Abstract

The influence of temperature-time gelatinisation conditions on the gel forming kinetics and final gel mechanical features of commonly used starches as potato starch was studied. The proximate physicochemical properties of potato starch as well as the thermorheological and textural characteristics of the corresponding potato starch gels (native, NPS, and at different GD, PS) were determined. Thermorheological testing at small amplitude oscillatory shear and texture profile analysis were used to evaluate the systems structure evolution and the final gel texture, respectively. High purity (total starch content > 98.5 ± 0.7% dry basis, d.b.), intermediate amylose content (21.2 ± 0.8%), low damaged starch levels (2.7 ± 0.8%), crystallinity (B-pattern) level of 22.9 ± 1.1% and average particle size (60.3 ± 4.3 μm) were the main physicochemical features of tested NPS. Rheological outcomes indicated that only potato starch samples heated at temperatures above 50 °C for tested gelatinisation times were able to form gels. The largest gel strength was identified for NPS, PS70:20 (temperature/time) and PS80 independently of gelatinisation time. Viscoelasticity of PS85 and PS90 gels significantly drop with increasing temperature-time gelatinisation conditions. Temperatures between peak (58 °C) and final (70 °C) gelatinisation temperatures favour the formation of stronger and fully thermal reversible gels, remaining practically invariant until 80 °C. Texture studies indicated that an acceptable linear dependence (R 2 > 0.96) between viscoelastic gel properties determined by rheology and textural parameters can be established.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Starch is one of the most useful biopolymer used in the food and non-food industries because it is a relatively inexpensive material easy to obtain with useful properties (Przetaczek-Roznowska, 2017). This biopolymer is mainly extracted from potato, rice, corn or wheat, although many other alternative sources as quinoa or chestnut have been recently studied with interesting properties (Witczak et al., 2015; Li et al., 2016). Potato starch features competitive advantages over other sources of starch owing to its physical nature (Zhang et al. 2017a). This starch is commonly used in food formulations, as a gelling or water-retention agent, thickener or colloidal stabiliser (Moreira et al., 2012; Waterschoot et al., 2015). Namely, potato starch readily forms gels, being one of the main responsible of structural and functional characteristics in edible gelling systems (Chenlo et al., 2011; Pérez-Santos et al., 2016). Potato starch has been also used as film former in the packing industry (Jiménez et al., 2012), as fill material in nanotechnology in filtration (Alcázar-Alay & Meireles, 2015) or as raw material for biofuel production (Sheikha & Ray, 2017), among many others.

The desirable physical starch characteristics in industrial applications are achieved following a granule gelatinisation process linked with crystalline order loss. Recent works (Bhattacharjya et al., 2015) indicated that the annealing of starch, which improves crystal perfection of starch, makes it more resistant to heat and enhance its texture. Many starch-based food formulations do not require fully gelatinised starch for best product characteristics (Przetaczek-Roznowska, 2017). Shear and heat stability of starch granules can be modified throughout different physical or chemical methods, as, e.g. gelatinisation and heat-moisture treatment (to increase the heat sensitivity) or chemical cross-linking (Zhang et al., 2017b), respectively. Therefore, the previous processing of the starch should be considered in order to select the optimum gelatinisation conditions (Malumba et al., 2013). Even though the potato starch gelatinisation has long been studied, the temperature and time gelatinisation dependence is still not fully understood. Most of the studies have been focused on quantifying the starch gelatinisation kinetics based on temperature and enthalpy of gelatinisation (Sheikha & Ray, 2017). It is well-known that the physicochemical starch properties and conditions imposed during the gelatinisation influence the progression and extent of gelatinisation, which is critically relevant since these systems can be submitted to different thermal processes during the starchy products manufacturing (Pérez-Santos et al., 2016). Surprisingly, scarce background information is available in the literature about the effects of temperature and time on different gelatinisation stages for common starches, which poses a relevant research challenge.

Thermorheological and textural characteristics of starch or modified starch dispersions can provide essential information for structural characterisation and for the selection of adequate processing conditions (Lagarrigue & Alvarez, 2010). In the processing of starchy food products, direct relationships were found between the gel rheology, its structure and the end product quality (Manohar & Rao, 2002). Even though the rheological behaviour of different starch pastes and gels has been extensively studied both experimentally and theoretically (Moreira et al., 2013; Pérez-Santos et al., 2016; Jan et al., 2017) or even the tribology (i.e. the resultant rheological and lubrication dynamics) of maize and potato starches (Zhang et al., 2017b), the authors are not aware that the temperature-time dependence during gelatinisation on the mechanical gel characteristics have been reported.

Further insight about the starch behaviour during the gelling process would allow better designing of gel structures and functions as well as developing better quality end products, since their properties are highly dependent on processing temperature-time, cooling rates and starch characteristics (Joshi et al., 2014). During the gel formation, all these factors can critically impact the dynamic process of competition between the phase separation and the gel formation (Nunes et al., 2006). In this context, this work is aimed at determining the temperature-time dependence on the gel forming kinetics, final mechanical characteristics and thermoreversible behaviour of commonly used starches as potato starch. For this purpose, a research on the thermorheological and textural properties of commercial potato starch systems (native, NPS and at different gelatinisation degrees (GD), PS) was carried out. The structural evolution was evaluated using thermorheological testing at small amplitude oscillatory shear, and the final gel texture was determined by texture profile analysis. Proximate physicochemical characteristics of tested potato starch were obtained as a reference for the tested systems understanding.

Materials and Methods

Raw Materials

Commercial potato starch (NPS) (CAS 9005-84-9, Panreac Química S.A., Barcelona, Spain) was used without any further purification. This starch was selected as raw material for this work as it is a widely used reference starch. All chemicals used for pH solutions and other reagents for different experiments were of analytical grade.

Proximate Physicochemical Characterisation

Moisture content of potato starch was obtained following standard methods (AOAC, 2000). Total starch content, amylose/amylopectin ratio and damage starch were determined by means of standard enzymatic tests kits (Megazyme, Co., Wicklow, Ireland) as detailed elsewhere (Moreira et al., 2012). These experiments were made at least in triplicate.

The average particle size (D w) and particle size distributions of tested starch were calculated following a standard procedure (ASAE Standards, 1995). Several standard sieves (500, 250, 200, 125, 80, 63, 40 μm) were used and procedure was made at least in duplicate.

The crystalline structure analysis of starch was performed on a Philips diffractometer using CuKα radiation (λ, 0.154 nm) operating at 40 KV and 20 mA. The samples were scanned at room temperature through the 2θ (diffraction angle) from 2 to 50° at a scanning rate of 4°/min. The relative crystallinity degree was determined according to a method reported elsewhere (Correia et al., 2012). Briefly, crystallinity (%) is calculated as Ic/(Ia + Ic)100, where Ia is the amorphous area and Ic is the crystallised area on the X-ray diffractogram. This assay was carried out at least in duplicate.

Sample Preparation

Aqueous potato starch dispersions were prepared at fixed starch content (30% w/w) with distilled water and dispersed by stirring (1100 rpm) for 15 min on a magnetic stirrer at room temperature (25 ± 0.5 °C). The starch concentration and protocol to form the gels followed the optimised conditions provided for other starchy materials in a previous work (Torres et al., 2014a). Briefly, starch dispersions were quickly (< 5 min) heated on the hotplate magnetic stirrer (Arex, Velp Scientifica, Italy) to several temperatures (45, 50, 54, 58, 65, 70, 80, 85 and 90 °C) and held at each temperature for 60 min in order to obtain different GD, labelled as (PS45, PS50, PS54, PS58, PS65, PS70, PS80, PS85 and PS90). Afterwards, samples were placed in a fridge (for 24 h at 5 °C) to allow the full gel maturation before texture tests. For rheological tests, the starch dispersions were directly placed on the measuring system of the rheometer (after initial stirring time, 15 min at 25 °C) in order to monitor the gelatinisation in situ, which allow avoiding further gel matrix perturbations.

Rheological Behaviour

Small amplitude oscillatory shear testing (storage (G') and loss (G") moduli) were used to study the thermorheological behaviour of gels from potato starch gelatinised at different time/temperature conditions. Rheological assays were conducted on a stress-controlled rheometer (MCR 301, Anton Paar Physica, Austria) using Couette geometry (cup diameter 26 mm and bob height 25 mm). Starch dispersions were poured into the rheometer-measuring system, covered with paraffin oil to prevent water evaporation and kept at rest for 15 min before measuring to allow temperature equilibration (25 °C). Stress sweep tests (from 0.1 to 100 Pa at several frequencies 0.1, 1 and 100 Hz) were made on both dispersions and gels to define the linear viscoelastic region (LVR). In all cases, temperature, time and frequency sweep assays were set up within the LVR (from 0.1 to 10 Pa for dispersions and from 0.1 to 35 Pa for gels). Note here that the upper limit of the LVR range was shifted to 40 for gels from treated starches.

NPS dispersions were heated to 80 °C (1 °C/min). Thereafter, time sweep tests were carried out at 80 °C for 60 min. Then, samples were cooled down to 25 °C (1 °C/min). Temperature sweep tests were made at 0.1 Hz and shear stress of 5 Pa. After cooling, time sweep tests were made at 25 °C for 60 min (1 Hz, 30 Pa). In all cases, 60 min was adequate to achieve the gel equilibrium conditions since G" and G' moduli got steady values. Afterwards, without disturbing the gel, frequency sweep tests (from 0.01 to 100 Hz, 30 Pa) were conducted at 25 °C. For determining the thermal reversibility of gels, all above steps (heating/time sweep/cooling/time sweep/frequency sweep) were repeated using the same protocol. Similar procedure was previously described for other biopolymers elsewhere (Torres et al., 2017). All experiments were performed in triplicate.

In order to study the temperature-time dependent behaviour of the starch gelatinisation and its influence on the mechanical properties of the gels, potato starch dispersions were poured into the rheometer-measuring systems and immediately heated up (45, 50, 54, 58, 65, 70, 80, 85 and 90 °C) for different times (10, 20, 30 and 60 min) in order to obtain different GD. The starches gelatinised for 60 min were labelled as (e.g. from PS45 to PS90), while for shorter periods, the ‘time’ was added to the label (e.g. PS54:10, PS54:20, PS54:30). Subsequently, cycle steps (heating/time sweep/cooling/time sweep/frequency sweep) were repeated.

Textural Behaviour

Hardness, adhesiveness, springiness, cohesiveness, chewiness and gumminess of potato starch gels were determined from the texture profile analysis (TPA) using a TA-XT plus (Stable Micro Systems, UK) texture analyser (load cell of 5 kg) following a procedure (Torres et al., 2014a). Concisely, penetration tests (cylinder P/05R, 5 mm of penetration and 2 mm/s of crosshead speed) were made in the gels formed in a flask (diameter, 2.5 cm, height, 4.5 cm, 75% filled). Experiments were made 24 h after samples preparation. Before tests, potato starch gels were equilibrated at 25 °C for about 1 h. All samples were measured at least in triplicate.

Statistical Analyses

The experimental data sets were analysed using one-way analysis of variance (ANOVA). Whenever the variance analysis showed differences among means, a Scheffé test was carried out to differentiate means with 95% confidence (p ≤ 0.05). All statistical analyses were made by means of PASW Statistics (IBM SPSS Statistics 22.0.0).

Results and Discussion

Proximate Physicochemical Characteristics

NPS showed a moisture content (% d.b.) of 23.9 ± 1.2, and high purity, total starch content (% d.b.) above 98.5 ± 0.7. The amylose content (%) was intermediate (21.2 ± 0.8) when compared with data reported for other starches extracted from rice (19.6 ± 1.2), corn (25.3 ± 1.7) or wheat (24.9 ± 2.1) (Wani et al., 2016). NPS showed low damaged starch levels (%), 2.7 ± 0.8, which agrees with results for starches from soft flours (< 3%) (Torres et al., 2014b).

The X-ray diffractogram of NPS (data not shown) was compared with those standard patterns of crystalline types (Cheetham & Tao, 1998). NPS showed a characteristic B-pattern, with the strongest diffraction peak at around 17° 2θ and a few small peaks at around 2θ values of 20, 22 and 23°. An additional peak was observed at 5° 2θ. The crystallinity level (%) of NPS, calculated from the ratio of diffraction peak and total diffraction area, was 22.9 ± 1.1. This value agrees to those reported for other starches such as maize (Cheetham & Tao, 1998), rice (Lai et al., 2011), chestnut (Correia et al., 2012) or quinoa (Jan et al., 2017) with similar amylose content.

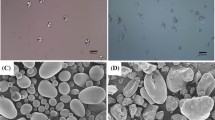

Average particle size, D w, of tested potato starch was 60.3 ± 4.3 μm. NPS exhibited the largest population (60.3%) from 80 to 63 μm. Particles with sizes between 63 and 40 μm represented the second most important mass fraction (29.8%) followed by fractions lower than 40 μm (9.9%). These values are consistent with those reported for potato starches, from 5 to 100 μm (Wang et al., 2016). Overall, the proximate physicochemical features are critically relevant since they may greatly influence the pasting, rheological and gel texture characteristics (Charoenkul et al., 2011).

Thermorheological Characteristics

Heating Profiles of Aqueous Potato Starch Dispersions

Figure 1a shows the thermorheological behaviour of NPS samples (30% w/w) indicating that, during initial heating, G' remained practically invariant whereas G" increased (about a decade). It is well-known that when heating the water starch suspension, some swelling happens, until a critical temperature is reached (Pérez-Santos et al., 2016). The first common inflexion point, which corresponds to the initial gelatinisation temperature (T 0), was observed around 45 ± 1.0 °C. These results are consistent with those obtained for potato starches (Sheikha & Ray, 2017). Afterwards, both moduli exhibited a quick rise (about five decades) with increasing temperature, getting a peak around 58 ± 0.5 °C, which corresponds to the gelatinisation peak (T p). NPS samples displayed G" > G' until 54 °C, where a crossover point was observed, indicating that the increase of both moduli (below 54 °C) is mainly due to the starch granule swelling (Santos et al., 2008). The final gelatinisation temperature (T 1) was around 70 ± 0.8 °C, being the slope change more clearly observed in G". Overall, the thermal profiles on heating showed similar patterns to those reported for other starches with similar amylose content such as rice (Jena & Bhattacharya, 2003) or chestnut (Moreira et al., 2012), although less thermostable than the latter one, since G' and G" dropped in a more restricted range above T p.

Thermorheology of potato starch dispersions (30% w/w): a temperature ramp on heating (25 to 80 °C at 1 °C/min) for NPS (squares); b time sweep (65 °C for 30 min) for PS65:30 (diamonds). Symbols: closed–storage modulus (G'), open–loss modulus (G"). In this and subsequent plots, error bars are not included whether the uncertainty is smaller than the symbol size

The variation of viscoelastic moduli with time for a representative starch sample, held during gelatinisation at 65 °C for 30 min (PS65:30), is shown in Fig. 1b. After initial rest time (5 min) for equilibration (at 25 °C), both G' and G" rapidly increased at fixed gelatinisation temperature. Note here than only data at 65 °C are plotted for easier viewing. After the initial heating step, G' > G" over the whole tested time. The necessary time to achieve the G' and G" threshold values decreased with increasing temperature up to 70 °C. The viscoelastic moduli values depended greatly on temperature-time gelatinisation conditions, increasing with increasing temperature (up to 70 °C) and time below 10 min. The variation of both moduli when the samples were isothermally held for different times indicates that gelatinisation is not only temperature-dependent but also time dependent (Tananuwong & Reid, 2004; Pérez-Santos et al., 2016). Above 70 °C, PS80 did not exhibit variations on the viscoelastic moduli threshold values with time, whereas those corresponding to PS85 and PS90 decreased with increasing temperature and time. This drop (above 80 °C) suggests the formation of decomposition products which reduce the viscoelastic character of the samples (Gunaratne & Hoover, 2002; Glampedaki et al., 2012). In all cases, no notable differences were noticed above 30 min. Note here that NPS dispersions heated at 45 and 50 °C at different tested times (between 10 and 60 min) were not able to fully gelatinise, exhibiting G" larger than G' (about one decade) and almost time independent. As expected, only the first gelatinisation step (swelling of the starch granules) was identified for these samples. The above results suggest that only samples heated at temperatures above 50 °C for tested gelatinisation times will be able to form gels. The selection of gelatinisation conditions, more driven for time or temperature, will arise from a compromise between required gel properties and processing costs.

Cooling Profiles of Potato Starch Gels

Figure 2 shows the thermal profiles on cooling for NPS after heating stabilisation at 80 °C (60 min). When cooling down to 25 °C, the NPS gel structure was reasonably reinforced, G' and G" gradually increased, reaching the largest values at the lowest temperatures indicating a gel structure reinforcement. The increase for G' was faster than that observed for G". In all cases, PS at tested temperature-time conditions exhibited similar structural development patterns to that presented for NPS, although with a less increase of both moduli during cooling. The viscoelastic moduli magnitude varied depending on the GD achieved. This structural development pattern agrees to results reported for maize starches (Nunes et al., 2006) and other starchy pastes (Cornejo-Villegas et al., 2010; Alcázar-Alay & Meireles, 2015). Latter authors explained the moderate variation in viscoelastic moduli by the combined effects of the gradual development of the swollen granules and an amylose gel network.

Maturation Kinetics of Potato Starch Gels

The maturation kinetics of NPS gels throughout the evolution of G' and G" with time at 25 °C were also determined (Fig. 3). Both moduli achieved stability (i.e. dynamic equilibration of the gel network) after 60 min, with steady G' (around 5 104 Pa) and G" (around 103 Pa) values. Similar patterns were observed for all tested PS gels, although much less time (below 20 min) was necessary to the gel maturation. The maturation times were greatly dependent on temperature-time gelatinisation conditions, decreasing with increasing temperature-time until 70 °C and no notable differences were observed for samples gelatinised above this temperature or more than 30 min. The tested gels achieved a stable and fully developed structure within the experiment time. The short time required for PS systems to get a stable gel structure is a relevant advantage from a practical viewpoint. The magnitude of both moduli for PS gels was highly dependent of temperature-time gelling conditions, being the strongest gel network obtained for PS70:20. No significant differences were observed with PS80 gels, independently of gelatinisation time. The cooling and maturation features are typical of biopolymer gelation (Nunes et al., 2006). Usually, an increase of moduli until achieving a threshold value is observed as here, although the structural development pattern can diverge for different biopolymers (Genovese & Rao, 2003).

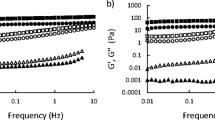

Mechanical Spectra of Potato Starch Gels

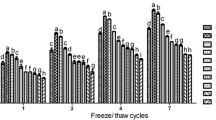

Figure 4a shows mechanical spectra of representative gels (NPS and PS65:30), at the end of the run at 25 °C. All systems showed a typical gel spectrum with G' > G" (around one decade) and both moduli almost frequency independent, except for G" > 1 Hz where a gradual increase was identified. This trend is clearly observed by the tan δ (G"/G') evolution, which is almost frequency invariant until 1 Hz and exhibits a slope change above this frequency (Fig. 4b). This behaviour is consistent with the solid features identified for other gels as those prepared from rice starch (Sodhi et al., 2010), rice flour (Marco & Rosell, 2008), amaranth flour (Houben et al., 2010) and chestnut flour (Torres et al., 2014a). The linear viscoelastic data for the studied gels are quantitatively different, with significant variations in G' and G" values at fixed angular frequencies depending on previous temperature-time gelatinisation conditions. In order to provide a general view of the obtained gel palette, G gel' (1 Hz) for all tested systems is presented in Fig. 5. The gel strength increased with increasing temperature (until 70 °C) and time (depending on applied temperature conditions). In general, no significant differences in G gel' values were observed for NPS samples gelatinised for more than 30 min. Samples from PS70:20 to PS80:60 exhibited the largest gel strengths, indicating that the final gelatinisation temperature (70 °C) applied for 20 min corresponds to the umbral temperature-time gelatinisation conditions, which were set up over the range 70–80 °C and 20–60 min. G gel' values of PS85 and PS90 samples significantly decreased with increasing temperature-time gelatinisation conditions, although this drop was more thermally driven. Reduction of the gel strength above the final gelatinisation temperature was also reported for other starches (Sasaki et al., 2004; Onyango et al., 2009). Latter authors hypothesised that this viscoelasticity reduction could be related to the sample thermal degradation with the consequent formation of non-carbohydrate polymers which leads to a viscoelasticity drop. The starch GD (%), estimated as the ratio between G gel' (1 Hz) values for each PS sample and NPS, exhibited the lowest values for PS54 (from 1.4 (PS54:10) to 1.9 (PS54:60)), followed by PS58 (from 29.5 (PS58:10) to 54.9 (PS58:60)), PS65 (from 62.7 (PS65:10) to 92.9 (PS65:60)) and PS70 (from 87.1 (PS70:10) to 100 (PS75:60)). The above results show that the production of PS gels with a wide range of viscoelastic properties is possibly controlling the temperature-time gelatinisation conditions.

Effect of the temperature-time dependence during starch gelatinisation on the mechanical properties of the final potato starch gels (G' gel, 1 Hz). Symbols: white–NPS, dotted, lined, grey and black–potato starch gelatinised at tested temperatures (54, 58, 65, 70, 80, 85, 90 °C) for 10, 20, 30 and 60 min

Thermal Reversibility of Potato Starch Gels

Different temperature-time gelatinisation conditions also provide NPS gels with different thermal reversibility features. The mechanical spectra of some tested gels in the second heating/cooling cycle are presented in Fig. 4b. The differences between mechanical spectra of the first and second cycles allowed determining the gelatinisation conditions’ impact on the thermal reversibility. Namely, G' and G" moduli of PS54 and PS58 gels of the second cycle exhibited lower values (around 0.9 times) when compared with those obtained in the first cycle, indicating no complete thermal reversibility. For longer gelatinisation times (> 20 min), differences were reduced to 0.95 times. In contrast, both moduli of NPS gels and those PS gels prepared at temperatures above gelatinisation peak temperature (PS65, PS70 and PS80) measured during the second cycle overlaps with those measured during the first one, meaning that full thermal reversibility was achieved and the network structures formed are more stable. No differences in thermal reversible behaviour were observed at different tested times. This thermal stability behaviour (considering only temperature effect) was also reported for other starchy (Lawal et al., 2011) and non-starchy biopolymers (Torres et al., 2017). PS85 and PS90 gels exhibited a reduction of viscoelastic moduli in comparison to the first cycle around 0.93 and 0.85 times, respectively. For longer gelatinisation times (> 10 min), differences were reduced to 0.97 and 0.89 times. These outcomes are consistent with the hypothesis that some polymer degradation is thermally promoted. To sum up, temperatures below T p and much higher than T 1 (around 15 °C) lead to stable, weak, no completely thermal reversible and notably time-dependant gels. However, temperatures between T p and T 1, favour the formation of stronger and fully thermal reversible gels, remaining practically invariant until 80 °C. These results provide a wide range of temperature-time conditions to starch gel processing without jeopardising the formulation stability.

Textural Characteristics

Table 1 summarises the measured textural properties for representative gels. Namely, hardness of tested gels varied significantly from 0.29 to 2.76 kg, exhibiting the largest values for PS70 and PS80 which are the gels with the largest GD. The differences for these last gels were not statistically significant when compared to NPS gels. Note here that hardness increased with increasing GD and decreased at the highest gelatinisation temperatures (i.e. PS85 and PS90). Consistently with the above rheological results, gels formed at temperatures below T p (58 ± 0.5 °C) exhibited the lowest hardness values, which suggest that the gel starch networks were partially developed. Similar tendencies were observed for springiness (from 0.21 to 2.10) and gumminess (from 0.03 to 1.03 kg). Cohesiveness (between 0.09 and 0.37) and chewiness (between 0.01 and 2.16) also exhibited similar patterns, except for NPS where statistical differences were observed when compared with PS70. For NPS, both parameters presented lower values than those calculated for PS70. In all cases, adhesiveness varied in a restricted range (from 0 to 0.04 kg s), achieving the lowest values for NPS gels with the lowest GD (PS54). Texture parameter values of studied gels produced between PS58 and PS90 were in the range of those found for commercially available desserts (Torres et al. 2014a). Texture features of the studied gels were also dependent of time gelatinisation conditions with same tendencies to those described with temperature. Increasing time led to a slight rise (around 10% from 10 to 30 min) to the texture parameter values for starches treated below 80 °C. Those treated at 85 and 90 °C exhibited a drop in texture values with increasing time (around 5% from 10 to 30 min). In all cases, no significant differences were observed above 30 min gelatinisation. The time-temperature texture dependences agreed with those reported for other starchy materials (Brites et al., 2008).

Overall, the results from the large deformation test (TPA) are consistent with those found from small deformation rheology and a wide set of gels can be obtained. Figure 6 presents the dependence of G gel' (1 Hz) from mechanical spectra with the ratio D 1/D 2 of TPA. An acceptable linear dependence (R 2 > 0.961) between both parameters can be observed. These results are consistent with those found for other foodstuffs (Lagarrigue & Alvarez, 2010), where D 1/D 2 (based on springiness) were correlated with the material elastic properties. Finally, gel separation from the liquid phase was noticed neither in NPS gels nor in PS gels aged during 1 week at room temperature. The absence of syneresis in potato gels makes them a valuable alternative to other starchy (Lan et al., 2008) and non-starchy (Torres et al., 2017) materials where syneresis occurs during gel formation.

Conclusions

Gel forming kinetics and final gel mechanical features for potato starches are greatly dependent on temperature-time gelatinisation conditions. NPS, PS70:20 and PS80, independently of applied gelatinisation time, presented the largest gel strength. A wide range of temperature (from 58 to 80 °C) and time (below 60 min) conditions to potato starch gels processing without jeopardising the formulation stability were identified. Although all systems (above 50 °C) presented gel properties, those gelatinised below 54 °C or above 80 °C lead to stable, weak, not completely thermal reversible and notably time-dependent gels. Times above 30 min did not significantly modify the mechanical gel properties. Results from TPA were in harmony with those found from small deformation rheology. In general, this study delivered a potato starch set exhibiting suited gelling features for a broad application range, resulting from different temperature-time gelling conditions.

References

Alcázar-Alay, S. C., & Meireles, M. A. A. (2015). Physicochemical properties, modification and applications of starches from different botanical sources. Food Science and Technology, 35, 215–236.

AOAC. (2000). Official Methods of Analysis (17th ed.). Washington: Association of Official Analytical Chemistry.

ASAE Standards. (1995). S319.2: Methods for determining and expressing fineness of feed materials by sieving. Michigan: American Society of Agricultural Engineers.

Bhattacharjya, B., Dutta, H., Patwari, K., & Mahanta, C. L. (2015). Properties of annealed jackfruit (Artocarpus heterophyllus Lam.) seed starch. Acta Alimentaria, 44, 501–510.

Brites, C., Trigo, M. J., Santos, C., Collar, C., & Rosell, C. M. (2008). Maize based gluten-free bread: influence of processing parameters on sensory and instrumental quality. Food Bioprocess Technology, 3, 707–715.

Charoenkul, N., Uttapap, D., Pathipanawat, W., & Takeda, Y. (2011). Physicochemical characteristics of starches and flours from cassava varieties having different cooked root textures. LWT - Food Science and Technology, 44, 1774–1781.

Cheetham, N. W. H., & Tao, L. (1998). Variation in crystallinity type with amylose content in maize starch granules: an X-ray powder diffraction study. Carbohydrate Polymers, 36, 277–284.

Chenlo, F., Moreira, R., Prieto, D. M., & Torres, M. D. (2011). Desorption isotherms and net isosteric heat of chestnut flour and starch. Food and Bioprocess Technology, 4, 1497–1504.

Cornejo-Villegas, M. A., Acosta-Osorio, A. A., Rojas-Molina, I., Gutiérrez-Cortéz, E., Quiroga, M. A., Gaytán, M., Herrera, G., & Rodríguez-García, M. E. (2010). Study of the physicochemical and pasting properties of instant corn flour added with calcium and fibers from nopal powder. Journal of Food Engineering, 96, 401–409.

Correia, P., Cruz-Lopes, L., & Beirão-da-Costa, L. (2012). Morphology and structure of chestnut starch isolated by alkali and enzymatic methods. Food Hydrocolloids, 28, 313–319.

Genovese, D. B., & Rao, M. A. (2003). Role of starch granule characteristics (volume fraction, rigidity and fractal dimension) on rheology of starch dispersions with and without amylose. Cereal Chemistry, 80, 350–355.

Glampedaki, P., Petzold, G., Dutschk, V., Miller, R., & Warmoeskerken, M. C. G. (2012). Physicochemical properties of biopolymer-based polyelectrolyte complexes with controlled pH/thermo-responsiveness. Reactive and Functional Polymers, 72, 458–468.

Gunaratne, A., & Hoover, R. (2002). Effect of heat-moisture treatment on the structure and physicochemical properties of tuber and root starches. Carbohydrate Polymers, 49, 425–437.

Houben, A., Götz, H., Mitzscherling, M., & Becker, T. (2010). Modification of the rheological behavior of amaranth (Amaranthus hypochondriacus) dough. Journal of Cereal Science, 51, 350–356.

Jan, K. N., Panesar, P. S., Rana, J. C., & Singh, S. (2017). Structural, thermal and rheological properties of starches isolated from Indian quinoa varieties. International Journal of Biological Macromolecules, 102, 315–322.

Jena, R., & Bhattacharya, S. (2003). Viscoelastic characterization of rice gel. Journal of Texture Studies, 34, 349–360.

Jiménez, A., Fabra, M. J., Talens, P., & Chiralt, A. (2012). Edible and biodegradable starch films: a review. Food and Bioprocess Technology, 5, 2058–2076.

Joshi, M., Aldred, P., Panozzo, J. F., & Kasapis, S. (2014). Rheological and microstructural characteristics of lentil starch-lentil protein composite pastes and gels. Food Hydrocolloids, 35, 226–237.

Lagarrigue, S., & Alvarez, G. (2010). The rheology of starch dispersions at high temperature and high shear rates: a review. Journal of Food Engineering, 50, 189–202.

Lai, P., Li, K. Y., Lu, S., & Chen, H. H. (2011). Physicochemical characteristics of rice starch supplemented with dietary fibre. Food Chemistry, 127, 153–158.

Lan, W., Hihua, Y., Yun, Z., Bijun, X., & Zhida, S. (2008). Morphological, physicochemical and textural properties of starch separated from Chinese water chestnut. Starch-Starke, 60, 181–191.

Lawal, O. S., Lapasin, R., Bellich, B., Olayiwola, T. O., Cesàro, A., Yoshimura, M., & Nishinari, K. (2011). Rheology and functional properties of starches isolated from five improved rice varieties from West Africa. Food Hydrocolloids, 25, 1785–1792.

Li, G., Wang, S., & Zhu, F. (2016). Physicochemical properties of quinoa starch. Carbohydrate Polymers, 137, 328–338.

Malumba, P., Jacquet, N., Delimme, G., Lefebvre, F., & Béra, F. (2013). The swelling behavior of wheat starch granules during isothermal and non-isothermal treatments. Journal of Food Engineering, 114, 199–206.

Manohar, R. S., & Rao, P. H. (2002). Interrelationship between rheological characteristic of dough and quality of biscuits; use of elastic recovery of dough to predict biscuit quality. Food Research International, 35, 807–813.

Marco, C., & Rosell. (2008). Rice. In E. K. Arendt & F. Dal Bello (Eds.), Gluten free cereal product and beverages. London: Academic Press.

Moreira, R., Chenlo, F., Torres, M. D., & Glazer, J. (2012). Rheological properties of gelatinized chestnut starch dispersions: effect of concentration and temperature. Journal of Food Engineering, 112, 94–99.

Moreira, R., Chenlo, F., Torres, M. D., & Rama, B. (2013). Influence of the chestnuts drying temperature on the rheological properties of their doughs. Food and Bioproducts Processing, 91, 7–13.

Nunes, M. C., Raymundo, A., & Sousa, I. (2006). Rheological behaviour and microstructure of pea protein/k-carrageenan/starch gels with different setting conditions. Food Hydrocolloids, 20, 106–113.

Onyango, C., Unbehend, G., & Lindhuaer, M. G. (2009). Effect of cellulose-derivatives and emulsifiers on creep-recovery and crumb properties of gluten-free bread prepared from sorghum and gelatinized starch. Food Research International, 42, 949–955.

Pérez-Santos, D. M., Velazquez, G., Canonico-Franco, M., Morales-Sanchez, E., Gaytan-Martínez, M., Yañez-Limon, J. M., & Herrera-Gomez, A. (2016). Modelling the limited degree of starch gelatinization. Starch/Stärke, 68, 727–733.

Przetaczek-Roznowska, I. (2017). Physicochemical properties of starches isolated from pumpkin compared with potato and corn starches. International Journal of Biological Macromolecules, 101, 536–542.

Santos, E., Rosell, C. M., & Collar, C. (2008). Retrogradation kinetics of high fibre wheat flour blends: a calorimetric approach. Cereal Chemistry, 85, 450–458.

Sasaki, T., Kohyama, K., & Yasui, T. (2004). Effect of water-soluble and insoluble non-starch polysaccharides isolated from wheat flour on the rheological properties of wheat starch gel. Carbohydrate Polymers, 57, 451–458.

Sheikha, A. F. E., & Ray, R. C. (2017). Potential impacts of bioprocessing of sweet potato: review. Critical Reviews in Food Science and Nutrition, 57, 455–471.

Sodhi, N. S., Sasaki, T., Lu, Z.-H., & Kohyama, K. (2010). Phenomenological viscoelasticity of some rice starch gels. Food Hydrocolloids, 24, 512–517.

Tananuwong, K., & Reid, D. (2004). DSC and NMR relaxation studies of starch-water interactions during gelatinization. Carbohydrate Polymers, 58, 345–358.

Torres, M. D., Chenlo, F., & Moreira, R. (2017). Thermal reversibility of kappa/iota-hybrid carrageenan gels extracted from Mastocarpus stellatus at different ionic strengths. Journal of the Taiwan Institute of Chemical Engineers, 71, 414–420.

Torres, M. D., Fradinho, P., Raymundo, A., & Sousa, I. (2014a). Thermorheological and textural behaviour of gluten-free gels obtained from chestnut and rice flours. Food and Bioprocess Technology, 7, 1171–1182.

Torres, M. D., Moreira, R., Chenlo, F., Morel, M. H., & Barron, C. (2014b). Physicochemical and structural properties of starch isolated from fresh and dried chestnuts and chestnut flour. Food Technology and Biotechnology, 52, 135–139.

Wang, H., Zhang, B., Chen, L., & Li, X. (2016). Understanding the structure and digestibility of heat-moisture treated starch. International Biological Macromolecules, 88, 1–8.

Wani, I. A., Sogi, D. S., Hamdani, A. M., Gani, A., Bhat, N. A., & Shah, A. (2016). Isolation, composition, and physicochemical properties of starch from legumes: a review. Starch/Strakë, 68, 834–845.

Waterschoot, J., Gomand, S. V., Fierens, E., & Delcour, J. A. (2015). Starch blends and their physicochemical properties. Starch-Starke, 67, 1–13.

Witczak, M., Ziobro, R., Juszczak, L., & Korus, J. (2015). Starch and starch derivatives in gluten-free systems—a review. Journal of Cereal Science, 67, 46–57.

Zhang, D., Mu, T., & Sun, H. (2017a). Calorimetric, rheological, and structural properties of potato protein and potato starch composites and gels. Starch/Stärke, 69, 1600329.

Zhang, B., Selway, N., Shelata, K. J., Dhital, S., Stokes, J. R., & Gidleya, M. J. (2017b). Tribology of swollen starch granule suspensions from maize and potato. Carbohydrate Polymers, 155, 128–135.

Acknowledgements

The authors acknowledge the financial support (ED431B) to the Consellería de Cultura, Educación e Ordenación Universitaria (Xunta de Galicia) and the use of RIAIDT-USC analytical facilities for X-ray diffraction measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Torres, M.D., Chenlo, F. & Moreira, R. Rheological Effect of Gelatinisation Using Different Temperature-Time Conditions on Potato Starch Dispersions: Mechanical Characterisation of the Obtained Gels. Food Bioprocess Technol 11, 132–140 (2018). https://doi.org/10.1007/s11947-017-2000-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-017-2000-6