Abstract

Medium-and long-chain triacylglycerol (MLCT) is a type of structured lipid where the glycerol backbone is made up of medium chain fatty acid (MCFA) (C6-12) and long chain fatty acid (C14-C22). It is produced through structural modification process. Studies demonstrated that MLCT has the ability in managing obesity which is attributed to the unique metabolic pathway of MCFA. MCFAs are rapidly metabolised in the body due to its small size and hyrophilicity. Therefore, it can prevent the accumulation of fat. Meanwhile the presence of LCFAs allow the delivery of essential fatty acid to our bodies. Various modification pathways can be utilised to synthesise MLCT from conventional fats and oils including esterification, interesterification, and glycerolysis catalysed either by enzyme or chemical catalyst. This chapter aims to highlight the overview of MLCT which includes metabolism, production, health benefits, and its applications in the various food systems.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Medium-long chain triacylglyceride

- Obesity

- β-oxidation

- Medium chain fatty acid

- Interesterification

- Esterification

9.1 Introduction

World Health Organisation (WHO ) estimated that there were around 1.9 billion adults who were overweight. Out of this approximately 650 million of them were clinically obese as in year 2016. The epidemic of overweight and obesity is a challenging issue as it is not only strongly linked with the development of several life-threatening metabolic diseases such as cardiovascular disease, stroke, diabetes, osteoarthritis, and certain types of cancer but also possesses a major economic burden to the country (Must et al. 1999). The fundamental cause of obesity is mainly attributed to the imbalance between energy intake and energy expenditure in which energy intake exceeds the energy expenditure, resulting in the excessive accumulation of fat in the body. However, obesity is preventable. Among the various interventions, changes in dietary patterns and increased physical activity are believed to be the safest approach in managing the prevalence rise of obesity.

Today, with the aid of enzyme lipase or chemical catalyst, vegetable oils and animal fats can be structurally modified via esterification, interesterification and glycerolysis process to change the composition or the position of fatty acids that are attached to the glycerol backbone to improve their healthful functional properties. Such structural alteration also indirectly changes the physicochemical characteristics of the conventional fats and oils such as the melting and crystallisation properties. Typically, modification is aimed to not only to improve the nutritional value, provide low or zero calories attributes but also for the development of fat substitutes. For instance, structured lipids, such as diacylglycerol (DAG), medium-and long-chain triacylglycerol (MLCT ), medium chain triglyceride (MCT) along with short and long-chain triacylglycerol (SLCT) are developed to manage obesity. On the other hand, those like cocoa butter substitute, or human milk fat substitute are meant for the replacement of the expensive and limited supply of cocoa butter and human breast milk, respectively. The aforementioned structured lipid are not new. They are commercially sold in the market and widely distributed across different countries.

MLCT is a type of structured lipid that is made up of medium chain fatty acid (MCFA) (C6-C12) and long chain fatty acid (LCFA) (C14-C22). It demonstrated to have the capability in managing obesity by suppressing visceral fat accumulation due to the presence of MCFA (Hu et al. 2018; Matsuo and Takeuchi 2004; Ogawa et al. 2007). MCFA is unique as it is small and hydrophilic. Hence, it can be delivered directly to the liver to undergo β-oxidation process instead of re-synthesized to form the new triacylglycerol (Papamandjaris et al. 1998). The development of MLCT was initially prompted by the initiative of lipid scientists to overcome several setbacks of the MCT that tends to foams easily when used as a frying medium and deprive of the essential fatty acid necessary to maintain the physiological function of the body. Nisshin Ollio Ltd. was the first company to commercialise the MLCT in the Japanese market. A patented was filed by Nisshin Oilio Ltd. for the synthesis of MLCT in 2004 via chemical and enzymatic routes. Approximately 60% of MLCT managed to be synthesised from these approaches. With strong evidence, MLCT was sold widely as healthy cooking oil under the brand name of “Resetta” to modulate obesity. It bears with it the claim of functional oil that “refrains fat accumulation in the body”. In this chapter, we will highlight the processes used for MLCT production, focusing mainly on the enzymatic routes; the unique metabolism of MLCT ; its touted health benefits and recent applications in the various food systems.

9.2 Structure of MLCT

MLCT is made up of MCFA (C6 to C12) and LCFA (C14 to C20) attached to the glycerol backbone. It gives rise to six different types of configurations which are MLM, LLM, MML, LML, MLL and LML, depending on the position of these fatty acids that are bound to the glycerol backbone (M = medium chain fatty acid, L = long chain fatty acid). Figure 9.1 shows the structure of MLCT and the six different configurations of the MLCT species. In Resetta, the MLCT species is mainly composed of 2L1M followed by 1L2M. Among them, MLM configuration is preferred for its anti-obesity effect.

9.3 Metabolism

In the normal metabolism of fats and oils, lingual lipase in the mouth and pancreatic lipase in the stomach are responsible for the digestion and breakdown of triacylglycerol . Due to the sn-1,3-regiospecific property of the lipase, the triacylglycerol is hydrolysed at the sn-1 and sn-3 position. It results in the formation of glycerol, free fatty acid (FFA) and 2-monacylglycerol (2-MAG). Subsequently, the 2-MAG is utilised for the re-synthesis of a new triacylglycerol molecule. The newly synthesised triacylglycerol is then circulated to the lymphatic system and distributed throughout the whole body as chylomicron. Ultimately, the newly formed triacylglycerol is deposited as fatty tissue in the body.

Digestion and breakdown of MLCT is similar to most of the vegetable oils and animal fats. However, as compared to conventional fats and oils, MLCT has a unique metabolism. It acquires both the metabolism of MCFA and LCFA. When broken down by the endogenous lipase, MLCT produces 2-MAG and FFA (MCFA or LCFA). Since MCFA is shorter in chain length, smaller in size and more hydrophilic than LCFA, it can be rapidly metabolised in the body (Papamandjaris et al. 1998). MCFAs are transported directly into the liver via the hepatic portal vein to go through β-oxidation, producing ketones bodies, such as acetoacetate, acetone, β-hydroxybutyrate , which bypasses the carnitine transport system within the mitochondria matrix. Ketones bodies will then enter the Kerbs cycle and be converted into Acetyl-CoA that can provide a rapid source of energy . Thus, MCFA can be easily burned off without being used to form a new triacylglycerol molecule that potentiates to be accumulated as adipose tissue in the body. In contrast, 2-MAG are metabolised to produce new triacylglycerol molecules that serve to deliver the essential fatty acid to the body. Hence, MCLT is able to be metabolised rapidly as well as to provide the LCFA needed by our body.

When taken into consideration such metabolism of MLCT , it was postulated the MLM is more preferred over the other types of MLCT species in managing obesity since it will release two MCFAs upon digestion to give a better weight-reducing effect than other MLCT isomers. This, however, remains to be investigated as no studies so far were conducted to assess and compare the health benefits of all the individual MLCT species albeit its structural differences.

In short, the metabolism of fats and oils varies depending on the chain length of the fatty acid. Majority of the vegetable oils and animal fats follow the conventional metabolism pathway. There are only a few exceptional cases whereby the fats and oils undergo a different mode of metabolism, particularly, those that are made up of MCFA .

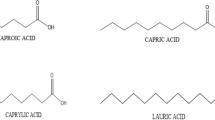

9.4 Source of Medium Chain Fatty Acid

The health attributes of MLCT are mainly contributed by the presence of MCFA viz. caproic (C6), caprylic (C8), capric (C10) and lauric (C12) acid. As compared to vegetable oils that is make up of LCFA, fats and oils with high MCFA content are limited in the market. Table 9.1 shows the MCFA content in animal fats and vegetable oils. Tropical oils like coconut oil and palm kernel oil are the only few examples of vegetable oils that contain high amount of MCFA (around 50%). Hence, tropical oils it is considered to be more suitable for the synthesis of MLCT . Of the 50% of MCFA in coconut oil and palm kernel oil, there are 40% of them that are bound to glycerol backbone together with LCFA. Thus, MLCT are said to be present naturally in the coconut and palm kernel oil. Apart from that, MCFA can also be found in milk fat at around 20% which is significantly lower than the MCFA present in tropical oils making it insignificant to be utilised for MLCT production.

9.5 Production of MLCT

Synthesis of MLCT involves the modification of fats and oils via a few routes such as esterification (FFA and glycerol), interesterification (triacylglycerol with triacylglycerol ) and acidolysis (triacylglycerol and free fatty acid) catalysed by enzyme lipase or chemical catalyst like sodium methoxide (Xu et al. 2016). Unlike other approaches in producing structured lipid, one of the prerequisites to synthesise MLCT is the use of the vegetable oil or animal fats containing MCFA . Even though MLCT produced through chemical reaction is fast and economical, it has several drawbacks. Chemical catalyst is harsh in the reaction which may cause the degradation of the thermal sensitive essential fatty acids. It may also lead to instrument corrosion and the formation of dark coloured products. Furthermore, the reaction catalysed by the chemical catalyst is random and often resulted in the formation of nonspecific MLCT species. On the other hand, enzyme-catalysed reaction provides a promising alternative to overcome the setbacks of the chemical catalysed reaction. Enzyme lipase is specific in its reaction and requires only a mild condition to react. Thereby, it can help to protect the degradation of thermo sensitive fatty acid. Enzyme is usually dosed at around 1–10% (depending enzyme activity) for the synthesis MLCT . Table 9.2 shows the list of the available enzyme used for the production of MLCT which is manufactured and distributed by Novozymes. However, the disadvantage of utilising enzyme lipase is that it can be slightly expensive and may incur additional production costs. However, with immobilization technology, the operating cost of the enzymatically catalysed reaction could be reduced as the enzyme immobilisation allows multiple reuses of the enzyme without sacrificing its activity. As such, it was more environmentally friendly compared to chemical catalysts. Under certain circumstances, the enzyme-catalysed reactions are performed in the presence of a chemical solvent such as hexane. Chemical solvent is used for the purpose to increase the miscibility between the reactants and further reducing the mass transfer of reaction. Nevertheless, most of the reactions nowadays are conducted in a solvent-free system due to sustainability and safety issues. Furthermore, organic solvents were toxic to enzymes, resulting in the reduction of their activity. In some studies, various type of reactors such as bubble column reactor or pack bed reactor is used to increase the mass transfer reaction apart from the used of organic solvent . Generally, the production of structured lipid is always followed suit by purification process to remove the impurities formed during the reaction such as FFA , MAG, diacylglycerol and non-targeted TG. These secondary compounds were produced due to acyl migration, a secondary reaction promoted by the enzymes, which involves the movement of a fatty acid chain from the sn-2 to sn-1,3 position (Utama et al. 2019). Purification is often carried out via molecular distillation or deodorisation to remove these impurities and often resulted in around 80–90% of the MLCT .

9.5.1 Esterification

The production of MLCT via esterification process involves the esterification between free fatty acid in the form of MCFA and LCFA with glycerol. Water is generated or released as the by-products during the reaction. Usually, the free fatty acid to glycerol is supplied in the mass ratio of 3:1 (w/w) and 3.5:1 (w/w) and water is eliminated to push forward the reaction to form triacylglycerol . Studies demonstrated the use of MCFA sources like capric acid and caprylic acid and LCFA sources such as oleic acid for the synthesis of MLCT via the esterification process. Today, only four studies utilised this approach for the production of MLCT (Arifin et al. 2012; Kamariah et al. 2012; Koh et al. 2010; Yang et al. 2014). Few works were conducted utilising this approach because the esterification process took a long duration to complete which is more than 12 h. Furthermore, extra equipment such as a vacuum pump is needed to push forward the esterification process. Otherwise, it will lead to the formation of MAG and DAG. Apart from that, the FFA used particularly, MCFA is relatively costly compared to vegetable oil.

9.5.2 Interesterification

Interesterification takes place via the exchange of fatty acid between two triacylglycerol molecules. Table 9.3 shows the interesterification reaction used for the production of MLCT for the past 5 years. The feedstock commonly used comes from the two different types of vegetable oils, each contributed to MCFA and LCFA, respectively. It is much easier to produce MLCT using the interesterification process than esterification due to the formation of lesser amount of by-products. The source of MCFA is usually contributed by vegetable oil like MCT, palm kernel, coconut oil while the LCFA is provided by soybean oil, sunflower oil, palm oil, camellia oil and single cell oil (Korma et al. 2018; Lu et al. 2017; Zhang et al. 2020; Zou et al. 2014). Recently, ethyl linoleate was utilised to synthesis MLCT given that the by-products formed are much easier to be removed when the feedstock is in ester form (Lian et al. 2019). Usually, a higher substrate molar ratio of the vegetable oil that is rich in MCFA is preferred to increase the production yield of MLCT . Lee et al. (2015) showed that MLCT yield increased with the increase in the ratio of palm kernel oil to palm oil where the substrate ratio of 80:20 (w/w) of palm kernel oil: palm oil resulted in 60% of MLCT as compared to the 20:80 (w/w) of palm kernel oil: palm oil that gives around 40% of MLCT (Lee et al. 2015). Also, interesterification achieves equilibrium at a shorter period. Around 8 h of reaction time is usually needed for interesterification to reach the equilibrium state as compared to esterification that usually took more than 12 h.

9.5.3 Acidolysis

Acidolysis is the most commonly used approach for the synthesis of MLCT among other methods. Table 9.4 shows the acidolysis process used for the production of MLCT for the past 5 years. Acidolysis involves the reaction between FFA in the form of MCFA (capric acid, caprylic acid and lauric acid) and vegetable oil (corn oil, mango kernel fat, pumpkin seed oil, avocado oil, canola oil and olive oil) that provides LCFA (Sneha and Jeyarani 2018; Sousa et al. 2018; Yue et al. 2019; Zhang et al. 2020). On the other note, acidolysis between FFA of LCFA like oleic acid and MCFA containing vegetable oil such as Cinnamomum camphora was currently be used to produce MLCT meant for the production of human milk fat substitute (Zou et al. 2014). Typically, the substrate ratio of the FFA to the triacylglycerol used for acidolysis is in the range of 2.5:1 (w/w) to 5:1 (w/w).

9.5.4 Two-Step Reactions

As the yield of structure lipids produced can be considerably low, it was believed that a two-step reaction can help to promote the synthesize MLCT with a high purity. Two-step reactions had various types of strategies. For instance, 2-MAG could be obtained and purified from a pure LCT through alcoholysis. The concentrated 2-MAG was then esterified with caprylic/capric acid to form MLCT (Adamczak 2004). However, an alternative procedure was conducted by Morales-Medina et al. (2017) to produce PUFA rich MLCT . The authors they investigated and compared the efficiency of a one-step esterification reaction, which involves a direct esterification between glyceride, PUFA and MCFA , and a two-step esterification process, where DAG was firstly prepared between glyceride and MCFA and subsequently reacted with PUFA to form MLCT . It was discovered that the later resulted in a higher MLM content, with a 72% increase in the fatty acid regiodistribution, compared to the former. While two-step reactions had yet to be researched on extensively, they a great potential to improve the yield of MLCT compared to the conventional means.

9.6 Characterisation of MLCT

One of the most important analyses to determine the success of interesterification, acidolysis and esterification reaction is by quantifying the changes in the acylglycerols content or by observing the transformation of the acylglycerol profile via liquid chromatography or gas chromatography before and after interesterification. Lee et al. (2015) observed that MLCT triacylglycerol species increases after interesterification reaction (Lee et al. 2015). Some new peaks started to form while other existing peaks decrease after the reaction which is an indication the modification of the triacylglycerol structure. For instance, the triacylglycerol species present prior to the enzymatic reaction were LaLaLa, LaLaM, LaLaP/LaMM, LaLaO while major triacylglycerol species after reaction include LaLaLa, LaLaM, LaLaO, LaLaP/LaMM, LaMO, LaMP, MMO. Similar study also found that the major triacylglycerol species for MLCT were LaCC/CLaC, LaCO/LCL, CCO/LaCL, COO/OCO after interesterification (Hu et al. 2018).

Apart from that, interesterification can also be assessed via the changes of the thermal profile using differential scanning calorimeter. Melting and crystallisation behaviours of the fats and oils mainly depend on the mixture of the triacylglycerol species. Thus, changes in the triacylglycerol profile will definitely influence the melting or crystallisation profile. Nusantoro et al. (2016), in their study on the interesterification of lauric fat blends, found that there was a significant reduction in the melting point of the lauric-vegetable oil mixture along with a decrease in crystallization temperature after interesterification due to the loss of the high-melting TAG fractions upon MLCT formation. Also, analysis from the solid fat content can also provide an alternative to evaluate the changes of the acylglycerol composition after the reaction. Sneha and Jeyarani (2018) showed that the solid fat content profile of the interesterified fat produced through the acidolysis reaction between mango kernel fat and capric acid was lower than the non interesterified fat when analysed by the differential scanning calorimeter (Sneha and Jeyarani 2018). Analogously, a lower solid fat content was attributed to the reduction of high melting triacylglycerol after interesterification. However, monitoring only the changes in the melting and crystallisation profile of fats and oils has its downside where it is not able to distinguish the types of triacylglycerol formed or diminished during the reaction but merely an indirect indication of the changes in the triacylglycerol profile.

9.7 Health Implications of MCLT

9.7.1 Anti-Obesity Effect of MLCT

MLCT was developed by Nisshin Oillio Ltd. right after the successful launching of the DAG oil by Kao Corporation. DAG is a type of anti-obesity functional oil that shows a promising effect in tackling the rising incidence of obesity. Like DAG, MLCT is able to manage obesity. Weight management of MLCT is touted to be contributed greatly by the rapid metabolism of MCFA that reduces the formation of newly synthesized triacylglycerol that subsequently lower the tendency of the triacylglycerol to be accumulated as fatty tissue in the body. Lee et al. (2018) demonstrated that mice fed with palm-based MLCT have a lower body weight gain, particularly in the perirenal, epididymal, retroperitoneal and mesenteric regions (Lee et al. 2014, 2018). A similar study also demonstrated that MLCT reduces body weight, body fat, waist circumferences, and hip circumferences in Chinese hypertriglyceridemic subjects (Xue et al. 2009; Zhang et al. 2010). However, the weight reduction is more pronounced in overweight hypertriglyceridemic subject than the normal or obese hypertriacylglyceridemic subjects. This inconsistency was caused by the difference in metabolic characterization between the individuals, resulting in variations in fat oxidation and energy expenditure. Apart from the patient’s clinical background, it was shown that the weight reduction of MLCT depends on the amount of MCFA . Mice fed with MLCT having 30% of MCFA have a lesser body weight gain as compared to the mice fed with MLCT having 10% and 20% of MCFA , further indicating the dose-dependent effect of MLCT (Matsuo and Takeuchi 2004; Zhou et al. 2017). In a review by Lee et al. (2012), it was determined that at least 12% of MCFA must present in MLCT to exert its anti-obesity properties. It was then postulated that the reduction in weight gain was attributed to the β-oxidation of MCFA in the liver. This was further confirmed where a study revealed that the consumption of a liquid meal containing MLCT with 12% of MCFA increases the diet induced thermogenesis where it elevated the resting energy expenditure (Ogawa et al. 2007). A fundamental study showed that the activity of the enzyme that involves in lipid mobilisation such as cyclic adenosine monophosphate, protein kinase A, hormone-sensitive lipase, adipose triglyceride lipase was elevated whilst enzyme that responsible for de novo fatty acid biosynthesis like fatty acid synthase was reduced following the consumption of MLCT (Hu et al. 2018). Furthermore, there was evidence that the weight reduction effect of the MLCT could be attributed to the microbiota that controls the body weight. The ratio of Firmicutes to Bacteroidetes as well as the abundance of the Proteobacteria that are responsible for weight loss was lesser in mice subject that consumed MLCT (Zhou et al. 2017). Apart from reducing body fat mass, MLCT is also beneficial in improving blood profile whereby the plasma triacylglycerol and total cholesterol level, as well as hepatic triacylglycerol and total cholesterol level, was significantly lower in the subject that consumed MLCT (Hu et al. 2018). However, in the study carried out by Lee et al. (2018), consumption of MLCT demonstrated to increase the cholesterol level mainly because of the present of mytristic acid that showed to be hypercholesterolemic (Lee et al. 2018). Nevertheless, the rule of thumb to obtain both weight reduction effect without elevating the cholesterol level is to have a proper selection of fats and oils used for modification. Lastly, in another study, consumption of MLCT showed to have remarkably reduced the inflammatory markers such as tumour necrosis factor-α, interleukin-6 in mice subjects (Du et al. 2020). This would eventually aid in preventing chronic metabolic disorders, such as type 2 diabetes and coronary diseases.

9.8 Applications

The first commercially available MLCT was sold in the Japanese market by Nisshin Oillio Ltd. as a healthy version cooking oil. It is the one of the few cooking oils in the world that demonstrates to suppress visceral fat deposition besides DAG oil which was also sold in Japan. However, DAG oil has been banned from sales for the past few years due to the presence of probable carcinogenic processing contaminants, glycidol esters. Hence, the only healthy functional cooking oil left in the market that shows to exert weight suppression effect nowadays was MLCT . As a result of the increasing demand of consumer towards healthier choice product and the beneficial health attributes of MLCT , many studies were conducted to evaluate the suitability and possibility of incorporating MLCT into various food system such as deep-frying medium, shortening , and salad dressing for the preparation of reduced calorie and trans fat free food products. Recently, MLCT had shown to be suitable human milk fat substitute as a cheaper alternative to human breast milk. Thus far, it is challenging to find a commercial food product made from MLCT in the market mainly because of the price of the structured lipid that is relatively higher than the conventional fats and oils. However, with the tremendous clinical and preclinical evidences demonstrating the purported health benefits, it is wise to rethink the way forward of using MLCT as the healthier version of edible fats and oils in the future.

9.8.1 Deep Frying Medium

The initial intention to develop MLCT was to overcome the short-comings of MCT. MCT tends to foam and smoke easily when used as deep frying medium due to the high concentration of MCFA . Incorporation of LCFA managed to increase the smoke point and reduce foaming, thereby rendering it suitable for deep frying purposes. Deep fat frying is the most popular method used for food preparation. As medium of deep frying, fats and oils act to provide the fried foods with the desirable organoleptic properties (crunchiness, aroma, flavour) that is loved by everyone. Koh et al. (2011b) studied the deep-frying performance of palm-based MLCT with the addition of synthetic and natural antioxidant for 5 consecutive days. It was found that the when palm-based MLCT was added with 200 ppm of TBHQ and 1000 ppm of oleoresin sage extract, it possessed a better oxidative and thermal stability than refined bleached deodorised palm olein despite the presence of MCFA (Koh et al. 2011a, b). MLCT shows to have a lower FFA content and anisidine value as well as high induction period. Nevertheless, MLCT resulted in a higher total polar compound after frying. A high total polar compound produced is mainly attributed to the presence of MCFA . They also discovered that the potato chips fried with palm-based MLCT or palm olein show no significant different in terms of odour, taste, crispiness and overall acceptability when evaluated by the sensory panellists. Besides that, blending of MLCT oil with other vegetable oils also provide another alternative to enhance the deep-frying performance of the MLCT . Blending increases the the smoke point of the MLCT . Furthermore, blending also serves the purpose to reduce the production cost of MLCT . Koh et al. (2008) blended the MLCT with palm olein and soybean oil prior to further evaluating their deep-frying performance. It was found that MLCT blended with soybean oil has a better frying stability than those blended with palm olein (Koh et al. 2009). It was revealed that soybean oil contains more LCFA such as oleic, linoleic acid and linolenic acid than palm olein which contributed to the higher thermal and oxidative stability.

9.8.2 Human Milk Fat Substitute

Breast milk is recognised as the optimal choice of nutrition for preterm infant during the first year of life. It provides infant with balanced nutrients and bioactive compounds that are essential for their proper growth and development. Breast milk contains around 3–5% of lipid. Approximately 50% of the infant ’s dietary energy is supplied by the fat component in breast milk. The breast milk fat is predominantly made from 98% of triacylglycerol with 20–25% of palmitic acid (C16:0) (Zou et al. 2016). Majority of the palmitic acid occupied the sn-2 position of the milk fat, thus giving rise to OPO configuration. It was only recently that MLCT gain tremendous interest to be used as substitute for human milk fats, particularly, the MLL species, following a study conducted to evaluate the fatty acid composition and triacylglycerol composition of the human breast milk as compared to infant formula (Yuan et al. 2019). It was found that the human breast milk fat is mainly composed of MLCT that exists in the form of MLL which is typically different from the desired MLM species that is well sought after for its weight management attributes. The types of MCFA present in human breast milk range from C8-C14 with C10 and C12 being the major fatty acid. It was also revealed that the content of MCFA increases with lactation whereby the MCFA content increases from colostrum to mature milk. Nonetheless, a thorough study by the author found that most of the infant formula available in the market are mainly made up of the MCT instead of MLCT . MCT is undesirable for infant as the sn-1, sn-2 and sn-3 position of MCT are composed entirely of MCFA . As a result, it has a higher rate of metabolism as compared to MLCT . In addition, MCT is undesirable as it will not increase the body mass of infant . This was also the concern of Łós-Rycharska et al. (2016), who reviewed that there was no explicit evidence on the improvement in the infant ’s body mass upon MCT consumption. It was also noted that when MCT was consumed in large doses (>400 mOsm/kg), the infant was inflicted with diarrhoea and essential fatty acid deficiencies. Thus, replacement of MCT with MLCT was needed to render the consumers with more nutritional benefits. With that in mind, several studies were conducted in China to use MLCT as a source of human milk fat substitute. In one study, catfish oil was interesterified with the coconut oil to produce MLCT with MLL species for use as human milk fat substitute. Around 39.85% of the MLL was synthesised under the optimized operating condition (Yuan et al. 2020). In another study, acidolysis of Cinnamomum camphora seed oil with oleic acid was used to produce MLL structured lipid catalysed by RMIM (Zou et al. 2014). MLCT received a lot of attention to be used as human milk fat substitute recently mainly because of the food regulation in China which specifies that MLCT is needed to be claimed as human milk fat substitute. Under the Chinese national standard, the fat emulsion must consist of MLCT , MCT, and LCT content within 70–80%, 5–15% and 1–20%, respectively.

9.8.3 Shortening

Shortening is widely used for baking purposes to give flaky and crispy texture. It is commonly made up of 100% of fats and oils. Conventionally, shortening is mainly made from hydrogenated fat as hard stock. However, the use of hydrogenated fat as shortening was not in favour today because of the presence of trans fatty acid. Structured lipid turns out to be a better alternative to replace the hydrogenated fat. Apart from that, interesterified fat is able to provide the desired melting and crystallization properties for shortening that is not possible to be achieved by simple blending of the hydrogenated fat with other vegetable oils. It was found that interesterified fat enhanced the formation of the β′ and small crystal as compared to the dense crystal that is formed during physical blending. A sophisticated study was furthermore conducted to evaluate the blending of MLCT with hardstock such as palm stearin or partially hydrogenated soybean oil in order to increase the solid fat content for the preparation of shortening . Arifin et al. (2011) showed that the shortening with solid fat content of 15% to 25% at 25 °C was obtained by blending MLCT with 10–30% of palm stearin or a mixture containing 30–40% of palm stearin and 10–20% of palm olein. Madeira cake produced from the aforementioned shortening was well accepted by the sensory panellists (Arifin et al. 2011). Similar study also demonstrated that blending MLCT with 30% of palm stearin is able to produce fat with β′ crystal polymorphism which is required to produce shortening with a smooth texture. In another study, MLCT-based shortening was prepared through the blending of coconut oil with MLCT (Adhikari et al. 2012; Zhang et al. 2014). Adhikari et al. (2012) used MLCT produced through the blending of coconut oil and interesterified fat (rice bran oil and fully hydrogenated soybean oil) to prepare shortening . The MLCT blend showed to have softer texture and a lower solid fat content besides inducing the formation of β′ crystal which is desired to prevent post hardening as compared to the shortening prepared from physical blend of the rice bran and coconut oil. Nevertheless, the shortening produced through interesterified fat demonstrated to have a lower oxidative stability as most of the tocopherols and phytosterols were destroyed during the refining process that is meant to eliminate the FFA formed during interesterification. Similar study was conducted by Shi et al. (2015) to prepare a blend from interesterified fat (rice bran stearin and fully hydrogenated soybean oil) and coconut oil that is suitable for shortening production.

9.8.4 Margarine

Margarine is developed as a cheaper substitute for butter that is usually used as bakery fat. It is a type of oil-in-water emulsion that constitutes of up to at least 80% of fat. Similar to shortening , hydrogenated fat is commonly used to provide the solid like texture to margarine . However, the use of hydrogenated fat started to phase out and being replaced with trans-fat free structured lipid following the mandatory labelling of trans fatty acid in food products. Interestingly, it was revealed that the use of structured lipid has the advantages of not only able to reduce the trans-fat content but also promote the development of β′ fat crystal in margarine . Arifin et al. (2010) utilised MLCT for margarine production. MLCT prepared was blended with palm olein and palm stearin in ratio of 60:30:10 (w/w/w) and 70:20:10 (w/w/w) prior to incorporating it into cookies (Arifin et al. 2010). The cookies incorporated with MLCT-based margarine had a higher value for all the texture properties but lower sensory score than the cookies made from commercial margarine . Further improvement in the formulation of the margarine is needed to produce cookies with a better organoleptic attribute.

9.8.5 Salad Dressing

Salad dressing is an emulsified fat that is typically pourable and stabilised by egg yolk as primary emulsifier or starch as secondary stabiliser . The most common example of salad dressing is mayonnaise which has around 75% of fat. As it is considered as a high fat product, consumption of salad dressing may increase the risk of obesity. Koh et al. (2008) evaluated the feasibility of using MLCT as salad dressing. It was found that the salad dressing prepared from MLCT has similar rheological properties as those prepared from soybean oil. In order to extend the shelf life of the mayonnaise, the authors further incorporated natural and synthetic antioxidants to prevent fat hydrolysis caused by the presence of water in the salad dressing (Koh et al. 2008). Study revealed that addition of either synthetic or natural antioxidant managed to retard the degradation rate of MLCT in the salad dressing. Nevertheless, the incorporation of the natural antioxidant which is oleoresin sage extract tends to result in a stronger colour and odour than the synthetic antioxidant when evaluated by the trained panellists via the quantitative descriptive analysis.

9.8.6 Parenteral Nutrition

Structolipid 20% is well known intravenous lipid emulsion containing structured lipid MLCT . It was made from interestefication process between 36% soybean oil and 64% MCT. This combination allows adequate consumption of essential fatty acids while exhibiting less inflammatory properties (Raman et al. 2017). Its clinical safety was proven by Rubin et al. (2000), who studied the differences in blood lipid profile of the patients administrated with Structolipid 20% and Intralipid 20%, a pure LCT emulsion , for 4 weeks. They assessed that there was no significant difference in the plasma TG, FFA , phospholipid and free cholesterols between the two group of subjects. The study also noted that Structolipid (20%) had the potential to treat liver dysfunction as it successfully treated 2 patients who had this disorder after the infusion of Intralipid 20%. Furthermore, a short-term study by Piper et al. (2006) showed that patients treated with Structolipid 20% had less plasma triglyceride levels compared to those treated with Lipofundin 20%, a physical emulsion blend of MCT and LCT, after 5 days of research. Hence, the structured triglyceride emulsion led to a more significant effect compared to the MCT/LCT physical blend.

9.9 Conclusion

Since the banning of the sales of DAG oil by Kao Corporation due to the presence of probable carcinogen-glycidol ester, MLCT is the only healthy cooking oil with anti-obesity effect that is sold commercially in the Japanese market currently. With the use of lipase, the production of MLCT through modification of conventional vegetable oil via esterification, interesterification and acidolysis route has become feasible. Study showed that MLCT offered a significant reduction in body weight gain and suppressed body fat accumulation due to the rapid metabolism of the MCFA . Nevertheless, only a few vegetable oils can contribute MCFA such as coconut oil and palm kernel oil whilst MCFA from other sources are typically low in amount, rendering the production of MLCT in large scale a challenging task. As the tropical oils contain certain amount of the myristic acid that are hypercholesterolemic, it is important to relook into the synthesis of MLCT using these vegetable oils. More works can be conducted to further improve the nutritional profile of the MLCT oil that works best not only to reduce body weight gain but also blood lipid profile.

References

Adamczak M (2004) The application of lipases in modifying the composition, structure and properties of lipids—a review. Pol J Food Nutr Sci 54(1):3–10

Adhikari P, Shin J-A, Lee J-H, Kim H-R, Kim I-H, Hong S-T, Lee K-T (2012) Crystallization, physicochemical properties, and oxidative stability of the interesterified hard fat from rice bran oil, fully hydrogenated soybean oil, and coconut oil through lipase-catalyzed reaction. Food Bioproc Tech 5(6):2474–2487

Arifin N, Peng KS, Long K, Ping TC, Affandi Yusoff MS, Nor Aini I, Ming LO (2010) Relationship between textural properties and sensory qualities of cookies made from medium-and long-chain triacylglycerol-enriched margarines. J Sci Food Agric 90(6):943–948

Arifin N, Cheong L-Z, Koh S-P, Long K, Tan C-P, Yusoff MSA, Aini IN, Lo S-K, Lai O-M (2011) Physicochemical properties and sensory attributes of medium-and long-chain triacylglycerols (MLCT)-enriched bakery shortening. Food Bioproc Tech 4(4):587–596

Arifin N, Soo-Peng K, Long K, Chin-Ping T, Yusoff MSA, Oi-Ming L (2012) Modeling and optimization of Lipozyme RM IM-catalyzed esterification of medium-and long-chain triacyglycerols (MLCT) using response surface methodology. Food Bioproc Tech 5(1):216–225

Du Y-X, Chen S-N, Zhu H-L, Niu X, Li J, Fan Y-W, Deng Z-Y (2020) Consumption of interesterified medium-and long-chain triacylglycerols improves lipid metabolism and reduces inflammation in high-fat diet-induced obese rats. J Agric Food Chem 68(31):8255–8262

Hu J-N, Shen J-R, Xiong C-Y, Zhu X-M, Deng Z-Y (2018) Investigation of lipid metabolism by a new structured lipid with medium- and long-chain triacylglycerols from cinnamomum camphora seed oil in healthy C57BL/6J mice. J Agric Food Chem 66(8):1990–1998

Kamariah L, Norlelawati A, Koh S-P, Oi-Ming L, Chin-Ping T, Affandi MS (2012) Modeling and optimization of lipozyme RM IM-catalyzed esterification of medium-and long-chain triacyglycerols (MLCT) using response surface methodology. Food Bioproc Tech 5:216–225

Koh SP, Arifin N, Tan CP, Yusoff MSA, Long K, Idris NA, Lai OM (2008) Rheological properties, oxidative stability and sensory evaluation of enzymatically synthesized medium-and long-chain triacylglycerol-based salad dressings. Eur J Lipid Sci Technol 110(12):1116–1126

Koh SP, Arifin N, Lai OM, Yusoff MSA, Long K, Tan CP (2009) Oxidative stability of palm-and soybean-based medium-and long-chain triacylglycerol (MLCT) oil blends. J Sci Food Agric 89(3):455–462

Koh S, Tan C, Lai O, Arifin N, Yusoff M, Long K (2010) Enzymatic synthesis of medium-and long-chain triacylglycerols (MLCT): optimization of process parameters using response surface methodology. Food Bioproc Tech 3(2):288–299

Koh S, Arifin N, Tan C, Yusoff M, Long K, Lai O (2011a) Deep frying performance of enzymatically synthesized palm-based medium-and long-chain triacylglycerols (MLCT) oil blends. Food Bioproc Tech 4(1):124–135

Koh S, Long K, Tan C, Yusoff M, Lai O, Arifin N (2011b) The use of enzymatically synthesized medium—and long-chain triacylglycerols (MLCT) oil blends in food application. Int Food Res J 18(1):355–366

Korma SA, Zou X, Ali AH, Abed SM, Jin Q, Wang X (2018) Preparation of structured lipids enriched with medium-and long-chain triacylglycerols by enzymatic interesterification for infant formula. Food Bioprod Process 107:121–130

Lee Y-Y, Tang T-K, Lai O-M (2012) Health benefits, enzymatic production and application of medium- and long-chain triacylglycerol (mlct) in food industries: a review. J Food Sci 77(8):R137–R144

Lee Y-Y, Tang T-K, Ab Karim NA, Alitheen NBM, Lai O-M (2014) Short term and dosage influences of palm based medium-and long-chain triacylglycerols on body fat and blood parameters in C57BL/6J mice. Food Funct 5(1):57–64

Lee Y-Y, Tang T-K, Phuah E-T, Ab Karim NA, Alwi SMM, Lai O-M (2015) Palm-based medium-and-long-chain triacylglycerol (P-MLCT): production via enzymatic interesterification and optimization using response surface methodology (RSM). J Food Sci Technol 52(2):685–696

Lee Y-Y, Tang T-K, Phuah E-T, Karim NAA, Alitheen NBM, Tan C-P, Razak ISA, Lai O-M (2018) Structural difference of palm based medium-and long-chain triacylglycerol (MLCT) further reduces body fat accumulation in DIO C57BL/6J mice when consumed in low fat diet for a mid-term period. Food Res Int 103:200–207

Lian W, Wang W, Tan CP, Wang J, Wang Y (2019) Immobilized Talaromyces thermophilus lipase as an efficient catalyst for the production of LML-type structured lipids. Bioprocess Biosyst Eng 42(2):321–329

Łós-Rycharska E, Kieraszewicz Z, Czerwionka-Szaflarska M (2016) Medium chain triglycerides (MCT) formulas in paediatric and allergological practice. Przeglad Gastroenterologiczny 11(4):226–231

Lu J, Jin Q, Wang X, Wang X (2017) Preparation of medium and long chain triacylglycerols by lipase-catalyzed interesterification in a solvent-free system. Process Biochem 54:89–95

Lubary M, Hofland GW, Ter Host JH (2011) The potential of milk fat for the synthesis of valuable derivatives. Eur Food Res Technol 232(1):1–8

Matsuo T, Takeuchi H (2004) Effects of structured medium-and long-chain triacylglycerols in diets with various levels of fat on body fat accumulation in rats. Br J Nutr 91(2):219–225

Morales-Medina R, Munio M, Guadix A, Guadix E-M (2017) Development of an up-grading process to produce MLM structure lipids from sardine discards. Food Chem 228:634–642

Must A, Spadano J, Coakley EH, Field AE, Colditz G, Dietz WH (1999) The disease burden associated with overweight and obesity. JAMA 282(16):1523–1529

Nusantoro B-P, Xanthina M, Kadivar S, Yanty N-A-M, Dewettinck K (2016) Enzymatic interesterification of lauric fat blends formulated by grouping triacylglycerol melting points. J Am Chem Oil Soc 93(8):1051–1062

Ogawa A, Nosaka N, Kasai M, Aoyama T, Okazaki M, Igarashi O, Kondo K (2007) Dietary medium-and long-chain triacylglycerols accelerate diet-induced thermogenesis in humans. J Oleo Sci 56(6):283–287

Pantzaris TP, Ahmad MJ (2001) Properties and utilization of palm kernel oil. Palm Oil Dev 35(11–15):19–23

Papamandjaris AA, MacDougall DE, Jones PJ (1998) Medium chain fatty acid metabolism and energy expenditure: obesity treatment implications. Life Sci 62(14):1203–1215

Piper S, Röhm K, Mengitsu A, Wolf M, Suttner S, Boldt J (2006) Utilisation of structured triglycerides (Structolipid ®) in surgical ICU patients receiving parenteral nutrition. Crit Care 10(1):P206

Raman M, Almutairdi A, Mulesa L, Alberda C, Beattie C, Gramlich L (2017) Parent Nutr Lipids Nutr 9(4):388

Rubin M, Moser A, Vaserberg N, Greig F, Levy Y, Spivak H, Ziv Y, Lelcuk S (2000) Structured triacylglycerol emulsion, containing both medium- and long-chain fatty acids, in long-term home parenteral nutrition: a double-blind randomized cross-over study. Nutrition 16(2):95–100

Shi C, Chang M, Liu R, Jin Q, Wong X (2015) Trans free shortenings through the interesterification of rice bran stearin, fully hydrogenated soybean oil and coconut oil. Int J Food Eng 11(4):467–477

Sneha R, Jeyarani T (2018) Lipase-catalysed acidolysis of mango kernel fat with capric acid to obtain medium-and long-chain triacylglycerol. Int J Food Sci Technol 53(6):1527–1534

Sousa V, Campos V, Nunes P, Pires-Cabral P (2018) Incorporation of capric acid in pumpkin seed oil by sn-1, 3 regioselective lipase-catalyzed acidolysis. OCL 25(3):A302

Utama Q-D, Sitanggang A-B, Adawiyah D-R, Hariyadi P (2019) Lipase-catalyzed interesterification for the synthesis of medium-long-medium (MLM) structured lipids—a review. Food Technol Biotechnol 57(3):305–318

Xu Z, Jin J, Adhikari P, Liang J, Xu X, Liu Y, Wang X (2016) Sheaolein-based cold-soluble powder fats with medium-and long-chain triacylglycerol: production via chemical interesterification using sheaolein and palm kernel stearin. RSC Adv 6(22):18632–18640

Xue C, Liu Y, Wang J, Zhang R, Zhang Y, Zhang J, Zheng Z, Yu X, Jing H, Nosaka N (2009) Consumption of medium-and long-chain triacylglycerols decreases body fat and blood triglyceride in Chinese hypertriglyceridemic subjects. Eur J Clin Nutr 63(7):879–886

Yang K, Bi Y, Sun S, Yang G, Ma S, Liu W (2014) Optimisation of Novozyme-435-catalysed esterification of fatty acid mixtures for the preparation of medium- and long-chain triglycerides (MLCT) in solvent-free medium. Int J Food Sci Technol 49(4):1001–1011

Yuan T, Zhang H, Wang X, Yu R, Zhou Q, Wei W, Wang X, Jin Q (2019) Triacylglycerol containing medium-chain fatty acids (MCFA-TAG): The gap between human milk and infant formulas. Int Dairy J 99:104545

Yuan T, Wei W, Wang X, Jin Q (2020) Biosynthesis of structured lipids enriched with medium and long-chain triacylglycerols for human milk fat substitute. LWT 128:109255

Yue C, Ben H, Wang J, Li T, Yu G (2019) Ultrasonic pretreatment in synthesis of caprylic-rich structured lipids by lipase-catalyzed acidolysis of corn oil in organic system and its physicochemical properties. Foods 8(11):566

Zhang Y, Liu Y, Wang J, Zhang R, Jing H, Yu X, Zhang Y, Xu Q, Zhang J, Zheng Z (2010) Medium-and long-chain triacylglycerols reduce body fat and blood triacylglycerols in hypertriacylglycerolemic, overweight but not obese, Chinese individuals. Lipids 45(6):501–510

Zhang Y, Yang B, Wang Y (2014) Physicochemical properties of shortening base oil rich in medium-and long-chain triacylglycerols. China Oils Fats 39(6):53–56

Zhang Z, Zhang S, Lee WJ, Lai OM, Tan CP, Wang Y (2020) Production of structured triacylglycerol via enzymatic interesterification of medium-chain triacylglycerol and soybean oil using a pilot-scale solvent-free packed bed reactor. J Am Oil Chem Soc 97(3):271–280

Zhou S, Wang Y, Jacoby J, Jiang Y, Zhang Y, Yu LL (2017) Effects of medium-and long-chain triacylglycerols on lipid metabolism and gut microbiota composition in C57BL/6J mice. J Agric Food Chem 65(31):6599–6607

Zou X-G, Hu J-N, Zhao M-L, Zhu X-M, Li H-Y, Liu X-R, Liu R, Deng Z-Y (2014) Lipozyme RM IM-catalyzed acidolysis of Cinnamomum camphora seed oil with oleic acid to produce human milk fat substitutes enriched in medium-chain fatty acids. J Agric Food Chem 62(43):10594–10603

Zou L, Pande G, Akoh CC (2016) Infant formula fat analogs and human milk fat: new focus on infant developmental needs. Annu Rev Food Sci Technol 7:139–165

Zou X, Ye L, He X, Wu S, Zhang H, Jin Q (2020) Preparation of DHA-rich medium- and long-chain triacylglycerols by lipase-catalyzed acidolysis of microbial oil from Schizochytrium sp.with medium-chain fatty acids. Appl Biochem Biotechnol 191

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Lee, YY. et al. (2022). Medium-and Long-Chain Triacylglycerol: Production, Health Effects and Applications. In: Lee, Y., Tang, TK., Phuah, ET., Lai, OM. (eds) Recent Advances in Edible Fats and Oils Technology. Springer, Singapore. https://doi.org/10.1007/978-981-16-5113-7_9

Download citation

DOI: https://doi.org/10.1007/978-981-16-5113-7_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-5112-0

Online ISBN: 978-981-16-5113-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)