Abstract

The effect of inoculated or co-cultured halophilic lactic bacteria (Tetragenococcus halophilus) and yeasts (Zygosaccharomyces rouxii and Candida versatilis) on the quality of soy sauce moromi was investigated. Results showed no significant change in the major physicochemical properties of soy sauce moromi such as amino nitrogen, total acid, and reducing sugar at the end of fermentation, whereas the composition of free amino acids slightly changed with different fermentation patterns. In the sample inoculated with T. halophilus, the concentration of proline and tryptophan decreased by 18.83 and 50.87 % compared with the blank sample, whereas tyrosine and histidine increased by 32.41 and 27.04 %. In the sample inoculated with Z. rouxii and C. versatilis, the concentration of bitter-tasting lysine, tyrosine, and phenylalanine increased by more than 20 %, and the concentration of tryptophan decreased by 56.71 %. The proportion of amino acids with sweet taste increased by 0.8 % through the co-culture of the three strains. Meanwhile, the total amount of volatile compounds increased by 117.66, 23.28, and 216.88 % in the T. halophilus inoculated sample, two yeast strain inoculated sample, and three strain inoculated sample, respectively. Increased odour activity values of the nine compounds that mainly contributed to the flavour of moromi ranged from 1 to 7.87 times in the three strain inoculated sample. These findings revealed that the co-culture of the three strains during moromi fermentation was beneficial to the improvement of flavour of soy sauce moromi.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soy sauce manufacture has a long history spanning 3,000 years and originated from the Zhou Dynasty in China. Presently, soy sauce is an essential oriental fermented condiment and is becoming increasingly popular worldwide because of its intense umami taste and characteristic aroma [1]. The processes of soy sauce manufacture can be roughly divided into five major stages, namely, soybean meal steaming, wheat grains roasting and crushing, koji culturing, soy sauce moromi (mash) fermentation, as well as pressuring and pasteurizing. Moromi fermentation is one of the key stages in soy sauce manufacture because the physicochemical properties and flavour characteristics of moromi are closely related with soy sauce. For Chinese-type soy sauce, moromi is fermented and aged in a spontaneous environment for more than 6 months.

The unique flavour of moromi is attributed to microbial community succession and metabolic regulation. Lactic acid bacteria, producing lactic acid [2], acetic acid [3] reportedly propagates rapidly in the first stage of moromi fermentation, resulting in decreased pH in moromi to <6.0, at which yeast-producing alcohol such as Zygosaccharomyces rouxii starts to propagate [4, 5]. To produce soy sauce moromi at the industrial scale, halophilic yeasts such as Z. rouxii, Candida versatilis, and Candida etchellsii [6–10] are necessary because these organisms play an important role in improving the quality of soy sauce moromi. For example, the concentration of volatile flavour compounds is increased by the co-culture of Pichia guilliermondii and Z. rouxii in the model system of Thai soy sauce fermentation [6]. Udomsil et al. [7] improved the flavour of fish sauce by inoculating Tetragenococcus halophilus during fermentation.

However, previous studies have mainly focused on the effect of major volatile flavours such as volatile esters (ethyl palmitate, ethyl linoleate, ethyl oleate, and so on) or on screening and modifying strains that can produce compounds with special flavour [11–15]. In fact, many other strains exist in soy sauce moromi apart from halophilic lactic acid bacteria and yeasts, such as Staphylococcus gallinarum and Weissella cibaria [16, 17]. Moreover, the unique flavour of the moromi was endowed by the interaction of indigenous microbial community and strains extra inoculated.

To regulate moromi fermentation and shorten the fermentation period, the effects of halotolerant yeast, lactic acid bacteria, and co-culture of both on moromi flavour and taste need to be elucidated. The mechanism of interaction between indigenous microbial community and strains inoculated extra, which play an important role in improving the quality of soy sauce, must also be examined. Therefore, in the present study, Aspergillus oryzae 3.042, a very important filamentous fungus in soy sauce koji fermentation in China, was used as the mould strain of koji making, and T. halophilus, Z. rouxii, and C. versatilis were used as the inoculated strains during fermentation. This study aimed to investigate the effects of inoculated halotolerant strains on the major physicochemical properties, free amino acids, and volatile compounds of moromi during fermentation.

Materials and methods

Strains, growth media, and culture conditions

The mould strain used was Aspergillus oryzae 3.042 (DIFA Co. Ltd., Shanghai, China), which was propagated in malt extract medium at 30 °C for 72 h. The halophilic yeasts used were Z. rouxii CGMCC 3791 and C. versatilis CGMCC 3790, which were isolated in our laboratory from soybean paste, identified by 26S rDNA and ITS sequences, and stored in CGMCC. Yeasts were also propagated in malt extract medium at 30 °C for 72 h. T. halophilus CGMCC 3792 was isolated in our laboratory from soy sauce moromi, identified by 16S rDNA sequences, and stored in CGMCC. T. halophilus was propagated in MRS at 30 °C for 36 h. Wheat and soybeans were purchased from a local market.

Manufacture of soy sauce moromi

Soy sauce moromi was traditionally produced by koji fermentation and post-fermentation of soybeans and wheat. Figure 1 showed the manufacture of 4 moromi samples, and Table 1 showed the fermentation parameters of moromi. In a typical procedure, samples produced by four fermentation processes (A1, A2, A3, and A4) were inoculated with different strains. T. halophilus was inoculated at the beginning of moromi fermentation at a cell concentration of 5 × 107 cfu/mL, whereas Z. rouxii and C. versatilis were inoculated on the third and seventh day at cell concentrations of 4.5 × 106 and 5 × 106 cfu/mL, respectively. Sample A1, which had no starter culture inoculated, was used as a blank. A monthly sampling plan was taken and all samples used were stored at −20 °C. All samples were performed in triplicate.

Analytical methods

Determination of amino nitrogen (AN), total acid (TA), and reducing sugar (RS): About 20.0 g of moromi was diluted with ultrapure water to 50 mL, filtered through filter paper (Whatman No. 4), and appropriately diluted. AN was analysed by formol titration [18], and TA was determined by alkali titration. In alkali titration, 20 mL of sample diluents were mixed with 60 mL of ultrapure water, titrated to pH 8.2 with 0.05 M NaOH, and added with 10 mL of formalin solution (40 %). The consumed volume was recorded to calculate the TA of the samples. The samples were finally titrated to pH 9.2 with 0.05 M NaOH, and the consumed volume was recorded to calculate the AN of the samples. RS in the samples was determined by the dinitrosalicylic acid method [19].

Determination of free amino acids: To determine individual free amino acids, 10 mL of the previously filtered liquor was precipitated with 50 mL of 10 % trichloroacetic acid for 2 h at ambient temperature to remove large peptides and then centrifuged (10,000×g, 4 °C) for 10 min. The supernatant was filtered through 0.45 μm filter and appropriately diluted. Sample solutions with 20 μL volume each were prepared and determined for free amino acid composition using an amino acid analyser (A300, membraPure GmbH, Germany). The concentrations of free amino acids in the samples were calculated by calibrating with standard amino acids. Determination of AN, TA, RS, and free amino acids was performed in triplicate.

Extraction and analysis of volatile compounds from soy sauce: The volatile compounds of the samples were extracted according to Zheng et al. [20]. Internal standard solution ((±)-2-octanol (4.11 mg/L), Sigma-Aldrich, St. Louis, MO, USA) was added into the sample before extraction. 5 mL of the previously filtered liquor was added into 20 mL extraction solution of anhydrous ether: dichloromethane (1:1, v:v) and the mixture was treated in the ultrasound cleaner (KQ-100E, Kunshan, China) under the 30 °C water bath for 5 min. Then, the organic phase was transferred into the graduated test tube and concentrated to 0.5 mL slowly under the gentle stream of nitrogen in ice bath. All extractions were performed in triplicate.

Analysis of the volatile compounds: The concentrated organic extracts were analysed triplicate by GC–MS using the Trace GC Ultra gas chromatograph-DSQ ΙΙ mass spectrometer (Thermo Electron Corporation, USA) equipped with a HP-5MS capillary column (30.0 m × 0.25 mm i.d., 0.25 μm film thickness, Agilent, USA). The conditions of GC analyses were as follows: 0.5 microlitre of the sample extract was injected at 250 °C with a split ratio of 10:1, and Helium (purity: 99.999 %) carrier gas flow of 1 mL/min. The oven temperature was held at 40 °C for 3 min, followed by an increase in 5 °C/min to 100 °C, and then programmed at 6 °C/min until 220 °C, and held for 10 min. For mass spectrometer, the mass selective detector capillary direct interface temperature was 250 °C. The mass spectrum was generated in the electron impact (EI) mode at 70 eV. The spectrum was taken over the m/z range of 40–400, and the solvent elution delay time was 3 min. Relative amounts (mg/100 mL) of certain volatiles were compared to the known concentration of internal standard on GC total ion chromatograms.

Statistical analysis

Identification and quantification of volatile compounds: Each volatile compound was identified by comparing their mass spectrum with the NIST05 library database and previous literature. At the same time, retention indices (RI) of each compound were calculated by the method of Zheng et al. [1, 20].

One-way ANOVA with Duncan’s test was performed to evaluate significant differences in volatile compounds. Significance of differences was defined at p < 0.05 (n = 3). One-way ANOVA was conducted using SPSS software (version 19.0). Odour activity values (OAVs) were calculated by dividing concentrations with their respective odour thresholds. Origin 7.5 was used to create the figures in this study.

Results and discussion

Changes in AN, TA, and RS in soy sauce moromi

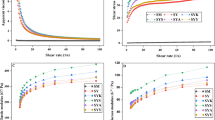

Changes in AN, TA, and RS in moromi during the process are shown in Fig. 2. The AN concentrations evidently increased at the initial stage (first 30 days) because of the high activities of protease and amylase [21]. Thereafter, the AN concentrations slightly increased in A1 and A2 until the end of fermentation. By contrast, concentrations began to decrease from 120 days onwards in A3 and A4 (Fig. 2a) because of the consumption of AN by yeasts and lactic acid bacteria or by the Maillard reaction [22]. When fermentation finished, the co-cultured samples, two yeast strain, and three strain samples, exhibited slightly lower concentrations of AN at 0.77 and 0.74 g/100 mL, respectively. Regarding TA, the concentration sharply increased until 120 days of fermentation due to the accumulation of lactic acid and then slightly increased (Fig. 2b). The range of change of TA in A4 was slightly higher than that in A1 and A2 in the first month, and then almost no change was observed in the next month. When fermentation was finished, no difference in AN and TA was observed among the four different fermentation patterns, except that A4 was less than the others. Regarding the RS concentrations (Fig. 2c), the trends of change can be divided into two types: one is that the concentrations of RS increased in the first 30 days and decreased afterwards (A1 and A2); the other is that the RS concentrations continuously decreased (A3 and A4). Meanwhile, the RS concentration in the blank sample was the lowest. The RS concentrations in A3 and A4 markedly decreased until 60 days of fermentation, which can be ascribed to yeast growth. By contrast, increased concentrations of RS in A1 and A2 were due to the hydrolysing effect of amylase and organic acid secreted by bacteria at the first stage of moromi fermentation. The decreased RS concentrations were due to consumption by propagating strains and the inhibition of amylase activity through alcohol, organic acid [23], and salt stress [19, 24]. This result was consistent with the results of Kim et al. [19]. In addition, AN and RS were metabolised as nutrition components by inoculated strains, which can be another reason that the RS concentration in the blank was the highest (5.86 g/100 mL) when fermentation was finished.

Changes in AN (a), TA (b), and RS (c) during soy sauce moromi fermentation. Lines with hollow triangle marks represent blank (A1); lines with solid square marks represent inoculated with T. halophilus (A2); lines with circle marks represent co-culture with Z. rouxii and C. versatilis (A3); lines with solid triangle marks represent co-culture with Z. rouxii, C. versatilis and T. halophilus (A4)

Effects on free amino acids composition

Nineteen kinds of common free amino acids were quantitatively analysed among the samples for the four different fermentation patterns (Table 2), and glutamate, proline, leucine, and arginine were found to be the main amino acids. Similar amino acids were found in soy sauce, soybean, and fish sauce [7, 25, 26]. According to the data showed in Table 2, the total concentration of amino acids of A3 was highest and that of A4 was lowest, which was in agreement with the concentrations of AN. In addition, the concentration of free amino acids in A2 and A3 slightly increased compared with the blank after fermentation for 180 days. Similarly, the concentration of umami taste amino acids (aspartate and glutamate) and sweet taste amino acids (threonine, serine, glycine, and alanine) increased, which would make a contribution to increase the umami and sweet taste of soy sauce. Udomsil et al. reported that it is good for increase of glutamate by inoculating with T. halophilus [7, 25, 26]. The proportion of amino acids with sweet taste also increased by 0.8 % in the co-culture of the three strains (Table 2). Compared with the blank sample, the proline and tryptophan concentrations decreased by 18.83 and 50.87 %, whereas the tyrosine and histidine concentrations increased by 32.41 and 27.04 % in A1. The concentration of bitter-tasting lysine, tyrosine, and phenylalanine increased by more than 20 %, and the tryptophan concentration decreased by 56.71 % in A2, it is similar with the result of which can be attributed to the inoculation of Z. rouxii and C. versatilis, as well as the metabolism and autolysis of inoculated strains [27].

Effects on volatile compounds

The effect of added halophilic strains on the change in volatile compounds with the ageing time was investigated. A total of 44 volatile compounds comprising 3 acids, 7 alcohols, 9 esters, 1 aldehyde, 4 ketones, 3 phenols, 2 furans, 2 pyrans, and 13 miscellaneous compounds were identified (Table 3). The total amount of volatile compounds increased by 117.66 % in A1, 23.28 % in A2, and 216.88 % in A3. Generally, the concentrations of acids, aldehyde, ketones, and miscellaneous decreased, although only the miscellaneous monotonously decreased, and concentrations of alcohols, esters, furans, and pyrazines non-monotonously increased.

For the nine different groups of volatile compounds, the changes depended on the fermentation patterns. Figure 3a shows that the acid concentration gradually decreased during fermentation by the increase of 3-methyl butanoic acid and benzeneacetic acid. Meanwhile, the alcohol concentration initially increased and then decreased with further fermentation. The highest value of alcohols appeared in A3 and A4 (at the 60th day) followed by A2 (at the 90th day) (Fig. 3b). The alcohols in soy sauce are mainly produced from sugars and amino acids during the fermentation under aerobic conditions, and a small number of alcohols are produced by yeasts through the reduction in the corresponding aldehydes [28, 29]. Similar to the alcohols, the trends in ester concentration depended on the kind of strains inoculated. Figure 3c shows that the highest value was found at the 60th day for the four fermentation patterns, and almost no change was observed at the 60th and 120th day of fermentation between the blank sample and A2. The blank sample decreased until the 180th day of fermentation, whereas A2 decreased until the 150th day. For A3, the ester concentration decreased until the 120th day of fermentation and remained stable until the end of fermentation. For A4, the ester concentration decreased until the 150th day of fermentation and then evidently increased to 491.61 mg/L upon the end of fermentation. Esters were mostly formed from the esterification of alcohols with fatty acids during the fermentation process [28] and a large numbers of high molecular weight fatty acid esters such as ethyl palmitate and ethyl linoleate were likely produced by the action of fungal lipases on the soybean lipid [30]. Changes of aldehydes and ketones, phenols mainly depended on the materials and fermentation process. Generally, phenols are generated from the degradation of lignin glycoside in cereal bran during fermentation process, such as 4-ethyl-2-methoxy-phenol [30]. In the present study, the trends in aldehyde, ketone, and phenol concentrations were similar (Fig. 3d–f), whereas the phenol concentration slightly increased in A4 and remained stable in the other samples. The concentration of furans increased to a maximum value at the 60th day for A3 and A4, with the former lasting for another 30 days and then decreasing to 2.28 mg/L, and the latter decreasing after fermentation for 150 days and then increasing up to 6.86 mg/L. For A2, the furan concentration remained relatively stable in the first 120 days and then gradually increased to 6.28 mg/L (Fig. 3g). The pyrazines have basic characteristics resulting from the presence of two nitrogen atoms. They can be formed either via the Maillard reaction between saccharide and amino residues or through the ambient temperature reaction of microbial metabolites [28, 31]. As shown in Fig. 3h, the concentration of pyrazines in the four different moromi slightly fluctuated for 150 days and then increased to 11.38 and 14.93 mg/L in A2 and A4, respectively. The concentration of miscellaneous amino acids continued to decrease until the end of fermentation (Fig. 3i).

Changes in volatile compounds during fermentation. a acids; b alcohols; c esters; d aldehydes; e ketones; f phenols; g furans; h pyrazines; i miscellaneous. Lines with hollow triangle marks represent blank (A1); lines with solid square marks represent inoculated with T. halophilus (A2); lines with circle marks represent co-culture with Z. rouxii and C. versatilis (A3); lines with solid triangle marks co-culture with Z. rouxii and C. versatilis and T. halophilus (A4)

When fermentation was finished, the concentrations of the volatile compounds in the four fermentation patterns were found to differ from each other (Table 3). 2,3-Butanediol had the highest concentration among the seven types of alcohols detected, especially for A4 (143.59 mg/L) but had high threshold and low OAVs (0.41, 1.19, 0.69, and 1.43 in A1, A2, A3, and A4, respectively) (Table 4), which had little effect on the flavour of soy sauce moromi. Nevertheless, the OAVs of benzene ethanol and 3-(methylthio)-1-propanol were high. These two compounds, which had the highest concentrations in A4, endowed moromi with a malty odour and a potato-like odour, respectively [29, 32]. Among the nine identified esters, ethyl palmitate, ethyl linoleate, and ethyl oleate increased in A4 by almost two times than the others and endowed a sweet, coconut, and waxy odour to the moromi, respectively [29, 33]. Thus, the enhancement of esters was mainly due to the inoculated strains. 4-Ethylguaiacol and matol also increased in A4 to 1.65 and 0.72 mg/L, respectively. 3-Hydroxy-2-butanone increased to 4.78 mg/L in A2, and 3-furaldehyde increased to 0.24 mg/L in A4. 3-Hydroxy-2-butanone and 4-ethylguaiacol gave buttery and burnt odours to moromi, respectively, because of their high OAVs, whereas 3-furaldehyde that had low OAVs had little effect on soy sauce moromi sensory characterization (Table 4). 4-Hydroxy-2,5-dimethyl-3(2H)-furanone (4-HDMF) contributed a caramel-like odour to moromi and can also be formed through the Maillard reaction of pentoses during heating or through a biosynthetic pathway involving yeasts and lactic acid bacteria [28, 34, 35]. In the present study, 4-HDMF in A2 and A4 had higher concentrations (5.92 and 5.38 mg/L) than the others. As suggested by the results, inoculation with T. halophilus, Z. rouxii, and C. versatilis benefited the flavour improvement of soy sauce moromi.

Quantitation of odour-active compounds

Although the concentrations of various volatile compounds in moromi can be used to characterize the contribution of inoculated strains, understanding the effects on moromi sensory characteristics was still difficult. Results (Table 4) showed among the 11 compounds having high concentrations in the samples, only 9 compounds can be considered as key compounds based on their concentrations, which clearly exceeded their odour thresholds. An aroma-like profile with a six-point scale from 0 (little contribution) to 6 (very good contribution) was constructed to compare the effect of the flavour feature on strains inoculated in moromi (Fig. 4). To evaluate the contribution of the fermentation patterns to the flavour characteristics of moromi, 9 compounds with higher OAVs were selected from the identified compounds (Table 4). Compared with the blank sample, intense flavours of dark chocolate, potato-like, and buttery were enhanced by T. halophilus. Flavours of dark chocolate, potato-like, waxy, sweet, and coconut, as well as a buttery odour, were increased by the co-culture of three strains. No significant change in flavour was induced by the inoculation of the two yeasts.

Conclusions

In the present study, the effects of halotolerant strains on the major physicochemical properties, free amino acids, and volatile compounds of soy sauce moromi were investigated. Although the concentration trends of the major physicochemical parameters such as AN, TA, and RS differed among the four different samples, no significant difference was observed upon the end of fermentation. Flavour profiles were constructed based on moromi aged by inoculation with different microbial strains. The concentration of alcohols, ketones, and pyrazines was evidently enhanced by inoculation with T. halophilus (increased by 171.43, 224.59, and 170.95 %, respectively), whereas alcohols (54.65 %) and esters (19.34 %) were slightly increased by the co-culture of the two yeast strains. The increase in the 9 different groups of volatile compounds ranged from 70.86 to 255.48 %, with the alcohols, esters, and pyrazines increasing by 245.51, 222.26, and 255.48 % through the co-culture of the three strains. Analysis of odour thresholds and increased proportion identified 9 compounds as the major contributors to moromi flavour (Table 4). Among these compounds, 5 demonstrated increased concentration in T. halophilus by more than 100 %, especially 3-hydroxy-2-butanone (increased by 5.46 times). For the yeast-inoculated sample, the increase in concentration of 6 compounds ranged from 0.11 to 1.12 times, whereas the decrease range of 2 compounds was from 0.34 to 0.49 times. Regarding the samples of the three strain co-culture, the range of increase in OAV of all compounds was 1–7.87 times. Given the contribution of dark chocolate, potato-like, rose-like, waxy, sweet, buttery, and phenolic odour to moromi by 9 kinds of compounds, co-culture of three strains was beneficial to the improvement of the flavour characteristics of moromi. Research on the metabolic regulation and flavour-formation mechanisms of salt-tolerant strains, as well as their application in co-culture, will be carried out to develop new technology for moromi fermentation.

References

Steinhaus P, Schieberle P (2007) Characterization of the key aroma compounds in soy sauce using approaches of molecular sensory science. J Agric Food Chem 55:6262–6269

Somboon T, Jaruwan T, Sanae O, Kazuo K (2002) Lactic acid bacteria isolated from soy sauce mash in Thailand. J Gen Appl Microbiol 48:201–209

Uchida M, Ou J, Chen BW, Yuan CH, Zhang XH, Chen SS, Funatsu Y, Kawasaki KI, Satomi M, Fukuda Y (2005) Effects of soy sauce koji and lactic acid bacteria on the fermentation of fish sauce from freshwater silver carp Hypophthalmichthys molitrix. Fish Sci 71:422–430

van der Sluis C, Tramper J, Wijffels RH (2001) Enhancing and accelerating flavour formation by salt-tolerant yeasts in Japanese soy-sauce processes. Trends Food Sci Technol 12:322–327

Yong FM, Wood BJB (1976) Microbial succession in experimental soy sauce fermentations. Int J Food Sci Tech 11:525–536

Wah TT, Walasiri S, Assavanig A, Niamsiri N, Lertsiri S (2013) Co-culturing of Pichia guilliermondii enhanced volatile flavor compound formation by Zygosaccharomyces rouxii in the model system of Thai soy sauce fermentation. Int J Food Microbiol 160:282–289

Udomsil N, Rodtong S, Choi YJ, Hua YL, Yongsawatdigul J (2011) Use of Tetragenococcus halophilus as a starter culture for flavor improvement in fish sauce fermentation. J Agric Food Chem 59:8401–8408

Kobayashi T, Kajiwara M, Wahyuni M, Hamada-Sato N, Imada C, Watanabe E (2004) Effect of culture conditions on lactic acid production of Tetragenococcus species. J Appl Microbiol 96:1215–1221

Yong FM, Wood BJB (1977) Biochemical changes in experimental soy sauce moromi. Int J Food Sci Tech 12:263–273

Hamada T, Sugishita M, Motai H (1990) Contributions of immobilized and free cells of salt-tolerant Zygosaccharomyces rouxii and Candida versatilis to the production of ethanol and 4-ethylguaiacol. Appl Microbiol Biot 33:624–628

Gao XH, Hou LH, Lu MF, Wang CL (2010) Improvement of soy-sauce flavour by genome shuffling in Candida versatilis to improve salt stress resistance. Int J Food Sci Tech 45:17–22

Tanasupawat S, Thongthai J, Okada S, Komagata K (2002) Lactic acid bacteria isolated from soy sauce mash in Thailand. J Gen Appl Microbiol 48:201–209

Cao XH, Song Q, Wang CL, Hou LH (2012) Genome shuffing of Hansenula anomala to improve flavour formation of soy sauce. World J Microbiol Biotechnol 28:1857–1862

Jie F, Zhan XB, Zheng ZY, Wang D, Zhang LM, Lin CC (2013) New model for flavour quality evaluation of soy sauce. Czech J Anim Sci 31:292–305

Moy YS, Lu TJ, Chou CC (2012) Volatile components of the enzyme-ripened sufu, a Chinese trational fermented product of soy bean. J Biosci Bioeng 113:196–201

Wei CL, Chao SH, Tsai WB, Lee PS, Tsau NH, Chen JS, Lai WL, Tu JCY, Tsai YC (2013) Analysis of bacteria diversity during the fermentation of inyu, a high-temperature fermented soy sauce, using nested PCR-denaturing gradient gel electrophoresis and the plate count method. Food Microbiol 33:252–261

Yasushi T, Jun W, Yoshinobu M (2012) Monitoring of the microbial communities involved in the soy sauce manufacturing process by PCR-denaturing gradient gel electrophoresis. Food Microbiol 31:100–106

Feng J, Zhan XB, Wang D, Zhang LM, Lin CC (2012) An unstructured kinetic model to study NaCl effect on volatile ester fermentation by Candida etchellsii for soy sauce production. Biotechnol Bioprocess Eng 17:242–249

Kim JS, Lee YS (2008) A study of chemical characteristics of soy sauce and mixed soy sauce: chemical characteristics of soy sauce. Eur Food Res Technol 227:933–944

Zheng J, Wu CD, Huang J, Zhou RQ, Liao XP (2013) Analysis of volatile compounds in Chinese soy sauces moromi cultured by different fermentation processes. Food Sci Biotechnol 22:605–612

Gao XL, Cui C, Zhao HF, Zhao MM, Yang L, Ren JY (2010) Changes in volatile aroma compounds of traditional Chinese-type soy sauce during moromi fermentation and heat treatment. Food Sci Biotechnol 19:889–898

Jaeger H, Janositz A, Knorr D (2010) The Maillard reaction and its control during food processing. The potential of emerging technologies. Pathol Biol 58:207–213

Huang YC, Edwards CG, Peterson JC, Haag KM (1996) Relationship between sluggish fermentations and the antagonism of yeast by lactic acid bacteria. Am J Enol Vitic 47:1–10

Giri A, Osako K, Okamoto A, Okazaki E, Ohshima T (2011) Effect of meat washing on the development of impact odorants in fish miso prepared from spotted mackerel. J Sci Food Agric 91:850–859

Gao XL, Sun PF, Lu J, Jin Z (2013) Characterization and formation mechanism of proteins in the secondary precipitate of soy sauce. Eur Food Res Technol 237:647–654

Zarkadas CG, Gagnon C, Gleddie S, Khanizadeh S, Cober ER, Guillemette RJD (2007) Assessment of the protein quality of fourteen soybean [Glycine max (L.) Merr] cultivars using amino acid analysis and two-dimensional electrophoresis. Food Res Int 40:129–146

Jiang JJ, Zeng QX, Zhu ZW, Zhang LY (2007) Chemical and sensory changes associated Yu-lu fermentation process-A traditional Chinese fish sauce. Food Chem 104:1629–1634

Sun SY, Jiang WG, Zhao YP (2012) Profile of volatile compounds in 12 Chinese soy sauces produced by a high-salt-diluted state fermentation. J Inst Brew 116:316–328

Qian MC, Wang YY (2005) Seasonal variation of volatile composition and odor activity value of ‘Marion’ (Rubus spp. hyb) and ‘Thornless Evergreen’ (R. laciniatus L.) blackberries. J Food Sci 70:C13–C20

Chung HY (1999) Volatile components in fermented soybean (Glycine max) curds. J Agric Food Chem 47:2690–2696

Fan WL, Xu Y, Zhang YH (2007) Characterization of pyrazines in some Chinese liquors and their approximate concentrations. J Agric Food Chem 55:9956–9962

Fritsch HT, Schieberle P (2005) Identification based on quantitative measurements and aroma recombination of the character impact odorants in a Bavarian Pilsner-type beer. J Agric Food Chem 53:7544–7551

Chung HY, Fung PK, Kim JS (2005) Aroma impact components in commercial plain sufu. J Agric Food Chem 53:1684–1691

Dahlen T, Hauck T, Wein M, Schwab W (2001) 2,5-dimethyl-4-hydroxy-3(2H)-furanone as a secondary metabolite from D-fructose-1,6-diphosphate metabolism by Zygosaccharomyces rouxii. J Biosci Bioeng 91:352–358

Hayashida Y, Hatano M, Tamura Y, Kakimoto M, Nishimura K, Igoshi K, Kobayashi H, Kuriyama H (2001) 4-Hydroxy-2,5-dimethyl-3(2H)-furanone (HDMF) production in simple media by lactic acid bacterium, Lactococcus lactis subsp. cremoris IFO 3427. J Biosci Bioeng 91:97–99

Acknowledgments

This work was financially supported by the National Science Foundation of China (31171742).

Conflict of interest

None.

Compliance with Ethics Requirements

This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, RY., Zheng, J., Wu, CD. et al. Effect of different halophilic microbial fermentation patterns on the volatile compound profiles and sensory properties of soy sauce moromi. Eur Food Res Technol 239, 321–331 (2014). https://doi.org/10.1007/s00217-014-2225-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-014-2225-9