Abstract

Bacterial l-asparaginase catalyzes the hydrolysis of l-asparagine to l-aspartic acid. It is normally used as an antineoplastic drug applied in lymphoblastic leukemia chemotherapy and as a food processing aid in baked or fried food industry to inhibit the formation of acrylamide. The present study demonstrates cloning, expression, and characterization of a thermostable l-asparaginase from Thermococcus zilligii AN1 TziAN1_1 and also evaluates the potential for enzymatic acrylamide mitigation in French fries using this enzyme. The recombinant l-asparaginase was purified to homogeneity by nickel-affinity chromatography. The purified enzyme displayed the maximum activity at pH 8.5 and 90 °C, and the optimum temperature was the highest ever reported. The K m, k cat, and k cat/K m values toward l-asparagine were measured to be 6.08 mM, 3267 s−1, and 537.3 mM−1 s−1, respectively. The enzyme retained 70 % of its original activity after 2 h of incubation at 85 °C. When potato samples were treated with 10 U/mL of l-asparaginase at 80 °C for only 4 min, the acrylamide content in final French fries was reduced by 80.5 % compared with the untreated control. Results of this study revealed that the enzyme was highly active at elevated temperatures, reflecting the potential of the T. zilligii l-asparaginase in the food processing industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

l-Asparaginase (l-asparagine amidohydrolase; EC 3.5.1.1) catalyzes the hydrolytic deamination of l-asparagine, resulting in the production of l-aspartic acid and ammonia. l-Asparaginase has been identified in bacteria, fungi, yeasts, archaea, plants, and animals (Chohan and Rashid 2013; Verma et al. 2007). It takes an active part in basic amino acid catabolism by transforming l-asparagine to l-aspartic acid, which can join the citric acid cycle. l-Asparagine is normally used as nitrogen storage and transport in plants, so L-asparaginase plays an important role in utilization of this vital resource (Sieciechowicz et al. 1988).

Several decades ago, the interest in L-asparaginase arose owing to its antitumor activity. The application in medicine is the original and the main application of this enzyme. l-Asparaginases from Escherichia coli (Mashburn and Wriston 1964) and Erwinia chrysanthemi (Gervais et al. 2013) have been used for nearly 40 years as effective antitumor drugs in the treatment of pediatric acute lymphoblastic leukemia. The normal cells of human are able to synthesize l-asparagine, while certain cancer cells, especially acute lymphoblastic leukemia cell, cannot synthesize the non-essential amino acid l-asparagine, due to having mutations. Therefore, leukemic cells require plenty of exogenous l-asparagine and are strongly dependent on the supply of the host. l-Asparagine may be depleted in the extracellular fluid through the decomposition by l-asparaginase, and then the protein synthesis, cell division, and cell growth of tumor cells are inhibited by the l-asparagine depletion (Broome 1981).

In addition, a novel use of l-asparaginase is as a processing aid in food industry recently. l-Asparaginase can be used to reduce the formation of acrylamide, which is classified as “probably carcinogenic to humans” (Kornbrust et al. 2009). Acrylamide is easily formed in fried and baked foods, particularly in carbohydrate-rich foods, such as French fries, potato chips, ginger bread, and biscuits. It has been demonstrated that l-asparagine is an important precursor of acrylamide during food processing. During food heating, the l-asparagine and reduced sugars undergo a non-enzymatic process called the Maillard reaction, which is responsible for the predominant formation pathway of acrylamide (Stadler et al. 2002; Mottram et al. 2002). By adding l-asparaginase before food baking or frying, l-asparagine can be biologically converted into l-aspartic acid, which does not participate in the formation of acrylamide, and thus the formation of acrylamide can be significantly reduced (Kornbrust et al. 2009). In the previous works, l-asparaginase treatment has been demonstrated to have a significant effect on the acrylamide mitigation in cereal- and potato-based foods (Kumar et al. 2014a; Anese et al. 2011; Kukurova et al. 2009; Hendriksen et al. 2009; Pedreschi et al. 2008). And currently, l-asparaginases from Aspergillus niger (Koster 2007) and Aspergillus oryzae (Hendriksen et al. 2009) have been commercially used for the purpose of reducing acrylamide formation.

For both clinical and food industrial applications, stability is a critical factor determining the applicability of enzyme. Improving the thermostability of l-asparaginase is an important way to broaden its application. Attempt made to enhance the stability of l-asparaginase includes enzyme immobilization (Kumar et al. 2014b) and molecular modification (Vidya et al. 2014). Another way to obtain the thermostable l-asparaginase was to screen the enzyme from thermophilic microorganisms. Recently, some thermophilic or hyperthermophilic source of l-asparaginases have been studied, including the enzymes from Pyrococcus horikoshii OT3 (Yao et al. 2005), Pyrococcus furiosus DSM 3638 (Bansal et al. 2010), Thermus aquaticus T351 (Curran et al. 1985), Thermus thermophilus HB8 (Pritsa and Kyriakidis 2001), Thermococcus kodakaraensis KOD1 (Chohan and Rashid 2013), Thermococcus gammatolerans EJ3 (Zuo et al. 2014), and Streptomyces thermoluteus subsp. fuscus NBRC 14270 (Hatanaka et al. 2011).

Potato is an important agricultural crop throughout the world, and it has been processed into all kinds of popular snack products. But potato-based food products are considered to be among the foods containing the highest levels of acrylamide, due to the high concentration of free l-asparagine and reducing sugars naturally existing in potatoes (Taeymans et al. 2004). The contents of acrylamide varies greatly with the sources of raw materials and processing methods in different commercial potato products, ranging from 339 to 4653 µg/kg, with an average of 619 µg/kg. This content is relatively high compared with other products according to previous survey about the acrylamide levels in Chinese foods (Chen et al. 2008). Herein, a representative of potato products, French fries, was selected as the food matrix for the application of l-asparaginase. The present study is a report about cloning and expression, as well as the purification and characterization of an L-asparaginase from hyperthermophilic archaeon Thermococcus zilligii AN1 TziAN1_1. The effect of this thermostable l-asparaginase on the acrylamide formation in French fries was also investigated.

Materials and methods

Strains, plasmids, and reagents

The pET-22b(+) expression vector and the host strain E. coli BL21(DE3) were from Novagen (Darmstadt, Germany). The resin for protein purification, the Chelating Sepharose Fast Flow, was purchased from GE Healthcare (Uppsala, Sweden). The Nessler’s reagent for ammonia detection was purchased from Sigma (St., Louis, MO, USA). Standard proteins marker (low range) for sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) was obtained from Sangon Biological Engineering Technology and Services (Shanghai, China). All other chemicals were at least of analytical grade purchased from Sigma (St. Louis, MO, USA) and Sinopharm Chemical Reagent (Shanghai, China).

Gene cloning

The whole genome of T. zilligii AN1 TziAN1_1 chromosome was released in GenBank (NCBI accession number: NZ_AJLF01000001.1) (Kim et al. 2012). The full-length nucleotide sequence of the putative l-asparaginase-coding gene (NCBI accession number: WP_010478656.1) with locus_tag TZI_RS0105015 from T. zilligii AN1 TziAN1_1 was synthesized and incorporated with NdeI and XhoI sites in the 5′- and 3′-terminal of the gene, respectively, and then was cloned into pET-22b(+) vector by Shanghai Generay Biotech Co. Ltd (Shanghai, China). The recombinant plasmid, named pET-Thzi-L-ASN, was introduced into the host cell E. coli BL21(DE3) for expression. An in-frame 6 × histidine sequence at the C-terminus was provided in the recombinant plasmid, allowing one-step purification by metal-chelating chromatography.

Expression and purification of the recombinant l-asparaginase

The transformed E. coli BL21(DE3) cells, harboring plasmid pET-Thzi-L-ASN, were cultivated with shaking (200 rpm) at 37 °C in 200 mL of LB medium containing 50 μg/mL ampicillin. Expression of T. zilligii l-asparaginase gene was then induced with 1 mM isopropyl β-D-1-thiogalactopyranoside (IPTG) when the OD600 value was 0.6–0.8. After IPTG induction for 6 h, the cells were harvested using refrigerated centrifuge at 8000g for 20 min. Cells were washed twice using lysis buffer (50 mM Tris–HCl buffer, 100 mM NaCl, pH 8.5) and then were resuspended in the lysis buffer. For extraction of crude enzyme, cells were disrupted by sonication for 15 min at 4 °C. The insoluble cell debris was then removed by centrifuged at 20,000g for 30 min at 4 °C. The recombinant l-asparaginase, expressed as 6× His-tagged fusion protein, was purified by nickel-affinity chromatography (Novagen) according to the manufacture’s protocol (pET His Taq System; Novagen). The purified enzyme was dialyzed twice against 50 mM Tris–HCl buffer (pH 8.5), and analyzed by SDS-PAGE on a 12 % gel.

Enzyme assay

The activity assay was measured by calculating the amount of ammonia produced during the hydrolysis reaction of l-asparagine. The reaction mixture (1 mL) contained l-asparagine (20 mM), Tris–HCl (50 mM, pH 8.5), and 25 μL of enzyme solution. The reactions were performed at 90 °C for 2.5 min and were stopped by adding 250 μL of 1.5 M trichloroacetic acid. The reaction mixture was centrifuged at 20,000g for 10 min, and 150 μL of supernatant was added to 1.4 mL of deionized water and 200 μL of Nessler’s reagent to measure the released ammonia. The measurements were conducted spectrophotometrically at 450 nm. The enzyme activity was measured using an ammonium sulfate calibration curve. One unit of the enzyme activity was defined as the amount of enzyme required to release 1 μmol of ammonia per minute at 90 °C and pH 8.5. The enzyme activity was calculated on the basis of monomeric form of the protein.

Effect of temperature, pH, and metal ions

The optimal temperature for the l-asparaginase activity was determined at different temperatures from 40 to 95 °C in 50 mM Tris–HCl buffer (pH 8.5). The optimal pH was determined at 90 °C using four buffer systems, including acetate buffer (50 mM, pH 4.0–6.0), phosphate buffer (50 mM, pH 6.0–7.0), Tris–HCl buffer (50 mM, pH 7.0-9.0), and glycine–NaOH buffer (50 mM, pH 9.0–10.0). All the buffers were prepared at each temperature. The thermostability was determined by detecting the residual activity of the enzyme after pre-incubating the enzyme in Tris–HCl (50 mM, pH 8.5) at various temperatures for different periods.

The effects of various metal ions were determined by the addition of 1 mM of various metal salts and assaying the l-asparaginase activity under standard conditions. The tested metal salts included MgSO4, CaCl2, ZnSO4, CoCl2, MnSO4, BaCl2, NiSO4, and CuSO4.

Determination of kinetic parameters

The kinetic parameters were determined in 50 mM of Tris–HCl (pH 8.5) containing 1–20 mM of l-asparagine at 90 °C. The observed data were fitted to the Michaelis–Menten equation, and the kinetic constant (K m) and V max were calculated from Lineweaver–Burk plots. Using the molecular mass, the turnover number (k cat) and catalytic efficiency (k cat/K m) were calculated.

Inhibition of acrylamide formation in French fries

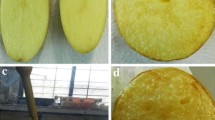

Large potatoes (Fovorita, 70 g/100 g water content) were obtained from a local supermarket. Potatoes were washed and peeled manually, and then were cut into 0.8 × 0.8 cm2 strips. Strips were rinsed using distilled water immediately after cutting for 1 min to eliminate starch adhering to the surface before frying. The following pre-treatments were applied before frying: (a) the potato strips were blanched in hot water at 80 °C for 0, 1, 2, 5 and 10 min, respectively. (b) The potato strips were treated with thermostable l-asparaginase at 80 °C for 1 min with enzyme concentration 0, 1, 2, 5, 10 and 20 U/mL, respectively. (c) The potato strips were treated with 10 U/mL of enzyme at 80 °C for 0, 1, 2, 4, 8 and 15 min, respectively. All the samples mentioned above were dried at 85 °C for 10 min to control moisture content, and then were fried at 175 °C for ~5 min using electric fryer. French fries were cooled to ambient temperature after frying.

Acrylamide determination

The extraction of acrylamide from French fries was performed according to Jia et al. (2013). First, French fries was finely ground using a food mixer homogenizer. One gram of sample was transferred to a 50 mL of Teflon centrifuge tube and 10 mL of n-hexane was added into the tube. The long-chain fatty acids in samples were removed under violent agitation. Following solutions, 10 mL of distilled water, 500 µL of Carrez I (15 g potassium hexacyanoferrate/100 mL water), and 500 µL of Carrez II (30 g zinc sulfate/100 mL water), were added, respectively. The sample was mixed for 30 min in a thermostated water bath under agitation to extract acrylamide. And then the homogenates were centrifuged at 10,000 rpm for 20 min at 4 °C. The precipitate was discarded and the supernatant was filtered through 0.22 μm Millipore filters prior to acrylamide analysis. Acrylamide was measured using a Waters 2695 liquid chromatography system equipped with a Waters 596 photodiode array detector (Waters, Milford, MA, USA) and an Aminex HPX-87H (300 mm × 7.8 mm) column (Bio-Rad, Berkeley, CA, USA). The column was eluted at 30 °C with 10 mM of sulfuric acid solution at a flow rate of 0.5 mL/min, and the acrylamide was detected by ultraviolet detection at 210 nm.

Results and discussion

Sequence analysis of T. zilligii l-asparaginase

Enzymes obtained from thermophilic sources are highly stable due to their evolutionary adaptation to extremes of environment, and the thermophilic enzymes are advantageous in the commercial and industrial applications (Ludlow and Clark 1991). l-Asparaginases from mesophilic sources are considered unstable and disadvantageous for the practical use of the enzymes, and thus a search for stable alternative sources for l-asparaginase is meaningful. In this work, the l-asparaginase from hyperthermophilic archaeon T. zilligii AN1 TziAN1_1 was characterized as a novel thermostable l-asparaginase, displaying a great potential for both medical and food applications.

The l-asparaginase gene revealed an open reading frame of 993 bp encoding a protein of 330 amino acid residues with a calculated subunit molecular mass of 35.5 kDa and a pI of 5.48. Among the seven characterized thermostable l-asparaginases, four archaeon l-asparaginases and one Streptomyces l-asparaginase have known amino acid sequences (Fig. 1; Table 1). The T. zilligii l-asparaginase exhibits high sequence homology with the archaeon l-asparaginases from T. kodakaraensis KOD1 (78 %), P. furiosus DSM 3638 (57 %), P. horikoshii OT3 (58 %), and T. gammatolerans EJ3 (78 %). The phylogenetic tree of l-asparaginases also reveals that the T. zilligii AN1 TziAN1_1 l-asparaginase is more closely related to the reported archaeon l-asparaginases (Fig. 2). While the sequence displayed very low identity with those non-archaeon strains, such as 19 % with E. chrysanthemi 3937 (Kotzia and Labrou 2007), 18 % with Bacillus subtilis W168 (Onishi et al. 2011), and 14 % with Rhizobium etli (Moreno-Enriquez et al. 2012). In previous crystallographic studies on P. horikoshii (Yao et al. 2005), eight residues, including Thr11, Tyr21, Ser52, Thr53, Thr83, Asp84, Lys154, and Lys274, were found to be involved in the active site and to play a pivotal role in substrate recognition and catalysis. As shown in Fig. 1, these residues are highly conserved in T. zilligii l-asparaginase, except the residues corresponding to Lys274 is substituted by glutamic acid. And the analysis of P. horikoshii l-asparaginase structure indicated that it has an active-side flexible loop, so the T. zilligii l-asparaginase probably also has one, and the replacements of opposite charge residues in Glu275 may makes the loop more flexible and mobile.

Multiple sequence alignment of reported l-asparaginases from thermophilic and hyperthermophilic microorganisms. The alignment was performed using DNAMAN program. The abbreviated names at the left side represent the organisms from which the sequence originated. Amino acid residues that are identical in all of the displayed sequences are marked by blue, and strongly and weakly conserved residues are indicated by pink and green, respectively. The active-side residues are symbolized by closed circles according to the crystal structure of P. horikoshii l-asparaginase (Yao et al. 2005). The origins of l-asparaginase and their GenBank accession numbers are as follows: T. zilligii AN1 TziAN1_1 (Thzi; GenBank accession no. WP_010478656.1), T. gammatolerans EJ3 (Thga; YP_002959808.1), T. kodakaraensis KOD1 (Thko; YP-184069.1), P. furiosus DSM 3638 (Pyfu; NP_579776.1), and P. horikoshii OT3 (Pyho; NP_142084.1)

Expression and purification of T. zilligii l-asparaginase

Plasmid pET-Thzi-l-ASN was transformed into E. coli BL21(DE3), and the recombinant l-asparaginase was heterogeneously expressed by IPTG induction, in fusion with a C-terminal 6× His-tag, which allowed for a convenient single-step purification using nickel-affinity column chromatography. The molecular weight of recombinant enzyme on SDS-PAGE was approximately 36 kDa, which was consistent with the theoretical value calculated from the amino acid sequence (35.5 kDa). In addition, the native enzyme eluted as a single 71 kDa peak from the Superdex 200 10/300 GL gel filtration column chromatography (data not shown). Therefore, the native T. zilligii AN1 TziAN1_1 l-asparaginase should be a homodimer composed of two identical subunits.

The l-asparaginases are mostly tetrameric forms from mesophilic sources reported in previous studies, including E. coli K-12 (Khushoo et al. 2004), Helicobacter pylori CCUG 17874 (Cappelletti et al. 2008) and Pectobacterium carotovorum MTCC 1428 (Kumar et al. 2011). As for the reported l-asparaginases from thermophilic or hyperthermophilic microbes, the ones from S. thermoluteus subsp. fuscus NBRC 14270 (Hatanaka et al. 2011) and the archaeon strains, including P. horikoshii OT3 (Yao et al. 2005), P. furiosus DSM 3638 (Bansal et al. 2010), T. kodakaraensis KOD1(Chohan and Rashid 2013), and T. gammatolerans EJ3 (Zuo et al. 2014), were identified as homodimers, but the l-asparaginases from T. aquaticus T351 (Curran et al. 1985) and T. thermophiles HB8 (Pritsa and Kyriakidis 2001) was monomeric and hexameric, respectively.

Effects of pH and temperature on T. zilligii l-asparaginase activity

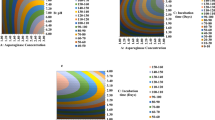

The recombinant enzyme showed the optimum temperature at 90 °C, and displayed more than 70 % of the highest activity in the range of 70–95 °C (Fig. 3a). And the optimum temperature was the highest in all previous reported literature (Table 1). The activation energy (E a) could be calculated according to Arrhenius’ equation: k = Ae−Ea/(RT), where k is rate constant of a chemical reaction, A is the pre-exponential factor, R is the universal gas constant, and T is the absolute temperature. The activity of T. zilligii l-asparaginase increased with increasing temperature from 40 to 90 °C (Fig. 3a). Fitting of the experimental data to Arrhenius equation showed the lnk toward 1/T was a straight line, the temperature range where linearity is 40–90 °C, and the slope was the activation energy E a (Fig. 3c). So the E a was calculated to be 64.88 kJ mol−1, which was higher than that of T. kodakaraensis KOD1 (E a = 58 kJ mol−1) (Chohan and Rashid 2013).

The enzyme displayed a relatively wide pH spectrum with optimum pH at 8.5, and more than 80 % of its maximum activity was maintained from pH 6.5 to 10.0 (Fig. 3b). It had higher activity in neutral to alkaline range, which was similar with many other microbial l-asparaginases. The specific activity for substrate l-asparagine was 5,278 U/mg at the optimum conditions. Even at 40 °C, the enzyme showed a specific activity of 431 U/mg, which was seven times higher than E. coli l-asparaginase (Yoshimoto et al. 1986).

Effect of temperature on T. zilligii l-asparaginase stability

The purified l-asparaginase displayed relatively high stability at higher temperature. The enzyme exhibited promising stability at 70–85 °C with a small decrease in activity after incubation for 2 h, and showed about 20 % retention of its original activity after 2 h incubation in 90 or 95 °C due to the inactivation at higher temperatures (data not shown). By comparison, T. zilligii l-asparaginase exhibited lower thermostability than l-asparaginases from T. gammatolerans EJ3, while it exhibited higher thermostability than T. kodakaraensis KOD1. Time course of irreversible thermal inactivation of purified l-asparaginase was shown in Fig. 4. The decay constant k d was 1.2 × 10−3, 1.3 × 10−3 and 6.8 × 10−3 min−1 at 80, 85, and 90 °C, respectively. According to the calculation formula of half-life, t 1/2 = ln2/k d, the half-time was calculated to be 557, 533, and 102 min, respectively. The l-asparaginase from T. kodakaraensis KOD1 displayed high thermostability with half-life of 130 min at 85 °C (Chohan and Rashid 2013), and the one from T. gammatolerans EJ3 retained more than 43 % of its initial activity after 2 h of incubation at all tested temperature (70–95 °C) (Zuo et al. 2014).

Effect of metal ions on T. zilligii l-asparaginase stability

The relative activity of T. zilligii l-asparaginase was determined in the presence of various divalent mental ions with the final concentration of 1 mM. The enzyme activity was slightly stimulated in the presence of Mn2+ and Mg2+, while the other metal ions nearly had no effect on the enzyme activity (Fig. 5). This result was in accord with the studies on the l-asparaginase from T. gammatolerans EJ3, except Zn2+ also restricted the enzyme activity of T. gammatolerans l-asparaginase (Zuo et al. 2014). The activity of T. kodakaraensis l-asparaginase was not significant effect for all the tested metal ions (Chohan and Rashid 2013). And the activity of T. thermophilus HB8 l-asparaginase was inhibited by 40 or 60 % in the presence of 0.5 or 1 mM of Zn2+, respectively (Pritsa and Kyriakidis 2001).

Determination of kinetic parameters

The K m for substrate l-asparagine was estimated to be 6.08 mM, which was similar to the archaeon l-asparaginases from T. kodakaraensis KOD1 (K m = 5.5 mM) (Chohan and Rashid 2013), but was lower than the enzymes from T. aquaticus T351 (K m = 8.6 mM) (Curran et al. 1985) and T. gammatolerans EJ3 (K m = 10.0 mM) (Zuo et al. 2014) (Table 1). Generally, the K m values of l-asparaginases from archaea were significantly higher than those of the non-archaeon l-asparaginases. The recombinant T. zilligii l-asparaginase displayed k cat/K m at 537.3 mM−1 s−1, which was similar to the l-asparaginases from T. gammatolerans EJ3 (572.1 mM−1 s−1), but higher than those of T. kodakaraensis KOD1 (254 mM−1 s−1) and P. furiosus l-asparaginase (72.5 mM−1 s−1).

Application of T. zilligii l-asparaginase in French fries

Blanching is a unit operation of a typical industrial process of French fries, which is usually performed at hot water (65–80 °C) for 10–30 min (Kornbrust et al. 2009). Herein, acrylamide content in French fries without blanching or l-asparaginase treatment was measured to reach 1592 µg/kg, and acrylamide level could be slightly reduced by blanching from 1323 to 967 µg/kg with blanching time from 1 to 10 min (Fig. 6a). The slight reduction of acrylamide formation was due to that the acrylamide precursors could be partially leached out during blanching. The effect of blanching on acrylamide reduction mainly depends on the operation temperature and blanching time (Mestdagh et al. 2008). Blanching temperature is the crucial factor for acrylamide mitigation and blanching at high temperature for a short time has higher efficiency than lower temperature blanching. But blanching at higher temperature (97 °C) may bring about unacceptable sensory properties, such as higher oil levels and inferior textural characteristics, compared with unblanched products during frying process (Alvarez et al. 2000).

Effect of l-asparaginase treatment on the acrylamide formation in French fries. a Acrylamide content of French fries with different blanching time. Blanching was conducted in hot water at 80 °C. b Acrylamide content of French fries treated with different enzyme dose at 80 °C for 1 min. c Acrylamide content of French fries treated with 10 U/mL of enzyme at 80 °C for different time. Values are means of three replications ± standard deviation

Obviously, the typical high blanching temperature is disadvantageous for the treatment of L-asparaginase from mesophilic organisms as it easily inactivates the enzyme. Therefore, to effectively display the l-asparagine hydrolysis activity, an additional operation process at a lower temperature should be brought to this process after blanching. l-asparaginase from T. zilligii exhibited high optimum temperature (90 °C) and good thermal stability, and thus, the enzyme treatment could be combined together with the blanching process, to control the acrylamide formation in French fries. Shown in Fig. 6b, T. zilligii l-asparaginase treatment during blanching could significantly reduce the amount of acrylamide formation. The acrylamide content remarkably decreased upon increasing l-asparaginase dosage and treatment time. After enzyme treatment during blanching at 80 °C for 1 min, the acrylamide level was reduced to 778, 526, 396, and 353 µg/kg, by adding 2, 5, 10, and 20 U/mL of l-asparaginase, respectively. In addition, the acrylamide level could be further reduced when enzyme treatment time was extended (Fig. 6c). By treatment with 10 U/mL of l-asparaginase during blanching at 80 °C, the acrylamide level was reduced to 353, 311, 275, and 232 µg/kg, after blanching for 2, 4, 8, and 15 min, respectively. The results may be caused by the strong hydrolytic activity of thermostable l-asparaginase toward l-asparagine during blanching at 80 °C.

Numerous strategies have been applied to inhibit acrylamide formation in lab-scale or pilot-scale. The mitigation strategies can be considered from two aspects, the removal of precursors and interference with the Maillard reaction. However, the latter usually has potential negative effects on organoleptic properties of the final products, owing to much of the desired color and flavor in foods obtained from the Maillard reaction (Medeiros Vinci et al. 2012). The concentration of free l-asparagine in potatoes is more abundant than that of reducing sugars (Amrein et al. 2003), so removal of l-asparagine, one of precursors of acrylamide formation, has significant influence on the inhibition of the formation of acrylamide. There have been some research articles about the application of l-asparaginase for reduction of acrylamide in potato-based foods (Table 2). Typically, a commercialized l-asparaginase product named Acrylaway® from Novoenzymes A/S, produced by Aspergillus oryzae expressing the l-asparaginase gene from A. oryzae, has been proved to be able to significantly inhibit acrylamide formation in various kinds of foods including the potato-based products (Hendriksen et al. 2009; Pedreschi et al. 2008, 2011). The Acrylaway® has been approved as generally recognized as safe (GRAS) and has been widely used in food industry. In addition, acrylamide level in potato samples was significantly reduced from 2.53 to 0.46 mg/kg by treatment with l-asparaginase produced by Bacillus subtilis B11-06 (Jia et al. 2013); using enzyme treatment by l-asparaginase from Bacillus licheniformis RAM-8, the acrylamide content in potato strips was reduced by 80 % (Mahajan et al. 2012); and the acrylamide formation was almost completely inhibited in microwaved potato snack by E. coli l-asparaginase treatment (Zyzak et al. 2003).

All previous studies used the non-thermostable l-asparaginases to reduce acrylamide formation, and the enzyme treatment was performed at no more than 50 °C (Table 2), meaning that the enzyme treatment process should be separated from the blanching. Herein, the acrylamide content was maximally reduced by 80 % when treated with 10 U/mL of thermostable l-asparaginase at blanching temperature for only 4 min (Fig. 6c). l-Asparaginase treatment at high temperature of around 80 °C for a short period of time was considerably efficient herein, and it seemed relatively time-consuming for reduction of acrylamide content. Results of the current study suggested that the thermostable l-asparaginase from T. zilligii AN1 TziAN1_1 had a good potential application for reducing acrylamide formation in French fries, by means of combining blanching and l-asparaginase treatment into one step.

References

Alvarez MD, Morillo M, Canet W (2000) Characterization of the frying process of fresh and blanched potato strips using response surface methodology. Eur Food Res Technol 211:326–335

Amrein TM, Bachmann S, Noti A, Biedermann M, Barbosa MF, Biedermann-Brem S, Grob K, Keiser A, Realini P, Escher F (2003) Potential of acrylamide formation, sugars, and free asparagine in potatoes: a comparison of cultivars and farming systems. J Agric Food Chem 51:5556–5560

Anese M, Quarta B, Frias J (2011) Modelling the effect of asparaginase in reducing acrylamide formation in biscuits. Food Chem 126:435–440

Bansal S, Gnaneswari D, Mishra P, Kundu B (2010) Structural stability and functional analysis of l-asparaginase from Pyrococcus furiosus. Biochem Moscow 75:375–381

Broome JD (1981) l-Asparaginase: discovery and development as a tumor-inhibitory agent. Cancer Treat Rep 65(Suppl 4):111–114

Cappelletti D, Chiarelli LR, Pasquetto MV, Stivala S, Valentini G, Scotti C (2008) Helicobacter pylori l-asparaginase: a promising chemotherapeutic agent. Biochem Bioph Res Co 377:1222–1226

Chen F, Yuan Y, Liu J, Zhao G, Hu X (2008) Survey of acrylamide levels in Chinese foods. Food Addit Contam 1:85–92

Chohan SM, Rashid N (2013) TK1656, a thermostable l-asparaginase from Thermococcus kodakaraensis, exhibiting highest ever reported enzyme activity. J Biosci Bioeng 116:438–443

Curran MP, Daniel RM, Guy GR, Morgan HW (1985) A specific l-asparaginase from Thermus aquaticus. Arch Biochem Biophys 241:571–576

Gervais D, Allison N, Jennings A, Jones S, Marks T (2013) Validation of a 30-year-old process for the manufacture of l-asparaginase from Erwinia chrysanthemi. Bioproc Biosyst Eng 36:453–460

Hatanaka T, Usuki H, Arima J, Uesugi Y, Yamamoto Y, Kumagai Y, Yamasato A, Mukaihara T (2011) Extracellular production and characterization of two Streptomyces l-asparaginases. Appl Biochem Biotech 163:836–844

Hendriksen HV, Kornbrust BA, Østergaard PR, Stringer MA (2009) Evaluating the potential for enzymatic acrylamide mitigation in a range of food products using an asparaginase from Aspergillus oryzae. J Agric Food Chem 57:4168–4176

Jia M, Xu M, He B, Rao Z (2013) Cloning, expression and characterization of l-asparaginase from a newly isolated Bacillus subtilis B11-06. J Agric Food Chem 61:9428–9434

Khushoo A, Pal Y, Singh BN, Mukherjee KJ (2004) Extracellular expression and single step purification of recombinant Escherichia coli l-asparaginase II. Protein Expres Purif 38:29–36

Kim BK, Lee SH, Kim SY, Jeong H, Kwon SK, Lee CH, Song JY, Yu DS, Kang SG, Kim JF (2012) Genome sequence of an oligohaline hyperthermophilic archaeon, Thermococcus zilligii AN1, isolated from a terrestrial geothermal freshwater spring. J Bacteriol 194:3765–3766

Kornbrust BA, Stringer MA, Lange NEK, Hendriksen HV (2009) Asparaginase—an enzyme for acrylamide reduction in food products. In: Whitehurst RJ, Oort MV (eds) Enzymes in food technology, 2nd edn. Wiley-Blackwell, Hoboken, pp 59–87

Koster F (2007) Development and application of Aspergillus niger asparaginase to prevent the formation of acrylamide in food products. Ann Nutr Metab 51:393

Kotzia GA, Labrou NE (2007) l-Asparaginase from Erwinia chrysanthemi 3937: cloning, expression and characterization. J Biotechnol 127:657–669

Kukurova K, Morales FJ, Bednarikova A, Ciesarova Z (2009) Effect of l-asparaginase on acrylamide mitigation in a fried-dough pastry model. Mol Nutr Food Res 53:1532–1539

Kumar S, Veeranki VD, Pakshirajan K (2011) Assessment of physical process conditions for enhanced production of novel glutaminase-free l-asparaginase from Pectobacterium carotovorum MTCC 1428. Appl Biochem Biotech 163:327–337

Kumar NM, Shimray CA, Indrani D, Manonmani H (2014a) Reduction of acrylamide formation in sweet bread with l-asparaginase treatment. Food Bioproc Tech 7:741–748

Kumar NSM, Kishore V, Manonmani HK (2014b) Chemical modification of l-asparaginase from Cladosporium sp. for improved activity and thermal stability. Prep Biochem Biotech 44:433–450

Ludlow JM, Clark DS (1991) Engineering considerations for the application of extremophiles in biotechnology. Crit Rev Biotechnol 10:321–345

Mahajan RV, Saran S, Kameswaran K, Kumar V, Saxena RK (2012) Efficient production of l-asparaginase from Bacillus licheniformis with low-glutaminase activity: optimization, scale up and acrylamide degradation studies. Bioresour Technol 125:11–16

Mashburn LT, Wriston JC Jr (1964) Tumor inhibitory effect of l-asparaginase from Escherichia coli. Arch Biochem Biophys 105(2):450–453

Medeiros Vinci R, Mestdagh F, De Meulenaer B (2012) Acrylamide formation in fried potato products—present and future, a critical review on mitigation strategies. Food Chem 133:1138–1154

Mestdagh F, De Wilde T, Fraselle S, Govaert Y, Ooghe W, Degroodt J-M, Verhé R, Van Peteghem C, De Meulenaer B (2008) Optimization of the blanching process to reduce acrylamide in fried potatoes. LWT-Food Sci Technol 41:1648–1654

Moreno-Enriquez A, Evangelista-Martinez Z, Gonzalez-Mondragon EG, Calderon-Flores A, Arreguin R, Perez-Ruedas E, Huerta-Saquero A (2012) Biochemical characterization of recombinant l-asparaginase (AnsA) from Rhizobium etli, a member of an increasing Rhizobial-Type family of l-asparaginases. J Microbiol Biotechn 22:292–300

Mottram DS, Wedzicha BL, Dodson AT (2002) Acrylamide is formed in the Maillard reaction. Nature 419:448–449

Onishi Y, Yano S, Thongsanit J, Takagi K, Yoshimune K, Wakayama M (2011) Expression in Escherichia coli of a gene encoding type II l-asparaginase from Bacillus subtilis, and characterization of its unique properties. Ann Microbiol 61:517–524

Pedreschi F, Kaack K, Granby K (2008) The effect of asparaginase on acrylamide formation in French fries. Food Chem 109:386–392

Pedreschi F, Mariotti S, Granby K, Risum J (2011) Acrylamide reduction in potato chips by using commercial asparaginase in combination with conventional blanching. LWT-Food Sci Technol 44:1473–1476

Pritsa AA, Kyriakidis DA (2001) l-Asparaginase of Thermus thermophilus: purification, properties and identification of essential amino acids for its catalytic activity. Mol Cell Biochem 216:93–101

Sieciechowicz KA, Joy KW, Ireland RJ (1988) The metabolism of asparagine in plants. Phytochemistry 27:663–671

Stadler RH, Blank I, Varga N, Robert F, Hau J, Guy PA, Robert M-C, Riediker S (2002) Acrylamide from Maillard reaction products. Nature 419:449–450

Taeymans D, Wood J, Ashby P, Blank I, Studer A, Stadler RH, Gonde P, Eijck P, Lalljie S, Lingnert H (2004) A review of acrylamide: an industry perspective on research, analysis, formation, and control. Crit Rev Food Sci 44:323–347

Verma N, Kumar K, Kaur G, Anand S (2007) l-Asparaginase: a promising chemotherapeutic agent. Crit Rev Biotechnol 27:45–62

Vidya J, Ushasree MV, Pandey A (2014) Effect of surface charge alteration on stability of l-asparaginase II from Escherichia sp. Enzyme Microb Tech 56:15–19

Yao M, Yasutake Y, Morita H, Tanaka I (2005) Structure of the type I l-asparaginase from the hyperthermophilic archaeon Pyrococcus horikoshii at 2.16 Å. Acta Crystallogr D Biol Crystallogr 61:294–301

Yoshimoto T, Nishimura H, Saito Y, Sakurai K, Kamisaki Y, Wada H, Sako M, Tsujino G, Inada Y (1986) Characterization of polyethylene glycol-modified l-asparaginase from Escherichia coli and its application to therapy of leukemia. Jpn J Cancer Res 77:1264–1270

Zuo S, Xue D, Zhang T, Jiang B, Mu W (2014) Biochemical characterization of an extremely thermostable l-asparaginase from Thermococcus gammatolerans EJ3. J Mol Catal B Enzym 109:122–129

Zyzak DV, Sanders RA, Stojanovic M, Tallmadge DH, Eberhart BL, Ewald DK, Gruber DC, Morsch TR, Strothers MA, Rizzi GP (2003) Acrylamide formation mechanism in heated foods. J Agric Food Chem 51:4782–4787

Acknowledgments

This work was supported by the 973 Project (No. 2012CB720802), NSFC Project (Nos. 21276001 and 31171705), the 863 Project (No. 2011AA100904), and the Support Project of Jiangsu Province (No. BK20130001) and Shaoxing city (No. 2013A23002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by H. Atomi.

Rights and permissions

About this article

Cite this article

Zuo, S., Zhang, T., Jiang, B. et al. Reduction of acrylamide level through blanching with treatment by an extremely thermostable l-asparaginase during French fries processing. Extremophiles 19, 841–851 (2015). https://doi.org/10.1007/s00792-015-0763-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00792-015-0763-0