Abstract

In view of the growing threat of climate change, there is a need to put intense research efforts to reverse global warming effects. Use of inexpensive and abundantly available lignocellulose as a carbon source for reducing societal dependence on fossil fuels and anthropogenic CO2 emissions is vital in the current scenario. There is a need to emphasize on gradual shift from petroleum-based technologies toward renewable feedstock-based technologies for value-added chemical synthesis. Catalytic conversion of low-cost biomass into diversified industrially significant platform chemicals is of great research interest. Lignocellulose-derived levulinic acid (LA) is increasingly gaining attention among industrialists and academicians owing to its useful properties and potential industrial applications. Notable chemicals that are synthesized/derived from LA include levulinate esters, γ-valerolactone, acrylic acid, 1,4-pentanediol, β-acetylacrylic acid, α-angelica lactone, 2-methyltetrahydrofuran, δ-aminolevulinic acid, etc. Among these, levulinate esters find useful applications as plasticizing agents, fragrance chemicals, solvents, intermediates in organic process industries, oxygenate additives in fuels, etc. Levulinate esters are generally obtained by esterification reaction in the presence of suitable acid catalysts, either in homogeneous (liquid acid) and heterogeneous (solid acid) medium. The solid acid catalysts are mostly favored over liquid acids to avoid issues related to handling, separation, regeneration, and disposal due to the corrosive and toxic nature of liquid acids. This chapter presents a brief account on several value-added chemicals that are derived from LA and discussion on homogeneously and heterogeneously catalyzed esterification reaction of LA to yield various valuable levulinate esters. Zeolite-/mesozeolite-catalyzed esterification of LA to synthesize n-butyl levulinate and pentyl levulinate has been covered in detail. Zeolites as a heterogeneous catalyst are important in the development of cleaner technologies. This effort will serve as an aid for industrialists and academicians who are working in the area of conceptualizing LA biorefineries.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Bioenergy

- Biomass-derived value-added chemicals

- Levulinic acid

- Solid acid catalysis

- Hierarchical zeolites

- Levulinic esters

1 Biomass-Derived Scaffolds

The design and efficient synthesis of versatile molecules marks as a leading research front in today’s time. The reaction products—the prime focus—have shared the importance equivocally with the method of production and the side products generated in the process. The “method” of production has imbibed in it an important attribute, viz., the source. Wherein terminologies like environmental degradation and climate change have caught the eye of the world, all associated sectors need to adapt and evolve urgently. The sources mentioned here need to be environmentally compatible at the first place. Naturally available sources come to the mind in a go and upon proper research and enlightenment have taken the frontline of modern research.

Deriving viable chemicals from biologically alive things or part thereof is one such subclass to this horizon of research. The “biomass” enriched with molecular dexterity can be scientifically exploited for the better good—extracting or synthetically converting to numerous derivatives [1].

It has been established till now that this source-class has advantages in versatile domains, and at this point, it becomes important to gist out a few of the n-numbered benefits it withholds.

-

Environmentally Benign—This point is listed out the first and therefore the primal importance. The source comes from the environment itself and hence should be environmentally aligned and friendly.

-

Biological Compatibility—Biomass is compatible to organic matter and also is the biomass-derived product.

-

Noncarcinogenic —Most of the bio-derived scaffolds as well as the side products involved in their production process are noncarcinogenic, enhancing their usability.

However, forming an unbiased reference certifies biomass with a few barriers, a low content of energy, discrete availability, seasonality, high content of moisture, and collection costs [1, 2]. In addition, available biomass is highly scarce. As an alternative raw material, on the other hand, biomass would be a preferable resource as chemical manufacturing needs far lower volumes of biomass to fulfill the demand [2,3,4].

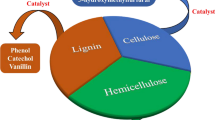

In the current scenario, research toward the conversion of biomass having rich lignocellulose content to produce fuels, chemicals, and energy due to the rapidly increasing global energy consumption and environmental concerns has garnered considerable interest [5,6,7]. Meeting energy demands in the future will require alternatives and adequate substitution to the prevailing technologies based on fossil fuels with renewable and sustainable carbon-neutral technologies utilizing lignocellulosic biomass as an important feedstock and raw material. To economically utilize biomass, we should not just aim for a single component but also the other components present. Biomass, in general, is composed of mainly three components: cellulose, lignin, and hemicellulose [8, 9]. All these three components of lignocellulose biomass have signification potential and approaching for one at a time would waste two of the other active components.

The biochemical industry has constantly been driving a dedicated emphasis on the production of some chemical intermediates that can prove to be the building blocks for the subsequent design and synthesis of a family of end-user-centric chemicals . These chemicals, called the “platform chemicals,” are the promising candidates that can be transformed into commercially important chemicals. The US Department of Energy (2004) report has made a remarkable amount of reference on the identification of these promising bio-derived platform molecules and presented the well-known list of 12 highly valued building blocks [10]. In their own words, they defined these platform chemicals as follows: “Building block chemicals, as considered for this analysis, are molecules with multiple functional groups that possess the potential to be transformed into new families of useful molecules.” Platform chemicals have the potential to create high-value commercial products. However, by merely being intermediaries, they will not add value to the industrial chain. That value can actually be substantiated by transforming these intermediates into high-value end products which can properly be adopted by the end users. Glucose monomers are end products of cellulose (biomass precursor) hydrolysis. And various value-added compounds can be derived from this glucose and the end product obtained based on the type of catalyst selected and reaction conditions adapted. Few of them are sorbitol via hydrogenation reaction, gluconic acid via oxidation, fructose through isomerization, and 5-hydroxymethylfurfural (5-HMF). The latter can be further converted into levulinic acid (LA) through hydration and formic acid through hydrolysis [11].

LA is an important platform chemical produced from a biomass-based feedstock for several petrochemical operations. An extensive literature is available on useful properties and prospective industrial applications of LA and its derivatives [11,12,13].

2 Levulinic Acid: An Introduction

In the current scenario, LA is gaining considerable attention as it is sourced from biomass and is an essential feedstock for the current petrochemical operations/processing. 4-Oxypentanoic acid, popularly known as levulinic acid, is one of the 12 platform organic chemicals that can be efficaciously derived from biomass and utilized for the economical production of biofuels [11]. The significance of LA is mainly attributed to the presence of carboxylic acid and ketone functional groups in them which can lead to various value-added adducts via several organic reactions.

On the molecular level, conversion of lignin-rich biomass to levulinic acid follows a complicated scheme of reactions involving several byproducts and intermediates [14]. Cellulose and hemicellulose, two major constituents of biomass, belong to a class of polymers which are carbohydrate-based and can be hydrolyzed to low weight sugars using acid catalysis. The catalytic decomposition of the six-membered sugar fragments (e.g., glucose) produces 5-hydroxymethyl-2-furaldehyde as an intermediate. This is then subsequently rehydrated giving levulinic acid and formic acid as final products (Scheme 1).

As mentioned in the preceding paragraph, the presence of both the ketone and a carboxylic acid group in the molecule at the same time helps in deriving numerous potent chemicals, to name a few, levulinate esters, acrylic acid, γ-valerolactone, 1,4-pentanediol, α-angelica lactone, β-acetylacrylic acid, δ-aminolevulinic acid, 2-methyl THF, etc. [15]. They have many end-user applications; for instance, 2-methyl-THF (2-MTHF) and levulinic esters may find use as gasoline and biodiesel additives, respectively. δ-Aminolevulinate , a popularly known herbicide, and various other bisphenol derivatives may substitute bisphenol A with added properties [16]. Ethyl levulinate , the product of the esterification reaction between LA and ethanol, is utilized as an oxygenating additive in fuels [17]. Another levulinate ester, n-butyl levulinate, is an important intermediate in the organic processing industries for purposes such as solvents, odorous substances, and plasticizing agents [18].

Another important derivative is the γ-valerolactone (GVL) [19], which is a sustainable liquid and is produced by the catalytic hydrogenation of LA [20]. GVL has successfully been used for the synthesis of pentane-1,4-diol, ionic liquids, butene isomers, adipic acid, alkanes, transportation fuels, and polymers [19, 21,22,23,24,25].

Considering the commercial aspects of the levulinic acid, it is reported that DIBANET project (Development of Integrated Biomass Approaches NETwork) focuses on the utilization of organic waste and residues to produce ethyl levulinate and on the production of δ-aminolevulinic acid (DALA) and methyltetrahydrofuran (MTHF) from biologically defined processes. DIBANET aims to promote the collaboration of seven and six universities, respectively, from Latin America and Europe. The budget of the project was €3.7 million. Therefore, it could be concluded that there is a remarkable interest to scale up to the desired production because of its significant potential for both research and industrial applications.

3 Levulinic Acid as a Platform Chemical for Value-Added Products

The presence of dual functional groups like ketone and carboxylic acid made levulinic acid an important platform for the productions of useful value-added products. It is the most important class of gamma-keto acids , which can be derived from the biomass and can undergo various chemical reactions to produce value-added products, such as animal feed, textile dye, coating material, pharmaceuticals, food flavoring agents, polymers, herbicides, anti-freezing agents, etc. [12, 26, 27]. Due to such kind of properties, the US National Renewable Energy Laboratory (NREL) has considered it as the most promising building block for various organic transformations [28].

Levulinic acid can be used to produce γ-valerolactone by hydrogenation reaction. Further hydrogenation of γ-valerolactone gives 1,4-pentanediols, and subsequent hydrogenation affords 2-methyltetrahydrofuran (2-MTHF), which can be used in the lithium rechargeable batteries as the source of electrolyte [29]. Alkyl levulinates can be produced by the esterification reaction of the levulinic acids with various alcohols, which can be utilized as the oxygenated fuels and solvent additives [29] (Scheme 2).

Some of the potentially interesting derivatives of levulinic acid are explained as follows:

3.1 Synthesis of GVL from LA

Hydrogenation reaction of LA gives γ-valerolactone , which is found to be the most sustainable intermediate product and can be further applied to produce renewable biofuels. Horvath et al. [30] have first proposed the potential use of GVL as renewable biofuel, due to its excellent energy carrier property. They have reported two-step process involving Shvo catalyst and GVL as solvent. In the first step, they have applied sulfuric acid as homogeneous acid catalyst for the conversion of fructose into LA. Formic acid is also produced during this step which will further act as an H-donor to convert levulinic acid into GVL. Homogeneous catalyst system has the drawback of separation of the catalyst from the reaction mixture, and hence research in LA conversion through heterogeneously catalyzed system is highly in demand nowadays. Various metal-based catalyst systems have been studied, and among them, Ru-based catalyst system is found to be more efficient for LA conversion with 72% yield of GVL at 800 psi H2 and about 150 °C temperature [31, 32]. Lin et al. have also found similar observation and confirmed that the catalytic activity of the Ru/C is far better than the compared catalysts, i.e., Raney Ni, Urushibara Ni, and Pd/C [33]. In α-hydrogenation of LA, LA conversion of 92% is observed with 99% selectivity of GVL using Ru/C catalyst in methanol. However, this system which is suffering in terms of reusability of the catalyst due to the leaching of Ru decreases the conversion gradually. GVL can further be catalytically converted into valuable chemicals and fuels such as 1,4-pentanediol, 2-methyltetrahydrofuran, valeric biofuels, 5-nonanone, and α-methylene-γ-valerolactone (Scheme 3) .

3.2 Synthesis of 1,4-Pentanediol and 2-Methyltetrahydrofuran from LA

The use of GVL as a liquid fuel is restricted due to its high solubility in water. Hence, researchers are now focusing on converting GVL to another useful product, which can be further utilized as a biofuel additive. The hydrogenation of GVL produces other useful fuel additives like 1,4-pentanediol (1,4-PDO) and 2-methyltetrahydrofuran (2-MTHF). Palkovits et al. [34] have reported the catalytic hydrogenation reaction of GVL to produce 2-MTHF in a solvent-free reaction condition using Ru/C as heterogeneous catalyst. The conversion of GVL is found to be about 99% with 43% yield of 2-MTHF at 190 °C and 24-h reaction time. Du et al. have reported the conversion of GVL to 2-MTHF with 98% conversion and 93% selectivity over an inexpensive Cu catalyst. They have also reported that if the reaction is carried out at low temperature in the presence of calcined Cu catalyst and H2 instead of air, the formation of 1,4-pentanediol is observed [35] (Scheme 4).

Direct conversion of LA into 2-MTHF in the presence of noble metal catalysts using 1,4-dioxane and water as a solvent system is reported by Elliott and Frye [35]. The conversion proceeds via the formation of GVL and 1,4-PDO as the reaction intermediates. The literature is also available for the conversion of LA into 2-MTHF via GVL using both homogeneous and heterogeneous catalyst systems. Leiner et al. have reported the homogeneous catalyst system based on Ru with acidic additives to produce 2-MTHF from LA. The best performance, i.e., 92% yield of 2-MTHF , was observed for the Ru(acac)3/triphos catalyst with cooperation of NH4PF6 and acidic ion liquid additives at 10 MPa H2 and 160 °C reaction temperature [36].

3.3 Synthesis of Valeric Biofuels from LA

As shown above, GVL and LA as well can be converted to other useful value-added products. Similar to 1,4-PDO and 2-MTHF, GVL and, ultimately, LA can be converted into liquid hydrocarbon fuels like alkanes by applying selective catalytic pathways. The reaction path goes away in two different steps, in which the first step involves the ring opening reaction of GVL and generation of pentanoic acid. While in the second step, the reaction of pentanoic acid with dicarboxylic acid leads to the formation of butenes. Butenes can be further applied as a precursor for the synthesis of C8 alkanes.

Lange et al. [37] have introduced valeric biofuels, which are the new derivatives of LA and are fully compatible as transportation fuels. In the report, GVL is first converted into pentanoic acid over Pt/ZSM-5 as the bifunctional metal acid catalyst. By the use of Pt-based bifunctional catalyst, a yield of up to 90% of pentanoic acid is achieved. Further, pentanoic acid is converted to valerate ester by esterification reaction in the presence of solid acid catalyst and alcohols. Zaccheria et al. have reported the simple one-step process for the production of pentylvalerate from GVL using Cu-supported SiO2-ZrO2 catalyst [38] (Scheme 5).

3.4 Synthesis of Succinic Acid from LA

Succinic acid is one of the top 12 value-added products derived from the biomass because it possesses dicarboxylic group at positions 1 and 4. It is another significant value-added chemical that can be obtained from LA. It has various applications and can be used as a fuel additive, polymer, solvent, food/cosmetic/pharmaceuticals, etc. Zeikus [39] was the first to recognize the industrial significance of succinic acid. Succinic acid serves as a pH regulator and flavoring agent and has many medicinal applications [40] such as a antimicrobial agent and vitamin additive and for the production of antibiotics and amino acid synthesis [41]. Succinic acid is also one of the useful precursors for the industrially important chemicals, such as 1,4-butyrolactone, pyrrolidinone, tetrahydrofuran, and g-butyrolactone [42]. Moreover, succinic acid can be produced from LA by oxidation reaction. Dunlop et al. patented the process of oxidation of LA over V2O5 as catalyst at higher temperature which is around 360–400 °C [43]. Ru-based magnetic nanoparticles have been efficiently utilized by Parvulescu et al. for the production of succinic acid from LA. One-step conversion of LA to SA has been reported by Kawasumi et al. [44] using I2/t-BuOK system with 3% H2O2. They achieved 83% yield within 1-h room temperature. Dutta et al. have also reported the synthesis of SA through oxidation using H2O2 in trifluoroacetic acid. They got 62% yield of SA within 2 h at 90 °C [45] (Scheme 6).

3.5 Synthesis of Pyrrolidinones from LA

Pyrrolidinones are one of the value-added chemicals derived from levulinic acid, which serve as the platform to produce other high value-added chemicals. They are also useful for various industrial applications, such as organic solvents and as precursors in the production of surfactants, and in various pharmaceutical products [46,47,48]. The presence of carboxylic groups along with the presence of ketone in the structure of LA provides the possible environment for its conversion into pyrrolidinones via catalytic tandem reductive amination and amidation reactions. The reaction proceeds through the formation of imine, which further gives γ-amino pentanoic acid as an intermediate. Finally, pyrrolidinone is produced via amidation of γ-amino pentanoic acid. Many reports are available for both catalytic systems, i.e., homogeneous and heterogeneous for the transformation of LA into pyrrolidinone. Fu et al. have reported the homogeneous catalyst system based on Ru and formic acid as hydrogen donor [49]. Sun et al. [50] have designed very efficient heterogeneous solid acid catalyst NHC-Ru, which shows excellent activity even after 37 catalytic recycles (Scheme 7).

In heterogeneous catalytic system, the catalysts loaded with metals and metal oxides over the supports show noticeable improved catalytic activity for the reaction of reductive amination. Rode et.al have carried out the synthesis of pyrrolidinones over ZrO2-supported Au catalyst with formic acid as hydrogen donor [51]. Siddiki and coworkers [52] have developed TiO2-supported Pt-based catalyst. They have proposed that the Pt sites surrounded by TiOX species enhance the chemoselectivity of the catalyst and exhibited higher catalytic performance with ~98% yield of pyrrolidinone in the reductive amination process [50]. Other metal alloy-based catalysts were developed by Esposito et al., and they have applied it in the continuous flow reactor . It was observed that there is not any variation found in the activity of catalyst FeNi even after 52.5 h [53]. Further text of the chapter is focused on levulinate esters, the most important levulinic acid-derived value-added chemical.

3.6 Levulinic Acid-Derived Levulinic Esters: Properties and Applications

Levulinic esters, like methyl levulinates, ethyl levulinates, and n-butyl levulinates, can be efficiently produced from the esterification reaction of levulinic acid with various alcohols. Levulinic esters are the most promising and versatile compounds which are regarded as the alternate energy source and a promising replacement of fossil fuels. Various organic transformations (condensation, addition, etc.) are realized in synthetic pathways of biochemicals, due to the presence of keto ester groups of levulinic esters, creating possibility for them to be used as significant platform chemicals in the list of futuristic biorefinery. They can be used as an important intermediate in flavoring and fragrance industries, plasticizer, solvent biofuel additives, etc. In recent times, the utilization of the long alkyl-chain levulinate as the green solvent is explored widely, due to its low cytotoxicity and mutagenicity properties [54]. Levulinates possess remarkable fuel blending properties like low toxicity, stable flash point, higher lubricant property, and moderate flow properties, and because of these properties, they can be efficiently utilized as additives for diesel and gasoline [55]. Grove and co-workers have studied the properties of the diesel blends with various levulinates and other esters as well [56].The study carried out by Lake and Burton for the blend of ultralow sulfur diesel, biodiesel, and ethyl levulinate in a turbocharged engine (3.1 L) indicates possibilities of utilization of ethyl levulinate as the fuel blend. The study shows that the particulate matter and oxides of nitrogen emission were reduced in the EL blend (80% ULSD +13.33% biodiesel +6.47% ethyl levulinate) as compared to the 20% biodiesel blend [57]. Similar kinds of studies have been carried out by Janssen and coworkers; they have investigated the combustion study of the higher blend ratio of BL (60–80%) with n-tetradecane, in the single-cylinder diesel engine [58]. They observed soot-free combustion with this high blend but found incompatibility of the fuel with high butyl levulinate blend with the hoses and sealed engine fuel system. They have also studied a 10% ethyl levulinate blend with diesel fuel and observed reduction in the particulate matter emission up to 50% [59].The blending octane numbers for methyl levulinate, ethyl levulinate, and iso-/secondary butyl levulinate were found to be 106.5, 107.5, and 102.5 [54]. The internal molecule organization, specifically hydrogen bond network, makes alkyl levulinates more compressible. Esters derived from levulinic acid possess very low vapor pressures as compared to the most commonly utilized solvent. Chlorinated solvents show more than 400 kPa vapor pressure, at 100 °C, while methyl, ethyl, and butyl levulinates show very less, i.e., 5.96, 4.69, and 1.56 kPa vapor pressure, respectively. Due to such kind of properties, Bayarri Ferrer et al. have claimed the degreasing efficiency of alkyl levulinates equivalent to the industrially utilized harmful trichloroethylene [60]. They have also reported the VOC classification, cytotoxicity, and mutagenicity data for butyl and pentyllevulinates . According to the reported data, they have confirmed the potential of alkyl levulinate to be utilized as the green solvent [61].

4 Esters and Esterification Reaction: Chemistry

Esters are naturally occurring and vital organic compounds. They are responsible for the fragrant odor of flowers and many fruits (e.g., methyl butanoate in pineapples, isopentyl acetate in banana oil). These pleasant smelling liquids are constitutional parts of animal fats and biologically significant molecules. Esters are commonly made by a nucleophilic acyl substitution reaction between a carboxylic acid and an alcohol. It involves initial protonation of carboxylic acid followed by nucleophilic attack of ROH, an excess of the latter normally being employed to get ester product as it facilitates shifting of equilibrium in the desired direction. Esters result from simply heating a carboxylic acid in methanol or ethanol solution containing a small amount of mineral acid catalyst, as per discovery made by Fischer and Speier in 1895 [62]. In this nucleophilic acyl substitution reaction, free carboxylic acids are hard to be attacked by most nucleophiles, but use of strong mineral acid such as HCl and H2SO4 boosts its reactivity. The mineral acid facilitates protonation of oxygen atoms of the carbonyl group, thereby generating positive charge on carboxylic acid, thus making it much more reactive toward nucleophilic attack by alcohol to yield tetrahedral intermediate. Transfer of proton from one oxygen to another generates second tetrahedral intermediate and converts the –OH group into a good leaving group. In the final step, protonated ester is formed by subsequent loss of water, and the final deprotonation step leads to regeneration of acid catalyst to form free ester product. Overall, Fischer esterification is nothing but is simply a substitution of an –OH group by –OR′. The reaction steps involved are all reversible, and one can get either ester or carboxylic acid based on proper selection of reaction conditions. The use of excess alcohol leads to ester formation, whereas the use of excess water leads to carboxylic acid formation via acidic hydrolysis (initial protonation of ester being followed by nucleophilic attack by water).

5 Catalysis for Production of Levulinic Esters

Usually, a catalyst is a substance that increases the rate of reaction without being consumed in the chemical reaction, and the phenomenon occurring when a catalyst acts is termed as catalysis. The word “catalysis” was first coined by Berzelius in 1836, which originates from two words, the prefix cata-, meaning down, and the verb lysein, meaning to split or break [63]. He probably used the term “catalysis” to denote breaking down of the normal forces that are preventing the reaction of molecules. The catalyst primarily influences a chemical reaction, which is already thermodynamically feasible or lowers the reaction temperature at which the reaction achieves a given rate. Catalyst does not alter the equilibrium constant. The progress of catalyzed chemical reaction occurs through new and more energetically favored reaction pathway. Such phenomenon of lowering of activation energy is basic principle of catalysis and applied to all class of catalysis [63].

As far as esterification reaction of levulinic acid with primary alcohols is concerned, the reaction occurs even at room temperature; however, the rate is very slow, which can be accelerated either by using higher temperature and catalyst to get equilibrium conversion within reasonable time period. Conventionally, alkyl levulinates can be obtained by levulinic acid esterification in the presence of mineral acid catalysts such as H2SO4, HCl, or H3PO4 [64]. A variety of catalysts have been reported for the esterification of levulinic acid to yield levulinate esters that include homogeneous, heterogenized homogeneous catalysts, heterogeneous catalysts, enzymatic catalysts, supported catalysts, etc. An overview of several types of catalysts that are reported for synthesis of levulinic esters is provided herein, in the subsequent text.

In the homogeneous system, it is convenient to manipulate acidic strength by adding acid/water/native solvent. Varkolu et al. [65] demonstrated synthesis of various levulinates via esterification over environmentally benign bio-glycerol-derived carbon-sulfonic acid catalyst. Negus et al. [66] prepared ethyl levulinate using p-toluenesulfonic acid (PTSA) and other mineral acid (HCl, H2SO4, HNO3) homogeneous catalysts. The authors obtained better results with H2SO4 and PTSA due to their higher acid strength among all studied catalysts.

In the last two decades, ionic liquids (ILs) have emerged as versatile green building blocks and have wide applications in the area of separation, materials, catalysis, green solvents etc. The use of IL for lignocellulose conversion into value-added chemicals and fuel products is of great research interest. ILs are molten salts at room temperature having wide applications in the area of green chemistry due to its bifunctional role as green solvent and catalyst. Mostly, the IL framework consists of a combination of cation and anion, wherein, IL cation is organic and IL anion is inorganic/organic [67]. The salient properties of ILs that are responsible for increasing the popularity of these materials are good thermal stability, broad liquid state range, non-volatility, better slvation ability, wide electrochemical window, nonflammability, and higher ionic conductivity. They can be a robust reaction medium for organic synthesis due to their better solubilizing and stabilizing behavior to reactive intermediates [67, 68]. Khiratkar et al. used ionic liquid-based phase-transfer catalyst (sulfonic acid-functionalized benzimidazolium-based poly-IL) for the synthesis of ethyl levulinate, while Bhanage and coworkers have used imidazole-based IL (1-methyl-imidazolium hydrogen sulfate) as both a catalyst and a solvent for the synthesis of levulinates [69].

It is worthy to mention that homogeneous catalysis shows excellent catalytic activity in esterification reaction. However, major drawbacks associated with such homogeneous system are difficulty in isolation, corrosiveness of reactor, high reaction temperature, waste disposal, toxicity, non-reusability, non-regeneration, etc. Such practical difficulties necessitate the need for replacement of such conventional homogeneous toxic and corrosive acid catalysts with recyclable strong solid acid (heterogeneous) catalysts in synthetic organic reactions. Thus, the development of cost-effective and robust solid acid catalyst via energy-efficient synthetic protocols to improve the yield of levulinic esters is currently of great research interest.

6 Solid Acids as Catalysts for Esterification of Levulinic Acid

According to the name, the solid acid catalysts are the solid materials which work similar to the liquid catalyst. They provide active surface having active hydrogen ions and act as a hydrogen donor to produce reaction intermediates, which is further converted to the desired products by giving back the hydrogen ions [70]. The important properties of solid acid catalysts consist of their acidity in terms of Brønsted and Lewis, the strength of these acid sites in terms of NH3-TPD, and the surface properties, i.e., morphology, surface area, and pore size [71].

Reactions of LA with various alcohols using several solid acid catalysts have been reported, such as various metal oxide (SnO2, ZrO2, Nb2O5, TiO2, etc.)-supported catalysts, various zeolites (HBEA, HZSM-5, H-Y, HMOR, MCM-22, etc.) (Scheme 8), metal organic frameworks, ion exchange resins, graphene oxides, etc. [72,73,74,75,76,77]. The subsequent text covers discussion on major class of heterogeneous catalysts that are currently in practice for esterification of levulinic acid.

6.1 Metal Organic Frameworks (MOFs)

Porous materials have grabbed significant levels in modern science and technology. They are strategic materials and have contributed significantly in the area of petroleum, catalysis, gas separation, or nuclear storage. Currently, intense research has been generated for the discovery of new porous materials with larger pores, in order to cope up with the demand of industry for obtaining special dimensions and shapes. Metal organic frameworks, abbreviated as MOFs, are such collection of compounds which contain metal ions linked through molecular species, which first appeared in the literature in 1997. However, co-ordinatively bridged metal centers with organic ligand concept were first reported in 1991. They are three-dimensional porous hybrid materials made up of organic units (multidentate hydrophobic linkers) and metal ions (metal-ions-oxo clusters) [78,79,80]. These organic structures have the potential for manipulation, through varying the metal ions, their counter-anions, organic linkers, and mixed organic linkers and through the control of the architectures and functionalization of the pores [81, 82]. Various combinations of organic unit and metal ion-oxo-cluster generates a library of MOFs. High variability and possibility of modifications are two salient features of MOFs which enables one to design tailor-made MOFs for desired end-use applications [72, 73, 79]. In the last decade, the design and synthesis of such supramolecular assemblies have attracted considerable attention due to their potential applications as smart optoelectronics, magnetic, heterogeneous catalysis, sensors, and gas storage and in separation, due to their inherently high surface areas, uniform and tuneable pore sizes, and ample possibilities for functionalization [80, 83,84,85,86,87]. MOFs may be produced to act as highly selective molecular sieves, sensors, or catalysts. Incorporation of guest species generates sensing capabilities of MOFs. The guest species can be removed and reintroduced reversibly without collapse of the framework [88].

Catalysis is often regarded as a desirable attribute of MOFs. Kim and coworkers [85] studied the enantiopure Zn-based MOFs involving coordination linkages with pyridinium functional groups and demonstrated catalytic activity in transesterification reaction.

An esterification reaction can also be well executed using Brønsted acidity of MOFs, which is attributed to the functional groups present in them. Because of improved mass transport and structure tunability, these materials have tremendous possibilities from the point of view of designing a highly active heterogeneous catalyst for targeted applications [89]. UiO-66 MOF whose nominal composition is Zr6O4(OH)4(BDC)6 (BDC = 1,4-benezene dicarboxylate). This MOF is made of 12-coordinated Zr6O4(OH)4 metal clusters (Zr6 nodes linked with benzene dicarboxylate linkers). [90,91,92]. From catalysis perspective, favorable porosity and extraordinary high surface area of the MOF improve mass transfer due to enhanced accessibility of active sites, thus increasing the catalytic activity. In particular, the exposed Zr sites exhibit excellent catalytic behavior which offers an advantage of efficiently catalyzing various acid-catalyzed reactions [93]. UiO-66,35, MOFs exhibited robust mechanical, thermal, and chemical stabilities. In addition, versatile synthesis methods and ease of functionalization are other key favorable factors of these MOFs.

Literature is available on use of UiO-66-(COOH) (Zr-based MOF) as a heterogeneous catalyst for levulinic acid esterification with ethanol [94]. The authors have mentioned that, the excellent activity of this MOF, for this reaction stem from synergistic effect between the Lewis acidic Zr clusters and Brønsted acidity due to organic functionality (–COOH groups) within the framework. Such proven Brønsted acidity enables this material to be used as active acid catalytic material for the esterification of biomass-derived acids with alcohols [72, 73, 91, 95]. The authors have mentioned, based on computational studies, that the Zr sites form coordination bonds with carbonyl groups of levulinic acid, while the free carboxylic group forms H-bond with the substrate, facilitating the removal of –OH group from levulinic acid. The author confirmed reusability of catalyst across five runs [94].

Further, the scope exists for applications of MOFs in upgradation of lignocellulosic biomass and biomass-derived platform chemicals, and this area holds much potential for further development. However, there are issues associated with control of orientation of building blocks in the solid state and prediction of resulting framework structure [96]. Due to weak coordination bonding, MOFs are expected to be less thermally stable. Thermal stability can be improved by appropriate combination of ligand and metals, and an introduction of chelate effect can also be beneficial to enhance stability of porous MOFs.

6.2 Ion-Exchange Resins

Resins are organo-polymeric materials that exhibit high surface area, high ion-exchange capacities, and characteristic functional groups which determine the nature of resultant resins [76, 77, 97, 98]. Several types of organic transformations are catalyzed by acid or base, which can be preferentially carried out with ion-exchange resins/solids. Easy separation, ease of continuous operations, loss of valuable reactant, reusability of resin, non-corrosiveness to the reactor, and elimination of removal acid/base from the product mixture and liquid effluent are some of the merits of using ion-exchange solids/resins [99]. One can design tailor-made resins to get selective product with proper choice of monomers and manipulate the degree of cross-linking. However, one has to look into thermodynamic aspects of sorption of reactants and products as it also affects the selectivity problem to a larger extent.

The degree of cross-linking, stiffness, swelling, functionality type, etc. are significant as they largely affect the activity of resins. The swelling property of resin is associated with the flexibility and stiffness of resin which in turn depends on the amount of cross-linker. Higher cross-linking causes more stiffness and lesser swelling. The gel type Dowex 50Xx2 affords higher yield than macroporous resins in polar media (e.g., esterification of levulinic acid with alcohol) due to swelling which causes enlargement of the pore size, recurrence of new pores, and subsequent improvement in mass transfer of reactants and surface area. Trombettoni et al. [77] used cationic sulfonated resins (Aquivion mP90, micronized pellets of perfluorosulfonic polymer) for esterification of levulinic acid with long-chain alcohols. Ramli et al. [98] have made use of Amberlyst-15 resin as a solid acid catalyst for alkyl levulinate compounds. SO3H and SO4 functional groups present in Amberlyst-15 were found to play a crucial role in esterification of levulinic acid. Tejero et al. [76] have carried out an esterification of levulinic acid with butanol by employing Dowex 50Wx2, a gel-type resin. Several other resin-based catalysts such as Amberlyst-based resins, Purolite, Dowex, and polystyrene-supported PTSA are reported for levulinate synthesis. In esterification reaction, the resin which prevents adsorption of byproduct (water molecules) from its own surface performs better and offers higher yield. Adsorption of water declines the catalytic activity and slows down the reaction in the case of resins like Amberlyst and polystyrene-supported PTSA [77, 100]. Amberlyst-70 is found efficient among all macroporous Amberlyst catalysts for levulinate synthesis and found to exhibit exceptional thermal stability and flexibility among all Amberlyst resins [76]. Use of Amberlyst-15 and Amberlyst-70 type of resins, in the reaction medium, is very simple and is less expensive than other resin-based catalysts; hence, they are widely used. So far, inorganic ion-exchange resins like tetravalent metal acid salts are not much explored for levulinic acid esterification reaction.

Resins play a vital role in maintaining appropriate flexibility, hydrophobicity, and porosity in reaction media. However, they could not withstand high boiling stiffness and disintegrate at high temperatures. Moreover, high cost, sluggish thermostability, tendency to form H-bonds, and destabilization of active groups are some of the major challenges associated with such materials [71, 101,102,103].

6.3 Zirconia

Zirconia (ZrO2) is the metal oxide-based solid acid catalyst, specifically zirconium metal, which of great interest as it possesses higher catalytic activity with typical characteristic porosity. Such porosity provides easy access to the long-chain and bulky molecules and facilitates smooth mass transport on the pore surfaces [104,105,106,107,108]. It also possesses semiconducting nature, anticorrosion property, and reducing nature [109]. Both Brønsted and Lewis acidities are available in zirconia [109, 110]. Various zirconia-based catalysts have been explored for the synthesis of levulinate esters. Su et al. have synthesized zirconia-supported phosphotungstic heterogeneous solid acid catalyst which is utilized for the production of methyl levulinate from LA. The yield of 99 mol% methyl levulinate was observed at 65 °C, 1:7 LA to methanol ratio in 3-h reaction time [107].

6.4 Carbonaceous Materials

Carbonaceous material is one of the important classes of solid acid catalysts derived from the partial pyrolysis process followed by sulfonation of the carbon-based materials at specified temperature. These types of materials have advantages like high catalyst dispersion ability, high thermal stability, high adsorption capacity, reusability, and easy separation from the reaction mixture [69, 111,112,113,114,115,116]. Such kind of solid acid catalyst has the ability to hold various protonic sites and shows very good catalyst activity in the various organic reactions like esterification, hydration, and hydrolysis [117]. Carbonaceous materials can be derived by stepwise procedure, pyrolysis, sulfonation, and carbonization [118]. In the second step, sulfonation is carried out by means of mineral acids like sulfuric acid of the carbon materials [119,120,121], which is further subjected to hydrothermal carbonization process to get the catalytic material [122,123,124]. Li et al. have synthesized such kind of carbonaceous catalyst using loofah sponge as renewable biomass source and applied for the esterification of ethanol to produce ethyl levulinate. The conversion of LA is obtained up to 91% using this catalyst with satisfactory reusability [112].

Yang et al. [55] have evaluated the catalytic performance of various solid acid catalysts and compared with the carbonaceous solid acid catalysts. Zeolites H-ZSM-5 and H-BEA and resins Amberlyst-15 and Nafion-212 were compared with carbonaceous solid acid catalysts such as GC400 (glucose-derived amorphous carbon) and AC400 (commercial grade activated carbon). It was observed that under optimized reaction conditions, i.e., LA/n-butanol ratio of 1:5, 10% catalyst, 4-h reaction time, and 100 °C temperature, GC400 displayed a much higher catalytic efficiency toward esterification among the studied catalysts (sulfonated active carbon, HZSM-5, Nafion-212). The authors concluded that the high acid (–SO3H) density and acid strength along with weak acid sites linked on the surface of catalysts (due to –COOH and phenolic –OH) are responsible factors behind the higher catalytic activity of GC400. This fact is found in accordance with the reported literature wherein, the authors (Fernandes et al.) have performed comparative catalytic screening of catalysts [zeolites (ZSM-5, Beta, USY, Mordenite, and MCM-22) (SnO2, ZrO2, Nb2O5, TiO2)] for LA esterification reaction. They observed lower activity of zeolite than sulphated oxides, which is attributed to the formation of transition state inside the channel structure rather than acidity of microporous zeolite. Author has mentioned that the same reason is responsible for the activity gap between H-BEA and HZSM-5 i.e. the gap is due to different pore structure [74].

6.5 Solid-Supported Reagents

Solid-supported reagents comprise polymeric/non-polymeric solid supports (alumina, silica, zeolite, etc.) on which reagents (in dissolved form) are supported. In such cases, problems of removal of the products may arise, but if the chemical reagent is covalently linked to solid support [62], the product can be easily separated from the reaction mixture. Usually, porous support is preferable as it provides higher surface area. Thus, insoluble support provides powerful means to facilitate synthesis. There are several examples of some reactions which are difficult to carry out in homogeneous medium or offer very poor yields which can be effectively carried out with solid-supported reagents under mild reaction conditions with high selectivity.

Silica gel-supported reagents are reported to recover valuable scaffolds [62]. Silica is a low-cost significant inorganic porous solid which is the widely accepted support due to its high surface area and chemical and mechanical stability and the feasibility of surface functionalization [29, 100, 125,126,127,128,129]. Moreover, they possess excellent mechanical stability. Pasquale et al. [29] performed a study of the catalytic activity toward synthesis of ethyl levulinate via esterification of levulinic acid with ethanol over silica-based catalyst. Yang and coworkers [129] studied the synthesis of alkyl levulinates over perchloric acid-decorated nano-porous silica. Enumula et al. demonstrated [125] the use of tungsten oxide-based silica catalyst in alkyl levulinate under continuous mode vapor-phase conditions. Malero et al. [127] performed the synthesis of ethyl levulinates over sulfonic mesoporous silica catalyst. Furthermore, they could reuse the catalyst up to three runs without its regeneration . Ramli et al. [100] carried out the synthesis of methyl levulinate and obtained 69% yield over sulfated silica under mild conditions. Chermahini and Nazeri [128] used Al-MCM-41 as the solid acid catalyst for the synthesis of isobutyl and butyl levulinates. Maggi et al. [126] have successfully utilized silica-supported sulfonic acid catalysts for ethyl levulinate and achieved excellent yield and selectivity for ethyl levulinate. Tungsten oxide-based SBA-16 silica catalyst was found to exhibit better acidity and afforded subsequent yield of levulinate ester, owing to dispersion of dynamic acidic sites of tungsten oxide over larger surface area of SBA-16 [125]. The authors concluded that sulfonic acid mesostructured silica exhibits promising catalytic features such as higher surface area and higher hydrophobicity which lead to higher activity and better recyclability than various homogeneous sulfonic acid catalysts under study (H2SO4, PTSA, propylsulfonic acid). It is noteworthy to mention that the silica-based catalyst leads to form the H– bonding in polar solvent (like alcohol in esterification of levulinic acid with alcohol), leading to dissolution of the active functionality of silica-supported catalyst, consequently causing decrease in activity and reusability of the catalyst [29].

Heteropolyacids (HPAs) are well-known as acid catalysts in view of their significant high acidity, redox properties, catalytic activity, pseudo-liquid behavior, and physicochemical properties [130]. HPAs are well-known for its Brønsted acidity. Especially, in organic media, the molar catalytic activity of HPAs is extremely higher as compared to mineral acid like sulfuric acid [131,132,133]. This feature makes possible to carry out the catalytic reaction through “chemie douce” approach, i.e., a soft chemical route involving lower catalyst concentration and/or at a lower temperature. Moreover, no side reactions occur during HPAs-assisted sulfonation, chlorination, nitration, etc. which are obvious with mineral acids [131, 132]. However, these solid acids are lacking in terms of surface area, thermal stability, uneven dispersion of the positive charges, solubility in the polar solvent, and porosity. They exhibit very low surface area (typically 1–10 m2 g−1) and low porosity (<0.1cm3 g−1). To overcome these difficulties, these salts are supported on various supports such as titania, zirconia, mesoporous silica, etc. and exchanging the HPAs protons with suitable metal cations [29, 134, 135]. To avoid the leaching issue, hydrophobic graphene-anchored HPAs compounds are reported, which furnish well acidity and are considered as good graphene-based compounds anchored onto HPAs. The HPAs-supported catalysts furnish well acidity and are regarded as good candidates for better conversion of the levulinate compounds, due to their improved surface area and free dynamic active sites required to facilitate the reaction.

Quereshi et al. have prepared zirconia-supported Keggin silicotungstic acid to produce ethyl levulinate from LA and get more than 90 mol% ethyl levulinate at 110 °C in 30 min using a microwave reactor [136]. Pasha and Raj [137] synthesized Zr exchanged phosphotungstic acid with retention of Keggin’s structure of TPA and applied to the esterification reaction of LA and ethanol. The authors have successfully demonstrated the use of zirconia to enhance the catalytic activity of the HPAs. Wu et al. [138] have studied extensively porous 3D graphene aerogel-anchored tungstophosphoric acid catalyst for the synthesis of ethyl levulinate. Shimizu et al. [139] prepared Cs+, Ag+ Al3+,Ti4+, Y3+, Zr4+, Sn4+, and Hf4+ salts of tungstophosphoric acid. Among the studied catalysts, Zr0.75TPA has been found to be the best catalyst for the conversion of LA to ethyl levulinate with a yield of 91% in 2 h and at 120 °C. The catalyst also showed five-time reusability. Zhou et al. [140] have assessed the catalytic activity of silver or ammonium co-doped phosphotungstic acid for the synthesis of ethyl levulinate. The catalytic activity of Al-MCM-41 and zirconia-supported dodeca-tungstophosphoric acid for the synthesis of hexyl levulinate and ethyl levulinate, respectively, is also reported [98, 141, 142]. These catalysts displayed excellent recyclability.

Zheng et al. [143] and Wu et al. [144] have undertaken catalytic studies of tungstophosphoric acid supported on graphene oxide and MCM-41 catalysts, respectively, in esterification of LA to synthesize ethyl levulinate. Luan et al. [145] demonstrated the synthesis of alkyl levulinates (ethyl, methyl, and isobutyl levulinates) using organic salt of H4SiW12O40. Dharne and Bokade [18] performed the synthesis of butyl ester from levulinic acid over dodeca-tungstophosphoric acid-treated clay (K − 10). H4SiW12O40 catalyst is reported for the synthesis of several levulinates by Vilanculo et al. [146]. Numerous catalysts are reported for such as heteropolyacid-supported silicalites, heteropolyacid-supported STA-AlSBA-15, and tungstosilicic acid H4SiW12O40-SiO2 for an efficient synthesis of alkyl levulinates [147,148,149]. In all cases, the heteropolyacid-supported catalysts performed better than the sole support (Al-SBA15/silica/K10/MCM-41/Al-MCM-41/desilicated H-ZSM-5, etc.).

Several sulfated metal oxides (SnO2, ZrO2, Nb2O5, TiO2) have also been used as solid acid catalysts for esterification reactions including zeolites. Since the last decade, we have been working in the area of zeolite-/mesozeolite-catalyzed organic transformations including an esterification reaction of levulinic acid for the synthesis of n-butyl levulinate. Further text of the chapter provides insight of our related research efforts , starting with a brief introduction to zeolites.

7 Synthesis of Levulinic Esters Using Zeolites as Solid Acid Catalysts

Zeolites are inorganic crystalline materials of aluminum and silicates having an intricate and delicate porous structure. These materials are distinguished in terms of the framework “corner atoms” and have cavities and channels in their design. Different constituent atoms and their subsequent arrangements lead to a plethora of structures which are formally attributed with a nomenclature by the Structure Commission of the International Zeolite Association (IZA-SC) [150]. The famously known sieves, viz., zeolites, MOFs, aluminophosphates, as well as a few other silicates, fall under this category. Although each of these materials is equally important and finds relevant applications in various fields [151, 152], the likes of zeolites and silicates are many in the recent times [153].

Zeolites are naturally occurring three-dimensional microporous aluminosilicates interlinked by oxygen atoms and possessing specific sized molecular pores, cavities, and channels.

Henceforth, they are widely used as ion-exchange materials, adsorbents, and solid acid catalysts in various industrial sectors, like oil refining plants, petroleum industry, water purification, wastewater treatment plants, and perfumery industry, and in effluent treatment. Due to the presence of uniform molecular cavities, pores, and channel system, they allow entry of selective molecules which in turn depends on the size of channels, pores, and cavities [69, 154,155,156,157,158,159]. The constituent atoms can be replaced by a variable number of other elements imparting interesting properties and the same applicability. The channels and cavities possess a diameter in the range of 0.3–1.3 nm, depending upon the structure. Generally, the values of internal surface area and pore volume are 800 m2 g−1 and 0.35 cm3 g−1, respectively [160, 161].

A comprehensive insight into the formation, mechanistic growth, as well as structures of the zeolitic materials has been elaborately presented by Barrer and Richard [162]. They present the growth and crystallization mechanism as a bottom-up phenomenon wherein small preformed framework building blocks known as the secondary building units (SBUs) condense into the three-dimensional microporous structures [150]. The synthesis strategy of microporous zeolites involves the precursors, viz., alumina and silica polycondensed using the sol-gel process. The method often involves the use of structure-directing materials commonly termed as templates. The templates bring about a horizon of crystalline structures that can be synthesized and put forward into applications. The templates used are mostly organics of amines, quaternary ammonium cations, cyclic ethers, and coordination compounds (or the organometallics) [163]. A perfect highly ordered porous structure imparts the properties of sieving and selective catalysis. Moreover, the presence of compensating cations in its structure adds the properties of ion exchangeability and catalysis.

Zeolites have established themselves as efficient catalysts for various industrial and laboratory-scale reactions. This catalytic activity is expressed by the Brønsted as well as Lewis acid sites present in their framework [164]. The pores (of varied ring sizes) of zeolites can always act as encapsulating agents for guest species of adequate sizes. These species can be treated and reacted inside these pores, given the catalytically active sites present in their structure. They also endow the advantages of high thermal stability and easy availability of the precursors for production [165]. Zeolites contain ambient number of Brønsted acid sites. The number of these sites will be equivalently proportional to the number of aluminum atoms present in the zeolitic framework. These sites can be highly active as proton donors to a number of catalytic reactions. Substitution of silicon atoms with high valence metals like tin, titanium, and zirconium can help produce Lewis acid sites into the zeolitic framework. Reactions which require Lewis acidity can be run inside the pores of these catalysts. A relevant example that requires Lewis acidity is the aldol condensation of keto esters generating diacid esters as products. Also, zeolites can be modified to introduce both Lewis and Brønsted acidities to their overall framework. These come handy in reactions which require both of these catalytic sites in different steps.

The most fundamental and conventional catalytic activity shown by a zeolite is that of ZSM-5 for the selective formation of the para-isomer of xylene [166]. The catalytic activity of zeolites owes to the presence of both Lewis and Brønsted acidic sites in their three-dimensional framework. The cavities in these porous materials can effectively embed small molecules and can henceforth act as reactors. Moreover, the heterogeneous nature of the catalyst adds the benefits of easy separation and reusability. The refining and petrochemical industry depends heavily on zeolites as catalysts for carrying out several important chemical processes [167, 168]. To name a few, cracking, cyclization, isomerization, dehydrogenation, and transalkylation are some of the reactions applying zeolites as catalysts [165]. The channels present in their structures imply properties of proton and ion conduction to these materials.

Although microporous zeolites have several advantages attributed to their name, a pore size of 2 nm is considerably small. Also, the accessibility to these pores is tough and is limited only to small molecules. To address these problems in virtue, the design of materials having bigger cavities is critically being looked upon.

The strategies commonly applied for the design of these materials having “mesopores” may be one of the following:

-

1.

Pre-synthesis strategy—Supramolecular aggregates like surfactants and block copolymers have sizes in the dimensions of a few nanometers. Their use as a template for the structural development of large pored zeolitic materials is obvious. A research group at Mobil Oil Corporation was the first one to adopt this strategy [169], and henceforth, they did prepare the mesoporous silica which is today famously known as the MCM.

Surfactant molecules of different chain lengths can help design zeolitic pores of varying dimensions [170]. The same is the case with the block copolymers. These templating molecules can then be subsequently removed after the utility using various methods (preferably a calcination treatment).

-

2.

Post-synthesis strategy—The removal of silicon and/or aluminum atoms present within the framework leads to an effective increase in the void size. Respectively called as desilication and dealumination , they can efficiently be carried forward by the treatment of varying alkali and acid concentrations, respectively (Fig. 1).

In case of conventional zeolites, being its crystal size in micrometer range, they suffer lack of external surface, thereby external active sites and whatever active sites available are located inside the microporosity of zeolite; hence, the accessibility to these pores is tough and is limited only to small molecules. This feature limits to utilization of potential of zeolites to a fuller extent. One of the solutions to this shortcoming is reduction of crystal size to enhance the external surface, i.e., formation of nanozeolites. These nanozeolites (pore size <100 nm) with high external surface area and narrow pore size distribution have wide applicability as film preparation/coating materials.

The porosity of zeolite need not be uniform and highly ordered always. Instead of the conventional uniformity setup, different pore systems with varying dimensions can be imbibed into the zeolitic material. Building such a “multimodal” system helps build hybrid composite materials with several added features and properties. Trends in the development of less hindered and more active cavities have led to the development of the multiple porosity containing zeolites (usually micro- or mesoporous) and are often termed as the “hierarchical zeolites.” They serve to increase external surface and accessibility to pores. These materials possess secondary porosity along with typical and uniform microporosity of zeolites. This secondary porosity may comprise of varied porosity range from supermicropore to mesopores/marcropores. Mostly, it lies in mesopore range depending upon the method of synthetic modification involved in making of hierarchical zeolites. General post-synthetic approaches for hierarchical zeolites are depicted in Fig. 2 [171,172,173]. Synthetic strategies are classified into major top-down (demetallation) and bottom-up approaches (use of soft and hard templates/template-free) [174].

The procedure of dealumination used for making hierarchical zeolites involves severe acid treatments that can severely damage the zeolite framework. Moreover, the process involves the reduction in the number of interconnecting channels from the external surface to the pores leading to a serious accessibility drawback [173]. Henceforth, the process of desilication for the generation of mesoporosity is often preferred over the dealumination one. It is reported that hierarchical zeolites prepared by desilication offer better mesopore accessibility and preserved acidity as compared to those by dealumination [175]. Ogura et al. in their studies concluded that desilication process could be a promising approach for creation of uniform mesoporous framework structure with zeolitic acidity [176]. During desilication, base treatment causes leaching of Si species from zeolite framework, creating interconnected mesopores that are accessible from the external surface of zeolite.

The use of templates is regarded as less energy efficient and environmentally benign with high temperature requirement for toxic organic template removal and greenhouse gas emission during its combustion. Zhijie Wu and coworkers have recently reviewed green synthesis of hierarchical zeolites [177].

Hierarchical zeolites possess several advantages over microporous zeolites, such as improved mass transport of reactants, facilitated by mesopores, due to enhanced accessibility of the acid sites, and due to shorter diffusion path length of hierarchical materials, products retained for lesser time in micropores, thus causing reduction in probability of side reactions which consequently increases preference toward primary products and enhances the catalyst’s life by improving the transport of coke precursors out of the catalyst. Also, they are far better over individual mesoporous materials in terms of hydrothermal stability (due to introduction of zeolite building blocks on the surface of mesoporous walls), which leads to improved reusability of the catalyst in many organic reactions’ regeneration cycles, and zeolitic acidity, which creates new possibilities for applications of mesoporous zeolites in the catalytic reactions demanding strong acidity [171]. Due to such positive attributes, hierarchical zeolites are preferable and gaining attention as heterogeneous catalysts/supports to execute various organic transformations involving demanding acidity and bulkier entities (which is generally the case with fine chemical synthesis) over conventional zeolites due to their improved catalytic activity. One can envisage the wide utility of mesozeolites and their functionalized derivatives for biomass-derived chemical synthesis. Verboekend and Pérez-Ramírez [178] have provided in-depth discussion on the catalyst design aspect of mesoporous zeolites for catalytic applications from the point of view of synthesis-property-function relationship. They suggested that the functionalization of mesopores can exposed zeolites to novel applications; however, one has to think of large-scale synthesis of mesozeolites/hierarchical zeolites in which the shape of the catalyst is a key factor, as each size has its different role to play. Activity, intracrystalline mass transport, and practical implementation for mesozeolite synthesis are key functions of micropores, mesopores, and shape-geometry, respectively. Further, the authors suggested that, for large-scale industrial success, one has to look into the economic aspect critically while keeping in mind both the production cost and advantage in catalysis which demands for close collaborations between inventors and industrial partners.

Zeolites have extensively been used for the preparation of numerous ester derivatives, an important one being alkyl levulinates. Since the last decade, our research group has been engaged on research related to the development of environmentally benign methods for the synthesis of complex drug molecules via multicomponent reactions and the conversion of biomass-based derivatives into value-added chemicals, especially esterification of biomass-derived levulinic acid to produce n-butyl levulinates using hierarchical zeolite catalysts.

Initially, attempts have been made for the development of mesozeolite BEA (via desilication approach using alkali-treated zeolite precursors) and employing them in biologically active drug-like molecules [derivatives of dihydopyridinones (DHPMs), dialkylpyrimidinones (DAPMs), amino alkyl naphthols (AANs), etc.]. In this research, the success of mesozeolites is realized as improved catalytic activity is observed in case of the synthesis of bulkier products as compared to parent zeolite H-BEA catalyst. In the subsequent research, several mesoporous zeolites (meso-ZSM-5 and meso-H-BEA) have been developed after employing a series of synthetic modifications in terms of change in reaction conditions, use of varied templates [surfactants: [cetyltrimethylammonium bromide (CTAB), tetradecyltrimethylammonium bromide (TTAB)], rice husk, pH, stirring period, etc.], etc. [179, 180]. The resulting hierarchical materials were characterized for their morphology (by SEM/TEM/low- and wide-angle XRD, 27Al and 29Si-MAS-NMR), thermal stability (by TG-DTA), elemental analysis (by ICP-AES), surface area (by BET), pore volume (by BJH), acidity (by NH3-TPD), etc. using several sophisticated analytical techniques [181, 182].

Maheria et al. demonstrated a study of the effect of different protozeolites of varied catalytic characteristics on % LA conversion into n-butyl levulinate. This butyl ester is one of the value-added chemicals as mentioned earlier in the text and finds its wide applications as a reaction intermediate in bio-based chemical synthesis, a plasticizing agent, a solvent, and an odorous substance. One hundred percent selectivity and higher % LA conversion was obtained in case of H-BEA zeolite owing to its three-dimensional structure along with its moderate acidity and medium pore size. The order of catalytic activity was found as H-BEA > H-Y > H-ZSM-5 > H-MOR [183].

Subsequent research was focused on generating hierarchical zeolites (meso-H-ZSM-5 and meso-H-BEA) and applying them as solid acid catalysts in levulinic acid esterification reaction to synthesize n-butyl levulinate [179, 180, 182]. Morawala et al. synthesized mesozeolite BEA using controlled desilication by sol-gel method with the help of rice husk, CTAB, and microporous zeolite BEA precursor. Zeolite BEA derivatives have been synthesized with rice husk and CTAB (designated as MCRK) and with only CTAB surfactant (designated as MCCK). The bimodal porosity of mesozeolite BEA is confirmed by XRD, BET surface area, solid-state NMR, and thermal (TGA) analysis. Both mesozeolites were found to exhibit higher thermally stability as compared to the parent zeolite. MCRK was found more thermally stable as compared to MCCK and parent H-BEA, which may be due to thicker walls (due to introduction of zeolite building units into the mesopore walls) of MCRK and MCCK. They concluded that use of rice husk has contributed toward increasing the thermal stability of the compounds. Also, upon analysis of spent catalysts, the authors have observed enhanced ability of mesozeolite to retain acidity after converting microporous structure of zeolite H-BEA into hierarchical structure. Further, the surface area of both mesoporous materials was found higher as compared to parent microporous H-BEA. Both hierarchical zeolites performed better than parent microporous zeolite BEA in LA esterification to generate n-butyl levulinate. Higher % LA conversion (95.6%) and selectivity (91%) were observed in the case of MCRK as compared to parent H-BEA and MCCK due to higher acidity and lower Si/Al ratio of MCRK. The authors observed the preferential order of activity as MCRK > MCCK > parent H-BEA (18) > Al-MCM-41 [182].

Further, an attempt was made to synthesize mesoporous zeolite BEA using TTAB surfactant as structure-directing agent via desilication approach. Further, catalysis efficiency of synthesized mesozeolite BEA (MTCK) was studied toward synthesis of n-butyl levulinate from LA esterification. An optimization study was undertaken using the Box-Behnken method . The material was characterized by using usual catalyst characterization techniques. MTCK was found to exhibit improved surface area and acidity and possess bimodal porosity. XRD and BET surface area analysis confirmed the creation of mesopores within microporous zeolite H-BEA. The authors obtained a 99.4% LA conversion, 91.51% yield, and 99% selectivity of n-butyl levulinate, over micromeso-MTCK catalyst under reaction condition of 120 °C reaction temperature and 13% catalyst concentration. At optimized process parameters (by BBD), an optimum of 99.44% LA conversion was obtained. From response surface methodology analysis, reaction time parameter is found as the most influential parameter in the esterification of LA with n-butanol over MTCK catalyst. The catalyst reusability study was performed up to four catalytic runs, and the catalyst was found reusable without any significant loss of its activity. The authors claimed that the green protocol developed for LA esterification to synthesize n-butyl levulinate can also be further explored in green conversion of other biomass-derived scaffolds into other value-added chemicals [180].

Many other researchers are working on esterification of levulinic acid with various alcohols to synthesize alkyl levulinates. Several reports exist on use of various zeolite-based catalysts for alkyl levulinate synthesis. Some examples of use of hierarchical zeolites BEA with a secondary porosity were reported [159] and Nandiwale et al. [157]-synthesized ZSM-5 mesozeolites through a post-synthetic extraction of framework silicon with NaOH. Newly introduced mesoporosity was found to contribute in enhancing the catalytic activity of these materials in the esterification of levulinic acid with ethanol. Hierarchical ZSM-5 zeolite obtained by desilication has also been used as support to incorporate a second acid functionality, like dodeca-tungstophosphoric acid [184]. The study revealed that modified desilicated H-ZSM-5 gives higher yield as compared to the parent H-ZSM-5 zeolite, due to the increase of higher surface area after desilication. Modification through desilication involves the extraction of silicon selectively, thus enhancing the surface area, generating mesoporosity, and increasing the mass transfer at the catalytic active sites [154, 157, 184].

8 Concluding Remarks and Outlook

LA provides remarkable potential for the development of several linear as well as heterocyclic systems and an economical alternative to the carbon-derived fossil fuels for designing novel derivatives. Researches in the field promise a larger objective of conversion of biological residues and wastes into sophisticated synthesized valuable chemicals. LA, however, having a potential for dozens of other molecules, has had the authors inclined toward the class of molecules—levulinate esters—which are being used in numerous industries in today’s time and promise of greater utilization in several other undiscovered applications. The conversion is an esterification reaction with alcohol molecules, requiring the presence of an acid catalyst.

Catalyzing the above-said reaction has seen a groundbreaking research with scientists bringing out several moieties for undergoing the strenuous transformation with an optimum yield. Research has yielded featured materials like MOFs, zirconia, heteropolyacids, zeolites, and even carbonaceous and supported catalytic entities for the aforementioned purpose [93, 180, 182, 183, 185, 186]. Special focus has been on zeolites, which possess sized pores which can be engineered using processes like dealumination, desilication , as well as the merging of two or more zeolite molecules with a high yield and affinity toward the reactant molecules.

The monitoring of the reaction however becomes a bit difficult and hard to handle, requiring the confirmation of the same using several spectroscopic techniques, given that the boiling points of the reactants and the product near each other with a narrow margin. This situation becomes tedious in the case of lower molecular weight alcohols which are in actuality very near in boiling point to levulinic acid. Also, the generation of the zeolites sometimes requires high-temperature transformations for several hours making the processes highly energetic ones [182]. Decreasing the same using alternative methods is another aspect of research scientists are working upon. The process of desilication is often favored over dealumination for several reasons proposed in the chapter. Stability of the catalyst is a property that forms a primal importance, as the regeneration of catalyst goes through intensive temperatures as mentioned above. Frutiful results have show that zeolite catalysts have high stability due to which they can withstand temperatures as high as 823 K with an almost the same activity even after two catalytic cycles [182].

Hierarchical zeolites have also been introduced in this chapter, showing a promising future with multimode porosity, high acidity, high catalytic activity, high stability, and optimum yields [187]. This blend shows manifold active sites in the moieties with adequate pore sizes for the reacting molecules. Several pathways for their generation were also brought into notice of the readers for further synthesis pursuits.

With an emphasis on lignocellulose biomass-derived economically viable chemicals instead of the hydrocarbon-based one, increased research in the field is a call of the hour. Given the manifold advantages of the translational processes involved outweighing the equally important challenges, several associated industrial sectors in a larger front will be impacted. Henceforth, further research work employing the development and design of efficacious solid acid catalysts for the purpose as well as the understanding of important processes for the decomposition of biomasses into important derivatives is necessary for an enhanced economical and commercial production of the value-added chemicals being referred to in this chapter.

References

Laurijssen J, Marsidi M, Westenbroek A et al (2010) Resources, conservation and recycling paper and biomass for energy? The impact of paper recycling on energy and CO2 emissions. Resour Conserv Recycl 54:1208–1218. https://doi.org/10.1016/j.resconrec.2010.03.016

Urbaniec K, Bakker RR (2015) Biomass residues as raw material for dark hydrogen fermentation – a review. Int J Hydrog Energy 40:3648–3658. https://doi.org/10.1016/j.ijhydene.2015.01.073

Matti Parikka (2004) Global biomass fuel resources. 27:613–620. https://doi.org/10.1016/j.biombioe.2003.07.005

Singh P, Sulaiman O, Hashim R et al (2013) Using biomass residues from oil palm industry as a raw material for pulp and paper industry: potential benefits and threat to the environment. Environ Dev Sustain 15:367–383. https://doi.org/10.1007/s10668-012-9390-4

Sheldon RA, Sheldon R (2014) Green and sustainable manufacture of chemicals from biomass: state of the art several books on catalysis as well. Green Chem 16:950–963. https://doi.org/10.1039/c3gc41935e

Van Haveren J, Scott EL, Sanders J (2008) Bulk chemicals from biomass. Biofuels Bioprod Biorefin 2:41–57. https://doi.org/10.1002/bbb

Zhang Y, Bi P, Wang J et al (2015) Production of jet and diesel biofuels from renewable lignocellulosic biomass. Appl Energy 150:128–137. https://doi.org/10.1016/j.apenergy.2015.04.023

Raveendran K, Ganesh A, Khilar KC (1996) Pyrolysis characteristics of biomass and biomass components. Fuel 75:987–998. https://doi.org/10.1016/0016-2361(96)00030-0

Vassilev SV, Baxter D, Andersen LK, Vassileva CG (2010) An overview of the chemical composition of biomass. Fuel 89:913–933. https://doi.org/10.1016/j.fuel.2009.10.022

Werpy T, Petersen G (2004) Top value added chemicals from biomass: volume I -- results of screening for potential candidates from sugars and synthesis gas full record other related research. US Department of Energy (US). https://doi.org/10.2172/15008859

Muranaka Y, Suzuki T, Sawanishi H, et al (2014) Effective production of levulinic acid from biomass through pretreatment using phosphoric acid, hydrochloric acid, or ionic liquid 53, 11611−11621. https://doi.org/10.1021/ie501811x

Morone A, Apte M, Pandey RA (2015) Levulinic acid production from renewable waste resources: bottlenecks, potential remedies, advancements and applications. Renew Sust Energ Rev 51:548–565. https://doi.org/10.1016/j.rser.2015.06.032

Pileidis FD, Titirici M-M (2016) Levulinic acid biorefineries: new challenges for efficient utilization of biomass. ChemSusChem 9:562–582. https://doi.org/10.1002/cssc.201501405

Pradipta MSA, Purnamasari NR, Pradana YS (2019) Levulinic acid synthesis from Indonesian sugarcane bagasse using two-step acid catalyzed treatment. AIP Conf Proc 2085:20065. https://doi.org/10.1063/1.5095043

Leonard RH (1956) Levulinic acid as a basic chemical raw material. Ind Eng Chem 48:1330–1341. https://doi.org/10.1021/ie50560a033

Sasaki K, Watanabe M, Tanaka T, Tanaka T (2002) Biosynthesis, biotechnological production and applications of 5-aminolevulinic acid. Appl Microbiol Biotechnol 58:23–29. https://doi.org/10.1007/s00253-001-0858-7

Windom BC, Lovestead TM, Mascal M et al (2011) Advanced distillation curve analysis on ethyl levulinate as a diesel fuel oxygenate and a hybrid biodiesel fuel. Energy Fuel 25:1878–1890. https://doi.org/10.1021/ef200239x

Dharne S, Bokade VV (2011) Esterification of levulinic acid to n-butyl levulinate over heteropolyacid supported on acid-treated clay. J Nat Gas Chem 20:18–24. https://doi.org/10.1016/S1003-9953(10)60147-8

Marosvölgyi-Haskó D, Lengyel B, Tukacs JM et al (2016) Application of γ-valerolactone as an alternative biomass-based medium for aminocarbonylation reactions. ChemPlusChem 81:1224–1229. https://doi.org/10.1002/cplu.201600389

Wright WRH, Palkovits R (2012) Development of heterogeneous catalysts for the conversion of levulinic acid to g-valerolactone. ChemSusChem 5:1657–1667. https://doi.org/10.1002/cssc.201200111

Bond JQ, Alonso DM, Wang D, et al (2010) Integrated catalytic conversion of g-Valerolactone to liquid alkenes for transportation fuels. 1110–1115 https://doi.org/10.1126/science.1184362

Fegyverneki D, Orha L, Láng G, Horváth IT (2010) Gamma-valerolactone-based solvents. Tetrahedron 66:1078–1081. https://doi.org/10.1016/j.tet.2009.11.013

Orha L, Tukacs JM, Gyarmati B, Szilágyi A, Kollár L, LTM (2018) Modular synthesis of γ-valerolactone-based ionic liquids and their application as alternative media for copper-catalyzed ullmann-type coupling reactions. ACS Sustain Chem Eng, vol 6, p 5097. https://doi.org/10.1021/acssuschemeng.7b04775