Abstract

It is well demonstrated in the past that the lime or sulfate-resistant cement effectively controls the volume change and increases the strength of stabilized expansive soil due to both soil modification and pozzolanic reactions. Also, the rapid industrialization has increased the chances of contamination of stabilized soils with sulfate which significantly deteriorates the stabilized soil. Therefore, the effect of sodium sulfate intrusion into the lime and sulfate-resistant cement-stabilized soil on the volume change and strength behavior is brought out in this study. To achieve this objective, the expansive soil was stabilized with lime and sulfate-resistant cement and cured for 1, 7, and 28 days. Upon completion of the required curing period, the stabilized soils were contaminated with sulfate solutions of 5,000, 10,000, and 20,000 ppm for a period of 30 days before evaluating the volume change and strength properties. The current study reveals that the performance of the sulfate-resistant cement-stabilized specimens cured for long periods (28 days) was better than the lime-stabilized expansive soil in terms of the strength.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Expansive soils occur in abundance in south India. As such these soils are very difficult to work with due to their inherent potential to swell when they are exposed to moisture. Hence, the need to stabilize this type of soils arises. In general, these soils are stabilized with the help mechanical, chemical, or structural modification of the soil [1]. Of the methods available for stabilization, the chemical stabilization is the fast, efficient, and reliable method of stabilization for ground improvement. Of the various chemical stabilizers used, lime is one of the most popular methods of stabilization for expansive soils owing to its ready availability and need for the less-skilled workforce for the stabilization projects [2,3,4]. Based on the literature available, the lime stabilization of the expansive soil is deemed reliable as long as the soil is not contaminated with sulfate salts. The availability of sulfate salts renders the lime-stabilized expansive soil ineffective by the formation of ettringite and thaumasite [5,6,7], whereas the studies on the post stabilization attack with sulfate on the lime-stabilized expansive soil are limited. Hence, this study aims at understanding the behavior of lime and sulfate-resistant cement-stabilized expansive soil attacked with external sulfate solution. The results of lime and cement-stabilized expansive soils are also compared.

2 Materials

Expansive soil used for the current study is obtained near the outskirts of Solagampatti, Thiruchirapalli, Tamil Nadu, India, from a depth of 2 m below the ground surface. The expansive soil thus obtained was spread over a tarpaulin sheet for air-dring and made to pass through a 4.75 mm sieve to retain the coarse fraction, following which the processed soil was pulverized and made to pass through a 425 μm sieve. This processed expansive soil was kept in airtight plastic bins and utilized for the current study. Based on the unified soil classification system, the expansive soil used in the current study is classified as fat clays or inorganic clay of high compressibility. Determination of initial consumption of lime (ICL) was carried out following the Eades and Grim [8] protocol, by which the ICL value was determined to be 3.5%. The cement used for the current study was Type V sulfate-resistant cement [9].

The chemicals used in the current study were laboratory grade sodium sulfate (Na2SO4) and hydrated lime (CaOH2) with a purity of 99% and 90%, respectively. Among the sulfate salts available, sodium sulfate was selected as the contaminating solution due to its highest solubility in water (49.7 mg/100 ml) in comparison with all other sulfate salts.

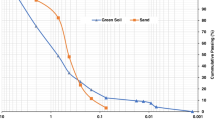

3 Representative Expansive Soil Properties

The following properties such as physicochemical properties (pH and electrical conductivity), index properties (Atterberg limits), initial consumption of lime (ICL), grain size distribution, specific gravity (GS), differential free swell index (DFSI), and standard Proctor compaction characteristics were determined following the Indian standards (IS), and the experimental results are given in Table 1.

4 Testing Procedure

4.1 Unconfined Compression Tests

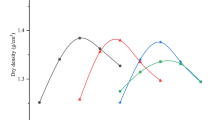

The soil specimens of 38 mm diameter and 76 mm height were used for unconfined compression tests. A measured quantity of 143.13 g of expansive soil, having a natural water content of 6.51%, was added with the desired quantity of stabilizer (i.e., 3.5% lime by dry weight/ 10% sulfate-resistant cement (SRC)) and water and statically compacted at the OMC to the corresponding MDD of the expansive soil. The mixtures were stored in airtight polythene bags and stored for curing in moisture-controlled desiccators. After the desired period of curing (1, 7, and 28 days), the stabilized soil specimens were carefully transferred into a sand bath of size 170 mm diameter and 300 mm in height. A single sand bath container can hold four identical specimens. The arrangement of the specimens inside the sand bath was made such that sufficient clearance was provided between specimens to deter the interaction between specimens. The procedure for the placement of the specimens is as follows. First, a thin layer of 10 mm thick fine clear sand was spread, on top of which the specimens were placed, providing a minimum clearance of 35 mm between each specimen. This was followed by filling up of the void space between the specimens with the clean fine sand. The clean sand was filled up to a height of 20 mm above the specimens. The specimens were then loaded with a surcharge of 6.25 kPa, and the sand bath was flooded with distilled water or sulfate contaminant (of 5,000, 10,000, and 20,000 ppm). Separate containers were used for flooding with distilled water and sulfate contaminant of different concentration. This setup was left undisturbed for a period of 30 days, after which the specimens were carefully removed out and tested at a strain rate of 0.625 mm/min.

4.2 Oedometer Swell Tests

A measured quantity of 146.72 g of expansive soil with a natural water content of 6.51% was added with the desired quantity of stabilizer (3.5% lime or 10% sulfate-resistant cement), and then, the soil-stabilizer mix was mixed with the required quantity of water to bring the water content up to the OMC value. The soil-stabilizer mix was compacted to achieve a size of 75 mm diameter and 30 mm height in oedometer rings to the predetermined maximum density of the soil (1.637 Mg/m3) in a single layer of 20 ± 0.5 mm thickness. These compacted specimens were wrapped with a cling film so as to maintain the moisture content of the compacted soil specimens and are stored in desiccators for various curing periods of 1, 7, and 28 days. After the desired period of curing, the treated soil specimens were carefully transferred into oedometer test assemblies. The separate oedometer cells were filled with distilled water and sulfate solutions of desired concentration. After which, the swell measurements were monitored with time through a dial gauge assembly.

5 Results and Discussion

5.1 Unconfined Compressive Strength (UCS)

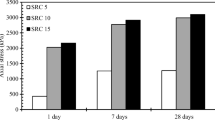

Figures 1a, 2a, and 3a highlight the effect of sulfate contamination on stress–strain plots of lime-stabilized soil specimens cured for 1, 7, and 28 days, respectively. The UCS of uncontaminated lime-stabilized specimens increased with curing period. This improvement in UCS is due to the admixed lime to the expansive soil, which increases its pH value, thus resulting in the silica (Si) and alumina (Al) ions dissolution in the clay lattice [10, 11], which aids in the development of different cementitious gels such as calcium silicate hydrate (CSH) and calcium aluminate hydrate (CAH) gels. These cementitious gels that are formed within the clay lattice cement them together. This cementation of the soil improves the strength of lime-stabilized soils [8, 11,12,13,14]. The strength of lime-stabilized specimens decreased upon sulfate contamination, and the lime-stabilized specimens cured for 7–28 days showed a significant reduction in strength. The reduction in UCS values of the lime-stabilized specimens cured for longer duration (7–28 days) is attributed to the decrease in pH upon the addition of sulfate solution, which in turn resulted in the leaching out of Ca ions from the cemented soil–lime mix.

Similarly, Figs. 1b, 2b, and 3b highlight the effect of sulfate contamination on stress–strain plots of sulfate-resistant cement-stabilized soil specimens cured for 1, 7, and 28 days, respectively. From the figures, it is clear that the strength of SRC stabilized soil specimens increased with the curing period similar to that of the lime-stabilized specimens. However, the sulfate contamination decreased the strength of SRC stabilized specimens, and the decrease is significant for specimens cured for 1 and 7 days. The reduction in strength is negligible for specimens cured for long duration (28 days), which points that the reduction in the pH upon sulfate contamination is not significant enough to deter the cementation reactions occurring in the SRC stabilized specimens.

5.2 Swell Potential

Figures 4a, 5a, and 6a highlight the effect of sulfate contamination on the swell potential of lime-stabilized soil cured for 1, 7, and 28 days, respectively. The ion exchange process and the development of CSH and CAH cementation compounds in the 3.5% lime-stabilized soil and cured for 28 days decreased the swell potential from 33.2% to 0.15%. However, the specimens contaminated wtih sulfate contaminant of 20,000 ppm showed a compressive strain during the initial period, the compressive strain was leveled out after a long period of time. The initial compression of the soil may have been due to the difference in the osmotic gradient between the soil and the solution which might have been equaled out by the decrease in the matrix suction produced within the soil during the long period of curing. However, in the soils treated with SRC, there was no initial compression in the soil (Figs. 4b, 5b, and 6b). The soils cured for longer duration showed improved resistance to swelling.

6 Summary and Conclusions

Both the lime and SRC stabilized expansive soil exhibited improved resistance to the swelling and improved the unconfined compressive strength. The resistance to swelling and the strength increment was proportional with the curing period. Both lime and SRC stabilized expansive soil did not change their swelling characteristics even after 30 days of interaction with 20,000 ppm sodium sulfate solution, suggesting that the intrusion of the sulfate after the stabilization of the expansive soil will not have much effect on the swelling behavior of the stabilized soil cured up to 28 days. However, the decrease in strength of lime-stabilized expansive soil is considerable, suggesting that a long-term investigation is needed to completely understand the sulfate contamination and its effects on the lime and SRC stabilized expansive soil.

References

Hausmann MR (1990) Engineering principles of ground modification. McGraw-Hill, New York

Diamond S, Kinter EB (1965) Mechanism of soil-lime stabilization. Bureau of public roads, U.S

Diamond S (1996) Delayed ettringite formation-processes and problems. Cement Concrete Compos

Osinubi KJ, Nwaiwu CMO (2006) Compaction delay effects on properties of lime-treated soil. J Mater Civ Eng 18:250–258

Hunter D (1988) Lime-induced heave in sulfate-bearing clay soils. J Geotech Eng 114(2):150–167

Puppala AJ, Griffin JA, Hoyos LR, Chomtid S (2004) Studies on sulfate-resistant cement stabilization methods to address sulfate-induced soil heave. J Geotech Geoenviron Eng 130:391–402

Mccarthy M, Csetenyi LJ, Sachdeva A, Dhir RK (2012) Identifying the role of fly ash properties for minimizing sulfate-heave in lime-stabilized soils. Fuel 92(1):27–36

Eades JL, Grim RE (1996) A quick test to determine lime requirements for lime stabilization. highway research board. National Research Council, Washington DC 139, 61–72

Raja PSK, Thyagaraj T (2019) Effect of sulfate contamination on compaction and strength behavior of lime treated expansive soil. In: McCartney, John S, Hoyos LR (eds) Recent advancements on expansive soils. Proceedings of the 2nd GeoMEast international congress and exhibition on sustainable civil infrastructures 2018. Springer, Switzerland, . pp. 15–28

Boardman DI, Glendinning S, Rogers CDF (2001) Development of stabilisation and solidification in lime-clay mixes. Geotechnique 50(6):533–543

Barker JE, Rogers CD, Boardman DI (2006) Physio-chemical changes in clay caused by ion migration from lime piles. J Mater Civil Eng 18(2):182–189

Rajasekaran G, Narasimha Rao S (1990) Lime stabilization technique for the improvement of marine clay. Soils Foundations, Japan 37:97–104

Thyagaraj T, Zondinsanga S (2014) Swell-shrink behavior of lime precipitation treated soil. Ground Improvement 167(14):260–273

Diamond S, White JL, Dolch WL (1963) Transformation of clay minerals by calcium hydroxide attack. Joint Highway Research Project, Purdue University, Lafayette, Indiana31

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Raja, P.S.K., Thyagaraj, T. (2022). Sulfate Effects on Lime and Sulfate-Resistant Cement-Stabilized Expansive Soil. In: Dey, A.K., Mandal, J.J., Manna, B. (eds) Proceedings of the 7th Indian Young Geotechnical Engineers Conference. IYGEC 2019. Lecture Notes in Civil Engineering, vol 195. Springer, Singapore. https://doi.org/10.1007/978-981-16-6456-4_14

Download citation

DOI: https://doi.org/10.1007/978-981-16-6456-4_14

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6455-7

Online ISBN: 978-981-16-6456-4

eBook Packages: EngineeringEngineering (R0)