Abstract

Even though the effectiveness of sulfate-resistant cement (SRC) in stabilizing the high sulfate-bearing expansive soils is proven, its effectiveness in controlling the volume change of expansive soils when exposed to external sulfate contaminants is not known. The physico-chemical and index properties provide basic insight into the volume change behavior of clays. Therefore, this study brings out the effect of external sulfate contamination on the physico-chemical and index properties of SRC-treated expansive soil. Three SRC contents of 5, 10, and 15% were added to the expansive soil separately and reconstituted with distilled water and cured for 1–28 days. After the desired curing period, the SRC-treated expansive soil was reconstituted with sulfate solutions of 5000, 10,000, and 20,000 ppm separately and moisture equilibrated for 1 day for the determination of the properties. The experimental results showed that the SRC treatment increased the pH from 8.75 to 11.95–12.21 and the subsequent sulfate contamination decreased the pH to 9.33–11, where the decalcification of calcium silicate hydrate occurred. Further, the effect of sulfate contamination on liquid limit of SRC-treated soil was negligible, while the plastic and shrinkage limits increased upon sulfate contamination. The increase in the shrinkage limit is attributed to the formation of ettringite/thaumasite in the voids of SRC-treated samples contaminated with 10,000–20,000 ppm sulfate solutions, whereas the monosulfate formation and destruction of cementation gels occurred in samples contaminated with 5000 ppm. These formations are evidenced with the scanning electron microscopy, energy dispersive X-ray analysis, and X-ray diffraction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Owing to the rapid urbanization, the infrastructure and commercial establishments need to be constructed even in areas found with problematic soils such as expansive soils. These soils contain montmorillonite as the principal mineral group, which exhibits high swell-shrink volume changes with variation in the moisture content. Suitably, many methods such as material replacement, vertical barrier usage, prewetting, and chemical treatment are engaged to improve the volumetric and strength behavior of these soils (Puppala et al. 2004; Sivapullaiah et al. 2004; Little and Nair 2009; Khemissa and Mahamedi 2014). Cement treatment is one of the economic, efficient, and environmentally amicable methods. Cement treatment helps in improving the engineering properties of foundation soils for lightly loaded buildings, road embankments, earth dams, canal levees, etc. (Bell 1993; Nunes et al. 1996; Jullien et al. 2012; Kitazume and Terashi 2013; Ho et al. 2017). However, both sulfates present in the natural soils such as gypsiferous soils and the external contamination of natural soils with sulfates from the surrounding environment may result in the formation of ettringite or thaumasite in the cement-treated soils. This deteriorates the cement-treated soils by decreasing the volume stability; i.e., the swell-shrink volume changes increase (Krause 1976; Mitchell 1986; Hunter 1988; Dermatas 1995; Rajasekaran 2005; Little et al. 2010; Orejarena and Fall 2010; Seif 2015; Abdi et al. 2019; Hou et al. 2019; Raja and Thyagaraj 2019a).

The naturally occurring sulfates in soils can be identified prior to the treatment of the soils and therefore suitable alternative treatment methods can be employed for stabilizing the expansive soils, whereas the sulfate contamination from the surrounding environment occurs after the treatment of natural soils through various means, e.g., the industrial effluents. The industrial effluents contain high concentrations of sulfates, chlorides, and heavy metals. Of these compounds, sulfate is proven to be hazardous for the chemical stabilization of expansive soils. The literature shows that the concentration of sulfate ions in the chemical industrial effluents ranges between 12,500 and 35,000 mg/L (Silva et al. 2002). Further, the concentration of sulfate in other sources such as municipal wastewater and seawater can also reach to the levels that are detrimental to the stabilized expansive soils (Canfield and Farquhar 2009; Van Den Brand et al. 2015). The most probable sulfate contamination occurs from the secondary sulfate contamination in mine wastes, tailing dumps, and outcrops; wherein the sulfate is derived from the oxidative weathering of the sulfide-bearing metamorphic rocks (Alpers et al. 2000). The dissolution of sulfate from these metamorphic rock outcrops results in the formation of leachate. Generally, the sulfate concentrations in the leachate are in excess of 1000 ppm (Hammarstorm et al. 2005). This leachate reduces the pH and increases the specific conductance of surface water and groundwater.

The event of sulfate contamination of cement-treated expansive soils through groundwater or surface water during the service life of treated expansive soils is not farfetched. In view of this, the research studies carried out by Cordon (Cordon 1961) showed that the resistance of type V cement to the external sulfate attack was better than the type I cement. The recent study by Puppala (2003, 2004, 2018) demonstrated that the low calcium-based stabilizers like fly ash and sulfate-resistant cement (SRC) have improved resistance to swelling and shrinkage when the expansive soils contain sulfate contents up to 30,000 ppm. However, the efficiency of low calcium-based stabilizers in stabilizing the expansive soils that are subjected to external sulfate contamination is not explored in detail and needs examination. Such studies with an external source of sulfate contamination are essential as the soluble sulfate concentrations are much higher and readily available for reactions in comparison with the naturally occurring sulfate salt. The sulfate salts, in general, exist as small pockets in natural soil deposits which form the nucleation site for ettringite formation, whereas the availability of soluble sulfates is not restrained in case of stabilized soils contaminated through external sulfate sources, which leads to increased soil disruption through ettringite formation. Further, the external sulfate solutions decrease the pH of the treated soils and favor the inhibition of pozzolanic reactions, which facilitates the leaching of calcium ions from the cemented matrix (Le Roux 1969; Le Roux and Toubeau 1987; Locat et al. 1990). Due to the reasons discussed above, the intrusion of external sulfate into the stabilized soils can cause more distress in comparison with the naturally occurring sulfate salts, which results in deterioration of the treated soils. Therefore, it becomes essential to understand the effect of external sulfate contamination on the treated soils.

Puppala et al. (2003) found that the sulfate-resistant type V cement was the most effective stabilizer in stabilizing the sulfate containing soils in comparison with other stabilizers—class F fly ash, ground-granulated blast-furnace slag, and lime combined with fibrillated polypropylene fibers. However, the tests were carried out on compacted specimens cured for 14 days only and the effect of long-term sulfate contamination on SRC-treated expansive soils is not explored. Moreover, the ettringite formation is also restricted in the short duration as the inundation of compacted specimens with sulfate solution does not provide favorable conditions, such as availability of essential Ca2+, Si, and (SO4)2− ions and moisture, for the maximum formation of ettringite. Therefore, an effort is made in the present laboratory study to mimic the best possible condition for the maximum formation of ettringite that can be anticipated in the field. This is achieved by remolding the SRC-treated expansive soil with a moisture content of 1.15 times the liquid limit value using sulfate solutions of 5000, 10,000, and 20,000 ppm concentrations, separately. Three SRC contents and three different curing periods were adopted for this study.

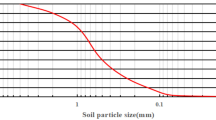

Materials

The expansive clay from Solgampatti village, located to the east of Tiruchirapalli, India, was collected for the present study. The air-dried soil was pulverized and passed through 425-μm sieve and then stored in airtight plastic bins for use in the present study. The particle size analysis showed that the fines content is 76%. The soil specific gravity of the soil was found to be 2.75. The liquid, plastic, and shrinkage limits were found to be 95%, 22%, and 7.5%, respectively. Based on the Unified Soil Classification System (USCS), the soil is classified as inorganic clay of high compressibility (CH). The pH and conductivity were found to be 8.75 and 1.06 mS/cm, respectively. The maximum dry unit weight and optimum moisture content of the soil were found to be 15.3 kN/m3 and 23%, respectively. X-ray diffraction (XRD) pattern of clay fraction is characterized with the montmorillonite peaks at 6.2°, 20.5°, and 60° devoid of other clay minerals, following these peaks, the quartz peaks are found at 26.45°, 59.9°, and 68.15°. X’pert highscore software was used for the semi-quantitative analysis of the XRD spectra, which showed that the clay consists of montmorillonite and quartz in the proportions of 68% and 32%, respectively. The basic properties of the expansive soil are tabulated in Table 1.

The sulfate-resistant Portland cement was used in this study and it is hereafter called as sulfate-resistant cement, which consists of 3% C3A content and 1% magnesia and deleterious content. The laboratory grade sodium sulfate (Na2SO4) of 99% purity was used for preparing contaminant solutions in this study.

Experimental program

Sample preparation

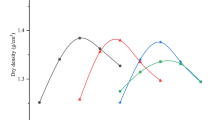

The optimum SRC content was determined based on the unconfined compressive strength (UCS) of SRC-treated expansive soil specimens cured for different periods. The UCS tests were conducted on compacted cylindrical specimens of 38 mm × 76 mm size. The expansive soil mixed with different SRC contents were compacted to their maximum dry density at the corresponding optimum moisture content. Then, the compacted specimens were cured in desiccators for the desired periods of 1, 7, and 28 days. After the desired curing period, the UCS of compacted specimens was determined using a constant strain rate of 0.625 mm/min. Figure 1 presents the variation of UCS with SRC content at different curing periods. From Fig. 1, it can be seen that the increase in UCS of SRC-treated expansive soil is marked up to SRC content of 10%, and above this SRC content, the increase in UCS is negligible at all the curing periods, and thus, the SRC content of 10% can be taken as the optimum SRC content for the expansive soil. Therefore, three SRC contents were used in the present study, namely, 10% corresponding to optimum SRC content, and 5% and 15% corresponding to optimum SRC content − 5% and optimum SRC content + 5%. The air-dried natural soil was mixed thoroughly with the required amount of SRC to yield the desired SRC content on a dry weight basis (5%/10%/15%). The expansive soil-SRC mixtures were reconstituted with distilled water and sodium sulfate solutions of 5000, 10,000, and 20,000 ppm (0.042 M, 0.083 M, and 0.166 M), which are hereafter referred in this paper as DW, S5, S10, and S20, respectively. Sodium sulfate was selected as the contaminating fluid as it has the maximum solubility in water (49.7 mg/100 mL) and sodium sulfate is known for causing both physical sulfate attack (PSA) in combination with chemical sulfate attack (CSA). Hence, the sodium sulfate represents the worst-case scenario that can be experienced by any cement-stabilized expansive soil (Skalny et al. 2003; Haynes and Bassuoni 2011; Bassuoni and Rahman 2016; Bezerra and Azeredo 2019).

Physico-chemical and index properties

About 250 g of natural expansive soil was dry mixed thoroughly with SRC contents of 5, 10, and 15%, separately. Then, the desired quantity of distilled water was added to these expansive soil-SRC mixtures so as to attain a water content of 1.15 times the liquid limit value and thoroughly mixed with the help of spatulas to attain a uniform consistency. As mentioned earlier, three SRC contents and three different curing periods were adopted for this study. These remolded samples were then placed in ziplock polythene bags and cured in desiccators for different curing periods of 1, 7, and 28 days, separately.

At the end of the desired curing periods, the samples were reconstituted with sulfate solutions of 5000, 10,000, and 20,000 ppm separately. Enough care was taken during the addition of sulfate solutions to ensure that the concentration/molarity across all identical soil-SRC mixtures was maintained constant. Then, the sulfate-contaminated expansive soil-SRC mixtures were moisture equilibrate in desiccators for a duration of 24 h, after which the samples were used for the determination of the physico-chemical and index properties according to the procedures given below.

The cone penetration method was adopted for the determination of liquid limit and the plastic limit was determined using the standard thread-rolling method. The mercury displacement method was used for the determination of the shrinkage limit. For the determination of pH and electrical conductivity, the soil samples were oven-dried at 45 °C for 24 h. These samples were then pulverized and passed through 425-μm sieve for obtaining 30 g of representative samples. Seventy-five milliliters of distilled water was added to the 30 g of soil for maintaining the soil-water ratio of 1:2.5 for determination of both pH and electrical conductivity. All the tests were carried out at a room temperature of 28 ± 2 °C and the average value of three determinations are reported here.

Scanning electron microscopic studies

The microstructural studies were carried out at remolded state on natural expansive soil and SRC-treated expansive soil with and without sulfate contamination using Thermo Fisher Quanta 400. A portion of these remolded samples was placed in molds of 40-mm diameter and 30 mm height and then, the molds were tapped on a hard rubber base for removing any entrapped air. Then, the brass tube samplers of 10-mm diameter and 40 mm height were pushed into these molds and the samples were collected with the help of an ejector. These samples were stored in paraffin wax-sealed glass containers and the glass containers were in turn freeze stored for lyophilization. Lyophilization was performed so as to maintain the soil fabric intact.

Mineralogical studies

The XRD analysis was carried out on untreated expansive soil and selected expansive soil-SRC mixtures with and without sulfate contamination. These samples were grounded, sieved through 75-μm sieve, and glycolated before placing them on clean glass slides. The glass slides were then mounted on a Bruker AXS-D8-Discover X-ray diffractometer and the XRD patterns were obtained using a Cu Kα radiation of wavelength (λ) of 1.5148 Å. X-ray tube with an input voltage of 30 kV and a current of 30 mA. The samples were scanned from 5 to 90° with a continuous scan speed of 1°/min. The X’pert highscore software was used for recording and analyzing the data. The presence of clay minerals, ettringite, and cementitious compounds in the soil samples were obtained through the peak angle analysis of the recorded pattern.

Results and discussion

Physico-chemical properties of SRC-treated expansive soil

Before sulfate contamination

The effect of sulfate contamination on pH and electrical conductivity of SRC-treated expansive soil cured for 1, 7, and 28 days is brought out in Figs. 2a, 3a, and 4a, respectively. The pH of 1 day cured SRC-treated expansive soil increased from an untreated value of 8.75 to 12.21 for a SRC content of 15%. This rapid increase in the pH of the soil upon addition of SRC can be related to the hydration of the cement. This, in turn, results in the crowding of Ca2+ ions around the clay particles, thereby changing the structure of the clay-cement mixture (Chew et al. 2004). Similarly, the electrical conductivity of 15% SRC-treated soil cured for 1 day increased from an untreated value of 1.06 to 2.57 mS/cm. The above increase in pH is conducive for the cement hydration and dissolution of silica and alumina from the clay lattice and results in the formation of new cementation compounds such as calcium silicate hydrate (CSH) and calcium aluminate hydrate (CAH) gel formation. This formation of CSH and CAH can be confirmed through the SEM and EDAX analysis performed on the untreated and SRC-treated expansive soil (Figs. 5a–c and 6a, b). From Figs. 5a–c and 6a, b, it can be observed that the untreated soil has the Ca2+ ions content of 1.2% by weight, while the expansive soil treated with 10% SRC content increased to 10.4%. From the data in Figs. 2a, 3a, and 4a, the variation of pH and electrical conductivity with curing period are re-plotted in Figs. 7a and b, 8a and b, and 9a and b for SRC content of 5%, 10%, and 15%, respectively. It is evident from Figs. 7, 8, and 9 that for a particular SRC content of 15%, the pH and electrical conductivity decreased from 12.21 to 11.06 and 2.57 to 1.98 mS/cm, respectively, upon increasing the curing period from 1 to 28 days. This decrease in pH is due to the formation of new cementation gels and pozzolanic reactions occurring in the treated soil. The cementation formations can be visualized from the SEM and EDAX analysis provided in Fig. 6a and b.

After sulfate contamination

The pH reduced with the sulfate contamination and the reduction decreases with the increase in the SRC content and curing period (Figs. 7a, 8a, and 9a). In general, at any given SRC content, the reduction in pH increased with the increase in the concentration of the sulfate contaminant which is attributed to the neutral pH value (7) of the sulfate contaminant. Upon addition of 20,000 ppm sulfate contaminant, the pH of 15% SRC-treated expansive soil cured for 1 day reduced from 12.21 to 10.05, while it reduced from 11.06 to 11 for the 28-day cured sample, which is negligible in comparison with the reduction in 1-day cured sample. Even though the reduction in pH is negligible for sample treated with 15% SRC content and cured for 28 days, the pH value of 11 is still conducive for the decalcification of the CSH formed. Revertegat et al. (1992) reported that the degradation of portlandite starts at a pH of 11.5 along with the decalcification of the CSH, which occurs progressively upon further reduction of pH because of sulfate addition. Hence, the decrease in pH destabilizes the CSH and CAH formed in the soil-cement mixtures. The above degradation can also be visualized with the help of SEM images which is discussed in the subsequent section. Furthermore, the pH of 5% SRC-treated expansive soil cured for 1 day decreased to 9.53 from 11.95 upon contamination with 20,000 ppm sulfate solution, which also inhibits the formation of CSH and CAH even within the short duration of contact (1 day) with sulfate contaminant. Similar behavior was observed in expansive soils stabilized with calcium-based stabilizers (e.g., lime) upon sulfate contamination (Revertegat et al. 1992; Šiler et al. 2016; Raja and Thyagaraj 2019a, b).

The contamination of the SRC-treated expansive soil with sulfate solutions resulted in an increase in the electrical conductivity of the soil-cement-sulfate mixtures. This increase in electrical conductivity is related to the increase in free ion concentration due to the addition of salt solution as pore fluid. Also, the destabilization or degradation of portlandite and CSH gel releases the free exchangeable Ca2+ ions into the soil matrix. This will contribute to the increase in electrical conductivity. From Figs. 7b, 8b, and 9b, it is clear that with an increase in the curing period, the electrical conductivity of the expansive soil-SRC mixtures reduced by a marginal amount upon contamination with sulfate for a short contact period of 1 day. The long-term effects of the sulfate contamination on the SRC-treated soil need investigation.

Index properties

Before sulfate contamination

Figures 2 b–d, 3 b–d, and 4 b–d bring out the effect of sulfate contamination on liquid, plastic, and shrinkage limits of SRC-treated expansive soil cured for 1, 7, and 28 days, respectively. The liquid limit of 5% uncontaminated SRC-treated expansive soil cured for 1, 7, and 28 days decreased marginally to 87%, 91.5%, and 91% in comparison with the liquid limit of natural expansive soil (95%). The decrease in the liquid limit is due to the ion-exchange reactions between the soil and Ca2+ ions produced from the hydration of cement. With further increase in the cement content to 10 and 15%, the liquid limit of the SRC-treated soil increased to 90–94 and 93–96%, respectively. Mahedi et al. (2018) reported a decrease in the liquid limit with the increase in cement content using various types of cements for soils collected from Austin and San Antonio. In contrast, Al-Rawas et al. (2002), Al-Rawas et al. (2004), and Bayat et al. (2013) reported that the liquid limit of cement-treated expansive soil reconstituted with distilled water increased with the increase in cement content. Based on the present research, it can be stated that the liquid limit decreases upon initial addition of cement content up to optimum content and beyond which the liquid limit increases to values higher than the liquid limit of the untreated expansive soil. This increase in the liquid limit can be attributed to the increase in the fines content imparted by the unreacted excess cement particles present in the expansive soil-SRC mixtures. This behavior is similar to the behavior of soil-lime mixtures.

From Fig. 2d, it is evident that the shrinkage limit of expansive soil reconstituted with distilled water increased from 7.5 to 30% for an addition of 15% SRC content and cured for 1 day. The shrinkage limit of cement-treated soils increases due to the formation of cementation gels and aggregation of clay particles in case of samples cured for short term (1 day), while in samples cured for long term (i.e., 7 and 28 days), the increase in shrinkage limit is related to the formation of crystalline CSH and CAH. This is evidenced with the help of the SEM images of SRC-treated soil as discussed in the subsequent sections. The aggregation/cementation of the clay particles results in the conversion of clay particles to silt-sized particles, thereby changing the plasticity characteristics of SRC-treated expansive soil and making the soil more friable. This is depicted in the Casagrande’s plasticity chart as shown in Fig. 10a–c. The SRC treatment altered the high compressible clay (CH) to low compressible silt (ML).

Effect of sulfate contamination on plasticity characteristics of SRC-treated expansive soil depicted in Casagrande’s plasticity chart for SRC contents of a 5%, b 10%, and c 15%. US, untreated expansive soil; D, days (data points move from left to right with the curing period for SRC-treated soil upon sulfate contamination)

After sulfate contamination

The addition of sulfate to the SRC-treated expansive soil resulted in complex reactions between the cementation products and the sulfate contaminant, which resulted in a marginal increase in the liquid limit of soils treated with SRC contents of above 10% (Figs. 2b, 3b, and 4b). The liquid limit of 15% SRC-treated expansive soil cured for 1 day, upon contamination with 20,000 ppm sulfate solution increased to 97% from uncontaminated value of 93% (Fig. 2b). This is attributed to the hydration of cement along with the formation of ettringite which can hold a higher amount of water, resulting in the increased liquid limit values of the contaminated soils. While for the expansive soil treated with 5% SRC content and cured for 28 days, upon sulfate contamination with 20,000 ppm, the liquid limit decreased from uncontaminated value of 91 to 89% (Fig. 4b). The plastic limit of the SRC-treated soil cured for 1–28 days increased with the increase in the sulfate concentration, resulting in an overall decrease in plasticity index of the SRC-treated soil contaminated with sulfate solutions (Figs. 2c, 3c, and 4c).

Upon sulfate contamination, the shrinkage limit of 10 and 15% SRC-treated expansive soil further increased, while the sulfate contamination had a negligible effect on the shrinkage limit of 5% SRC-treated soil (Figs. 2d, 3d, and 4d). The above increase in the shrinkage limit can be related to the formation of ettringite in the voids of 10 and 15% SRC-treated soil contaminated with sulfate. This can be clearly seen in the marked rectangular box in Fig. 11a, where the small ettringite needles can be seen developing from the CSH into the surrounding void space, thereby increasing the shrinkage limit of the sulfate-contaminated SRC-treated expansive soil. This increase in the shrinkage limit indicates the volume stability of the soils and thus, the ettringite formation in this case appears to be beneficial. Even though the short contamination period with sulfate appears to be beneficial for SRC-treated expansive soil, the effect of long-term sulfate contamination and durability during seasonal moisture fluctuations needs further investigation. Furthermore, the changes in the plasticity characteristics of SRC-treated expansive soil contaminated with sulfate are depicted in the Casagrande’s plasticity chart shown in Fig. 10a–c. Contamination of SRC-treated expansive soil with sulfate solutions changed the soil from the low compressible silt (ML) to high compressible silt (MH) (Fig. 10a–c). The above transformation from the low compressible silt to high compressible silt is due to the destruction of the cementation compounds formed in the SRC-treated soil, which leads to the strength loss and volume instability in the long run.

SEM micrographs of 15% SRC-treated expansive soil cured for 28 days and subsequently contaminated with a 10,000 ppm sulfate solution (magnification: 6000×), b 20,000 ppm sulfate solution (magnification: 40,000×); c EDAX corresponding to micrograph presented in a, and d EDAX corresponding to micrograph presented in b

Microstructural analysis

Figure 12 a–c show the micrographs of expansive soil treated with 5%, 10%, and 15% SRC, respectively. The EDAX corresponding to Fig. 12c is presented in Fig. 12d. The formation of different phases of CSH can be seen in Fig. 12, which is in accordance with the SRC content. The quantity of CSH gel formed increased with the increase in the SRC content. The crystallization of thin elongated, needle-like CSH crystals from the gel-form can be seen in the rectangular boxes marked in Fig. 12b and c. Similar observations were made by Raja and Thyagaraj (2019b) and Sante et al. (2014) on the lime-stabilized soils cured under saturated condition. From Fig. 12a and b, it is evident that the CSH crystallization also increased with the increase in SRC content, and the EDAX analysis presented in Figs. 12d and 13d also confirms the same. However, the quality of crystallized CSH depended on the SRC content in the treated expansive soil. Hence, the crystallization of CSH gel depends on the moisture content, curing period, and SRC content in the soil.

SEM micrographs of SRC-treated expansive soil: a with 5% SRC content and cured for 1 day, b with 10% SRC content and cured for 1 day, c with 15% SRC content and cured for 1 day, d EDAX corresponding to micrograph presented in c, e with 5% SRC content and cured for 7 days and subsequently contaminated with 5000 ppm sulfate solution, f with 10% SRC content and cured for 7 days and subsequently contaminated with 5000 ppm sulfate solution, g with 15% SRC content and cured for 7 days and subsequently contaminated with 5000 ppm sulfate solution, and h EDAX corresponding to micrograph presented in g

Figure 12 e–h brings out the effect of sulfate contamination on the SRC-treated expansive soil. Upon sulfate contamination with 5000 ppm solution, the CSH gels, which were formed due to the SRC treatment of expansive soil, disintegrated, and the aggregation of the soil particles along with the formation of monosulfate platelets can be observed in the micrographs. The EDAX elemental analysis presented in Fig. 12d and h indicates the decalcification of the SRC-treated expansive soil, wherein the weight percentage of Ca2+ ions decreased from a value of 15.5 to 10% due to sulfate contamination. The above formation of monosulfates and the disintegration of the cementitious bonds results in a decrease in volume stability along with an increase in the plasticity characteristics of the SRC-treated expansive soil. While contamination of SRC-treated expansive soil with sulfate solutions of 10,000 and 20,000 ppm, the ettringite and thaumasite formation can be observed in the soil fabric (Fig. 11a and b). The EDAX analysis presented in Fig. 11c and d also confirms the formation of ettringite and thaumasite.

From the above discussion, it can be concluded that the monosulfate formation occurs when the available sulfate ions are lower than the amount of readily available reactive alumina in the soil fabric (i.e., with the use of 5000 ppm sulfate solutions). However, more stable phases of ettringite are formed in SRC-treated expansive soil in the presence of excess sulfate ions in the soil fabric (i.e., with the use of sulfate solutions greater than 10,000 ppm) (Dermatas 1995). Thus, it can be concluded that the presence of CSH crystals acts as a precursor for the formation of ettringite and thaumasite in the soil fabric.

XRD analysis

The X-ray diffraction patterns of the untreated expansive soil, 5% and 15% SRC-treated expansive soil, and 15% SRC-treated expansive soil contaminated with 5000 and 20,000 ppm sulfate solutions are presented in Fig. 14a–e, respectively. As discussed earlier, Fig. 14a shows the broad peak at 6.2° for the untreated expansive soil which confirms the presence of montmorillonite mineral. The X-ray diffraction patterns of the 5% and 15% SRC-treated expansive soil clearly show the suppression of the montmorillonite peak intensities (Fig. 14b and c). Further, Fig. 14b and c show the peaks at 29.75° and 50.45° which confirm the formation of calcium silicate hydrate (CSH) and calcium aluminate silicate hydrate (CASH) in 5% and 15% SRC-treated expansive soil, respectively, indicating the occurrence of pozzolanic reactions in the SRC-treated expansive soil.

The appearance of the new peaks at 10.85° and 8.45°, 14.65°, and 20.15° in the 15% SRC-treated expansive soil contaminated with 5000 and 20,000 ppm sulfate solutions, respectively, confirms the formation of monosulfates in the samples contaminated with 5000 ppm solution and formation ettringite/thaumasite in the samples contaminated with 20,000 ppm solution (Fig. 14d and e). This is also accompanied by the complete destruction of the montmorillonite peaks. Even though the sulfate contamination of SRC-treated expansive soil resulted in complete suppression of montmorillonite peaks, the ettringite/thaumasite compounds indicate the large volume change potentials which are evidenced by the deterioration in plasticity characteristics as discussed in previous sections.

Conclusions

The pH and electrical conductivity of SRC-treated expansive soil increased with the increase in SRC content and decreased with the increase in curing period at all SRC contents. This is due to the formation of cementation gels and pozzolanic reactions in the SRC-treated expansive soil. Upon sulfate contamination, the pH of the SRC-treated expansive soil decreased with the increase in sulfate concentration, whereas the electrical conductivity increased. This decrease in pH led to the decalcification of the CSH compound formed and destroyed the cementation gels formed due to the SRC treatment. However, the pH of the SRC-treated expansive soil cured for different periods, upon sulfate contamination, increased with the increase in the curing period except for 5% SRC-treated soil, whereas the electrical conductivity decreased marginally with curing period.

Addition of 5% SRC to expansive soil resulted in the maximum decrease in the liquid limit with respect to the untreated value and beyond this SRC content, the liquid limit increased, whereas the plastic and shrinkage limits of SRC-treated expansive soil increased with the SRC content, resulting in a decrease in the plasticity index. This improvement is mainly attributed to strong cement hydration reactions and formation of cementation compounds such as CSH and CAH in SRC-treated expansive soil. The high shrinkage limit values show the improvement in volume stability (i.e., lower volume reduction) upon drying. The microstructural analysis using EDAX and mineralogical analysis using XRD identify the development of CSH and CAH gels in 1-day cured SRC-treated samples and the development of CSH crystalline phase in 7- and 28-day cured SRC-treated samples. This is visualized through the SEM and XRD analysis of the SRC-treated expansive soil.

The sulfate contamination had a negligible effect on the liquid limit of SRC-treated expansive soil, whereas the plastic and shrinkage limits of SRC-treated expansive soil increased with the sulfate concentration, resulting in a reduction in the plasticity index. The increase in shrinkage limit of samples contaminated with 10,000 and 20,000 ppm sulfate solutions is attributed to the rapid formation of the ettringite/thaumasite in voids of 10% and 15% SRC-treated expansive soil. Whereas in the 5% SRC-treated soil, the sulfate contamination did not result in the formation of ettringite. The micro-analysis shows that the sulfate contamination of 5% SRC-treated expansive soil resulted in the destruction of the cementation gels formed during SRC treatment and the formation of monosulfate, while in 10% and 15% SRC-treated soil, the sulfate contamination with 10,000 and 20,000 ppm solutions resulted in ettringite/thaumasite crystal formation from the CSH crystals, which developed into the voids. This suggests that the crystalline CSH and CAH in the SRC-treated soils act as the nucleation site for ettringite/thaumasite formation. These formations were confirmed through EDAX and XRD analysis as well.

References

Abdi MR, Askarian A, Gonbad MSS (2019) Effects of sodium and calcium sulphates on volume stability and strength of lime-stabilized kaolinite. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-019-01592-1

Alpers CN, Jambor JL, Nordstrom DK (2000) Sulfate minerals crystallography, geochemistry, and environmental significance. Rev Mineral Geochem 40

Al-Rawas AA, Hago AW, Al-Sarmi H (2004) Effect of lime, cement and Sarooj (artificial pozzolan) on the swelling potential of an expansive soil from Oman Amer. Build Environ 40(5):681–687. https://doi.org/10.1016/j.buildenv.2004.08.028

Al-Rawas AA, Taha R, Nelson J, Al-Shab B, Al-Siyabi H (2002) A comparative evaluation of various additives used in the stabilization of expansive soils. Geotech Test J 25(2):199–209. https://doi.org/10.1520/GTJ11363J

Bassuoni MT, Rahman MM (2016) Response of concrete to accelerated physical salt attack exposure. Cem Concr Res 79:395–408. https://doi.org/10.1016/j.cemconres.2015.02.006

Bayat M, Asgari MR, Mousivand M (2013) Effects of cement and lime treatment on geotechnical properties of a low plasticity clay. International conference on civil engineering architecture and urban sustainable development, Nov 27–28; Tabriz: Iran

Bell FG (1993) Engineering treatment of soils. E & FN SPON, New York (NY)

Bezerra WVDC, Azeredo GA (2019) External sulfate attack on compressed stabilized earth blocks. Constr Build Mater 200:255–264. https://doi.org/10.1016/j.conbuildmat.2018.12.115

Canfield DE, Farquhar J (2009) Animal evolution, bioturbation, and the sulfate concentration of the oceans. Proc Natl Acad Science 106:8123–8127. https://doi.org/10.1073/pnas.0902037106

Chew SH, Kamruzzaman AHM, Lee FH (2004) Physicochemical and engineering behavior of cement treated clays. J Geotech Geoenviron 130(7):696–706. https://doi.org/10.1061/(ASCE)1090-0241(2004)130:7(696)

Cordon WA (1961) Resistance of soil-cement exposed to sulphates. Transp Res Board 309:37–56 http://onlinepubs.trb.org/Onlinepubs/hrbbulletin/309/309-003.pdf

Dermatas D (1995) Ettringite-induced swelling in soils: state-of-the-art. Appl Mech Rev 48(10):659–673. https://doi.org/10.1115/1.3005046

Hammarstrom JM, Seal RR, Meierb AL, Kornfeldc JM (2005) Secondary sulfate minerals associated with acid drainage in the eastern US: recycling of metals and acidity in surficial environments. Chem Geol 215:407–431. https://doi.org/10.1016/j.chemgeo.2004.06.053

Ho LS, Nakarai K, Ogawa Y, Sasaki T, Morioka M (2017) Strength development of cement-treated soils: effects of water content, carbonation, and pozzolanic reaction under drying curing condition. Constr Build Mater 134:703–712. https://doi.org/10.1016/j.conbuildmat.2016.12.065

Hou J, Li J, Chen Y (2019) Coupling effect of landfill leachate and temperature on the microstructure of stabilized clay. Bull Eng Geol Environ 78:629–640. https://doi.org/10.1007/s10064-017-1099-z

Hunter D (1988) Lime-induced heave in sulphate bearing clay soils. J Geotechnical Eng ASCE 114:150–167. https://doi.org/10.1061/(ASCE)0733-9410(1988)114:2(150)

Haynes H, Bassuoni MT (2011) Physical salt attack on concrete. Concr Int 33:38–42

IS (Indian Standard), Method of test for soils – determination of pH value. Bureau of Indian Standards 2720 (Part 26) 1987. India, New Delhi

IS (Indian Standard), Method of test for soils – determination of water content. Bureau of Indian Standards 2720 (Part 2) 1973. India, New Delhi

IS (Indian Standard), Determination of specific electrical conductivity of soils. Bureau of Indian Standards 14767–2000. India, New Delhi

IS (Indian Standard), Method of test for soils – determination of specific gravity of soils. Bureau of Indian Standards 2720 (Part 3) 1980a. India, New Delhi

IS (Indian Standard), Method of test for soils – determination of liquid and plastic limit. Bureau of Indian Standards 2720 (Part 5) 1985a. India, New Delhi

IS (Indian Standard), Determination of shrinkage factors. Bureau of Indian Standards 2720 (Part 6) 1972. India, New Delhi

IS (Indian Standard), Method of test for soils – grain size analysis. Bureau of Indian Standards 2720 (Part 4) 1985b. India, New Delhi

IS (Indian Standard), Method of test for soils – determination of water content-dry density relation using light compaction. Bureau of Indian Standards 2720 (Part 7) 1980b. India, New Delhi

IS (Indian Standard), Method of test for soils – determination of free swell index of soils. Bureau of Indian Standards 2720 (Part 40) 1977. India, New Delhi

Jullien A, Proust C, Martaud T, Rayssac E, Ropert C (2012) Variability in the environmental impacts of aggregate production. Resour Conserv Recycl 62:1–13. https://doi.org/10.1016/j.resconrec.2012.02.002

Khemissa M, Mahamedi A (2014) Cement and lime mixture stabilization of an expansive overconsolidated clay. Appl Clay Sci 95:104–110. https://doi.org/10.1016/j.clay.2014.03.017

Kitazume M, Terashi M (2013) The deep mixing method. CRC Press, London

Krause (1976) Sulphate rocks in Baden-Wurttemberg and their importance in relation to civil engineering. Bull Int Assoc Eng Geol 13:45–49

Le Roux A (1969) Traitement des sols argileux par la chaux. Bull Liaison Lab Ponts Chausses 40:59–95

Le Roux A, Toubeau Ph (1987) Mise en evidence du seuil de nocivite et du mecanisme d’action des sulfures au cours d’un traitement a la chaux. 9th South East Asian Geotechnical Conference; Bangkok

Little DN, Nair S (2009) Recommended practice for stabilization of sub grade soils and base materials. National cooperative highway research program. Transportation research board of the national academies 144. https://doi.org/10.17226/22999

Little DN, Nair S, Herbert B (2010) Addressing sulfate-induced heave in lime stabilized soils. J Geotech Geoenviron 136(1):110–118. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000185

Locat J, Berube MA, Choquet M (1990) Laboratory investigations on the lime stabilization of sensitive clays: shear strength development. Can Geotech J 27(3):294–304. https://doi.org/10.1139/t90-040

Mahedi M, Cetin B, White DJ (2018) Performance evaluation of cement and slag stabilized expansive soils. Transp Res Rec 2672(52):164–173. https://doi.org/10.1177/0361198118757439

Mitchell JK (1986)Practical problems from surprising soil behaviour. Journal of geotechnical engineering. ASCE 112(3):259–289. https://doi.org/10.1061/(ASCE)0733-9410(1986)112:3(255)

Nunes MCM, Bridges MG, Dawson AR (1996) Assessment of secondary materials for pavement construction: technical and environmental aspects. Waste Manag 16(1–3):87–96

Orejarena L, Fall M (2010) The use of artificial neural networks to predict the effect of sulfate attack on the strength of cemented paste backfill. Bull Eng Geol Environ 69:659–670. https://doi.org/10.1007/s10064-010-0326-7

Puppala AJ, Wattanasanticharoen E, Hoyos L (2003) Ranking of four chemical and mechanical stabilization methods to treat low-volume road sub grades in Texas. Transp Res Board 1819(1):63–71. https://doi.org/10.3141/1819b-09

Puppala AJ, Griffin JA, Hoyos LR, Chomtid S (2004) Studies on sulfate-resistant cement stabilization methods to address sulfate-induced soil heave. J Geotech Geoenviron 130(4):391–402. https://doi.org/10.3141/1819b-09

Puppala AJ, Talluri N, Congress SSC, Gaily A (2018) Ettringite induced heaving in stabilized high sulfate soils. Innov Infrastruct Solutions 3(72). https://doi.org/10.1007/s41062-018-0179-7

Raja PSK, Thyagaraj T (2019a) Effect of sulfate contamination on compaction and strength behaviour of lime treated expansive soil. Recent advancements on expansive soils. Springer, Switzerland, pp 15–27

Raja PSK, Thyagaraj T (2019b) Effect of short-term sulphate contamination on lime-stabilized expansive soil. Int J Geotech Eng:1–13. https://doi.org/10.1080/19386362.2019.1641665

Rajasekaran G (2005) Sulphate attack and ettringite formation in the lime and cement stabilized marine clays. Ocean Eng 32:1133–1159. https://doi.org/10.1016/j.oceaneng.2004.08.012

Revertegat E, Richet C, Gegout P (1992) Effect of pH on the durability of cement pastes. Cem Concr Res 22(2–3):259–272. https://doi.org/10.1016/0008-8846(92)90064-3

Sante MD, Fratalocchi E, Mazzieri F, Pasqualini E (2014) Time of reactions in a lime treated clayey soil and influence of curing conditions on its microstructure and behavior. Appl Clay Sci 99:100–109. https://doi.org/10.1016/j.clay.2014.06.018

Seif ESSA (2015) Efficiency of quicklime in reducing the swelling potential of pulverized expansive shale, northern Jeddah, Saudi Arabia. Bull Eng Geol Environ 74:637–650. https://doi.org/10.1007/s10064-014-0658-9

Šiler P, Kolárová I, Sehnal T, Másilko J, Opravil T (2016) The determination of the influence of pH value of curing conditions on Portland cement hydration. Procedia engineering 151:10–17. https://doi.org/10.1016/j.proeng.2016.07.393

Silva AJ, Varesche MB, Foresti E, Zaiat M (2002) Sulphate removal from industrial wastewater using a packed bed anaerobic reactor. Process Biochem 37:927–935. https://doi.org/10.1016/S0032-9592(01)00297-7

Sivapullaiah PV, Subbarao KS, Gurumurthy JV (2004) Stabilisation of rice husk ash for use as cushion below foundations on expansive soils. Ground Improvement 8(4):137–149. https://doi.org/10.1680/grim.2004.8.4.137

Skalny JP, Marchand J, Odler I (2003) Sulfate attack on concrete. Spon press, London

Van Den Brand TPH, Roest K, Chen G.H, Brdjanovic D, Van Loosdrecht MCM (2015) Long-term effect of seawater on sulfate reduction in wastewater treatment. Environ Eng Sci 32:622–630. https://doi.org/10.1089/ees.2014.0306

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Raja, P.S.K., Thyagaraj, T. Sulfate effects on sulfate-resistant cement–treated expansive soil. Bull Eng Geol Environ 79, 2367–2380 (2020). https://doi.org/10.1007/s10064-019-01714-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-019-01714-9