Abstract

Zirconium exchanged phosphotungstic acid catalysts were prepared and studied for esterification of levulinic acid with ethanol. The catalysts were characterized by powder XRD, BET surface area, Raman spectroscopy, FT-infrared spectroscopy, Temperature programmed desorption of NH3 and Pyridine adsorbed FT-IR analysis. The presence of Zr resulted in the generation of strong Lewis acidic sites. Among all the catalysts the catalyst with partially exchanged Zr (Zr0.75TPA) showed higher activity due to the present of stronger Brønsted and Lewis acidic sites. The Zr0.75TPA catalyst exhibits amazing reusability with constant activity.

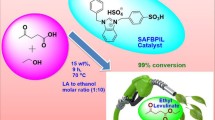

Graphic Abstract

Zr exchanged TPA is active in the esterification of levulinic acid into ethyl levulinate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The utilization of biomass and its derivatives have received significant attention in the last year sowing to diminish of fossil fuel resources and the raise in the energy consumption [1,2,3]. Levulinic acid esters can be gain from renewable cellulosic resources. They are more attractive because of their vast potential applications either in flavouring and fragrance industries or as blending component in biodiesel. In particular, Ethyl levulinate is a very good diesel miscible biofuel; 5 wt% of ethyl levulinate can be directly added to normal diesel [4,5,6,7]. The production of levulinate esters from levulinic acid (LA) has been under special concern, since LA is one of the top biomass-derived platform molecules that can be synthesised by the acid treatment of C6-membered sugar carbohydrates from renewable biomass for instance starch or lignocelluloses [8]. Conventionally, levulinate esters were prepared by esterification of LA using strong Brønsted liquid acids such as H2SO4, HCl, polyphosphoric and p-toluenesulfonic acid. These homogeneous catalyst exhibit high catalytic activity and selectivity to the esterification of LA because of strong Brønsted acidity. However, these are not suitable as they are soluble in the reaction medium. Esterification process by homogeneous mineral acid catalysts serves problems from corrosion and safety. Substitute of these homogeneous catalysts with the heterogeneous ones is tremendously desirable [9]. Design of stable solid acid catalysts is desirable to improve the ability of levulinate ester production.

Heteropolyacid HPAs for example Keggin heteropolytungstate are environmentally friendly and economically viable substitute to conventional acid catalysts since their strong Brønsted acidity, stability, and they exhibit tremendous catalytic behaviour in acid and oxidation catalysis [10, 11]. However, the easy dissolving nature in polar solvents, less thermally stability and small surface area control its application of solid acid catalyst. These disadvantages can be overcome by supporting them on appropriate supports [12,13,14] or exchanging the protons of HPAs with metal cations [15,16,17]. It is anticipated that Zr4+ can be used to substitute the protons of TPA to influence the catalytic properties related with Zr along with TPA. Shmizu et al. [18] prepared Ag+, Cs+, Al3+, Y3+, Ti4+, Zr4+, Hf4+, Sn4+ salts of tungstophosphoric acid and catalytic ability was examined for alkylation of toluene with cyclohexene. We believe that, detailed study has not been reported on zirconium exchanged tungstophosphoric acid for the ethyl levulate synthesis from LA. Zirconia (ZrO2) has received extensive attention due to it has semiconducting nature, thermally stable, anti corrosion property, reducing nature and acid–base catalytic activity [19, 20]. ZrO2 alone possess both Brønsted and Lewis acidity [21, 22]. The modification of Keggin units by exchange of protons with Zr would enhance the acidic features through strong W–O–Zr covalent bindings between H3PW12O40 clusters and the ZrO2 [23,24,25,26,27]. Meanwhile, the strong relation between H3PW12O40 and ZrO2 can efficiently inhibit H3PW12O40 leaching. The objective of the work is to exchange the phosphotungstic acid proton with varying content of Zr and characterize by X-ray diffraction, BET surface area, FT-IR, NH3-TPD and pyridine FT-IR. The catalytic performance of prepared catalysts was evaluated for the conversion of LA to Ethyl levulinate. The influence of different reaction parameters such as weight of catalyst, effect of reaction temperature, effect of reaction time and solvent molar ratio were also optimized.

2 Experimental

2.1 Preparation of Zirconium Salt of Phosphotungstic Acid

The Zirconium-exchanged phosphotungstic acid catalyst series (ZrxTPA) was synthesized as per reported literature [28]. In a typical procedure, calculated amount of TPA (M/s. Sigma Aldrich, USA) dissolved in distilled water and to this solution the required amount of ZrOCl·8H2O (M/s. Sigma Aldrich, USA) dispersed in smallest amount of water was added with vigorous stirring at room temperature. The resulting precipitate was stirred for 2 h and the excess water was evaporated on a hot plate at low temperature. The obtained samples was hot air oven dried at 100 °C for overnight and calcined at 300 °C for 2 h. The samples were denoted as ZrxTPA, where x designates the number of Zirconium ions (x = 0.25, 0.5 and 0.75, respectively).

Powder X-ray diffraction patterns of the samples were analyzed by using a Ultima-IV (M/s. Rigaku Corporation, Japan) XRD item operated at 40 kV and 40 mA provided with nickel-filtered Cu Kα(λ = 1.54056 Å) radiation.

The Temperature-programmed desorption (TPD) of NH3 was measured on BELCAT-II (Japan) instrument. In a typical procedure, 0.05 g of dry sample loaded and pre-treated at 300 °C for 1 h in presence of pure He gas (99.9%, 30 mL per min). After pre-treatment, ammonia (10% NH3 in He gas) was adsorbed on the catalyst surface for 1 h. For removing physisorbed ammonia, sample was flushed with pure He gas. Finally, the temperature programmed was performed from 100 to 800 °C with a temperature ramping of 10 °C/min. Desorbed NH3 was monitored by using TCD (thermal conductivity detector) of the apparatus.

Surface area (BET) was determined from the N2 adsorption–desorption method at liquid Nitrogen temperature using BEL Sorb-II apparatus, Japan. Before the analyses the samples were degassed at 200 °C for 2 h.

Fourier transform IR spectra were recorded on DIGILAB (USA) IR spectrometer. For calculating acidic sites (Brønsted and Lewis) of the catalysts, pyridine adsorbed FT-IR spectra was adapted. Diffuse reflectance infrared Fourier Transform (DRIFT) method was used for recording the spectra. Before adsorption of pyridine the sample was degassed in the vacuum at 200 °C for 2 h. After that, dry pyridine was suspended into the sample. Then, the sample was heated at 120 °C for 1 h. FT-IR spectra of the pyridine-adsorbed samples were recorded at room temperature.

Raman spectra were recorded using a Horiba Jobin–Yvon Lab Ram HR spectrometer with an excitation wavelength of 632.8 nm. The powdered samples were spread on a glass plate below the microscope for measurements.

LA esterification was carried out in a 15 mL pressure tube. In a typical experiment, LA (0.116 g) was mixed in ethanol (3 mL) and 0.05 g of catalyst was added in the tube. The reaction mixture was heated to desired temperature and magnetically stirred at 350 rpm. After completion of the reaction, the reaction mixture was centrifuge to remove the catalyst. The products were analysed by a Gas chromatograph with DB-5 capillary column (M/s Shimadzu, Japan) equipped with flame ionization detector (FID).

3 Results and Discussion

3.1 XRD

XRD patterns of the ZrxTPA and TPA samples were shown in Fig. 1. All the catalysts exhibit the distinguishing peaks related to Keggin ion at 2θ of 10.5°, 14.7°, 18.1°, 21°, 23.4°, 25.7°, 29.8°, 35.2° and 38.3°. These results confirmed that the intact Keggin ion in Zr exchanged TPA (ZrxTPA) catalysts [29, 30]. According to the literature, exchanging of TPA protons with metal ions such as Cs+ and Sm3+ the XRD peaks corresponding to TPA were shifted to lower angles, its indicates the expansion of unit cell volume [16, 31]. Similarly, the ZrxTPA catalysts XRD peaks are shifted to lower angles, demonstrating the expansion of unit cell volume, since the size of the proton is much smaller when compare to that of the Zr4+ ion. These results indicate the protons of TPA exchanged with the Zr4+ ions. There was no XRD peak related to ZrO2 and this also suggests the TPA protons exchanged with Zr4+ ions.

3.2 FT-IR Spectra

The FT-IR spectra of zirconium salts of tungstophosphoric acid catalysts are presented in Fig. 2. All the samples exhibited the characteristic band at 1080, 990, 889 and 812 cm−1, which can be designated to the stretching vibrations of P–O, W = Ot (Ot—assigned to the terminal oxygen), W–Oc–W (Oc—assigned to the corner sharing oxygen), and W–Oe–W (Oe—assigned to edge sharing oxygen), respectively [16]. The zirconium ion exchanged TPA exhibited all the characteristic bands associated to heteropoly anion, indicating the retention of Keggin ion structure after exchange with zirconium ions.

3.3 Raman Spectra

The Raman spectra of ZrxTPA and along with pristine TPA are shown in Fig. 3. All the samples showed the Raman bands at 1005, 988, 900, 529, 235, and 217 cm−1 [32,33,34]. The Raman bands at 1005 and 988 cm−1 are attributed to the asymmetric and symmetric vibration of double-bonded tungsten with terminal oxygen (W = Ot). The band at 900 cm−1 is ascribed to asymmetric stretching vibrations of W–Oc–W (Oc—indicates bridge oxygen atom at corner sharing) and the band at 529 cm−1 is attributed to symmetric stretching vibrations of W–Oe–W (Oe–indicates bridge oxygen atom at edge sharing). The peak which observed at 235 and 217 cm−1 is associated to W–O–W bending vibrations [32]. The presence of characteristic Raman bands of Keggin structure in the catalysts conform the exchange of Zr ion with retention Keggin primary structure. The Raman analysis support the observation made from XRD and FT-IR.

3.4 Temperature Programmed Desorption of Ammonia

Acidity of the zirconium exchanged phosphotungstic acid was measured by temperature programmed desorption of ammonia. Ammonia and profiles are shown in Fig. 4. The acidity values are calculated from desorbed ammonia and presented in Table 1. All the samples showed two desorption peaks in low and high temperature region. The low temperature peak at 180 °C might be due to ammonia molecule adsorbed on weak acidic sites probably Lewis acidic sites and the peak at 500 to 620 °C related to ammonia molecule adsorbed on strong acidic sites are Brønsted sites [35, 36]. As increase in amount of Zr desorption of high temperature peak was shifted to low temperature. The high temperature peak intensity was increased with an increase in the amount of Zr and desorption of lower temperature peak intensity remains same. These results suggest that the Lewis acidity is increased with increase in the content of Zr from 0.25 to 0.75. The acid site density for TPA is 0.487 mmol/m2; where as in Zr modified TPA catalysts the acid site densities are 0.508, 0.793 and 1.118 mmol/m2 for Zr0.25TPA, Zr0.5TPA and Zr0.75TPA respectively. The modification of TPA with Zr results in enhanced acid site densities of the catalysts which in turn enhanced the catalytic activity.

3.5 Py IR

Pyridine adsorbed technique was used to determine the presence of Brønsted and Lewis sites on the surface of solid acid catalysts. Figure 5 shows the Py-IR spectra of ZrxTPA catalysts along with TPA and ZrO2. The Py-IR spectra showed band in the region of 1400–1600 cm−1 due to stretching vibration of metal nitrogen (M‒N) and nitrogen hydrogen (N‒H) of pyridinium ion. The adsorption bands at 1440 and 1586 cm−1 correspond to pyridine adsorbed to Lewis acid sites presence in the catalyst. The other bands at 1533 and 1632 cm‒1 were the characteristic of Brønsted acid sites of formed pyridinium ion, due to the protonation on the surface of catalyst [16]. The band at 1486 cm‒1 corresponds to the combined band that is related to pyridine adsorbed Lewis and Brønsted acid sites. All the ZrxTPA catalysts exhibited the same intensity of bands. There was no increase in band intensities with increase in zirconium content. The results indicate that the ZrxTPA catalyst showed the presence of Lewis and Brønsted acid sites.

4 Activity Studies

4.1 Effect of Loading

The catalytic activity of zirconium exchanged phosphotugstic acid and ZrO2 sample were tested for esterification of LA with ethanol and results are displayed in Fig. 6. The ZrO2 has about 11% of LA conversion and the catalyst with partially exchanged Zr0.25TPA catalyst shows only 62% LA conversion and yield towards ethyl levulinate. Further increase in Zr content from 0.5 to 0.75, the conversion of LA increased and the catalyst Zr0.75TPA showed 91% ethyl levulinate yield. The catalytic activity can be explained based on the characteristic of catalysts. The activity of the catalyst mainly depends on the nature and strength of acid sites. Patil et al. [37] studied LA esterification with Ethanol over the H/BEA catalyst has exhibiting 48% LA conversion with 98% selectivity of EL. SBA-16 supported WO3 catalyst showed 95% selectivity of Ethyl levulinate with complete conversion of LA [38] and K10 clay-TPA catalyst showed 97% conversion of LA with 100% selectivity towards EL [39]. Above given the entire example showed the acidity major role in the catalytic activity. The acidity values of Zr0.25TPA, Zr0.5TPA and Zr0.75TPA are 1.525, 1.586 and 1.678 mmol/g, respectively (Table 1). The acid site densities are also followed the same trend. These results clearly suggest that the activity profiles of the catalyst reflect on the acidity (Scheme 1).

4.2 Effect of Reaction Temperature

Esterification of LA with ethanol was carried out at various temperatures limits from 80 to 140 °C and results are displayed in Fig. 7. The results suggest that the conversion of LA and ethyl levulinate yield was low at 80 °C. With increase in reaction temperature from 80 to 100 °C the conversion increased up to 50%. Further increased the reaction temperature to 120 °C, the conversion of LA reached 91% was obtained and there was no formation of any by product. The ethyl levulinate yield was not increased significantly at 140 °C. The maximum conversion of LA is 91% even though the temperature is increased to 140 °C. It indicates that the amount of energy needed to achieve maximum conversion of LA is obtained at 120 °C. These results indicate that the optimum reaction temperature for esterification of LA over Zr0.75TPA catalyst is 120 °C.

4.3 Effect of Reaction Time

In order to optimise the reaction time the best catalyst Zr0.75TPA was studied at various reaction time intervals and the results are presented in Fig. 8. It can be observed that the conversion increased with increase in reaction time up to 2 h. The LA conversion was 23% at 1 h reaction time. The conversion of LA was increased to 66% when the reaction time increased to 1.5 h. The optimum yield of ethyl levulinate is obtained at 2 h reaction time. When the duration of reaction is further increased to 3 h, the conversion of LA does not increased significantly. These results suggest that the 2 h is an optimum reaction time for this catalyst.

4.4 Effect of Catalyst Weight

The efficiency of Zr0.75TPA catalyst was studied with different catalyst weight from 25 to 100 mg, as shown in Fig. 9. It was noticed that as increase in catalyst weight from 25 to 50 mg, the conversion of LA increased from 50 to 91%. The increase in the activity with increase in the weight of catalyst, due to more number of active sites was available. Further increase in weight of catalyst to 75 mg and 100 mg, there is no significant increase in conversion levels. It indicates the relative amount of reactants to the catalyst amount, i.e. available active sites need an optimum value to obtain maximum conversion of LA. The optimum catalyst weight is 50 mg for present catalyst.

4.5 Effect of LA to Ethanol Molar Ratio

The effect of LA to ethanol molar ratio was examined over Zr0.75TPA catalyst and results are displayed in Fig. 10. The LA to ethanol molar ratio was varied from 1:17 to 1:68. As the concentration of ethanol increasing the conversion of LA increased. The maximum conversion of LA (91%) was observed at a molar ratio 1:51. Further increasing the amount of ethanol the yield of Ethyl levulinate decreased to 75% due to the mass transfer limitation since the existence of more solvent may be reduce the concentration of the reactant and conversion of LA was decreased. As the esterification of LA with ethanol is an equilibrium reaction, relatively more amount of alcohol is needed to move the reaction in forward direction. However, relatively large amount of alcohol may dilute LA which in turn decreases the conversion of LA. Therefore, the optimum molar ratio of LA to Ethanol was achieved as 1:51.

4.6 Effect of Different Alcohols

The role of different alcohols towards esterification of LA to corresponding alkyl levulinates over Zr0.75TPA catalyst was studied and results are displayed in Fig. 11. The esterification of LA with ethanol, methanol, iso-propanol and n-butanol resulted in there corresponding alkyl levulinates with 100, 91, 79 and 90% of yield respectively. In the case iso-propanol the yield of alkyl levulinate less when compare to other alcohols. This might be due to steric hindrance of iso-propanol. These results suggest that the ZrxTPA catalysts are useful for the synthesis of alkyl levulinate with different alcohols.

4.7 Reusability of Catalyst

The best catalyst Zr0.75TPA was selected to test its stability and the results are displayed in Fig. 12. After completion of the reaction, the catalyst was recovered from reaction mixture by centrifugation. The separated catalyst than washed with ethanol for three times and dried at 100 °C for 2 h. The catalyst is evaluated of for consecutive cycles. The catalyst showed insignificant loss of conversion and yield. Fresh catalyst showed about 91% conversion. After the fifth cycle the conversion is reached to 85%. The loss in the activity is marginal due to some weight loss in the catalyst. These results indicated the stability of the Zr0.75TPA catalyst.

5 Conclusion

Zirconium exchanged phosphotungstic acid were prepared with retention of Keggin structure of TPA and investigated for esterification of LA with ethanol. The main objective was to enhance the surface acidity of pristine TPA and decreasing its solubility. The structural and physicochemical properties have confirmed that the Keggin ion structure of Zr exchanged TPA. Among the studied catalyst Zr0.75TPA was found to be the best catalyst for the conversion of LA to EL with 91% yield at 120 °C with in 2 h. The reaction conditions were optimized by varying the reaction temperature, reaction time, catalyst weight and different alcohols. The catalyst showed five times reusability without any significant loss in the activity.

References

Huber GW, Iborra S, Corma A (2006) Chem Rev 106:4044–4098

Roman-Leshkov Y, Barrett CJ, Liu ZY, Dumesic JA (2007) Nature 447:982–986

Zhou CH, Xia X, Lin CX, Tong DS, Beltramini J (2011) Chem Soc Rev 40:5588–5617

Pileidis FD, Tabassum M, Coutts S, Titirici M (2014) Chin J Catal 35:929–936

Hayes DJ (2009) Catal Today 145(1):138–151

Wang ZW, Lei TZ, Leu L, Zhu JL, He XF, Li ZF (2012) BioResources 7:5972–5982

Windom BC, Lovestead TM, Mascal M, Nikitin EB, Bruno TJ (2011) Energy Fuels 25:1878–1890

Rackemann DW, Doherty WOS (2011) Biofuels Bioprod Biorefin 5:198–214

Kuwahara K, Kaburagi W, Nemotob K, Fujitani T (2014) Appl Catal A Gen 476:186–196

Pasquale G, Vázquez P, Romanelli G, Baronetti G (2012) CatalCommun 18:115–120

Zhang ZH, Dong K, Zhao ZB (2011) Chemsuschem 4:112–118

Armatas GS, Bilis G, Louloudi M (2011) J Mater Chem 21:2997–3005

Kumar ChR, Prasad PSS, Lingaiah N (2010) Appl Catal A 384:101–106

Xu L, Li W, Hu J, Yang X, Guo Y (2009) Appl Catal B 90:587–594

Shimizu K, Furukawa H, Kobayashi N, Itaya Y, Satsuma A (2009) Green Chem 11:1627–1632

Kumar ChR, Jagadeeswaraiah K, Prasad PSS, Lingaiah N (2012) Chem Cat Chem 4:1360–1367

Srilatha K, Rekha S, Devi BLAP, Prasad PSS, Prasad RBN, Lingaiah N (2012) Bioresour Technol 116:53–57

Shimizu K, Niimi K, Satsuma A (2008) Appl Catal A 349:1–5

Yamaguchi T (1994) Catal Today 20:199–217

Kaspar J, Fornasiero P, Hickey N (2003) Catal Today 77:419–449

Alsalme AM, Wiper PV, Khimyak YZ, Kozhevnikova EF, Kozhevikov IV (2010) J Catal 276:181–189

Samaranch B, Piscina PR, Clet G, Houalla M, Gélin P, Homs N (2007) Chem Mater 19:1445–1451

Su F, An S, Song DY, Zhang XH, Lu B, Guo YH (2014) J Mater Chem A 2:14127–14138

Rajkumar T, Ranga Rao G (2008) J Mol Catal A Chem 295:1–9

Salinas EL, Cortéz JGH, Schifter I, García ET, Navarrete J, Carrillo AG, López T, Lottici PP, Bersani D (2000) Appl Catal A Gen 193:215–225

Jacobson K, Gopinath R, Meher LC, Dalai AK (2008) Appl Catal B Environ 85:86–91

Su F, Wu QY, Song DY, Zhangn XH, Wang M, Guo YH (2013) J Mater Chem A. 1:13209–13221

Shimizu K, Niimi K, Satsuma A (2008) CatalCommun 9:980–983

Jagadeeswaraiah K, Kumar ChR, Prasad PSS, Lingaiah N (2014) Catal Sci Technol 4:2969–2977

Kumar ChR, Rambabu N, Lingaiah N, Prasad PSS, Dalai AK (2014) Appl Catal A 471:1–11

Corma A, Martinez A, Martinez C (1996) J Catal 164:422–432

Takashima T, Nakamura R, Hshimoto K (2009) J Phys Chem C 113:17247–17253

Reddy KM, Babu NS, Prasad PSS, Lingaiah N (2008) Catal Commun 9:2525–2531

Caliman E, Dias JA, Dias SLC, Garcia FAC, Macedo JL, Almeida LS (2010) Microporous Mesoporous Mater 132:103–111

Sun M, Zhang J, Cao C, Zhang Q, Wang Y, Wan H (2008) Appl Catal A 349:212–221

Sun M, Zhang J, Zhang Q, Wang Y, Wan H (2009) Chem Commun 34:5174–5176

Patil CR, Niphadkar PS, Bokade VV, Joshi PN (2014) Catal Commun 43:18–191

Enumula SS, Gurram VRB, Chada RR, Burri DR, Kamaraju SRR (2017) J Mol Catal A: Chem 426:30–38

Dharne S, Bokade VV (2011) J Nat Gas Chem 20:18–24

Acknowledgements

Author NP thank DST (SERB) project for financial support. Project No. SB/FT/CS/074/2014.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pasha, N., Lingaiah, N. & Shiva, R. Zirconium Exchanged Phosphotungstic Acid Catalysts for Esterification of Levulinic Acid to Ethyl Levulinate. Catal Lett 149, 2500–2507 (2019). https://doi.org/10.1007/s10562-019-02862-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-02862-z