Abstract

The beany flavor adversely influences consumer acceptance of soymilk (SM) products. Thus, in this work, the co-fermentation of isolated new yeasts (Kluyveromyces marxianus SP-1, Candida ethanolica ATW-1, and Pichia amenthionina Y) and Kluyveromyces marxianus K (a commercial yeast) along with an XPL-1 starter (including five strains of lactic acid bacteria (LAB)) was utilized to mend the beany flavor of fermented SM (FSM) beverages. Probiotic count, pH, titratable acidity, syneresis, water holding capacity, rheological characteristics, and sensory attributes were investigated. Furthermore, the free amino acids, nucleotides, and volatile compounds (VCs) were analyzed, also presenting the collected VC data by exploiting a principal component analysis (PCA) and a heatmap with a hierarchical cluster analysis. The co-fermentation with Kluyveromyces marxianus SP-1 and K remarkably enhanced the LAB strain growth and acid production, improving the rheological attributes, whereas that of yeast along with XPL-1 as a mullite starter could reduce the beany odor. PCA chart displayed that higher amounts of alcohols, ketones, acids, and esters that significantly improved the flavor quality of FSM beverages were generated throughout the co-fermentation process. The co-fermentation with Pichia amenthionina Y generated the highest acetoin (36.19%) and diacetyl (2.02%), thus improving the overall acceptance of FSM, as well as the sensory characteristics of FSM beverages with the highest umami, sweet, odorless amino acids, and umami nucleotides, and the lowest content of alcohol and inosine. Taken together, the co-fermentation of Pichia amenthionina Y along with XPL-1 within SM provides novel insights regarding the development of FSM and fermented beverages.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the last one to two decades, plant-based proteins have attracted much attention worldwide and have been proposed as promising alternatives to animal sources [1, 2]. Soybeans (Glycine max (L.) Merrill) are among the most important leguminous crops, providing high protein content, essential fatty acids, high amount of dietary fibers, high concentrations of phenolic acids, minerals, oligosaccharides, peptides, and vitamins [3,4,5]. Recently, the demand for series of soybean-based products has become noticeable and increased, primarily due to their beneficial influence, especially in Western countries [5], along with the usual consumption in Asian countries [6]. Among them, soymilk (SM) is considered an efficient alternative to animal milk, particularly for vegan people and consumers with milk protein allergy or intolerance to lactose [7, 8]. Moreover, SM is characterized by antioxidant compounds, including isoflavones, and, thus, it allows to decrease the blood pressure and to avoid chronic and degenerative diseases [9]. Despite its health benefits, many consumers have not entirely accepted it due to the present green off-flavor (beany flavor), mainly caused by the green alcohols and aldehyde production during lipid oxidation and lipoxygenase activities [10]. Numerous studies have reported diverse approaches to mask or remove the green off-flavor: i) the use of genetic engineering to create new soybean varieties devoid of the lipoxygenase gene; ii) the use of physicochemical methods (e.g., the addition of reducing agents or oxidizing agents, acid-base treatment, supercritical carbon dioxide extraction, high vacuum and steam distillation, high-pressure processing, ohmic heating, and pulse electrification) to inactivate the lipoxygenase [5, 11,12,13]. However, some of these approaches have specific hidden food safety hazards, costly, and consume a lot of energy, while others are ineffective at removing the green off-flavor. Furthermore, it has been reported that the addition of natural ingredients, such as fruit pulp, vegetable extracts, and flavoring substances, is highly valued and could provide a mild taste, appropriate sensory properties, and appropriate health benefits to soybean-based products, thereby increasing their acceptance and consumption [14].

Concerning the fermentation process which allows to obtain functional, nutritional, organoleptic, and shelf-stable products, numerous studies have highlighted that lactic acid bacteria (LAB) can reduce or mask the soybean-based product off flavors, as well as enhance their functional and sensorial features [5, 7, 9, 15,16,17,18]. LAB can originate a wide plethron of aromatic compounds, providing characteristic flavors from the breakdown of the main food matrix macronutrients to the fermented products. Furthermore, they can reduce complex organic compounds to smaller molecules with further physiological functions in addition to their own original features [19,20,21]. Similarly, the effect of using yeast to remove the green off-flavor from soybean-based products is an intriguing idea that deserves more research. Indeed, yeast strain is involved in volatile compound (VC) production through fermentation [22]. It has been reported that Saccharomyces cerevisiae strain Y03 could effectively remove the green off-flavor from soybean powder [23], and Nedele et al. [5] used Lycoperdon pyrifome to reduce the green off-flavor in fermented SM (FSM) beverages.

Kefir and Koumiss are two types of lactic yeast-containing fermented milk products that are popular in Europe and Asia and stand out relatively well. The interaction between LAB and yeast has the potential to change the characteristics and quality of the fermentation product, most notably the profile of compounds that are important for boosting organoleptic qualities [24]. It has been reported that XPL-1, as a commercial LAB starter, could efficiently improve the texture of fermented milk with well consumer preference scores for taste and flavor [22, 25] and is also commonly used with Kluyveromyces marxianus K as a commercial Kefir starter [26]. Furthermore, it has been stated that Kluyveromyces marxianus, a food-grade yeast, can generate fragrant aromas and flavor compounds [27], Candida ethanolica, abundantly present in industrial beer wastes, can also produce fragrant aromas [28]. In addition, previous work stated that the Y18 strain of Candida ethanolica could enhance the pleasant fruity and flowery flavors of Shanxi-aged vinegar [29]. Moreover, our patent stated that Pichia amenthionina Y could produce fragrant flavors and remove the off-flavors of soy yogurt [30]. Overall, Kluyveromyces spp., Saccharomyces spp., Pichia spp., and Candida spp. are applied to produce fermented dairy and non-dairy beverages worldwide [31, 32].

A lactic yeast co-fermentation system, including LAB and yeast, has been applied to manufacture acidified goat milk and goat yogurt with distinct sensory flavor and health benefits [27, 33, 34]. In this framework, the present work proposes a co-fermentation system to improve the organoleptic attributes of FSM beverages, for the first time, using three novel isolates of yeasts (Kluyveromyces marxianus SP-1, Candida ethanolica ATW-1, and Pichia amenthionina Y) and one commercial yeast (Kluyveromyces marxianus K), combined with a commercial XPL-1 starter (LAB). The selected yeast strains for SM fermentation were supposed to enhance the FSM beverage features, particularly flavor. To determine differences in the properties of the formulated FSM beverages, syneresis, water holding capacity (WHC), rheological properties, pH, acidity, probiotic count, VCs produced during the fermentation process, free amino acids (FAAs), nucleotides, and sensory attributes were studied. Furthermore, to categorize the fermented beverages in accordance with the VC levels and types, a principal component analysis (PCA) was presented, as well as a heatmap with a hierarchical cluster analysis (HCA).

Materials and methods

Chemicals and cultivation media

Yellow soybeans (29.60 g protein, 18.50 g oil, and 15.40 g carbohydrates per 100 g) were bought from Shenyang Xinchang Grain Trade Co., Ltd. (Shenyang, China). Potato dextrose agar (PDA) and plate count agar (PCA) were obtained from Guangdong Huankai Microbial SCI. & TECH. Co., Ltd. (Guangzhou, China). MSE (Mayeux, Sandine & Elliker) agar was purchased from Shanghai GuanDao Biotech Co., Ltd. (Shanghai, China), M17 agar from Qingdao Hope Bio-Technology Co., Ltd. (Shandong, China). Series of n-alkane standard (C7–C40) solution was obtained from o2si smart solutions (An LGC standards company, Shanghai, China). The standard mixture of 17 amino acids, O-phthaldialdehyde, 2-mercaptoethanol, methanol HPCL grade, acetonitrile HPCL grade, sodium acetate, and trichloroacetic acid were bought from Sigma-Aldrich Chemical Reagent Co., Ltd. (Shanghai, China). Deuterium oxide (D2O) containing sodium 3-(trimethylsilyl) propionate-2,2,3,3-d4 (TMSP, 0.05% (m/v)) was purchased from the Tengfei company (Qingdao, China). All the other chemicals were of high purity and analytical grade.

Strains and cultivation conditions

Candida ethanolica ATW-1 and both Pichia amenthionina Y and Kluyveromyces marxianus SP-1 were isolated and purified from sufu pehtze and acidic tofu whey, respectively. Pichia amethionina Y and Candida ethanolica ATW-1 are new strains, kept in Guangdong Microbial Culture Collection Center (GDMCC) under preservation numbers of GDMCC no. 10183 and no. 61360, respectively. Kluyveromyces marxianus K and XPL-1 starter (LAB), containing five strains, i.e., Lactococcus lactis subsp. Lactis, Leuconostoc mesenteroides subsp. cremoris, Lactococcus lactis subsp. lactis biovar diacetylactis, Lactococcus lactis subsp. cremoris, and Streptococcus thermophilus, were furnished by Chr. Hansen AS. (Guangzhou, China). The activation of yeast strains was performed twice in yeast potato dextrose medium for 24 h at 30 °C. Afterward, the yeast cultures were collected utilizing a high-speed refrigerated centrifuge at 8000 rpm and 4 °C for 5 min. The resultant pellets were washed two times with 15 mL of sterilized distilled water and resuspended for inoculation. Prior to the fermentation, starting inoculums of XPL-1 starter, arranged following the producer’s guidelines, and yeast strains (initial population of approximately 106 CFU/mL) were spread in SM.

Preparation of SM and FSM beverages

SM was prepared according to our previous study with some modifications [18]. Briefly, fresh soybeans were soaked with 0.5% NaHCO3 solution (1:5, w/v) in the refrigerator at 4 ℃ for 14 h. After that, the soaked soybeans were washed with distilled water 3 to 4 times and then mixed with distilled water (1:7, w/v) at 85 °C for 25 min. The obtained mixture was filtered using a 180-mesh filter to yield SM. Then, SM mixed with 8% (w/v) sucrose was sterilized for 20 min at 110 °C. After the temperature was down to 36 °C, five various FSM beverages were prepared in triplicate. On the basis of previous studies of Korma et al. [22] and Huang et al. [27], 5% (v/v) and 2% (v/v) were selected as optimal concentrations in the co-fermentation conditions for the activated XPL-1 starter and activated yeast, respectively. Additionally, on the ground of preliminary experiments with various times and temperatures, followed by sensory evaluation (flavor, taste, appearance, texture, and overall acceptance), 36 °C and 5 h were selected as the optimal conditions (data not shown). FSM beverages were then cooled at 4 °C for 12 h until further analysis. The applied conditions and the fermentation treatments for the preparation of SM beverages co-fermented with XPL-1 starter and different yeasts are summarized in Table 1. The obtained formulations have been labeled as follows: SM, non-fermented SM; SY, fermented SM using XPL-1 starter; SYK, co-fermented SM using XPL-1 starter with Kluyveromyces marxianus K; SYS, co-fermented SM using XPL-1 starter with Kluyveromyces marxianus SP-1; SYA, co-fermented SM using XPL-1 starter with Candida ethanolica ATW-1; SYY, co-fermented SM using XPL-1 starter with Pichia amenthionina Y.

Microbiological analysis

A standard plate count approach was employed to determine the viable cell of LAB and yeast strains [22]. Each FSM sample (10 mL) was added to 90 mL of sterilized normal saline solution (0.85%, w/v), and the mixture was stirred for 30–60 s, resulting in a dilution of 10−1. Successively, serial dilutions were prepared to count the strains of LAB and yeast. M17 agar was utilized to number lactococci spp. after incubation for 24 h at 30 °C and Streptococcus thermophilus after incubation for 3 days at 37 °C. MSE agar was used to count Leuconostoc mesenteroides subsp. cremoris after incubation for 4 days at 22 °C. PDA with chloramphenicol (0.01%, w/w) was used to number the yeasts after incubation for 2 days at 30 °C. Plates with 30 to 300 colonies were counted after incubation, and the collected data were presented as log CFU mL−1 of FSM beverage. Three plates of each dilution were inoculated from each sample.

pH and titratable acidity

The pH values of FSM samples were determined in triplicate utilizing a digital pH meter (Mettler Toledo, Five Easy Plus). Titratable acidity (TA) values were measured in triplicate according to Li et al. [35]. Ten grams of each sample was mixed with 20 mL of sterilized distilled water using magnetic steering. Four drops of phenolphthalein solution (0.5 wt. % in 1:1 ethanol:water) were then added. The mixture was then titrated with NaOH (0.1 M) until a stable faint pink color (30 s) was shaped. TA values (Thorner degree; °T × 0.009 = lactic acid %) were calculated by multiplying the titer by 10.

Syneresis and WHC

Syneresis and WHC of FSM samples were performed in triplicate by the centrifugation method following Bakry et al. [36] with some modification. Every sample (10 g) was centrifuged (10,000 rpm) at 4 °C for 5 min. For each sample, the syneresis value (g/10 g) was stated as a weight percentage of the supernatant with respect to the initial FSM sample weight. WHC was estimated by the following Eq. (1):

where Y is the FSM sample weight (g) and W the supernatant weight (g) after centrifugation.

Rheological measurements

The rheological behavior of SM and FSM beverage samples (3 mL) was investigated by means of a Haake RS60 rheometer (HAAKE Co., Ltd., Germany) connected with a stainless-steel parallel plate geometry (diameter 60 mm; gap 1.0 mm), on the basis of procedures reported in Huang et al. [27] with some modification. The temperature was kept at 25 °C using a Universal Pe Peltier system and water bath (MultiTemp III, Amersham Biosciences). A shear rate range of 0.01 to 100.00 s−1 was applied to show the flow viscosity curves, while the frequency sweep analyses were carried out at a constant stress of 0.1 Pa from 0.1 to 10.00 Hz within linear viscoelastic region. Elastic (G') and viscous (G″) moduli were stated as frequency functions. Moreover, the consistency coefficient index (k) and flow behavior index (n) were determined by means of the power-law model, Eq. (2) [37]:

where σ represents the shear stress (Pa), k the consistency coefficient index (Pa.sn), γ the shear rate (s−1), and n the flow behavior index. All the measurements were taken in triplicates.

Analysis of VCs

The VCs in SM and FSM beverage samples after 5 h of fermentation were carried out utilizing a gas chromatograph (GC, Agilent 7890B) connected with a 7000C triple-quadrupole mass spectrometer (MS, Agilent, Santa Clara, CA, USA). The separation of VCs was carried out using a capillary column of a HP-INNOWax (Agilent Technologies; 30 m × 250 μm; ID 0.25 μm film thickness). The solid phase microextraction (SPME) was carried out by means of a DVB/CAR/PDMS fiber (50/30 μm, Supelco, Bellefonte, PA, USA). Briefly, 5 g of each sample was sealed in a 25 mL of glass headspace vial in the existence of 0.5 g of NaCl. Subsequently, the mixture was agitated for 20 min at 50 °C before SPME fiber was inserted into the vial headspace for 45 min at the same temperature. After that, SPME fiber was immediately held in the GC injection port at 250 °C for 5 min. The column was initially kept for 3 min at 40 °C, raised to 120 °C (5 °C/min), and maintained for 2 min, further heated up to 220 °C (7 °C/min) for 5 min until the end of the program. Helium was utilized as a carrier gas (flow rate of 1 mL/min), and a 5:1 split ratio was employed. Runs of 40 min were performed, setting the interface and ion source temperatures 250 ℃ and 230 ℃, respectively, and the ion production by electron ionization (70 eV). The acquired mass spectra were presented in the 33 to 400 m/z range with a 0.5 s scan duration. Agilent Mass Hunter Qualitative Analysis software (Agilent, Santa Clara, CA, USA) was employed to analyze the raw data. The VCs were labeled on the basis of the National Institute of Standards and Technology database and retention indices (RI). Series of n-alkanes solution were examined under the same conditions to calculate RI for the VCs [38]. The findings were presented as percentages of each compound content with respect to total VCs.

Free amino acids (FAAs)

The FAA profiles of SM and FSM beverage samples were carried out utilizing a high-performance liquid chromatography (HPLC) system (Agilent 1100) coupled with a UV detector (diode array detector, Agilent Corp., Karlsruhe, Germany) and a reversed-phase column of ODS Hypersil (125 mm × 4.6 mm × 5 μm particle size; Agilent, USA) following Xu et al. [39]. The samples were lyophilized using a freeze dryer (SCIENTZ-18 N, Zhejiang, China), the pressure was set at 1 Pa, and the temperature was adjusted at − 45 °C. Briefly, 1 g of each lyophilized powder was dissolved in trichloroacetic acid (5%, w/w, 25 mL) solution and treated for 5 min at 20 °C in an ultrasonic water bath (40 kHz, 0.06 W/cm3, KQ300DE, Kunshan Shumei Ultrasonic Equipment Corp., Suzhou, Jiangsu, China). After that, the samples were left for 1 h at room temperature, and then the mixture was submitted to centrifugation for 10 min at 10,000 rpm and 20 °C. The supernatant was collected and filtered using a 0.22 μm Millipore membrane filter (MCE, Navigator Lab Instrument Co., Ltd., Tianjin, China). Subsequently, the amino acid solution was derivatized with O-phthaldialdehyde [40]. An aliquot (1 μL) was injected into the chromatographic system for the sample analysis. Mobile phase A was 7.35 mM/L sodium acetate:triethylamine:tetrahydrofuran (500:0.12:2.5, v/v/v), mobile phase B was 7.35 mM/L sodium acetate:methanol:acetonitrile (1:2:2, v/v/v), and both of them were adjusted to pH 7.20 with acetic acid. The utilized mobile phase elution gradient was as following: 0 min, 8% B; 17 min, 50% B; 20.1 min, 100% B; 24.0 min, 0% B. The flow rate was set at 1.0 mL/min, the column temperature at 40 °C, and the UV detector at 338 nm. A standard solution of 17 amino acids was used to identify and quantify each amino acid. The FAAs were stated as mg per 100 g. Triplicates of each measurement were done.

Analysis of nucleotides

SM and FSM beverage sample nucleotide compounds were analyzed, in triplicate, utilizing 1H NMR spectroscopy, according to the method described in our previous study by Jin et al. [41]. Briefly, 0.1 g (freeze-dried powder) of each sample was dissolved with 99.9% D2O (1 mL) containing TMSP (0.05%, m/v) as an internal standard. Subsequently, the mixture was submitted to centrifugation (10,000 rpm) at 4 °C for 10 min. The resulting supernatant (600 μL) was then transferred into a 5 mm NMR capillary tube. The detection was performed at 298.15 K using an Avance III hydrogen proton resonance frequency 600.13 MHz NMR spectrometer (Bruker, Germany) and a 5 mm PATXI probe. The one-dimensional liquid 1H NMR test parameters were set as follows: the number of scans was 16 and the pulse sequence noesygppr1d. The nucleotide compounds were identified and quantified using the Chenomx NMR Suite software (version 8.4; Chenomx, Edmonton, Canada), and their concentrations were expressed as μmol/L.

Sensory evaluation

The sensory assessment of FSM was performed by 16 panelists in the 25- to 30-year range. They participated and got trained in previous related projects on sensory evaluation in the laboratory. A nine-point unstructured hedonic scale from 1 (extremely weak) to 9 (extremely strong) was used to estimate the intensity of beany flavor [42] and was also used to assess the points of taste, appearance, texture, and overall acceptance with a scale range from 1 (extremely dislike) to 9 (extremely like) [43]. The evaluations were performed under natural light in a room. Samples contained in classified polyethylene cups were given to the panelists in randomized order. Purified water was offered to the panelists, after every sample testing, to cleanse their palate and proceed to the next sample.

Statistical analysis

A statistical analysis of the acquired data was performed by one-way analysis of variance (ANOVA), setting them as mean ± standard deviation. To evaluate the significant variances with P ˂ 0.05, Duncan’s multiple range test was employed with the CoStat software (Version 6.4, Monterey, CA, USA). R software (Version 4.0.3, Auckland, New Zealand) was used to draw the dendrogram of heatmap with HCA, while Origin 2021 software was employed to draw the PCA and other charts.

Results and discussion

Microbiological analysis

The probiotic microorganisms in fermented beverages have been confirmed to offer many benefits to human health by experts in nutritional standards and regulations [32]. Previous studies of Saadat et al. [44], Fernandes et al. [45], and Fei et al. [46] reported, respectively, that Kluyveromyces marxianus, Candida ethanolica, and Pichia amenthionina could be useful as potential probiotics yeast. The values of viable cell count of LAB and yeast strains in FSM are presented in Table 2. The findings show that the SM environment could support the growth of all LAB and yeast strains. There were significant variances (p < 0.05) in the viable cell counts among LAB strains. Streptococcus thermophilus better multiplied in 8.42–8.84 log CFU/mL range than other LAB strains. This phenomenon may be due to variations in the nutritional requirements, the utilization rate of raw material, and the microorganism type of multi-starters [35]. These findings comply with Niamah [47], who found that the yeast addition increased the starter bacteria growth and viable cell count. This may also be ascribed to some amino acids and vitamins released during the fermentation process, promoting the LAB strain growth [48]. A remarkable increment of the viable yeast cell number was also revealed with respect to the initial inoculation of approximately (6 log CFU/mL), probably due to the yeast strain consumption of glucose and fructose units and organic acids obtained from the LAB strain metabolism during the fermentation [49]. Moreover, it was observed that Kluyveromyces marxianus SP-1 (7.87 ± 0.05 log CFU/mL) grew better than other yeast strains. The growth variances of yeast strains can probably be attributed to the property of the strain itself and the type of available nutrients on each fermented sample. Overall, cell counts for the potential probiotic microorganisms overcome the minimum value of 7 log CFU/mL, that have been reported to provide potential health benefits in humans by the scientific community and US legislation [50, 51].

Physicochemical characteristics

The collected values of pH, TA, syneresis, and WHC are presented in Table 3. The average FSM sample pH values were found to be in the range of 4.26 to 4.59. Hauly et al. [52] found that the pH value of soy yogurt fortified with inulin can reach 4.63. Moreover, Karleskind et al. [53] stated that the optimum pH value for soy yogurt was 4.30. Thus, the results of our study show that the fermentation process was normal. The acidity is one of the determinants of fermented beverage quality, being strongly linked with the texture and flavor of the final fermented product [54]. TA values of the FSM samples were in the range of 38.43 to 61.64 °T. These results were higher than the value (41.11 °T) reported by Hauly et al. [52] in the manufactured soy yogurt. This indicated that the microorganisms used in this study could more adapt and survive in the SM environment. The variations in pH and TA results among the FSM samples could be related to the used mixed starter culture kind and the bacteria activity. According to this study, SYS beverage was found with a relatively lower pH (4.26 ± 0.01) and higher acidity (61.64 ± 7.64 °T) compared to other samples. This phenomenon is probably due to the availability of more nutrients produced by Kluyveromyces marxianus SP-1, which could support the growth of LAB strains and resulted in the production of more acidity. Furthermore, it has been reported that yeast could generate some protein enzymes to promote the protein hydrolysis into small peptides and amino acids that were possibly consumed as a nitrogen source during the bacteria starter growth in milk [55]. This could also lead to the high bacteria growth and acidity found in the fermented beverages. Similarly, other authors [27] evidenced the ability of the co-fermentation system to enhance the acidity and the LAB growth in goat yogurt.

The syneresis and WHC of all FSM beverage samples ranged from 3.11 to 3.54 g per 10 g and 64.65 to 68.88%, respectively (Table 3). The relationship between syneresis and WHC in all FSM samples was found to be inversely proportional. There were significant differences in syneresis values (g/10 g) among the FSM beverages (p < 0.05). The lowest value of syneresis was revealed in SY samples (3.11 ± 0.13), while the highest value in SYS samples (3.54 ± 0.10). These findings indicated that syneresis increased with a decrease in pH values in most of the FSM samples. The collected findings are in agreement with Bakry et al. [36], who found an inverse proportionality among syneresis and yogurt pH. Results on WHC evaluations revealed significant variations among the samples (p < 0.05). The highest WHC was documented for SY (68.88 ± 1.32%), and the least ratio was found in SYS (64.65 ± 0.98%) (Table 3). The WHC values are probably related to the acidity, in agreement with Kokabian et al. [56], who found an inverse relation between WHC and yogurt acidity.

Rheological measurements

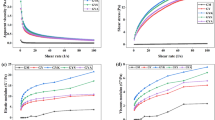

The processing, handling, quality control, and storage of fermented dairy beverages are strongly influenced by their rheological attributes [36]. The relation between the apparent viscosity and shear rate is displayed in Fig. 1A. The results showed that the fermentation process improved the apparent viscosity of SM. With the shear rate increase, the SM and FSM sample apparent viscosity was also found to decrease (Fig. 1A). As evident in Fig. 1A, SYS samples showed the highest apparent viscosity compared with the other samples within the same shear rate range. Indeed, the FSM beverage apparent viscosity increment is due to the protein binding, promoted by the SM pH decrease, due to the accumulation of the lactate generated by LAB through the fermentation. Moreover, Behare et al. [57] stated that exopolysaccharides formed by LAB could improve fermented milk’s texture and sensory properties. At the same time, the co-fermentation system remarkably (p < 0.05) enhances the apparent viscosity with respect to SM only fermented with XPL-1 starter. This experimental evidence can be ascribed to the LAB growth enhanced by yeast and increased acidity. Similar results were reported in fermented goat milk [27]. Figure 1B evidenced that a shear stress increment as a function of shear rate was determined, representing non-Newtonian rheological behavior of FSM samples, typical of fermented beverages [58].

Two factors of the rheological attributes, i.e., elastic modulus (G′) and viscous modulus (G″), were assessed through the frequency sweep analysis, indicating the elastic and viscous behaviors of the gels, respectively. For all samples, G′ values were higher than G″ ones (Fig. 1C, D), suggesting the obtainment of weak viscoelastic gels supplied with an essentially elastic structure, with consequent sample better stability during storage [36]. For the fermented samples (SY, SYK, SYS, SYA, and SYY), enhanced G′ and G″ values were detected with respect to non-fermented SM, which showed the lowest G′ and G″ values in the observed range. In detail, SYS displayed the highest G′ and G″, associated with the highest elastic and viscous behavior. It has to be considered that the Gʹ and G″ value increment during the fermentation could be ascribed to protein binding by increasing the acidity of FSM [59].

The rheological parameter (K, n, and η) values are shown in Table 3. The power-law model revealed a good fit for the rheological parameters, with a determination coefficient (R2) in the range of 0.91 to 0.97 (Table 3). SYS samples presented the highest average consistency index (k) values (30.56 ± 0.14) (Table 3), suggesting a higher apparent viscosity of SYS than other samples [60]. This high K value could be ascribed to the potential probiotic organism’s metabolic activity, contributing to the produced gels’ higher pseudoplastic properties. Comparable rheological behavior was described by Xia et al. [61] in set-type soy yogurt, whereas the same trend of k and η values was shared. Overall, a shear-thinning non-Newtonian fluid behavior was determined for all of them since the flow behavior index values were less than 1 [37].

Volatile compounds (VCs)

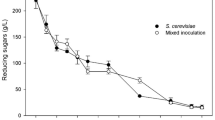

The major VCs evolved in both non-fermented and fermented SM samples are collected in Table 4. Thirty-four VCs were detected: six aldehydes, nine ketones, twelve alcohols, four acids, two furans, and one ester. In general, the VCs that appeared in the SYY samples were significantly different compared to other treatments. Aldehyde compounds are frequently linked with off-flavors, and, among them, hexanal, which is generated via lipoxidase oxidation of linoleic acid, is considered to be responsible for the beany, green, and grassy flavors in SM [62]. The fermentation process decreased hexanal, which was the most abundant aldehyde VC in SM (18.68%), to small levels, while the co-fermentation system had much stronger abilities to decrease the beany flavor (Table 4). Indeed, the aldehydes detected in SM could be transformed into either acids or alcohols throughout the fermentation, resulting in low levels detected in fermented samples. Acetoin and 2,3-butanedione are the two most important flavor compounds in dairy products and own attractive creamy and buttery aromas [63, 64]. SM co-fermented with Pichia amenthionina Y showed significantly higher levels of acetoin (36.19%) and 2,3-butanedione (2.02%) than the other yeast strains. 2-nonanone (fruity or hot milk flavor), which is mostly formed from the biotransformation of linoleic acid [18], was increased after fermentation with the highest amount in SYK (5%) in comparison with the other fermented samples. Volatile alcohols were abundant and detected in all samples, even in raw SM. Among the alcohols, 1-hexanol was identified in the current work in terms of high VCs with a marked decrease in SYK (17.94%), SYS (20.88%), and SYY (17.05%). 1-hexanol was possibly formed through the reduction of hexanal by alcohol dehydrogenase [65]. 1-hexanol, 1-octen-3-ol, 2-heptanol, 1-heptanol, and (Z)-2-hexen-1-ol were related to green odor [65]. The co-fermentation system could reduce those compounds. 3-methylbutan-1-ol and 2-phenylethanol compounds were detected more in SYK (15.49 and 11.75%) and SYS (11.74 and 9.67%), respectively. This may be ascribed to the conversion of the related aldehydes to alcohols due to the starter culture metabolic activities [66]. L-lactic, hexanoic, and octanoic acids were observed after fermentation, probably due to the amino acid degradation and the oil lipolysis in SM through the starter culture metabolism [67]. L-lactic and acetic acids with sour flavor were the most abundant acids, especially in SYK (10.01 and 2.58%) and SYS (10.04 and 3.03%), respectively. Furans are usually shaped by the oxidation of unsaturated fatty acids connected with unpleasant flavor in SM [62]. Compared to raw SM, the quantity of furans was significantly reduced in the fermented samples, suggesting the ability of the starter cultures to reduce the unwanted aromatic compounds from SM.

A heatmap with HCA dendrogram and PCA was prepared to designate the variations in the different starter culture metabolites in SM throughout the fermentation. The HCA dendrogram grouped all formulations into four significant clusters (Fig. 2A): raw SM was categorized into cluster one, SYY into cluster two, SYK and SYS into cluster three, and SY and SYA into cluster four. This means that the fermentation process strongly influenced the VC production compared to raw SM. In addition, the HCA dendrogram showed that the strains of each cluster were similar to the production of the VCs. As shown in Fig. 2A, the heatmap revealed the variations in the VC relative concentration through the fermentation process. A positive correlation between the color strength and the VC groups relative concentration was evidenced. For example, SYY samples had the lowest content of aldehydes and alcohols with the highest content of ketones. PCA bioplot was also employed to find out further variations between the reported samples in terms of VC groups, as shown in Fig. 2B. The total variance (85.23%) was defined by the first two principal components (PC1 and PC2). PC1 exhibited the highest data variation (51.96% vs. 33.27% for PC2) and was well connected with aldehydes, furans, and SM, confirming that more aldehydes (23.32%) and furans (4.45%) (Table 4) were detected in SM. In contrast, the negative correlation between PC1, SYK, and SYS suggested low aldehyde and furan contents in SYK and SYS. At the same time, SYK and SYS presented the highest amount of acids (13.38 and 14.46%) and esters (4.20 and 2.47%), respectively (Table 4), compared with other samples. On the other hand, PC2 revealed a good correlation with alcohols in SYA samples, whereas it was negatively correlated with SY and SYY, suggesting low alcohol contents in these samples. Likewise, SY and SYY had the highest content of ketones (14.90 and 42.54%, respectively). In accordance with the PCA bioplot, a high amount of alcohols, acids, esters, and ketones was formed during the fermentation process.

The volatile compound (VC) groups present in non-fermented soymilk (SM) and fermented soymilk samples (SY, SYK, SYS, SYA, and SYY). A A heatmap with a hierarchical cluster analysis dendrogram and B a principal component analysis bioplot. The color intensity is proportional to the relative concentration of VC groups. The scale’s color represents the normalized relative content value

Free amino acids (FAAs) and nucleotides

FAAs are important items that play a vital role in the final taste attributes of fermented beverages [70]. Moreover, the influence of the fermentation process on the types or/ and levels of FAAs is a controversial subject [71], as the types or/and levels of FAAs in fermented beverages depend on several factors, including the fermentation period, fermentation temperature, the used organism, the substrate type, and the moisture conditions. The FAA levels in unfermented and fermented SM beverages produced by LAB (SY) or by combining LAB and different yeasts (SYK, SYS, SYA, and SYY) are shown in Table 5. There was a more decrease in the FAA content after fermentation in the samples produced by LAB alone compared with the other samples co-fermented with yeasts. This FFA reduction might be due to LAB culture, which used the amino acids for their nutrition and metabolic activities [48, 72]. The content of total FAAs, essential amino acids, and non-essential amino acids in the SYY beverage samples (238.89 ± 0.84, 113.86 ± 0.01, and 125.03 ± 0.85 mg/100 g, respectively) was remarkably (P < 0.05) higher with respect to that of other FSM samples. The significant changes in the levels of various FAAs might be due to the fact that yeasts generate some enzymes able to hydrolyze peptides and proteins through the co-fermentation system [73]. The yeast proteolytic activity in co-fermented SM beverages might have produced a good amount of some amino acids, which probably contributed to the increase in growth and higher cell viability of LAB strains [48]. Moreover, the comparisons among the fermented beverages revealed that SYY beverages had the highest level of umami (66.82 ± 0.37 mg/100 g), sweet (70.11 ± 0.08 mg/100 g), and odorless (28.04 ± 0.64 mg/100 g) amino acids. Glutamate, which provides umami or a savory taste [74], was the most abundant FFAs in SYY beverages, followed by threonine (sweet taste), which increased after fermentation in all treatments. Arginine (163.35 ± 0.26 mg/100 g) and histidine (56.61 ± 0.02 mg/100 g), which impart bitter tastes [70], were the major FAAs in unfermented SM and they more decreased during the fermentation depending on each condition. These increases of umami, sweet, and odorless amino acids with decreases of bitter amino acids provided a greater contribution to improving the taste of fermented SM beverages, particularly SYY beverages.

As shown in Table S1, the 5′-nucleotides in terms of inosine 5′-monophosphate (IMP), adenosine 5′-monophosphate (AMP), guanosine 5′-monophosphate (GMP), adenosine 5′-triphosphate (ATP), adenosine 5'-diphosphate (ADP), inosine, and hypoxanthine were determined in the samples. Total nucleotide content in SYY samples was 509.50 µmol/L, significantly higher than that of other fermented samples (P < 0.05). Hypoxanthine was the most abundant nucleotide (135.30 µmol/L), followed by GMP (81.30 µmol/L), AMP (73.77 µmol/L), ATP (71.27 µmol/L), ADP (59.17 µmol/L), IMP (51.23 µmol/L), and inosine (37.47 µmol/L), with significant differences (P < 0.05) compared to the other fermented samples. According to Sabikun et al. [75], the hypoxanthine did not contribute to any taste response. Moreover, Liu et al. [76] and Bi et al. [77] reported that AMP, IMP, and GMP are the characteristic sources of umami taste that synergize with umami amino acids (aspartate and glutamate); thus, they can significantly improve the umami taste. Inosine, which produces a bitter taste [78], was found in the lowest amount in SYY samples. The differences in the nucleotides contents could be attributed to the yeast types. Overall, the obtained results of the present study related to FAAs and nucleotides showed that SYY samples are characterized by an umami taste among the other fermented samples.

Sensory evaluation

The findings of the sensory assessment analyses carried out on FSM beverages, including the flavor and taste, important indicators for the consumer acceptance of fermented beverages [79], are shown in Fig. 3. There were no significant variations (P > 0.05) in appearance between all the samples. SYK and SYS had the highest score for texture as compared to other fermented samples. SYY samples presented the highest score of taste (7.63 ± 0.48) and overall acceptance (7.69 ± 0.46), with the lowest beany flavor score (2.13 ± 0.70). Smell for co-fermented SM with Pichia amenthionina Y was identified as a distinctive yogurt-like odor, and these results are consistent with the VCs detected by solid-phase microextraction followed by gas chromatography-mass spectrometry (SPME–GC–MS) analysis. This smell could be due to the high content of acetoin (36.19%) and 2,3-butanedione (2.02%) with buttery and creamy odors, which were deemed to reduce and mask the beany flavor. Moreover, hexanal and 1-hexanol, which are responsible for the beany and green flavors, were significantly lower in SYY than in the other fermented samples, and the high proportions of umami, sweet, odorless amino acids, and umami nucleotides could be responsible for the delicious taste of SYY beverages [80]. Overall, SYY samples had the lowest total content of alcohol compounds (46.13%). Nemo, Bacha [81] reported that the fermented drinks with the lowest alcoholic content are good for their safety, nutritional value, and livelihood. In the end, SM co-fermented with Pichia amenthionina Y had the highest overall sensory score (7.69 ± 0.46) among all the samples.

Conclusions

In the current research, it can be seen that the co-fermentation of isolated yeasts (Kluyveromyces marxianus SP-1, Candida ethanolica ATW-1, Pichia amenthionina Y) and Kluyveromyces marxianus K (a commercial yeast) along with XPL-1 starter had different effects on the quality of FSM beverages. Pichia amenthionina Y showed a stronger ability to remove the beany flavor and could produce rich aromatic components, like acetoin and 2,3-butanedione, which significantly improved the flavor and taste of FSM drinks. SM seems to be an appropriate environment for improving the growth of LAB and yeast strains. The co-fermentation system significantly increased the LAB strain expansion and acid production while improving the rheological properties. In particular, for the first time, it has been demonstrated that Pichia amenthionina Y, isolated from acidic tofu whey, is able to generate a high content of acetoin and 2,3-butanedione with the highest umami, sweet, odorless amino acids, and umami nucleotides, and the lowest content of alcohol and inosine. Therefore, Pichia amenthionina Y appears to have significant potential applications in FSM beverages. Further investigation on the probiotic and safety properties of the new yeast strains is necessary before industrial application.

References

Ismail BP, Senaratne-Lenagala L, Stube A, Brackenridge A (2020) Protein demand: review of plant and animal proteins used in alternative protein product development and production. Anim Front 10(4):53–63

Sá AGA, Moreno YMF, Carciofi BAM (2020) Plant proteins as high-quality nutritional source for human diet. Trends Food Sci Technol 97:170–184

Wang J, Li H, Meng X, Tong P, Liu X (2022) Biosynthesis of c9, t11-conjugated linoleic acid and the effect on characteristics in fermented soy milk. Food Chem 368:130866

Ceh A, Su C, Du H, Hyl A, Hks B, Kmc A, Jin H (2020) Enhancement of isoflavone aglycone, amino acid, and CLA contents in fermented soybean yogurts using different strains: screening of antioxidant and digestive enzyme inhibition properties. Food Chem 340:128199

Nedele A-K, Gross S, Rigling M, Zhang Y (2021) Reduction of green off-flavor compounds: comparison of key odorants during fermentation of soy drink with Lycoperdon pyriforme. Food Chem 334:127591

Saadoun JH, Calani L, Cirlini M, Bernini V, Neviani E, Del Rio D, Galaverna G, Lazzi C (2021) Effect of fermentation with single and co-culture of lactic acid bacteria on okara: evaluation of bioactive compounds and volatile profiles. Food Funct 12(7):3033–3043

Kaczmarska KT, Chandra-Hioe MV, Frank D, Arcot J (2018) Aroma characteristics of lupin and soybean after germination and effect of fermentation on lupin aroma. LWT Food Sci Technol 87:225–233

Jsc A, Jyf A, Zjn B, Rhma B, Kta B, Sw C, Fei H, Jgza B, Zjwa B (2021) An update on the nutritional, functional, sensory characteristics of soy products, and applications of new processing strategies. Trends Food Sci Technol 112:676–689

Nissen L, Casciano F, Gianotti A (2021) Volatilome changes during probiotic fermentation of combined soy and rice drinks. Food Funct 12(7):3159–3169

Kaneko D, Igarashi T, Aoyama K (2014) Reduction of the off-flavor volatile generated by the yogurt starter culture including Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus in soymilk. J Agric Food Chem 62(7):1658–1663

Zhang Y, Guo S, Liu Z, Chang SKC (2012) Off-flavor related volatiles in soymilk as affected by soybean variety, grinding, and heat-processing methods. J Agric Food Chem 60(30):7457–7462

Yuan SH, Chang SKC (2010) Selected odor compounds in cooked soymilk as affected by soybean materials and direct steam injection. J Food Sci 72(7):S481–S486

Paul AA, Kumar S, Kumar V, Sharma R (2019) Milk Analog: plant based alternatives to conventional milk, production, potential and health concerns. Crit Rev Food Sci Nutr 60(18):3005–3023

Silva C, Santos FL, Santana L, Silva M, Conceição T (2018) Development and characterization of a soymilk Kefir-based functional beverage. Food Sci Technol 38(3):543–550

Zhou X, Du H-h, Jiang M, Zhou C, Deng Y, Long X, Zhao X (2021) Antioxidant effect of Lactobacillus fermentum CQPC04-fermented soy milk on D-galactose-induced oxidative aging mice. Front Nutr 8:727467

Sharma A, Noda M, Sugiyama M, Ahmad A, Kaur B (2021) Production of functional buttermilk and soymilk using Pediococcus acidilactici BD16 (alaD+). Molecules 26(15):4671

Myagmardorj B, Purev M-E, Batdorj B (2018) Functional properties of fermented soymilk by Lactobacillus fermentum BM-325. Mong J Chem 19(45):32–37

Zheng Y, Fei Y, Yang Y, Jin Z, Li L (2020) A potential flavor culture: Lactobacillus harbinensis M1 improves the organoleptic quality of fermented soymilk by high production of 2,3-butanedione and acetoin. Food Microbiol 91:103540

Coolbear T, Weimer B, Wilkinson MG (2011) Lactic acid bacteria | lactic acid bacteria in flavor development. Encyclopedia Dairy Sci 73(2):160–165

Ścieszka S, Gorzkiewicz M, Klewicka E (2021) Innovative fermented soya drink with the microalgae Chlorella vulgaris and the probiotic strain Levilactobacillus brevis ŁOCK 0944. LWT Food Sci Technol 151:112131

Piazentin A, Silva T, Florence-Franco AC, Bedani R, Converti A, Oliveira R (2020) Soymilk fermentation: effect of cooling protocol on cell viability during storage and in vitro gastrointestinal stress. Braz J Microbio 51(4):1645–1654

Korma SA, Li L, Khalifa SA, Abdrabo KA, Huang Y, An P, Fu J (2021) Microbiological, physicochemical, and sensory properties of goat milk co-fermented with isolated new yeasts. J Food Meas Charact 1-14. https://doi.org/10.1007/s11694-021-01091-6

Tang Q, Hu MF, Liu SC (2014) Screening of beany-flavor removement yeast from fermented soybean meal. Mod Food Sci Technol 30(6):116-120+180

Narvhus JA, Gadaga TH (2003) The role of interaction between yeasts and lactic acid bacteria in African fermented milks: a review. Int J Food Microbiol 86(1–2):51–60

Vasilean I, Segal R (2011) The influence of biosynthesized exopolysaccharides on some characteristics of fermented dairy products. Ann Univ Dunarea Jos Galati Fascicle VI: Food Technol 35(1):71–76

Barukčić I, Gracin L, Režek Jambrak A, Božanić R (2017) Comparison of chemical, rheological and sensory properties of kefir produced by kefir grains and commercial kefir starter. Mljekarstvo: časopis za unaprjeđenje proizvodnje i prerade mlijeka 67(3):169–176

Huang Z, Huang L, Xing G, Xu X, Tu C, Dong M (2020) Effect of co-fermentation with lactic acid bacteria and K. marxianus on physicochemical and sensory properties of goat milk. Foods 9(3):299

Wong LS, Oweida AFM, Kong SY, Iqbal DM, Regunathan P (2020) The surface coating mechanism of polluted concrete by Candida ethanolica induced calcium carbonate mineralization. Constr Build Mater 257:10. https://doi.org/10.1016/j.conbuildmat.2020.119482

Xing XY, Wang YH, Huo NR, Wang RF (2018) Candida ethanolica strain Y18 enhances aroma of shanxi aged-vinegar. Food Sci Technol Res 24(6):1069–1081. https://doi.org/10.3136/fstr.24.1069

Li L, Liu L, Fei Y, Feng J (n.d.) New Pichia amethionina Y for producing yeast aroma for fermenting soymilk, is preserved in China General Microbiological Culture Collection Center. Univ South China Technol (Uysc-C) Patent CN105039187-A; CN105039187-B, CN105039187-A 11 Nov 2015 C12N-001/16 201607

Vilela JdAS, de Figueiredo VL, Ramos CL, Schwan RF (2020) Physiological and genetic characterization of indigenous Saccharomyces cerevisiae for potential use in productions of fermented maize-based-beverages. Braz J Microbiol 51(3):1297–1307

Farag MA, Jomaa SA, El-Wahed AA (2020) The many faces of kefir fermented dairy products: quality characteristics, flavour chemistry, nutritional value, health benefits, and safety. Nutrients 12(2):346

Yilmazersan L, Ozcan T, Akpinarbayizit A, Sahin S (2016) The antioxidative capacity of kefir produced from goat milk. Int J Chem Eng 7(1):22

Cais-Sokolińska D, Wójtowski J, Pikul J, Danków R, Majcher M, Teichert J, Bagnicka E (2015) Formation of volatile compounds in kefir made of goat and sheep milk with high polyunsaturated fatty acid content. J Dairy Sci 98(10):6692–6705

Li C, Li W, Chen X, Feng M, Dong M (2014) Microbiological, physicochemical and rheological properties of fermented soymilk produced with exopolysaccharide (EPS) producing lactic acid bacteria strains. LWT Food Sci Technol 57(2):477–485

Bakry AM, Chen YQ, Liang L (2019) Developing a mint yogurt enriched with omega-3 oil: physiochemical, microbiological, rheological, and sensorial characteristics. J Food Process Preserv 43(12):e14287

Korma SA, Wei W, Ali AH, Abed SM, Zheng L, Jin Q, Wang X (2019) Spray-dried novel structured lipids enriched with medium-and long-chain triacylglycerols encapsulated with different wall materials: Characterization and stability. Food Res Int 116:538–547

Xiao Z, Yu D, Niu Y, Chen F, Song S, Zhu J, Zhu G (2014) Characterization of aroma compounds of Chinese famous liquors by gas chromatography–mass spectrometry and flash GC electronic-nose. J Chromatogr B 945:92–100

Xu D, Zhang H, Xi J, Jin Y, Chen Y, Guo L, Jin Z, Xu X (2020) Improving bread aroma using low-temperature sourdough fermentation. Food Biosci 37:100704

Avino P, Campanella L, Russo MV (2001) High-performance liquid chromatography intercomparative study for amino acid analysis in two tissues by PITC-and OPA-derivatizations. Anal Lett 34(6):867–882

Jin ZK, Li L, Zheng Y, An PP (2020) Inhibition of Bacillus cereus by garlic (Allium sativum) essential oil during manufacture of white sufu, a traditional Chinese fermented soybean curd. LWT Food Sci Technol 130:109634

Pu D, Zhang H, Zhang Y, Sun B, Ren F, Chen H, Xie J (2019) Characterization of the oral breakdown, sensory properties, and volatile release during mastication of white bread. Food Chem 298:125003

Gaze L, Oliveira B, Ferrao L, Granato D, Cavalcanti R, Júnior CC, Cruz A, Freitas M (2015) Preference mapping of dulce de leche commercialized in Brazilian markets. J Dairy Sci 98(3):1443–1454

Saadat YR, Khosroushahi AY, Movassaghpour AA, Talebi M, Gargari BP (2020) Modulatory role of exopolysaccharides of Kluyveromyces marxianus and Pichia kudriavzevii as probiotic yeasts from dairy products in human colon cancer cells. J Funct 64:9. https://doi.org/10.1016/j.jff.2019.103675

Fernandes T, Carvalho BF, Mantovani HC, Schwan RF, Avila CLS (2019) Identification and characterization of yeasts from bovine rumen for potential use as probiotics. J Appl Microbiol 127(3):845–855

Fei Y, Li L, Chen L, Zheng Y, Yu B (2018) High-throughput sequencing and culture-based approaches to analyze microbial diversity associated with chemical changes in naturally fermented tofu whey, a traditional Chinese tofu-coagulant. Food Microbiol 76:69–77. https://doi.org/10.1016/j.fm.2018.04.004

Niamah AK (2017) Physicochemical and microbial characteristics of yogurt with added Saccharomyces boulardii. Curr Res Nutr Food Sci 5(3):300–307

Zhang D-D, Liu J-L, Jiang T-M, Li L, Fang G-Z, Liu Y-P, Chen L-J (2017) Influence of Kluyveromyces marxianus on proteins, peptides, and amino acids in Lactobacillus-fermented milk. Food Sci Biotechnol 26(3):739–748

Lourens-Hattingh A, Viljoen B (2001) Growth and survival of a probiotic yeast in dairy products. Food Res Int 34(9):791–796

de Almada CN, De Almada CN, Martinez RCR, de Souza Sant’Ana A (2015) Characterization of the intestinal microbiota and its interaction with probiotics and health impacts. Appl Microbiol Biotechnol 99(10):4175–4199

dos Santos DC, de Oliveira Filho JG, Santana ACA, de Freitas BSM, Silva FG, Takeuchi KP, Egea MB (2019) Optimization of soymilk fermentation with kefir and the addition of inulin: physicochemical, sensory and technological characteristics. LWT Food Sci Technol 104:30–37

Hauly MCdO, Fuchs RHB, Prudencio-Ferreira SH (2005) Soymilk yogurt supplemented with fructooligosaccharides: probiotic properties and acceptance. Rev de Nutr 18(5):613–622

Karleskind D, Laye I, Halpin E, Morr CV (2010) Improving acid production in soy-based yogurt by adding cheese whey proteins and mineral salts. J Food Sci 56(4):999–1001

Li C, Song J, Kwok LY, Wang J, Dong Y, Yu H, Hou Q, Zhang H, Chen Y (2017) Influence of Lactobacillus plantarum on yogurt fermentation properties and subsequent changes during postfermentation storage. J Dairy Sci 100(4):2512–2525

Zaouche A, Loukil C, De Lagausie P, Peuchmaur H, Macry J, Fitoussi F, Bernasconi P, Bingen E, Cezard JP (2000) Effects of oral Saccharomyces boulardii on bacterial overgrowth, translocation, and intestinal adaptation after small-bowel resection in rats. Scand J Gastroenterol 35(2):160–165

Kokabian A, Daraei Garmakhany A, Jafarzadeh S, Aghajani N (2020) Incorporation of omega-3 fatty acid-rich grape seed oil in yoghurt: response surface optimization of physicochemical, textural, and sensory attributes during refrigerated storage. Food Sci Nutr 9(4):2345–2345. https://doi.org/10.1002/fsn3.1998

Behare PV, Singh R, Tomar SK, Nagpal R, Kumar M, Mohania D (2010) Effect of exopolysaccharide-producing strains of Streptococcus thermophilus on technological attributes of fat-free lassi. J Dairy Sci 93(7):2874–2879

Vimercati WC, Araujo CS, Macedo LL, Fonseca HC, Guimaraes JS, de Abreu LR, Pinto SM (2020) Physicochemical, rheological, microbiological and sensory properties of newly developed coffee flavored kefir. LWT Food Sci Technol 123:109069

Damin M, Alcântara M, Nunes A, Oliveira M (2009) Effects of milk supplementation with skim milk powder, whey protein concentrate and sodium caseinate on acidification kinetics, rheological properties and structure of nonfat stirred yogurt. LWT Food Sci Technol 42(10):1744–1750

Doğan M (2011) Rheological behaviour and physicochemical properties of kefir with honey. J Verbrauch Lebensm 6(3):327–332

Xia J, Zu Q, Yang A (2019) Allergenicity reduction and rheology property of Lactobacillus-fermented soymilk. J Sci Food Agric 99(15):6841–6849. https://doi.org/10.1002/jsfa.9969

Poliseli-Scopel FH, Gallardo-Chacón J-J, Juan B, Guamis B, Ferragut V (2013) Characterisation of volatile profile in soymilk treated by ultra high pressure homogenisation. Food Chem 141(3):2541–2548

McSweeney PLH, Sousa MJ (2000) Biochemical pathways for the production of flavour compounds in cheeses during ripening: A review. Lait 80(3):293–324

Clark S, Winter CK (2015) Diacetyl in foods: a review of safety and sensory characteristics. Compr Rev Food Sci Food Saf 14(5):634–643. https://doi.org/10.1111/1541-4337.12150

Achouri A, Boye JI, Zamani Y (2006) Identification of volatile compounds in soymilk using solid-phase microextraction-gas chromatography. Food Chem 99(4):759–766

Dan T, Wang D, Wu S, Jin R, Ren W, Sun T (2017) Profiles of volatile flavor compounds in milk fermented with different proportional combinations of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus. Molecules 22(10):1633

de Souza JV, Dias FS (2017) Protective, technological, and functional properties of select autochthonous lactic acid bacteria from goat dairy products. Curr Opin Food Sci 13:1–9

Liu J, Liu Y, Jia M, Kang X, Wang S, Sun H, Liu M, Wang A, Strappe P, Zhou Z (2021) Association of enriched metabolites profile with the corresponding volatile characteristics induced by rice yellowing process. Food Chem 349:129173

Lu Y, Song Y, Zhu J, Xu X, Pang B, Jin H, Jiang C, Liu Y, Shi J (2021) Potential application of CHS and 4CL genes from grape endophytic fungus in production of naringenin and resveratrol and the improvement of polyphenol profiles and flavour of wine. Food Chem 347:128972

Huang Y-y, Yu J-j, Zhou Q-y, Sun L-n, Liu D-m, Liang M-h (2020) Preparation of yogurt-flavored bases by mixed lactic acid bacteria with the addition of lipase. LWT Food Sci Technol 131:109577

do Amaral Santos CCA, da Silva Libeck B, Schwan RF (2014) Co-culture fermentation of peanut-soy milk for the development of a novel functional beverage. Int J Food Microbiol 186:32–41

Ahmad N, Li L, Yang X-Q, Ning Z-X, Randhawa MA (2008) Improvements in the flavour of soy cheese. Food Technol Biotechnol 46(3):252–261

Shi H, Zhang M, Wang W, Devahastin S (2020) Solid-state fermentation with probiotics and mixed yeast on properties of okara. Food Biosci 36:100610

Tang KX, Zhao CJ, Gänzle MG (2017) Effect of glutathione on the taste and texture of type I sourdough bread. J Agric Food Chem 65(21):4321–4328

Sabikun N, Bakhsh A, Rahman MS, Hwang YH, Joo ST (2021) Volatile and nonvolatile taste compounds and their correlation with umami and flavor characteristics of chicken nuggets added with milkfat and potato mash. Food Chem 343:128499

Liu CS, Ji WZ, Jiang HZ, Shi YH, He L, Gu ZF, Zhu ST (2021) Comparison of biochemical composition and non-volatile taste active compounds in raw, high hydrostatic pressure-treated and steamed oysters Crassostrea hongkongensis. Food Chem 344:128632

Bi S, Chen L, Sun Z, Wen Y, Xue Q, Xue C, Li Z, Sun C, Wei Z, Liu H (2021) Investigating influence of aquaculture seawater with different salinities on non-volatile taste-active compounds in Pacific oyster (Crassostrea gigas). J Food Meas Charact 15(2):2078–2087

Mateo J, Dominguez MC, Aguirrezabal MM, Zumalacarregui J (1996) Taste compounds in chorizo and their changes during ripening. Meat Sci 44(4):245–254. https://doi.org/10.1016/s0309-1740(96)00098-8

Gomes JJL, Duarte AM, Batista ASM, de Figueiredo RMF, de Sousa EP, de Souza EL, do Egypto RdCR (2013) Physicochemical and sensory properties of fermented dairy beverages made with goat’s milk, cow’s milk and a mixture of the two milks. LWT Food Sci Technol 54(1):18–24

Liu F, Chen Z, Shao J, Wang C, Zhan C (2017) Effect of fermentation on the peptide content, phenolics and antioxidant activity of defatted wheat germ. Food Biosci 20:141–148

Nemo R, Bacha K (2020) Microbial, physicochemical and proximate analysis of selected Ethiopian traditional fermented beverages. LWT Food Sci Technol 131:109713

Funding

This investigation was financially supported by the Open Fund of Guangdong Provincial Key Laboratory of Enterprises, China (grant number 2017B030302002) and the Science and Technology Program for People’s Livelihood of Guangzhou, China (grant number 201803010118).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Responsible Editor: Rosane Freitas Schwan

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Korma, S.A., Li, L., Ghamry, M. et al. Effect of co-fermentation system with isolated new yeasts on soymilk: microbiological, physicochemical, rheological, aromatic, and sensory characterizations. Braz J Microbiol 53, 1549–1564 (2022). https://doi.org/10.1007/s42770-022-00773-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42770-022-00773-7