Abstract

We investigated the molecular characteristics of 4-α-glucanotransferase (4αGTase)-modified rice starch (MRS) and corn starch (MCS) gels and the NaCl release properties depending on their mechanical properties. Also, encapsulation efficiency (EE) and oil globule size of water-in-oil-in-water (W/O/W) emulsions containing MRS or MCS in the inner aqueous phase (W1) with NaCl as a model core material were measured after preparation and 14 days of storage. The characteristics of MRS and MCS were examined by analyzing amylose content, molecular fine structure, microstructure, and mechanical properties to better understand their associations with emulsion stability. At 20 % concentration, the gel strength of MCS (~105 pa) was greater than that of MRS (~103 pa) as MCS had higher apparent amylose content than MRS. The rate of NaCl release from the gel was highly correlated with the gel strength that depended on the type and concentration of the enzymatically-modified starch. As the gel strength increased, EE of freshly prepared and stored W/O/W emulsions increased. Osmotic swelling of NaCl-containing W/O/W was significantly reduced with the incorporation of the modified starch gels in W1 phase. These results indicated that physicochemical properties of 4αGTase-modified starch gels in W/O/W emulsions largely affected the encapsulation efficiency and stability of the emulsions, which could be utilized to formulate W/O/W emulsions with improved stability and the potential for broader applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water-in-oil-in-water (W/O/W) double emulsions consist of a water-in-oil (W/O) emulsion dispersed in outer aqueous phase. Due to their double compartment structure, it have been widely used for drug delivery as multifunctional nanocarriers in pharmaceuticals, producing low-fat foods, and encapsulating functional ingredients such as vitamins, minerals, antioxidants (Choi et al. 2009; Bonnet et al. 2009; O’Regan and Mulvihill 2010; Aditya et al. 2015; Carrillo-Navas et al. 2012; Giroux et al. 2016; Prichapan and Klinkesorn 2014). They are also used to mask unpleasant flavors in foods and improve the stability of oil mixtures in cosmetics (Gutiérrez et al. 2008; Garti and Bisperink 1998). However, their manufacture, stabilization, and controlled release are still challenging, being more difficult than for simple emulsion, even though there has been a number of research papers published on this subject (Mun et al. 2011; Pays et al. 2002a; Schuch et al. 2014).

Various attempts have been made to solve the stability issues, including the use of steric stabilizers and fat crystals, and incorporating a polymer or protein into the internal phase water droplets (Dickinson 2011; Fechner et al. 2007; O’Regan and Mulvihill 2010; Sapei et al. 2012; Su et al. 2006). Several studies have reported that incorporating polymers or proteins in internal water droplets to solidify the droplets could improve W/O/W emulsion stability (Benichou et al. 2004; Dickinson 2009; Fechner et al. 2007; O’Regan and Mulvihill 2010; Sapei et al. 2012; Su et al. 2006). Perez-Moral et al. (2014) suggested that these approaches can improve not only the stability of the W/O/W emulsions, but also their resilience to change during processing when the pH, osmotic, and chemical potential of the exterior aqueous phase are typical subject to change (Perez-Moral et al. 2014). Numerous studies have revealed that the addition of thickening and gelling polymer into the inner aqueous phase (W1) could improve the stability and release profiles of W/O/W emulsions, because polymer network formed throughout W1 or a gel-like layer at the interface of W/O/W emulsions increased the resistance of inner water droplets to mechanically-induced stress during homogenization (Mun et al. 2011; Su et al. 2006; Surh et al. 2007).

In our previous study, 4-α-glucanotransferase (4αGTase)-treated rice starch was successfully incorporated into W1 to improve encapsulation efficiency (EE) of W/O/W emulsions (Mun et al. 2011). The 4αGTase-treated starch had unique rheological properties as it maintained a liquid state with relatively low viscosity during the emulsion preparation stage and formed a solid gel during storage at 4oC. We also found that, a 20 wt.% 4αGTase-treated starch incorporated in W1 of W/O/W, EE significantly improved (Mun et al. 2011). The enzyme 4αGTase has multiple modes of action, including disproportionation, cyclization, and hydrolysis (Do et al. 2012; Takaha and Smith 1999; van der Maarel and Leemhuis 2013). Through these modes of action, 4αGTase can produce the modified starches that can form a thermoreversible gel, which cannot be obtained from conventional starch hydrolyzing enzyme such as alpha-amylase and is not usually observed in control starch gels (Lee et al. 2006).

In the present study, we investigated whether diversification of the mechanical properties of enzymatically modified starch gel incorporated within the internal aqueous phase could control the EE and stability of W/O/W emulsions even at the condition of osmotic mismatch by adding a salt in W1 phase only. With a better understanding of the relationship between mechanical properties of modified starch included in the internal aqueous phase and the EE and stability of W/O/W emulsions, such W/O/W emulsions could be more broadly applied to various food and pharmaceutical industries.

Materials and methods

Materials

Rice starch was isolated from a native rice (Ilpum byeo, Korea) by using a traditional alkaline method (Wang and Wang 2004) and corn starch was obtained from Samyang Genex Co. (Seoul, South Korea). To produce the 4αGTase enzyme, we used a recombinant strain of Escherichia coli containing thermostable 4αGTase gene isolated from Thermus aquaticus (Food Enzymology Laboratory, Sangmyung University, Korea). Isoamylase, a debranching enzyme, was purchased from Megazyme (Wicklow, Ireland). Pullulan standards (Shodex Standards, Japan) were used to set the starch molecular weight (Mw)-calibration curve. Sodium phosphate (dibasic, anhydrous) and sodium phosphate (monobasic, anhydrous) were purchased from Showa Chemical Co. (Tokyo, Japan). Polyglycerol polyricinoleate (PGPR CRS-75, Sakamoto Yakuhin Kogyo Co. Ltd) and polyoxyethylene sorbitan monolaurate (Tween 20, Sigma Chemical Co., St. Louis, MO) were used as hydrophobic and hydrophilic emulsifiers, respectively. Sodium hydroxide (NaOH), sodium chloride (NaCl), sodium azide (NaN3) and hydrochloric acid were purchased from Sigma Chemical Co. (St. Louis, MO). Soybean oil was purchased from a local supermarket and used without further purification. All solutions were prepared with deionized and double distilled water.

Enzymatically modification of rice and corn starch

Rice and corn starch dispersions (5 %, w/w) were heated in boiling water for 30 min with mechanical stirring. The pastes were cooled and incubated at 75 °C with 4αGTase (5 U/g, dry basis) for 72 h. The enzyme reaction was terminated by boiling the mixtures for 20 min. Five volumes of ethanol were added to the reaction mixture for precipitation. The supernatant was discarded after centrifugation at 6,000 rpm for 20 min and three volumes of acetone were added. After centrifugation, the precipitant was dried at room temperature for 24 h and grinded by using blender (HR 1720 blender, Philips). Grinded powder was sieved through 100-mesh screen before analysis. The apparent amylose contents of each raw starch and modified starch were measured using the method of Juliano (1981).

Determination of molecular weight distributions

The native starches and enzymatically modified starches (120 mg) were dispersed in 12 mL 90 % dimethyl sulfoxide (DMSO). The suspensions were mechanically stirred with heating in a boiling water bath for 1 h and then stirred for 24 h at room temperature. An aliquot (0.4 mL) of starch dispersion (1 %, w/v) was mixed with five volumes of ethanol (2 mL) to precipitate the starch. Ethanol-precipitated starch was separated by centrifugation at 6,000 rpm for 20 min. The pellet was redissolved in boiling water. The hot sample solution was filtered through a nylon membrane filter (5.0 μm) and then injected into a high-performance size-exclusion chromatography (HPSEC) analysis (Yoo and Jane 2002).

Determination of side chain distribution

To analyze the side chain distribution of starches, each starch, 10mg samples were dissolved in 100 mM sodium acetate-HCl buffer (1 mL, pH 4.5) and boiled for 15 min. Samples were debranched by adding an isoamylase (1 U/mg, megazyme) at 40 °C for at least 2 h. After the reaction, mixtures were terminated by boiling for 10 min and then filtered using 0.45 μm disposable membrane filters. The side chain distribution of samples was analyzed using a high-performance anion-exchange chromatography with pulse amperometric detection (HPAEC-PAD) system (Dionex DX 500 Sunnyvale, CA, USA). The system was equipped with a CarboPac PA1 analytical column (4 mm × 250 mm) and a pulsed amperometric detector (ED40, Dionex). The two mobile phase eluents were solution of 150 mM sodium hydroxide and 150 mM sodium hydroxide in 600 mM sodium acetate.

Preparation of water-in-oil (W/O) emulsion

Prior to the preparation of W/O emulsion, modified starch pastes (5, 10, and 20 wt. %) containing 2 wt. % (0.34 M) NaCl were prepared by heating modified starches with phosphate buffer (5 mM, pH 7) at 95 °C for 20 min. A lipophilic emulsifier solution was prepared by dispersing 2 wt. % PGPR into soybean oil at approximately 60 °C, as the PGPR and oil mixtures become much less viscous upon heating and the emulsions produced by homogenization have smaller droplet sizes (Surh et al. 2007). The 20 % w/w aqueous phase (W1) containing 4αGTase-treated starch and NaCl was dispersed gradually into the 80 % w/w oil phase under agitation with a magnetic stirrer and pre-homogenized using a blender (ULTRA-TURRAX model T25 digital, IKA, Germany) at 14,000 rpm for 2 min. After pre-homogenization, coarse emulsions were sonicated for 4 min at a frequency of 20 kHz, an amplitude of 40 %, and a duty cycle of 1 s (VCX 750; Sonics & Materials, Inc., Newtown, CT). The preparation of W/O emulsion was followed by cooling the samples in the refrigerator for 3 h to form gels inside the W1.

Preparation of water-in-oil-in-water (W/O/W) emulsion

The primary W1/O emulsion (40 %, w/w) was pre-homogenized with W2 aqueous surfactant solution (1 % Tween 20, 5 mM phosphate buffer, pH 7) using a blender (ULTRA-TURRAX model T25 digital, IKA, Germany) at 10,000 rpm for 1 min and then sonicated for 2 min at a frequency of 20 kHz, an amplitude of 40 %, and a duty cycle of 1 s. All W/O/W emulsion samples were stored at room temperature.

Dynamic rheological properties of modified starch gels

The elastic properties of each modified starch gel at concentrations of 5, 10, 20 % (w/v) were measured using an AR 1500 ex rheometer (TA instruments Ltd, UK). Parallel plate geometry with a diameter of 20 mm was used and zero gap was 1 mm. After boiling a modified starch for 15 min, the dispersion was loaded between parallel plates in a rheometer. A thin layer of silicon oil was gently covered the edge of the exposed sample to minimize loss of moisture during the measurements. During the time sweep test, dynamic rheological property (G’) was measured at 4 °C, 1 % strain and 1 Hz frequency.

Textural properties of modified starch gels

Hardness and fracturability of modified starch gels were measured using a texture analyzer (TA-XT2i, Stable Microsystems, Surrey, UK). Modified starch pastes (20 %, w/v) were placed in petri dishes (35 mm × 10 mm, diameter × width), and gelated at 4 °C for 24 h. A compression test was performed at pre-test speed and test speed of 2.0 mm/s and 70 % of strain.

Microstructures of modified starch gels

The microstructure of each modified starch gel was assessed using a field emission scanning electron microsope (FE-SEM, JSM-6700F, JEOL, Japan). Freeze-dried gels were split and sprinkled on double-sided adhesive tape mounted on copper sample holders. They were sputter-coated with gold and observed at an acceleration voltage of 15 kV. Micrographs of each gel were taken at 35× magnification to observe their inner structure.

NaCl release of modified starch gels

The NaCl released from modified starch gels was measured with a conductivity meter (SevenGo Duo SG23-FK2, Mettler-toledo) using the method of Mills et al. (Mills et al. 2011) with a slight modification. The conductivity meter probe was dipped into 100 mL double distilled water placed in a glass double jacket and then modified starch gel which was opened one direction within petri dish (35 mm × 10 mm, diameter × width) was added into the jacket. As soon as the gel was added, monitoring of NaCl release was started. The release % was defined as the percentage of released NaCl amount (Wr) to originally existed amount (W0) in modified starch gel (Eq. (1)). Also, the release kinetics and diffusion exponent of each gel were drawn using the Higuchi equation (Eq. (2)) from Fick’s second law. This power exponential expression has been extensively used to analyze the release behavior of various pharmaceutical systems for initial 60 % release curves (diffusion phenomenon) (Ritger and Peppas 1987; Peppas and Sahlin 1989).

where Mt/M∞ is the fraction of NaCl released at each time point (t), K is the release kinetic constant, and n is the diffusion exponent, which is 0.5 for Fickian diffusion and 1.0 for relaxation-controlled release (Nikolaos and David 1997; Peppas and Sahlin 1989; Ritger and Peppas 1987). The experiment was done in triplicate for each W/O/W emulsion.

Encapsulation efficiency (EE) of W/O/W emulsion

The NaCl was used as a marker to evaluate EE, which was defined as the percentage of NaCl still entrapped within inner aqueous phase (W1) during homogenization with external aqueous phase (W2) and the storage period. A stock solution (0.01 %, w/v) was prepared by dissolving NaCl in buffer solution (5 mM phosphate buffer, pH 7) to measure a standard curve (r2 = 0.999). In preliminary tests, the conductivity of known amount of NaCl dissolved in O/W emulsion and water was measured, and it was confirmed that oil droplets does not significantly interfere with conductivity readings at measurement conditions used for this study (data not shown). Then, the conductive intensity of W2 was recorded using a conductivity meter (SevenGo Duo SG23-FK2, Mettler-toledo). To measure the conductive intensity of W2, approximately 4 mL W/O/W emulsion contained in a 15 mL falcon tube was placed in a 25 °C water bath. The NaCl released fraction into W2 was calculated using a calibration curve with R2 = 0.9989 (not shown) and converted into the release rate.

where Mi is the mass of NaCl initially present in the internal water droplets in the W/O emulsion and Me is the mass of released NaCl into the W2 of the W/O/W emulsion during storage.

Particle size measurement

Particle sizes of W/O/W emulsions were determined with size analyzer (Multisizer 3, Beckman Coulter, U.K). Oil droplets (W1/O) dispersed in W2 which freshly made and after storage were characterized by measuring the mean volume-weight diameter (d43). Droplet size measurements were made in triplicate and all measurements were conducted at room temperature.

Statistics

The particle size and EE data were analyzed using one-way analyses of variance (ANOVA) followed by Duncan’s mean comparison test to establish significance of differences at p < 0.05. Correlation coefficients between the EE of W/O/W emulsions and the mechanical properties of modified starch gels were computed using the SPSS statistics program (version 22, IBM).

Results and discussion

Physical properties of enzymatically modified starch gel

Molecular fine structures

The Mw distribution of rice and corn starches, as well as their corresponding 4αGTase-treated starches, was measured using the HPSEC system (Fig. 1). 4αGTase catalyzes the transfer of α-glucan chains from the non-reducing end of one α-glucan molecule to the non-reducing end of another molecule (Takaha and Smith 1999; Takaha et al. 1993). This inter-molecular glucan transfer reaction is called ‘disproprotionation’ and this enzyme can also catalyze intramolecular glucan transfer reaction, which form cyclic glucans or cyclo-amylose (Cho et al. 2009; Park et al. 2007; Takaha and Smith 1999; Takaha et al. 1998).

Molecular weight distributions of native and modified rice (a) and corn (b) starch. RS: native rice starch, MRS: 4αGTase-treated rice starch, CS: native corn starch, MCS: 4αGTase-treated corn starch. Fractions I: 1200-1800 s (Mw ≥ 1 × 106), II: 1800-2400 s (1 × 105 ≤ Mw ≤ 1 × 106), III: 2400-3300 s (1 × 103 ≤ Mw ≤ 1 × 105). The points of standard bar in (a) stand for an Mw (Da) of 7.88 × 105, 4.04 × 105, 2.12 × 105, 1.12 × 105, 4.73 × 104, 2.28 × 104, 1.18 ×104, 5.9 × 103 from left to right, respectively.

After modification of rice and corn starch with 4αGTase for 72 h, the first fraction in the elution profile (1200-1800 s, Mw ≥ 1 × 106), which corresponds to the amylopectin macromolecules, decreased and the second fraction (1800-2400 s, 1 × 105 ≤ Mw ≤ 1 × 106) and third fraction (2400-3300 s, 1 × 103 ≤ Mw ≤ 1 × 105) developed. Although the second fraction also decreased after modification compared to that of native starch, after treatment with 4αGTase, the second fraction consisted of intermediate-Mw glucans, which might be modified amylopectin by 4αGTase and amylose molecules (Cho et al. 2009; Do et al. 2012; Kim et al. 2012). The third fraction consisted of non-cyclic intermediate-Mw glucans and cyclic glucans such as cycloamylose (4 × 103 ≤ Mw ≤ 7.5 × 103) (Mun et al. 2009; Takaha et al. 1998).

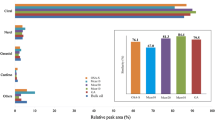

The distribution of amylopectin branch chain length of the rice and corn starches, as well as the corresponding 4αGTase-treated starches, were measured using the HPAEC system after debranching with isoamylase (Fig. 2.). Regarding side chain distribution, the short chain (DP < 12) and long chain (25 < DP < 36) of MRS and MCS dramatically increased compared to rice and corn starch. According to previous reports (Do et al. 2012; Cho et al. 2009), this result is caused by the disproportionation of 4αGTase that the amylose transferred to the amylopectin branch chains. This was attributed to the disproportionation reaction of 4αGTase, that is, the transfer of α–glucans from amylose and amylopectin to amylopectin (Park et al. 2007). Kaper et al. (2004b) also reported the partial elongation of the amylopectin branch chains after treatment of starch with 4αGTase from Thermus thermophiles (Kaper et al. 2004). Do et al. (2012) reported similar results and suggested that the external chains of amylopectin mainly composed of A and short B chains (DP 4-24) were highly susceptible to the disproportionation reaction of 4αGTase from Thermus acuaticus (TAαGT), through which their chain lengths were rapidly redistributed more evenly (Do et al. 2012).

Apparent amylose content (AAC) of native starches and enzymatically modified starches (MRS, MCS) were measured using the iodine-binding method (Table 1). When compared to AAC of native starches (9.21% for rice starch and 33.35% for corn starch, data not shown in Table 1), AAC significantly increased after 4αGTase treatment showing 16.82 % for MRS and 37.29 % for MCS. The higher AAC indicated that, after treatment with 4αGTase, more products that could form iodine-binding complex were produced in the modified starches. This result could be related to the increase in long amylopectin branch chains after the enzyme treatment as evidenced in Fig. 2. Cycloamyloses produced by the cyclization reaction of 4αGTase might also contribute to increases AAC. Kitamura et al. (1999) reported that cycloamyloses could possess helical structures in their unique three-dimensional conformation, showing an affinity to iodine (Kitamura et al. 1999). The different AAC values between MRS and MCS might be attributed to the different inherent structures of the starches. The inherent structures of starch before modification play an important role in determining functionality of modified starch. In other words, amylose content, the molecular sizes of amylose and amylopectin, and short and long branch chains in amylopectin could affect the functionality of modified starches (Wang et al. 2003).

Mechanical properties of modified starch gels

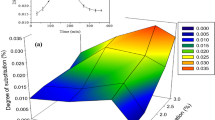

Starch pastes with different concentrations (5, 10, and 20 wt. %) of 4αGTase-treated (5 U/g starch for 72 h) rice and corn starches were prepared and a dynamic oscillatory time sweep test was performed (Fig. 3). Unlike MCS, only 20 wt. % MRS paste formed a gel, whereas 5 and 10 wt. % of MRS remained as liquid pastes throughout the test period of 1000 min at 4oC showing G” higher than G’. This might be attributable to the difference in amylose content and structure of the two native starches (Freitas et al. 2004). Gel formation of 20 % MCS was the fastest and the final G’ was the highest among samples. As the concentration of MCS decreased, gel formation rate slowed down and the G’ decreased. Lee et al. (2006) reported that 4αGTase-treated starch showed higher G” than G’ immediately after the solution preparation, indicating liquefaction of the starch solution (Lee et al. 2006). However, during the storage at 4°C, G’ and G” crossed over and it became a rigid gel.

Through compression tests, hardness and fracturability of MRS and MCS gels at the levels of 20 % were compared (Table 1). The textural parameters for 20 % MCS gel were significantly higher than those of MRS gel. Do et al. (2012) reported that general changes upon TAαGT (4-α-glucanotransferase isolated from Thermus aquaticus) treatment included a decrease in fracture strain and an increase in hardness, indicating that gels became rigid and brittle from enzyme treatment. Structural changes in both molecular weight and amylopectin branch chain length distributions could positively influence gel rigidity and brittleness of 4αGTase-modified starch gels.

The inner microstructures of 20 % MRS and MCS gels showed a porous network with a number of cracks (Fig. 4). The MCS gel appeared to have thicker and denser wall than the MRS gel, although the microstructures of both gels were relatively discontinuous. These structural differences might be related to the difference in mechanical properties and furthermore in the release profile of the gels.

NaCl release profiles of modified starch gel

Fig. 5 shows the % release of salt ions from MRS and MCS gels as a function of time. From these release profiles, K and n values were obtained according to Eq. (2). The K values (Table 1) of 20 % MCS gel was the lowest among the samples, indicating that NaCl diffusion from 20 % MCS gel was the slowest. Also, as MCS concentration decreased, thus the gel strength decreased, K value increased. This result suggested that the K value could be negatively correlated to the elastic modulus (G’) of the gel as evidenced in Table 2. Interestingly, 20 % MRS and 10 % MCS gels that had similar G’ values showed highly comparable release kinetic parameters.

Diffusion exponent, n value between 0.5 and 1.0 usually indicates that release is controlled by polymer relaxation (non-Fickian kinetics corresponding to a couples diffusion/and other parameter mechanism) (Peppas and Sahlin 1989; Ritger and Peppas 1987; van Dijk-Wolthuis et al. 1997). According to previous studies, a polymer gel with n value between 0.5 and 1.0 displayed anomalous behavior, which meant that the release was controlled by the swelling of the matrix and drug solubility (Mourtas et al. 2007; Nikolaos and David 1997; van Dijk-Wolthuis et al. 1997). Therefore, the result indicated that the release behavior of NaCl from 10 % and 20 % MCS gel and 20 % MRS gel (0.50 < n < 0.80) was largely governed by the mechanical properties of the MCS and MRS gels. Panouillé et al. (2011) reported that a hard protein network led to a decrease in the diffusion kinetic coefficient of NaCl and this was negatively correlated with the firmness of samples (Panouillé et al. 2011). Similar study by Boland et al. (2004) showed that the diffusion kinetic coefficients of flavor compounds decreased with increasing elastic moduli of the gel (Boland et al. 2004).

Characterization of W/O/W emulsions containing 4αGTase-treated starch

Droplet diameter

The mean diameters of the oil droplets (W1/O) of freshly prepared and stored for 2 weeks are shown in Fig. 6. The mean droplet diameter of freshly prepared emulsions was affected by the presence of NaCl and 4αGTase-treated starch in W1. The oil droplets of freshly prepared control emulsion without NaCl had the smallest mean size of 10.45 μm in comparison to the emulsions with NaCl in W1 phase (18.18 μm). This result may could be attributed to the osmotic gradient between the two water W1 and W2 phases, which would cause promote rapid water diffusion from the external to the inner water phase when the W/O emulsion containing NaCl in the water phase was homogenized with external water phase (Geiger et al. 1998; Mezzenga et al. 2004). This water flux would result in the volume expansion of internal water droplets and a consequent swelling of oil globules (Hindmarsh et al. 2005; Iqbal et al. 2013; Leal-Calderon et al. 2012; Sapei et al. 2012). In the comparison between the presence of 4αGTase-treated starch, the oil droplet size significantly decreased as low as 12.27 μm of for MRS 20, and MCS 5, 10, 20 which could form gels in W1 phase were significantly lower as compared to that without 4αGTase-treated starch (control w/NaCl). In addition, after 14 days of storage there were no significant changes in droplet size for all emulsions when compared with those of freshly made emulsions.

Mean droplet diameters of W/O/W emulsions prepared with various modified starches. Blank bar: freshly made W/O/W emulsions, solid bar: W/O/W emulsions after 14 days of storage. Error bars show standard deviation of at least three measurements. Different letters above bars (upper case for 0 day and lower case for 14 days) represents significant difference in particle size (p < 0.05).

This result indicated that gelation of W1 using MRS and MCS before 2nd homogenization step significantly prevented the swelling and volume expansion by osmotic gradient during W/O/W preparation process. In other words, modified starch gels which formed in W1 phase during preparation limited the increase of globule size by partially swelling compared to fully swelled control droplet. Sapei et al. (2012) have performed similar experiments using W/O/W with gelation gel and NaCl in W1 phase. They reported that the osmotic swelling of oil droplets was even slightly enhanced with NaCl (2 % w/w) and gelatin gel (3 % w/w) in W1 phase as compared to NaCl only in W1 phase, which seemed inconsistent with the above results in Fig. 6. The discrepancy between the two results could lie in the characteristics of the gels. As gelatin formed highly elastic and flexible gel at relatively low concentrations, MRS and MCS gels were characterized as rigid and brittle texture (Do et al. 2012) with relatively dense network (Fig. 4). The dense and rigid structure of MRS and MCS gels would be very ineffective in molecular diffusion and swelling, which, on the other hand, could be highly beneficial in maintaining stability and encapsulating small molecules. Yet, the elucidation of the detailed mechanism for the oil globule size change in the presence of the enzymatically modified starch gels requires further study.

EE of W/O/W emulsions

The EEs of freshly prepared W/O/W emulsions and stored for 2 weeks emulsions are shown in Fig. 7. For freshly prepared emulsions (0 day, blank bar), when 5 % and 10 % MRS was incorporated into W1, the EE values were not different from that of W/O/W emulsion prepared without modified starch (i.e., control). However, when 20 % MRS and 5, 10, and 20 % MCS were incorporated, the EE value improved compared to that of control. This result suggests that the mechanical properties of modified starch are related to the EE values of W/O/W emulsions containing modified starches. As mentioned previously (Section 3.1), 5 and 10 % MRS did not form a gel, whereas 20 % MRS and all concentrations of MCS did. When modified starches were incorporated into W1, the EE value of freshly prepared emulsions improved. When modified starches that did not form gel were included, the EE value was not different from that of control emulsion. In addition, the incorporation of 20 % MCS, which had the fastest gel formation and the highest G’, provided the greatest improvement in EE.

Encapsulation efficiency (EE) of W/O/W emulsions prepared with various modified starches during storage. Blank bar: EE of freshly made W/O/W emulsions, solid bar: EE of W/O/W emulsion after 14 days of storage. Error bars show standard deviation computed from at least three measurements. Different letters above bars (upper case for 0 day and lower case for 14 days) represents significant difference in EE (p < 0.05).

Other studies have reported that W/O/W emulsions are usually produced using a conventional homogenization technique using a two-step procedure. In the second step of preparation, such emulsions can be prepared by homogenizing a W/O emulsion with another aqueous phase in the presence of a hydrophilic emulsifier. However, the mechanical stress during this second step disrupted the primary W/O emulsion droplets, thereby reducing the EE of the W/O/W emulsion. Hence, we suggest that the improved EE of freshly prepared W/O/W emulsions in the presence of MRS and MCS gels, is caused by improved water droplet resistance to mechanically induced stresses (Surh et al. 2007).

We also measured the EE of W/O/W emulsions with and without 4αGTase-treated starch, in W1 after storage at room temperature for 14days. The values of emulsions prepared with 20 % MCS gel were significantly (p < 0.05) higher than those for the other gels.

Two major release mechanisms responsible for the release of NaCl entrapped in W1 of W/O/W double emulsions are (1) coalescence of the thin liquid film separating the internal droplets and the surfaces of globules, and (2) compositional ripening-diffusion/permeation through the oil membrane (Benichou et al. 2004; Pays et al. 2002b). Some studies have reported that magnesium release in double emulsions is due to diffusion and/or permeation mechanisms rather than droplet coalescence (Sapei et al. 2012). Therefore, it can be suggested that rigid gels formed within W1 prevents diffusion of NaCl and coalescence of W1 to W2 during the storage of emulsions.

To understand how the mechanical properties of modified starch gels were related to the prevention of the NaCl release, NaCl-containing MRS and MCS gels were prepared at different concentrations and their NaCl release properties were measured over time (Fig. 5). Release of NaCl from 20 % MCS gel, which had the highest G’ value, was the slowest among the modified gel samples. The 20 % MRS and 10 % MCS gels had similar G’ values and showed similar release patterns. These results indicated that the release properties of modified gels were closely related to their mechanical properties and the rigid modified starch gel network strongly prevented the diffusion of materials incorporated in it (Mun et al. 2014).

Sapei et al. (2012) also reported that the amount of gelatin present within W1 altered the release behavior and stability of double emulsions. The release of NaCl for the first 20 h was much slower in double emulsions stabilized with 10 % gelatin compared to 3 % gelatin, which was likely due to a firmer gelled W1 that delayed NaCl release during secondary homogenization. Panouillé et al. (2011) reported that when gel viscoelasticity increased, the diffusion coefficient decreased for the gelled samples.

Correlation analysis between the mechanical properties of modified starch gels and the EE of W/O/W emulsions

Pearson’s correlation coefficients (r) between the mechanical properties of modified starch gels and the EE of W/O/W emulsions are presented in Table 2. The ln G’ of modified starch gel showed a strong negative correlation (r = -0.962) with the release kinetic constant, K, of the gel and a strong positive correlated (r = 0.928) with EE of freshly made W/O/W emulsions containing the gel, indicating that mechanical properties of enzymatically modified starch gels governed the release rate of NaCl from the gel, which directly affected the EE of W1/O/W2 containing the gel in W1.

Conclusions

In the present study, we examined the effects of mechanical properties of 4αGTase-modified rice and corn starch gels on the salt release properties of the gels and EE of W1/O/W2 emulsions containing the gels in W1. The enzymatically modified corn starch formed a more rigid and brittle gel than modified rice starch at the same concentration. This was possibly due to the higher amylose content and different molecular structure after treatment. The salt release rate was strongly dependent on the mechanical properties of the gel, not the concentration. Also, the incorporation of modified starch gels into the W1 reduced the osmotic swelling of the oil globule and increased the EE of W1/O/W2 emulsions during the preparation stage. Correlation study indicated the EE of W1/O/W2 emulsions, which was qualitatively correlated to the mechanical properties of the modified starch gels embedded in W1. These results clearly demonstrated that the mechanical properties of modified starch gel could affect the EE of W/O/W emulsion during preparation. However, it has no direct relationship between release profile of gel and EE of W/O/W emulsion during storage. These results may provide useful information for food and pharmaceutical industries looking for starch-based novel encapsulating agents and their applications.

References

Aditya, N. P., Aditya, S., Yang, H., Kim, H. W., Park, S. O., & Ko, S. (2015). Co-delivery of hydrophobic curcumin and hydrophilic catechin by a water-in-oil-in-water double emulsion. Food Chemistry., 173, 7–13.

Benichou, A., Aserin, A., & Garti, N. (2004). Double emulsions stabilized with hybrids of natural polymers for entrapment and slow release of active matters. Advances in Colloid and Interface Science., 108–109, 29–41.

Boland, A. B., Buhr, K., Giannouli, P., & van Ruth, S. M. (2004). Influence of gelatin, starch, pectin and artificial saliva on the release of 11 flavour compounds from model gel systems. Food Chemistry., 86(3), 401–411.

Bonnet, M., Cansell, M., Berkaoui, A., Ropers, M. H., Anton, M., & Leal-Calderon, F. (2009). Release rate profiles of magnesium from multiple W/O/W emulsions. Food Hydrocolloids., 23(1), 92–101.

Carrillo-Navas, H., Cruz-Olivares, J., Varela-Guerrero, V., Alamilla-Beltrán, L., Vernon-Carter, E. J., & Pérez-Alonso, C. (2012). Rheological properties of a double emulsion nutraceutical system incorporating chia essential oil and ascorbic acid stabilized by carbohydrate polymer–protein blends. Carbohydrate Polymers., 87(2), 1231–1235.

Cho, K. H., Auh, J. H., Ryu, J. H., Kim, J. H., Park, K. H., Park, C. S., & Yoo, S. H. (2009). Structural modification and characterization of rice starch treated by Thermus aquaticus 4-α-glucanotransferase. Food Hydrocolloids., 23(8), 2403–2409.

Choi, S. J., Decker, E. A., & McClements, D. J. (2009). Impact of iron encapsulation within the interior aqueous phase of water-in-oil-in-water emulsions on lipid oxidation. Food Chemistry., 116(1), 271–276.

Dickinson, E. (2009). Hydrocolloids as emulsifiers and emulsion stabilizers. Food Hydrocolloids., 23(6), 1473–1482.

Dickinson, E. (2011). Double emulsions stabilized by food biopolymers. Food. Biophysics., 6(1), 1–11.

Do, H. V., Lee, E.-J., Park, J.-H., Park, K.-H., Shim, J.-Y., Mun, S., & Kim, Y.-R. (2012). Structural and physicochemical properties of starch gels prepared from partially modified starches using Thermus aquaticus 4-α-glucanotransferase. Carbohydrate Polymers., 87(4), 2455–2463.

Fechner, A., Knoth, A., Scherze, I., & Muschiolik, G. (2007). Stability and release properties of double-emulsions stabilised by caseinate–dextran conjugates. Food Hydrocolloids., 21(5–6), 943–952.

Freitas, R. A., Paula, R. C., Feitosa, J. P. A., Rocha, S., & Sierakowski, M. R. (2004). Amylose contents, rheological properties and gelatinization kinetics of yam (Dioscorea alata) and cassava (Manihot utilissima) starches. Carbohydrate Polymers., 55(1), 3–8.

Garti, N., & Bisperink, C. (1998). Double emulsions: Progress and applications. Current Opinion in Colloid & Interface Science., 3(6), 657–667.

Geiger, S., Tokgoz, S., Fructus, A., Jager-Lezer, N., Seiller, M., Lacombe, C., & Grossiord, J. L. (1998). Kinetics of swelling–breakdown of a W/O/W multiple emulsion: possible mechanisms for the lipophilic surfactant effect. Journal of Controlled Release., 52(1–2), 99–107.

Giroux, H. J., Robitaille, G., & Britten, M. (2016). Controlled release of casein-derived peptides in the gastrointestinal environment by encapsulation in water-in-oil-in-water double emulsions. LWT - Food Science and Technology., 69, 225–232.

Gutiérrez, J. M., González, C., Maestro, A., Solè, I., Pey, C. M., & Nolla, J. (2008). Nano-emulsions: New applications and optimization of their preparation. Current Opinion in Colloid & Interface Science., 13(4), 245–251.

Hindmarsh, J. P., Su, J., Flanagan, J., & Singh, H. (2005). PFG-NMR analysis of intercompartment exchange and inner droplet size distribution of W/O/W emulsions. Langmuir., 21(20), 9076–9084.

Iqbal, S., Baloch, M. K., Hameed, G., & McClements, D. J. (2013). Controlling W/O/W multiple emulsion microstructure by osmotic swelling and internal protein gelation. Food Research International., 54(2), 1613–1620.

Kaper, T., van der Maarel, M., Euverink, G., & Dijkhuizen, L. (2004). Exploring and exploiting starch-modifying amylomaltases from thermophiles. Biochemical Society Transactions., 32(2), 279–282.

Kim, Y., Kim, Y.-L., Trinh, K. S., Kim, Y.-R., & Moon, T. W. (2012). Texture properties of rice cakes made of rice flours treated with 4-α-glucanotransferase and their relationship with structural characteristics. Food Science and Biotechnology., 21(6), 1707–1714.

Kitamura, S., Nakatani, K., Takaha, T., & Okada, S. (1999). Complex formation of large-ring cyclodextrins with iodine in aqueous solution as revealed by isothermal titration calorimetry. Macromolecular rapid communications., 20(12), 612–615.

Leal-Calderon, F., Homer, S., Goh, A., & Lundin, L. (2012). W/O/W emulsions with high internal droplet volume fraction. Food Hydrocolloids., 27(1), 30–41.

Lee, K. Y., Kim, Y.-R., Park, K. H., & Lee, H. G. (2006). Effects of α-glucanotransferase treatment on the thermo-reversibility and freeze-thaw stability of a rice starch gel. Carbohydrate Polymers., 63(3), 347–354.

Mezzenga, R., Folmer, B. M., & Hughes, E. (2004). Design of double emulsions by osmotic pressure tailoring. Langmuir., 20(9), 3574–3582.

Mills, T., Spyropoulos, F., Norton, I. T., & Bakalis, S. (2011). Development of an in-vitro mouth model to quantify salt release from gels. Food Hydrocolloids., 25(1), 107–113.

Mourtas, S., Fotopoulou, S., Duraj, S., Sfika, V., Tsakiroglou, C., & Antimisiaris, S. G. (2007). Liposomal drugs dispersed in hydrogels: effect of liposome, drug and gel properties on drug release kinetics. Colloids and Surfaces B: Biointerfaces., 55(2), 212–221.

Mun, S., Choi, Y., Park, S., Surh, J., & Kim, Y.-R. (2014). Release properties of gel-type W/O/W encapsulation system prepared using enzymatically-modified starch. Food Chemistry., 157, 77–83.

Mun, S., Choi, Y., Shim, J.-Y., Park, K.-H., & Kim, Y.-R. (2011). Effects of enzymatically modified starch on the encapsulation efficiency and stability of water-in-oil-in-water emulsions. Food Chemistry., 128(2), 266–275.

Mun, S., Rho, S.-J., & Kim, Y.-R. (2009). Study of inclusion complexes of cycloamylose with surfactants by isothermal titration calorimetry. Carbohydrate Polymers., 77(2), 223–230.

Nikolaos, A. P., & David, J. (1997). Controlled release of perfumes from polymers. II. Incorporation and release of essential oils from glassy polymers. Journal of Applied Polymer Science., 66, 509–513.

O’Regan, J., & Mulvihill, D. M. (2010). Sodium caseinate–maltodextrin conjugate stabilized double emulsions: Encapsulation and stability. Food Research International., 43(1), 224–231.

Panouillé, M., Saint-Eve, A., De Loubens, C., Déléris, I., & Souchon, I. (2011). Understanding of the influence of composition, structure and texture on salty perception in model dairy products. Food Hydrocolloids., 25(4), 716–723.

Park, J.-H., Kim, H.-J., Kim, Y.-H., Cha, H., Kim, Y.-W., Kim, T.-J., Kim, Y.-R., & Park, K.-H. (2007). The action mode of Thermus aquaticus YT-1 4-α-glucanotransferase and its chimeric enzymes introduced with starch-binding domain on amylose and amylopectin. Carbohydrate Polymers., 67(2), 164–173.

Pays, K., Giermanska-Kahn, J., Pouligny, B., Bibette, J., & Leal-Calderon, F. (2002a). Double emulsions: how does release occur? Journal of Controlled Release., 79(1), 193–205.

Pays, K., Giermanska-Kahn, J., Pouligny, B., Bibette, J., & Leal-Calderon, F. (2002b). Double emulsions: how does release occur? Journal of Controlled Release., 79(1–3), 193–205.

Peppas, N. A., & Sahlin, J. J. (1989). A simple equation for the description of solute release. III. Coupling of diffusion and relaxation. International Journal of Pharmaceutics, 57(2), 169–172.

Perez-Moral, N., Watt, S., & Wilde, P. (2014). Comparative study of the stability of multiple emulsions containing a gelled or aqueous internal phase. Food Hydrocolloids. 42. Part, 1, 215–222.

Prichapan, N., & Klinkesorn, U. (2014). Factor affecting the properties of water-in-oil-in-water emulsions for encapsulation of minerals and vitamins. Songklanakarin Journal of Science and Technology., 36, 651–661.

Ritger, P. L., & Peppas, N. A. (1987). A simple equation for description of solute release I. Fickian and non-Fickian release from non-swellable devices in the form of slabs, spheres, cylinders or discs. Journal of Controlled Release., 5(1), 23–36.

Sapei, L., Naqvi, M. A., & Rousseau, D. (2012). Stability and release properties of double emulsions for food applications. Food Hydrocolloids., 27(2), 316–323.

Schuch A, Helfenritter C, Funck M & Schuchmann H (2014) Observations on the influence of different biopolymers on coalescence of inner water droplets in W/O/W (water-in-oil-in-water) double emulsions. Colloids and Surfaces A: Physicochemical and Engineering Aspects.

Su, J., Flanagan, J., Hemar, Y., & Singh, H. (2006). Synergistic effects of polyglycerol ester of polyricinoleic acid and sodium caseinate on the stabilisation of water–oil–water emulsions. Food Hydrocolloids., 20(2–3), 261–268.

Surh, J., Vladisavljević, G. T., Mun, S., & McClements, D. J. (2007). Preparation and characterization of water/oil and water/oil/water emulsions containing biopolymer-gelled water droplets. Journal of Agricultural and Food Chemistry., 55(1), 175–184.

Takaha, T., & Smith, S. M. (1999). The functions of 4-α-glucanotransferases and their use for the production of cyclic glucans. Biotechnology and Genetic Engineering Reviews., 16(1), 257–280.

Takaha, T., Yanase, M., Okada, S., & Smith, S. (1993). Disproportionating enzyme (4-alpha-glucanotransferase; EC 2.4. 1.25) of potato. Purification, molecular cloning, and potential role in starch metabolism. Journal of Biological Chemistry., 268(2), 1391–1396.

Takaha, T., Yanase, M., Takata, H., Okada, S., & Smith, S. M. (1998). Cyclic Glucans Produced by the Intramolecular Transglycosylation Activity of Potato D-Enzyme on Amylopectin. Biochemical and Biophysical Research Communications., 247(2), 493–497.

van der Maarel, M. J. E. C., & Leemhuis, H. (2013). Starch modification with microbial alpha-glucanotransferase enzymes. Carbohydrate Polymers., 93(1), 116–121.

van Dijk-Wolthuis, W., Hoogeboom, J., Van Steenbergen, M., Tsang, S., & Hennink, W. (1997). Degradation and release behavior of dextran-based hydrogels. Macromolecules., 30(16), 4639–4645.

Wang, L., & Wang, Y.-J. (2004). Rice starch isolation by neutral protease and high-intensity ultrasound. Journal of Cereal Science., 39(2), 291–296.

Wang, Y.-J., Truong, V.-D., & Wang, L. (2003). Structures and rheological properties of corn starch as affected by acid hydrolysis. Carbohydrate Polymers., 52(3), 327–333.

Yoo, S.-H., & Jane, J.-L. (2002). Molecular weights and gyration radii of amylopectins determined by high-performance size-exclusion chromatography equipped with multi-angle laser-light scattering and refractive index detectors. Carbohydrate Polymers., 49(3), 307–314.

Acknowledgements

This work was supported by National Research Foundation of Korea (NRF) grants funded by the Ministry of Education (No. 2012R1A2A2A01014594) and the Ministry of Science, ICT, and Future Planning (NRF-2015R1A1A3A04001485).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, YL., Mun, S., Rho, SJ. et al. “Influence of physicochemical properties of enzymatically modified starch gel on the encapsulation efficiency of W/O/W emulsion containing NaCl”. Food Bioprocess Technol 10, 77–88 (2017). https://doi.org/10.1007/s11947-016-1799-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1799-6