Abstract

Micro-aeration is a situation that will be encountered in bacterial cell growth especially when the saturated dissolved oxygen level cannot match the demand from cells grown to a high density. Therefore, it is desirable to separate aerobic growth and micro-aerobic product formation into two stages using methods including anaerobic or micro-aerobic promoters that are inducible under low aeration intensity. Eleven potential low aeration-inducible promoters were cloned and studied for their induction strengths under micro-aerobic conditions. Of them, Vitreoscilla hemoglobin promoter (P vgb ) was found to be the strongest among all 11 promoters. At the same time, six E. coli hosts harboring poly(R-3-hydroxybutyrate) (PHB) synthesis operon phaCAB were compared for their ability to accumulate poly(hydroxyalkanoates) (PHA). E. coli S17-1 was demonstrated to be the best host achieving a 70 % (mass fraction) PHB in the cell dry weigh (CDW) after 48 h under micro-aerobic growth. Cascaded P vgb repeats (P nvgb ) were investigated for enhanced expression level under micro-aerobic growth. The highest PHA production was obtained when a promoter containing eight cascaded P vgb repeats (P 8vgb ) was used, 5.37 g/l CDW containing 90 % PHB was obtained from recombinant in E. coli S17-1. Cells grew further to 6.30 g/l CDW containing 91 % PHB when oxygen-responsive transcription factor ArcA (arcA) was deleted in the same recombinant E. coli S17-1. This study revealed that vgb promoter containing cascaded P vgb repeats (P 8vgb ) is useful for product formation under low aeration intensity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

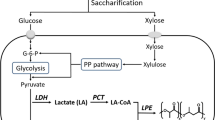

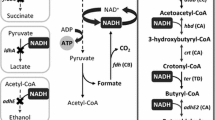

Microbial poly(hydroxyalkanoates) (PHA), as a family of biodegradable and biocompatible thermal polyesters with diverse structures (Matsumoto and Taguchi 2013; Steinbuchel and Valentin 1995; Tian et al. 2001), have the potentials to be developed as environmentally friendly bioplastics with many applications (Chen 2009; Chen and Patel 2012; Gao et al. 2011; Laycock et al. 2014; Park et al. 2012). However, the high production cost, due to low substrate to PHA conversion, high-energy consumption, non-continuous processes, etc. (Koller et al. 2011; Wang et al. 2014), impedes the wide applications of PHA as environmentally friendly materials (Meng et al. 2014; Keshavarz and Roy 2010; Khosravi-Darani et al. 2013). Many attempts have been made to reduce PHA production cost (Wu et al. 2001; Obruca et al. 2010; Passanha et al. 2014; Quillaguaman et al. 2010; Wang et al. 2014; Yue et al. 2014). Cheap carbon sources, such as cheese whey (Pais et al. 2014), digested liquors (Passanha et al. 2013), soy waste (Hong et al. 2000), starch (Ali and Jamil 2014), kitchen wastes (Yue et al. 2014), and crude glycerol, a by-product from biodiesel production (Mothes et al. 2007; Ibrahim and Steinbüchel 2010; Hermann-Krauss et al. 2013; Song et al. 2008), were used also as substrates for PHA production, respectively. Antibiotics-free plasmid expression systems were constructed to increase the biomass and PHA content avoiding the use of expensive antibiotics (Akiyama et al. 2011; Fleige et al. 2011). An unsterile and continuous fermentation process was developed based on a halophile bacterium named Halomonas sp. TD01 (Fu et al. 2014; Tan et al. 2011); 80 g/l cell dry weigh (CDW) and 80 % poly(R-3-hydroxybutyrate) (PHB) content was achieved on glucose salt medium during a 56-h open fed-batch process. This unsterile and continuous fermentation process opens a new area for reducing the cost in PHA production (Wang et al. 2014). So far, all those successful processes for PHA production are aerobic, requiring energy-intensive aerations. In fact, cells must go through micro-aerobic conditions during the late growth phase in both shake flasks and fermenters due to inefficient oxygen supply in aqueous cultures, especially when cell density is high (Lee et al. 1994, 2000).

PHA production under micro-aerobic conditions has been considered as a more economical process as micro-aeration can effectively reduce energy for air compressors and agitation (Carlson et al. 2005; Chen and Page 1997). PHB, the well-known member of the PHA family, was studied for production under micro- or anaerobic condition by recombinant Escherichia coli (Carlson et al. 2005; Wei et al. 2009). Two major oxygen-responsive regulators in E. coli coordinate the metabolic synthesis pathways: these are the fumarate nitrate reduction regulator (FNR) and aerobic respiration regulator arcAB (Compan and Touati 1994). The FNR dimer, with a sequence-specific domain to target promoters, acts as an activator of anaerobic genes and a repressor of aerobic genes (Bettenbrock et al. 2014), while arcA regulates gene expression in response to deprivation of oxygen. Together with its cognate sensory kinase arcB, arcAB regulate the expressions of hundreds of genes either negatively or positively based on intracellular redox states (Perrenoud and Sauer 2005; Shalel-Levanon et al. 2005a, b). Nikel et al. (2006, 2008) showed that arcA mutant increased cell growth and PHB content by 24 % in E. coli when glucose was replaced with glycerol as the substrate.

Usually, PHA synthesis genes are constructed and expressed in high copy number vectors inside recombinants. However, PHA native promoters are characterized by their low activities under micro-aerobic conditions. It is therefore important to find anaerobic or micro-aerobic promoters for induction of micro- or anaerobic PHA production. Wei et al. (2009) reported the use of a promoter of alcohol dehydrogenase (P adhE ) that was very effective to increase 18 % PHB accumulation compared with PHB synthesis native promoter in plasmid pBHR68. Overexpression of Vitreoscilla hemoglobin (VHb) on plasmids or on the genome was revealed to improve oxygen uptakes by recombinants, therefore enhancing PHB and biomass accumulation under hypoxic conditions (Roos et al. 2004; Wei and Chen 2008).

Along with steam sterilization, aeration is the most energy-consuming step in microbial fermentation processes (Kreyenschulte et al. 2014), especially when cells grown to high density. Various strategies including pumping more fresh air, the use of pure oxygen, increasing reactor air pressure, increasing agitation rate, and use of air bubble breakers have to apply so that dissolved oxygen concentration can satisfy the demand from cell growth (Pena et al. 2014). However, all of these strategies require more energy inputs, resulting in increasing cost for the final products (Kreyenschulte et al. 2014).

Therefore, attentions have been paid to manipulate the microbial cells, so that they can grow at low aeration intensity yet produce sufficient products for economic recovery (Pena et al. 2014). One of these possibilities is to grow the cells first under full aeration conditions to allow formation of enough biomass, followed by product accumulation under micro-aerobic conditions that are created automatically when cells reach high density (Moita et al. 2014). Another possibility is to increase microbial oxygen uptake efficiency using Vitreoscilla hemoglobin VHb (vgb) which can be expressed in recombinant microbial cells (Liu et al. 2005). The third way is to use a micro- or anaerobic promoter to induce product formation when oxygen demand cannot be met by all the above strategies; this was the aim of this paper.

In this study, we aimed to find strong promoter(s) that helped increase cell growth and PHB production under micro-aerobic conditions.

Materials and methods

Cloning anaerobic promoters from E. coli

Genomic DNA of E. coli was prepared according to the standard protocol (Bergthorsson and Ochman 1995). Primers used for amplifying the anaerobic promoters from the E. coli genomic DNA were digested while XbaI and BstBI sites were added at 5′-end of the forward and reverse primers, respectively.

A series of potential low aeration induction promoters were cloned based on the E. coli Gene Expression Database (http://chase.ou.edu) (Table 1). Genes encoding red fluorescent protein (RFP) and PHB synthesis operon phaCAB from Ralstonia eutropha were constructed in a plasmid to allow induction under low aeration by these promoters, respectively.

Selection of bacterial host strains

Six E. coli host strains were used to test the ability of PHA accumulation. Strains Trans1T-1, Trans109, Trans5α, and DMT were commonly used for genetic recombination. Strains S17-1 and EC100D are frequently employed for bacterial conjugation; they are also hosts for PHA production. The ability of these strains to grow at a low oxygen level was studied in order to select a suitable candidate for PHA production under low aeration intensity.

Plasmid pBHR68 containing PHB synthesis operon phaCAB, in which PHA synthase, 3-ketothiolase, and acetoacetyl-CoA reductase were encoded by phaC, phaA, and phaB, respectively, was kindly donated by Professor Alexander Steinbuchel of Münster University in Germany (Spiekermann et al. 1999). pBHR68 was transformed into the six host strains, respectively. After shake flask studies, the CDW and PHA content provided evidences for selection on the most suitable strain for PHB production under micro-aerobic condition.

Plasmids construction

Plasmids used in this study were all listed in Table 1. Molecular cloning standard procedures including vector isolation, DNA amplification, restriction enzyme digestion, and other DNA manipulations were employed for plasmids construction (Sambrook and Russell 2001). DNA purification and plasmids isolation kits were purchased from Biomed (Beijing, China). Restriction enzymes and ligation kits were supplied by Thermo (Beijing, China). pfu-DNA polymerase used in this study was from TransGen (Beijing, China). Primers were synthesized by Invitrogen (Shanghai, China).

The amplified target PCR fragments of different anaerobic promoters were digested by XbaI/BstBI and then inserted into XbaI/BstBI site in vector PcI-pR-RFP, resulting in a series of plasmids PcI-RFP-P promoter (Table 1), in which rfp was under the control of each anaerobic promoter (or low aeration intensity promoter). Those constructed plasmids were verified by PCR and DNA sequencing.

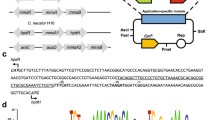

The construction of a series of plasmids pBHR-P promoter (Table 1) was similar with that of PcI-RFP-P promoter . Molecular manipulations were carried out according to the standard procedures (Sambrook and Russell 2001). Cascaded P vgb repeats were obtained using Gibson Assembly (Gibson et al. 2008). To construct two cascaded vgb promoters (P 2vgb ), three target PCR fragments including one short linear plasmid and two P vgb with different overlapped base pairs were amplified using Q5® High-Fidelity DNA Polymerase purchased from NEB (Beijing, China). The primers were designed based on NEBuilder (http://nebuilder.neb.com). The three fragments were purified and mixed in 6:6:1 molar ratio for P vgb , P vgb , and linear plasmid to the Gibson Assembly Master Mix purchased from NEB. After incubation at 50 °C for 30 min, 2 μl Gibson Assembly reaction mixture was transformed into the competent E. coli culture. A colony harboring plasmid containing P 2vgb (P-P 2vgb ) was selected via colony PCR and DNA sequencing. Based on this P-P 2vgb and the above-described procedure, the plasmid containing P 4vgb was assembled with two P 2vgb fragments and one short linear plasmid. Based on this approach, cascaded various P vgb repeats were obtained. Six plasmids with P vgb repeats ranging from 1 to 10 were constructed, and the amplified target fragments of different promoters were digested and inserted into pHBR68 using XbaI/BstBI, generating pBHR-P promoter .

arcA knockout in E. coli

The E. coli arcA mutant was constructed by one-step disruption on the chromosome (Datsenko and Wanner 2000). To investigate the possible recombination of gene deletion fragments with arcA in plasmids, 39 bp homologous upstream of arcA gene was used, and pKD13 was used as the template for the middle part of the PCR fragments. PCR amplification of gene deletion fragment using pfu-DNA polymerase was carried out to generate a ∼1.5-kb fragment. The fragment was separated by agarose gel electrophoresis and purified from the gel by DNA purification kits to generate a DNA concentration of 50 ng/μl.

E. coli S17-1 was grown in Luria-Bertani (LB) medium until OD600 reached 0.1–0.2, then 0.2 % L-arabinose was added to the culture at 37 °C. After that, the bacteria were maintained ice-cold for 30 min in order to prepare the electro-competent cells. The ice-cold cells were harvested through centrifugations to an appropriate concentration. The precipitated cells were washed by pre-cooling distilled water once followed by addition of a 10 % pre-cooled glycerol twice. Then, 10 μl of the deletion DNA fragment was added into the 100-μl competent cells; the mixture was added into an ice-cold 0.1 cm cuvette for electroporation which was conducted at 1.25 kV under 25 μF and 200 Ω (Bio-Rad Inc., USA). The resulting cells were supplemented with 600 μl LB medium. Subsequently, they were incubated for 2 h at 37 °C. Furthermore, cells were spread onto an LB agar plate with 50 μg/ml kanamycin for selection purpose. PCR verification was employed for positive colony screening. When transforming plasmid pCP20 which expresses the FLP recombinase and loses at 42 °C, the Kan resistant gene on the chromosome was eliminated. The elimination of KanR and loss of pCP20 were verified by negative selection on LB plates along with PCR analysis. Finally, DNA sequencing was employed to confirm the gene knockout. At the end, chromosomal arcA deleted strain E. coli S17-1 was obtained.

Culture medium and growth conditions

During DNA manipulations and construction, all strains were cultured in LB medium containing 10 g/l tryptone, 5 g/l yeast extract, and 10 g/l NaCl at a pH 7.2 and 37 °C. When antibiotic selection was required, the medium was supplemented with ampicillin (100 μg/ml), kanamycin (50 μg/ml), or chloramphenicol (30 μg/ml). For PHA production, glucose (20 g/l) was added into the medium as carbon source.

Aerobic growth was conducted using a 500-ml baffled shake flask containing 50 ml LB under vigorous agitation at 200 rpm (HNY, HONOUR, Tianjin, China), while micro-aerobic growth was conducted using a 500-ml shake flask without baffles containing 100 ml culture medium at 100 rpm on the same rotary shaker.

Fluorescence assays and real-time quantitative PCR

Fluorescence assays were carried out using microplate reader (ABI-7500, Invitrogen, USA). Red fluorescent protein was measured to observe relative expression levels of different promoters in E. coli under micro-aerobic condition.

The total RNA of E. coli was isolated by RNAprep pure Cell/Bacteria Kit. The cDNA was synthesized using Fastquant RT Kit for mRNA analysis. Real-time PCR assay for mRNA was performed with SuperReal PreMix (SYBR Green), while 16S rRNA was used as the inner standard. All manipulations were carried out according to the specifications.

The calibration of the real-time quantitative PCR (RT-PCR) was conducted using 16S rRNA of E. coli. The primers (16S forward: CACACTGGAACTGAGACAC; 16S reverse: CTTCTTCTGCGGGTAACG) were used to amplify the calibration fragment. The length of the calibration part was less than 300 bp. On the other hand, the product of phaC was also less than 300 bp. Calculation was carried out based on reported method (Schmittgen and Livak 2008).

Study on cell growth and PHA production

Cells were harvested by centrifugation at 10,000×g for 10 min and washed with distilled water twice. CDW was measured after lyophilization over 10 h. Methanolysis was carried out by adding 2 ml CH3OH/H2SO4 (100/3 vol) together with 1 g/l benzoic acid internal standard and 2 ml CHCl3 to the samples, and then incubated at 100 °C for 4 h. After cooling to room temperature and addition of 1 ml ddH2O, the organic phase was analyzed by gas chromatography using a Spectra System P2000 (Thermo Separation, USA) (Sim et al. 1997) to determine the intracellular PHA content (Brandl et al. 1988). Pure PHB (Sigma, USA) was used as a standard sample.

Results

Screening for promoters inducible under micro-aerobic conditions

Ten potential low aeration induction promoters were cloned based on the E. coli Gene Expression Database (http://chase.ou.edu) (Table 1). As a comparison, Vitreoscilla hemoglobin promoter (P vgb ) inducible under micro-aerobic condition was used as a control. To quantitatively evaluate strengths of the 11 promoters, they were constructed upstream red fluorescent protein gene rfp to generate 11 plasmids termed PcI-RFP-P promoter (Table 1).

When E. coli Trans 109 was transformed with the 11 promoters, respectively, intensities of the RFP emission from the recombinant E. coli were in proportion to the relative expression levels (strength) of different promoters (Fig. 1). It was demonstrated that five recombinant strains harboring plasmids PcI-RFP-P slp , PcI-RFP-P hya , PcI-RFP-P dmsA , PcI-RFP-P nirB , and PcI-RFP-P vgb , respectively, showed approximately twofold higher red fluorescence intensity compared with that of six other recombinants grown under micro-aerobic conditions (Fig. 1). No significant difference among the five strong strains in terms of RFP expression was observed. Thus, these five promoters, namely, P hya , P dmsA , P nirB , P slp , and P vgb , were demonstrated to have similarly higher strength induced under micro-aerobic conditions.

RFP expression levels under different promoters in E. coli Trans 109 under micro-aerobic conditions. The relative expression of RFP was measured as the RFP levels/OD, and expression level of RFP under P adhE was defined as 100 here. Data shown were the average values of three parallels studies. PcI-RFP-P adhE represented E. coli Trans 109 harboring plasmid PcI-RFP-P adhE , and the rest were named in the same way

These five strong micro-aerobic promoters, namely, P hya , P dmsA , P nirB , P slp , and P vgb , were used to construct PHB production strains inducible under micro-aerobic conditions, respectively. They were inserted upstream the PHB synthesis operon phaCAB genes using SmaI and BstBI enzymes, respectively, into plasmid pBHR68, to generate five plasmids including pBHR-P hya , pBHR-P dmsA , pBHR-P nirB , pBHR-P slp , and pBHR-P vgb (Tables 1 and 2). Subsequently, the five plasmids were transformed into E. coli Trans109, respectively, for evaluating PHB production under micro-aerobic conditions.

Under micro-aerobic conditions, recombinant E. coli harboring the native promoter P Re grew to 2.3 g/l containing 61 % PHB after 48 h, better than all other recombinants containing micro-aerobic promoters except the one containing recombinant P vgb , which grew to 2.5 g/l dry weight containing 68 % PHB, the highest among all recombinants (Table 2), suggesting that P vgb was the strongest promoter for growth and for inducing PHB accumulation under micro-aerobic conditions. Therefore, Vitreoscilla hemoglobin promoter P vgb was selected for further study.

Screening for the most suitable E. coli host for PHB accumulation under micro-aerobic conditions

Six commonly used E. coli strains containing PHB synthesis operon encoded in pBHR68 were investigated for their growth and PHB accumulation under micro-aerobic conditions (Table 3). E. coli S17-1 synthesized over 70 % PHB in 2.7 g/l CDW, the highest among all six tested strains, followed by E. coli Trans 109 with 2.6 g/l CDW containing 69 % PHB. Other four hosts accumulated 18–60 % PHB in their respective CDW. Based on this result, E. coli S17-1 was chosen as a host for further study.

Enhanced promoter P vgb strength via cascaded P vgb tandem repeats

Since P vgb was found the strongest promoter under micro-aerobic conditions, and E. coli S17-1 the most suitable host for PHB accumulation, P vgb was used to induce PHB synthesis in recombinant E. coli S17-1 grown under micro-aerobic conditions.

Recombinant E. coli S17-1 (pBHR-P vgb ) accumulated approximately 70 % PHB in 2.4 g/l CDW after 48 h growth under micro-aerobic conditions (Table 2). In contrast, recombinant E. coli S17-1 (pBHR-P vgb ) grew to 7.5 g/l CDW containing 62 % PHB under full aeration conditions as described in “Materials and methods.” This showed that the micro-aerobic condition reduced cell growth from aerobic 7.5 g/l to micro-aerobic 2.4 g/l, even though micro-aerobic 70 % PHB was a bit higher than aerobic 62 % PHB.

To improve cell growth and PHB accumulation, plasmids harboring different tandem repeat numbers of vgb promoter (P vgb ), including 2, 4, 6, 8, and 10 P vgb repeats, were constructed and named pBHR-P nvgb (n = 2, 4, 6, 8, and 10, respectively) (Table 1). The total length of vgb promoter (P vgb ) was less than 165 bp, allowing tandem assembly of up to 10 repeats. It was difficult to prepare repeats >10 P vgb due to their self recombination effort.

When P vgb tandem repeats reached eight, recombinant E. coli S17-1 (pBHR-P 8vgb ) grew to 5.4 g/l CDW containing over 90 % PHB (Table 4 and Fig. 2). Obviously, increasing P vgb tandem repeat number from two to eight improved PHB accumulation associated with CDW increases (Fig. 2). However, dramatic decreases on CDW and PHB accumulation were visible when P vgb tandem repeats reached 10.

Cell growth and PHA production by E. coli S17-1 harboring plasmid pBHR-P nvgb under micro-aerobic conditions (n = 1–10). Cells were cultivated in LB medium containing 20 g/l glucose at 37 °C for 48 h. Data shown were the average values of three parallels studies. P 1vgb represented E. coli S17-1 harboring plasmid pBHR-P 1vgb and so on

As the number of vgb promoter increases, the efficacy of gene expression level under the promoter control could also be improved. However, when the repeat number reaches a threshold value, the gene expression level could be down-regulated. As evidenced from real-time quantitative PCR, the mRNA transcription level of phaC was higher in the strain harboring P 8vgb than that having native promoter P Re or P 1vgb (Fig. 3). During a 48-h shake flask study, the mRNA level of phaC in recombinant (pBHR-P 8vgb ) was two- to fourfold higher than that of strains harboring pBHR-P 1vgb at least after 16 or 48 h. As the PHB production was related to the transcription level of phaC, this should be the reason why P 8vgb had the highest PHA content. When the repeats time of vgb promoter reached 10 (P 10vgb ), the mRNA transcription level was reduced to the minimum value with poor cell growth and PHB accumulation (Fig. 3). Therefore, P 8vgb was selected for cell growth and PHA accumulation by recombinant E. coli S17-1 incubated under micro-aerobic condition.

mRNA transcription levels of phaC in E. coli S17-1 harboring different plasmids under micro-aerobic conditions. The total RNA of E. coli was isolated by RNAprep pure Cell/Bacteria Kit. The cDNA was synthesized using Fastquant RT Kit for mRNA analysis. Real-time PCR assay for mRNA was performed with SuperReal PreMix (SYBR Green), while 16S rRNA was used as the inner standard. The mRNA expression levels of phaC were shown in the y-axis. Data shown were the average values of three parallels studies

ArcA deletion improved growth and PHB production of E. coli S17-1 (pBHR-P 8vgb )

ArcAB and FNR systems regulate catabolic gene expressions, thus affecting cell growth under different oxygen conditions (Nikel et al. 2006). Bacteria can grow better under micro-aerobic conditions when gene arcA was deleted compared with its wild type (Nikel et al. 2006). The arcA mutant E. coli S17-1 ΔarcA (pBHR-P 8vgb ) grew to a CDW of 6.3 g/l containing over 91 % PHB after 48-h shake flask incubation under micro-aerobic conditions (Table 4). In contrast, all control strains produced significantly reduced CDW and PHB contents (Table 4). Remarkably, E. coli S17-1 ΔarcA (pBHR68) produced similar results containing 6.5 g/l CDW with 47 % PHB under full aeration conditions. These results showed a successful combination of strong micro-aerobic promoter, strain, and manipulation on aerobic respiration regulator arcAB can lead to better PHB formation under micro-aerobic conditions comparable or better to full aerobic growth.

Discussion

Li et al. (2012) used a uniquely designed in vitro assembling process to construct a series of tac promoter clusters. The transcription strength of these promoter clusters showed a stepwise enhancement with the increase of tandem repeats number until it reached the critical value of five. Application of the tac promoter clusters proved that it was efficient in enhancing PHB accumulation to 23.7 % PHB of the cell dry weight in batch cultivation. Therefore, it is interesting to use similar approach for enhancing oxygen uptake employing multiple vgb promoters.

Among all the micro- or anaerobic promoters found on the E. coli Gene Expression Database (http://chase.ou.edu), 10 most promising ones were cloned and constructed upstream of RFP gene to allow evaluate promoter strengths based on expression of RFP in the recombinant (Table 1). Five promoters (including vgb promoter P vgb ) were found similarly strong in expressing RFP under micro-aerobic conditions (Fig. 1). They were selected to induce PHB production micro-aerobically (Table 2). All five promoters induced PHB production in different intensities, P vgb was the strongest accumulating over 68 % PHB under micro-aerobic conditions compared with all other strong promoters inducing only 25–58 % PHB accumulation (Fig. 2). Therefore, P vgb was chosen for further applications.

Among the six common E. coli strains studied, E. coli S17-1 stood out as the most capable one to produce PHB under micro-aerobic conditions (Table 3), as it synthesized over 70 % PHB in 2.7 g/l CDW while all other five strains accumulated less than 70 % PHB in 1.2–2.6 g/l CDW. However, E. coli S17-1 (pBHR-P vgb ) grew better under aerobic condition, producing over 7.5 g/l CDW containing 62 % PHB, significantly higher than 7.1 g/l CDW containing 47 % PHB by E. coli S17-1 (pBHR68). The results showed that P vgb was useful both under micro-aerobic or aerobic conditions.

Efforts must be made so that both cell growth and PHB accumulation can be improved under micro-aerobic conditions compared with full aerobic ones. By assembling repeated P vgb promoter in a tandem way, it was found that eight tandem repeated P vgb created the strongest induction effect, leading to 5.7 g/l CDW, the highest cell dry weight, and over 90 % PHB accumulation (Fig. 2). The PHB accumulation was much high than 62 % accumulated under aerobic growth. The strongest P 8vgb was due to the strong mRNA transcription induced by the promoter itself (Fig. 3). More P vgb assembly (such as P 10vgb ) resulted in a dramatic reduction of induction intensity (Figs. 2 and 3).

Finally, PHB accumulation and cell growth were further improved when oxygen-responsive transcription factor ArcA (arcA) was deleted in the same recombinant E. coli S17-1 (pBHR-P 8vgb ); the resulting strain E. coli S17-1ΔarcA (pBHR-P 8vgb ) grew to 6.3 g/l CDW containing over 91 % PHB, very close to 6.5 g/l CDW produced by the control E. coli S17-1 ΔarcA (pBHR68) which accumulated only 47 % PHB. The results demonstrated that the combination of various possibilities could lead to similar growth between aerobic and micro-aerobic conditions, yet PHB accumulation was always better under micro-aerobic conditions

In summary, the assembling of eight repeated vgb promoters formed a much stronger promoter able to improve PHB accumulation significantly. Combined with deletion of oxygen-responsive transcription factor ArcA (arcA), PHB accumulation improved further to over 91 % under micro-aerobic conditions. It thus becomes possible to produce PHB under less energy-demanding conditions, the micro-aerobic conditions, with more efficiency than under energy-intensive aeration conditions.

References

Akiyama H, Okuhata H, Onizuka T, Kanai S, Hirano M, Tanaka S, Sasaki K, Miyasaka H (2011) Antibiotics-free stable polyhydroxyalkanoate (PHA) production from carbon dioxide by recombinant cyanobacteria. Bioresour Technol 102:11039–11042

Ali I, Jamil N (2014) Enhanced biosynthesis of poly(3-hydroxybutyrate) from potato starch by Bacillus cereus strain 64-ins in a laboratory scale fermenter. Prep Biochem Biotechnol 44:822–833

Bergthorsson U, Ochman H (1995) Heterogeneity of genome sizes among natural isolates of Escherichia coli. J Bacteriol 177:5784–5789

Bettenbrock K, Bai H, Ederer M, Green J, Hellingwerf KJ, Holcombe M, Kunz S, Rolfe MD, Sanguinetti G, Sawodny O, Sharma P, Steinsiek S, Poole RK (2014) Towards a systems level understanding of the oxygen response of Escherichia coli. Adv Microb Physiol 64:65–114

Brandl H, Gross RA, Lenz RW, Fuller RC (1988) Pseudomonas oleovorans as a source of poly(beta-hydroxyalkanoates) for potential applications as biodegradable polyesters. Appl Environ Microbiol 54:1977–1982

Carlson R, Wlaschin A, Srienc F (2005) Kinetic studies and biochemical pathway analysis of anaerobic poly-(R)-3-hydroxybutyric acid synthesis in Escherichia coli. Appl Environ Microbiol 71:713–720

Chen GQ (2009) A polyhydroxyalkanoates based bio- and materials industry. Chem Soc Rev 38:2434–2446

Chen GQ, Page WJ (1997) Production of poly-beta-hydroxybutyrate by Azotobacter vinelandii in a two-stage fermentation process. Biotechnol Tech 11:347–350

Chen GQ, Patel MK (2012) Plastics derived from biological sources: present and future: a technical and environmental review. Chem Rev 112:2082–2099

Compan I, Touati D (1994) Anaerobic activation of arcA transcription in Escherichia coli: roles of Fnr and arcA. Mol Microbiol 11:955–964

Datsenko KA, Wanner BL (2000) One-step inactivation of chromosomal genes in Escherichia coli K-12 using PCR products. Proc Natl Acad Sci U S A 97:6640–6645

Fleige C, Kroll J, Steinbuchel A (2011) Establishment of an alternative phosphoketolase-dependent pathway for fructose catabolism in Ralstonia eutropha H16. Appl Microbiol Biotechnol 91:769–776

Fu XZ, Tan D, Aibaidula G, Wu Q, Chen JC, Chen GQ (2014) Development of Halomonas TD01 as a host for open production of chemicals. Metab Eng 23:78–91

Gao X, Chen JC, Wu Q, Chen GQ (2011) Polyhydroxyalkanoates as a source of chemicals, polymers, and biofuels. Curr Opin Biotechnol 22:768–774

Gibson DG, Benders GA, Axelrod KC, Zaverl J, Alglre MA, Moodle M, Montague MG, Venter JC, Smlth HO, Hutchlson CA (2008) One-step assembly in yeast of 25 overlapping DNA fragments to form a complete synthetic Mycoplasma genitalium genome. Proc Natl Acad Sci U S A 105:20404–20409

Hermann-Krauss C, Koller M, Muhr A, Fasl H, Stelzer F, Braunegg G (2013) Archaeal production of polyhydroxyalkanoate (PHA) co-and terpolyesters from biodiesel industry-derived by-products. Archaea 2013:1–10

Hong K, Leung YC, Kwok SY, Law KH, Lo WH, Chua H, Yu PH (2000) Construction of recombinant Escherichia coli strains for polyhydroxybutyrate production using soy waste as nutrient. Appl Biochem Biotechnol 84:381–390

Ibrahim MH, Steinbüchel A (2010) Zobellella denitrificans strain MW1, a newly isolated bacterium suitable for poly (3-hydroxybutyrate) production from glycerol. J Appl Microbiol 108:214–225

Keshavarz T, Roy I (2010) Polyhydroxyalkanoates: bioplastics with a green agenda. Curr Opin Microbiol 13:321–326

Khosravi-Darani K, Mokhtari ZB, Amai T, Tanaka K (2013) Microbial production of poly(hydroxybutyrate) from C1 carbon sources. Appl Microbiol Biotechnol 97:1407–1424

Koller M, Gasser I, Schmid F, Berg G (2011) Linking ecology with economy: insights into polyhydroxyalkanoate-producing microorganisms. Eng Life Sci 11:222–237

Kreyenschulte D, Krull R, Margaritis R (2014) Recent advances in microbial biopolymer production and purification. Crit Rev Biochem 34:1–15

Laycock B, Halle P, Pratt S, Werker A, Lant P (2014) The chemomechanical properties of microbial polyhydroxyalkanoates. Prog Polym Sci 39:397–442

Lee SY, Lee KM, Chang HN, Steinbuchel A (1994) Comparison of recombinant Escherichia coli strains for synthesis and accumulation of poly-(3-hydroxybutyric acid) and morphological changes. Biotechnol Bioeng 44:1337–1347

Lee SH, Oh DH, Ahn WS, Lee Y, Choi J, Lee SY (2000) Production of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) by high-cell-density cultivation of Aeromonas hydrophila. Biotechnol Bioeng 67:240–244

Li MJ, Wang JS, Geng YP, Li YK, Wang Q, Liang QF, Qi QS (2012) A strategy of gene overexpression based on tandem repetitive promoters in Escherichia coli. Microb Cell Factories 11:19

Liu T, Chen JY, Zheng Z, Wang TH, Chen GQ (2005) Construction of highly efficient E. coli expression systems containing low oxygen induced promoter and partition region. Appl Microbiol Biotechnol 68:346–354

Matsumoto K, Taguchi S (2013) Enzyme and metabolic engineering for the production of novel biopolymers: crossover of biological and chemical processes. Curr Opin Biotechnol 24:1054–1060

Meng DC, Shen R, Yao H, Chen JC, Wu Q, Chen GQ (2014) Engineering the diversity of polyesters. Curr Opin Biotechnol 29:24–33

Moita FR, Ortigueira J, Freches A, Pelica J, Gonçalves M, Mendes B, Lemos PC (2014) Bio-oil upgrading strategies to improve PHA production from selected aerobic mixed cultures. New Biotechnol 31:297–307

Mothes G, Schnorpfeil C, Ackermann JU (2007) Production of PHB from crude glycerol. Eng Life Sci 7:475–479

Nikel PI, Pettinari MJ, Galvagno MA, Mendez BS (2006) Poly(3-hydroxybutyrate) synthesis by recombinant Escherichia coli arcA mutants in microaerobiosis. Appl Environ Microbiol 72:2614–2620

Nikel PI, Pettinari MJ, Galvagno MA, Mendez BS (2008) Poly(3-hydroxybutyrate) synthesis from glycerol by a recombinant Escherichia coli arcA mutant in fed-batch microaerobic cultures. Appl Microbiol Biotechnol 77:1337–1343

Obruca S, Marova I, Stankova M, Mravcova L, Svoboda Z (2010) Effect of ethanol and hydrogen peroxide on poly(3-hydroxybutyrate) biosynthetic pathway in Cupriavidus necator H16. World J Microbiol Biotechnol 26:1261–1267

Pais J, Farinha I, Freitas F, Serafim LS, Martinez V, Martinez JC, Arevalo-Rodriguez M, Auxiliadora PM, Reis MA (2014) Improvement on the yield of polyhydroxyalkanotes production from cheese whey by a recombinant Escherichia coli strain using the proton suicide methodology. Enzym Microb Technol 55:151–158

Park SJ, Kim TW, Kim MK, Lee SY, Lim SC (2012) Advanced bacterial polyhydroxyalkanoates: towards a versatile and sustainable platform for unnatural tailor-made polyesters. Biotechnol Adv 30:1196–1206

Passanha P, Esteves SR, Kedia G, Dinsdale RM, Guwy AJ (2013) Increasing polyhydroxyalkanoate (PHA) yields from Cupriavidus necator by using filtered digestate liquors. Bioresour Technol 147:345–352

Passanha P, Kedia G, Dinsdale RM, Guwy AJ, Esteves SR (2014) The use of NaCl addition for the improvement of polyhydroxyalkanoate production by Cupriavidus necator. Bioresour Technol 163:287–294

Pena C, Castillo T, Garcia A, Millan M, Segura D (2014) Biotechnological strategies to improve production of microbial poly-(3-hydroxybutyrate): a review of recent research work. Microb Biotechnol 7:278–293

Perrenoud A, Sauer U (2005) Impact of global transcriptional regulation by ArcA, ArcB, Cra, Crp, Cya, Fnr, and Mlc on glucose catabolism in Escherichia coli. J Bacteriol 187:3171–3179

Quillaguaman J, Guzman H, Van-Thuoc D, Hatti-Kaul R (2010) Synthesis and production of polyhydroxyalkanoates by halophiles: current potential and future prospects. Appl Microbiol Biotechnol 85:1687–1696

Roos V, Andersson CI, Bulow L (2004) Gene expression profiling of Escherichia coli expressing double Vitreoscilla haemoglobin. J Biotechnol 114:107–120

Sambrook J, Russell DW (2001) Molecular cloning: a laboratory manual, 3rd edn. Cold Spring Harbor Laboratory, Cold Spring Harbor

Schmittgen TD, Livak KJ (2008) Analyzing real-time PCR data by the comparative CT method. Nat Protoc 3:1101–1108

Shalel-Levanon S, San KY, Bennett GN (2005a) Effect of ArcA and FNR on the expression of genes related to the oxygen regulation and the glycolysis pathway in Escherichia coli under microaerobic growth conditions. Biotechnol Bioeng 92:147–159

Shalel-Levanon S, San KY, Bennett GN (2005b) Effect of oxygen, and ArcA and FNR regulators on the expression of genes related to the electron transfer chain and the TCA cycle in Escherichia coli. Metab Eng 7:364–374

Sim SJ, Snell KD, Hogan SA, Stubbe J, Rha CK, Sinskey AJ (1997) PHA synthase activity controls the molecular weight and polydispersity of polyhydroxybutyrate in vivo. Nat Biotechnol 15:63–67

Simon R (1994) High frequency mobilization of gram-negative bacterial replicons by the in vivo constructed Tn5-Mob transposon. Mol Gen Genet 196:413–420

Song JH, Jeon CO, Choi MH, Yoon SC, Park W (2008) Polyhydroxyalkanoate (PHA) production using waste vegetable oil by Pseudomonas sp. strain DR2. J Microbiol Biotechnol 18:1408–1415

Spiekermann P, Rehm BH, Kalscheuer R, Baumeister D, Steinbuchel A (1999) A sensitive, viable-colony staining method using Nile red for direct screening of bacteria that accumulate polyhydroxyalkanoic acids and other lipid storage compounds. Arch Microbiol 171:73–80

Steinbuchel A, Valentin HE (1995) Diversity of bacterial polyhydroxyalkanoic acids. FEMS Microbiol Lett 128:219–228

Tan D, Xue YS, Aibaidula G, Chen GQ (2011) Unsterile and continuous production of polyhydroxybutyrate by Halomonas TD01. Bioresour Technol 102:8130–8136

Tian G, Wu Q, Sun SQ, Noda I, Chen GQ (2001) Study of thermal melting behavior of microbial polyhydroxyalkanoate using two-dimensional Fourier transform infrared correlation spectroscopy. Appl Spectrosc 55:888–893

Wang Y, Yin J, Chen GQ (2014) Microbial polyhydroxyalkanoates, challenges and opportunities. Curr Opin Biotechnol 30:59–65

Wei XX, Chen GQ (2008) Applications of the VHb gene vgb for improved microbial fermentation processes. Methods Enzymol 436:273–287

Wei XX, Shi ZY, Yuan MQ, Chen GQ (2009) Effect of anaerobic promoters on the microaerobic production of polyhydroxybutyrate (PHB) in recombinant Escherichia coli. Appl Microbiol Biotechnol 82:703–712

Wu Q, Huang HH, Hu GH, Chen JC, Ho KP Chen GQ (2001) Production of poly-3-hydroxybutyrate by Bacillus sp. JMa5 cultivated in molasses media. Antonie Van Leeuwenhoek 80:111–118

Yue HT, Ling C, Chen XB, Chen YL, Deng HT, Wu Q, Chen JC, Chen GQ (2014) A seawater-based open and continuous process for polyhydroxyalkanoates production by recombinant Halomonas campaniensis LS21 grown in mixed substrates. Biotechnol Biofuels 7:108–119

Acknowledgments

This collaborative research was supported by the State Basic Science Foundation 973 Grant (No. 2012CB725201) to GQC. JCC received support from State Industrialization Grant (Zhicheng Grant No. 2012BAD32B02) to develop process for a scale-up PHA production under low aeration.

Author information

Authors and Affiliations

Corresponding author

Additional information

Hong Wu and Huan Wang contributed equally to this study and share first authorship.

Rights and permissions

About this article

Cite this article

Wu, H., Wang, H., Chen, J. et al. Effects of cascaded vgb promoters on poly(hydroxybutyrate) (PHB) synthesis by recombinant Escherichia coli grown micro-aerobically. Appl Microbiol Biotechnol 98, 10013–10021 (2014). https://doi.org/10.1007/s00253-014-6059-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-6059-y