Abstract

As rich in polyunsaturated fatty acid (PUFA), sea urchin gonad could be used as a potential resource of such type ingredients. In the present study, lipid was extracted from sea urchin (Strongylocentrotus nudus) gonad, without using organic solvent but using an enzyme-assisted aqueous method and a supercritical carbon dioxide (SC-CO2) method. The yield of lipid extracted was calculated in comparison with the soxhlet extraction using ethyl ether as solvent. The results showed that enzyme-assisted aqueous extraction allowed recovering 82.0 ± 2.1, 76.0 ± 2.3, 72.9 ± 3.6, and 61.5 ± 1.6% of sea urchin gonad lipid from the sample hydrolyzed by papain, neutral protease, alkaline protease, and trypsin, respectively. Meanwhile, a lipid yield of 53.7 ± 2.6% was achieved by SC-CO2 extraction. The lipid obtained was divided into unsaponifiable (sterol) and fatty acid, and analyzed by GC–MS. Results demonstrated that the compositions of sterol and fatty acid were very similar for samples extracted by different methods. PUFA was the chief component which accounts for approximately 35% of the total fatty acid.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sea urchin belongs to the marine invertebrate Echinoidea live on the ocean floor. To date more than 800 species of sea urchin have been found. Gonad, the edible portion of sea urchin, accounts for approximately 10% of the total weight [1]. It is half-moon shaped, yellow-orange in color, and chiefly composed of moisture, protein, sugar, and lipid [2]. With distinctive aroma and good taste, sea urchin gonad is a kind of popular seafood in many countries. In recent years, the nutritional and medicinal values of sea urchin gonad have drawn increasing attention. It was reported that sea urchin gonad contained high content of carotenoids with bioactivity of quenching of reactive oxygen species (ROS) and other excited-state oxidants [3]. In addition, sea urchin gonad is a good protein resource with nutritive values similar to casein [4].

Lipid is one of the major nutrient compounds found in sea urchin gonad. So far the fatty acid composition of gonad from sea urchin Strongylocentrotus droebachiensis [5], Paracentrotus lividus [6], and Psammechinus miliaris [7] has been reported. These studies all revealed that PUFA account for approximately 40% of the total sea urchin gonad fatty acid. To utilize sea urchin gonad lipid, effective extraction methods are required. Solvent extraction is a common method for extraction of lipids from raw materials. However, the application of the method can produce organic solvent emission and lead to environmental pollution. In recent years, enzyme-assisted aqueous method and SC-CO2 method have received increasing attention as two important alternatives to conventional methods. In environmental aspects, both the methods show potential advantages [8, 9].

Purple sea urchin, Strongylocentrotus nudus, is one of the most popular edible species in China and Japan, and is plentiful on the coasts of Dalian (Huang-Bo Sea). In the present study, the lipid was extracted from Strongylocentrotus nudus gonad using enzyme-assisted aqueous method and SC-CO2 method.

Materials and methods

Material and chemicals

Sea urchin (Strongylocentrotus nudus) was collected from Yellow sea, China, from May to August, in 2008. After dissection, the fresh gonad tissue was collected, homogenized, and freeze-dried, and the dried powder was stored at −20 °C until use.

Alkaline protease (Alc, EC 3.4.21.62) was purchased from Hua-wei Biological High-tech Co. (Meishan, Sichuan, China). Neutral protease (Neu, EC 3.4.24.28) was purchased from Pangbo Biological Engineering Co. (Nanning, Guangxi, China). Trypsin (Try, EC 3.4.21.4) was purchased from Sanland Chemicals Co. (Xiamen, Fujian, China). Papain (Pap, EC 3.4.22.2) was purchased from Sangon Biological Engineering Technology & Services Co. (Shanghai, China). All other chemicals and solvents used in this study were of analytical or HPLC grade.

Determination of chemical composition

Moisture, ash content, and crude protein were determined according to AOAC methods as 952.08, 938.08, and 981.10, respectively [10]. Total sugars were determined by the phenol–sulfuric acid method, using Glc as the standard [11]. All experiments were carried out in triplicate and presented as means ± standard deviations (n = 3).

Determination of hydrolysis degree

The hydrolysis degree (DH) was defined as the percent ratio of the number of peptide bonds cleaved to the total number of peptide bonds in the substrate studied, it was assayed using the pH-stat method, and the calculation formula was expressed as below [12]:

where B is the amount (mL) of base consumed to keep the pH constant during the reaction; N b is the normality of the base; M p is the mass (g) of protein (N × 6.25); h tot is the total number of peptide bonds in the substrate, which was assured to be 7.5 according to Al-Sayed Mahmoud et al. [13]; α is the average degree of dissociation of the α-NH2 groups released during hydrolysis expressed as below:

where pH and pK are the values at which the proteolysis was conducted. The experiments were carried out in triplicate and presented as means ± standard deviations (n = 3).

Enzyme-assisted aqueous extraction

The dried powder of sea urchin gonad was hydrolyzed by four proteases, respectively. Briefly, 10 g of dried sea urchin gonad powder was suspended in deionized water to 200 mg/mL containing a required dosage of protease (2,500 U of enzyme/1 g of substrate). After adjusting to a required pH with 1 M NaOH, the mixture was incubated at a required temperature for 3 h, with continuously stirring. The parameters for each proteolytic reaction are summarized in Table 1. After adjusting to pH 7, the fluid was boiled (100 °C) for 10 min to inactivate protease. After boiling, the mixture was cooled to room temperature in a cold water bath.

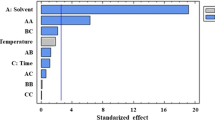

To extract lipid, the hydrolysate should be divided into lipid, solid, and aqueous phases by centrifugation. For facilitating the separation, three individual operations and their combinations were used separately to pretreat the hydrolysate: (1) A, freezing and thawing; (2) B, adding sodium chloride; (3) C, adding ethanol; (4) A + B; (5) A + C; (6) B + C; and (7) A + B + C. After the pretreatment, the sample was centrifuged at 2,000g for 25 min. The centrifugation procedure was repeated 2 times with a 30 s of vortex between each time. Following the centrifugation procedure, 5 mL of hexane was added to the centrifuge tube, and then the upper layer was collected by Pasteur pipette. Hexane in the sample collected was evaporated by flushing with N2 at 35 °C, and the lipid was weighed and stored at −20 °C until further treatment. The yield of lipid extracted was calculated in comparison with the soxhlet extraction using ethyl ether as solvent. All experiments were carried out in triplicate and presented as means ± standard deviations (n = 3).

Soxhlet extraction

Total lipids were extracted and quantified by soxhlet extraction method [14]. One gram of sea urchin gonad powder was wrapped by filter paper and placed in a soxhlet extractor, and the lipid was extracted for 10 h using ethyl ether as solvent. Ethyl ether in the sample collected was evaporated by flushing with N2 at 35 °C, and the lipid was weighed and stored at −20 °C until further treatment. Results were expressed as grams of lipid/100 g of dried matter. The experiments were carried out in triplicate and presented as means ± standard deviations (n = 3).

Supercritical fluid extraction

All SC-CO2 extraction trials were carried out in a Hua’an supercritical fluid apparatus (HA121-50-01-C, Jiangsu, China). A schematic diagram of the SC-CO2 extraction system was displayed in a published literature [15]. As much as 30 g of sea urchin gonad powder was placed into the extraction vessel. After an initial air purge, liquefied carbon dioxide was pumped into the extraction vessel by a high-pressure pump to get a pressure of 28 MPa, and the temperature inside the vessel was raised to, and maintained at 50 °C. The flow rate of the CO2 was regulated at 20 L/h. After 80 min of extraction, the lipid was collected, weighed, and stored at −20 °C until further treatment. The yield of lipid extracted was calculated in comparison with the soxhlet extraction using ethyl ether as solvent. The experiments were carried out in triplicate and presented as means ± standard deviations (n = 3).

Extraction of unsaponifiables

Saponification of the samples was carried out according to the methods described before with slight modification [16, 17]. Briefly, 100 mg of lipid sample was transferred into a Teflon-lined screw-capped vial containing 2.5 mL of 50% (w/v) KOH and 5 mL of 95% ethanol. After tightly capping, the vial was heated at 60 °C for 2 h in a warm water bath, with moderate stirring. After incubation, the mixture was cooled to room temperature in a cold water bath. The lipid phase (upper layer) containing the unsaponifiables was collected and extracted 6 times with 4 mL of hexane each time. The combined hexane extracts were washed with distilled water until soap-free, and evaporated to dryness by flushing with N2 at 35 °C. The residue was collected, weighed as total unsaponifiables, and stored at −20 °C until GC–MS analysis.

Preparation of fatty acids

After extraction of the unsaponifiables mentioned above, the remaining aqueous phase was adjusted to pH 1 with 6 M HCl. After cooling to room temperature, the solution was extracted 6 times with 4 mL of hexane each time. The hexane extracts were combined and then the solvent was removed by flushing with N2 at 35 °C, and the residue was weighed as total crude fatty acids. The residue was dissolved in hexane to get a certain concentration of 10 mg/mL, and 2.5 mL of the solution was transferred into a Teflon-lined screw-capped vial. After adding 2 mL of freshly prepared transmethylating reagent [1% (v/v) sulfuric acid in HPLC-grade methanol], the vial was heated in a warm water bath for 1 h at 70 °C. After the incubation, the mixture was cooled, and 1 mL of distilled water was added to it. The upper layer containing fatty acid methyl esters was collected and stored at −20 °C until GC–MS analysis.

GC–MS analysis

The unsaponifiables and fatty acid methyl esters were analyzed by an Agilent 6890N GC-5973 MSD (Palo Alto, CA, USA) equipped with a HP-5-MS capillary column (30 m × 0.25 mm × 0.25 μm). Helium was used as the carrier gas, and the pressure was constant at 16.09 psi. The column temperature profile for the analysis of the unsaponifiables was: 200 °C for 5 min, ramping to 320 °C at a rate of 5 °C/min, and holding for 10 min. The column temperature profile for the analysis of fatty acid methyl esters was: 140 °C for 5 min, ramping to 250 °C at a rate of 2.5 °C/min, and holding for 10 min, ramping to 300 °C at a rate of 50 °C/min, and holding for 10 min. The MS was in EI mode (70 eV) with a 1.0 scan/s interval over a 50–550 m/z range. Solvent delay was 4 min. Sterols were identified by comparison of their mass spectra with the NIST02 mass spectral database. The identification of fatty acid methyl esters was performed by comparison of relative retention times and mass spectra with authentic standards (37 Component FAME Mix, Supelco Inc.) and NIST02 mass spectral database. The compositions of the sterols and fatty acids were calculated from their peak areas.

Results and discussion

Fresh Strongylocentrotus nudus gonad used in this study contained 11.1 ± 0.2% of protein, 5.3 ± 0.3% of sugar, 7.1 ± 0.2% of lipid, 1.5 ± 0.1% of ash, and 74.9 ± 0.5% of moisture. The results were consistent with the reported values measured by Dincer et al. [2] in their studying of sea urchin, Paracentrotus Lividus. As containing 28.3% of lipid in dry weight basis, Strongylocentrotus nudus gonad is an exploitable source of lipids in food industry.

The Strongylocentrotus nudus gonad homogenate was hydrolyzed separately by four proteases. The DH of hydrolysate derived from Neu, Pap, Alc, and Try was 24.7, 17.3, 13.9, and 8.2%, respectively. Rosenthal et al. [8] thought that the DH of hydrolysate is a key factor influencing lipid yield in enzyme-assisted aqueous extraction. However, the relationship between DH value and lipid yield is very complex. Though in principle, the higher DH means more free lipids released, but which can also result in more emulsion which impacts negatively on lipid extraction [8]. Therefore, the optimum DH is an experiment value obtained by method optimization, and is related to the property of substrate and the type of protease used.

To extract lipid, the hydrolysate should be divided into lipid, solid, and aqueous phases by centrifugation. However, the effect of direct centrifugation was very bad. There was a cream layer rather than lipid layer in the centrifuge tube after centrifugation (see Fig. 1a). To break the emulsion, several methods and their combinations were tried (the hydrolysate derived from Pap was used as an experimental subject). Freezing and thawing is a conventional procedure for demulsification [18]. The method has achieved very good results in several lipid extractions using aqueous process [19–22]. However, in this case, freezing and thawing operation was ineffective for the recovery of free lipid. Agboola and Dalgleish [23] reported that lipid-in-water emulsions could be destabilized by addition of ethanol. However, the demulsification effect of adding ethanol (60%, v/v) was also unsatisfactory in this study. Borges et al. [24] reported that an increase in salinity tends to boost the effect of the non-ionic demulsifier in breaking of water-in-crude-lipid emulsions. Our results showed that the effect of adding sodium chloride alone (7%, w/v) was not satisfied, which confirms that salinity is just an accessory factor in demulsification.

Since the effects of using single emulsion-breaking method were not satisfied, the combinations of the methods were tried. In the four kinds of combinations, adding ethanol + sodium chloride and adding ethanol + sodium chloride + freezing and thawing both successfully broke the emulsion and achieved the phase separation (see Fig. 1b). The lipid yield for the combination of the two and three methods was 31.8 ± 0.7 and 31.4 ± 1.1%, respectively, indicating the freezing and thawing procedure was unnecessary. Therefore, the combination of adding ethanol + sodium chloride was ascertained as emulsion-breaking method in this study. Ethanol can decrease the charge and steric repulsion between lipid droplets, and then destabilizes emulsion [25]. Other effects, such as protein denaturation [26] and polysaccharide precipitation [27] caused by ethanol may also influence the stability of emulsion. High electrolyte (such as sodium chloride) concentration is expected to strengthen hydrophobic interactions, and thereby can boost the effect of the non-ionic demulsifier [24]. In this study, ethanol was a non-ionic demulsifier, and its emulsion-breaking effect was strengthened by sodium chloride.

To improve lipid yield, the adding amounts of ethanol and sodium chloride were optimized by single-factor experiment. Results showed that the lipid yield increased with increase in ethanol concentration, reached a maximum value at the ethanol concentration of 65% (v/v), and decreased slowly after that (see Fig. 2). The lipid yield also increased along with increase in salinity, and reached a plateau at the sodium chloride concentration of 25% (w/v) (see Fig. 3). Under conditions of an ethanol concentration of 65% (v/v) and a sodium chloride concentration of 25% (w/v), the lipid yield was 82.0 ± 2.1, 76.0 ± 2.3, 72.9 ± 3.6, and 61.5 ± 1.6% for the samples hydrolyzed by Pap, Neu, Alc, and Try, respectively. Zhang et al. [28] reported that the DH evidently influenced the yield of lipid in enzyme-assisted aqueous extraction. However, there was no linear relationship between DH and lipid yield [29]. The lipid yield was 53.7 ± 2.6% for SC-CO2 extraction method. It was reported that a higher lipid yield for enzyme-assisted aqueous method [29] and SC-CO2 extraction method [15] could be achieved through optimization experiment.

In the process of enzyme-assisted aqueous extraction, there are two points which are needed to be explained. First, a very complex centrifugation procedure was used. To achieve the phase separation, different centrifugation conditions were tried. In this process, we found that one time centrifugation could not achieve good results no matter what centrifugal force and centrifugation time was used. However, repeated centrifugation with a vortex between each time could achieve good results. Orafidiya et al. [30] reported that centrifugation of the emulsions can induce coalescence of lipid droplets. Rosenthal et al. [8] reported that appropriate levels of stirring can promote coalescence of lipid droplets which results in the formation of a greater amount of free lipid after the centrifugation step. In this case, the repeated vortex and centrifugation can facilitate the coalescence of lipid droplets, and then improve the phase separation. By simple optimization of centrifugal force, centrifugation time and number of centrifugation, the centrifugation process was ascertained eventually. Second, a small amount of hexane was added to the centrifuge tube to solubilize and separate the free lipid fraction. To be exact, about 5 ml of hexane was added to 50 ml of hydrolysate. The purpose of adding hexane is to collect lipid thoroughly for quantification [19]. If the experimental scale is expanded, the very small amount of lipid absorbed by the surface of centrifuge tube could be ignored as that which could not significantly affect lipid yield.

The compositions of the unsaponifiables from the lipids extracted by different methods are shown in Table 2. The unsaponifiables were composed of cholesterol, desmosterol, ergosta-5,24-dien-3-ol,(3beta), and fucosterol, of which cholesterol was the chief component accounting for proximately 90% of the total weight. The results basically agreed with the reported values measured by Lopez-Hernandez et al. [31] in their study of lipid extracted from sea urchin gonad (Paracentrotus lividus). Table 3 presents a comparison of the fatty acid compositions of lipids extracted by different methods. Obviously, no great differences in fatty acid compositions were observed between those samples. PUFA dominated sea urchin gonad fatty acids with approximately 35% of the total weight. The high content of C20 fatty acids, such as C20:1n-9, C20:3n-6, C20:4n-3, C20:4n-6, and C20:5n-3 is a distinctive feature for lipids extracted from sea urchin gonad [7].

Compared to the conventional solvent extraction method, both enzyme-assisted aqueous method and SC-CO2 method have obvious advantages in the environmental aspect. Although most organic solvents used to extract lipids in industry can be recycled, the releasing part still can cause serious environmental problems [32]. In contrast, the solvent emissions in lipid extraction process using enzyme-assisted aqueous method or SC-CO2 method are nearly zero. If the problem of low-extraction efficiency of enzyme-assisted aqueous method and SC-CO2 method could be overcome, the two methods should have strong potential for application. The SC-CO2 extraction method is limited to application for its difficulty to run and maintain, requiring the high cost of instrumentation. In contrast, enzyme-assisted aqueous method is more easy to be carried out for its ease operation and no special equipment. Moreover, it enables simultaneous recovery of lipid and protein (peptide) from raw materials [33]. Consequently, the method deserves further investigation.

Conclusion

In the present study, an enzyme-assisted aqueous method was developed to extract lipid from Strongylocentrotus nudus gonad. The process was accomplished in five basic steps: (1) homogenate, (2) hydrolysis, (3) demulsification, (4) centrifugation, and (5) collection. By optimizing the type of enzyme, emulsion-breaking method and centrifugation condition, the highest lipid yield could achieve 82.0 ± 2.1%. Meanwhile, a SC-CO2 extraction method achieved a lipid yield of 53.7 ± 2.6%. The lipid extracted was divided into unsaponifiable (sterols) and fatty acid and analyzed by GC–MS. Results demonstrated that the compositions of sterol and fatty acid were very similar for samples extracted by different methods, indicating there was little difference between the quality of the samples.

References

De la Cruz-García C, López-Hernández J, González-Castro MJ, Rodríguez-Bernaldo De Quirós AI, Simal-Lozano J (2000) Protein, amino acid and fatty acid contents in raw and canned sea urchin (Paracentrotus lividus) harvested in Galicia (NW Spain). J Sci Food Agric 80:1189–1192

Dincer T, Cakli S (2007) Chemical composition and biometrical measurements of the Turkish sea urchin (Paracentrotus Lividus, Lamarck, 1816). Crit Rev Food Sci 47:21–26

Foss BJ, Nadolski G, Lockwood SF (2006) Hydrophilic carotenoid amphiphiles: methods of synthesis and biological applications. Mini Rev Med Chem 6:953–969

González M, Caride B, Lamas A, Taboada C (2001) Nutritive value of protein from sea urchin, and its effects on intestinal leucine aminopeptidase and intestinal and hepatic gamma-glutamyltranspeptidase. Int J Food Sci Nutr 52:219–224

Liyana-Pathirana C, Shahidi F, Whittick A (2002) The effect of an artificial diet on the biochemical composition of the gonads of the sea urchin (Strongylocentrotus droebachiensis). Food Chem 79:461–472

Cook EJ, Hughes AD, Orr H, Kelly MS, Black KD (2007) Influence of dietary protein on essential fatty acids in the gonadal tissue of the sea urchins Psammechinus miliaris and Paracentrotus lividus (Echinodermata). Aquaculture 273:586–594

Cook EJ, Bell MV, Black KD, Kelly MS (2000) Fatty acid compositions of gonadal material and diets of the sea urchin, Psammechinus miliaris: trophic and nutritional implications. J Exp Mar Biol Ecol 255:261–274

Rosenthal A, Pyle DL, Niranjan K (1996) Aqueous and enzymatic processes for edible oil extraction. Enzyme Microb Technol 19:402–420

Valle J, De La Fuente J (2006) Supercritical CO2 extraction of oilseeds: review of kinetic and equilibrium models. Crit Rev Food Sci 46:131–160

AOAC (1990) Official methods of analysis of the Association of Official Analytical Chemists, 15th edn. Association of Official Analytical Chemists, Washington

DuBois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Adler-Nissen J (1982) Limited enzymic degradation of proteins: a new approach in the industrial application of hydrolases. J Chem Technol Biotechnol 32:138–156

Al-Sayed Mahmoud K, Linder M, Fanni J, Parmentier M (2008) Characterisation of the lipid fractions obtained by proteolytic and chemical extractions from rainbow trout (Oncorhynchus mykiss) roe. Process Biochem 43:376–383

Heemken OP, Theobald N, Wenclawiak BW (1997) Comparison of ASE and SFE with soxhlet, sonication, and methanolic saponification extractions for the determination of organic micropollutants in marine particulate matter. Anal Chem 69:2171–2180

Liu G, Xu X, Hao Q, Gao Y (2009) Supercritical CO2 extraction optimization of pomegranate (Punica granatum L.) seed oil using response surface methodology. Lwt-Food Sci Technol 42:1491–1495

Jeong WS, Lachance PA (2001) Phytosterols and fatty acids in fig (Ficus carica, var. Mission) fruit and tree components. J Food Sci 66:278–281

Kovacs MIP, Anderson WE, Ackman RG (1979) A simple method for the determination of cholesterol and some plant sterols in fishery-based food products. J Food Sci 44:1299–1301

Roxas PG (1963) Recovering oils from oleaginous meats of nuts, beans and seeds. US Patent 3083365

Lamsal BP, Johnson LA (2007) Separating oil from aqueous extraction fractions of soybean. J Am Oil Chem Soc 84:785–792

Lin C, He G, Li X, Peng L, Dong C, Gu S, Xiao G (2007) Freeze/thaw induced demulsification of water-in-oil emulsions with loosely packed droplets. Sep Purif Technol 56:175–183

Chen G, He G (2003) Separation of water and oil from water-in-oil emulsion by freeze/thaw method. Sep Purif Technol 31:83–89

Jean DS, Lee DJ, Wu JCS (1999) Separation of oil from oily sludge by freezing and thawing. Water Res 33:1756–1759

Agboola SO, Dalgleish DG (1996) Effects of pH and ethanol on the kinetics of destabilisation of oil-in-water emulsions containing milk proteins. J Sci Food Agric 72:448–454

Borges B, Rondó́n M, Sereno O, Asuaje J (2009) Breaking of water-in-crude-oil emulsions. 3. Influence of salinity and water-oil ratio on demulsifier action. Energ Fuel 23:1568–1574

Horne DS (1992) Ethanol stability. In: Fox PF (ed) Advanced dairy chemistry. Volume 1 Proteins. Elsevier Applied Science, London

Huppertz T, Grosman S, Fox PF, Kelly AL (2004) Heat and ethanol stabilities of high-pressure-treated bovine milk. Int Dairy J 14:125–133

Nunes FM, Coimbra MA (1998) Influence of polysaccharide composition in foam stability of espresso coffee. Carbohydr Polym 37:283–285

Zhang SB, Wang Z, Xu SY (2007) Optimization of the aqueous enzymatic extraction of rapeseed oil and protein hydrolysates. J Am Oil Chem Soc 84:97–105

Womeni HM, Ndjouenkeu R, Kapseu C, Mbiapo FT, Parmentier M, Fanni J (2008) Aqueous enzymatic oil extraction from Irvingia gabonensis seed kernels. Eur J Lipid Sci Technol 110:232–238

Orafidiya LO, Oladimeji FA (2002) Determination of the required HLB values of some essential oils. Int J Pharm 237:241–249

Lopez-Hernandez J, Gonzalez-Castro MJ, Pineiro-Sotelo M (1999) Determination of sterols in sea urchin gonads by high-performance liquid chromatography with ultraviolet detection. J Chromatogr Sci 37:237–239

Johnson LA, Lusas EW (1983) Comparison of alternative solvents for oils extraction. J Am Oil Chem Soc 60:229–242

De Moura JMLN, Campbell K, Mahfuz A, Jung S, Glatz CE, Johnson L (2008) Enzyme-assisted aqueous extraction of oil and protein from soybeans and cream de-emulsification. J Am Oil Chem Soc 85:985–995

Acknowledgments

This work was financially supported by “The National Great Project of Scientific and Technical Supporting Programs Funded by Ministry of Science & Technology of China During the 11th Five-year Plan (No. 2008BAD94B07)” and “The Research Start-up Project for Doctor Funded by Liaoning Science and Technology Department (No. 20091002)”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, BW., Qin, L., Zhou, DY. et al. Extraction of lipid from sea urchin (Strongylocentrotus nudus) gonad by enzyme-assisted aqueous and supercritical carbon dioxide methods. Eur Food Res Technol 230, 737–743 (2010). https://doi.org/10.1007/s00217-010-1216-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-010-1216-8