Abstract

Aim of the present study was to evaluate the suitability of two different types of n-octenylsuccinate-derivatised starch, which significantly differed in viscosity, for microencapsulation of a fish oil rich in long-chain polyunsaturated fatty acids. Stable feed emulsions for microencapsulation could be prepared with both types of n--octenylsuccinate starch, however at a high oil load (50%), a low pH (pH 4.5) of the emulsion was crucial for emulsion stability. At 50% oil content, lower oil droplet size in reconstituted spray-dried emulsions and lower content of non-encapsulated oil was reached by low viscosity starch compared to medium viscosity starch. Conjugated dienes were significantly increased in samples with a high oil load and 40% starch indicating that to a certain degree lipid oxidation already occurred in these samples during the drying process. Finally, moderate spray-drying conditions must be considered as advantageous, since ballooning of the particles and lipid oxidation during spray drying were limited compared to drying at high spray-drying temperatures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microencapsulation is defined as a process by which one material or mixture of materials is coated with or entrapped within another material or system [1]. Aims of the microencapsulation process initially were simply a conversion of a liquid into solids, thus increasing product stability, and improved handling, as well as masking of unpleasant flavours. Nowadays, due to an increasing demand for functional ingredients and sophisticated food products, prevention of oxidative deterioration and controlled-release-characteristics become more important. For several decades, microencapsulation by spray-drying has been applied in the food industry and is still the predominating technology as it is rather inexpensive and straightforward [2].

Typical wall materials for microencapsulation by spray-drying are low molecular weight carbohydrates like maltodextrins or saccharose, milk or soy proteins, gelatine and hydrocolloids like gum arabic or mesquite gum [4–10]. Gum arabic has been described as the standard of excellence as a flavour encapsulation material for many years [11]. However, it is a comparably expensive raw material and quality problems have frequently been reported [11, 12]. A potential inexpensive alternative for gum arabic is n-octenylsuccinate-derivatised starch (n-OSA starch). Derivatisation of starch with alkenylated dicarboxylic acid anhydrides results in an ingredient with high emulsifying properties (Fig. 1).

n-OSA starch is usually prepared in three steps: granular starch is derivatised with octenyl-substituted succinic acid in an aqueous alkaline medium below gelatinisation temperature. The second step, gelatinisation, provides solubility of the starch ester and additionally, to reduce viscosity of the solution, starch is degraded in a third step in a process called “acid-thinning” [13]. Current applications are the stabilisation of flavour concentrates in beverages, oils in salad dressings and the encapsulation of flavours, fragrances and vitamins [14]. For microencapsulation by spray-drying, a low viscosity of the n-OSA starch is desirable in terms of a high total solids concentration of the feed emulsion and prevention of excessive air inclusion in the microcapsules. On the other hand, molecular weight must not be too low, since the film-formation property of starch is a prerequisite for coating and entrapping the active substances by forming microcapsules.

n-OSA starch has been approved for the use in foods by the FDA and within the EU. Recently, n-OSA starch has been permitted for use as an additive for formulae and weaning foods for infants and young children in the EU. Products may contain n-OSA starch resulting from the addition of vitamin preparations or polyunsaturated fatty acid preparations. The carry over of n-OSA starch in the product ready for consumption is limited to 100 mg/kg from vitamin preparations and 1000 mg/kg from polyunsaturated fatty acid preparations [15].

Studies on microencapsulation of oils rich in long-chain polyunsaturated fatty acids, like fish oil, with sodium caseinate, dextrins and highly-branched cyclic dextrins or modified cellulose are available [16, 17], but studies on microencapsulation with n-OSA starch are lacking. Aim of the present study was to evaluate the technical properties of two different types of n-OSA starch, which significantly differed in viscosity, for microencapsulation of a fish oil rich in long-chain polyunsaturated fatty acids. In the first part feed emulsions were tested regarding their stability. After spray-drying of the emulsion physical characterisation of the microcapsules was performed and the lipid oxidation status was investigated.

Materials and methods

Two different types of n-OSA starch, which differed in viscosity but not in degree of substitution, were chosen as wall materials. The low viscosity starch (L) had a viscosity of 132 mPas at 30% solids at 25°C, the medium viscosity starch (M) had a viscosity of 340 mPas at 30% solids at 25°C. The core material for encapsulation was a fish oil rich in long-chain polyunsaturated fatty acids provided by Henry Lamotte GmbH, Bremen, Germany. The concentration of docosahexanoic acid and eicosapentanoic acid was 12.3 and 18.0%, respectively.

Preparation of feed emulsions

Preparation of stable emulsions via optimisation of homogenisation conditions was performed in three subsequent two-level full factorial experiments (Table 1). Experimental factors were the starch content, the type of starch, the oil content, homogenisation pressure and number of passes. Total solids of each emulsion was made up to 100% using glucose syrup with a DE value of 38 (Cerestar Germany GmbH, Germany).

The three experiments differed in total solids and pH value of the emulsion. In experiment 1 and experiment 2, total solids of the emulsion were set at 30%. While in experiment 1 pH was not adjusted, in experiment 2 pH was adjusted to 4.5. In experiment three total solids content of the emulsion was increased to 45%. All water-soluble ingredients were dissolved in water prior to emulsification. Afterwards the oil was dispersed in the aqueous phase using a hand blender. A coarse emulsion was prepared by subsequent homogenisation at 50 bar in a high pressure homogeniser (Panda 2K, Niro Soavi Deutschland, Lübeck, Germany) followed by a final two-step homogenisation according to the factorial design.

Spray drying

The spray drying experiment was performed as a two-level full factorial design. Factors varied were type of starch (low level: medium viscosity starch; high level: low viscosity starch), composition (low level: 40% n-OSA starch, 50% oil, 10% glucose syrup; high level: 10% n-OSA starch, 20% oil, 70% glucose syrup) and spray drying conditions. An air inlet temperature of 160°C and an outlet air temperature of 60°C were chosen as a moderate spray drying process and an air inlet temperature of 210°C and an outlet air temperature of 90°C reflected severe drying conditions. The spray drying experiment was performed on a laboratory scale spray dryer (1–7 kg/h water evaporative capacity, Mobile Minor, Niro A/S, Denmark) equipped with a rotating disk for atomisation. Disk rotation was 18000 Upm.

Viscosity and stability of the emulsions

Viscosity of the emulsions was determined using a rotational viscometer (Haake Viscotester 7L, Thermo Electron Corporation, Dreiech, Germany). For evaluation of the emulsion stability, 10 ml of the emulsion were centrifuged at 440 g for 5 min. The volume of the supernatant oil phase was recorded.

Oil droplet size of the emulsions, particle size of the microcapsules and oil droplet size of the reconstituted microcapsules

All oil droplet size and particle size analyses were determined using a laser-diffraction sensor (Helos, Sympatec GmbH, Clausthal-Zellerfeld, Germany) equipped with a cuvette. Results are reported as 10th, 50th and 90th percentile of the size of the particles. Oil droplet size of the emulsions was determined after dilution of the sample with water, for analysis of the oil droplet size of the microcapsules, an aliquot of powder was reconstituted in water. Particle size analysis of the microcapsules was performed after dispersing an aliquot of the powder in an inert oil (Miglyol 812, Sasol Germany, Hamburg, Germany). All analyses were performed with four replicates.

Determination of the BET surface area

BET analyses was performed using a Gemini 2360 (Micromeritics, Mönchengladbach, Germany). Samples were degassed under vacuum in a Vacprep 061 (Micromeritics, Mönchengladbach, Germany).

True density, apparent density and porosity of the microcapsules

True density of the powder particles was determined using a Pycnomatic helium pycnometer (Thermo Electron Corporation, Dreiech, Germany).

Porosity and apparent density were analysed using a PASCAL 140 low pressure mercury porosimeter (Thermo Electron Corporation, Dreiech, Germany). It is a liquid displacement technique suitable to measure the porosity in macro and ultramacroporous materials and powders using mercury. A portion of sample is placed in a sample chamber of known volume. The sample, is not initially intruded with mercury because of the high surface tension and, thus, the apparent density of the sample can be determined at this stage. Gradually, increasing amounts of pressure are applied and with increasing pressure, mercury is intruded into the pores. The change in intrusion volume of mercury into the pores is measured. Volume of mercury is equal to the volume of the pores whose diameters fall within an interval that corresponds to the particular pressure interval. Thus the pore size, pore volume and taking into account the apparent density, the porosity of the sample can be calculated.

Bulk density, moisture content, water activity and determination of non-encapsulated fat

For determination of bulk density a 50 ml graduated cylinder was filled with 25 ml of powder. No tapping was applied and the weight of the sample was recorded. Analysis was performed in duplicate. Water activity was measured using a TH500 AW Sprint (Novasina, Pfäffikon, Switzerland), moisture content was analysed using an electronic moisture analyser MA30 (Sartorius, Göttingen, Germany). The amount of non-encapsulated fat in the microcapsules was determined using a reference method for determination of free fat in dried milk products including extraction of the fat in a Soxhlet apparatus with petrol ether and gravimetric determination of the extracted fat [18].

Scanning electron microscopy

A LEO S420 (Oberkochen, Germany) was used to view and describe the characteristics of the microcapsules. Samples were mounted onto stubs using double stick tape. In a sputter coater (BAL-TEC SCD 050, Witten, Germany) a thin layer of gold was applied to the surface of the particles to make samples conductive.

Lipid oxidation parameters

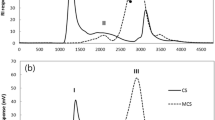

For the evaluation of oxidative changes in the fish oil during spray-drying of the microcapsules, three different parameters were analysed. Conjugated dienes and the peroxide value were analysed to cover initial stages of lipid oxidation in the oil fraction. Therefore, oil was isolated from the microcapsules as described by Satué-Gracia et al. [19]. Conjugated dienes were photometrically determined after dilution of the oil with 2-propanol at 234 nm. For calculation of the concentration, the results were expressed as millimoles of hydroperoxide per kilogram oil using a molar coefficient of 26000 for methyl linoleate hydroperoxides [20]. Peroxide value was determined using the IDF standard method 74A:1991 for the determination of the peroxide value in anhydrous milk fat with slight modifications [21].

Volatile aldehydes were analysed via static headspace gas chromatography. Briefly, 2 g of sample were weighed into a 20 ml headspace vial, sealed and incubated at 70°C for 15 min. An aliquot of the headspace (1 ml) was injected into a HP 6890A gas chromatograph equipped with a DB-1 column (30 m*0.32 mm*3 μm). Injector and detector temperature were set at 180°C and 220°C, respectively. Oven temperature was initially set at 40°C and increased after 5 min to 94°C within 10 min. The major volatile aldehyde resulting from the degradation of omega-3 fatty acids, which was used in the present study for evaluation of the oxidation of the surface fat, is propanal.

Statistical analysis

All experiments were planned and analysed using Design Expert, Version 6.0.10 (Stat Ease Inc, Minneapolis, USA). For the three experiments for optimisation of the homogenisation conditions a two-level half-factorial design was chosen. Power at 5% alpha level for effect of twofold standard deviation was 94.9%. The spray-drying experiment was performed as a two level full factorial design. In this case, power at 5% alpha level for effect of twofold standard deviation was 57.2%. Constants and regression coefficients of the multiple linear regression equation and probability values are reported.

Results and discussion

Table 2 compares the droplet size of emulsions prepared with medium and low viscosity starch after different homogenisation treatments. The oil content varied between 20 and 50%. In the first experiment, in which pH was not adjusted, the 50th percentile of the oil droplet size ranged from 0.75–11.53 μm, the 90th percentile from 1.45 to 34.9 μm. The interaction between the type of starch and oil content significantly influenced oil droplet size (Fig. 2). A high oil load of 50% and the use of a low viscosity n-OSA starch resulted in large oil droplets and therefore led to a significantly decreased stability of the emulsions (Table 3). In contrast, use of medium viscosity starch resulted in moderate oil droplet size even at the 90th percentile (1.45 and 2.87 μm).

Bangs and Reineccius were able to incorporate 81% oil into a 40 w/w% dispersion of n-OSA starch. However, the authors encapsulated lemon oil and not a triglyceride oil. Whereas Tesch et al. [22] showed that at a concentration of 5% n-OSA starch 30% triglyceride oil can be emulsified, but not 80% oil. The authors explained their observation with an increase in collision frequency of the oil droplets resulting in an increase in coalescence. It is rather likely, that the molecular weight of the n-OSA starch molecules is of importance, since in the present study medium viscosity n-OSA starch was capable of emulsifying 50% of oil under the chosen homogenisation conditions. It seems that due to a high viscosity of these samples, hydrodynamic stabilisation was sufficient for emulsifying 50% of oil, but not in samples prepared with low viscosity n-OSA starch.

The influence of a difference in pH was investigated in the present study. pH was only affected by starch content of the emulsion, but not by type of starch (Table 3), which significantly influenced emulsion stability. Therefore, pH directly can not be responsible for the decreased stability of high oil emulsions prepared with low viscosity n-OSA starch.

In order to change stabilisation properties without changing viscosity in emulsions it was of interest to reduce mobility of the low viscosity n-OSA starch molecules. A decrease in pH would lead to a reduction of electrophoretic mobility of the molecules, since the carboxylic group in the molecule is protonated, and brings net surface charge close to zero [23]. For example, improved stability may be caused by closer packaging of the starch molecule at the oil/water interface, resulting in a stable film with high visco-elasticity.

Therefore, in a second experiment pH was adjusted to 4.5 prior to homogenisation. In this experiment, the 50th percentile of the oil droplet size ranged from 0.64 to 1.69 μm, the 90th percentile from 1.38 to 4.55 μm (Table 2). All emulsions were stable upon centrifugation.

This was in contrast to findings of Tesch et al. [22], who did not observe an effect of pH in the range of 3–7 and ionic strength on oil droplet size and stability of emulsions with 30% oil and 5% n-OSA starch.

Since the statistically dominating effect of poor emulsifying properties of the n-OSA starch were overcome, more subtle effects became obvious. Table 4 shows that the 50th percentile of the oil droplet size was significantly influenced by homogenisation pressure and oil content. The number of passes significantly affected the 90th percentile of the oil droplet size indicating that after one homogenisation step there are still larger oil droplets present, which were reduced after the second homogenisation.

The importance of a second passing of the emulsion through the homogeniser becomes even more pronounced when total solids of the emulsion was increased (Experiment 3). Emulsion stability and oil droplet size were in an acceptable range in all samples. The maximum value for the 50th percentile of the oil droplet size was 1.85 μm and the maximum value for the 90th percentile was 4.30 μm (Table 2). At all percentiles, oil droplet size was significantly affected by the number of passes (Table 5). Furthermore oil content itself, and, at a high oil content, starch content significantly influenced oil droplet size.

Spray drying of four different emulsion recipes (45% total solids) was carried out under two different drying conditions. The moisture content in the samples ranged from 1.10 to 3.23% and the a w value from 0.097 to 0.273. Both parameters indicate that spray-drying resulted in a stable product in terms of microbiological and physicochemical alterations during storage. A moisture content below 3% and an a w value of less than 0.300 are generally considered to ensure product stability.

Particle size expressed as 50th percentile of the particle distribution ranged from 22 to 29 μm (Table 6) and is markedly higher than in microcapsules prepared from an emulsion with a decreased content of 30% total solids (data not shown). In previous experiments with n-OSA starch an emulsion with 30% total solids resulted in microcapsules with a 50th percentile of the particle size of about 15 μm.

Particle size was significantly affected by composition of the emulsion and drying conditions. Data from the multiple linear regression indicate that microcapsules size decreased with a decrease in oil and starch content, whereas an increase in drying air inlet and outlet temperature led to an increase in particle size (Table 7). With a regression coefficient of 2.33 for the 50th percentile of the particle size, the influence of drying conditions on particle size was higher than the influence of the composition with a regression coefficient of 0.88 for the 50th percentile of the particle size.

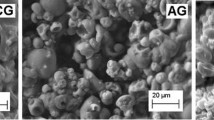

Scanning electron microscopy showed that drying conditions not only affected particle size, but also particle morphology. At high drying temperatures of 210/90°C “ballooning” occurred (Fig. 3A and 3C). “Ballooning” is a phenomenon, which occurs during drying of film-forming materials at high temperatures. Walton and Mumford [24] described the effect of ballooning for skin-forming materials like, e.g. milk powder as follows: “A skin covered the whole droplet surface virtually instantaneously; this was rapidly followed by internal bubble nucleation. The bubbles expanded to violently distort, and eventually rupture, the skin surface causing the particle to collapse, shrivel and then re-inflate. This cycle was repeated three or four times until most of the internal moisture had evaporated. As the skin dried-out and hardened, vaporisation of residual moisture inflated the particle permanently to form a hollow particle with, in the majority of cases, a relatively smooth surface structure.” A similar mechanism has occurred during drying at 210/90°C in the present study. Figure 3A and 3C also show, that viscosity influences droplet formation during atomisation and particle shape. The use of low viscosity n-OSA starch resulted in spherical particles (Fig. 3C) whereas the use of medium viscosity n-OSA starch partly resulted in filamentous particles (Fig. 3A).

Drying at 160/60° resulted in shrivelled and deformed particles (Fig. 3B and 3D). At low drying temperatures, solid precipitation occurs by formation of a skin. As a consequence, particles decrease in size and internal bubble nucleation is limited. Shrivelling of particles and deformation on drying is also reported as “indentation”. For example Onwulata et al. [25] described regular indentation for microencapsulated butter oil or cream, emulsified with n-OSA starch and dried at maximum temperatures of 196/88°C. Generally, “ballooning” temperature is determined by wall material and dryer design [1].

Figure 4 shows that ballooning also effects air inclusion in the microcapsules. In the present study, particles dried at 210/90°C show a large central void (Fig. 4A and 4C), whereas at a low drying temperature of 160/60°C volume of the central void is decreased and wall thickness is increased. Apart from air inclusion, although not statistically significant, oil droplet size in the reconstituted emulsion was affected by type of starch and starch content. The use of a medium viscosity starch at a level of 40% resulted in a shift in the 50th percentile of the oil droplet size from 1.2 to 1.3 μm in the emulsion (Experiment 3, Table 2) to 8.18 μm and 7.16 μm in the reconstituted emulsions, for low and high spray-drying temperatures, respectively. This marked increase in oil droplet size was also observed at a high spray-drying temperature when using 40% of the low viscosity starch, but not at low drying temperatures and at 20% oil load with 10% of starch. In previous experiments with 30% total solids in the feed emulsion, oil droplet size in emulsions prepared from spray-dried microcapsules was unchanged compared to the oil droplet size in the feed emulsion (data not published). This indicates that a 50% oil load in combination with a high total solids concentration in the feed emulsion may be disadvantageous with respect to stability of the reconstituted microcapsules. Although effects were not significant, a high oil and starch content tended to result in a higher percentage of non-encapsulated fat (Table 8). At 50% oil load, moderate spray-drying conditions (160/60°C) resulted in 4.3 and 8.8% of non-encapsulated fat compared to 2.5 and 1.9% at high spray drying temperature for microcapsules with low and medium viscosity n-OSA starch, respectively. However, in terms of lipid oxidation and thus shelf-life stability, the amount of surface fat, which probably represents a high proportion of the non-encapsulated fat, has been reported to be less significant [9, 26, 27].

True density and apparent density were significantly influenced by composition and drying conditions (Table 7). Drying at 210/90°C significantly lowered true and apparent density of the microcapsules compared to drying at 160/60°C. This observation is in accordance with data from the literature. Higher inlet air temperatures result in lower density powders, which is partly due to more rapid drying of the particle, and therefore, fixing of the particle dimensions before much water has been evaporated [1]. A high oil and starch content in the composition significantly decreased the apparent and true density, which can be explained by the above described effect of “ballooning” and a co-occurring increase in air inclusion. Since the effect of microcapsules composition on true density was more pronounced than the influence of drying conditions (Table 7), also a significant influence of the composition on microcapsules porosity was observed. Porosity increased with lowering the starch and oil content and thus increasing the percentage of glucose syrup. The increase in porosity explains the significant increase in BET surface area, which was observed for the samples high in glucose syrup. Porosity may gain importance during storage of the products, since it affects oxygen diffusion and thus lipid oxidation in the microcapsules.

Composition of the microcapsules also had a significant influence on the presence of conjugated dienes in the oil (p=0.0140). It seems likely, that this is related to structural differences caused by the increased oil content in the powder rather than to the starch content. Both, maltodextrins and n-OSA starch, are described as excellent oxygen barriers for microcapsules [12]. In the present study, a significant increase in conjugated dienes also was observed with high spray-drying temperature (p=0.0121) indicating oxidative changes in the complete oil fraction during drying. Although not significant, an increase in propanal at high spray-drying temperature was observed (Table 8). This reflects more severe damage of the surface oil, which may impair sensorical quality of the product and its use.

In conclusion, stable feed emulsions for microencapsulation of fish oil may be prepared with both types of n-OSA starch. At a high oil load, a low pH of the emulsion is crucial for stability of emulsions based on the low viscosity n-OSA starch, i.e. highly degraded starch. Repeated passing of the emulsion through the homogeniser was more efficient for reduction of oil droplet size than increasing homogenisation pressure.

Regarding physicochemical parameters of the microcapsules low viscosity n-OSA starch demonstrated better technical properties than medium viscosity n-OSA starch. The use of a n-OSA starch with increased viscosity led to coalescence of the oil droplets resulting in a high proportion of large oil droplets in the reconstituted emulsion, which may cause stability problems in fortified foods. Furthermore, a high oil load of 50% and a starch content of 40% in combination with a high total solids concentration in the feed emulsion may be disadvantageous. Oil droplet size of the reconstituted emulsion was increased as well as non-encapsulated oil. Conjugated dienes were significantly increased in these samples indicating that to a certain degree lipid oxidation already occurred in these samples during the drying process. Since porosity, which is more important for lipid oxidation than e.g. surface fat, was decreased at a starch content of 40%, long term oxidative stability should be monitored to determine the most stable formulation. Finally, moderate spray-drying conditions can be considered as advantageous, since ballooning and lipid oxidation during spray drying were limited compared to drying at high spray-drying temperatures.

References

Finney J, Buffo R, Reineccius GA (2002) J Food Sci 67:1108–1114

Gouin S (2004) Trends Food Sci Technol 15:330–347

Porzio M (2004) Food Technol 58:40–47

Fäldt P, Bergenståhl B (1995) J Am Oil Chem Soc 72:171–176

Hogan SA, McNamee BF, O'Riordan ED, O'Sullivan M (2001) J Agric Food Chem 49:1934–1938

Hogan SA, McNamee BF, O'Riordan ED, O'Sullivan M (2001) J Food Sci 66:675–680

Hogan SA, McNamee BF, O'Riordan ED, O'Sullivan M (2001) Int Dairy J 11:137–144

Kim YD, Morr CV (1996) J Agric Food Chem 44:1314–1320

Keogh MK, O'Kennedy BT, Kelly J, Auty MA, Kelly PM, Fureby A, Haahr AM (2001) J Food Sci 66:217–224

Lin C-C, Lin S-Y Hwang LS (1995) J Food Sci 60:36–39

Buffo R, Reineccius GA (2000) Perfumer Flavorist 25:45–54

Reineccius GA (1991) Food Technol 144–149

Fitton MG (1996) US Patent 5,505,783, 09.06.1996

Shogren RL, Viswanathan A, Felker F, Gross RA (2000) Starch/Stärke 52:196–204

Directive 2003/114/EC of the European parliament and of the Council of 22 December 2003 amending Directive 95/2/EC on food additives other than colours and sweeteners. http://europa.eu.int/eur-lex/pri/en/oj/dat/2004/l_024/l_02420040129en00580064.pdf. Visited: 05.08.2004

Hogan SA, O'Riordan ED, O'Sullivan M (2003) J Microencaps 20:675–688

Kagami Y, Sugimura S, Fujishima N, Matsuda K, Kometani T, Matsumura Y (2003) J Food Sci 68:2248–2255

VerbandDeutscherLandwirtschaftlicherUntersuchungs-undForschungsanstalten (1985) Handbuch der landwirtschaftlichen Versuchs- und Untersuchungsmethodik (Methodenbuch) Band VI: C15.12.14.

Satué-Gracia T, Frankel EN, Rangavajhyala N, German JB (2000) J Agric Food Chem 48:4984–4990

Chan HWS, Levett G (1976) Lipids 12:99–104

International Dairy Federation (1991) International IDF standards square vergot 41, Brussels, Belgium, sec 74A

Tesch S, Gerhards C, Schubert H (2002) J Food Eng 54:167–174

Runge FE (2001) Multiple-core encapsulation. In: Vilstrup P (ed) Microencapsulation of food ingredients, Leatherhead, Surrey, UK, pp 133–144

Walton DE, Mumford CJ (1999) Trans IChem E 77A:442–460

Onwulata CI, Smith PW, Cooke PH, Holsinger VH (1996) Lebensmittel-Wissenschaft Technol 29:163–172

Partanen R, Yoshii H, Kallio H, Yang B, Forssell P (2002) J Am Oil Chem Soc 79:219–223

Minemoto Y, Adachi S, Matsuno R (1997) J Agric Food Chem 45:4530–4534

Acknowledgements

This work is part of the research of the Working Group on Food Quality and Safety at the University of Kiel, which is funded by the State government of Schleswig-Holstein. The study was financially supported by Cerestar Deutschland GmbH. We also thank Y. Jansen and J. Knipp for skilful work in the laboratory

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Drusch, S., Schwarz, K. Microencapsulation properties of two different types of n-octenylsuccinate-derivatised starch. Eur Food Res Technol 222, 155–164 (2006). https://doi.org/10.1007/s00217-005-0020-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-005-0020-3