Abstract

Toxicity assessment of water is of great important to the safety of human health and to social security because of more and more toxic compounds that are spilled into the aquatic environment. Therefore, the development of fast and reliable toxicity assessment methods is of great interest and attracts much attention. In this study, by using the electrochemical activity of Shewanella oneidensis MR-1 cells as the toxicity indicator, 3,5-dichlorophenol (DCP) as the model toxic compound, a new biosensor for water toxicity assessment was developed. Strikingly, the presence of DCP in the water significantly inhibited the maximum current output of the S. oneidensis MR-1 in a three-electrode system and also retarded the current evolution by the cells. Under the optimized conditions, the maximum current output of the biosensor was proportional to the concentration of DCP up to 30 mg/L. The half maximal inhibitory concentration of DCP determined by this biosensor is about 14.5 mg/L. Furthermore, simultaneous monitoring of the retarded time (Δt) for current generation allowed the identification of another biosensor signal in response to DCP which could be employed to verify the electrochemical result by dual confirmation. Thus, the present study has provided a reliable and promising approach for water quality assessment and risk warning of water toxicity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water toxicity has become of great concern over the past decade as more and more toxic contaminants are spilled into the water owing to the fast development of modern industry and agriculture [1, 2]. These toxic contaminants in water seriously threaten the safety of human health as well as the ecosystem on the earth, which might also result in serious social problems [3]. Thus, various methods have been developed to monitor the toxic contaminants in water. Conventional physical-chemical methods including gas/liquid chromatography or coupled with mass spectrometry provide an accurate and sensitive method for determination of the quantity of specific contaminating compound [1, 4]. However, the water contaminations became more and more complex, where the diversity of the toxic compounds dramatically increased, and emerging or inter-react contaminants also occurred [5,6,7,8]. It is quite a challenge to quantify all the toxic compounds in contaminated water samples fast with the conventional methods. Moreover, due to the presence of inter-react or synergetic toxicity, the composition of chemical compounds and the quantity of specific compounds in “combined pollutants” or “co-contaminations” may not accurately reflect the toxicity of the contaminations, which is a more direct and meaningful indicator for the water quality [9]. Therefore, it is urgently needed to develop a new method for fast determination of the toxicity of the water, which is of great importance for water quality assessment and toxicity risk warning.

During the past decades, various methods have been developed to detect the water toxicity. Living organisms including vertebrate model organism zebrafish and algae are often used as biological recognition elements for toxicity biosensor development, due to its inherent advantage of providing the biological effects which might be more meaningful than the information of chemical composition or quantity [9,10,11]. The water toxicity usually affected the key biological processes such as detoxification, photosynthesis, stress response, or respiration, which could be monitored by various biochemical methods, and could therefore provide the information on toxicity level [9, 10, 12]. However, these higher organism-based biosensors suffered from long incubation time (cell doubling time, days or weeks) and complicated operation. Microorganism which grows much faster (cell doubling time, minutes to hours) and with easier operation procedure can meet this challenge to provide a simple, fast, low-cost, and easy operation method for toxicity assay [13]. More important, microorganisms showed quick and sharp response to various toxins/toxic compounds [13, 14]. Thus, toxicity biosensors based on microorganism showed great promise and have been extensively studied.

The biosensors based on living microorganism (especially for bacteria) could be categorized as electrochemical, optical, and spectroscopic sensors on the basis of the signal-transducing technology. Among them, the electrochemical biosensor attracted much attention owing to its simple instrument requirement, readable signal provided, and easy operation [11, 15]. Thus, various whole-cell-based microbial electrochemical biosensors have been adapted and are emerging as a unique alternative to other analytical methods for water toxicity assessment [15]. This kind of biosensor usually relied on the determination of toxin/toxic compound inhibition on the respiratory/metabolic activity of the cells, which could be estimated by the oxidation current of electron mediators/shuttles. Because the mediator/shuttle could be used as the intracellular electron carrier and could be reduced by the cellar respiratory chain or enzymatic events within the cells to form a reduced mediator, which would be reoxidized at the working electrode surface resulting in a current flow [16, 17]. For example, by using benzoquinone as the mediator, the toxicity of heavy metal ions, phenol, or pesticides was determined by bacterial biofilm composed of Escherichia coli or mixed culture [15, 18, 19]. Besides, other bacterial species such as Psychrobacter [16] and Bacillus [15] have been employed for biosensor development, and other chemicals such as ferricyanide ion and dimethylferrocene, are also used as the mediator [15].

Recently, another kind of bacterial species called exoelectrogens which is capable of self-wiring the intracellular electrons to the solid electrode showed great promise in developing various whole-cell-based electrochemical devices [6, 20, 21]. It is speculated that exoelectrogens might be another ideal choice for construction of whole-cell-based electrochemical biosensor for toxicity detection. In this work, a whole-cell-based electrochemical toxicity biosensor was developed using the model exoelectrogen of Shewanella oneidensis MR-1. The effects of different sensing parameters on the analytical performance of the biosensor were also analyzed. Impressively, it was found that this biosensor could generate dual signals in response to the model toxic compound of 3,5-dichlorophenol (DCP). With the cross confirmation of dual signals, this biosensor provided a more reliable way for toxicity detection and water quality assessment.

Materials and methods

Bacteria strains and chemicals

Shewanella oneidensis MR-1 was routinely cultivated in Luria-Bertani (LB) broth (peptone 10 g/L, yeast extract 5 g/L, NaCl 5 g/L, pH 7.0) at 30 °C with shaking (150 rpm) [22]. After being cultured in LB broth to the OD of 2.0, the cells were harvested by centrifugation and resuspended with the electrolyte (95% M9 mineral medium plus 5% LB broth, 10 mM lactate, 5 μM riboflavin) [22, 23] to the designed cell density. The cell suspension was then used for biosensor assembly. DCP and riboflavin with analytical grade were purchased from Sinoreagent (Shanghai, China) and directly used without further purification.

Electrochemical measurement

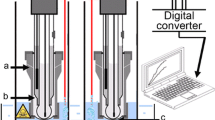

All electrochemical measurements and analyses were performed by CHI-660E electrochemical workstation (Chenhua Instruments Co., Ltd., Shanghai, China) equipped with a three-electrode system (platinum wire counter electrode, a saturated calomel electrode (SCE, + 0.243 V vs. SHE) as reference electrode, and a carbon cloth (1 cm × 2 cm) working electrode). All potentials mentioned are reported versus SCE. The electrochemical cell used is a 15-mL cylindrical borosilicate glass bottle. All tests are performed in triplicate.

Biosensing system assembly and biosensing operation

For biosensing system assembly, a three-electrode system was firstly equipped in the electrochemical cell (see Electronic Supplementary Material (ESM) Fig. S1). Then, 12 mL cell suspension (suspended in electrolyte with designed cell density) was added into the electrochemical cell. Next, DCP, Cu2+, or Cr6+ with the designed concentration was injected into the electrochemical cell and incubated for another 1 h. After that, a poised potential was applied to the working electrode and the current output was monitored with the CHI-660E electrochemical workstation. All assays were conducted at 30 °C. The electrochemical cells and the electrolyte were autoclaved under 121 °C for 20 min, and all the electrodes used were sterilized by 75% ethanol and UV illumination.

Results and discussion

Biosensing system development and dual-signal generation

S. oneidensis MR-1 is a typical exoelectrogen that is capable of efficient electron transfer between bacteria and the electrode [22, 24] (ESM Fig. S2). It was proved that the electron flow between cells and the electrode was associated with the metabolic activity of the cells [25, 26] (ESM Fig. S2). It was also successfully used for electrochemical detection of different biomarkers by analyzing the relationship between the electron flow and corresponding biological reactions [27,28,29]. Thus, S. oneidensis MR-1 was considered as an ideal bacterial species for construction of bioelectrochemical system for biosensing. With the aim to determine the water toxicity using the electrochemical activity of bacteria as the indicator, the electrochemical response of S. oneidensis MR-1 to the model toxic compound DCP was determined.

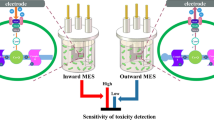

Although most of the whole-cell-based electrochemical biosensors need long time for biofilm growth [6] or complicated procedure for cell immobilization on the electrode surface [15], we tried to directly use suspension cells for electrochemical detection to simplify the operation and reduce the time consumption. In accordance with previous report [30], the cells generated significant current output under a poised potential on the working electrode in the three-electrode electrochemical cell (Fig. 1). After the ~ 500-s adaptation, the current output gradually increased. Impressively, after about 1100 s, the current output increased exponentially and reached the maximum current of about 3.8 μA (i 0) at about 1250 s. After DCP addition, the trend for current generation by S. oneidensis MR-1 was similar to that without DCP addition; i.e., after a lag phase with stable baseline current, the current gradually increased and followed an exponential increase and finally reached a stable plateau with the maximum current output reached. As expected, the maximum current output reached was dramatically inhibited by DCP addition. It was found that the maximum current output is only about 2.0 μA (i 0) when 20 mg/L DCP was presented. The inhibition ratio calculated for 20 mg/L DCP was 47.4%. The inhibition might be due to the repression of DCP on the metabolic activity of the bacterial cells, which, in turn, limited the extracellular electron transfer between cells and the electrode. More strikingly, after DCP addition, there was a longer lag phase (t 20 = 1854 s) than that of the control (t 0 = 1187 s) for cell adaptation observed (Δt = 667 s), which might be another indicator for the toxicity of DCP. Thus, the results indicated that the electrochemical activity of S. oneidensis MR-1 was in response to the toxicity of DCP, and suggested that the electrochemical cell inoculated with the S. oneidensis MR-1 might be used as a biosensor for water toxicity.

Effect of biosensing conditions on the analytical performance

For toxicity biosensor, the time for incubation with the toxicity is an important parameter that determined the performance of the biosensor. Theoretically, longer incubation time might induce more serious damage to the microorganism and thus resulted in higher inhibition ratio. However, the cells survived during the incubation might gradually repair and recover by themselves after prolonged culture. In addition, there is also a trade-off between the detection time and the analytical performance. Therefore, optimization of the incubation time was of great importance to the toxicity biosensor. The biosensor response to 20 mg/L DCP with different incubation times ranging from 10 to 300 min was then determined. As shown in Fig. 2a, the inhibition ratio increased along with the prolonged incubation time from 10 to 60 min. After that, the incubation time did not significantly affect the inhibition ratio. The potential poised on the working electrode is another determining parameter for the biosensor output. It was found that, when the working electrode was poised at 0 or 0.5 V, the inhibition ratio (55 ± 3.4% for 0 V, 58 ± 3.2% for 0.5 V) obtained was much higher than that from the electrode poised at 0.2 V (38 ± 2.6%) or 0.3 V (48 ± 4%) (Fig. 2b). Moreover, the current signal output generated from the biosensor at 0.5 V was about 50% higher than that from the biosensor at 0 V. Thus, 0.5 V was selected as the optimum potential as higher current output is crucial for the biosensor sensitivity. In addition, as cells served as the biocatalyst for electron generation in this biosensor system, the density of the cells in this system was believed to significantly affect the performance of the biosensor. As expected, the current output increased along with the elevated cell density (OD 0.5 to OD 2.0) (Fig. 2c). However, the inhibition ratio reached its maximum at OD 1.0 (62 ± 2.5%) and then decreased to 41 ± 5.6% at OD 1.5 or 39 ± 6.0% at OD 2.0. According to these results, the optimum conditions for biosensing should be set as follows: incubation time of 60 min, working electrode poised at 0.5 V, and cell density maintained at OD 1.0. Under the optimized condition, the interference resistance and storage stability of this biosensor were tested (ESM Fig. S3). It was found that the biosensor output was not significantly affected by the addition of chemical interferences such as glucose and lactate (ESM Fig. S3a). Moreover, as most of the bacterial species is non-electroactive which cannot produce obvious electric signal output, bacterial contamination (Pseudomonas aeruginosa or Escherichia coli) also only showed marginal influence on the biosensor output (ESM Fig. S3a). Storage stability is another important consideration for biosensor development. As S. oneidensis MR-1 is resistant to low temperature, the biosensor can be stored at 4 °C and the biosensor output did not show a significant decrease after 1 week storage (ESM Fig. S3b). These results substantiated that the biosensor developed here is robust enough and showed great potential for practical applications.

The effect of (a) preincubation time (working electrode potential set at 0.5 V, the cell density is OD600 = 0.5), (b) poised potential (preincubation with DCP for 60 min, the cell density is OD600 = 0.5), and (c) cell density (preincubation with DCP for 60 min, working electrode potential set at 0.5 V) on the performance of the developed biosensor (DCP, 20 mg/L). The amperometric response from cells without DCP addition at designed condition was used as the control for inhibition ratio calculation

Determination of water toxicity with the developed system

Next, the biosensor response to different concentrations of DCP was determined at the optimized conditions. The i-t curves of the biosensor at different DCP concentrations showed the similar sigmoid trends; i.e., there is a stable baseline current output with about 0.5 μA immediately generated after the biosensor was set up; then, the current output exponentially increased after a lag phase; finally, the current output reached its plateau and formed a stable maximum current (Fig. 3). It was found that the current output was inhibited by the addition of DCP, and the inhibition ratio increased along with the elevated concentration of DCP (Fig. 3). More interestingly, the time (tr) needed for biosensor to reach the maximum current output was varied when different concentrations of DCP were added. It was speculated that the bacterial cells under normal growth condition required additional time (lag phase) [31] to adapt to the electrochemical conditions probably by optimizing or reconstituting the extracellular electron transfer machinery [32]. Moreover, the adaptation process might be affected by the bacterial viability and metabolic activity which directly associated with the DCP concentration added. As shown in Fig. 3, the lag phase and tr increased along with the elevated DCP concentration. Thus, the tr could be considered as another signal to determine the DCP toxicity.

The relationship between the inhibition ratio and the DCP concentrations was analyzed. As shown in Fig. 4a, the inhibition ratio increased linearly below the concentration of 20 mg/L and then increased slowly above 20 mg/L. Based on the linear dependency (R 2 = 0.9755) between the inhibition ratio and the DCP concentration ranging from 0 to 20 mg/L, the half maximal inhibitory concentration (IC50) of DCP determined was 14.5 mg/L, which is comparable with other assays with activated sludge (Respirometer [33] or Cellsense [34]) (ESM Table S1). However, the results obtained from assessment with activated sludge might show a significant difference which is even not comparable between different laboratories due to the variation of the bacterial community between different activated sludge [15]. The IC50 obtained here is also comparable with E. coli- or P. aeruginosa-based colorimetric biosensors [14, 35] and much lower than Vibrio fischeri-based Cellsense assessment [34] (ESM Table S1). Moreover, this biosensor showed good dose-dependent response to the heavy metal ions and could be applied for determination of heavy metal toxicity (Cu2+ and Cr6+) (ESM Fig. S4).

(a) The inhibition ratio of different concentrations of DCP measured by the developed biosensor. (b) The Δt of different concentrations of DCP obtained with the developed biosensor. (c) The relationship between the signal output of inhibition ratio and Δt in response to different concentrations of DCP

In good agreement with the DCP toxicity determined by the current output, the response of Δt to different concentrations of DCP (Fig. 4b) showed the similar trends with that of the current output (Fig. 4a). Strikingly, it was found that an excellent linear dependency (R 2 = 0.9989) could be established between Δt and the DCP concentration (below 20 mg/L). The results confirmed that Δt could serve as another signal output for toxicity detection (Fig. 4b). Moreover, the relationship between Δt and inhibition ratio was analyzed. It was found that Δt showed a linear dependency (R 2 = 0.9541) upon the inhibition ratio of biosensors with different DCP concentrations (Fig. 4c). Therefore, the results indicated that the toxicity of DCP determined by inhibition ratio with current signal output could be confirmed by another signal output (Δt) and thus guaranteed a reliable detection result. To the best of our knowledge, this is the first whole-cell-based toxicity biosensor with dual-signal confirmation, which would be promising for reliable toxicity assessment. To create the credit of this biosensing method, simulated real samples were prepared using river water spiked with different amount of DCP and toxicity analyses were performance with this newly developed biosensor. It was found that the recovery obtained by the biosensor was over 85% and the variation was less that 6%, indicating good accuracy and repeatability (ESM Table S2).

Conclusion

In this work, a bioelectrochemical biosensor with dual-signal generation for water toxicity determination was developed. By using the model exoelectrogen S. oneidensis MR-1 cells as the recognition and signal generation elements, the electrochemical response (current output) of cells to the model toxic compounds was determined. More impressively, this biosensor generated another signal output (Δt) besides the current response, which showed excellent linear relationship with the DCP concentration and could be used as another confirmation signal for the electrochemical assessment. The toxicity assessment method developed here provided a simple, fast, and reliable tool for water toxicity detection, and the idea of dual-signal confirmation would be promising for new toxicity biosensor design.

References

Chibwe L, Titaley IA, Hoh E, Sirnonich SLM. Integrated framework for identifying toxic transformation products in complex environmental mixtures. Environ Sci Technol Lett. 2017;4:32–43.

Noguera-Oviedo K, Aga DS. Lessons learned from more than two decades of research on emerging contaminants in the environment. J Hazard Mater. 2016;316:242–51.

Schwarzenbach RP, Egli T, Hofstetter TB, von Gunten U, Wehrli B. Global water pollution and human health. Ann Rev Environ Res. 2010;35:109–36.

Hoh E, Dodder NG, Lehotay SJ, Pangallo KC, Reddy CM, Maruya KA. Nontargeted comprehensive two-dimensional gas chromatography/time-of-flight mass spectrometry method and software for inventorying persistent and bioaccumulative contaminants in marine environments. Environ Sci Technol. 2012;46:8001–8.

Sun FH, Zhou QX. Metal accumulation in the polychaete Hediste japonica with emphasis on interaction between heavy metals and petroleum hydrocarbons. Environ Pollut. 2007;149:92–8.

Wang X, Gao NSJ, Zhou QX. Concentration responses of toxicity sensor with Shewanella oneidensis MR-1 growing in bioelectrochemical systems. Biosens Bioelectron. 2013;43:264–7.

Alves A, Kucharska A, Erratico C, Xu FC, Den Hond E, Koppen G, et al. Human biomonitoring of emerging pollutants through non-invasive matrices: state of the art and future potential. Anal Bioanal Chem. 2014;406:4063–88.

Murray KE, Thomas SM, Bodour AA. Prioritizing research for trace pollutants and emerging contaminants in the freshwater environment. Environ Pollut. 2010;158:3462–71.

Tsopela A, Lale A, Vanhove E, Reynes O, Seguy I, Temple-Boyer P, et al. Integrated electrochemical biosensor based on algal metabolism for water toxicity analysis. Biosens Bioelectron. 2014;61:290–7.

Hung KWV, Suen MFK, Chen YF, Cai HB, Mo ZX, Yung KKL. Detection of water toxicity using cytochrome P450 transgenic zebrafish as live biosensor: for polychlorinated biphenyls toxicity. Biosens Bioelectron. 2012;31:548–53.

Rodriguez-Mozaz S, de Alda MJL, Barcelo D. Biosensors as useful tools for environmental analysis and monitoring. Anal Bioanal Chem. 2006;386:1025–41.

Lagarde F, Jaffrezic-Renault N. Cell-based electrochemical biosensors for water quality assessment. Anal Bioanal Chem. 2011;400:947–64.

Catterall K, Robertson D, Hudson S, Teasdale PR, Welsh DT, John R. A sensitive, rapid ferricyanide-mediated toxicity bioassay developed using Escherichia coli. Talanta. 2010;82:751–7.

Zhai JF, Yong DM, Li J, Dong SJ. A novel colorimetric biosensor for monitoring and detecting acute toxicity in water. Analyst. 2013;138:702–7.

Gao GY, Qian J, Fang DY, Yu Y, Zhi JF. Development of a mediated whole cell-based electrochemical biosensor for joint toxicity assessment of multi-pollutants using a mixed microbial consortium. Anal Chim Acta. 2016;924:21–8.

Wang XJ, Liu MA, Wang X, Wu Z, Yang LZ, Xia SQ, et al. P-benzoquinone-mediated amperometric biosensor developed with Psychrobacter sp. for toxicity testing of heavy metals. Biosens Bioelectron. 2013;41:557–62.

Ikeda T, Kano K. An electrochemical approach to the studies of biological redox reactions and their applications to biosensors, bioreactors, and biofuel cells. J Biosci Bioeng. 2001;92:9–18.

Li JM, Yu Y, Wang YN, Qian J, Zhi JF. The benzoquinone-mediated electrochemical microbial biosensor for water biotoxicity assay. Electrochim Acta. 2013;97:52–7.

Fang DY, Gao GY, Shen J, Yu Y, Zhi JF. A reagentless electrochemical biosensor based on thionine wrapped E. coli and chitosan-entrapped carbon nanodots film modified glassy carbon electrode for wastewater toxicity assessment. Electrochim Acta. 2016;222:303–11.

Sun JZ, Kingori GP, Si RW, Zhai DD, Liao ZH, Sun DZ, et al. Microbial fuel cell-based biosensors for environmental monitoring: a review. Water Sci Technol. 2015;71:801–9.

Yong YC, Zhong JJ. Recent advances in biodegradation in China: new microorganisms and pathways, biodegradation engineering, and bioenergy from pollutant biodegradation. Process Biochem. 2010;45:1937–43.

Yong YC, Yu YY, Zhang XH, Song H. Highly active bidirectional electron transfer by a self-assembled electroactive reduced-graphene-oxide-hybridized biofilm. Angew Chem Int Ed. 2014;53:4480–3.

Sun DZ, Yu YY, Xie RR, Zhang CL, Yang Y, Zhai DD, et al. In-situ growth of graphene/polyaniline for synergistic improvement of extracellular electron transfer in bioelectrochemical systems. Biosens Bioelectron. 2017;87:195–202.

Logan BE. Exoelectrogenic bacteria that power microbial fuel cells. Nat Rev Microbiol. 2009;7:375–81.

Yong YC, Yu YY, Yang Y, Li CM, Jiang RR, Wang X, et al. Increasing intracellular releasable electrons dramatically enhances bioelectricity output in microbial fuel cells. Electrochem Commun. 2012;19:13–6.

Liu J, Yong YC, Song H, Li CM. Activation enhancement of citric acid cycle to promote bioelectrocatalytic activity of arcA knockout Escherichia coli toward high-performance microbial fuel cell. ACS Catal. 2012;2:1749–52.

Si RW, Yang Y, Yu YY, Han S, Zhang CL, Sun DZ, et al. Wiring bacterial electron flow for sensitive whole-cell amperometric detection of riboflavin. Anal Chem. 2016;88:11222–8.

Si RW, Zhai DD, Liao ZH, Gao L, Yong YC. A whole-cell electrochemical biosensing system based on bacterial inward electron flow for fumarate quantification. Biosens Bioelectron. 2015;68:34–40.

Yang Y, Yu YY, Wang YZ, Zhang CL, Wang JX, Fang Z, et al. Amplification of electrochemical signal by a whole-cell redox reactivation module for ultrasensitive detection of pyocyanin. Biosens Bioelectron. 2017;98:338–44.

Peng L, You SJ, Wang JY. Electrode potential regulates cytochrome accumulation on Shewanella oneidensis cell surface and the consequence to bioelectrocatalytic current generation. Biosens Bioelectron. 2010;25:2530–3.

Ding CM, Liu H, Zhu Y, Wan MX, Jiang L. Control of bacterial extracellular electron transfer by a solid-state mediator of polyaniline nanowire arrays. Energy Environ Sci. 2012;5:8517–22.

Busalmen JP, Esteve-Nunez A, Feliu JM. Whole cell electrochemistry of electricity-producing microorganisms evidence an adaptation for optimal exocellular electron transport. Environ Sci Technol. 2008;42:2445–50.

Gutierrez M, Etxebarria J, de las Fuentes L. Evaluation of wastewater toxicity: comparative study between Microtox (R) and activated sludge oxygen uptake inhibition. Water Res. 2002;36:919–24.

dos Santos LF, Defrenne L, Krebs-Brown A. Comparison of three microbial assay procedures for measuring toxicity of chemical compounds: ToxAlert (R) 10, CellSense and Biolog MT2 microplates. Anal Chim Acta. 2002;456:41–54.

Yu DB, Yong YC, Liu CY, Fang YX, Bai L, Dong SJ. New applications of genetically modified Pseudomonas aeruginosa for toxicity detection in water. Chemosphere. 2017;184:106–11.

Acknowledgements

This work was supported by the Natural Science Foundation of Jiangsu Province for Distinguished Young Scholars (BK20160015), National Natural Science Foundation of China (NSFC 51578266, 21306069), a project supported by the Fundamental Research Funds for the Central Universities (Grant No. 30916014102), and a project funded by the Priority Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Published in the topical collection Microbial Biosensors for Analytical Applications with guest editor Gérald Thouand.

Electronic supplementary material

ESM 1

(PDF 401 kb)

Rights and permissions

About this article

Cite this article

Yang, Y., Wang, YZ., Fang, Z. et al. Bioelectrochemical biosensor for water toxicity detection: generation of dual signals for electrochemical assay confirmation. Anal Bioanal Chem 410, 1231–1236 (2018). https://doi.org/10.1007/s00216-017-0656-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-017-0656-4