Abstract

Antibacterial-modified cellulose fiber was prepared by covalently bonding β-cyclodextrin (β-CD) with cellulose fiber via citric acid (CA) as crosslinking agent, followed by the inclusion of ciprofloxacin hydrochloride (CipHCl) as antibiotic. Effects of reaction time, temperature, concentration of β-cyclodextrin citrate (CA-β-CD) and pH on the grafting reaction were investigated, and the grafting ratio of β-CD onto cellulose fibers was 9.7 % at optimal conditions; the loading and releasing behaviors of CipHCl into/from β-CD grafted cellulose fibers were also revealed, the load amount of CipHCl into grafted cellulose fibers increased remarkably, and the release of CipHCl from the grafted cellulose fibers was prolonged. The microstructure, phase and thermal stability of modified cellulose fibers were characterized by FT-IR, 13C CPMAS NMR, X-ray diffraction and TGA. Considerably longer bacterial activity against E. coli and S. aureus was observed for grafted fibers loading CipHCl compared to virgin ones. Optical and mechanical properties of the paper sheets decreased generally with more antibacterial-modified fibers added.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the increasing awareness of infectious diseases caused by various microorganisms and the development of antibiotic resistance (Martins et al. 2012), cellulose-based substrates such as paper products with antibacterial activities are attracting considerable attention, especially in applications in medical, packaging and other health-related areas. Antibacterial paper sheets can be prepared by introducing antimicrobial agents into paper via coating, spraying and application as wet-end chemicals or incorporating microbicidal functional groups with cellulose fibers. In general, coating and spraying are convenient ways to prepare antimicrobial paper products; however, the main drawback of the physical methods is the risk of premature delamination, which can have negative effects on paper strength and short-term antibacterial effects (Hiriart-Ramírez et al. 2012). On the other hand, cellulose fibers functionalized with microbicidal chemical groups, such as N-halamines (Liu and Sun 2006; Luo and Sun 2006; Ren et al. 2008), immobilized enzymes (Miao et al. 2011), guanidine salts (Guan et al. 2007) or quaternary ammonium salts (Lu et al. 2004; Yao et al. 2008), have also shown significant inhibition activities to microorganisms. In this way, cellulose fibers can serve as a backbone for chemically bonded groups (Desmet et al. 2011), which can be functionalized permanently. Cyclodextrins (CDs), as environment-friendly auxiliaries to host antimicrobial agents, can also be grafted onto cellulose fibers to impart antimicrobial properties. It is a promising technology for introducing functional agents into cellulose fibers using CD as a carrier that can readily form inclusion complexes with various small molecules.

CDs are cyclic and non-reducing oligosaccharides containing 6 (α-CD), 7 (β-CD) or 8 (γ-CD) d-glucose units linked by α-1, 4 glycosidic bonds in a doughnut-shaped ring, and they are formed from the enzymatic degradation of starch by bacteria. Among them, β-CD is the most commercially attractive because of its simple synthesis, availability and low cost. Moreover, CDs contain a hydrophobic central cavity, which can entrap a wide variety of small molecules to improve the chemical stability, absorption and bioavailability and control their release. Because of their benign toxicological and ecological properties, CDs are assumed to have great importance in many fields (Peila et al. 2012), such as pharmaceuticals, cosmetics, environmental protection and the food industry (Astray et al. 2009; Buschmann et al. 1998; Kurkov et al. 2011; Singh et al. 2002).

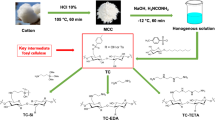

CDs can also be grafted onto macromolecules with crosslinkers to modify them. A number of crosslinking agents have been utilized to graft β-CD onto natural fibers, such as epichlorohydrin (Szejtli 1998), cyanuric chloride (Denter and Schollmeyer 1997), N-methylol acrylamide (Lee et al. 2000, 2001) and polycarboxylic acids (Voncina and Le Marechal 2005; Gawish et al. 2009). Indeed, the widely used polycarboxylic acids, such as CA and butane tetracarboxylic acid (BTCA), are well-known nontoxic and eco-friendly crosslinking reagents (Bajpai et al. 2010). CA has three carboxylic acid groups that can react with hydroxyl groups of cellulose fibers and β-CDs, the primary hydroxyl groups in particular, to form ester bonds. The esterification can be activated in the presence of a weak acid salt catalyst, such as sodium hypophosphite (SHP). In this work, CA was used as a crosslinking agent to graft β-CD onto cellulose fibers in an attempt to generate a green-based antibacterial material with a variety of applications. As previously reported (Martel et al. 2002), the reactivity of CA toward cellulose is higher than that of CA toward β-CD; therefore, the desired reaction conditions of CA toward cellulose and β-CD are not the same. Furthermore, the duration of cellulose fibers at higher temperatures is shorter in two-step reactions (1, synthesis of CA-β-CD; 2, curing) compared to that of one-step reactions (CA and β-CD are impregnated), and curing at higher temperatures for too long a period can cause the degradation and yellowness of cellulose fibers. In order to obtain a higher grafting ratio of β-CD and reduce the side effects on cellulose fibers, a two-step reaction was employed. CA-β-CD was first obtained by a semidry reaction and then grafted onto cellulose fibers. Various parameters influencing the chemical grafting of β-CD and the inclusion of ciprofloxacin hydrochloride (CipHCl) (as a model antibiotic) with β-CD grafted cellulose fibers were investigated. In addition, the phase and thermal stability, antibacterial activities and mechanical properties of β-CD grafted cellulose fibers were studied.

Experimental

Materials

Softwood fibers were provided by Liangmianzhen Co., Ltd., Guangxi, China. The fibers were treated with 1.5 mol/l sodium hydroxide solutions for 2 h at 50 °C, and then the pretreated pulp fibers were beaten to 35°SR using PFI (model Mark V1; Pulp and Paper Research Institute of Norway). E. coli (ATCC 8739), S. aureus (ATCC 6538), LB agar and LB broth were purchased from Huankai Microbial Sci. & Tech. Co., Ltd. (Guangdong, China). CA, β-CD, SHP, anhydrous ethanol, sodium hydroxide and CipHCl were of analytical reagents and used without further purification.

Grafting β-CD onto cellulose fibers

The grafting process was a two-step reaction. CA-β-CD was first obtained by the condensation of β-CD with CA and then grafted onto cellulose fibers. CA-β-CD was prepared using a semidry reaction method (El-Tahlawy et al. 2006). The mixture of 3.0 g of β-CD, 1.1 g of CA, 0.29 g of SHP and 1.8 g of distilled water was reacted at 100 °C for 1.5 h. The sample was purified by washing with ethanol using a soxhlet for 6 h to remove unreacted components as well as any soluble fragments or byproducts, then treated with dialysis membranes of 1,000 Da to further purify CA-β-CD followed by drying at 60 °C for 24 h to obtain the purified CA-β-CD. The β-CD content of CA-β-CD was determined by means of the phenolphthalein colorimetric method (Zhao et al. 2009). The mass spectrum of CA-β-CD was obtained using mass spectrometry (HCT PLUS, Bruker) in electron impact mode with the following conditions: potential ionization 70 eV; source temperature 230 °C; transfer line temperature 280 °C; scan range from 1,000 to 3,000 m/z. A scan frequency of 5 scans/s was used for generating the mass chromatography.

SHP (0.1 g) and the various amounts of CA-β-CD were dissolved in distilled water (10 ml), and the pH of the solution was then adjusted with hydrochloric acid and sodium hydroxide solution, followed by adding pretreated cellulose fiber (1 g, oven dried) to obtain sufficient swelling. After removing excess solution from the fiber slurry, the reaction proceeded at various temperatures (130–170 °C) in the oven for a specific time. The obtained fibers were washed in distilled water and dried at 60 °C for 24 h. The grafting ratio of CA-β-CD onto the cellulose fibers was calculated by the weight difference between the virgin and grafted cellulose fibers.

Loading and releasing of CipHCl

Virgin or grafted cellulose fibers (1 g) were immersed in 50 ml CipHCl aqueous solution (100 mg/g oven-dried fiber) at room temperature for a specific time under stirring. The obtained samples were washed with distilled water and dried at 60 °C for 24 h in a vacuum drying oven. The amount of loaded drug was calculated as the difference between the initial and the final amounts in the solution using a UV–visible spectrophotometer (DR 5000; HACH) at 275 nm (Peila et al. 2012; Rukmani and Sundrarajan 2012). The loading and adsorption amount of CipHCl as a function of time was calculated using the following equation.

where C 0 is the initial concentration of CipHCl, C t is the concentration of CipHCl at any time, V(L) is the volume of the solution, and W (g) is the mass of oven-dried fibers.

The 0.5 g of β-CD grafted fibers loaded with CipHCl (13.6 mg/g oven-dried fibers) or virgin fibers loaded with CipHCl (3.6 mg/g oven-dried fibers) was dispersed in distilled water (25 ml) at room temperature. The cumulative releasing amount of CipHCl was determined using a UV–visible spectrophotometer at 275 nm as a function of time and expressed as the percentage of loaded antibiotic. The cumulative release rate of CipHCl as a function of time was calculated using the following equation.

where m 0 (mg) is the initial load amount of CipHCl in fiber samples, C t is the concentration of CipHCl at any time, and V(L) is the volume of the solution.

FT-IR, XRD, TG and CP/MAS 13C-NMR

FT-IR spectra of β-CD, CA-β-CD, cellulose fibers and grafted fibers were obtained using a Fourier transform infrared spectrophotometer (Vector 33; Bruker) in a wavenumber range from 4,000 to 500 cm−1 using the KBr disk method. X-ray diffraction (XRD) measurements were performed on a Bruker D8 Advance diffractometer system. The diffracted intensity of Cu Kα radiation (λ = 0.1542 nm; 40 kV and 30 mA) was measured in a 2θ range between 10° and 50° with a scanning step width of 0.02°. Thermogravimetric (TG) measurements were performed using a TA Q-500 instrument. Temperature programs for dynamic tests were run from 25 to 600 °C at a heating rate of 10 °C/min. The tests were carried out under nitrogen atmosphere (25 ml/min) in order to prevent any thermooxidative degradation. CP/MAS 13C-NMR spectra were obtained on a Bruker II Advance-300 spectrometer (Karlsruhe, Germany) operating at the resonance frequencies of 300.14 MHz for 1H and 75.47 MHz for 13C using a Bruker 4.0-mm MAS NMR spinning probe. The spinning speed of the samples was set to 5 kHz at the magic angle at room temperature. Each spectrum was obtained with an accumulation of 5,000 scans. The delay time was 60 s, the proton 90° pulse width was 9 μm, and the contact time for cross polarization was 2.5 ms.

Antibacterial activity of the fibers loaded with antibiotics

The antibacterial activities of the fibers loaded with CipHCl against E. coli and S. aureus were assessed using a shaking flask method (Qian et al. 2009) and a disc diffusion method (Scott and Higham 2003; Thatiparti et al. 2010). The paper samples were prepared with various percentages of grafted fiber loading CipHCl (13.6 mg/g oven-dried fibers) and virgin fibers, whereas the control sample was obtained by 100 % virgin fibers loaded with CipHCl (3.6 mg/g oven-dried fibers). The basis weight of both samples was 60 g/cm2. For the shaking flask method, 0.75 g of paper scraps was mixed with 5 ml of E. coli (2.5 × 107 CFU ml−1) or S. aureus (1.5 × 107 CFU ml−1) suspension, then shaken at 200 rpm at 37 °C for 1 h. After shaking, various dilution samples were made successively, followed by 0.1 ml of the samples being seeded on LB agar in petri dishes. The plates were incubated at 37 °C for 24 h, and the number of colonies was counted. The growth inhibition of bacteria was expressed as the percentage of the killed bacteria to the original ones. For the inhibition zone method, 200 μl of E. coli or S. aureus suspension was uniformly spread on the agar discs, and circles of paper with a 6-mm diameter were put on it. After the discs had been incubated overnight at 37 °C, the bactericidal activity was observed by visual inspection of the clearance of the bacterial lawn as well as the size of the clearance as measured by calipers across an average diameter. Drug-loaded circles were moved daily to a new lawn using the above-described process. Experiments were done in triplicate.

Mechanical and optical properties of paper sheets

The paper sheets with various contents of β-CD grafted fibers loaded with CipHCl were made according to the ISO 5269/2 standard, using the model PTI-Flank Rapid-Koethen sheet former (model RK3AKWT; Austria). The basis weight was 60 g/cm2. The tensile index of the paper sheets was measured using an Alweron TH1 tensile tester (model CE064, AB Lorentzen & Wettre). The preconditioned sheets were cut into 15 mm × 180-mm strips and tested according to ISO 1942/2. The tear index was performed in accordance with ISO 1974 with a tearing tester (model 83-10;Lorentzen & Wettre). The brightness was determined using a whiteness meter (model CTPC; Technidyne Color Touch PC) according to TAPPI T452 m-98.

Results and discussion

Characterization of β-CD-grafted cellulose fibers

The mechanism for preparing the β-CD-grafted cellulose fibers and the inclusion of antibiotics are shown in Scheme 1. Two adjacent carboxyl groups in citric acid dehydrate to form a reactive cyclic anhydride at a specific temperature, which reacts with hydroxyl groups in β-CD to obtain CA-β-CD. Furthermore, the remaining carboxyl groups by the end of CA dehydratation, controlled by the feed molar ratios of CD to CA, might react with hydroxyl groups in cellulose to form β-CD-grafted cellulose (Martel et al. 2002). The resulting fibers grafted with β-CD could form the inclusion complexes with CipHCl. The β-CD content of CA-β-CD is 72.5 % based on the weight of CA-β-CD. As shown in Fig. 1, [β-CD + 2CA–2H2O + 2Na–H]+ and [β-CD + 3CA–3H2O + 3Na–2H]+ were observed at m/z 1,530 and m/z 1,729, respectively, which indicates that one β-CD molecule reacts with two or three CA molecules, respectively. Other peaks are also observed because CA-β-CD coordinated to various cations including NH4 +, Na+ or K+ under these conditions.

The FT-IR spectra were used to characterize the structure of β-CD-grafted cellulose fibers (shown in Fig. 2). For β-CD, the adsorptions at 3,404, 2,933, 1,416, 1,370, 1,180 and 1,029 cm−1 in the spectrum are indications of β-CD (Rukmani and Sundrarajan 2012). The region between 1,416 and 1,029 cm−1 relates to the C–H and C–O bond stretching frequencies; a band at 2,933 cm−1 is assigned to C–H vibration; the band range from 3,200 to 3,400 cm−1 corresponds to the vibration stretching of inter- and intramolecular hydrogen bonds of β-CD. Comparatively, the bands in CA-β-CD are the same except for a new vibration at 1,727 cm−1, which is indicative of the ester group formed in the esterification between β-CD and CA. Compared to the spectra of virgin cellulose fibers, a new vibration at 1,708 cm−1 of β-CD grafted fibers can be assigned to a C=O stretching vibration for an ester bond obtained in the reaction between carboxylic acid from CA-β-CD and hydroxyl groups from cellulose fibers.

The esterification is also further confirmed by solid-state CP/MAS 13C-NMR spectra (Fig. 3). It is shown that for the spectra of the CA-β-CD, cellulose fibers and β-CD-grafted cellulose fibers, the signals between 55 and 110 ppm are assigned to the C-atoms in the glucose, and the assignments of each carbon were made with reference to the literature (Ramos et al. 2013). Compared with the free β-CD (Karoyo et al. 2013), a significant signal is present at 175.2 ppm for CA-β-CD, which is assigned to the carbonyl group (Larsen et al. 2011), indicating that the esterification occurred between β-CD and CA. For cellulose fibers and β-CD-grafted fibers, the signals between 55 and 110 ppm are also attributed to various carbon atoms in the glucose, with six peaks corresponding to 13C chemical shifts of cellulose carbons, C1 (105 ppm), C4 (79–82 ppm), C2/C3/C5 (70–80 ppm) and C6 (60–69 ppm) of anhydroglucose units of cellulose (Sathitsuksanoh et al. 2011). Moreover, the chemical shifts of C4 and C6 might drift slightly depending on the cellulose in crystalline and amorphous areas. Compared to the spectrum of cellulose fibers, a new signal at 173.8 ppm is assigned to the carbonyl group of modified cellulose fibers for an ester bond, which confirms the reaction between carboxylic acid from CA-β-CD and hydroxyl groups from cellulose fibers. In addition, an obvious signal at 45.1 ppm appears because of –CH2– from CA. This also confirmed the reaction between CA-β-CD and cellulose; therefore, β-CD was grafted onto cellulose fibers with citric acid as a bridging agent.

Factors influencing grafting of β-CD to fibers and the inclusion of antibiotics

The effects of reaction time, temperature and concentration of the CA-β-CD and pH value on the grafting ratio are shown in Fig. 4. The longer the treatment time is, the greater the amount of β-CD bonded onto the cellulose fibers. The grafting ratio was nearly proportional to the reaction time before 15 min and then increased slowly. Therefore, 15 min was sufficient to obtain the desired result. As shown in Fig. 4b, the grafting ratio increased significantly from 2.1 to 9.6 % when the temperature was raised from 130 to 160 °C because of the higher reaction efficiency and easier diffusion of CA-β-CD molecules into the vicinity of the cellulose fiber for larger pore size (Leitner et al. 2013). It almost reached to a plateau for the grafting ratio from 160 to 180 °C. Moreover, the higher temperature might be harmful for the fiber length and the brightness as a result of the acid degradation. Therefore, the reaction temperature should not be higher than 160 °C. The grafting ratio increased when the concentration of CA-β-CD increased. Higher concentration increases the diffusion of CA-β-CD into the vicinity of cellulose fibers and the number of available reactive molecules. The grafting ratio first increased and then decreased with rising pH and obtained the optimal value when the pH was between 3 and 4. The form of the catalyst after hydrolysis was controlled by pH, thereby affecting the catalytic ability. From the above discussion, the optimal reaction conditions should be a 15-min reaction time, a reaction temperature of 160 °C, [CA-β-CD] = 300 g/l and pH 3.4, at which the grafting ratio was 9.7 %.

Effects of reaction time (a), temperature (b), the concentration of CA-β-CD (c) and pH value (d) on the grafting ratio. The other parameters: a T = 150 °C, [CA-β-CD] = 400 g/l, pH = 3.4; b t = 15 min, [CA-β-CD] = 400 g/l, pH = 3.4; c t = 15 min, T = 160 °C, pH = 3.4; d t = 15 min, T = 160 °C, [CA-β-CD] = 300 g/l. Experiments were done in triplicate, and error bars represent ± standard deviation

Effects of time on loading and releasing of CipHCl into/from virgin and grafted cellulose fibers with β-CD are shown in Fig. 5. It can be seen that the virgin fibers showed little affinity to CipHCl; about 3.6 mg of CipHCl absorbed onto 1 g of oven-dried cellulose fibers when the absorption reached equilibrium. In distilled water, the pH of the CipHCl solution is slightly acidic and the 1-tertiary amine of quinolones is protonated to make ciprofloxacin cationically charged, which facilitate its absorption onto anionically charged cellulose fibers (Khan and Shah 2009). For the β-CD grafted cellulose fibers, the amount of loaded CipHCl increased dramatically with prolonging time before 4 h and reached equilibrium after that. The loading amount of CipHCl to β-CD-grafted cellulose fibers increased remarkably compared to that to virgin cellulose fibers, and the equilibrium loading amount to grafted cellulose fibers was about 13.6 mg/g—more than triple the amount of that of virgin cellulose fibers. Except for the CipHCl absorbed onto the cellulose fibers, most of them were loaded into the cavity of β-CD to form host–guest complexes, and the inclusion was also promoted by the electrostatic interaction between the carboxyl group of CA and protonated quinolones (Khan and Shah 2009). Effects of time on the cumulative release of CipHCl from the cellulose fibers are shown in Fig. 5b; both virgin fibers and β-CD grafted fibers show similar patterns in which the antibiotics are released dramatically in the first period and reached equilibrium at different durations. The cumulative release of CipHCl from the virgin fibers was 90 % in the first 30 min, while that from the β-CD grafted fibers reached the same level after 240 min. This is due to the fact that the antibiotics absorbed onto the cellulose fibers by electrostatic interaction could be readily desorbed and released, whereas the ones hosted in the cavity of β-CD were not easily released, resulting in the prolonged equilibrium time for the grafted cellulose fibers (Cusola et al. 2013). From the above, both virgin fibers and grafted fibers retained the CipHCl, and β-CD grafted onto the cellulose fibers increased the loading amount dramatically and slowed down the releasing process.

Phase and thermal stability of the modified cellulose fibers

Cellulose crystallinity is the key factor determining its mechanical properties (Chen et al. 2011). XRD studies on virgin and β-CD grafted cellulose fibers were conducted to reveal the crystallization behavior of the fibers. As shown in Fig. 6a, three diffraction peaks at 2θ of 15.3°, 22.6° and 34.7° corresponding to the typical diffraction patterns of cellulose type I (Guo et al. 2012) are observed in the XRD patterns. This indicates that the crystal structure of cellulose fibers was not changed after grafting. The crystallinity of each sample was also calculated, and the results are listed in Fig. 6a. A gradual increase of crystallinity from 72.41 % for natural cellulose fiber to 78.76 % for alkali-treated cellulose fibers was observed, which was due to the removal of hemicellulose and lignin in amorphous regions and the realignment of cellulose molecules after alkali treatment (Li et al. 2014; Dipa et al. 2009). After grafting with CA-β-CD, the differences in crystallinity between alkalized cellulose fibers and β-CD grafted ones were not significant. However, the crystallinity of grafted fibers loaded with CipHCl dropped to 70.13 %, which might be attributed to the adsorption of some antibiotic molecules on the fiber surface.

The TG behaviors of natural cellulose fibers, alkalized cellulose fibers, alkalized cellulose fibers grafted with β-CD and grafted fibers loaded with CipHCl are illustrated in Fig. 6b. Two-step degradation can be observed up to 600 °C; the first one at a temperature around 100 °C was due to the loss of water evaporation, while the second one at around 300 °C was due to the starting of the decomposition of cellulose or CipHCl in samples. The remaining weights at 600 °C were 15 % (a), 13 % (b), 11 % (c) and 16 % (d) for various samples, and the weights of β-CD grafted cellulose fibers were the minimal. Moreover, the temperatures at the maximum degradation rate (T max) of all samples were determined by the DTG curves. The peak corresponding to the maximum weight loss rate was 356 °C with 65 % weight loss for natural cellulose fibers; the rest of the peaks were 350 °C with 60 % weight loss for alkalized cellulose fibers and 323 °C with 49 % weight loss for grafted fibers loaded with CipHCl. In contrast, 15 % weight loss occurred at 292 °C and 63 % weight loss at 348 °C for β-CD grafted cellulose fibers. The presence of two important features are concluded: one is that the incorporation of β-CD into cellulose fibers led to a decrease in the T max, which might be attributed to the presence of β-CD and an increase in the disorder of cellulose molecular packing (Medronho et al. 2013); the second is that the introduction of CipHCl caused a decrease in the weight loss on the main degradation transition compared with that of cellulose and β-CD.

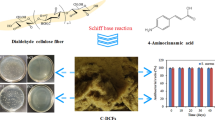

Antibacterial activity of the grafted fibers loaded with CipHCl

The effect of the content of β-CD-grafted fibers loaded with CipHCl in paper sheets on the remaining bacteria and the growth inhibition was characterized by the shaking flask method (shown in Fig. 7). As shown in Fig. 7a, the remaining bacteria decreased with increasing grafted fiber content, and the remaining bacteria against E. coli and S. aureus were both zero when the content of grafted fibers were 100 %, suggesting that all the bacteria were deactivated. Meanwhile, with increasing grafted cellulose fiber content, the growth inhibitions against E. coli and S. aureus increased and were higher than 93 % when the content of the grafted fibers was 25 %. The growth inhibitions against E. coli and S. aureus reached about 100 % when the fiber content was 50 % or higher. However, the growth inhibitions of paper sheets made from 100 % virgin fibers loading CipHCl against E. coli and S. aureus were only 20.1 and 17.6 %, mainly because most of the CipHCl was desorbed during the papermaking process, and the cumulative release rate reached 65 % at the initial 10 min. Generally, the growth inhibition against E. coli is higher that against S. aureus at the same fiber content, probably because of the difference between gram-negative and -positive bacteria in terms of cell structures and antimicrobial mechanism (Li et al. 2011).

The sustained antimicrobial activity of virgin fibers loading CipHCl and β-CD-grafted fibers loading CipHCl against E. coli and S. aureus determined by the ring diffusion method is presented in Fig. 8. The control fibers (unloading CipHCl) did not inhibit any bacterial proliferation. As expected, the zones of inhibition of fibers showed larger zones of inhibition at first and gradually reduced and became zero. Paper sheets made from grafted fibers loading CipHCl showed effective bactericidal activity in terms of the zone of inhibition against E. coli and S. aureus for 7–15 and 7–11 days with daily application to a lawn of freshly grown bacteria, respectively. However, paper sheets made from 100 % virgin fibers loading CipHCl showed bactericidal activity against E. coli and S. aureus for only 3 and 4 days, respectively. The difference in the diameter of the zone of inhibition between the virgin and grafted fibers can be attributed to the burst release of antibiotics seen in diffusion-based delivery systems (such as virgin fibers) as compared to affinity-based release (grafted fibers). The antimicrobial activity of β-CD-grafted fiber loading CipHCl against E. coli is higher than that against S. aureus, which is consistent with the results of growth inhibition. The overall results from both the shaking flask method and the ring diffusion method demonstrate that the β-CD grafted fibers loading CipHCl possess excellent antibacterial activity against E. coli and S. aureus. The resulting antibacterial papers may be useful to prevent wound and nosocomial infections in the medical field.

Optical and mechanical properties of the paper sheets

The paper sheets containing various amounts of β-CD-grafted fibers loading CipHCl were further characterized in terms of optical and mechanical properties (Table 1). The brightness of the paper presented a slight decrease with the increase of the amount of grafted fibers added. This behavior is obviously related to the fact that cellulose fibers under high temperature in the grafting reaction displayed a typically brown color. It is a drawback for some applications such as printing papers, but might be less relevant for air filters and packaging paper where the color of the paper is not critical. The tear strength of the paper first increased and then decreased with increasing grafted fiber content. The increasing of tear strength might be due to extra chemical bonds formed among cellulose fibers crosslinked by citric acid, whereas the decreasing of tear strength could be caused by shortening of fibers over the acidic treatment. The tensile index of the paper decreased with more grafted fibers added in the paper sheets because fibers is acid degraded in the grafting reaction, and the fiber length is decreased. The resulting antimicrobial paper is promising for various applications.

Conclusions

β-CD was grafted onto cellulose fibers via the crosslinking induced by CA in the presence of a weak acid salt catalyst. The optimal reaction conditions should be 15 min for the reaction time, 160 °C for the reaction temperature, CA-β-CD 300 g/l and pH 3.4, at which the grafting ratio was 9.7 %. The loading amount of CipHCl into β-CD grafted cellulose fibers increased remarkably by forming inclusion complexes compared to the virgin fibers. Meanwhile, the release of CipHCl from the grafted cellulose fibers was dramatically prolonged. The paper sheets made with β-CD grafted fibers loading CipHCl exhibited excellent antibacterial activities versus the virgin ones. In addition, with the increase of the amount of grafted fibers in paper samples, the brightness and the tensile index of the paper decreased, whereas the tear strength of the paper first increased and then decreased. The slow, sustained and affinity-based release of antibiotics from the β-CD grafted fibers reflects their potential applications as antibacterial products in clinical, packaging and other fields.

References

Astray G, Gonzalez-Barreiro C, Mejuto JC, Rial-Otero R, Simal-Gandara J (2009) A review on the use of cyclodextrins in foods. Food Hydrocoll 23(7):1631–1640

Bajpai M, Gupta P, Bajpai SK (2010) Silver (I) ions loaded cyclodextrin-grafted-cotton fabric with excellent antimicrobial property. Fibers Polym 11(1):8–13

Buschmann H, Denter U, Knittel D, Schollmeyer E (1998) The use of cyclodextrins in textile processes—an overview. J Text Inst 89(3):554–561

Chen W, Yu H, Liu Y, Chen P, Zhang M, Hai Y (2011) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr Polym 83(4):1804–1811

Cusola O, Tabary N, Belgacem MN, Bras J (2013) Cyclodextrin functionalization of several cellulosic substrates for prolonged release of antibacterial agents. J Appl Polym Sci 129(2):604–613

Denter U, Schollmeyer E (1997) Surface modification of synthetic and natural fibres by fixation of cyclodextrin derivatives. In: Proceedings of the 8th international symposium on cyclodextrins, pp 559–564

Desmet G, Takács E, Wojnárovits L, Borsa J (2011) Cellulose functionalization via high-energy irradiation-initiated grafting of glycidyl methacrylate and cyclodextrin immobilization. Radiat Phys Chem 80(12):1358–1362

Dipa R, Mahuya D, Debarati M (2009) Influence of alkali treatment on creep properties and crystallinity of jute fibres. Bioresources 4(2):730–739

El-Tahlawy K, Gaffar MA, El-Rafie S (2006) Novel method for preparation of β-cyclodextrin/grafted chitosan and it’s application. Carbohydr Polym 63(3):385–392

Gawish SM, Ramadan AM, Abo El-Ola SM, Abou El-Kheir AA (2009) Citric acid as a cross-linking agent for grafting β-cyclodextrin onto wool fabric. Polym Plast Technol Eng 48(7):701–710

Guan Y, Xiao H, Sullivan H, Zheng A (2007) Antimicrobial-modified sulfite pulps prepared by in situ copolymerization. Carbohydr Polym 69(4):688–696

Guo Y, Wang X, Shu X, Shen Z, Sun R (2012) Self-assembly and paclitaxel loading capacity of cellulose-graft-poly (lactide) nanomicelles. J Agric Food Chem 60(15):3900–3908

Hiriart-Ramírez E, Contreras-García A, Garcia-Fernandez MJ, Concheiro A, Alvarez-Lorenzo C, Bucio E (2012) Radiation grafting of glycidyl methacrylate onto cotton gauzes for functionalization with cyclodextrins and elution of antimicrobial agents. Cellulose 19(6):2165–2177

Karoyo AH, Sidhu PS, Wilson L, Hazendonk P (2013) Characterization and dynamic properties for the solid inclusion complexes of β-cyclodextrin and perfluorooctanoic acid. J Phys Chem B 117(27):8269–8282

Khan AM, Shah SS (2009) pH induced partitioning and interactions of ciprofloxacin hydrochloride with anionic surfactant sodium dodecyl sulfate using ultraviolet and fourier transformed infrared spectroscopy study. J Dispers Sci Technol 30(9):1247–1254

Kurkov SV, Ukhatskaya EV, Loftsson T (2011) Drug/cyclodextrin: beyond inclusion complexation. J Incl Phenom Macrocycl Chem 69(3–4):297–301

Larsen FH, Byg I, Damager I, Diaz J, Engelsen SB, Ulvskov P (2011) Residue specific hydration of primary cell wall potato pectin identified by solid-state 13C single-pulse MAS and CP/MAS NMR spectroscopy. Biomacromolecules 12(5):1844–1850

Lee MH, Yoon KJ, Ko S (2000) Grafting onto cotton fiber with acrylamidomethylated β-cyclodextrin and its application. J Appl Polym Sci 78(11):1986–1991

Lee MH, Yoon KJ, Ko S (2001) Synthesis of a vinyl monomer containing β-cyclodextrin and grafting onto cotton fiber. J Appl Polym Sci 80(3):438–446

Leitner J, Zuckerstätter G, Schmied F, Kandelbauer A (2013) Modifications in the bulk and the surface of unbleached lignocellulosic fibers induced by heat treatment without water removal: effects on tensile properties of unrefined kraft pulp. Euro J Wood Wood Prod 71(1):101–110

Li S, Jia N, Ma M, Zhang Z, Liu Q, Sun R (2011) Cellulose-silver nanocomposites: microwave-assisted synthesis, characterization, their thermal stability, and antimicrobial property. Carbohydr Polym 86(2):441–447

Li M, Wang LJ, Li D, Cheng YL, Adhikari B (2014) Preparation and characterization of cellulose nanofibers from de-pectinated sugar beet pulp. Carbohydr Polym 102(1):136–143

Liu S, Sun G (2006) Durable and regenerable biocidal polymers: acyclic N-halamine cotton cellulose. Ind Eng Chem Res 45(19):6477–6482

Lu D, Zhou X, Xing X, Wang X, Liu Z (2004) Quaternary ammonium salt (QAS) grafted cellulose fiber-preparation and anti-bacterial function. Acta Polym Sin 1:107–113

Luo J, Sun Y (2006) Acyclic N-halamine-based fibrous materials: preparation, characterization, and biocidal functions. J Polym Sci Part A Polym Chem 44(11):3588–3600

Martel B, Weltrowski M, Ruffin D, Morcellet M (2002) Polycarboxylic acids as crosslinking agents for grafting cyclodextrins onto cotton and wool fabrics: study of the process parameters. J Appl Polym Sci 83(7):1449–1456

Martins NCT, Freire CSR, Pinto RJB, Fernandes SCM, Pascoal Neto C, Silvestre AJD, Causio J, Baldi G, Sadocco P, Trindade T (2012) Electrostatic assembly of Ag nanoparticles onto nanofibrillated cellulose for antibacterial paper products. Cellulose 19(4):1425–1436

Medronho B, Andrade R, Vivod V, Ostlund A, Miguel MG, Lindman B, Voncina B, Valente AJ (2013) Cyclodextrin-grafted cellulose: physico-chemical characterization. Carbohydr Polym 93(1):324–330

Miao J, Pangule RC, Paskaleva EE, Hwang EE, Kane RS, Linhardt RJ, Dordick JS (2011) Lysostaphin-functionalized cellulose fibers with antistaphylococcal activity for wound healing applications. Biomaterials 32(36):9557–9567

Peila R, Migliavacca G, Aimone F, Ferri A, Sicardi S (2012) A comparison of analytical methods for the quantification of a reactive β-cyclodextrin fixed onto cotton yarns. Cellulose 19(4):1097–1105

Qian L, Guan Y, Ziaee Z, He B, Zheng A, Xiao H (2009) Rendering cellulose fibers antimicrobial using cationic β-cyclodextrin-based polymers included with antibiotics. Cellulose 16(2):309–317

Ramos AI, Braga TM, Fernandes JA, Silva P, Ribeiro-Claro PJ, Paz FAA, Lopes MDFS, Braga SS (2013) Analysis of the microcrystalline inclusion compounds of triclosan with β-cyclodextrin and its tris-O-methylated derivative. J Pharm Biomed Anal 30:34–43

Ren X, Kou L, Kocer HB, Zhu C, Worley SD, Broughton RM, Huang TS (2008) Antimicrobial coating of an N-halamine biocidal monomer on cotton fibers via admicellar polymerization. Colloids Surf A 317(1):711–716

Rukmani A, Sundrarajan M (2012) Inclusion of antibacterial agent thymol on β-cyclodextrin-grafted organic cotton. J Ind Text 42(2):132–144

Sathitsuksanoh N, Zhu Z, Wi S, Percival Zhang YH (2011) Cellulose solvent-based biomass pretreatment breaks highly ordered hydrogen bonds in cellulose fibers of switchgrass. Biotechnol Bioeng 108(3):521–529

Scott CP, Higham PA (2003) Antibiotic bone cement for the treatment of pseudomonas aeruginosa in joint arthroplasty: comparison of tobramycin and gentamicin-loaded cements. J Biomed Mater Res Part B 64(2):94–98

Singh M, Sharma R, Banerjee UC (2002) Biotechnological applications of cyclodextrins. Biotechnol Adv 20(5):341–359

Szejtli J (1998) Introduction and general overview of cyclodextrin chemistry. Chem Rev 98(5):1743–1753

Thatiparti TR, Shoffstall AJ, von Recum HA (2010) Cyclodextrin-based device coatings for affinity-based release of antibiotics. Biomaterials 31(8):2335–2347

Voncina B, Le Marechal AM (2005) Grafting of cotton with β-cyclodextrin via poly (carboxylic acid). J Appl Polym Sci 96(4):1323–1328

Yao C, Li X, Neoh KG, Shi Z, Kang ET (2008) Surface modification and antibacterial activity of electrospun polyurethane fibrous membranes with quaternary ammonium moieties. J Membr Sci 320(1):259–267

Zhao D, Zhao L, Zhu CS, Tian ZB, Shen XY (2009) Synthesis and properties of water-insoluble β-cyclodextrin polymer crosslinked by citric acid with PEG-400 as modifier. Carbohydr Polym 78(1):125–130

Acknowledgments

This work was supported by the grants from the National Natural Science Foundation of China (grant nos. 31200457 and 31270636), NSERC Sentinel Bioactive Paper Network (Canada) and the Fundamental Research Funds for the Central Universities (2013ZZ0072).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Dong, C., Ye, Y., Qian, L. et al. Antibacterial modification of cellulose fibers by grafting β-cyclodextrin and inclusion with ciprofloxacin. Cellulose 21, 1921–1932 (2014). https://doi.org/10.1007/s10570-014-0249-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0249-8