Abstract

Lauric fat blends (appreciable amount of lauric fat with liquid oil and hard fat) initially formulated for shortening production by grouping triacylglycerol (TAG) melting points were further modified by enzymatic interesterification (EIE) to improve their key functionalities as plastic fats. At a similar fat blend formulation, only the high melting fat and medium melting fat were interesterified in binary-EIE. Meanwhile, both fats and the liquid oil were interesterified in ternary-EIE. The solid fat content (SFC) of all binary-EIE blends was generally retained as similar in the temperature range between 0 and 20 °C when the amount of unsaturated TAGs was limited by excluding the liquid oil during EIE. However, the SFC was significantly reduced at temperatures above 20 °C compared to that of the initial blends. Furthermore, the melting point of binary-EIE blends at BH50H15 formulation prepared with palm stearin and fully hydrogenated rapeseed oil as the hard fat was found to be drastically reduced from 54.6 to 35.3 °C and from 62.8 to 39.2 °C, respectively. In contrast, the SFC of ternary-EIE blends was generally reduced when more unsaturated TAGs were available for EIE by including the liquid oil. However, higher SFC was noticed at temperatures around 10 °C in ternary-EIE blends, as the amount of high-melting fractions in their initial blends was increased from BH50H5 to BH50H15. Eventually, both binary and ternary-EIE were also found to significantly alter the crystal microstructure of lauric fat blends, in terms of crystal morphology, size and network density.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lauric fats (i.e., coconut oil/CO and palm kernel oil/PKO) contain mainly medium melting triacylglycerols (TAGs). These lauric fats can be blended with hard fats (mostly high melting TAGs) and liquid oils (mostly low melting TAGs) to produce plastic fats (i.e., shortening, margarine, fat spread). These lauric fat blends comprise medium and high melting fractions where the amount of both fractions can be adjusted to a desired level using melting TAG group formulation [1]. Although blending different oils and fats appeared to be a favored choice because of its simplicity, the liquid phase separation [2, 3] and formation of relatively coarse crystals [4] can sometimes not be avoided, as TAG composition is limited by the origin of raw materials [5]. As vegetable oils and fats used in blends are commonly in their natural form, lauric fat blends may have some limited applications as plastic fats due to their specific chemical composition [6, 7]. To improve their crystallization behavior and physical properties as plastic fats, lauric fat blends can further be modified by an interesterification process, either chemically or enzymatically.

The consistency and functional property of plastic fats will mainly depend on the solid–liquid ratio and crystal microstructure. The liquid component of plastic fats provides good lubricating function that enhances the mixing process [8, 9]. Meanwhile, an adequate amount of solid fraction in plastic fats provides good product viscoelasticity and this can be evaluated by the SFC profile. The values of SFC10, SFC20 and SFC35 (SFC at 10, 20 and 35 °C) are distinctly correlated to the rheological behavior of plastic fats at storage, packaging and utilization, respectively [10]. The SFC10 of a fat spread determines the hardness and ease of spreading of the product at refrigerator conditions [11]. The SFC20 is an important parameter for determining the feasibility of fat blends used in the production of shortening [12]. The SFC35 is particularly important with relation to the extent of melting in the mouth and should be maintained as low as possible to prevent a sandy and coarse texture of the final products [13].

Interesterification has been widely used as an alternative method to improve the physical properties of fat blends for the production of plastic fats such as shortening and margarine. Enzymatic interesterification (EIE) modifies the physicochemical properties of fat blends by rearranging the distribution of fatty acids (FAs) on the glycerol backbone [14]. It is acknowledged that the physicochemical characteristic of fat blends is mainly determined by their chemical composition (such as chain length, degree of unsaturation and positional arrangement of FA residues). As TAG composition is significantly changed, EIE fat blends will have a completely different overall melting profile, a better compatibility within the solid phase (not achievable by simple blending) and an improved plasticity of the final products [15]. EIE is preferred to the chemical interesterification process, as it has an enhanced selectivity (producing fewer low side products), requires mild reaction conditions (such as lower pressure and temperature, therefore reducing energy consumption and preserving the quality of antioxidant), gives better nutritional quality and is considered to be more natural [14]. In addition, the expensive price of the enzyme, which is acknowledged as the main drawback, can be reduced by reusing it [14, 16].

Furthermore, EIE of lauric fat blends can produce products of structured lipids with certain health benefits. In lauric fat blends, the lauric fat (e.g., PKO) provides medium-chain fatty acid (MCFA), while both the hard fat (e.g., palm stearin) and liquid oil (e.g., sunflower oil) provide long-chain fatty acid (LCFA). The interesterified lauric fat blends may thus contain MCFA and LCFA on the same glycerol backbone and are known as MLCT (medium- and long- chain triacylglycerols) [17]. Intake of products containing MLCT has been reported to be able to suppress body fat accumulation over long periods of time [18, 19]. Lipase-catalyzed interesterification can be random or regioselective. For the positional specificity, an sn-1,3 specific lipase is commonly used, and this lipase hydrolyzes specifically the acyl moieties from the sn-1 and sn-3 positions of the TAG [20]. In order to get MLCT with the desired structure, the sn-1,3 specific lipase is preferred as it ensures that essential FAs are maintained at the sn-2 position [21]. The FA at sn-2 position is conserved during digestion as 2-monoacylglycerol, which is easily absorbed in the body [22, 23].

In this investigation, lauric fat blends formulated at different ratios of medium and high melting TAG groups, prepared originally as fat stock for the production of bakery shortening, were further modified by EIE to improve and extend their functionality as plastic fats. The influence of different blend formulations, types of hard fats and interesterification strategies (binary/ternary-EIE) were also studied. In the meantime, the changes on the TAG composition, thermal properties, SFC profile and crystal microstructure of interesterified blends were compared to those of their initial blends. Furthermore, the formation of MLCT in interesterified blends was sought in order to enrich the products with some known health benefits.

Materials and Methods

Materials

All vegetable oils and fats were commercial products and the chemicals for analysis were of high purity grade. High oleic sunflower oil (HOSO), fully hydrogenated rapeseed oil (FHRO) and both palm kernel oil (PKO) and palm stearin (PS) were gifts from Oleon (Oelegem, Belgium), Palsgaard (Juelsminde, Denmark) and Loders Crocklaan (Wormerveer, the Netherlands), respectively. A commercial immobilized sn-1,3 regioselective lipase, Lipozyme RM IM, was bought from Novozymes (Bagsvaerd, Denmark).

Fat Blend Formulation and Interesterification Process

In this research, the formulation was based on the grouping of various TAG species according to their melting points (mp). The TAGs were divided into four groups: chilled/C (mp ≤ 5 °C), room/R (5 °C < mp < 25 °C), body/B (25 °C < mp < 45 °C) and heated/H (45 °C ≤ mp) melting TAG groups. For example, a formulation of BH50H15 indicated that the fat blend consisted of 50 % TAGs from a summation of B/H groups in which 15 % TAGs was from H group (thus, B group had 35 % TAGs). Consequently, the other 50 % of TAGs in the formulation was from a summation of C//R groups [1].

Lauric fat blends were then prepared from two different types of hard fats: HOSO/PKO/PS and HOSO/PKO/FHRO. Each ternary fat blend was also formulated at constant BH50 (the total amount of TAGs in the B and H groups was set at constant value 50 %), but varied H from 5 to 15. There were six lauric fat blends, coded as P-H5, P-H10, P-H15, S-H5, S-H10 and S-H15. Different types of hard fats used in the blends were denoted by P and S for PS and FHRO, respectively. In the meantime, different formulations of the blends were denoted by H5, H10 and H15 representing the amount of TAGs in the H group at 5, 10 and 15 %, respectively. Thus, for example, the P-H5 fat blend consisted of HOSO/PKO/PS at a BH50H5 formulation.

A modified method of Zainal and Yusoff [24] was applied for the interesterification process, where 10 % lipase (w/w) was added to 150 g fat blend in a suitcase-size glass reactor with an inner diameter of 10.5 cm and a height of 10 cm for laboratory scale enzymatic interesterification (Novozymes). The glass reactor was equipped with a water bath allowing a temperature set point up to ± 0.1 °C precision. The reaction was allowed to proceed for 4 h at 60 °C, with a continuous agitation at 300 rpm. A vacuum proof stirrer with Teflon blade (Novozymes) was used to invoke the agitation. Nitrogen gas was flushed into the reactor to prevent undesired oxidation reaction during interesterification. To stop the reaction, the entire mixture was vacuum filtered through a Whatman filter paper grade 41 to separate the interesterified fat blend from the enzyme. The EIE blend was then stored in the freezer without any additional treatment before further analysis.

Triacylglycerol Profile (by HPLC)

TAG Composition by NARP-HPLC

The TAG composition was determined by non-aqueous reversed-phase high-performance liquid chromatography (NARP-HPLC). The separation of TAGs in NARP-HPLC is on the basis of both chain length and degree of unsaturation of the FAs. The chromatographic system consisted of a Shimadzu HPLC system (Shimadzu, Kyoto, Japan) and fitted with a 150 × 3.0 mm Alltima HP C18-HL column with 3 µm particle diameter (Grace Alltech, Lokeren, Belgium). A precolumn with a silica packing was used. Detection was done with an Alltech 3300 ELSD (evaporative light scattering detector). An optimized method developed by Rombaut and co-workers [25] was used for the measurements. The elution was carried out using an acetonitrile/dichloromethane gradient at 0.72 mL/min. The elution program of NARP-HPLC is given in Table 1. The result was processed by LC solution software (Shimadzu) and the individual peaks were identified by comparing the retention times with that of common vegetable oils of known TAG composition.

Unsaturation Degree of TAG by Ag+-HPLC

The separation of TAGs in silver ion HPLC is based on the interaction between the silver ion and the double bonds of the carbon chain on the FA moieties. The chromatographic system consisted of a Shimadzu HPLC system (Shimadzu) fitted with a 250 × 4.6 mm ChromSpher 5 Lipids column (Varian, Middelburg, the Netherlands). A cation-exchange guard column was used to avoid any possible contamination present in the sample and eluent. Detection was done by an Alltech 3300 ELSD. An optimized method developed for stereospecific TAG analysis [26] was used for the measurement. The elution was carried out using an acetone/hepthane gradient at 1 mL/min. The elution program of Ag+-HPLC is given in Table 1. The result was processed by LC solution software (Shimadzu).

Solid Fat Content/SFC (by pNMR)

Solid fat content was measured by a Maran Ultra NMR (Oxford Instruments, Oxfordshire, UK) equipped with R4 cryostat cooler (Grant Instruments, Cambridgeshire, UK). The direct method according to the official IUPAC 2.150 and a stabilizing fat procedure were used for the SFC measurements. The samples in the NMR tube (Bruker, Karlsruhe, Germany) were completely melted at 70 °C for 15 min. The samples were then stabilized at 26 °C for 40 h and subsequently cooled at 0 °C for 1.5 h. The SFC values were eventually recorded at 5 °C intervals from 0 to 60 °C. Before each reading, the samples were conditioned for 1 h at that chosen measurement temperature.

Melting and Crystallization Behavior Measured by DSC

Thermal analyses of the samples were performed on a TA Q1000 differential scanning calorimetry (TA Instruments, New Castle, DE, USA) equipped with a refrigerated cooling system. Nitrogen was used to purge the system. The DSC was calibrated before analyses with indium (TA Instruments), azobenzene (Sigma-Aldrich, Bornem, Belgium) and undecane (Acros Organics, Geel, Belgium).

Samples (weighing approximately 5 - 15 mg) were sealed into aluminum pans. An empty pan was used as a reference during the measurements. The time–temperature program of the measurements was as follows: holding at 90 °C for 10 min, cooling at a rate of 5 °C/min to −70 °C, holding for 10 min at that temperature to allow complete crystallization, and then heating at a rate 5 °C/min to 90 °C. The obtained data were processed by TA Universal Analysis 2000 software (TA Instruments).

Crystal Morphology Measured by PLM

A CX41RF microscope (Olympus, Tokyo, Japan) equipped with a Linkam PE 94 temperature control system (Linkam, Surrey, UK) was used to study the microstructure of the fat crystals. The sample was completely melted and one drop of it was put on a microscope slide then immediately covered with a cover slip. After that, the slide was placed on a temperature-controlled metal plate to allow crystallization. The fat blends were measured at 15 °C, as their products were commonly stored at that temperature [27]. Meanwhile, the interesterified blends were measured at a lower temperature (10 °C) due to the decrease of melting temperature of fat blends after EIE. Samples’ images were taken by an E330 Zuiko Digital camera (Olympus) under 400× magnification (PLM), and these images were processed by Cell D software (Olympus).

Statistical Analysis

In all analyses, three replicates were used and the results were expressed as mean value ± standard deviation (SD). Statistical analyses of the obtained data were calculated using SPSS 12.0 software (SPSS Inc., Chicago, USA), and significant differences between means were determined at a 95 % confidence interval (p < 0.05) by one-way ANOVA. Tukey’s test was used to identify the differences in case of equal variances. In addition, standard deviation bars are plotted in the figures showing the unsaturation degree of TAG (Fig. 2, Fig. 3) and the SFC result (Fig. 4).

Results and Discussion

In this study, lauric fat blends were chosen from H5 to H15 formulations, as this interval contained suitable amounts of hard fractions, where H5 formulation contained a minimum amount of hard fractions (5 % high melting TAGs) while H15 formulation contained a maximum amount of fractions (15 % high melting TAGs) in the production of shortening [1]. The high melting fraction needs to be carefully controlled, as it may give undesired organoleptic and textural properties even if only a small amount of that fraction is found in the fat blends [4]. These initial blends were then interesterified by sn-1,3 regioselective lipase using two strategies. First, the binary-EIE, the medium (PKO) and high (PS or FHRO) melting fats were interesterified, followed by the addition of liquid oil (HOSO). This limited the amount of unsaturated TAGs involved in the reaction, as the liquid oil was excluded during interesterification. Second, the ternary-EIE, all raw materials (HOSO/PKO/[PS or FHRO]) were blended at once and then interesterified. This gave redistribution of FAs at a wider range of TAGs in the starting materials, as the liquid oil was included during interesterification, and thus more unsaturated FAs got involved in the reaction. The changes in the physicochemical properties of lauric fat blends, before and after interesterification (either binary or ternary-EIE), are described as follows.

Influence of EIE on TAG Composition

As shown in Table 2, PKO contained major TAGs rich in medium-chain saturated FAs: LaLaLa (37.34 %), LaLaM (21.91 %), CLaLa (9.78 %), LaMM (8.91 %) and CCLa (7.7 %). However, those TAGs had lower melting points compared to trisaturated TAGs of long-chain FAs (i.e., PPP, SSS), as they consisted mostly of medium-chain FAs. Therefore, PKO was suitable as the medium melting fat. HOSO was chosen as liquid oil that consisted mainly of OOO (87.99 %). Meanwhile, PS or FHRO was used as a hard fat that would provide solid fat fraction at higher temperature region. Palm stearin had PPP (80.41 %), while FHRO consisted mainly of SSS (81.87 %). Both PPP and SSS are high melting fats composed of fully saturated TAGs with long-chain FAs. Tristearin has a longer carbon chain length compared to that of tripalmitin, so it has significantly higher melting point. The melting point of SSS crystal in its β polymorph is 73.5 °C, while that of PPP crystal is 66.2 °C [28]. Eventually, the use of different high melting fats in the formulation of lauric fat blends is also aimed to study the effect of different structuring TAGs (derived from different FA chain-length) on their crystallization behavior.

TAG Composition by NARP-HPLC

The TAG composition of lauric fat blends was greatly dictated by the origin of starting materials, as the blends were a simple physical mixture of HOSO/PKO/PS or HOSO/PKO/FHRO. For example, as shown in Table 2, HOSO/PKO/PS blends had an increase of PPP content from 3.21 to 8.61 %, to 13.86 % when the H ratio was increased from 5 to 10, to 15, respectively. As the BH ratio in the blends was set at a constant value 50 %, the increase of H ratio would be compensated by the decrease of B ratio (i.e., a decrease of LaLaLa from 18.69 to 16.07 %, to 13.53 %, respectively). Similarly, HOSO/PKO/FHRO blends had an increase of SSS content (from 2.51 to 6.66 %, to 10.85 %, respectively) followed by a decrease of LaLaLa (from 18.94 to 16.80 %, to 14.64 %, respectively). In addition, all blends contained a substantial amount of OOO ranging from 40.44 to 41.13 %, as HOSO was used as the liquid oil.

After EIE, the TAG composition of all lauric fat blends was significantly altered where the FAs became more evenly distributed on the glycerol backbone. In general, the relative concentrations of main TAGs of starting samples (such as OOO, LaLaLa, PPP and SSS) were decreased substantially. The decreases of the main TAG concentrations were then followed by the formations of some newly synthesized TAGs. The formation rate of these new TAG species varies greatly. The changes of TAG profile of the blends formulated at BH50H15 before interesterification (initial blends) and after interesterification (binary and ternary EIE blends) are given in Fig. 1. It was shown that the amount of high melting fractions (PPP and SSS) was reduced after interesterification. Moreover, the different type of high melting fats (PS or FHRO) used in this study resulted in different TAG compositions of the interesterified blends in terms of both ratio of individual TAG and newly synthesized TAG species.

Chromatogram of lauric fat blends formulated at BH50H15, before and after enzymatic interesterification (EIE), obtained by NARP-HPLC. LaLaLa: trilaurin, PPP: tripalmitin, OOO: triolein and SSS: tristearin. For other abbreviations, see Table 2

Unsaturation Degree of TAG by Ag+-HPLC

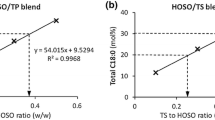

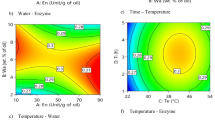

Silver-ion HPLC was used to analyze the unsaturation degree of lauric fat blends, before and after interesterification. As the separation of TAGs is based on the interaction between the silver ions and the double bond (DB), a manageable number of chromatogram peaks will be obtained. This is considered to be an advantage for analyzing complex TAG mixture, especially that of interesterified blends. Fully saturated TAGs have no double bond (0-DB), while liquid oil commonly has TAGs with 2-DB or more, such as POO (2-DB), OOO (3-DB) and LOO (4-DB). Figures 2 and 3 show that initial blends contained mostly 0-DB and 3-DB TAGs, of which 0-DB TAGs were from PKO and PS/FHRO, while 3-DB TAGs were from HOSO. After binary-EIE, only small changes of the decreasing 0-DB TAGs were observed. The decreases of 0-DB TAGs continued to a substantially lower after ternary-EIE. In addition, binary-EIE blends were found to have considerably higher amount of 0-DB TAGs compared to that of ternary-EIE blends. When HOSO was introduced in the ternary interesterification, more unsaturated FAs were available and randomly bound to the glycerol backbone. Consequently, this increased the unsaturation degree of TAGs in the blends.

Unsaturation degree of triacylglycerol in lauric fat blends prepared with palm stearin (PS) as the high melting fat. DB: number of double bonds in the fatty acids of triacylglycerol from 0 to 4. Values are means with their standard deviations of triplicate analyses. For other abbreviations, see Table 2

Unsaturation degree of triacylglycerol in lauric fat blends prepared with fully hydrogenated rapeseed oil (FHRO) as the high melting fat. DB: number of double bonds in the fatty acids of triacylglycerol from 0 to 4. Values are means with their standard deviations of triplicate analyses. For other abbreviations, see Table 2

Taking into account that high melting TAGs (PPP or SSS) in initial blends were diminished after binary interesterification (Fig. 1) while the amount of 0-DB TAGs was only slightly altered (Fig. 2, 3), it was believed that there were a formation of TAGs from a combination of high and medium melting fats. As the medium melting fat was PKO, the newly synthesized TAG would then be an MLCT. The binary-EIE blends had a higher amount of 0-DB TAGs compared to that of ternary-EIE blends; therefore, binary-EIE blends would contain higher amounts of MLCT with long-chain saturated FAs. The presence of MLCT in interesterified blends was considered to be an advantage, since MLCT products are known to impart some health benefits [17].

In general, the lipase-catalyzed interesterification changed the unsaturation degree of lauric fat blends in the comparable manner for all the different formulations.

Influence of EIE on Solid Fat Content (SFC)

The initial blends were formulated to have different amount of high melting fractions (H5, H10 and H15). High melting fat was commonly added into fat blends to extend their plastic range and improve their tolerance at high temperature [29]. Figure 4 shows that the addition of high melting fractions increased the SFC values at 20 °C and higher. Higher amount of high melting fractions also yielded higher melting points (temperature at which SFC = 0 %) of the fat blends. Different hard fats used in the blends also affected the SFC profile at this temperature range, where FHRO had slightly higher value compared to that of PS. However, the influence of different type of hard fats (PS or FHRO) on the SFC profile was less pronounced than that of different blend formulations (BH50H5, BH50H10 and BH50H15). In addition, the SFC curves in the temperature range between 0 and 20 °C were found to be approximately similar for all initial blends. At that temperature range, the solid fat was contributed by TAGs from both B and H groups, and the total amount of TAGs was set at a simlar value 50 % (BH50) in all fat blends.

SFC profile of lauric fat blends, before and after interesterification. Values are means with their standard deviations of triplicate analyses. For abbreviations, see Table 2

Enzymatic interesterification of fat blends prepared by liquid oil and hard fat commonly results in the decline of SFC at the higher temperature region. If a more diverse FA presents in the system, it will lead to an even sharper decrease of SFC curves [30]. Using binary-EIE strategy, it was demonstrated that the SFC values were reduced at 20 °C and higher for the interesterified blends. However, SFC curves of binary-EIE blends in the temperature range of between 0 and 20 °C were found to be approximately similar. As only high and medium melting fats were included in the interesterification, the randomization of FAs on the glycerol backbones was mostly limited between medium-chain saturated FAs of PKO and long-chain saturated FAs of PS/FHRO. This would keep those interesterified blends to have low degree of unsaturation, before the addition of liquid oil (Fig. 2, 3). The combination of medium-chain and long-chain FAs on newly synthesized TAGs produced MLCTs with physical properties in-between the medium and high melting fats. The majority of MLCTs in binary-EIE blends had melting points within the range of B group, as shown in the DSC-melting thermogram (Fig. 6). Binary-EIE lauric fat blends would then be suitable for shortening or margarine fat stock with an improvement on the SFC profile in the high melting range. The formation of undesired organoleptic properties (e.g., pasty, greasy and waxy tastes) on rich fat products can be avoided by having a lower SFC value at above body temperature [9].

When all starting samples were interesterified, the SFC of ternary-EIE blends would be drastically decreased from that of initial blends. The softening effect of these interesterified blends was caused by the introduction of unsaturated FAs from liquid oil into both high and medium melting fats. The initial blends were formulated to have a substantial amount of lauric fat (as the medium melting fat) that was composed mainly of medium-chain saturated FAs. Triacylglycerols composed of medium-chain FAs would have melting point below room temperature whatever unsaturated FA was introduced to their glycerol backbone, such as LaLaO and LaOO. In addition, TAGs composed of long-chain FAs (from high melting fat) would also have melting point below room temperature when their unsaturation degree was changed to at least 2-DB, such as POO and SOO (see Table 2). Both NARP-HPLC and Ag+ -HPLC chromatograms could be used to confirm the formation of these newly synthesized TAGs with varied unsaturation degree.

Furthermore, the SFC of ternary-EIE blends was found to be increased in the temperature range between 0 and 20 °C whenever the amount of hard fats in the initial blends was raised (from H5 to H10, to H15). As initial blends were formulated at BH50, higher amount of long-chain TAGs (from PS or FHRO) would be compensated with lower amount of medium-chain TAGs (from PKO). Despite the amount of 1-DB and 2-DB in the ternary-EIE blends being found to be comparable (Figs. 2, 3), there would be more newly synthesized TAGs with long-chain FAs for higher H group formulation. Triacylglycerols composed of long-chain FAs with 1-DB generally have melting points within the B group, such as MPO, POP and POS (Table 2). Higher ratio of B group would give higher SFC values, particularly in the temperature range between 0 and 20 °C. As ternary-EIE blends had substantial amount of solid fat at around 10 °C and completely melted (SFC = 0 %) below 35 °C, the blends were considered to be suitable as fat stock for soft rich fat products, such as fat spread [31].

Eventually, in a general overview, it was found that SFC profile of interesterified blends was not affected much by the different types of high melting fractions (PS or FHRO) used in lauric fat blends.

Influence of EIE on Crystallization and Melting Behavior (DSC)

Crystallization Behavior

The TAG composition of lauric fat blends was altered during EIE and the changes were clearly observed on the DSC crystallization and melting thermograms. The DSC crystallization thermogram of lauric fat blends formulated at BH50H15 before and after interesterification is displayed in Fig. 5. The initial blends exhibited three major peaks representing materials composed the blends. Two exothermic peaks at lower (a3, d3) and middle (a2, d2) temperature ranges were related to HOSO and PKO, respectively. These two exothermic peaks of HOSO/PKO/FHRO blends (a3, a2) had crystallization temperatures that were comparable to those of HOSO/PKO/PS blends (d3, d2). Eventually, the exothermic peak at the higher temperature range of the fat blends was associated with high melting fraction. However, the peak maximum of fat blends prepared with FHRO (a1) was found to crystallize at higher temperatures than those of fat blends prepared with PS (d1).

DSC crystallization thermogram of lauric fat blends formulated at BH50H15, before and after interesterification. A: S-H15 blend, B: binary-EIE S-H15, C: ternary-EIE S-H15, D: P-H15 blend, E: binary-EIE P-H15 and F: ternary-EIE P-H15. For abbreviations, see Table 2

After binary-EIE, the exothermic peaks at middle and higher temperature ranges were found to become broader exothermic peaks (b1, e1) and shifted to the lower crystallization temperature. This was in agreement with the diminishing high melting fraction followed by the appearance of newly synthesized TAGs in interesterified blends (Fig. 1). The other exothermic peak could be considered to represent the low melting fraction in binary-EIE blend. The peak was associated with liquid oil, which was added after the interesterification reaction. This exothermic peak (b2, e2) had a crystallization temperature comparable to the exothermic peak of the initial blend at lower temperature range (a3, d3).

For ternary-EIE, the unsaturation degrees of TAGs were adjusted to be more equal and followed a standard normal distribution when liquid oil was included in the reaction, as shown in Figs. 2 and 3. As a result, the ternary-EIE blend had a broad exothermic peak with a long shoulder that spanned from lower to higher temperature region (c1, f1).

Melting Behavior

The DSC melting thermogram of fat samples commonly contained more complex features (i.e., broad shoulders, multiple inseparable peaks) compared to their crystallization thermogram [5]. However, the melting thermogram of lauric fat blends formulated at BH50H15 was found to be reasonably comparable to its crystallization thermogram (Fig. 5). The DSC melting thermogram of lauric fat blends formulated at BH50H15 before and after interesterification is displayed in Fig. 6.

DSC melting thermogram of lauric fat blends formulated at BH50H15, before and after interesterification. A: S-H15 blend, B: binary-EIE S-H15, C: ternary-EIE S-H15, D: P-H15 blend, E: binary-EIE P-H15 and F: ternary-EIE P-H15. For abbreviations, see Table 2

For the initial blends prepared with either FHRO or PS as the hard fat, three major endothermic peaks were also observed, a6/a5/a4 or d6/d5/d4, respectively. After binary-EIE and ternary-EIE, the number of endothermic peaks were reduced to two (b4/b3 or e4/e3) and one (c2 or f2) peaks, respectively. The offset temperature of endothermic peak at higher temperature region was 62.8 °C for the initial blend prepared with FHRO, and drastically reduced to 39.2 and 34.5 °C for the binary-EIE and ternary-EIE blends, respectively. In the meantime, the offset temperature of endothermic peak at higher temperature region of the initial blend prepared with PS was 54.6 °C. This offset temperature was also drastically reduced to 35.3 and 30.1 °C for the binary-EIE and ternary-EIE blends, respectively. It was shown that the endothermic peak of high melting fractions in lauric fat blends was shifted to a lower temperature region after interesterification, for both binary and ternary-EIE.

The DSC crystallization and melting thermograms of other formulations (BH50H5 and BH50H10) were generally found to be comparable; thus, no further data and discussions are given.

Influence of EIE on Crystal Morphology (PLM)

The microstructure of solid fat in the lauric fat blends before and after interesterification was studied by PLM. Figure 7 shows the effects of interesterification (both binary-EIE and ternary-EIE) on the crystal morphology, size and network density of lauric fat blends formulated at BH50H15. In the initial blends, some distinct differences on crystal microstructure could be seen between the blend prepared by PS and that prepared by FHRO, even when both blends had a similar formulation and a comparable SFC profile (Fig. 4). The crystal microstructure of the initial blend prepared with PS showed a coarse network of small spherulitic particles with rod-like crystals and had no evidence of regular pattern. Meanwhile, the initial blend prepared by FHRO exhibited large spherulitic aggregates with more symmetrical pattern and a loosely crystal network. It is commonly observed that the presence of tristearin (i.e., from FHRO) induces the appearance of large spherulites and spherulitic aggregates, which eventually imparts grainy structure in the plastic fat [32].

Pictomicrographs of lauric fat blends formulated at BH50H15, before and after interesterification: (a) P-H15 blend, (b) binary-EIE P-H15, (c) ternary-EIE P-H15, (d) S-H15 blend, (e) binary-EIE S-H15 and (f) ternary-EIE S-H15. For abbreviations, see Table 2

Enzymatic interesterification of lauric fat blends caused a decrease in the spherulitic crystal sizes and produced low-density aggregates of fine crystals followed the changes of their chemical composition. The binary-EIE blends showed dense rod-like crystals agglomerated into fine spherulitic particles with an increase in the relative proportion of small fat crystals for both blends prepared with PS and FHRO. Further substantial changes were observed on the crystal microstructure of ternary-EIE blends. Large asymmetric spherulites with a dense core and a lower-density halo region around the core were observed in the ternary-EIE blend prepared with FHRO. Contrarily, the ternary-EIE blend prepared with PS showed low-density aggregates of fine crystals. Smaller fine crystals impart a better plasticity and overall texture properties rather than large spherical crystal clusters of non-interesterified fat blends [15].

In general, lower amounts of high melting fractions (from BH50H15 to BH50H10, to BH50H5) within blends prepared with a similar hard fat (PS or FHRO) produced a comparable crystal morphology, yet gave less dense crystal structure. Thus, no further data and discussion were elaborated.

Conclusion

This study demonstrated that lauric fat blends could further be modified by lipase-catalyzed interesterification to enhance their viscoelastic and textural properties as plastic fats. After EIE, there was a sharp decrease on SFC curves of binary-EIE blends at 20 °C and higher. However, their SFC curves were found to be approximately similar in the temperature range between 0 and 20 °C. The melting point of binary-EIE blends at BH50H15 formulation prepared with PS and FHRO was reduced to 35.3 and 39.2 °C, respectively. Therefore, binary-EIE lauric fat blends would be suitable for shortening or margarine fat stock with enhanced physical properties at body temperature. Meanwhile, ternary-EIE blends exhibited a sharp decrease of the overall SFC profile compared to their initial blends. However, the SFC values of those_ interesterified blends increased_ with the increment of H group formulation at temperatures around 10 °C. In addition, all these blends were completely melted below 35 °C. Thus, ternary-EIE blends were considered to be suitable as fat stock for soft rich fat products, such as fat spread. Under PLM measurement, crystal microstructure of the initial blends was a network of dense spherulitic crystal in nature. Enzymatic interesterification of lauric fat blends caused a decrease in the spherulitic crystal sizes and produced low-density aggregates of fine crystals. Eventually, the formation of MLCTs in the interesterified blends was considered as an advantage due to their health benefits.

References

Nusantoro BP, De Clercq N, Anthierens K, Dewettinck K (2013) Changing the SFC profile of lauric fat blends based on melting group triacylglycerol formulation. J Am Oil Chem Soc 90:1607–1619

Kanagaratnam S, Enamul Hoque M, Mat Sahri M, Spowage A (2013) Investigating the effect of deforming temperature on the oil-binding capacity of palm oil based shortening. J Food Eng 118:90–99

Mayamol PN, Samuel T, Balachandran C, Sundaresan A, Arumughan C (2004) Zero-trans shortening using palm stearin and rice bran oil. J Am Oil Chem Soc 81:407–413

Meng Z, Geng W, Wang X, Liu Y (2013) Fat crystal migration and aggregation and polymorphism evolution during the formation of granular crystals in beef tallow and palm oil. J Agric Food Chem 61:12676–12682

Criado M, Hernández-Martín E, López-Hernández A, Otero C (2007) Enzymatic interesterification of extra virgin olive oil with a fully hydrogenated fat: characterization of the reaction and its products. J Am Oil Chem Soc 84:717–726

Jin Q, Zhang T, Shan L, Liu Y, Wang X (2008) Melting and solidification properties of palm kernel oil, tallow, and palm olein blends in the preparation of shortening. J Am Oil Chem Soc 85:23–28

Reena MB, Reddy SRY, Lokesh BR (2009) Changes in triacylglycerol molecular species and thermal properties of blended and interesterified mixtures of coconut oil or palm oil with rice bran oil or sesame oil. Eur J Lipid Sci Technol 111:346–357

Stauffer CE (2005) In: Shahidi F (ed) Bailey’s industrial oil and fat products, 6th edn. Wiley-Interscience, New Jersey

O’Brien RD (2009) Fats and oils: formulating and processing for applications, 3rd edn. CRC Press, Boca Raton

Osório NM, da Fonseca MMR, Ferreira-Dias S (2006) Operational stability of thermomyces lanuginosa lipase during interesterification of fat in continuous packed-bed reactors. Eur J Lipid Sci Technol 108:545–553

Rasid M, Jaais M, Yusoff MSA, Elias BA (1996) PORIM’s experiments on low trans margarine. Palm Oil Technical Bulletin:9–13

Lai OM, Ghazalia HM, Cho F, Chong CL (2000) Physical and textural properties of an experimental table margarine prepared from lipase-catalysed transesterified palm stearin: palm kernel olein mixture during storage. Food Chem 71:173–179

Noor Lida HMD, Sundram K, Idris NA (2007) Effect of chemical interesterification on triacylglycerol and solid fat contents of palm stearin, sunflower oil and palm kernel olein blends. Eur J Lipid Sci Technol 109:147–156

De Clercq N, Danthine S, Nguyen MT, Gibon V, Dewettinck K (2012) Enzymatic interesterification of palm oil and fractions: monitoring the degree of interesterification using different methods. J Am Oil Chem Soc 89:219–229

Marangoni AG, Rousseau D (1995) Engineering triacylglycerols: the role of interesterification. Trends Food Sci Technol 6:329–335

Krishnamoorthi S, Banerjee A, Roychoudhury A (2015) Immobilized enzyme technology: potentiality and prospects. J Enzymol Metabol 1:104

Lee YY, Tang TK, Lai OM (2012) Health benefits, enzymatic production, and application of medium-and long-chain triacylglycerol (MLCT) in food industries: a review. J Food Sci 77:R137–R144

Kasai M, Nosaka N, Maki H, Negishi S, Aoyama T, Nakamura M, Suzuki Y, Tsuji H, Uto H, Okazaki M (2003) Effect of dietary medium-and long-chain triacylglycerols (MLCT) on accumulation of body fat in healthy humans. Asia Pac J Clin Nutr 12:151–160

Lee Y-Y, Tang T-K, Phuah E-T, Ab Karim NA, Alwi SMM, Lai O-M (2013) Palm-based medium-and-long-chain triacylglycerol (P-MLCT): production via enzymatic interesterification and optimization using response surface methodology (RSM). J Food Sci Technol 52:685–696

Zhang H, Jacobsen C, Adler-Nissen J (2005) Storage stability study of margarines produced from enzymatically interesterified fats compared to margarines produced by conventional methods. I. Physical properties. Eur J Lipid Sci Technol 107:530–539

Nunes PA, Pires-Cabral P, Guillén M, Valero F, Luna D, Ferreira-Dias S (2011) Production of MLM-type structured lipids catalyzed by immobilized heterologous Rhizopus oryzae lipase. J Am Oil Chem Soc 88:473–480

Kotani K, Yamamoto Y, Hara S (2015) Enzymatic Preparation of Human Milk Fat Substitutes and Their Oxidation Stability. J Oleo Sci 64:275–281

Soumanou MM, Pérignon M, Villeneuve P (2013) Lipase-catalyzed interesterification reactions for human milk fat substitutes production: A review. Eur J Lipid Sci Technol 115:270–285

Zainal Z, Yusoff MSA (1999) Enzymatic interesterification of palm stearin and palm kernel olein. J Am Oil Chem Soc 76:1003–1008

Rombaut R, De Clercq N, Foubert I, Dewettinck K (2009) Triacylglycerol analysis of fats and oils by evaporative light scattering detection. J Am Oil Chem Soc 86:19–25

Kadivar S, De Clercq N, Nusantoro BP, Le TT, Dewettinck K (2013) Development of an offline bidimensional high-performance liquid chromatography method for analysis of stereospecific triacylglycerols in cocoa butter equivalents. J Agric Food Chem 61:7896–7903

Danthine S, Lefébure E, Trinh HN, Blecker C (2014) Effect of palm oil enzymatic interesterification on physicochemical and structural properties of mixed fat blends. J Am Oil Chem Soc 91:1477–1487

Marangoni AG, Narine SS (2002) Physical properties of lipids. Marcel Dekker, New York

Chu BS, Ghazali HM, Lai OM, Che Man YB, Yusof S, Tee SB, Yusoff MSA (2001) Comparison of lipase-transesterified blend with some commercial solid frying shortenings in Malaysia. J Am Oil Chem Soc 78:1213–1219

Lai OM, Ghazali HM, Chong CL (1998) Physical properties of Pseudomonas and Rhizomucor miehei lipase-catalyzed transesterified blends of palm stearin: palm kernel olein. J Am Oil Chem Soc 75:953–959

Noor Lida HMD, Ali ARM (1998) Physico-chemical characteristics of palm-based oil blends for the production of reduced fat spreads. J Am Oil Chem Soc 75:1625–1631

Rousseau D, Marangoni AG, Jeffrey KR (1998) The influence of chemical interesterification on the physicochemical properties of complex fat systems. 2. Morphology and polymorphism. J Am Oil Chem Soc 75:1833–1839

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Nusantoro, B.P., Xanthina, M., Kadivar, S. et al. Enzymatic Interesterification of Lauric Fat Blends Formulated by Grouping Triacylglycerol Melting Points. J Am Oil Chem Soc 93, 1051–1062 (2016). https://doi.org/10.1007/s11746-016-2851-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-016-2851-4