 4:1126–1136. doi:10.1016/j.jece.2016.01.008

Liu L, Gao ZY, Su XP, Chen X, Jiang L, Yao JM (2015) Adsorption removal of dyes from single and binary solutions using a cellulose-based bioadsorbent. ACS Sustain Chem Eng 3:432–442

Mahdavinia GR, Bazmizeynabad F (2014) Synthesis of anti-salt hydroxypropyl methylcellulose-polyacrylamide/laponite RD nanocomposite hydrogel and its application to remove cationic dye. Polym Plast Technol Eng 53:411–422

Oladipo AA, Gazi M, Saber-Samandari S (2014) Adsorption of anthraquinone dye onto eco-friendly semi-IPN biocomposite hydrogel: equilibrium isotherms, kinetic studies and optimization. J Taiwan Inst Chem Eng 45:653–664. doi:10.1016/j.jtice.2013.07.013

Salama A, Shukry N, El-Sakhawy M (2015) Carboxymethyl cellulose-g-poly(2-(dimethylamino) ethyl methacrylate) hydrogel as adsorbent for dye removal. Int J Biol Macromol 73:72–75. doi:10.1016/j.ijbiomac.2014.11.002

Tian Y, Ju B, Zhang S, Hou L (2016) Thermoresponsive cellulose ether and its flocculation behavior for organic dye removal. Carbohydr Polym 136:1209–1217. doi:10.1016/j.carbpol.2015.10.031

Lin Q, Gao M, Chang J, Ma H (2016) Adsorption properties of crosslinking carboxymethyl cellulose grafting dimethyldiallylammonium chloride for cationic and anionic dyes. Carbohydr Polym 151:283–294

Zhou Y, Zhang M, Hu X, Wang X, Niu J, Ma T (2013) Adsorption of cationic dyes on a cellulose-based multicarboxyl adsorbent. J Chem Eng Data 58:413–421

Mahmoodi NM, Hayati B, Arami M (2012) Kinetic, equilibrium and thermodynamic studies of ternary system dye removal using a biopolymer. Ind Crops Prod 35:295–301. doi:10.1016/j.indcrop.2011.07.015

Zhou Y, Zhang M, Wang X, Huang Q, Min Y, Ma T, Niu J (2014) Removal of crystal violet by a novel cellulose-based adsorbent: comparison with native cellulose. Ind Eng Chem Res 53:5498–5506. doi:10.1021/ie404135y

Ozacar M, Sengil IA (2005) Adsorption of metal complex dyes from aqueous solutions by pine sawdust. Bioresour Technol 96:791–795. doi:10.1016/j.biortech.2004.07.011

Nandi BK, Goswami A, Das AK, Mondal B, Purkait MK (2008) Kinetic and equilibrium studies on the adsorption of crystal violet dye using kaolin as an adsorbent. Sep Sci Technol 43:1382–1403

Nordberg G, Fowler B, Nordberg M, Friberg L (2007) Handbook on the toxicology of metals. Academic, San Diego. doi:10.1017/CBO9781107415324.004

O’Connell DW, Birkinshaw C, O’Dwyer TF (2008) Heavy metal adsorbents prepared from the modification of cellulose: a review. Bioresour Technol 99:6709–6724. doi:10.1016/j.biortech.2008.01.036

Mudhoo A, Garg VK, Wang S (2012) Removal of heavy metals by biosorption. Environ Chem Lett 10:109–117. doi:10.1007/s10311-011-0342-2

Hokkanen S, Bhatnagar A, Sillanpää M (2016) A review on modification methods to cellulose-based adsorbents to improve adsorption capacity. Water Res 91:156–173. doi:10.1016/j.watres.2016.01.008

Yousif AM, Labib SA (2016) Fabrication of new cellulose-based sorbents for fast and efficient removal of hazardous Al(III) ions from their aqueous solutions. J Dispers Sci Technol 37:565–574

Abdel-Halim ES (2012) Preparation and characterization of poly(acrylic acid)-hydroxyethyl cellulose graft copolymer. Carbohydr Polym 90:930–936. doi:10.1016/j.carbpol.2012.06.022

Wichaita W, Samart C, Yoosuk B, Kongparakul S (2015) Cellulose graft poly(acrylic acid) and polyacrylamide: grafting efficiency and heavy metal adsorption performance. Macromol Symp 354:84–90

Rahman ML, Sarkar SM, Yusoff MM, Abdullah MH (2016) Efficient removal of transition metal ions using poly(amidoxime) ligand from polymer grafted kenaf cellulose. RSC Adv 6:745–757

Anirudhan TS, Nima J, Divya PL (2015) Adsorption and separation behavior of uranium(VI) by 4-vinylpyridine-grafted-vinyltriethoxysilane-cellulose ion imprinted polymer. J Environ Chem Eng 3:1267–1276. doi:10.1016/j.jece.2014.10.006

Zhu L, Zhang L, Tang Y, Ma D, Yang J (2015) Synthesis of kaolin/sodium alginate-grafted poly(acrylic acid-co-2-acrylamido-2-methyl-1-propane sulfonic acid) hydrogel composite and its sorption of lead, cadmium, and zinc ions. J Elastomers Plast 47:488–501

Singha AS, Guleria A (2015) Synthesis and applications of functional polymers from natural okra fibers for removal of Cu(II) Ions from aqueous solution. J Nat Fibers 12:587–603. doi:10.1080/15440478.2014.984049

Abdel-Halim ES, Al-Deyab SS (2012) Chemically modified cellulosic adsorbent for divalent cations removal from aqueous solutions. Carbohydr Polym 87:1863–1868. doi:10.1016/j.carbpol.2011.10.028

Tian Y, Wu M, Liu R, Wang D, Lin X, Liu W, Ma L, Li Y, Huang Y (2011) Modified native cellulose fibers—a novel efficient adsorbent for both fluoride and arsenic. J Hazard Mater 185:93–100. doi:10.1016/j.jhazmat.2010.09.001

Marsh K, Bugusu B (2007) Food packaging? Roles, materials, and environmental issues. J Food Sci 72:R39–R55. doi:10.1111/j.1750-3841.2007.00301.x

Cha DS, Chinnan MS (2004) Biopolymer-based antimicrobial packaging: a review. Crit Rev Food Sci Nutr 44:223–237. doi:10.1080/10408690490464276

Zhang D, Xiao H (2013) Dual-functional beeswaxes on enhancing antimicrobial activity and water vapor barrier property of paper. ACS Appl Mater Interfaces 5:3464–3468. doi:10.1021/am400585m

Qian L, Guan Y, He B, Xiao H (2008) Modified guanidine polymers: synthesis and antimicrobial mechanism revealed by AFM. Polymer (Guildf) 49:2471–2475. doi:10.1016/j.polymer.2008.03.042

Andresen M, Stenius P (2007) Water in oil emulsions stabilized by hydrophobized microfibrillated cellulose. J Dispers Sci Technol 28:837–844. doi:10.1080/01932690701341827

Missoum K, Sadocco P, Causio J, Belgacem MN, Bras J (2014) Antibacterial activity and biodegradability assessment of chemically grafted nanofibrillated cellulose. Mater Sci Eng C Mater Biol Appl 45:477–483. doi:10.1016/j.msec.2014.09.037

Fernandes SCM, Sadocco P, Alonso-Varona A, Palomares T, Eceiza A, Silvestre AJD, Mondragon I, Freire CSR (2013) Bioinspired antimicrobial and biocompatible bacterial cellulose membranes obtained by surface functionalization with aminoalkyl groups. ACS Appl Mater Interfaces 5:3290–3297. doi:10.1021/am400338n

Missoum K, Bras J, Belgacem MN (2012) Organization of aliphatic chains grafted on nanofibrillated cellulose and influence on final properties. Cellulose 19:1957–1973. doi:10.1007/s10570-012-9780-7

Wilson AE, Bergaentzlé M, Bindler F, Marchioni E, Lintz A, Ennahar S (2013) In vitro efficacies of various isothiocyanates from cruciferous vegetables as antimicrobial agents against foodborne pathogens and spoilage bacteria. Food Control 30:318–324. doi:10.1016/j.foodcont.2012.07.031

Saini S, Belgacem MN, Missoum K, Bras J (2015) Natural active molecule chemical grafting on the surface of microfibrillated cellulose for fabrication of contact active antimicrobial surfaces. Ind Crops Prod 78:82–90. doi:10.1016/j.indcrop.2015.10.022

Tankhiwale R, Bajpai SK (2009) Graft copolymerization onto cellulose-based filter paper and its further development as silver nanoparticles loaded antibacterial food-packaging material. Colloids Surf B Biointerfaces 69:164–168. doi:10.1016/j.colsurfb.2008.11.004

Vuoti S, Laatikainen E, Heikkinen H, Johansson LS, Saharinen E, Retulainen E (2013) Chemical modification of cellulosic fibers for better convertibility in packaging applications. Carbohydr Polym 96:549–559. doi:10.1016/j.carbpol.2012.07.053

Wu Y, Luo X, Li W, Song R, Li J, Li Y, Li B, Liu S (2016) Green and biodegradable composite films with novel antimicrobial performance based on cellulose. Food Chem 197:250–256. doi:10.1016/j.foodchem.2015.10.127

Elegir G, Kindl A, Sadocco P, Orlandi M (2008) Development of antimicrobial cellulose packaging through laccase-mediated grafting of phenolic compounds. Enzyme Microb Technol 43:84–92. doi:10.1016/j.enzmictec.2007.10.003

Lee SY, Lee SJ, Choi DS, Hur SJ (2015) Current topics in active and intelligent food packaging for preservation of fresh foods. J Sci Food Agric 95:2799–2810. doi:10.1002/jsfa.7218

Dong C, Ye Y, Qian L, Zhao G, He B, Xiao H (2014) Antibacterial modification of cellulose fibers by grafting β-cyclodextrin and inclusion with ciprofloxacin. Cellulose 21:1921–1932. doi:10.1007/s10570-014-0249-8

Lavoine N, Givord C, Tabary N, Desloges I, Martel B, Bras J (2014) Elaboration of a new antibacterial bio-nano-material for food-packaging by synergistic action of cyclodextrin and microfibrillated cellulose. Innov Food Sci Emerg Technol 26:330–340. doi:10.1016/j.ifset.2014.06.006

Barbiroli A, Bonomi F, Capretti G, Iametti S, Manzoni M, Piergiovanni L, Rollini M (2012) Antimicrobial activity of lysozyme and lactoferrin incorporated in cellulose-based food packaging. Food Control 26:387–392. doi:10.1016/j.foodcont.2012.01.046

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kumar, R., Sharma, R.K. & Singh, A.P. Grafted cellulose: a bio-based polymer for durable applications. Polym. Bull. 75, 2213–2242 (2018). https://doi.org/10.1007/s00289-017-2136-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2136-6