Abstract

Poly(3-hydroxybutyrate) (PHB) synthesis was analyzed under microaerobic conditions in a recombinant Escherichia coli arcA mutant using glycerol as the main carbon source. The effect of several additives was assessed in a semi-synthetic medium by the ‘one-factor-at-a-time’ technique. Casein amino acids (CAS) concentration was an important factor influencing both growth and PHB accumulation. Three factors exerting a statistically significant influence on PHB synthesis were selected by using a Plackett–Burman screening design [glycerol, CAS, and initial cell dry weight (CDW) concentrations] and then optimized through a Box–Wilson design. Under such optimized conditions (22.02 g l−1 glycerol, 1.78 g l−1 CAS, and 1.83 g l−1 inoculum) microaerobic batch cultures gave rise to 8.37 g l−1 CDW and 3.52 g l−1 PHB in 48 h (PHB content of 42%) in a benchtop bioreactor. Further improvements in microaerobic PHB accumulation were obtained in fed-batch cultures, in which glycerol was added to maintain its concentration above 5 g l−1. After 60 h, CDW and PHB concentration reached 21.17 and 10.81 g l−1, respectively, which results in a PHB content of 51%. Microaerobic fed-batch cultures allowed a 2.57-fold increase in volumetric productivity when compared with batch cultures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microbial fermentations and many other industrial processes mostly rely on two fossil fuels (petroleum and gas) as sources of energy. This biased strategy has contributed to global climate change by emitting large amounts of CO2 to the atmosphere and, as a collateral consequence, has favored the generation of an extended range of difficult-to-dispose goods by petrochemical industries. Thus, new strategies based on energy-saving processes and the manufacturing of non-petrochemical goods are needed to reduce contamination and fuel use, while the replacement of petroleum by renewable sources will also help to avoid oil dependence.

The particular situation described above has renewed the interest in biotechnological approaches that could fulfill these goals. For example, microbial processes in non-fully aerobic conditions and the generation of environmentally friendly bioproducts can be achieved in a sustainable manner (Carlson et al. 2005; Nikel et al. 2006b). Poly(3-hydroxybutyrate) (PHB) belongs to the group of polyhydroxyalkanoates (PHAs; Anderson and Dawes 1990; Khanna and Srivastava 2005). These polymers are synthesized naturally in a wide variety of bacterial species as a reserve compound for carbon and energy. Nowadays, PHAs continue to attract increasing industrial interest as renewable, biodegradable, and biocompatible thermoplastics (Suriyamongkol et al. 2007). However, current processes for the synthesis of PHAs require fully aerobic conditions, which means that they are high energy-consuming processes. The environmental impact of replacing oil derived plastics with biopolymers has been the subject of several studies, among them those regarding PHB production by bacterial fermentation (Heyde 1998; Gerngross 1999; Akiyama et al. 2003). Recently, a complete life cycle assessment for PHB production from the cradle to the factory gate has been published by Harding et al. (2007). Those studies pointed out that, in spite of the fact that PHB is more environmentally friendly than oil-derived polymers, the great amount of energy required for its production must be taken into account when assessing environmental damage.

A deeper understanding of the physiology of PHA-producing microorganisms in non-aerobic conditions is needed to design processes with lower energy consumption levels, thus enhancing sustainability. The model microorganism Escherichia coli has been used to generate recombinant pha strains that are good PHA producers (Steinbüchel and Füchtenbusch 1998; Li et al. 2007). E. coli is a facultative aerobe, so it is a suitable model organism to study how alterations in its redox control affect the synthesis of bioproducts under different aeration conditions.

The two-component regulatory ArcAB system of E. coli is a global regulation system that, together with Fnr, controls catabolic gene expression and operates to fine-tune catabolism in response to O2 (Lynch and Lin 1996). The ArcA regulator has a pleiotropic effect on a number of cellular functions. It regulates gene expression in response to deprivation of O2 and, together with its cognate sensory kinase ArcB, represents a global regulation system that negatively or positively controls the expression of over 175 genes according to the intracellular redox state (Salmon et al. 2005).

We have recently reported that heterologous PHB accumulation in E. coli ΔarcA mutants suppresses the Dye phenotype by decreasing the accumulation of intracellular reactive O2 species (Ruiz et al. 2006). Furthermore, it has been shown that a strain carrying a particular mutation (arcA2) could be used for PHB accumulation under microaerobic conditions using glucose as a carbon source (Nikel et al. 2006b). The current abundance of glycerol, which constitutes about 10% of the product of the biodiesel synthesis and has thus become a pollutant waste, prompted us to analyze this carbon source as an alternative to glucose for fermentations conducting to reduced bioproducts. Those studies showed that, in microaerobic E. coli arcA2 cultures grown in glycerol, a high reducing power availability, measured as the ratio NADH/NAD+, was obtained (Nikel et al. 2008).

In this work, we evaluate the adequacy of glycerol as a substrate. We also broaden our previous results by means of two kinds of approaches: the integrative screening and optimization of physico-chemical factors to improve PHB accumulation in shaken flasks through experimental designs and the assay of a fed-batch cultivation process under low O2 conditions. Our results show that fed-batch under low O2 supply conditions is a suitable strategy to obtain an appropriate PHB synthesis by this E. coli arcA2 strain from glycerol.

Materials and methods

Microorganisms and plasmid

Escherichia coli CT1061 [F–fadE62 lacI60 tyrT58(AS) fabB5 mel-1 supF58 arcA2] (Nikel et al. 2006b) was transformed with plasmid pJP24K (Nikel et al. 2006a) and used throughout this study (CT1061-PHB).

Culture media and growth conditions

Sabouraud glucose agar (SGA) medium was the same as the previously described SMAG medium (Nikel et al. 2006b) except that 30 g l−1 glycerol was used instead of glucose, and 50 mg l−1 kanamycin was added for plasmid maintenance. Shaken flask experiments were conducted in 250-ml Erlenmeyer flasks for 48 h at 37°C. Microaerobic cultivations used flasks filled with SGA and agitation provided by a magnetic stirrer (∼75 rpm) to prevent biomass sedimentation. Unless otherwise stated, cultures were inoculated at 0.1 g l−1 initial cell dry weight (CDW) with an overnight culture of CT1061-PHB grown in SGA under the same O2 availability condition to be used in the experiment.

Bioreactor cultivations were carried out in a 5.6-l stirred tank reactor equipped with six flat-bladed disk turbines (BioFlo 110; New Brunswick Scientific, USA) as described by Nikel et al. (2006b), with 4-l (batch cultures) or 3-l (fed-batch cultures) initial volumes. Inoculum was added at the initial CDW found to be optimal during experimental designs (see below). To prevent foam formation, 30 μl/l Antifoam 289 (Sigma-Aldrich) was manually added at the beginning of the run. Batch cultures were developed without air sparging, maintaining a stirring speed of 75 rpm. For fed-batch experiments, the vessel was sparged with 500 ml min−1 air, which corresponds to 0.1–0.2 vvm. Dissolved O2 concentration (dO2) was measured using an Ag/AgCl polarometric O2 probe (Mettler, Switzerland). The feeding solution consisted of 500 g l−1 glycerol, 40 g l−1 casein amino acids (CAS, Difco), and 4 g l−1 MgSO4 and was pumped into the fermentor as explained in the text.

Experimental designs and statistical analysis

Several additives were evaluated in shaken flasks using SGA medium using the ‘one-factor-at-a-time’ technique. A Plackett–Burman screening design and a Box–Wilson design were employed to find the combination of key factors that maximized PHB concentration as described elsewhere (Kennedy and Krouse 1999; Strobel and Sullivan 1999; Nikel et al. 2005). All experiments described in this paper were repeated at least twice, and average results are presented.

Analytical determinations

CDW and PHB were determined gravimetrically (Nikel et al. 2006a) and by gas chromatography (Braunegg et al. 1978), respectively. Fermentation products in the culture supernatants were quantified by gas chromatography after methyl-esterification (Nikel et al. 2007). Peaks were identified by using authentic standards from Sigma-Aldrich. Enzymatic kits were used to determine concentrations of ethanol (Wiener Lab, Argentina) and glycerol (Roche Diagnostics, Germany).

Results

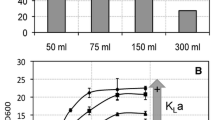

Effect of amendments on biomass and PHB concentration in batch cultures

An intriguing phenotype of arcA deletion mutants is their failure to grow in minimal medium, whereas arcA2 strains can grow in synthetic medium if it is supplemented with a low amount of CAS to prime growth (Fu et al. 1991). Due to its composition, this complex nutrient can also act as a reducing agent. To gain further insight into the effect of amendments, we tested other additives that could have influence on PHB accumulation, comparing them with CAS. The effect of replacing CAS by the amino acids l,d-cystein and l-methionine, or by Na2S, was analyzed in microaerobic cultures as described in “Materials and methods.” As it can be seen in Table 1, if the medium was devoid of supplements, no growth was observed, thus confirming our previous results (Nikel et al. 2006b). The highest biomass and polymer synthesis were obtained with the addition of CAS at 300 mg l−1, which resulted in a 34 ± 4% PHB accumulation. The addition of cysteine, which could function as nutrient and reducer, also gave a significant enhancement in PHB accumulation. Either Na2S or methionine were the less effective amendments. These results show that the addition of CAS was sufficient to ensure adequate biomass and PHB synthesis and suggest that the enhancing effect of CAS is not only due to its reducing properties.

Addition of certain amino acids has been shown to enhance PHB accumulation in aerobic cultures of recombinant E. coli carrying pha genes from Cupriavidus necator (formerly Ralstonia eutropha; Lee et al. 1995). Biosynthesis of some amino acids consumes intermediates from the tricarboxylic acid cycle or intermediates in the glycolytic pathway (which would otherwise form acetyl-CoA) and reducing equivalents. Therefore, external addition of amino acids could avoid acetyl-CoA and (or) nicotinamide adenine dinucleotide phosphate (reduced form) shortage, substrates for PHB biosynthetic enzymes. Considering both redox and nutritional properties, we decided to use CAS as an additive in the statistical experimental designs step.

Statistical design of culture conditions for PHB synthesis

As a first step in the selection of the variables that significantly affected PHB synthesis by E. coli CT1061-PHB, we studied the influence of medium components and some process variables using a Plackett–Burman design for seven independent variables at two levels. The independent variables were glycerol and CAS concentrations, initial pH, temperature of cultivation, inoculum size, and trace elements solution (TES) and MgSO4 concentrations (Table S1). Glycerol concentration was analyzed up to 30 g l−1, a range in which it should have a positive effect on PHB accumulation without exerting osmotic stress on bacterial growth.

The screening design and its results are presented in Tables S2 and S3 as supplementary material. As Plackett–Burman design considers only linear effects of the variables on the responses under study (Kennedy and Krouse 1999), CDW and PHB concentrations were explained by a first-order model from the multiple regression analysis presented in Table S3. In the following equations, A to G represent the codified values for glycerol, CAS, pH, temperature, inoculum, TES, and Mg2+, respectively:

Statistical analysis of this model through analysis of the variance (ANOVA) revealed that the first-order equation chosen to explain the responses was significant (data not shown). In addition, the model accounts for 95.6% (biomass) and 98.1% (PHB) of the total variations observed, as judged by the corresponding coefficients of determination (R2). As demonstrated by analysis of the model (Table S3), three variables had significant effect (P < 0.05, highlighted in boldface in the equations) on biomass and PHB synthesis: glycerol and CAS concentrations and inoculum size. From the linear equations, it can be seen that these three factors had larger regression coefficients than the other variables.

The three significant factors, which survived the screening step, were optimized using a rotatable central composite design (Box–Wilson design) to maximize PHB concentration. The 23-factorial design block required eight experiments, six axial points to assess curvature, and six additional replicates at the center of the design, which provide additional degrees of freedom for error estimation (Strobel and Sullivan 1999). Levels of the variables and the experimental plan are presented in Tables S4 and S5, respectively. Table S5 also shows the predicted values for PHB concentration for each trial. Results were fitted with a second-order model, which includes all two-way interactions between independent variables. This model proved to be adequate at the 95% confidence level when tested by ANOVA, Fischer’s F test (data not shown), and R 2 = 0.979. Multiple regression analysis of the experimental data was performed, and the results obtained are shown in Table S6, along with Student’s t test results and the corresponding P values. The model equation shown below, including only the significant terms (highlighted in boldface in Table S6), provides a suitable model to describe the PHB concentration experimental response as a function of the codified values of glycerol (G), CAS (C), and inoculum size (I) for the optimization step.

All quadratic terms were significant as well as the interactions involving glycerol. Response surface plots described by the regression model were drawn from the pair-wise combination of the three factors, while keeping the remaining one at zero level, to illustrate the main effects of the independent variables and their interactive effects on PHB concentration (Fig. 1). The elliptical nature of the contour plots indicates that interactions between the independent variables are significant (see Fig. 1a,b). In all cases, the maximum PHB concentration was located inside the experimental region.

Response surfaces for the optimization of microaerobic PHB synthesis by CT1061-PHB. PHB concentration (g l−1) was plotted as a function of the codified levels of: a glycerol and casein amino acids (CAS); b glycerol and inoculum; c CAS and inoculum. Contour plots are show at the bottom of each figure

Canonical analysis of the model equation reveals that the stationary point of the response surface corresponds to G = 0.2019, C = −0.0671, and I = 0.4404, representing a maximum. The actual values obtained for the independent variables were 22.02 g l−1 glycerol, 1.78 g l−1 CAS, and 1.83 g l−1 inoculum (CDW). At those optimal values, the model predicted a maximum response of 3.4012 g l−1 PHB. Shaken flask experiments using those values were performed under microaerobic conditions, attaining 3.35 ± 0.26 g l−1 PHB (N = 4).

Comparison between glycerol and glucose as carbon sources under optimized conditions

To provide a deeper understanding of PHB accumulation by CT1061-PHB, we decided to compare microaerobic polymer biosynthesis in shaken flask cultures using glycerol or glucose (at the molar carbon content found to be the optimal for glycerol, namely, 720 mM carbon atoms). Remaining culture conditions were kept as those described for optimal PHB synthesis.

Highest growth and polymer accumulation were promoted by glycerol (8.26 ± 0.97 g l−1 and 41 ± 8%) when compared to glucose (6.38 ± 0.22 g l−1 and 36 ± 7%). This difference could arise from the different redox characteristics of each carbon source, as glycerol yields twice the amount of reducing equivalents than glucose when fermented by E. coli (Dharmadi et al. 2006).

Validation of the optimization step in bioreactor batch cultures

Bioreactor batch cultures were carried out to analyze the behavior of CT1061-PHB under optimized conditions using glycerol as the carbon source. The strain grew with a specific growth rate of 0.63 ± 0.03 h−1. As it can be seen in Fig. 2, after 48 h, CDW and PHB concentrations reached 8.37 and 3.52 g l−1, respectively (corresponding to a PHB content of 42%). Regarding PHB content, this result almost equals polymer accumulation obtained in shaken flask cultures. Besides, the yield of PHB on glycerol was Y PHB/G = 0.21.

Time-course of the concentration of CDW (squares) and PHB (circles), as well as PHB content (triangles), in batch cultures of CT1061-PHB under optimized conditions using glycerol as the main carbon source. Microaerobic cultivation was performed without air supply and using soft agitation to avoid biomass sedimentation. Representative results from two bioreactor cultures are shown

To gain further insight into the metabolic behavior of this strain, we measured the concentrations of acetate and ethanol in culture supernatants, which provides information on the redox state of cells. At 48 h, 2.8 mM acetate and 38.5 mM ethanol were accumulated.

Microaerobic fed-batch cultures

Redox mutants such as those bearing mutations in arcA have characteristics that make them suitable for the synthesis of reduced products under different O2 concentrations. Because of this, they can be used in processes in which the aeration conditions are tailored to get improved product yields while diminishing energy consumption.

Fed-batch as a culture technique is not usually applied under low aeration or anaerobic growth environments. Clearly, an improvement in biomass accumulation produced by feeding with glycerol will correlate with higher biomass and, as a consequence, higher PHB volumetric productivity. Another approach that we considered was O2 supply. Thus, we decided to assay fed-batch cultivation and soft air sparging (500 ml min−1, about 0.2 vvm) to enhance PHB accumulation.

Microaerobic conditions were monitored by polarographic measurements of O2 in the bioreactor, and dO2 was ≤15% during the entire run. Batch phase was conducted under optimized conditions, and a feeding solution containing glycerol, CAS, and MgSO4 was added to the fermentor when glycerol decreased to approximately 5 g l−1 (and supplied thereafter to maintain its concentration above this value).

The time courses of CDW and PHB concentrations, as well as PHB content, are shown in Fig. 3. As expected, during the batch phase, CT1061-PHB grew faster (being = 0.71 ± 0.02 h−1) and synthesized more PHB when compared with batch cultures without air sparging. At the end of the cultivation, CDW and PHB concentrations were 21.17 and 10.81 g l−1, which implies a PHB content of 51%. Even when fed-batch cultures took 60 h, the volumetric productivity compared with batch cultures was 2.57-fold higher (0.18 and 0.07 g PHB l−1 h−1, respectively). In this case, acetate and ethanol were excreted at 3.9 and 64.7 mM.

Fed-batch culture of CT1061-PHB carried out under optimized conditions in microaerobiosis using glycerol. Concentration of CDW (squares) and PHB (circles) and PHB content (triangles) are shown from two representative bioreactor cultures. Air supply was fixed at 500 ml min−1 throughout the cultivation, and after 24 h, a feeding solution consisting of glycerol, casein amino acids, and MgSO4 was pumped into the fermentor when needed to maintain a glycerol concentration above 5 g l−1

Discussion

In the fermentation process conducting to PHB production, energy is needed for the generation of steam used for sterilization, aeration, and agitation in the reactor and downstream processing. Several strategies have been used to diminish the downstream costs (Nonato et al. 2001; Akiyama et al. 2003; Yu and Chen 2006). However, bacterial growth in the reactor needs a better understanding of microbial physiology and regulatory processes to select cultivation conditions for an enhanced energy-saving process.

E. coli arcA mutants appear as a very interesting choice for the synthesis of reduced bioproducts like PHB in conditions of low O2 availability. In this work, we tried approaches to improve the PHB synthesis/energy consumption ratio in strain CT1061-PHB. The statistical design of a suitable medium for growth was achieved using a highly reduced compound, glycerol, as the carbon source. Booth (2005) has commented on the failure of E. coli to ferment glycerol without external electron acceptors. However, Dharmadi et al. (2006) later showed that the production of CO2 from formate at low pH allows E. coli to utilize glycerol anaerobically. This and a previous paper (Nikel et al. 2008) contribute to demonstrate that the choice of suitable strains and growth conditions allow E. coli to ferment glycerol at low or null O2 concentrations.

There are very few reports in the scientific literature on fed-batch cultivation in microaerobiosis, and none describes the synthesis of a bioproduct in E. coli. The induction of the nar (nitrate reductase regulation) promoter, which is expressed in anaerobic conditions when nitrate functions as an electron acceptor (Iuchi and Lin 1991), was studied in fed-batch cultures in microaerobiosis to evaluate its use for the heterologous expression of proteins (Han et al. 1998). Similar growth conditions were used for the synthesis of 1,3-propanediol by Klebsiella pneumoniae (Chen et al. 2003).

We have previously reported the analysis of the synthesis of PHB in an arcA background in microaerobic batch cultures using glucose as the carbon source, obtaining 4.12 ± 0.21 g l−1 CDW and 1.44 ± 0.05 g l−1 PHB after 48 h. The results reported in this paper correspond to a 2.33-fold increment in PHB concentration. We also observed a decrease in acetate production accompanied by a rise in ethanol synthesis in batch and fed-batch cultures. The ethanol/acetate ratio is an indicator of reducing power availability (Shalel-Levanon et al. 2005), and an increase in this ratio reflects increased NADH availability. Carlson et al. (2005) observed that recombinant E. coli DH5α, carrying pha genes from C. necator can support PHB accumulation up to 50% in anaerobiosis when growing in rich medium. Even when the strain used by these authors did not contain redox mutations, they also reported that acetate synthesis is diminished under PHB-synthesizing conditions while ethanol is favored. These observations highlight the concomitant synthesis of valuable by-products during microaerobic PHB accumulation.

This work shows that to develop sustainable synthesis of bioproducts, it is necessary to undertake the search and analysis of adequate mutants or new organisms. It is also important to assay different culture methodologies and appropriate low- or null-value substrates that could contribute to lower the energy requirements of these processes, thus improving their sustainability.

References

Akiyama M, Tsuge T, Doi Y (2003) Environmental life cycle comparison of polyhydroxyalkanoates produced from renewable carbon resources by bacterial fermentation. Polym Degrad Stab 80:183–194

Anderson AJ, Dawes EA (1990) Occurrence, metabolism, metabolic role, and industrial uses of bacterial polyhydroxyalkanoates. Microbiol Rev 54:450–472

Booth IR (2005) Glycerol and methylglyoxal metabolism. In: Neidhardt FC, Curtiss R III, Ingraham JL, Lin ECC, Low KB, Magasanik B, Reznikoff WS, Riley M, Schaechter M, Umbarger HE (eds) Escherichia coli and Salmonella: cellular and molecular biology. ASM Press, Washington, DC. http://www.ecosal.org

Braunegg G, Sonnleitner B, Lafferty RM (1978) A rapid gas chromatographic method for the determination of poly-β-hydroxybutyric acid in bacterial biomass. Eur J Appl Microbiol Biotechnol 6:29–37

Carlson R, Wlaschin A, Srienc F (2005) Kinetic studies and biochemical pathway analysis of anaerobic poly-(R)-3-hydroxybutyric acid synthesis in Escherichia coli. Appl Environ Microbiol 71:713–720

Chen X, Zhang DJ, Qi WT, Gao SJ, Xiu ZL, Xu P (2003) Microbial fed-batch production of 1,3-propanediol by Klebsiella pneumoniae under micro-aerobic conditions. Appl Microbiol Biotechnol 63:143–146

Dharmadi Y, Murarka A, González R (2006) Anaerobic fermentation of glycerol by Escherichia coli: a new platform for metabolic engineering. Biotechnol Bioeng 94:821–829

Fu HA, Iuchi S, Lin ECC (1991) The requirement of ArcA and Fnr for peak expression of the cyd operon in Escherichia coli under microaerobic conditions. Mol Gen Genet 226:209–213

Gerngross TU (1999) Can biotechnology move us toward a sustainable society? Nat Biotechnol 17:541–544

Han SJ, Chang HN, Lee J (1998) Fed-batch cultivation of an oxygen-dependent inducible promoter system, the nar promoter in Escherichia coli with an inactivated nar operon. Biotechnol Bioeng 59:400–406

Harding KG, Dennis JS, von Blottnitz H, Harrison STL (2007) Environmental analysis of plastic production processes: comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J Biotechnol 130:57–66

Heyde M (1998) Ecological considerations on the use and production of biosynthetic and synthetic biodegradable polymers. Polym Degrad Stab 59:3–6

Iuchi S, Lin ECC (1991) Adaptation of Escherichia coli to regulatory conditions: regulation of gene expression. Cell 66:5–7

Kennedy M, Krouse D (1999) Strategies for improving fermentation medium performance: a review. J Ind Microbiol Biotechnol 23:456–475

Khanna S, Srivastava AK (2005) Recent advances in microbial polyhydroxyalkanoates. Process Biochem 40:607–619

Lee SY, Lee YK, Chang HN (1995) Stimulatory effects of amino acids and oleic acid on poly(3-hydroxybutyric acid) synthesis by recombinant Escherichia coli. J Ferment Bioeng 79:177–180

Li R, Zhang H, Qi Q (2007) The production of polyhydroxyalkanoates in recombinant Escherichia coli. Biores Technol 98:2313–2320

Lynch AS, Lin ECC (1996) Responses to molecular oxygen. In: Neidhardt FC, Curtiss R III, Ingraham JL, Lin ECC, Low KB, Magasanik B, Reznikoff WS, Riley M, Schaechter M, Umbarger HE (eds) Escherichia coli and Salmonella: cellular and molecular biology. ASM Press, Washington DC, pp 1526–1538

Nikel PI, de Almeida A, Melillo EC, Galvagno MA, Pettinari MJ (2006a) New recombinant Escherichia coli strain tailored for the production of poly(3-hydroxybutyrate) from agroindustrial by-products. Appl Environ Microbiol 72:3949–3954

Nikel PI, Pettinari MJ, Galvagno MA, Méndez BS (2006b) Poly(3-hydroxybutyrate) synthesis by recombinant Escherichia coli arcA mutants in microaerobiosis. Appl Environ Microbiol 72:2614–2620

Nikel PI, Pettinari MJ, Méndez BS, Galvagno MA (2005) Statistical optimization of a culture medium for biomass and poly(3-hydroxybutyrate) production by a recombinant Escherichia coli strain using agroindustrial by-products. Internatl Microbiol 8:243–250

Nikel PI, Pettinari MJ, Ramírez MC, Galvagno MA, Méndez BS (2008) Escherichia coli arcA mutants: metabolic profile characterization of microaerobic cultures using glycerol as a carbon source. J Mol Microbiol Biotechnol (in press)

Nonato RV, Mantelatto PE, Rossell CEV (2001) Integrated production of biodegradable plastic, sugar and ethanol. Appl Microbiol Biotechnol 57:1–5

Ruiz JA, Fernández RO, Nikel PI, Méndez BS, Pettinari MJ (2006) dye (arc) mutants: insights into an unexplained phenotype and its suppression by the synthesis of poly(3-hydroxybutyrate) in Escherichia coli recombinants. FEMS Microbiol Lett 258:55–60

Salmon KA, Hung SP, Steffen NR, Krupp R, Baldi P, Hatfield GW, Gunsalus RP (2005) Global gene expression profiling in Escherichia coli K-12: effects of oxygen availability and ArcA. J Biol Chem 280:15084–15096

Shalel-Levanon S, San KY, Bennett GN (2005) Effect of oxygen on the Escherichia coli ArcA and FNR regulation systems and metabolic responses. Biotechnol Bioeng 89:556–564

Steinbüchel A, Füchtenbusch B (1998) Bacterial and other biological systems for polyester production. Trends Biotechnol 16:419–427

Strobel R, Sullivan G (1999) Experimental design for improvement of fermentati. ons. In: Demain A, Davies J (eds) Manual of industrial microbiology and biotechnology. ASM Press, Washington DC, pp 80–93

Suriyamongkol P, Weselake R, Narine S, Moloney M, Shah S (2007) Biotechnological approaches for the production of polyhydroxyalkanoates in microorganisms and plants—a review. Biotechnol Adv 25:148–175

Yu J, Chen LX (2006) Cost-effective recovery and purification of polyhydroxyalkanoates by selective dissolution of cell mass. Biotechnol Prog 22:85–90

Acknowledgements

This work was partially supported by grants from Consejo Nacional de Investigaciones Científicas y Tecnológicas (CONICET) and Agencia Nacional para la Promoción Científica y Tecnológica. PIN is the recipient of a CONICET fellowship. MJP, MAG, and BSM are career investigators of CONICET.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article can be found at https://doi.org/10.1007/s00253-008-1379-4

Electronic supplementary material

Below is the link to the electronic supplementary material.

Table S1

Independent variables studied in the Plackett–Burman screening design(DOC 32.0 kb)

Table S2

Plackett–Burman design for the seven independent variables in codified values and measured responses (DOC 53.5 kb)

Table S3

Analysis of Plackett–Burman design for biomass and PHB synthesis (DOC 44.5 kb)

Table S4

Codified and actual values for the independent variables in the central composite design (DOC 26.0 kb)

Table S5

Central composite design for PHB optimization results and predicted values (DOC 47.5 kb)

Table S6

Analysis of the optimization design for PHD synthesis (DOC 34.5 kb)

Rights and permissions

About this article

Cite this article

Nikel, P.I., Pettinari, M.J., Galvagno, M.A. et al. Poly(3-hydroxybutyrate) synthesis from glycerol by a recombinant Escherichia coli arcA mutant in fed-batch microaerobic cultures. Appl Microbiol Biotechnol 77, 1337–1343 (2008). https://doi.org/10.1007/s00253-007-1255-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-007-1255-7