Abstract

Despite available reports on phenolic composition and antioxidant capacity (AOC) of fresh plums and prunes, there is a scarcity of published knowledge on the antioxidants formed and/or released during the drying process in the literature. To evaluate the compounds participating in reducing capacity of prunes, we compared aqueous and methanol extracts of fresh plums, commercial prunes and home-made prunes prepared at different drying temperatures using an HPLC method with amperometric detection (HPLC-ECD). The prunes dried at high temperature (90 °C, 18 h) in kitchen or laboratory oven with restricted ventilation gave up to 3.3 times higher electrochemical capacity (EC) than fresh plums (dry matter; P. domestica cv. Domestica) in dependence on production protocol. Drying at 60 °C (low-temperature drying) for 18 h did not change the EC significantly. Yet, lower EC was found in commercial tenderized prunes with sorbate; they were by a factor of 1.1–8.2 lower in EC than the prepared low-temperature prunes. The principle responsible for the increase in EC in the prunes prepared at high temperatures is 2,3-dihydro-3,5-dihydroxy-6-methyl-(4H)-pyran-4-one (DDMP). It was not detected until 74 °C was set during isothermal 18 h drying or until 6 h of drying passed at 90ºC drying. The ultimate acceptable dwell-time for the preparation of conveniently eatable prunes dried at 90ºC under the conditions used was assessed to 12 h. The EC of plums and prunes as well as the role of DDMP was confirmed by the use of several methods for the assessment of AOC-DPPH• assay, β-carotene bleaching method, Oxipres test and Schaal oven test.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is generally accepted that a plant-based diet may reduce the risk of oxidative stress-related diseases. One of the reasons for the protective effects may be the quantity and quality of antioxidants in plants. Fruits and vegetables have attracted a great deal of attention as one of the best available sources of antioxidants with a view to their high intake. The consumption of plums and plum-derived products (cultivars of Prunus domestica and several other species) was 3–6 kg per capita and year during the last decade in the Czech Republic. Plum comprises about 9% of the total consumption in the group of temperate zone fruit and berries, and therefore, it is the second most frequent domestic fruit following apples [1]. Plums rank among the richest sources of antioxidants among common fruits, and they are approaching many berries with high antioxidant capacity (AOC) [2, 3]. The published data on AOC of plums vary often dramatically in the dependence of cultivar, ripeness and AOC methodology, especially the mechanism of antioxidant action measured. In their extensive study, Wu et al. found 62 mg Trolox equivalents/kg fruit as a mean value by the means of ORAC methods. Using a DPPH• assay, higher antiradical activity was found ranging from 205 to 518 mg ascorbic acid equivalents (AAE)/kg [4]. When a FRAP method was used, roughly two times higher values were determined [5]. Even higher antioxidant potential amounting 2,660–5,590 mg AAE/kg fruit (various cultivars) was reported by Kim et al. [6] using an ABTS•− method.

Analogous to many other fruits, the AOC of plums is usually closely correlated with the content of phenolic acids and flavonoids; the contribution of phenolic compounds to AOC is much greater than those of vitamin C and carotenoids [7]. The major phenolic compounds in plums are caffeoylquinic acid isomers, which account for 61–90% of total phenols [6–8]. Piga et al. [8] found 1.95 and 3.82 g kg−1 neochlorogenic acid and 0.58 and 0.54 g kg−1 chlorogenic acid (on dry matter basis) in Sugar and President cultivars, respectively. The concentration of the hydroxycinnamic acids in the pulp of d’Agen plums was found several times lower than in the exocarp [9]. Flavonols and flavan-3-ols, such as (+)-catechin, account for 2–3% and 4–8% of phenolics in plums, respectively [10, 11]. Anthocyanins, with cyanidin-3-O-rutinoside and peonidin-3-O-rutinoside as principal pigments, were found in the fresh plums accounting for 4–30% of phenolic compounds [8, 12]. However, many results on phenolic compounds in extractable fractions may be underestimated, since their bound forms are usually not taken into account. Vinson et al. [13] showed that about 30% of phenolic compounds in plums may occur in various conjugated forms.

Fresh plums are traditionally processed into a number of products with higher durability such as puree, plum sauce (povidla in Czech, Powidln in Austrian German) and prunes (dried plums). The quality of these products may be affected by the content of sugars and sugar alcohols in plums and by the chemical changes that occur during processing. The sugar content of plums varies within cultivars and the stage of ripeness. Forni et al. analyzed the sugar content of 13 cultivars of plums. Of the individual sugars, glucose and sucrose were always the main sugars (2–6%). The fructose content ranged from 0.76 to 3.6% (fresh weight) [14]. The average amount of glucose, fructose and sucrose is 3.5, 2.0 and 3.4%, respectively [15]. Glucitol occurs in a variable amount of 0.6–13.9% (fresh weight) [16].

Home-made prune making is a traditional activity, which has been performed in central Europe for centuries. Prunes are conventionally dried to 16–24% moisture content, which obviated any need of preservation. From the view of marketing, the product is rather tough and therefore is preferably conditioned (tenderized, re-hydrated) prior to packaging while assuring antimicrobial stability by the treatment with sorbic acid (potassium sorbate). Currently marketed prunes usually possess a water activity of 0.75 or greater, corresponding to 28–35% moisture, in accordance with prevailing law [17].

To reach the desired water activity in commercial as well as home-made prunes, plums are dehydrated in hot air, mostly at 40–90 °C for 12–36 h in 1–4 drying steps using various protocols (thermo-drying curves) and drying equipment. Air temperature and humidity are designed to prevent excessive browning and burnt flavor. The moisture diffusivity of the waxy skins of fresh plums can be improved by chemical pre-treatment. Plums dried at higher temperatures (≥70 °C) do not need any pre-treatment unlike those prepared at lower (40–60 °C) temperatures [18]. Several physical as well as chemical pre-treatments of plums for enhancing drying rate, preventing enzyme action and killing the spoilage organisms have been proposed and are occasionally used [19].

Although the phenolic pool plays a key role in the health-promoting action of plums, the pattern as well as concentration of phenolic compounds can be significantly changed during the production of prunes. The phenolic compounds of plums are modified particularly in the initial stage of drying. Chemical changes like hydrolysis and oxidation of phenolic compounds together with non-enzymatic browning reactions play a very important role in the final quality of prunes [8]. Many factors can affect the levels of phenolics so the amount found in one sample may not reflect the average level on the market. Donovan et al. [10] reported the total phenolic concentration of 1.84 ± 0.39 g kg−1 pitted prunes. The range of 1.6–1.9 g kg−1 in edible fruit portion of 21% moisture with prevailing chlorogenic and cryptochlorogenic acids was found by Nakatani et al. [20]. Hydroxycinnamates made up 98% of the phenolic extractable and identifiable material, and neochlorogenic acid generally accounted for about two-thirds of the identified phenolics in commercial prunes. Flavonols, predominantly rutin, accounted for about 2% of total phenolic compounds and were the only flavonoids found in the prune samples. Prunes are usually characterized by the absence of anthocyanins. Similarly, the levels of flavan-3-ols, predominating in the plum skin, significantly decrease or totally disappear during the dehydration process [9].

Despite the losses in phenolic compounds during the drying process, prunes are frequently considered to possess extraordinary high AOC. Pellegrini et al. [21] concluded that among dried fruits, prunes exhibited the highest AOC. In other extensive study [22], prunes were classified into the top 50 food products highest in antioxidant concentration. In addition to the AOC, many other biological effects rank prunes among functional foods. The positive effects linked with prune consumption were summarized by Stacewicz-Sapuntzakis et al. [7]. Though prunes are often mentioned as more functional food than plums, published data usually advert to comparable or lower AOC than it is in the parent plums. Wu et al. [4] found 86 mg Trolox equivalents/kg as a mean value for prunes (32.7% moisture), which was nearly three times higher than the ORAC values for dates, figs and raisins. However, when based on dry matter, the total ORAC value was more than three times lower in prunes in comparison with the fresh plums. The description of marked AOC increase during a drying process was done only by Piga and Del Caro group [8, 23], who investigated the antiradical activity of the prunes prepared by high-temperature drying. In spite of numerous considerations on the role of the Maillard reaction, no compound really responsible for the marked increase in AOC has been found.

The main objective of our study was to measure the antioxidant capacity of prunes prepared by high-temperature drying processes and to compare their reducing power with that of prunes dried at lower temperatures and the tenderized prunes marketed with the addition of sorbate. The fundamental task was to find a principle responsible for the expected increase in AOC as well as optimum conditions for the formation of the induced active Maillard products.

Experimental section

Reagents

Butylated hydroxyanisole (BHA) and Tween 20 were obtained from Sigma (USA). Linoleic acid, 2,2-diphenyl-1-picrylhydrazyl radical, d-glucose, Trolox and 4-hydroxy-5-methyl-3-(2H)-furanone (norfuraneol) were purchased from Sigma–Aldrich (Germany). β-Carotene, 5-hydroxymethylfuran-2-carbaldehyde and γ-aminobutyric acid were obtained from Fluka (Switzerland). Sodium chloride, chloroform and methanol were obtained from Penta (Czech Republic). Potassium dihydrogen phosphate and sodium hydrogen phosphate were purchased from Lachema (Czech Republic). All the reagents were of analytical grade. Acetonitrile (HPLC grade) was purchased from Merck (Germany).

Commercial packaged prunes

Five pitted commercial prune samples of d’Agen variety (Prunus domestica, cv. d’Agen), the main prune-making variety used in many countries, and five samples of unknown variety were analyzed (country of origin—California, China, the Czech Republic and Greece). Three prunes were randomly selected from one freshly opened package and lyophilized; a 10.0 g portion was then homogenized in 20 mL of water or methanol.

Preparation of plum/prune samples

Slightly overripe plums of typical regional cultivar (Prunus domestica, cv. Domestica) were kept in sealed plastic bags purged with nitrogen and refrigerated at 4 ± 1 °C prior the drying. The weight of fresh plums was 9.6–14.3 g (from a set of 31 plums), median 11.4 g. For the analysis of fresh fruit, plums were pitted and lyophilized.

Prunes were prepared as follows. Prior to drying run, the fresh plums were in some cases pre-dried for 24 h at 30 ± 2 °C. Plums were pitted (not halved) to minimize the damage to the skin. The pitted plums were spread on a steel trays in a single layer and loaded into a drying oven. Drying was carried out in the range of 60–120 °C according to a particular protocol and controlled to ±1 °C. The fruit was dried for 1–20 h in a pre-heated laboratory drying oven with restricted ventilation that mimics a conventional kitchen oven. The dried plums were packed in plastic bags and kept in a freezer (−18 °C) before analysis. To evaluate the sample pre-treatment, plums were peeled and/or mixed before drying in addition to the regular procedure.

Three different drying procedures were used:

-

A—low-temperature drying at 60 °C for 18 h,

-

B—moderate-temperature drying at 75 °C; after 6 h, the temperature was set to 60 °C until the end of the process (18 h in total),

-

C—high-temperature drying at 90ºC for 18 h.

After drying, the prunes were ground and the aliquots extracted three times with water and then three times with methanol for 3 min. The extracts were fractionated by ultrafiltration (cellulose membrane, 1,000 Da).

Plum sauce (Damson cheese)

The amount of 2.5 kg of pitted plums was put into a saucepan, and 200 mL of table vinegar and 500 g of sucrose were added and mixed. The mixture was kept 24 h at room temperature. Then, the mixture was cooked without mixing for a period 5 h. Subsequently, the mixture was homogenized and bottled to fruit jar. Prepared sauce was stored at room temperature before analysis.

Amperometric HPLC method (HPLC-ECD)

To determine electrochemical capacity (EC), the prepared extracts and ultrafiltrates were diluted with the mobile phase (1:1–1:9, v/v) and analyzed (Atlantis C18, 150 × 3.9 mm, 3 μm, Waters, USA) using binary gradient elution-phosphate buffer pH 6.5/acetonitrile (Merck, Germany) with 5 mM NaCl (Lachema, Czech Republic), flow = 0.7 mL min−1-with serial connection of photodiode array (PDA, 996, Waters) and electrochemical detectors (ECD, 2465, Waters). The ECD was equipped with a flow cell, consisting of a gold electrode, operating at the potential of +0.8 V, and a HyREF reference electrode. Direct current of the separated sample components that are oxidizable at the fixed potential was measured. In the mode of flow injection analysis (FIA), the above HPLC system without the column, and a mixture of phosphate buffer pH 6.5/acetonitrile (9:1, v/v) with 5 mM NaCl as the electrolyte, was used.

In contrast to the common antioxidant references (such as l-ascorbic acid, Trolox and gallic acid), the elution bands of BHA did not co-elute with any electrochemically active compounds of the samples. Therefore, the response of the electrochemically active substances (EC value) was finally expressed on the basis of response of butylated hydroxyanisole as BHA equivalents (BHAE) in g of BHA per 1 kg of dry sample weight.

Though commercially unavailable DDMP was synthesized [36], the final preparation was only slightly over 90% of UV–Vis (190–600 nm) purity. Therefore, norfuraneol, a pentose-derived analogue of DDMP, possessing similar electrochemical properties-half-wave potential was +0.33 V and +0.30 V for DDMP and norfuraneol, respectively-was preferred as a calibration standard for the quantitation of DDMP. Electrochemically inactive (at +0.8 V) 5-hydroxymethylfuran-2-carbaldehyde was quantified spectrophotometrically at 283 nm using an HPLC–PDA method.

GC–MS method

GC–MS (electron ionization) analysis was carried out on an Agilent Technologies 6890 N gas chromatograph (Agilent Technologies, Palo Alto, CA, USA) equipped with a Series 5973 quadrupole mass selective detector Agilent 5973 MSD (70 eV) and data processing system (MSD ChemStation, G1701CA version C.00.00). The analysis was performed on a capillary column HP-5 (30 m × 0.25 mm i.d., 0.25 μm thickness, Hewlett-Packard). The injector was held at 250 °C (splitless), and the column temperature was programmed from 100 °C (1 min) to 180 °C (1 min) at a rate of 5 °C/min and then to 250 °C (20 min) at a rate of 40 °C/min. Helium at a flow rate of 0.7 mL min−1 was used as the carrier gas, and 1 μl sample was injected.

DPPH• assay

The procedure followed the method of Brand-Williams et al. with slight modifications [24]. The volume of 3 mL of DPPH• (2,2-diphenyl-1-picrylhydrazyl radical) solution in methanol (0.1 mmol L−1) was added to 20 μl of aqueous (methanol) extract and 20 μl of methanol (water). The decrease in absorbance was determined at 515 nm at 0 and 15 min and then every 30 min up to 240 min. Antioxidant capacity of the samples as determined by the DPPH• assay-and also by the other methods for the determination of AOC-was expressed on a dry weight basis as g BHAE/kg. If Trolox equivalents (in g/kg) for the expression of AOC at the DPPH• assay were used, the final values would be by a factor of 1.22 lower than the BHAE values.

β-Carotene bleaching method

The β-carotene solution (2 mL) in chloroform (3 mg mL−1) was put into the 100-mL flask. Chloroform was removed on a rotary evaporator at 40 °C; 0.2 g of Tween 20, 0.02 g of linoleic acid and 50 mL of distilled water were added to the residue, and the solution was vigorously agitated to form a stable emulsion. The volume of 130 μL of aqueous (methanol) extracts of plums and prunes and 130 μL of methanol (water) was added to the aliquot of 3.25 mL of the prepared emulsion. The absorbance was measured spectrophotometrically (Varian Cary 100 bio) at 470 nm every 15 min up to 240 min.

Oxipres test

The procedure followed the method of Trojáková et al. [25]. Briefly, the amount of 4–5 g of lard with dissolved samples (concentration 0.02%, w/w) was weighed to a glass vessel. This vessel was placed into the Oxipres device (0.5 MPa, 100 °C, Mikrolab Aarhus, Denmark). The induction period was determined, and protection factor (PF) was calculated.

Schaal oven test

The amount of 25 g of fat (rape oil) with dissolved samples (concentration 0.02%, w/w) was weighed to a glass vessel. The content of glass vessel was homogenized and evaporated using the vacuum evaporator. The vessel was placed in a drying oven (60 °C). The induction period was determined, and protection factor (PF) was calculated.

Moisture determination

Determination of the moisture content of dried fruits was accomplished gravimetrically by drying at a temperature of 103 °C (±2 °C) in a temperature-controlled oven for 6 h.

Statistical analysis

The data were expressed as the mean of at least three repetitions, unless otherwise stated; confidence intervals (α = 0.05) were used for the evaluation of the measurement uncertainty.

Results and discussion

Commercial prunes

In a series of 10 prunes (containing sorbate) obtained from the local market, we found marked differences in electrochemical capacity (EC) ranging over an order of magnitude. Using the amperometric HPLC method (HPLC-ECD), the EC of these prunes ranged from 0.29 to 2.2 g BHA equivalents (BHAE)/kg (dry matter basis) for the aqueous extracts and from 0.19 to 1.4 g BHAE/kg for the methanol ones (Table 1). Neither aqueous nor methanol extract of commercial prunes contained any quantifiable Maillard reaction product possessing electrochemical activity (EA). The EC values of the unlabeled prunes (BHAE range 0.29–1.4 g kg−1 in aqueous extracts) did not differ significantly (α = 0.05) from those of the prunes produced from d’Agen plums (0.39–2.2 g kg−1). Due to the broad BHAE range for d’Agen prunes, the plum variety cannot be referred to as the significant parameter determining EC. In addition to other plum qualities, the differences in EC could be caused by a great variability in the parameters of drying process and conditioning; different storage conditions could be an important factor too.

Fresh plums

To identify changes that result from a drying of plums, freshly harvested unprocessed plums (Prunus domestica, cv. Domestica) were analyzed for comparison. Rop et al. [26] showed that this typical regional cultivar had the highest total phenolic content (4.95 mg gallic acid equivalents/g, fresh matter) among regional as well as the most frequent traditional commercial cultivars cultivated also in other European regions. The EC of plums used for the laboratory and domestic preparation of prunes (Table 2) was close to the most active commercial prunes analyzed if their aqueous extracts were compared (Table 1). As for the EC of methanol extracts, the fresh plums were superior to commercial prunes markedly. The dry matter of the fresh plums ranged from 20.7 to 24.6% (n = 7) with median 21.6%. The most significant EA compound was neochlorogenic acid possessing 46 ± 5% of the EC in the methanol extract of fresh plums.

Home-made and laboratory prepared prunes

The plums were used for the preparation of prunes using common kitchen or laboratory oven with restricted air circulation, which is different from common practice in commercial dryers. Because of variations in air circulation, drying in conventional ovens could be up to twice as long as in dehydrators. The dehydration rate fundamentally depends on air humidity; using 80 °C for 18 h, roughly 14% difference in final weight loss was found comparing low and high humidity conditions [27].

To simulate the preparation of prunes by domestic procedures, three different drying regimes were chosen from a broad range of conventional recipes: isothermal drying for 18 h at 60 °C (low temperature; procedure A) and 90 °C (high temperature; procedure C), and two-stage drying (75 °C for 6 h, 60 °C for 12 h; medium temperature; procedure B). While the EC of prunes dried at 60 °C for 18 h was not significantly higher than that of fresh plums, the drying in laboratory oven starting at 75 °C resulted in a slight statistically significant (α = 0.05) increase (Table 2). The increase in EC could generally be the result of three factors: (1) it is known that polyphenols in an intermediate stage of oxidation have temporary greater activity than initially; (2) some phenolic compounds can be released from the insoluble matrix; (3) new compounds with antioxidant activity are formed, probably due to the Maillard reaction. Comparing to the procedure A, the slightly higher EC achieved at medium-temperature drying (B) can be attributed also to lower activity of polyphenoloxidases (PPO) that convert original phenolic compounds to less active products. In methanol extract of the prunes achieved by the procedure B, neochlorogenic acid contributed to the EC by 39%, compared with only 35% when the procedure A was applied. No EA Maillard products and intermediates were identified in the prunes prepared by the procedures A and B.

In contrast to the drying at low and moderate temperatures, the high-temperature treatment (C) caused a significant increase in EC in the dried plums (Table 2). The results are in accordance with the findings of Piga et al. using a DPPH• assay, who described AOC in the prunes dried at 60 °C as comparable with that of fresh plums [8]. When an 85 °C/70 °C drying programme was used, however, the authors found 1.8–2.5 times higher AOC (based on dry matter). When we re-dried the samples of d’Agen commercial prunes under the high-temperature conditions (C), we found the EC level similar to that of the prunes prepared by the procedure C in the laboratory (Table 1). A series of the plum drying in a common kitchen oven gave results that were very similar to those from laboratory experiments carried out under the same drying conditions (Table 2).

In contrast to the fresh plums, the aqueous extracts of both laboratory prepared and commercial dried plums showed significantly higher EC than the methanol ones (Tables 1, 2). It indicates the formation/release of more polar extractable compounds and/or the loss of less polar active compounds during the drying process. Moreover, our finding clearly shows that the choice of extraction solvent is crucial when the AOC of fresh and dried fruits is compared.

The EC of differently processed and treated plums and prunes (dried peeled; dried crushed; heated in water, all at 90 °C for 18 h; stewed) was also evaluated (Table 2). The activity of aqueous extracts of both peeled and crushed plums accounted for about 80% EC of whole pitted prunes, which may be caused by faster transformation of EA compounds, differences in water activity and/or increased volatilization during the drying process. The sample of plum sauce (povidla) possessed significantly lower EC than the fresh plums.

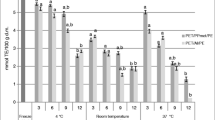

Using isothermal drying in the temperature range of 60–120 °C (Fig. 1), we monitored the effect of temperature on the formation of process-induced reducing compounds. When dried for 18 h, the prunes achieved the maximum yield of EC at 90 °C. The drying temperatures above 90 °C were evidently not suitable for prune preparation due to rapid dehydration to the point of brittleness and undesirable changes in their flavor profile. As shown by Price et al., drying of plums at ≥70 °C results in the disruption of the waxy layer structure and formation of skin fractures that increase the skin permeability and rapid depletion of water near the surface [18]. There is, though, a difference in the controlling mechanisms for moisture loss during the drying process between the setting of 60 °C and ≥70 °C.

The development of AOC in drying plums is strongly temperature dependent. The changes of EC were monitored during 20 h at 60 and 90 °C, respectively (Fig. 2) and were similar for both aqueous and methanol extracts. At 60 °C, almost immediate temporary increase in EA compounds extractable by water occurred; the EC then decreased after 2 h of drying and after about 6 h drying it reached approximately the EC of fresh plums. In the methanol extract, the initial increase was not so marked, probably due to larger amount of compounds degradable by PPO. The decrease in EC of high-temperature dried prunes during the first 2 h is also ascribable to the degradation of hydroxycinnamic acids caused by the residual PPO activity, though only moderate activity was described for temperatures higher than 75 °C [9]. However, Price et al. [18] showed that the surface temperature of plums increased within the first 30 min of drying to about 5–8 °C below the set drying temperature. Moreover, the actual stable temperature in plums during constant period has been assessed to about 75 °C when dried at 90 °C and in the low humidity environment.

Continued drying at 90 °C causes the rise of EC. When the maximum activity is reached after 16 h, the EC falls down again as the transformation of EA products to less active compounds occurs. In addition to the predominant formation of novel EA products, we found also marked decrease in the both major hydroxycinnamic acids in final stages of high-temperature drying (90 °C). Neochlorogenic acid content decreased to about an third of the original content in fresh plums after 16 h. This is in good accordance with the results of Kayano et al. [28] who estimated the contribution of caffeoylquinic acids to the AOC of high-temperature dried prunes to 28% on the basis of their ORAC values in 90% ethanol extract. On the other hand, Piga et al. [8] found no significant changes in the amounts of these acids during drying at 85/70 °C. Although dihydroxycinnamic acids are decreasingly degraded by enzymes as the drying temperature rises, at high-temperature drying, however, they may undergo non-enzymatic transformations leading to less active or less extractable and detectable products. Though not identified in this work, these compounds may be a result of thermal and oxidative non-enzymatic reactions of phenolic compounds that yield various quinones, lactones, oligomers, aldehydes, phenolic–Maillard adducts, etc. [29]. Kayano et al. [28] speculated that the AOC increase could be caused by conjugated phenolic antioxidants. Moreover, free cinnamates were found in prunes due to the ester hydrolysis, which may be acid catalyzed or catalyzed by esterases naturally occurring in plums [8]. In the extracts of prunes processed at 90 °C, we observed also trace amounts of p-coumaric acid. In addition to the major phenolic components of prunes, Fang et al. [30] identified 40 minor compounds, including coumaroyl-, trihydroxycinnamoyl-, and feruloylquinic acid isomers, caffeoylshikimic acids, esters formed from two caffeic acids and one quinic acid together with simple phenolic acids and their glycosides. Two lignin glucosides and several compounds derived from abscisic acid were also isolated from the antioxidative ethanol extract of prunes [31]. 2-(5-Hydroxymethyl-2′,5′-dioxo-2′,3′,4′,5′-tetrahydro-1′H-1,3′-bipyrrole)carbaldehyde and 4-amino-4-carboxychroman-2-one, acting probably as synergists, were identified as components of the non-phenol antioxidant fraction in prunes [32]. However, these active products are really minor components, and the markedly increased AOC cannot be explained by their formation.

Piga et al. [8] found a relatively close relation between AOC and the concentration of the Maillard reaction marker 5-hydroxymethylfuran-2-carbaldehyde (HMF). However, HMF does not show antioxidant properties [10]. Neither soluble melanoidins cannot be the principle, considering our finding that the EC of any extract from prunes is concentrated in low-molecular fraction after ultrafiltration with cellulose membrane (1,000 Da) amounting to 75–98% of the EC.

The main induced EA product

To find the compound(s) responsible for the increased reducing power, an amperometric determination of relative EA for individual reductants in prune extracts after an HPLC separation was chosen. When using this procedure, the major active low-molecular product found in the high-temperature dried prunes, which did not occur in the extracts of fresh plums, was 2,3-dihydro-3,5-dihydroxy-6-methyl-(4H)-pyran-4-one (DDMP, Fig. 3). The identity of DDMP was confirmed by GC–MS (EI) analysis of the elution band collected and concentrated from the HPLC system. DDMP was responsible for up to 74% of AOC in the extracts of prunes (90 °C, 16 h). It is the typical transformation product of hexoses within the Maillard reaction, formed most probably via 1-deoxy-d-erythro-hexo-2,3-diulose [33]. The half-wave redox potential of DDMP under the conditions of the used method was +0.33 V, and its concentration in the aqueous extract of high-temperature dried prunes (C) was 0.84 ± 0.08 g kg−1 (dry matter). Thus, the marked increase in the EC of high-temperature dried prunes is attributed to the Maillard reaction product.

As a plum dries, it becomes firmer, eventually sticky. The prunes obtained in several studies [8, 27, 34] using high-temperature drying (~90 °C) after a long dwell-time in a dehydrator were not described in relation to the residual moisture and overall eating quality. However, over-dried prunes (≤18% moisture) are not acceptable for direct consumption, particularly when dried at high temperatures. Such products have to be further processed by re-hydration or used in other prune products. The maximum acceptable dwell-time for the preparation of still conveniently eatable prunes at 90 °C under the conditions used was assessed to 12 h. In this case, the EC was higher by a factor of 2.2 than that of the fresh plums, with DDMP accounting for 43% of the total EC. We also found minimum condition criteria for the formation of DDMP in the prunes. DDMP was assessed to be detected only when the drying temperature was set to 74 °C for 18 h. Using 90 °C, the formation of DDMP was not detected until 6 h of drying. DDMP is the main EA product in the last period of the high-temperature drying (74% EC in 16 h). HMF, better detectable using UV detection, appeared in high-temperature dried prunes roughly at the same time as DDMP, though following different formation pathway. The concentration of HMF in high-temperature dried prunes (90 °C, 16 h) was 0.6 ± 0.1 g kg−1. Low pH promotes heat-induced hexose transformation to HMF, while DDMP formation is less pH dependent [33]; thus, the formation of DDMP is more favoured than that of HMF during the processing of less acidic, i.e. more ripe plums.

Although the stability of DDMP in solutions is not high [35, 36], only insignificant decrease in DDMP (only to 94 ± 12%) was found in the high-temperature dried plums (90 °C, 12 h) during one-year storage in tightly closed jars at room temperature. It is probably due to the binding of DDMP to prune macromolecules and the limited access of oxygen, but it may be also due to progressive Maillard reaction resulting in its formation. The latter possibility was assumed by Del Caro et al. [23] who observed an increase in AOC by a factor of 1.5–2 in dependence of prune variety during one-year storage at 50% relative humidity.

Other methods for the determination of AOC

The antioxidant pattern obtained using HPLC-ECD is based on redox potential, a thermodynamic variable that provides no information on a redox reaction rate. Thus, the EC values make only prediction of overall antioxidant potency in food and food-related systems. The employment of a set of specific assays covering different mechanisms of action is required for the true AOC assessment. The tests we used here are assays for radical scavenging activity in various media and assays that test the ability to inhibit lipid oxidation under accelerated conditions. The AOC of aqueous and methanol extracts of fresh plums and prunes (90 °C, 18 h) was evaluated using β-carotene bleaching method in emulsion (o/w), DPPH• assay in aqueous–methanol environment, the Oxipres test in lard and the Schaal test in plant oil. Using a DPPH radical assay, we found in high-temperature dried prunes (procedure C) by a factor of 2.8 (1.7) higher BHAE values than in aqueous (methanol) extracts of fresh plums (Table 3). Using β-carotene bleaching method, almost the same AOC was found in both aqueous and methanol extracts of dried plums, being by a factor of 4.4 (3.0) higher than those of fresh plums. The direct assays using radical scavenging principle were compared to the indirect methods based on the inhibition of lipid oxidation under accelerated conditions. Using the Oxipres test (100 °C), we observed that a complete thermal degradation of the natural plum antioxidants extractable to methanol proceeded. In prunes, the induced/released products in both aqueous and methanol extracts showed better carry-through effect, though much lower than BHA. The highest BHAE values of plum and prune extracts were found in the Schaal test (60 °C), probably due to more polar character of the active compounds in comparison with BHA, illustrating well the polar paradox. Though no correlations were carried out, the comparison of the AOC values for plums and prunes obtained from all the tested methods using different reaction media and mechanism of antioxidant action revealed similar behavior. Therefore, DDMP may be a principle of not only electrochemical capacity but also general AOC of the prunes prepared by high-temperature drying.

Conclusion

When more frequently used mild drying regimes (60 °C) are used, the electrochemical capacity (EC) of prunes does not significantly differ from that of fresh plums. Moreover, the pre-drying of plums at 30–40 °C can slightly lower the level of naturally occurring phenolic antioxidants. On the other hand, the EC of high-temperature (>75 °C) dried prunes increases markedly due to the Maillard reaction. The principal reducing Maillard compound formed is 2,3-dihydro-3,5-dihydroxy-6-methyl-(4H)-pyran-4-one (DDMP). The prunes that are still acceptable to consumer possess more than double EC in comparison with the parent plums. Therefore, the choice of proper processing procedure can lead to improvements in the functionality and health-promoting capacity of prunes.

References

Czech Statistical Office (2010). Consumption of food, beverages, and cigarettes in the Czech Republic in 2001–2009. Available at: http://www.czso.cz/csu/2010edicniplan.nsf/engp/3004-10. Accessed Jan 13, 2011

Carlsen MH, Halvorsen BL, Holte K, Bohn SK, Dragland S, Sampson L, Willey C, Senoo H, Umezono Y, Sanada C, Barikmo I, Berhe N, Willet WC, Phillips KM, Jacobs DR, Blomhoff R (2010) The total antioxidant content of more than 3100 foods, beverages, spices, herbs and supplements used worldwide. Nutr J 9:3

Wang H, Cao G, Pryor RL (1996) Total antioxidant capacity of fruits. J Agric Food Chem 44:701–705

Wu X, Beecher GR, Holden JM, Haytowicz DB, Gebhardt SE, Prior RL (2004) Lipophilic and hydrophilic antioxidant capacities of common foods in the United States. J Agric Food Chem 52:4026–4037

Gil MI, Tomás-Barberán FA, Hess-Pierce B, Kader AA (2002) Antioxidant capacities, phenolic compounds, carotenoids, and vitamin C contents of nectarine, peach, and plum cultivars from California. J Agric Food Chem 50:4976–4982

Kim DO, Chun OK, Kim YJ, Moon HY, Lee CY (2003) Quantification of polyphenolics and their antioxidant capacity in fresh plums. J Agric Food Chem 51:6509–6515

Stacewicz-Sapuntzakis M, Bowen PE, Hussain EA, Damayanti-Wood BI, Farnsworth NR (2001) Chemical composition and potential health effects of prunes: a functional food? Crit Rev Food Sci 41:251–286

Piga A, Del Caro A, Corda G (2003) From plums to prunes: influence of drying parameters on polyphenols and antioxidant activity. J Agric Food Chem 51:3675–3681

Raynal J, Moutounet M, Souquet JM (1989) Intervention of phenolic compounds in plum technology. 1. Changes during drying. J Agric Food Chem 37:1046–1050

Donovan JL, Meyer AS, Waterhouse AL (1998) Phenolic composition and antioxidant activity of prunes and prune juice (Prunus domestica). J Agric Food Chem 46:1247–1252

Hennning W, Herrmann K (1980) Flavonol glycosides of plums (Prunus domestica and Prunus salicina). Phenolics of fruits. Part 12. Z Lebensm Unters Forsch 171:111–118

Wu X, Prior RL (2005) Systematic identification and characterization of anthocyanins by HPLC-ESI-MS/MS in common foods in the United States: fruits and berries. J Agric Food Chem 53:2589–2599

Vinson JA, Su X, Zubik L, Bose P (2001) Phenol antioxidant quantity and quality in foods: fruits. J Agric Food Chem 49:5315–5321

Forni E, Erba ML, Maestrelli A, Polesello A (1992) Sorbitol and free sugar contents in plums. Food Chem 44:269–275

Belitz H-D, Grosch W, Schieberle P (2004) Food Chemistry, 3rd revised English edition. Springer, Berlin, 817

Velíšek J, Cejpek K (2008) Biosynthesis of food components. OSSIS Tábor, p 140

UNECE standard DDP-07 concerning the marketing and commercial quality control of prunes (2003) United Nations, New York and Geneva

Price WE, Sabarez HT, Storey R, Back PJ (2000) Role of the waxy skin layer in moisture loss during dehydration of prunes. J Agric Food Chem 48:4193–4198

Di Matteo M, Cinquanta L, Galiero G, Crescitelli S (2002) Physical pre-treatment of plums (Prunus domestica). Part 1. Modelling the kinetics of drying. Food Chem 79:227–232

Nakatani N, Kayano S, Kikuzaki H, Sumino K, Katagiri K, Mitani T (2000) Identification, determination and antioxidative activities of chlorogenic acid isomers in prune (Prunus domestica L.). J Agric Food Chem 48:5512–5516

Pellegrini N, Serafini M, Salvatore S, Del Rio D, Bianchi M, Brighenti F (2006) Total antioxidant capacity in spices, dried fruits, nuts, pulses, cereals and sweets consumed in Italy assessed by three different in vitro assays. Mol Nutr Food Res 50:1030–1038

Halvorsen BL, Carlsen MH, Phillips KM, Bohn Holte K, Jacobs DR Jr, Blomhoff R (2006) Content of redox active compounds (i.e., antioxidants) in foods consumed in the United States. Am J Clin Nutr 84:95–135

Del Caro A, Piga A, Pinna I, Agabbio M (2004) The effect of storage on polyphenolic content, antioxidant activity and ascorbic acid of prunes. J Agric Food Chem 52:4780–4784

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of free radical method to evaluate antioxidant activity. Lebensm Wiss Technol 28:25–30

Trojáková L, Réblová Z, Pokorný J (1999) Determination of the oxidative stability of fats and oils using the Oxipres apparatus. Czech J Food Sci 17:68–72

Rop O, Jurikova T, Mlcek J, Kramarova D, Sengee Z (2009) Antioxidant activity and selected utritional values of plums (Prunus domestica L.) typical of the White Carpathian Mountains. Sci Hortic 122:545–549

Sabarez HT, Price WE (1999) Prune dehydration: kinetic studies and modelling. J Food Eng 42:167–172

Kayano S, Yamada NF, Suzuki T, Ikami T, Shioaki K, Kikutaki H, Mitani T, Nakatani N (2003) Quantitative evaluation of antioxidant components in prunes (Prunus domestica L.). J Agric Food Chem 51:1480–1485

Jiang D, Peterson DG (2010) Role of hydroxycinnamic acids in food flavour: a brief overview. Phytochem Rev 9:187–193

Fang N, Yu S, Prior RL (2002) LC/MS/MS characterization of phenolic constituents in dried plums. J Agric Food Chem 50:3579–3585

Kikuzaki H, Kakyano S, Fulutsuka N, Aoki A, Kasamatsu K, Yamasaki Y, Mitani D, Nakatani N (2004) Abscisic acid related compounds and lignans in prunes (Prunus domestica L.) and their oxygen radical absorbance capacity (ORAC). J Agric Food Chem 52:344–349

Kayano S, Kikuzaki H, Fukutsuka N, Mitani T, Nakatani N (2002) Antioxidant activity of prune (Prunus domestica L.) constituents and a new synergist. J Agric Food Chem 50:3708–3712

Nursten H (2005) The Maillard reaction: chemistry, biochemistry and implications. RSC, Cambridge

Wilford LG, Sabarez HT, Price WE (1997) Kinetics of carbohydrate change during dehydration of d’Agen prunes. Food Chem 59:149–155

Konečný M, Cejpek K, Čechovská L, Velíšek J (2009) Transformation pathways of reductones in the advanced Maillard reaction. Czech J Food Sci 27:149–152

Kim MO, Baltes W (1996) On the role of 2,3-dihydro-3, 5-dihydroxy-6-methyl-4(H)-pyran-4-one in the Maillard reaction. J Agric Food Chem 44:282–289

Acknowledgments

This work was partially supported by the research grant MSM 6046137305 of the Czech Ministry of Education, Youth and Sports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Čechovská, L., Cejpek, K., Konečný, M. et al. On the role of 2,3-dihydro-3,5-dihydroxy-6-methyl-(4H)-pyran-4-one in antioxidant capacity of prunes. Eur Food Res Technol 233, 367–376 (2011). https://doi.org/10.1007/s00217-011-1527-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-011-1527-4