Abstract

Pressure-induced gelatinisation of buckwheat starch suspensions (25% w/w) was studied and compared to heat-induced gelatinisation. Starch suspensions were treated at increased pressure (200–600 MPa) or temperature (60–95 °C) for 10 min. The degree of gelatinisation and the temperature and pressure ranges of gelatinisation were determined using differential scanning calorimetry, changes in birefringence and pasting behaviour. Furthermore, the structural changes during gelatinisation were investigated using microscopy. The pressure-induced as well as the temperature-induced gelatinisation curves were sigmoid shaped. Gelatinisation occurred between 300 and 500 MPa or between 60 and 70 °C. Scanning electron microscopy images showed retention of the granular structure after treatment with 600 MPa. However, when heated at temperatures above 65 °C, the formation of a “sponge-like” structure was observed. Better preservation of the granular structure for pressure treatment compared to temperature treatment resulted in stronger gels for the former. Pre-treatment with pressure as well as temperature made the buckwheat starch granules more resistant to swelling and disintegration under the influence of additional heat.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Buckwheat is a non-glutinous pseudo-cereal that has a long and traditional history as a food source in Asia, Europe, and the United States and has many beneficial health aspects. Because of its functional and organoleptic properties, buckwheat has been utilised for enhanced processing and marketing opportunities by the food industry to manufacture products such as alcoholic beverages, pasta, blended bread and noodles [1]. However, it has suffered from declining production within the past years. In order to prevent further decline of buckwheat production, new products will need to be developed for the consumer market and more research will need to be conducted to study the effect of different processing parameters on buckwheat characteristics [2].

The potential application of high pressure (HP) for food processing and preservation is investigated with growing interest by various researchers as an alternative to traditional heat (T) treatments [3–5]. This technology has advantages over T treatment such as better retention of nutritional and functional ingredients in the processed product. HP also provides the possibility to produce foods with novel textures [6]. Till date, no studies on the effect of HP on buckwheat starch structure have been undertaken. However, several studies have investigated the effects of HP on other types of starch [7, 8]. The HP range in which starch gelatinisation occurs is dependent on the botanical origin [7] and partly dependent on the crystalline structure, e.g., B-type starches are more resistant to pressure than A- and C-type starches [7, 9]. It was reported that most of the starches subjected to HP (600 MPa) in excess of water retained their granular shape better compared to heating, demonstrating limited swelling power and limited amylose release [7, 10]. Furthermore, lower viscosity of HP-treated starch suspensions (550 MPa) was observed in comparison with T treatment [7]. As the physicochemical properties of buckwheat starch will affect the functional properties of foods containing buckwheat, the understanding of HP-induced gelatinisation of starch is vital for the development of new buckwheat applications using HP.

The objective of this study was to evaluate the effect of HP treatment on rheological and structural properties of buckwheat starch and to compare it to the one obtained by T treatment. Due to the fact that calorimeters, rheometers and microscopes available today cannot be operated at HP, the pressure dependence of the starch gelatinisation cannot be determined by continuous steady increase of the pressure as can be done for temperature. Therefore, starch–water suspensions were pre-treated with either HP or T and subsequently analysed for changes in their properties by a heating process, using either calorimetric measurements or rheology. The results obtained by these two methods were evaluated using microscopy.

Materials and methods

Material

The buckwheat flour used in this study was obtained from USDA-ARS, GMPRC, Manhattan, KS, USA.

Starch extraction

Starch granules were extracted according to Bultosa et al. [11] using only distilled water. Starch–water suspensions were filtered through a 250-μm sieve (Endecotts Limited, England). The liquid containing the starch was retained and filtered through a 100-μm sieve (Endecotts Limited, England). The residue on the sieves was discarded. The resulting liquid suspension was centrifuged at 5,000g for 10 min. After the supernatant was decanted, the brown protein layer was scraped off. The starch pellet was re-suspended in distilled water and centrifuged again. This procedure was repeated until an apparently pure starch pellet was obtained. The starch pellet was freeze-dried. The purity was checked by microscopy.

High pressure treatment

Buckwheat starch suspensions (25% w/w) were vacuum-packed in polyethylene bags (100 × 150 mm; Miller Pack Ltd, Finglas, Dublin 11, Ireland). Packed samples were vacuum-packed two more times to prevent contact between pressurisation fluid and the suspension. The HP treatment was performed using a Stansted Fluid Power Iso-lab 900 High Pressure Food Processor (Stansted Fluid Power, Stansted, Essex, UK) as described by Huppertz et al. [12]. The samples were treated at pressures of 300, 400, 500 or 600 MPa. Pressure was increased at a rate of 300 MPa/min, maintained at the desired HP for 10 min and released at a rate of 300 MPa/min. The temperature of the vessel of the pressure unit was thermostatically controlled at 20 °C throughout treatment. Due to compressive heating, increases in the temperature of the processing fluid by up to a maximum of 12 °C at 600 MPa were observed; increases in the temperature of the processing fluid were transient, and the set temperature ±1 °C was reattained at the end of the treatment.

Temperature (T) treatment

Buckwheat starch suspensions (25% w/w) were heated in a T-controlled water bath (Grant Instruments Ltd, Cambridge, England) for 10 min at T of 60, 65, 70, 75 or 95 °C.

Differential scanning calorimetry (DSC)

The degree of gelatinisation of the pressurised or heated buckwheat starch was investigated by DSC using a Mettler DSC 821e (Mettler Toledo, Switzerland), calibrated using gallium (mp 29.8 °C; ΔH = 28.45 J/g). About 10 mg of treated or control starch suspension was sealed into a standard 40 μl aluminium pan (Al-Crucibles, ME 27331) and an empty pan was used as a reference. Test was performed over a temperature range of 10–100 °C at a heating rate of 5 °C/min. Thermal transitions of starch suspensions were evaluated in terms of onset (T o), peak (T p) and endset (T e) gelatinisation temperatures. The melting enthalpy (ΔH) associated with starch gelatinisation was obtained from the area of the peak endotherm using STARe thermal analysis software (Mettler Toledo, Switzerland). In accordance with Blaszczak et al. [13], the values of the degree of gelatinisation were calculated using the following equation:

where ΔH ns and ΔH ts are the melting enthalpies of native and treated starches, respectively. The measurements were performed in triplicate.

Scanning electron microscopy (SEM)

Freeze-dried starch granules were mounted on aluminium stubs (Agar Scientific Ltd, England) covered with double-sided carbon tape (Agar Scientific Ltd, England) and sputter-coated with gold in a vacuum evaporator (E5175 Large Chamber “Cool” sputter Coater, Quorum Technologies Ltd, UK). Prepared samples were viewed in a JEOL 5510 scanning electron microscope (JEOL, Tokyo, Japan) at 3–5 kV using 10 mm working distance.

Confocal laser scanning microscopy (CLSM)

Loss of birefringence during gelatinisation was studied using a Fluoview FV300 confocal laser scanning microscope (Olympus UK Ltd) with a 60× oil immersion objective. Freeze-dried starch samples were stained using a 0.1% (w/v) solution of fluorescein isothiocyanate (FITC) in dimethyl formamide. The 488 nm line from an argon laser was used for excitation. A polarising plate was engaged in the light path for transmitted polarised light observation. The final images were obtained by an overlay of the image obtained by the transmitted light and the image obtained by the emitted fluorescence of the FITC.

Rheological measurements

The rheological measurements of the HP- and T-treated samples were carried out using a rotational rheometer (Physica MCR 301, Anton Paar GmbH, Stuttgart, Germany) using a parallel plate geometry (50 mm diameter) with sanded surface probe to prevent slippage. The temperature, initially set at 30 °C, was regulated by a circulating water bath and a peltier heating system. After loading, the sample was trimmed and left to rest for 5 min. The tests performed on the samples were:

-

1.

An amplitude sweeps (strain = 0.001–100%) at a constant frequency (10 Hz) to determine the limits of the linear visco-elastic range (data not shown).

-

2.

A temperature sweep at a constant deformation (within the linear viscoelastic range) and a constant frequency (10 Hz). For this test, the sample perimeter was covered with a thin layer of petroleum jelly to prevent dehydration. After equilibration at the initial temperature (30 °C) for 5 min, the samples were heated at a rate of 7.8 °C/min to the final temperature of 95 °C. After a holding time of 5 min at this temperature, the samples were cooled at a rate of 7.8 °C/min to the initial temperature at which they were held for another 5 min. The complex modulus (G*) was monitored at 10 s intervals. Changes in G* of the suspensions were evaluated in terms of onset (T o) and endset (T e) gelatinisation temperatures. Furthermore, onset (\( G_{ 0}^{ *} \)) and endset (\( G_{\rm e}^{ *} \)) complex moduli were extracted from the pasting profiles. The breakdown was calculated as the decrease (%) between \( G_{\rm e}^{ *} \) and the complex modulus at the end of the holding phase at 95 °C. The setback was calculated as the increase (%) between the complex modulus at the end of the holding phase at 95 °C and the final complex modulus at the end of the holding phase at 30 °C. Each test was performed at least in triplicate.

Statistical analysis

In order to assess the differences between samples at different measurement points, a two-sided t test for independent samples (Statistica 7.0 StatSoft, Inc., USA) with a significance level of 0.01 was used.

Results

Microscopy

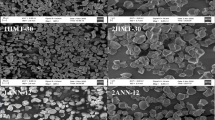

The loss of birefringence during HP- and T-induced gelatinisation was observed with CLSM using polarised light. Furthermore, the effects of HP and T on the microstructure of buckwheat starch were investigated by SEM. Figure 1a shows the change in birefringence of buckwheat starch granules after treatment with increasing HP or T. Untreated starch granules exhibited characteristic granular shapes and birefringence patterns. The number of “Maltese cross” showing granules decreased with increasing HP or T above 300 MPa and 60 °C, respectively, indicating loss of crystallinity. At 400 MPa and 65 °C, a significant loss in birefringence was observed. All granules lost their “Maltese cross” after treatment with 500 MPa or 70 °C, indicating complete gelatinisation. Furthermore, the CLSM pictures suggested partial preservation of granular structure after treatment with 600 MPa, while heating at 75 °C seemed to cause the loss of integrity of most granules. This difference between HP treatment and heating was investigated further with SEM, which revealed finer details of the granular structure. The SEM images are shown in Fig. 1b. Changes in the shape and surface of buckwheat starch granules induced by treatment with HP above 400 MPa were clearly visible. It was observed that some granules collapsed and became “doughnut-shaped”. Although most granules appeared swollen and deformed, the majority of granules retained some degree of integrity after treatment with 600 MPa. Treatment with 65 °C also caused the formation of “doughnut-shaped” granules. However, heating a buckwheat starch suspension to 75 °C caused almost all granules to lose their structure completely and a regular sponge-like structure, with the remaining empty spaces after water evaporation during freeze-drying, was clearly visible.

Differential scanning calorimetry

The HP- and T-induced gelatinisation of buckwheat starch suspensions was investigated using DSC. An endothermic melting peak, associated with melting of A-type crystals, was observed in the DSC scan for untreated buckwheat starch suspensions (results not shown). The effect of HP and T on the melting enthalpy (ΔH) and on the degree of gelatinisation calculated from ΔH, is shown in Table 1. Treatment with HP above 300 MPa or T above 60 °C significantly decreased ΔH and thus increased the resulting degree of gelatinisation. The correlation between the degree of gelatinisation and treatment pressure followed a sigmoidal-shaped curve (Fig. 2a), with a sharp increase between 300 and 500 MPa. T-induced gelatinisation of buckwheat starch resulted in a similar sigmoid gelatinisation curve (Fig. 2b) with most of the crystals melting between 60 and 70 °C. These results were in agreement with the CLSM images, where total loss of birefringence was observed between 300 and 500 MPa and between 60 and 70 °C.

Furthermore, DSC measurements were evaluated in terms of onset (T o), peak (T p) and endset (T e) gelatinisation temperatures of the endothermic peak (Table 1). Gelatinisation of untreated buckwheat starch occurred between 60 and 71.8 °C, with the peak of the endotherm at 65.6 °C. However, changes in the gelatinisation temperatures were observed with increased severity of the pre-treatment. Increasing degree of gelatinisation resulted in higher T o, T p and T e, which reached the maximum values of 70.4, 74 and 78.5 °C, respectively, after treatment with 500 MPa, and 73.2, 75.3 and 78.4 °C, respectively, after treatment with 70 °C.

Rheology

The effects of pre-treatment on the rheological properties of buckwheat starch suspensions were studied by temperature sweeps, in which samples were heated from 30 to 95 °C and subsequently cooled, resulting in the pasting profiles (Fig. 3). Due to leaching of amylose and swelling of the granules, the consistency of a starch–water suspension will increase during gelatinisation [14]. Several parameters, providing information on gelatinisation characteristics, can be extracted from a pasting curve. \( G_{ 0}^{ *} \) and T o are the complex modulus and temperature, respectively, at the beginning of the consistency increase and thus, at the begin point of gelatinisation. The end point is reached when G*reaches a maximum, \( G_{\text{e}}^{ *} \), at temperature T e (Table 2).

Untreated buckwheat starch suspensions showed a rapid increase in G*from 0.06 to 45.13 MPa upon pasting. When the samples were pre-heated at T above 60 °C, an increase in \( G_{ 0}^{ *} \) with T was observed (Fig. 3b). After the 70 °C treatment, the starch suspension showed a \( G_{ 0}^{ *} \) value that was slightly higher than \( G_{\text{e}}^{ *} \), and complete gelatinisation was obtained. Likewise, an increase in \( G_{ 0}^{ *} \) was observed with increasing HP (Fig. 3a). After pressurisation with 500 MPa, gelatinisation was nearly complete and only a very small increase in G* occurred upon pasting.

Figure 4 shows the changes in \( G_{ 0}^{ *} \) after different HP and T treatments. Similarly as observed for the degree of gelatinisation determined by DSC (Fig. 2), the plot of \( G_{ 0}^{ *} \) against HP or T exhibited a sigmoidal-shaped curve (Fig. 4). Above a critical HP or T, \( G_{ 0}^{ *} \) increased sharply. This phase was between 300 and 500 MPa for HP treatment and between 60 and 65 °C for T treatment.

Furthermore, a lower \( G_{\text{e}}^{ *} \) was observed for pre-treated starch suspensions compared to the control samples (Table 2). Untreated buckwheat starch suspensions showed a \( G_{\text{e}}^{ *} \) of 45.13 MPa. Pressurisation with 500 MPa for 10 min resulted in a reduced \( G_{\text{e}}^{ *} \) of 26.87 MPa. At HP above 500 MPa, \( G_{\text{e}}^{ *} \) increased again, reaching 32.68 MPa for starch treated at 600 MPa. Pre-heating the buckwheat starch suspensions also resulted in a decreased \( G_{\text{e}}^{ *} \) of approximately 24 MPa. However, the increase in \( G_{\text{e}}^{ *} \) observed between 500 and 600 MPa was not observed for T treatment, and no significant differences were observed for different pre-treatment T.

The gelatinisation temperatures, T o and T e, were influenced by the pre-treatment. Pasting of the untreated buckwheat starch was observed between 57.6 and 70.9 °C (Fig. 3; Table 2). For the T treatment, both gelatinisation temperatures increased with increasing T, with gelatinisation of samples treated at 65 °C occurring in the range 76.2–82.3 °C. However, T o was unaffected by the HP treatment, while T e increased to 77 °C after treatment with 500 MPa.

Two other parameters of the pasting profiles were of interest: the breakdown (decrease in G* for T > T e), representing the starch paste stability and resistance to shear stress, and the setback (increase in G* upon cooling), reflecting the rapid retrogradation of leached amylose in the starch paste (Fig. 3; Table 2). A breakdown and a setback of approximately 74 and 73%, respectively, were observed for the untreated buckwheat starch suspension. When treated at pressures of at least 400 MPa or temperatures of at least 65 °C, the swollen granule structure was better maintained when heated above T e, resulting in a lower consistency breakdown (approximately 51%). Likewise, a significantly lower setback was observed.

Discussion

Starch is used as an ingredient in a range of food systems, and controlling its gelatinisation is often critical in the manufacturing of starch-containing foods. Although gelatinisation is commonly induced by heating of an aqueous starch suspension, it is known that starch can also be gelatinised by HP [6–10]. Gelatinisation has been defined as an irreversible melting phase transition of the starch granules from an ordered to a disordered state, and whether induced by T or HP, it is a swelling phenomenon which starts as water from the suspension that enters the starch granules [15, 16]. The T range as well as HP range in which gelatinisation occurs is typical for each starch type [7]. Several methods were used in this study to determine these gelatinisation ranges. The most commonly used method to study the gelatinisation of starch is DSC, which determines the difference in the amount of heat required to increase the temperature of a sample and reference as a function of temperature. DSC measurements were evaluated in terms of onset (T o), peak (T p) and endset (T e) gelatinisation temperatures of the endothermic crystal melting peak (Table 1). Melting of untreated buckwheat starch occurred between 60 and 71.8 °C, with the peak of the endotherm at 65.6 °C. This range was in agreement with gelatinisation temperatures found in literature [17, 18]. Pre-treatment of the starch suspensions with HP or T before DSC-analysis led to a decrease in the melting enthalpy due to the presence of pre-gelatinised starch (Table 1). The T range in which this decrease occurred (60–70 °C) was in good agreement with the peak range for the untreated suspension. The HP-induced enthalpy decrease occurred between 300 and 500 MPa.

Due to the radial orientation of starch crystallites, native granules exhibit a “Maltese cross” when observed with a microscope under polarised light. This phenomenon is known as birefringence and is an indicator of the degree of order of the granule [14]. Hence, loss of birefringence can be used as a measure of gelatinisation [14, 19]. In this study, a CLSM with a polarising plate and a 488 nm argon laser were used to observe the loss of birefringence during gelatinisation. The simultaneous observation of transmitted and emitted light allowed for detailed, coloured images (Fig. 1a). Most of the granules lost their “Maltese cross” between 300 and 500 MPa or 60 and 70 °C. This microscopy result is in good agreement with the ranges obtained by DSC. Comparable results between DSC and microscopy have previously been shown for temperature [20] as well as pressure [7].

Finally, HP and T ranges of gelatinisation were extracted from the pasting profiles obtained by a temperature sweep (Fig. 3), in which gelatinisation was measured as an increase in resistance to deformation (G*). T o was determined as the temperature at the beginning of the consistency increase and T e the temperature at which the consistency reached a maximum (Table 2). These temperatures for the untreated samples (57.6 and 70.9 °C) were comparable to the T o and T e obtained by DSC. When \( G_{ 0}^{ *} \) of the sample was higher than \( G_{ 0}^{ *} \) of the untreated suspension, but G* still increased when heated above T o, partial gelatinisation was assumed. Complete gelatinisation induced by the pre-treatment was indicated by \( G_{ 0}^{ *} \ge G_{\text{e}}^{ *} \). The temperature sweeps resulted in gelatinisation ranges of 300 and 500 MPa and 60 and 70 °C, similar to DSC and CLSM.

Besides gelatinisation ranges, each of these methods provided a measure of the degree of gelatinisation corresponding to the pre-treatment. The melting enthalpy, the number of no-birefringence-showing granules and \( G_{ 0}^{ *} \) all give information on the amount of gelatinised granules due to the pre-treatment. The degree of gelatinisation calculated from the decrease in ΔH is given in Table 1. Plotting the melting enthalpy versus HP or T treatment resulted in a sigmoidal-shaped curve (Fig. 2). Likewise, sigmoid-shaped curves were obtained when \( G_{ 0}^{ *} \) was plotted against HP or T (Fig. 4). Similar correlations between starch suspension consistency and HP were previously reported by Oh et al. [21]. The amount of granules showing no birefringence was not counted in this study, as the differentiation between ungelatinised and gelatinised granules was not always clear due to partial loss or fading out of the birefringence. The limitations in determining the degree of gelatinisation objectively and quantitatively has been acknowledged in literature [7, 21]. However, similar sigmoid relations between birefringence and HP and T were previously observed by Bauer and Knorr [9] and Stute et al. [7].

The present study showed that both HP and T cause gelatinisation of buckwheat starch. Although HP causes starch gelatinisation in a manner similar to T, it has been reported that the rheological properties and the microstructure of HP-treated samples are different from those of T-treated samples [6, 10]. Gelatinisation is generally considered to be a multi-stage process in which the granules swell and amylose leaches, followed by the decomposition of the crystalline structure and disintegration of the granular structure [15, 17]. The results obtained in this study for T treatment were in agreement with this multi-stage model of gelatinisation. The SEM images (Fig. 1b) showed swelling of the granules in the first phase of gelatinisation, between 60 and 65 °C. At intermediate starch concentrations (25% w/w), this first swelling will lead to maximum occupancy of the available space by the swollen granules and the consistency of the starch paste will be mainly determined by the swelling capacity of the granules and their resistance to thermal and mechanical stresses [22, 23]. Accordingly, the swelling of the granules observed between 60 and 65 °C (Fig. 1b) caused a sharp increase in viscosity, as observed by the increase in \( G_{ 0}^{ *} \) between 60 and 65 °C (Table 2). In this T-interval, 70% of the starch crystals were melted, as calculated from the decrease in ΔH obtained by DSC (Table 1). Although at T above 65 °C, the remaining 30% of the crystals melted, \( G_{ 0}^{ *} \) did not increase further (Table 2), indicating the second step of gelatinisation in which granule disintegration occurred. In agreement, SEM images showed complete breakdown of the granular structure after treatment with T above 65 °C (Fig. 1b). When \( G_{ 0}^{ *} \) was plotted against ΔH, an outlier at 65 °C was observed, indicating this two-phase process (Fig. 5b). However, the relatively high correlation coefficient R = 0.9439 showed that swelling and crystal melting still occur mainly simultaneous.

For HP-induced gelatinisation, a very good correlation (R = 0.9954) was obtained between the melting enthalpy as determined by DSC, and the increase in \( G_{ 0}^{ *} \), as obtained from the pasting profiles (Fig. 5a). Thus, melting of the starch crystals and the increase in viscosity occurred in parallel, and no separate phases in the gelatinisation process could be determined. The T at which the granules started to disintegrate upon heating appears to be the transfer point between the two phases of the T-induced gelatinisation process. This indicates that the difference in gelatinisation process between P- and T-induced gelatinisation can be explained by the better preservation of the granular entity upon pressurisation. After treatment with 600 MPa, buckwheat starch suspensions still consisted of swollen granules, while treatment with 75 °C resulted in the formation of a gel-like structure (Fig. 1b). Stolt et al. [6] and Douzals et al. [10] previously observed better preservation of starch granules during HP-induced gelatinisation and related it to lower amylose release. Furthermore, Douzals et al. [10] stated that the lower amount of amylose surrounding the starch granules resulted in starch gels with a weaker matrix after HP treatment. In this study, however, \( G_{ 0}^{ *} \) values of starch suspensions treated at 600 MPa were significantly higher than those of samples treated at 75 °C. The fact that stronger gels were obtained for HP-induced starch pastes led to the assumption that the viscosity of the paste was determined by the swollen granule and the granule–granule interaction. Entanglement of leached amylose seemed to play a minor role. Consequently, disintegration of the granules when heated above 65 °C resulted in a weaker gel matrix. Such a starch system in which the swollen granules determine the paste viscosity was previously defined as a closed-packed system [15].

As pre-treatment with HP as well as T changed the granule structure and crystallinity, it changed the behaviour of the starch suspensions upon subsequent pasting (Fig. 3). For both HP and T, pre-treatment caused restricted swelling (as indicated by a decrease in \( G_{\text{e}}^{ *} \)), restricted granule disintegration (as indicated by an higher T e and a lower breakdown) and a decreased rapid retrogradation of the leached amylose (as indicated by a reduced setback; Table 2). Zondag [2] previously observed that annealed and microwaved buckwheat starch had significantly lower amylose leaching, which could stabilise the granules. Furthermore, Katopo et al. [8] stated that an intertwining of the leached amylose and the formation of amylose–lipid complexes caused by the pre-treatment could form a network restricting swelling and protecting the granules against mechanical shear and granule disintegration [8]. Limited disintegration of the starch granules might explain the significant decrease in setback observed for pre-treated starch suspension [24]. Overall, these results showed that buckwheat starch granules can be stabilised by pre-treatment at HP or T for 10 min, to make them more resistant to breaking apart under the influence of additional heat. Similar conclusions were previously made by Zondag [2] for microwave heat–moisture and annealing processes on buckwheat starch.

Conclusion

The purpose of this experiment was to explore the effect of HP on buckwheat starch properties, and to compare it to the effect of T. HP as well as T treatments caused gelatinisation of buckwheat starch within the ranges 300–500 MPa and 60–70 °C, respectively. However, better preservation of the granules and stronger gels was observed for HP treatment. Furthermore, both HP and T treatments seemed to make the buckwheat starch granules more resistant to destruction by further heating.

References

Zhou YG, Li D, Wang LJ, Li Y, Yang BN, Bhandari B, Chen XD, Mao ZH (2009) Effect of water content on thermal behaviors of common buckwheat flour and starch. J Food Eng 93:242–248

Zondag MD (2003) Effect of microwave heat-moisture and annealing treatments on buckwheat starch characteristics. Master thesis, University of Wisconsin-Stout

Fonberg-Broczek M, Windyga B, Szczawiński J, Szczawińska M, Pietrzak D, Prestamo G (2005) High pressure processing for food safety. Acta Biochim Pol 52:721–724

Hendrickx M, Ludikhuyze L, Van den Broeck I, Weemaes C (1998) Effects of high pressure on enzymes related to food quality. Trends Food Sci Tech 9:197–203

Knorr D, Heinz V, Buckow R (2006) High pressure application for food biopolymers. Biochim Biophys Acta 1764:619–631

Stolt M, Oinonen S, Autio K (2001) Effect of high pressure on the physical properties of barley starch. Innov Food Sci Emerg Tech 1:167–175

Stute R, Heilbronn, Klingler RW, Boguslawski S, Eshtiaghi MN, Knorr D (1996) Effects of high pressures treatment on starches. Starch/Stärke 48:399–408

Katopo H, Song Y, Jane JL (2002) Effect and mechanism of ultrahigh hydrostatic pressure on the structure and properties of starches. Carbohydr Polym 47:233–244

Bauer BA, Knorr D (2005) The impact of pressure, temperature and treatment time on starches: pressure-induced starch gelatinisation as pressure time temperature indicator for high hydrostatic pressure processing. J Food Eng 68:329–334

Douzals JP, Perrier Cornet JM, Gervais P, Coquille JC (1998) High-pressure gelatinisation of wheat starch and properties of pressure-induced gels. J Agric Food Chem 46:4824–4829

Bultosa G, Hall AN, Taylor JRN (2002) Physico-chemical characterization of grain tef [Eragrostis tef (Zucc.) Trotter] starch. Starch/Stärke 54:461–468

Huppertz T, Fox PF, Kelly AL (2004) High pressure-induced denaturation of α-lactalbumin and β-lactoglobulin in bovine milk and whey: a possible mechanism. J Dairy Res 71:489–495

Blaszczak W, Fornal J, Kiseleva VI, Yuryev V, Sergeev AI, Sadowska J (2007) Effect of high pressure on thermal, structural and osmotic properties of waxy maize and Hylon VII starch blends. Carbohydr Polym 68:387–396

Thomas DJ, Atwell WA (1999) Starch analysis methods. Eagan Press, St. Paul

Hermansson AM, Svegmark K (1996) Developments in the understanding of starch functionality. Trends Food Sci Tech 7:345–353

Douzals JP, Marechal PA, Coquille JC, Gervais P (1996) Microscopic study of starch gelatinisation under high hydrostatic pressure. J Agric Food Chem 44:1403–1408

Olkku J, Rha C (1978) Gelatinisation of starch and wheat flour starch—a review. Food Chem 3:293–317

Qian JY, Kuhn M (1999) Evaluation of gelatinization of buckwheat starch: a comparative study of Brabender viscoamylography, rapid visco-analysis, and differential scanning calorimetry. Eur Food Res Tech Z Lebensm Unters Forsch 209:277–280

Oh HE, Pinder DN, Hemar Y, Anema SG, Wong M (2008) Effect of high-pressure treatment on various starch-in-water suspensions. Food Hydrocoll 22:150–155

Baks T, Ngene IS, van Soest JJG, Janssen AEM, Boom RM (2007) Comparison of methods to determine the degree of gelatinisation for both high and low starch concentrations. Carbohydr Polym 67:481–490

Oh HE, Hemar Y, Anema SG, Wong M, Pinder DN (2008) Effect of high-pressure treatment on normal rice and waxy rice starch-in-water suspensions. Carbohydr Polym 73:332–343

Parker R, Ring SG (2001) Aspects of physical chemistry of starch. J Cereal Sci 34:1–17

Champenois Y, Rao MA, Walker LP (1998) Influence of gluten on the viscoelastic properties of starch pastes and gels. J Sci Food Agric 78:119–126

Chung HJ, Hoover R, Liu Q (2009) The impact of single and dual hydrothermal modifications on the molecular structure and physicochemical properties of normal corn starch. Int J Biol Macromol 44:203–210

Acknowledgments

Funding for this research was provided under the Irish National Development Plan, through the Food Institutional Research Measure, administrated by the Department of Agriculture, Fisheries & Food, Ireland, 2006–2010. The authors wish to thank Liam Ryan and Jim McNamara for their excellent technical assistance, Yrio Roos for his assistance with the DSC measurements and Christina Klose for her assistance with the gold coating.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vallons, K.J.R., Arendt, E.K. Effects of high pressure and temperature on buckwheat starch characteristics. Eur Food Res Technol 230, 343–351 (2009). https://doi.org/10.1007/s00217-009-1172-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-009-1172-3