Abstract

Asparaginase (E.C.3.5.1.1), an important enzyme, is broadly disseminated in all the three domains of life and responsible for catalysing conversion of asparagine into aspartic acid and ammonia. It is one of the most utilized clinical enzymes used in the treatment of different types of cancers. However, there has been a renewed interest in other application of this enzyme especially for minimizing the acrylamide content in baked/fried starchy food products. Acrylamide is generated as a by-product of Maillard reactions between asparagine and reducing sugars. The reactions usually occur at temperature above 100 °C and account for colour and flavour developments in fried/baked starchy foods. In the year 1994, Acrylamide was first time classified in Group B2, i.e. as probably carcinogenic to humans by the International agency for research on cancer. Significant contents of acrylamide have been detected in range of food products including roasted potatoes, root vegetables, chips, crisps, toasts, cakes, biscuits, cereals and coffee. Extensive efforts have been made to reduce the formation of acrylamide during baking/toasting or frying by incorporating asparaginase enzyme as pretreatment. The present chapter encompasses all these aspects and sources of asparaginases, their enzymatic properties, engineered thermostable asparaginase and their various applications in food processing.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

5.1 Introduction

Asparaginase (asparagine aminohydrolase; E.C.3.5.1.1) belongs to the amino acid amidohydrolase that catalyses the conversion of l-asparagine to l-aspartate and ammonia. This enzymatic reaction played a central role in a number of metabolic processes in diverse living organisms. Asparaginases have remarkable considerable attention from last few decades due to its application in amino acid metabolism, human health and food industry. The global demand of asparaginase was 380 million USD in 2017 and market will reach upto 420 million USD by 2025 (Global Asparaginase Sales Market Report 2018). Hence, it is important to deal with the limitation to meet this huge global demand. Although, the enzyme is widely distributed in almost all clade of life including plant, animal, bacteria and archaea, however, increasing attention has been drawn to microbial asparaginases particularly from bacterial sources due to high yield, easy maintenance, versatile characteristics and suitability for the industrial application.

For last more than 4 decades, asparaginase enzyme was widely studied and used in the treatment of different type of cancer mainly non-Hodgkin’s lymphoma, acute lymphoblastic leukemia (ALL) and acute myeloid leukemia (AML) in children. It is one of the leading medically important enzymes because of its high efficiency and efficacy against leukemia and lymphoblastic leukemia (Swain et al. 1993). Asparagine (a free amino acid) found in foods and taken up by the lymphoma or myeloid cells as a nutrient. Asparaginases convert asparagine into aspartate and ammonia (Krishnapura and Belur 2016), which reduces the asparagine availability to myeloid cells (Fig. 5.1). Generally, myeloid cells do not have asparagine synthetase enzyme which is responsible for asparagine production and due to unavailability of asparagine, it leads to starvation of cell (Asselin and Rizzari 2015).

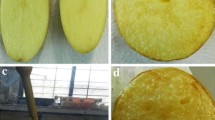

Apart from its medicinal use, in recent years, asparaginase was also explored in the food industry for the reduction of acrylamide formation in finished products. The International agency for research on cancer classified acrylamide in Group B2, i.e. as probably carcinogenic to humans (IARC 1994). Acrylamide is mainly formed during baking/frying of starchy/high carbohydrate food items, when reducing sugar and asparagine reacts at high temperature more than 120 °C and with low water content. The reference dose (RfD) established for acrylamide is around 25–35 µg of acrylamide per day for a person weighing 68 kg by different agencies like the US EPA, United Kingdom (British Food Standard Agency; www.foodstandards.gov.uk), Norway (www.snt.no), Switzerland (Swiss Federal Office of Public Health 2002) and Germany (www.bfr.bund.de). Hence, the food industry is under pressure to reduce the formation of acrylamide in different food products. Various mitigation strategies like physicochemical methods, asparaginase pretreatment, etc were reported by several researchers. Physicochemical methods were not well accepted due to the formation of different secondary attributes in the finished food. Asparaginase played a major role in the food industry for reducing the acrylamide content without forming any secondary attributes like odour, souring etc (Fig. 5.1). Asparaginases enzyme hydrolysed the asparagine during pretreatment which leads to the inhibition of Maillard reaction and the amount of acrylamide was reduced significantly (Pedreschi et al. 2008; Ravi and Gurunathan 2018). Although the use of asparaginase in food industry has several limitations like high cost, low productivity and low thermal stability still remain a matter of concern.

Some researchers have worked upon thermal stability of enzyme by screening asparaginase from thermostable microbial sources (Pradhan et al. 2013). Moreover, engineering of asparaginase enzyme using different techniques like immobilization of asparaginase (Balcao et al. 2001) and specific site saturation mutagenesis (Feng et al. 2018) for thermal stability and high yield were also studied.

There are commercially available asparaginases which were efficiently utilized for acrylamide reduction, i.e. PreventASeTM from DSM (Heerlen, The Netherlands) and Acrylaway® from Novozymes A/S (Bagsvaerd, Denmark). For better enzymatic properties, and thermal stability, enzymes need to be isolated from novel sources with enhanced properties.

This book chapter highlights different microbial sources of asparaginase and their enzymatic characteristics. Asparaginase mechanism of action, sequence-based structural and functional relationship, chemical and molecular modifications of enzyme for enhancing enzymatic properties is also elaborated.

5.1.1 History of Asparaginase

The discovery of asparaginase as anticancer drug started first in the year 1953, when J. G. Kidd showed the regressive effect of guinea pig serum on transplanted lymphomas in rat and mice model. They had proposed certain active constituents in serum leads to the regression of lymphomas (Kidd 1953). Earlier to this, Clementi in 1922 had suggested the characteristics of guinea pig serum and claimed that they were enriched with asparaginase enzyme (Clementi 1922). Progressive studies by Broome in 1961 also showed the inhibitory effect of asparaginase present in guinea pig serum on lymphoma 6C3HED cells (Broome 1963). Further, advanced studies by Mashburn and Wriston (1963) indicated the potential of microbial asparaginase as a mean of chemotherapeutic agent to inhibit tumour growth. Tumour cells require asparagine as nutrient source and the ability of asparaginase to deplete asparagine made it possible in the lost battle of fighting against malignant tumour and lymphoblastic lymphomas. Asparaginase from microbial sources came out as flawless weapon and explored widely for its medical application. Several trials were tested to treat Acute Lymphoblastic leukemia (ALL) and later it was proposed as an excellent approach for absolution in leukemic patients (Hill et al. 1967).

5.1.2 Types of Asparaginase

l-asparaginase of two types, i.e. type I and type II asparaginase, which are widely distributed in microorganisms, plants, vertebrates and animal tissues (Qeshmi et al. 2018). Type I asparaginases are found in the cytosol, and hence, these enzymes are named as cytosolic asparaginase which shows a low affinity towards l-asparagine and greater affinity towards l-glutamine. Hence, these enzymes are considered confound as they showed an affinity towards the unspecific substrate. Type II asparaginases are better studied and found at the vicinities of periplasmic spaces. They are produced extracellularly. They showed high affinity towards l-asparagine and less specific towards l-glutamine (Swain et al. 1993). Both enzymes were substrate specific but Type II enzymes were less immunogenic. Due to this, Type II asparaginase has been comprehensively used for medical applications, mainly in treatment of acute lymphoblastic leukemia (ALL) (Zuo et al. 2015). Type II asparaginase has also been implicated in the food industry for removal of asparagine from the primary ingredients before processing to reduce the acrylamide formation in the finished food items (Hendriksen et al. 2009).

5.1.3 Classification of Asparaginases

l-asparaginase is produced by all kingdoms of life: Plants, microorganisms and animals. Hence, enzymes are classified based on the sequences of amino acids and biochemical characteristics of the enzyme. It is classified and grouped into mainly three types: bacterial, plant and rhizobial type. Bacterial enzymes mainly from E. coli and Erwinia chrysanthemi were studied extensively because of their varied properties and has been used vigorously as chemotherapeutic agent in ALL treatment from last two decades (Duval et al. 2002; Shi et al. 2017).

-

(a)

Bacterial type asparaginase

Most of the Type II enzymes are isolated from mesophilic sources consisting tetra dimers and their molecular masses were analysed in the range of 140–170 KDa, whereas Type I enzymes are mainly isolated from thermophilic sources and are homodimer structurally. The molecular mass of this enzyme was up to 70 KDa. Some of the microbes like E. coli produced both isozymes in which Type I enzymes are cytosolic and have a low affinity for l-asparagine and considered to be a constitutive enzyme. Type II asparaginase showed higher affinity for l-asparagine and considered periplasmic. These enzymes are expressed subject to stress conditions, aeration and changes in the media or nutrient sources like carbon and nitrogen sources, etc. One of the two types of asparaginase showed antitumour activity and these properties vary from strain to strain and culture conditions. E. coli and P. geniculate comprise of type II asparaginase and known for their antitumour properties. Whereas in Mycobacterium tuberculosis, it has both isozymes but only one enzyme has shown antitumour activity. These unlike activities differ due to changes in pH, temperature, clearance rate (Half-life inside serum), activity profile and significant activity towards l-asparagine (Qeshmi et al. 2018; Badoei-Dalfard 2015).

Asparaginase from E. coli and E. chrysanthemi was studied extensively, and hence, asparaginase enzymes from different species were always harmonized with these microbes. Genus Bacillus contains both isozymes and genome sequencing of ansZ gene showed functional asparaginase, with 59% similarity with Erwinia asparaginase and 53% similarity with E. coli Type II asparaginase. Also, Gene ansA in Bacillus sp. encodes Type I asparaginase. Asparaginase from Bacillus sp. was utilized expeditiously for removal of acrylamide content in food processing but its role in antitumour activity is a matter of research.

-

(b)

Plant-type asparaginase

Asparagine hydrolysis in higher plants is done utilizing two different kinds of routes. In the first catabolic pathway, amino nitrogen was transaminated by the enzyme asparagine oxo acid amino transferase and produces 2-oxosuccinamic acid and an amino acid. The second route utilized l-asparaginase which hydrolysed the asparagine into aspartate and ammonia found mainly in temperate legumes. Plant-type asparaginase is produced as inactive precursor molecules and belongs to N-terminal hydrolases. High level of asparaginase was detected mainly in developing leaves or roots (Michalska et al. 2008). Plants contain two different kind of asparaginase—classified on the basis of reaction catalysis and their potassium dependence. These are immunological significant and separate from each other (Lea et al. 1984; Michalska and Jaskolski 2006).

Plants like Sphagnum fallax have two types of cytosolic l-asparaginase. Potassium ions have no effect on the overall stability of the enzyme but required for the synergistic higher activity of the enzyme (Heeschen et al. 1996). Comparatively, potassium-independent enzymes are highly stable than potassium dependent but potassium dependent enzymes have higher affinity for substrate (Chagas and Sodek 2001). l-asparaginase extracted from Phaseolus vulgaris has a low glutamine activity which removes unwanted side effects and the purpose of chemotherapy could be sorted in the treatment of ALL (Mohamed et al. 2016).

Plant asparaginases were studied exclusively on the basis of homology modeling comparison with the crystal structure of E. coli asparaginase (Michalska et al. 2008). Sphagnum fallax asparaginase has intermediate properties of microbial as well as plants of higher origin (Heeschen et al. 1996). Marine algae Chlamydomonas and Pisum reported to have better enzymatic activity in the light region. Two group of plant asparaginase showed higher sequence similarity with each other and it is unlike to the microbial asparaginase where they are distinct from each other (EcA I cytosolic and EcAII periplasmic).

-

(c)

Rhizobial-type asparaginase

Rhizobial-type asparaginase has shown sequence similarity with L-asparaginase from Rhizobium etli. R. etli are symbiont bacteria lived with the association of leguminous plants (Borek and Jaskólski 2001; Shi et al. 2017). Peculiar feature of these bacteria was associated with asparagine as they utilized it as a single source of carbon and nitrogen for their living. Asparaginase and aspartase enzymes were employed for this purpose. There are two kinds of asparaginases were reported from R. etli; asparaginase I which were constitutive enzyme and thermostable while asparaginase II was thermolabile and expressed only when asparagine is present other than any carbon source. Both the enzyme had not shown any sequence similarity with bacterial asparaginase like E. coli and E. chrysanthemi. However, type II asparaginase from R. etli. was having activity free from glutaminase, which shows a better potential for chemotherapy (Moreno-Enríquez et al. 2012).

5.2 Microbial Sources of Asparaginase

Asparaginase from microbial sources added value to the enzyme as enzymes would inherit the properties of the sources from which they were isolated. Microbial source of asparaginase enzyme is considered as effective as well as an easy way for industrial. A wide range of microbes such as fungi, bacteria, actinomycetes, yeast and algae has been well characterized for the production of l-Asparaginase till date. Different sources of microbial enzyme with their property were listed here in Table 5.1.

Bacillus sp. and Pseudomonas sp. are well-known producers of bacterial asparaginase. The prevalence of Bacillus sp. in the different environments can be correlated with their typical nature of spore formation, which can be aerially distributed for long distance (Chubukov et al. 2014). The asparaginase production is greatly influenced by media composition as well as the method of production, i.e. solid-state fermentation (SSF) or submerged fermentation (SmF). In bacteria, when the primary carbon source is present along with high concentrations of a variety of amino acids under anaerobic conditions, the asparaginase production can be enhanced by 100-fold (Cedar and Schwartz 1968). Since the different metabolites of amino acids like asparagine can contribute directly into the citric acid cycle, and its presence in the medium can trigger the asparaginase gene expression. Although, the model carbon source, glucose may serve as a catabolic repressor for enzyme expression.

The next important and limiting factors for production of asparaginases are their respective microbes. The enzyme catalytic property is importantly influenced by pH, temperature, substrate specificity and other kinetic parameters. It may vary among the same genus and or species. l-asparaginase from most of the Bacillus sp. exhibited optimum pH in the range of 6–8 and optimum temperature in the range of 30–40 °C while B. licheniformis (Mahajan et al. 2014), B. subtilis BsAIIS40M (Onishi et al. 2011), B. subtilis WB600 (Feng et al. 2017) and B. aryabhattai ITBHU02 (Singh et al. 2013) showed optimum pH around 8.5 and optimum temperature around 60–70 °C. Thermostable asparaginases from bacterial source like Thermococcus kodakaraensis, Thermococcus gammatolerans EJ3, Pyrococcus furiosus etc. are having optimum pH and temperature of 9 and 85°C respectively and can be of interest for industrial applications (Chohan and Rashid 2013; Zuo et al. 2014; Bansal et al. 2010).

When bacterial l-asparaginase used for medicinal purpose, it was found that there is some side effect such as hypersensitivity, pancreatitis, thrombosis, etc., which is mainly due to glutaminase activity (Killander et al. 1976; Ramya et al. 2012). To minimize the side effect, the search of eukaryotic microorganism like yeast and fungi was taken up for production of the enzyme. Several researchers reported that fungi and yeast can produce reasonable production of the enzyme under both solid-state fermentation (SSF) and submerged fermentation (SmF) (Dias et al. 2016; Kumar and Manonmani 2013). The fungal genera such as Aspergillus (Dias et al. 2016; Vala et al. 2018; Dange and Peshwe 2011), Penicillium (Shrivastava et al. 2012; Elshafei et al. 2012; Patro and Gupta 2012) and Trichoderma (Lincoln et al. 2015) are vastly studied for the production of asaparaginases.

Oceans were the cradle of life and they still host an enormous biodiversity which is rather under-explored. Research to explore the marine environment for microorganisms has rapidly increased over the past two decades. Marine microbes majorly include bacteria, archaea and actinomycetes (Izadpanah et al. 2018). Marine actinomycetes were also explored for l-asparaginase production and their application. Genus Streptomyces is the most studied actinomycetes till date (Basha et al. 2009; Dharmaraj 2011; Meena et al. 2015; Varma et al. 2016; Amena et al. 2010; El-Naggar et al. 2016, 2017).

5.3 Application of Asparaginase as Food Enzyme

In recent years, l-asparaginase has been successfully used as food enzyme as it has found an application in reducing acrylamide formation in food system. Asparagine is present in most of the starchy foods, which reacts with their reducing sugar during thermal processing leads to formation of neo formed contaminants named acrylamide which is a bi-product of Maillard reaction (Mottram et al. 2002). It is a potent chemical carcinogen and neurotoxic which forms adduct with the haemoglobin when consumed in high dose and causes reproductive disability (Tyl et al. 2003). Acrylamide toxicity is dose dependent and when ingested in high amount leads to cytotoxicity and necrosis. Acrylamide cytotoxic studies were conducted by Kacar et al. (2018) where acrylamide’s cytotoxicity and anti-proliferative properties were analysed on human cell lines A549 and acrylamide (IC50) dose was attained in 24 h was 4.5 mM. Hence, such a small concentration of acrylamide had a deep and regressive effect on human body.

In a view of food system and prevention of human health hazards, acrylamide toxicity and reduction of its content in food systems were studied extensively. Several International Food related agencies like U.S. Food and Drug Administration (FDA), European Food Safety Authority (EFSA) initiated the battle to reduce acrylamide contents in deep fried and baked food products formed during heat processing after its surprise discovery by Swedish scientists in 2002 (Tareke et al. 2002). FDA had issued several magazines and scientific reports claiming the formation of acrylamide in different kinds of food products and formation of other contaminants in heat-processed system (Robin and Clanci 2007). EFSA had done extensive research work on the contents of acrylamide in different food products along with the toxicity levels on human. They had also reported the acrylamide toxicity and its metabolism pathway inside human body where acrylamide is metabolized into glycidamide (GA) which forms an adduct with haemoglobin and leads to genotoxicity and neurotoxicity (EFSA 2015; Bandarra et al. 2013).

Hence, there was a sudden rush to cope up with this major issue. In the wake of this, several studies were conducted and guidelines for cooking were finalized (Robin and Clanci 2007). After that, several parameters were studied like decreasing pH, lowering the temperature for frying and blanching of the potato chips before frying for decreasing the levels of acrylamide in French fries (Pedreschi et al. 2007). Enzymatic pretreatment of food with asparaginase enzyme leads to reduction of acrylamide at significant levels apart from other treatment procedure (Meghavarnam and Janakiraman 2018). Different food products have been subjected to pretreatment with asparaginase and clearly shown the reduction of acrylamide in variety of food products. Some of the food products with high acrylamide contents and successful reduction of acrylamide using asparaginase enzyme will be listed here (Table 5.2).

5.4 Asparaginase Sequence Analysis Combined with Mode of Action

Many asparaginase gene sequences have been deposited into GenBank and crystal structure of functional enzymes also available in Protein Database (PDB) which comprises of various microbial sources. Type I asparaginase is from Lactobacillus reuteri (PDB ID: A5VMR3), Escherichia coli (PDB ID: 2HIM), Yersinia pestis (PDB ID: 3NTX), Vibrio cholera (PDB ID: 2OCD), Thermococcus kodakaraensis (PDB ID: 5OT0), Pyrococcus furiosus (PDB ID: 4Q0M) and P. horikoshii (PDB ID: 1WLS) while Type II asparaginases are from E. coli (PDB ID: 3ECA), E. chrysanthemi (PDB ID: 5F52), Erwinia carotovora (PDB ID: 2HLN), Wolinella succinogenes (PDB ID: 5K3O), Pseudomonas (PDB ID: 1DJP), Helicobacter pylori (PDB ID: 2WLT), Campylobacter jejuni (PDB ID: 3NXK) and Acinetobacter glutaminasificans (PDB ID: 1AGX). The phylogenetic relationship among the microbial asparaginase protein sequences retrieved from Protein Database (PDB) revealed high divergence among the Type I and Type II asparaginases (Fig. 5.2). For example, Type I and Type II asparaginase from E. coli shares only 24% of protein identity. The protein sequences of both Type I and Type II asparaginases consisted with larger N and smaller C terminal domains, connected with approximately 20 amino acid long linker region (Guo et al. 2017) (Fig. 5.3). The active sites of the asparaginase can be grouped into rigid and flexible regions (Nguyen et al. 2016). The rigid regions consisted of residues between first and third parallel β strands of N-terminal and residues of the C terminal of neighbouring monomer. The flexible region represent the residues involved in substrate-enzyme binding pocket and nucleophilic initiation of the reaction, which is situated at the starting of the N-terminal region (Borek and Jaskólski 2001).

Multiple sequence alignment of the asparaginase protein sequences showing the secondary structure characteristics. All the conserved residues are boxed and the fully conserved residues are coloured white with red background. The less conserved residues are coloured red. The alignment was performed using ESPript 3.0

The protein sequence of asparaginase may reveal its mechanism of action which shows similarity with serine protease (Tomar et al. 2014). The ‘catalytic triad’ composed with a nucleophilic residue, a general base and acidic residue which connected by hydrogen bonds define the complete mechanism of asparaginase. As per the reported crystal structures of asparaginases, the active site has two catalytic triad named as Triad I and Triad II. The Triad I is composed with Thr-Tyr-Glu residues are present at flexible region and act as nucleophilic (Thr), a base (Tyr) and an acidic (Glu) residue (Singh et al. 2015). In a similar way, Triad II is represented by Thr (nucleophilic)-Lys (base)-Asp (acid) residues (Bansal et al. 2012). These two triads function intensively for the conversion of substrate into the product in the presence of water as second nucleophile.

The reaction mechanism of asparaginase composed of two-step sequential ‘ping-pong’ nucleophilic mechanism (Ehrman et al. 1971; Yao et al. 2005). This reaction is initiated by the activation of the enzyme’s nucleophile via strong H bonding to the nearby basic residue which attacks the carbon atom of amide bearing substrate (Fig. 5.1). The rearrangement of tetrahedral transition state leads to the formation of acyl-enzyme intermediate product. In transition state, the negative charge on the O atom of amide group is stabilized by the H bond donors known as ‘oxyanion hole’. In the second step, activated water is acted as the second nucleophile and attacked on C atom of ester group and again a transition state with oxyanion hole is developed and finally converted into free enzyme and product. These two steps reactions are common in Type I and Type II asparaginase with some structural differences. The ‘open and closed’ conformations for substrate binding can be defined by a highly flexible β-hairpin at N-terminal domain (Aghaiypour et al. 2001). The enzyme to ligand binding induces the transition of nucleophilic Thr residue which allows the change in the conformation from open to close. This binding of substrate and induced conformational change of Thr residue for the closer of flexible N-terminal loop also revealed the substrate selection of l-asparagine or l-glutamine (Nguyen et al. 2016). The involvement of other residues in enzyme mechanism has also been discussed by various researchers as the sequence variation among various microorganisms leads to change the catalytic proximity of asparaginase.

5.5 Improvement in Asparaginase Characteristics

The biocatalyst gained its properties from the native living source like microorganism, plant, animal, etc. However, it is essential to alter the native properties of the biocatalyst within the purview of its utilization in applied sectors like industrial, agricultural or medical. Microbial production of asparaginase displayed several bottlenecks like less enzyme activity and narrow range of kinetic parameters like substrate specificity, reusability and thermal stability. These incompatibilities of microbial asparaginase need to be addressed for robust industrial physiochemical conditions. Several attempts have been made to optimize the asparginase enzyme at the molecular level which leads to higher productivity combined with improved properties favourable for industrial or medical applications. For asparaginase enzyme, these selected modifications were carried out by chemical or genetic modifications. The following sections specifically describe the most recent studies, advantages and disadvantages of both modifications.

5.5.1 Chemical Modifications of Asparaginase

The chemical modifications are important to rationalize the immunological responses as well as other characteristics. The immobilization of microbial asparaginase on nanofibers (Ghosh et al. 2012), nanoparticles (Ulu et al. 2018), PEG (Zhang et al. 2004), Sepharose CL-6B (Kotzia and Labrou 2007) agarose-glutaraldehyde (Balcao et al. 2001) and aluminium oxide pellets (Agrawal et al. 2018) which shows advancement of various chemical modifications and its contribution to the asparaginase desired properties. Most of the research has been carried out to possess the asparaginase activity for therapeutic applications (Table 5.3). However, few reports are also available which revealed that the asparaginase immobilization can induce higher reduction of asparagine content that decreases the acrylamide formation in heat-treated food materials. Studies show that immobilized asparaginase-based reduction of asparagine was significantly higher as compared with free asparaginase enzyme. Aiswarya and Baskar (2018) revealed that asparaginase immobilized on magnetic nanoparticle possess 75% mitigation of acrylamide formation in fried potato chips. Similar result was also obtained by Agrawal et al. (2018) and Hendriksen et al. (2016), where asparaginase immobilized on aluminium oxide pellets and silica-based carrier also reduce the asparagine content in fried food materials, respectively. The studies were also suggested that immobilization of asparaginase not only improve the kinetic parameters but thermostability was also shown to be enhanced which is essential of food applications. Different immobilization carrier materials including organic, inorganic and hybrid materials have been used in the studies. However, no study has been reported on the impact of these immobilized asparaginases or other carrier materials on the food quality, texture and flavours. Hence, the research has to be extended in a view of food sample specific carrier materials used for asparaginase immobilization.

5.5.2 Genetic Modifications of Asparaginase

The developments of biotechnological and bioinformatics techniques allowed to attain various approach to improve and assess diverse range of biocatalysts with desired characteristics. These tools can be used to rational or random alteration in the genetic information embedded in the native organism or recombinant host. Several asparaginase genes from microbial sources like Bacillus subtilis (Jia et al. 2013), Thermococcus kodakaraensis (Chohan and Rashid 2013), Pseudomonas fluorescens (Kishore et al. 2015), Nocardiopsis alba (Meena et al. 2016), Thermococcus litoralis (Washio and Oikawa 2018), E. coli (Vidya et al. 2011), Streptomyces (Sudhir et al. 2012), etc. were extracted, cloned and overexpressed by recombinant DNA technology. The molecular analysis of asparaginases has opened up a new avenue for exploring such information for the development of structure–function relationship, substrate binding and selectivity phenomenon, mechanism reestablishment and other identical physicochemical properties. Hence, this information can also be used to rearrange the molecular structure of asparaginase to obtain previously described characteristics. Improvement in thermostability of asparaginase has already been proven and most crucial factor which can broaden its application in therapeutics as well as food for eliminating the toxic content of acrylamide. Therefore, many researchers have attempted to alter the molecular state of native asparaginase proteins by three different and validated strategies: rational design, directed evolution or preparation of synthetic gene construct. Rational design through protein engineering can be defined as hypothesis-driven manipulation of the protein sequence that can change its biophysical properties in a controlled manner. However, the complete crystal structure of validated protein sequence with high resolution and enzyme–ligand binding modeling information is essential for rational protein engineering. The rational hypothesis can be made by algorithmically simulated and optimized designing of available natural sequences for desired protein properties. Few examples are available showing rational designing of asparaginase for the improvement of yield (Verma et al. 2014; Gervais and Foote 2014), substrate specificity (Nguyen et al. 2016) and thermostability (Long et al. 2016; Vidya et al. 2014). Most of the research has been made on the improvement of thermostability of asparaginase. Previous reports concluded that the thermostability of asparaginase can be improved by enhancing the hydrophobicity, H bond and salt bridge, low Ser/Cys content, high Tyr/Arg/Pro content, extra loop deletion, and increased surface polarity and area. Table 5.4 displayed different examples of the rational designing of asparaginase enzyme for the desired properties.

5.6 Conclusion

The book chapter comprehends to the evaluation of microbial asparaginase in terms of its utilization for food industries for the elimination of toxic acrylamide content. Getting insight into the precise mode of action will find the exploration of new microbial sources for mining novel asparaginase. The integration of Omics approaches needs to be explored to mine new candidates of asparaginase from the environments especially extreme environment. The sequence-based diverse interpretation of structure–function relationship has to be utilized for its future existence in dramatically improving the food products and generation of sequence-based rational protein engineering technology can help to decipher improved functional characteristics to meet the industrial desirability.

References

Abd El Baky HHE, Baroty GS (2016) Optimization of growth conditions for purification and production of L-asparaginase by Spirulina maxima. Evid Based Complement Alternat Med

Aghaiypour K, Wlodawer A, Lubkowski J (2001) Do bacterial L-asparaginases utilize a catalytic triad Thr-Tyr-Glu? BBA-Protein Struct M 1550(2):117–128

Agrawal S, Sharma I, Prajapati BP, Suryawanshi RK, Kango N (2018) Catalytic characteristics and application of l-asparaginase immobilized on aluminum oxide pellets. Int J Biol Macromol 114:504–511

Aiswarya R, Baskar G (2018) Enzymatic mitigation of acrylamide in fried potato chips using asparaginase from Aspergillus terreus. Int J Food Sci Tech 53(2):491–498

Amena S, Vishalakshi N, Prabhakar M, Dayanand A, Lingappa K (2010) Production, purification and characterization of L-asparaginase from Streptomyces gulbargensis. Braz J Microbiol 41(1):173–178

Asselin B, Rizzari C (2015) Asparaginase pharmacokinetics and implications of therapeutic drug monitoring. Leuk Lymphoma 56(8):2273–2280

Badoei-Dalfard A (2015) Purification and characterization of L-asparaginase from Pseudomonas aeruginosa strain SN004: production optimization by statistical methods. Biocatal Agric Biotechnol 4(3):388–397

Balcao VM, Mateo C, Fernández-Lafuente R, Malcata FX, Guisan JM (2001) Structural and functional stabilization of L-asparaginase via multisubunit immobilization onto highly activated supports. Biotechnol Prog 17(3):537–542

Bandarra S, Fernandes AS, Magro I, Guerreiro PS, Pingarilho M, Churchwell MI, Gil OM, Batinic-Haberle I, Gonçalves S, Rueff J, Miranda JP, Marques MM, Beland FA, Castro M, Gaspar JF, Oliveira NG (2013) Mechanistic insights into the cytotoxicity and genotoxicity induced by glycidamide in human mammary cells. Mutagenesis 28(6):721–729

Bansal S, Gnaneswari D, Mishra P, Kundu B (2010) Structural stability and functional analysis of L-asparaginase from Pyrococcus furiosus. Biochem (Mosc) 75(3):375–381

Bansal S, Srivastava A, Mukherjee G, Pandey R, Verma AK, Mishra P, Kundu B (2012) Hyperthermophilic asparaginase mutants with enhanced substrate affinity and antineoplastic activity: structural insights on their mechanism of action. FASEB J 26(3):1161–1171

Basha NS, Rekha R, Komala M, Ruby S (2009) Production of extracellular anti-leukaemic enzyme L-asparaginase from marine actinomycetes by solidstate and submerged fermentation: Purification and characterization. Trop J Pharm Res 8(4):353–360

Borek D, Jaskólski M (2001) Sequence analysis of enzymes with asparaginase activity. Acta Biochim Pol 48:893–902

Broome JD (1963) Evidence that the L-asparaginase of guinea pig serum is responsible for its antilymphoma effects. J Exp Med 118(1):99–120

Cedar H, Schwartz JH (1968) Production of L-asparaginase II by Escherichia coli. J Bacteriol 96(6):2043–2048

Chagas EP, Sodek L (2001) Purification and properties of asparaginase from the testa of immature seeds of pea (Pisum sativum). Braz Arch Biol Technol 44(3):239–245

Chohan SM, Rashid N (2013) TK1656, a thermostable L-asparaginase from Thermococcus kodakaraensis, exhibiting highest ever reported enzyme activity. J Biosci Bioeng 116(4):438–443

Chubukov V, Gerosa L, Kochanowski K, Sauer U (2014) Coordination of microbial metabolism. Nat Rev Microbiol 12(5):327–340

Ciesarova Z, Kukurova K, Bednáriková A, Marková L, Baxa S (2009) Improvement of cereal product safety by enzymatic way of acrylamide mitigation. Czech J Food Sci 27:96–98

Clementi A (1922) The enzymatic deamidation of asparagine in different animal species and the physiological significance of its presence in the body. Int Arch Physiol 19(4):369–398

Dange VU, Peshwe SA (2011) Production, purification and characterization of fungal L-asparaginase. Bionano Front 4:162–167

Dharmaraj S (2011) Study of L-asparaginase production by Streptomyces noursei MTCC 10469, isolated from marine sponge Callyspongia diffusa. Iran J Biotechnol 9(2):102–108

Dias FFG, Ruiz ALTG, Della Torre A, Sato HH (2016) Purification, characterization and antiproliferative activity of L-asparaginase from Aspergillus oryzae CCT 3940 with no glutaminase activity. Asian Pac J Trop Biomed 6(9):785–794

Domenech C, Thomas X, Chabaud S, Baruchel A, Gueyffier F, Mazingue F, Auvrignon A, Corm S, Dombret H, Chevallier P, Galambrun C, Huguet F, Legrand F, Mechinaud F, Vey N, Philip I, Liens D, Godfrin Y, Rigal D, Bertrand Y (2011) L-asparaginase loaded red blood cells in refractory or relapsing acute lymphoblastic leukaemia in children and adults: results of the GRASPALL 2005-01 randomized trial. Br J Haematol 153(1):58–65

Duval M, Suciu S, Ferster A, Rialland X, Nelken B, Lutz P, Benoit Y, Robert A, Manel AM, Vilmer E, Otten J, Philippe N (2002) Comparison of Escherichia coli-asparaginase with Erwinia-asparaginase in the treatment of childhood lymphoid malignancies: results of a randomized European Organisation for Research and Treatment of Cancer-Children’s Leukemia Group phase 3 trial. Blood 99(8):2734–2739

Ebrahiminezhad A, Rasoul-Amini S, Ghoshoon MB, Ghasemi Y (2014) Chlorella vulgaris, a novel microalgal source for L-asparaginase production. Biocatal Agric Biotechnol 3(2):214–217

EFSA Panel on Contaminants in the Food Chain (CONTAM) (2015) Scientific opinion on acrylamide in food. EFSA J 13(6):4104

Ehrman M, Cedar H, Schwartz JH (1971) l-Asparaginase II of Escherichia coli studies on the enzymatic mechanism of action. J Biol Chem 246(1):88–94

El-Bessoumy AA, Sarhan M, Mansour J (2004) Production, isolation, and purification of L-asparaginase from Pseudomonas aeruginosa 50071 using solid-state fermentation. BMB Rep 37(4):387–393

El-Naggar NEA, Deraz SF, Soliman HM, El-Deeb NM, El-Ewasy SM (2016) Purification, characterization, cytotoxicity and anticancer activities of L-asparaginase, anti-colon cancer protein, from the newly isolated alkaliphilic Streptomyces fradiae NEAE-82. Sci Rep 6:32926

El-Naggar NEA, Moawad H, Abdelwahed NA (2017) Optimization of fermentation conditions for enhancing extracellular production of L-asparaginase, an anti-leukemic agent, by newly isolated Streptomyces brollosae NEAE-115 using solid state fermentation. Ann Microbiol 67(1):1–15

Elshafei AM, Hassan MM, Abd M, Abouzeid E, Mahmoud DA, Elghonemy DH (2012) Purification, characterization and antitumor activity of L-asparaginase from Penicillium brevicompactum 2 NRC 829. Brit Microbiol Res J 2(3):158–174

El-Sharkawy AS, Farag AM, Embaby AM, Saeed H, El-Shenawy M (2016) Cloning, expression and characterization of aeruginosa EGYII L-Asparaginase from Pseudomonas aeruginosa strain EGYII DSM 101801 in E. coli BL21 (DE3) pLysS. J Mol Catal B Enzym 132:16–23

Erva RR, Goswami AN, Suman P, Vedanabhatla R, Rajulapati SB (2017) Optimization of L-asparaginase production from novel Enterobacter sp., by submerged fermentation using response surface methodology. Prep Biochem Biotechnol 47(3):219–228

Feng Y, Liu S, Jiao Y, Gao H, Wang M, Du G, Chen J (2017) Enhanced extracellular production of L-asparaginase from Bacillus subtilis 168 by B. subtilis WB600 through a combined strategy. Appl Microbiol Biotechnol 101(4):1509–1520

Feng Y, Liu S, Jiao Y, Wang Y, Wang M, Du G, Chen J (2018) Improvement of L-asparaginase thermal stability by regulating enzyme kinetic and thermodynamic states. Process Biochem https://doi.org/10.1016/j.procbio.2018.05.002

Gervais D, Foote N (2014) Recombinant deamidated mutants of Erwinia chrysanthemi L-asparaginase have similar or increased activity compared to wild-type enzyme. Mol Biotechnol 56(10):865–877

Ghosh S, Chaganti SR, Prakasham RS (2012) Polyaniline nanofiber as a novel immobilization matrix for the anti-leukemia enzyme l-asparaginase. J Mol Catal B Enzym 74(1–2):132–137

Gilbert HJ, Blazek R, Bullman HM, Minton NP (1986) Cloning and expression of the Erwinia chrysanthemi asparaginase gene in Escherichia coli and Erwinia carotovora. Microbiology 132(1):151–160

Global Asparaginase Sales Market Report (2018) https://www.marketinsightsreports.com/reports/0709674345/Global-Asparaginase-Sales-Market-Report-2018?source=thefreenewsman&Mode=15

Guo L, Wang J, Qian S, Yan X, Chen R, Meng G (2000) Construction and structural modeling of a single-chain Fv–asparaginase fusion protein resistant to proteolysis. Biotechnol Bioeng 70(4):456–463

Guo J, Coker AR, Wood SP, Cooper JB, Chohan SM, Rashid N, Akhtar M (2017) Structure and function of the thermostable L-asparaginase from Thermococcus kodakarensis. Acta Cryst D 73(11):889–895

Heeschen V, Matlok J, Schrader S, Rudolph H (1996) Asparagine catabolism in bryophytes: purification and characterization of two L-asparaginase isoforms from Sphagnum fallax. Physiol Plant 97(2):402–410

Hendriksen HV, Kornbrust BA, Østergaard PR, Stringer MA (2009) Evaluating the potential for enzymatic acrylamide mitigation in a range of food products using an asparaginase from Aspergillus oryzae. J Agric Food Chem 57(10):4168–4176

Hendriksen HV, Puder K, Olsen AG (2016) Method for reducing the level of asparagine in a food material. U.S. Patent Application No. 14/781,760

Hill JM, Roberts J, Loeb E, Khan A, MacLellan A, Hill RW (1967) L-asparaginase therapy for leukemia and other malignant neoplasms: remission in human leukemia. JAMA 202(9):882–888

Huang L, Liu Y, Sun Y, Yan Q, Jiang Z (2013) Biochemical characterization of a novel L-Asparaginase with low glutaminase activity from Rhizomucor miehei and its application in food safety and leukemia treatment. Appl Environ Microbiol 80(5):1561–1569

Husain I, Sharma A, Kumar S, Malik F (2016a) Purification and characterization of glutaminase free asparaginase from Enterobacter cloacae: in-vitro evaluation of cytotoxic potential against human myeloid leukemia HL-60 cells. PLoS ONE 11(2):e0148877

Husain I, Sharma A, Kumar S, Malik F (2016b) Purification and characterization of glutaminase free asparaginase from Pseudomonas otitidis: induce apoptosis in human leukemia MOLT-4 cells. Biochimie 121:38–51

IARC (International Agency for Research on Cancer) (1994) Acrylamide. IARC monographs on the evaluation of carcinogenic risks to humans. Ind Chem 60:389–434 (France: Lyon)

Izadpanah F, Homaei A, Fernandes P, Javadpour S (2018) Marine microbial L-asparaginase: Biochemistry, molecular approaches and applications in tumor therapy and in food industry. Microbiol Res 208:99-112

Jia M, Xu M, He B, Rao Z (2013) Cloning, expression, and characterization of L-asparaginase from a newly isolated Bacillus subtilis B11–06. J Agric Food Chem 61(39):9428–9434

Kacar S, Vejselova D, Kutlu HM, Sahinturk V (2018) Acrylamide-derived cytotoxic, anti-proliferative, and apoptotic effects on A549 cells. Hum Exp Toxicol 37(5):468–474

Kamble VP, Rao RS, Borkar PS (2006) Purification of L-asparaginase from a bacteria Erwinia carotovora and effect of a dihydropyrimidine derivative on some of its kinetic parameters. Indian J Biochem Biophys 43(6):391–394

Kavitha A, Vijayalakshmi M (2012) A study on L-asparaginase of Nocardia levis MK-VL_113. Sci World J Article ID 160434. https://doi.org/10.1100/2012/160434

Kidd JG (1953) Regression of transplanted lymphomas induced in vivo by means of normal guinea pig serum: I. course of transplanted cancers of various kinds in mice and rats given guinea pig serum, horse serum, or rabbit serum. J Exp Med 98(6):565–582

Killander D, Dohlwitz A, Engstedt L, Franzen S, Gahrton G, Gullbring B, Holm G, Holmgren A, Höglund S, Killander A, Lockner D (1976) Hypersensitive reactions and antibody formation during L-asparaginase treatment of children and adults with acute leukemia. Cancer 37(1):220–228

Kishore V, Nishita KP, Manonmani HK (2015) Cloning, expression and characterization of l-asparaginase from Pseudomonas fluorescens for large scale production in E. coli BL21. 3 Biotech 5(6):975–981

Kotzia GA, Labrou NE (2007) L-Asparaginase from Erwinia chrysanthemi 3937: cloning, expression and characterization. J Biotechnol 127(4):657–669

Krishnapura PR, Belur PD (2016) Partial purification and characterization of L-asparaginase from an endophytic Talaromyces pinophilus isolated from the rhizomes of Curcuma amada. J Mol Catal B Enzym 124:83–91

Kukurová K, Morales FJ, Bednáriková A, Ciesarová Z (2009) Effect of L-asparaginase on acrylamide mitigation in a fried-dough pastry model. Mol Nutr Food Res 53(12):1532–1539

Kumar NM, Manonmani HK (2013) Purification, characterization and kinetic properties of extracellular L-asparaginase produced by Cladosporium sp. World J Microbiol Biotechno 29(4):577–587

Kumar S, Dasu VV, Pakshirajan K (2011) Purification and characterization of glutaminase-free L-asparaginase from Pectobacterium carotovorum MTCC 1428. Bioresour Technol 102(2):2077–2082

Kumar NM, Ramasamy R, Manonmani HK (2013) Production and optimization of L-asparaginase from Cladosporium sp. using agricultural residues in solid state fermentation. Ind Crops Prod 43:150–158

Lea PJ, Festenstein GN, Hughes JS, Miflin BJ (1984) An immunological and enzymological survey of asparaginase in seeds of Lupinus. Phytochemistry 23(3):511–514

Lincoln L, Niyonzima FN, More SS (2015) Purification and properties of a fungal L-asparaginase from Trichoderma viride pers: sf grey. J Microbiol Biotechnol Food Sci 4(4):310

Long S, Zhang X, Rao Z, Chen K, Xu M, Yang T, Yang S (2016) Amino acid residues adjacent to the catalytic cavity of tetramer L-asparaginase II contribute significantly to its catalytic efficiency and thermostability. Enzyme Microb Technol 82:15–22

Maggi M, Chiarelli LR, Valentini G, Scotti C (2015) Tackling critical catalytic residues in Helicobacter pylori L-asparaginase. Biomolecules 5(2):306–317

Mahajan RV, Saran S, Kameswaran K, Kumar V, Saxena RK (2012) Efficient production of L-asparaginase from Bacillus licheniformis with low-glutaminase activity: optimization, scale up and acrylamide degradation studies. Bioresour Technol 125:11–16

Mahajan RV, Kumar V, Rajendran V, Saran S, Ghosh PC, Saxena RK (2014) Purification and characterization of a novel and robust L-asparaginase having low-glutaminase activity from Bacillus licheniformis: in vitro evaluation of anti-cancerous properties. PLoS ONE 9(6):e99037

Maruyama T, Izaki S, Kurinomaru T, Handa K, Kimoto T, Shiraki K (2015) Protein-poly(amino acid) precipitation stabilizes a therapeutic protein L-asparaginase against physicochemical stress. J Biosci Bioeng 120(6):720–724

Mashburn LT, Wriston JC Jr (1963) Tumor inhibitory effect of L-asparaginase. Biochem Biophys Res Commun 12(1):50–55

Meena B, Anburajan L, Dheenan PS, Begum M, Vinithkumar NV, Dharani G, Kirubagaran R (2015) Novel glutaminase free l-asparaginase from Nocardiopsis alba NIOT-VKMA08: production, optimization, functional and molecular characterization. Bioprocess Biosyst Eng 38(2):373–388

Meena B, Anburajan L, Vinithkumar NV, Shridhar D, Raghavan RV, Dharani G, Kirubagaran R (2016) Molecular expression of l-asparaginase gene from Nocardiopsis alba NIOT-VKMA08 in Escherichia coli: a prospective recombinant enzyme for leukaemia chemotherapy. Gene 590(2):220–226

Meghavarnam AK, Janakiraman S (2018) Evaluation of acrylamide reduction potential of L-asparaginase from Fusarium culmorum (ASP-87) in starchy products. LWT—Food Sci Technol 89:32–37

Michalska K, Jaskolski M (2006) Crystal structure of plant asparaginase. J Mol Biol 360(1):05–116

Michalska K, Borek D, Hernández-Santoyo A, Jaskolski M (2008) Crystal packing of plant-type L-asparaginase from Escherichia coli. Acta Cryst D 64(3):309–320

Mohamed SA, Elshal MF, Kumosani TA, Aldahlawi AM, Basbrain TA, Alshehri FA, Choudhry H (2016) L-Asparaginase isolated from Phaseolus vulgaris seeds exhibited potent anti-acute lymphoblastic leukemia effects in-vitro and low immunogenic properties in-vivo. Int J Environ Res Public Health 13(10):1008

Moorthy V, Ramalingam A, Sumantha A, Shankaranaya RT (2010) Production, purification and characterisation of extracellular L-asparaginase from a soil isolate of Bacillus sp. Afr J Microbiol Res 4(18):1862–1867

Moreno-Enríquez A, Evangelista-Martínez Z, González-Mondragón EG, Calderón-Flores A, Arreguín R, Pérez-Rueda E, Huerta-Saquero A (2012) Biochemical characterization of recombinant L-asparaginase (AnsA) from Rhizobium etli, a member of an increasing rhizobial-type family of L-asparaginases. J Microbiol Biotechnol 22(3):292–300

Mottram DS, Wedzicha BL, Dodson AT (2002) Acrylamide is formed in the Maillard reaction. Nature 419(6906):448

Mu X, Qiao J, Qi L, Dong P, Ma H (2014) Poly(2-vinyl-4, 4-dimethylazlactone)-functionalized magnetic nanoparticles as carriers for enzyme immobilization and its application. ACS Appl Mater Interfaces 6(23):21346–21354

Narta U, Roy S, Kanwar SS, Azmi W (2011) Improved production of L-asparaginase by Bacillus brevis cultivated in the presence of oxygen-vectors. Bioresour Technol 102(2):2083–2085

Nguyen HA, Su Y, Lavie A (2016) Structural insight into substrate selectivity of Erwinia chrysanthemi L-Asparaginase. Biochem 55(8):1246–1253

Onishi Y, Yano S, Thongsanit J, Takagi K, Yoshimune K, Wakayama M (2011) Expression in Escherichia coli of a gene encoding type II L-asparaginase from Bacillus subtilis, and characterization of its unique properties. Ann Microbiol 61(3):517–524

Onishi Y, Prihanto AA, Yano S, Takagi K, Umekawa M, Wakayama M (2015) Effective treatment for suppression of acrylamide formation in fried potato chips using L-asparaginase from Bacillus subtilis. 3 Biotech 5(5):783–789

Patro KR, Gupta N (2012) Extraction, purification and characterization of L-asparaginase from Penicillium sp. by submerged fermentation. Int J Biotechnol Mol Biol Res 3(3):30–34

Paul JH (1982) Isolation and characterization of a Chlamydomonas L-asparaginase. Biochem J 203(1):109–115

Pedreschi F, Kaack K, Granby K, Troncoso E (2007) Acrylamide reduction under different pre-treatments in French fries. J Food Eng 79(4):1287–1294

Pedreschi F, Kaack K, Granby K (2008) The effect of asparaginase on acrylamide formation in French fries. Food Chem 109(2):386–392

Pedreschi F, Mariotti S, Granby K, Risum J (2011) Acrylamide reduction in potato chips by using commercial asparaginase in combination with conventional blanching. LWT-Food Sci Technol 44(6):1473–1476

Pokrovskaia MV, Pokrovskiĭ VS, Aleksandrova SS, Anisimova N, Adrianov RM, Treshchalina EM, Ponomarev GV, Sokolov NN (2013) Recombinant intracellular Rhodospirillum rubrum L-asparaginase with low L-glutaminase activity and antiproliferative effect. Biomed Khim 59(2):192–208

Pokrovskaya MV, Aleksandrova SS, Pokrovsky VS, Omeljanjuk NM, Borisova AA, Anisimova NY, Sokolov NN (2012) Cloning, expression and characterization of the recombinant Yersinia pseudotuberculosis L-asparaginase. Protein Expr Purif 82(1):150–154

Pourhossein M, Korbekandi H (2014) Cloning, expression, purification and characterisation of Erwinia carotovora L-asparaginase in Escherichia coli. Adv Biomed Res 3:82

Pradhan B, Dash SK, Sahoo S (2013) Screening and characterization of extracellular L-asparaginase producing Bacillus subtilis strain hswx88, isolated from Taptapani hotspring of Odisha, India. Asian Pac J Trop Biomed 3(12):936–941

Qeshmi IF, Homaei A, Fernandes P, Javadpour S (2018) Marine microbial L-asparaginase: biochemistry, molecular approaches and applications in tumor therapy and in food industry. Microbiol Res 208:99–112

Ramya LN, Doble M, Rekha VPB, Pulicherla KK (2012) L-Asparaginase as potent anti-leukemic agent and its significance of having reduced glutaminase side activity for better treatment of acute lymphoblastic leukaemia. Appl Biochem Biotechnol 167(8):2144–2159

Ravi A, Gurunathan B (2018) Acrylamide mitigation in fried Kochchi Kesel chips using free and immobilized fungal asparaginase. Food Technol Biotechnol 56(1):51

Robin LP, Clanci S (2007) Acrylamide, Furan, and the FDA. Food Saf Mag 13(3):17–21

Sajitha S, Vidya J, Binod P, Pandey A (2015) Cloning and expression of L-asparaginase from E. coli in eukaryotic expression system. Biochem Eng J 102:14–17

Sanghvi G, Bhimani K, Vaishnav D, Oza T, Dave G, Kunjadia P, Sheth N (2016) Mitigation of acrylamide by L-asparaginase from Bacillus subtilis KDPS1 and analysis of degradation products by HPLC and HPTLC SpringerPlus 5(1):533

Shakambari G, Birendranarayan AK, Lincy MJA, Rai SK, Ahamed QT, Ashokkumar B, Saravanan M, Mahesh A, Varalakshmi P (2016) Hemocompatible glutaminase free L-asparaginase from marine Bacillus tequilensis PV9W with anticancer potential modulating p53 expression. RSC Adv 6(31):25943–25951

Shi R, Liu Y, Mu Q, Jiang Z, Yang S (2017) Biochemical characterization of a novel L-asparaginase from Paenibacillus barengoltzii being suitable for acrylamide reduction in potato chips and mooncakes. Int J Biol Macromol 96:93–99

Shrivastava A, Khan AA, Shrivastav A, Jain SK, Singhal PK (2012) Kinetic studies of L-asparaginase from Penicillium digitatum. Prep Biochem Biotechno 42(6):574–581

Singh Y, Gundampati RK, Jagannadham MV, Srivastava SK (2013) Extracellular L-asparaginase from a protease-deficient Bacillus aryabhattai ITBHU02: purification, biochemical characterization, and evaluation of antineoplastic activity in vitro. Appl Biochem Biotechnol 171(7):1759–1774

Singh J, Srivastava A, Jha P, Sinha KK, Kundu B (2015) L-Asparaginase as a new molecular target against leishmaniasis: insights into the mechanism of action and structure-based inhibitor design. Mol BioSyst 11(7):887–1896

Sinha RK, Singh HR, Jha SK (2015) Production, purification and kinetic characterization of L-asparaginase from Pseudomonas fluorescens. Int J Pharm Pharm Sci 7(1):135–138

Sudhir AP, Dave BR, Trivedi KA, Subramanian RB (2012) Production and amplification of an l-asparaginase gene from actinomycete isolate Streptomyces ABR2. Ann Microbiol 62(4):1609–1614

Sudhir AP, Dave BR, Prajapati AS, Panchal K, Patel D, Subramanian RB (2014) Characterization of a recombinant glutaminase-free L-asparaginase (ansa3) enzyme with high catalytic activity from Bacillus licheniformis. Appl Biochem Biotechnol 174(7):2504–2515

Sukhoverkov KV, Kudryashova EV (2015) PEG-chitosan and glycol-chitosan for improvement of biopharmaceutical properties of recombinant L-asparaginase from Erwinia carotovora. Biochem (Mosc) 80(1):113–119

Swain AL, Jaskólski M, Housset D, Rao JK, Wlodawer A (1993) Crystal structure of Escherichia coli L-asparaginase, an enzyme used in cancer therapy. Proc Natl Acad Sci USA 90(4):1474–1478

Tareke E, Rydberg P, Karlsson P, Eriksson S, Törnqvist M (2002) Analysis of acrylamide, a carcinogen formed in heated foodstuffs. J Agric Food Chem 50(17):4998–5006

Thakur M, Azmi W (2013) Extraction and purification of β-carotene from filamentous fungus Mucor azygosporus. Ann Phytomed 2:79–84

Tiwari N, Dua RD (1996) Purification and preliminary characterization of L-asparaginase from Erwinia aroideae NRRL B-138. Indian J Biochem Biophys 33(5):371–376

Tomar R, Sharma P, Srivastava A, Bansal S, Kundu B (2014) Structural and functional insights into an archaea l-asparaginase obtained through the linker-less assembly of constituent domains. Acta Cryst D 70(12):3187–3197

Tyl RW, Friedman MA (2003) Effects of acrylamide on rodent reproductive performance. Reprod Toxicol 17(1):1–13

Ulu A, Noma SAA, Koytepe S, Ates B (2018) Magnetic Fe3O4@ MCM-41 core–shell nanoparticles functionalized with thiol silane for efficient l-asparaginase immobilization. Artif Cells Nanomed Biotechnol 1–11

Vala AK, Sachaniya B, Dudhagara D, Panseriya HZ, Gosai H, Rawal R, Dave BP (2018) Characterization of L-asparaginase from marine-derived Aspergillus niger AKV-MKBU, its antiproliferative activity and bench scale production using industrial waste. Int J Biol Macromol 108:41–46

Varma RA, Kanapala S, Naga SBV, Bodaiah B, Poda S (2016) Partial purification, characterization and optimization of anti-leukemic enzyme L-asparaginase from mangrove soil actinobacteria. J Pharma Res 10(7):502–511

Verma S, Mehta RK, Maiti P, Röhm KH, Sonawane A (2014) Improvement of stability and enzymatic activity by site-directed mutagenesis of E. coli asparaginase II. Biochim Biophys Acta (BBA)-Proteins Proteomics 1844(7):1219–1230

Vidya J, Vasudevan UM, Soccol CR, Pandey A (2011) Cloning, functional expression and characterization of L-asparaginase II from E. coli MTCC 739. Food Technol Biotech 49(3):286–290

Vidya J, Ushasree MV, Pandey A (2014) Effect of surface charge alteration on stability of l-asparaginase II from Escherichia sp. Enz Microbiol Technol 56:15–19

Washio T, Oikawa T (2018) Thermostable and highly specific L-aspartate oxidase from Thermococcus litoralis DSM 5473: cloning, overexpression, and enzymological properties. Extremophiles 22(1):59–71

Yaacob MA, Hasan WANW, Ali MSM, Rahman RNZRA, Salleh AB, Basri M, Leow TC (2014) Characterisation and molecular dynamic simulations of J15 asparaginase from Photobacterium sp. strain J15. Acta Biochim Pol 61(4)

Yao M, Yasutake Y, Morita H, Tanaka I (2005) Structure of the type I L-asparaginase from the hyperthermophilic archaeon Pyrococcus horikoshii at 2.16 Å resolution. Acta Cryst D 61(3):294–301

Youssef MM, Al-Omair MA (2008) Cloning, purification, characterization and immobilization of L-asparaginase II from E. coli W3110. Asian J Biochem 3(6):337–350

Zhang JF, Shi LY, Wei DZ (2004) Chemical modification of L-asparaginase from Escherichia coli with a modified polyethyleneglycol under substrate protection conditions. Biotechnol Lett 26(9):753–756

Zhang S, Xie Y, Zhang C, Bie X, Zhao H, Lu F, Lu Z (2015) Biochemical characterization of a novel l-asparaginase from Bacillus megaterium H-1 and its application in French fries. Food Res Int 77:527–533

Zuo S, Xue D, Zhang T, Jiang B, Mu W (2014) Biochemical characterization of an extremely thermostable l-asparaginase from Thermococcus gammatolerans EJ3. J Mol Catal B Enzym 109:122–129

Zuo S, Zhang T, Jiang B, Mu W (2015) Reduction of acrylamide level through blanching with treatment by an extremely thermostable l-asparaginase during French fries processing. Extremophiles 19(4):841–851

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Alam, S., Pranaw, K., Tiwari, R., Khare, S.K. (2019). Recent Development in the Uses of Asparaginase as Food Enzyme. In: Parameswaran, B., Varjani, S., Raveendran, S. (eds) Green Bio-processes. Energy, Environment, and Sustainability. Springer, Singapore. https://doi.org/10.1007/978-981-13-3263-0_5

Download citation

DOI: https://doi.org/10.1007/978-981-13-3263-0_5

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-3262-3

Online ISBN: 978-981-13-3263-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)