Abstract

Six binary formulations of medium- and long-chain triacylglycerols (MLCT) fat and palm stearin and four ternary formulations of MLCT fat, palm stearin, and palm olein were produced. MLCT fat and palm stearin were mixed in ranges of 40–90% with 10% increments (w/w), while for the ternary formulations, 10% and 20% palm olein were substituted to palm stearin in MS 46 and MS 55 formulations. The solid fat content (SFC) by pulsed nuclear magnetic resonance and heating profiles using differential scanning calorimeter of these formulations were determined. Results obtained from SFC and heating profiles found that all the formulations melted completely at 55 °C. The high complete melting temperature is due to the stearic acid content in MLCT fat. Generally, increasing % MLCT fat (40–90%) in the formulations lowers the SFC curves at the measured temperatures (0–60 °C). The binary samples of MS 73, MS 82, and MS 91 showed SFC between 15% and 25% at room temperature (25 °C), which indicated that these formulations were suitable for shortening production. As the production cost of MLCT fat is high (approximately USD 3/kg), an attempt to reduce the proportion of MLCT fat in the shortening formulations was done by developing the ternary formulations. Shortenings formulated with 40:40:20 (MSO 442), 50:40:10 (MSO 541), and 50:30:20 (MSO 532) of MLCT fat/palm stearin/palm olein formulations had similar SFC% at 25 °C, and they were subsequently chosen to produce shortening. Using multivariate analysis, taste attribute showed positively and highly correlated to the melting temperature and SFC at 25 °C of the MLCT-enriched shortenings. In acceptance test, high correlation (R 2 = 0.98) was only found on cakes made from MSO 442 and MSO 541 shortenings. Both untrained and trained panelists rated the Madeira cakes made from MSO 532 shortening the highest for overall acceptability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Shortening is usually a blend of 100% fats and oils that is commonly used in the baking industry to make bakery products such as cake and pastry. It is normally associated with high calorie and high trans fatty acids, which cause health problems such as obesity and cardiac diseases. The fat-containing diets cannot be restricted at all due to some functionalities of fat in our body. Fat also plays an important role in texture and flavor development in food. Therefore, the consumption of food having low calories is suggested for consumers with lifestyle-related diseases (Sandrou and Arvanitoyannis 2000).

Recently, the production of structured lipid involving the incorporation of short/medium chain fatty acid has received much attention (Koh et al., 2008; Liu et al. 2008; Lai et al. 2005; Yankah and Akoh 2000). Some commercially available type of this structured lipids include SALATRIM/Benefat (Nabisco Food Group, Parsippany, NJ, USA/Cultor Food Science, New York, USA) and Caprenin (Procter & Gamble, Cinnati, OH, USA). The former tailor-made lipids comprise short- and long-chain fatty acid on the same glycerol molecule and used as additives in cookies, crackers, salted snacks, and chocolate (Kosmark 1996). Caprenin is a modified lipid containing caprylic, capric, and behenic fatty acids esterified randomly to a glycerol backbone. Both structured lipids provide 5 kcal/g (Osborn and Akoh 2002). In Japan, Healthy Resseta has been approved as Food for Specified Health Used by the Ministry of Health, Labor and Welfare of Japan in December 2002 for use as cooking oil (Aoyama et al. 2007). This product is made from medium- and long- chain triacylglycerol (MLCT).

MLCT is a structured lipid that contains medium-chain fatty acid (MCFA) and long-chain fatty acid (LCFA) on the same glycerol backbone (Kasai et al. 2003). Ingestion of MLCT containing 10–18% of MCFA has been reported to reduce body weight accumulation over long periods of time (Kasai et al. 2003; Shinohara et al. 2002; Matsuo et al. 2001). Beermann et al. (2003) investigated the effect of ingestion of dietary MCFA and n−3 long-chain polyunsaturated acids (PUFA) on the fat metabolism of healthy people after 15 days. They found that diet containing 72% MCFA and 22% n−3 LCPUFA increased stimulation of hepatocytic β-oxidation and release from adipocytes without affecting any safety parameters of venous blood in short term period. MLCT had no adverse effect on body fat reduction when ingested excessively (Nosaka et al. 2003).

The solid fat content (SFC) of oils and fats and their mixtures by pulsed nuclear magnetic resonance (NMR) spectroscopy remains of considerable interest to develop new products involving fats and oils. SFC in ranges of 15–25% at usage temperature (23 °C) is recommended for shortening to have excellent baking performance (Berger and Pollitt 1974). Shortening with lower SFC rated higher for sensory texture scores due to the desired soft texture of cake. However, some solids should remain at about 40 °C as these solids are necessary to support the structural formation of the cake.

The aim of this study was to investigate the compatibility of MLCT-enriched formulations to be used in shortening production. Six binary and four ternary MLCT-enriched formulations were developed. The fatty acid composition, solid fat content, and heating behaviors of the formulations were determined. The physicochemical properties of the MLCT-enriched formulations produced were also compared to commercial bakery shortening. Quantitative descriptive analysis was carried out to describe both qualitative and quantitative sensory aspects of cakes made from commercial and selected MLCT-enriched shortenings, while acceptance test (9-scale Hedonic) was run to evaluate the degree of liking for the product.

Materials and Methods

Materials

MLCT fat was produced using Lipozyme RM IM lipase-catalyzed esterification. The experimental details on the production of MLCT fat are shown in “Pilot-Scale Production of MLCT Fat”. The palm stearin IV44 was obtained from Golden Jomalina (Teluk Panglima Garang, Selangor). Palm olein IV60 and commercial shortening (Crisco, Pillsbury, USA) were purchased from Carrefour (Putrajaya, Kuala Lumpur) and Giant (Petaling Jaya, Selangor), respectively. Commercial shortening was made from soybean, sunflower, and hydrogenated palm oil. This shortening was chosen for this study as it contains 0 g trans fat and used for cake production. Commercialized immobilized lipase from Rhizomucor meihei (Lipozyme RM IM) was obtained from Novozymes A/S (Bagsvaerd, Denmark). All chemicals and solvents used were either of analytical or high-performance liquid chromatography grades, respectively.

Pilot-Scale Production of MLCT Fat

The production of MLCT fat was conducted in a 10-L stirred-tank bioreactor equipped with vacuum pump (Paramount Impact Sdn. Bhd,, Sri Kembangan, Selangor). The parameters of MLCT fat production were as follows: temperature, 65 °C; time, 14 h; enzyme concentration, 8% (w/w); and fatty acids/glycerol molar ratio, 3:1. A total of 8 kg (w/w) of melted capric and stearic acids was poured into the reactor vessel and mixed thoroughly using two vertically aligned three-bladed impellers in the feed tank at a speed approximately 500 rpm and equilibrated at 65 °C. A determined amount of glycerol (1.05 kg) was then added to the tank followed by 0.64 kg of enzyme. The vacuum pump was on to remove water during reaction. At the end of the reaction time, products were removed and filtered out from the bottom of the vessel.

Purification in a Pilot-Scale Short Path Distillation

Crude MLCT fat was purified using short path distillator. The distillation conditions are tabulated in Table 1. Other conditions were as follows: evaporator vacuum = 0.001 mbar; heat exchanger temperature, 80 °C. The addition of palm olein to crude MLCT fat at ratio 1:1 upon the first cut of SPD was done to decrease the solidification temperature. This mixing process was done due to the quick solidification of the MLCT fat in the feeding tank, and the purification process could not be carried out. Palm olein was chosen due to high thermal and oxidative stability, plasticity at room temperature, and tendency to crystallize in the β′ form (Noor Lida et al. 2003).

Sample Preparation

Six binary formulations of MLCT fat and palm stearin in ranges from 40% to 90% of MLCT fat with an increment of 10% (w/w) were produced, while 10% and 20% of palm olein replaced palm stearin in MS 46 and MS 55 formulations for ternary formulations. The fats and oil composition of binary and ternary formulations are shown in Table 2. MLCT fat, palm stearin, and palm olein were melted at 80 °C for 30 min in an oven to remove the crystal structures. The liquefied fats and oil were then mixed according to their proportions with total weight of 50 g fats and oils in sample bottles. All the formulations were kept at room temperature (25 °C) prior to SFC and thermal analyses.

Fatty Acid Composition

The fatty acid composition of MLCT fat, palm stearin, and palm olein was determined by AOCS (1993) Official Methods Ce 1-62. Fatty acid composition (FAC) of the samples were determined after converting free and glyceride fatty acid to their corresponding fatty acid methyl esters (FAME) and analyzing the FAME by gas chromatography (Hewlett-Packard, Wilmington, DE, USA), equipped with a flame-ionization detector. FAMEs were prepared by transesterification of fat (50 μL) with isopropanol (950 μL) and sodium methoxide (0.5 N, 50 μL). The conditions of FAC analysis were as follows: column oven, 170 °C (isothermal); carrier gas, helium 99.9%; carrier gas flow, 1 mL/min; running time, 13 min.

Solid Fat Content

Solid fat content was measured by pulsed NMR using Bruker PC/20 series NMR Analyzer (Minispec, Bruker, Karlsruhe, Germany; AOCS Official Method Cd 10-57). The samples were melted at 80 °C for 30 min to destroy the crystals’ history. During this study, the samples were evaluated at 5 °C intervals from temperatures of 0 to 60 °C.

Heating Profile

Heating profiles of MLCT fat, palm stearin, palm olein, and commercial and MLCT-enriched shortenings formulations were measured using Pyris Diamond differential scanning calorimeter (DSC) equipped with an intracooler 2P (Perkin Elmer, Norwalk, CT, USA). An empty aluminum pan was used as a reference, and samples (7–9 mg) were weighed. The samples were heated to 80 °C for 10 min to destroy the crystal memory. A crystallization curve was obtained by cooling to −60 °C at 5 °C/min and held for 10 min. The samples were then heated to 80 °C to determine the heating profile at heating rates of 5 °C/min. Although both cooling and heating profiles were done, only heating curves will be discussed here.

Production of Shortening

Shortenings were prepared according to the modified method of Danthine and Deroanne (2006, 2004). Appropriate weight compositions of 300 g of the melted fats were mixed in 1,000-mL beaker and put in an oven at 80 °C for 30 min to erase the crystal memory. The melted oils were kept in liquid form at 50 °C and mixed using food blender (Cornell, Kuala Lumpur, Malaysia) for 1 min to homogenize the sample. They were then put in a freezer at −20 °C for half an hour in order to simulate on a laboratory scale, an industrial scraped-surface heat exchanger. The shortenings were subsequently stored in room temperature (25 °C ± 1 °C) for 48 h prior to use in baking.

Production of Cake

The shortenings were evaluated for their sensory properties in cakes using a Madeira cake according to Nor Aini et al. (1989) with little modification to the ingredients (Table 3). Madeira cake was chosen due to its low fat content and is therefore particularly sensitive to the properties of the fat. The procedures to prepare the cake are discussed below.

Shortening and icing sugar were mixed using a KitchenAid Mixer model KSM150PS (KitchenAid, USA) for 15 min at speed 4. Speed 4 was used throughout the mixing process. After scraping the side of the bowl, eggs were poured into the batter-containing bowl and mixed for 10 s. Water, coloring, and vanilla flavor were added in the batter and mixed for 10 s. Self-rising flour was then added to the mixture followed by skimmed milk powder and then mixed again. Scraping was done just before each ingredient was added to ensure homogenous mixture was obtained. The batter was placed into two round cake baking tins with greaseproof paper and baked in an oven at 180 °C for 1 h.

Sensory Analysis

Two types of sensory evaluation, namely quantitative descriptive analysis and acceptance test, were carried out. Quantitative descriptive analysis of cakes made from commercial and MLCT-enriched shortenings were evaluated by ten trained panelists from Malaysian Palm Oil Board (MPOB). As panelists employed in the testing were used to evaluate this kind of samples, training was not provided. However, a few sessions were conducted to develop terminologies for the cake and to introduce the scaling method. The sensory parameters evaluated included color (light to dark), texture (hard to soft), oiliness (too oily to not oily), aroma (bad to good), taste (bad to good), moistness (dry to moist), and denseness (compact to airy). The scale used was 15-cm line with anchors at both two ends of the line (Meilgaard et al. 2000). Hedonic scale was used to evaluate the degree of liking of the products. One hundred untrained panelists were asked to rate the products in a scale of 1 to 9, with 1 representing extremely dislike and 9 representing extremely like for texture, taste, and overall acceptability properties. The samples were prepared by cutting them into equal thickness and size.

Statistical Analysis

Statistical Analysis System software (SAS, Cary, NC, USA) was used to perform statistical analysis (SAS Institute 2000). Analysis of variance with Duncan’s multiple range test was performed to determine significance of difference at P < 0.05.

Results and Discussion

Fatty Acid Composition

Table 4 shows the fatty acid composition of MLCT fat, palm stearin, and palm olein. The major fatty acids found in MLCT fat were capric and stearic acids (24.99% and 38.23%, respectively). Capric and stearic acids were the sole fatty acids used as raw materials in the lipase-catalyzed esterification process of MLCT fat and contributed to the high concentrations of these two fatty acids in the MLCT fat. In comparison, MLCT prepared by transesterification of 14% (w/w) and 86% (w/w) rapeseed oil contained 13% of medium chain fatty acids (caprylic and capric acids; Kasai et al. 2003). Matsuo et al. (2001) stated that transesterification of rapeseed oil and MCT at a ratio 9:1 (rapeseed oil/MCT) had 9.7% caprylic and capric acids. Total of myristic, palmitic, and stearic acids in MLCT fat was 54.7%. MLCT fat had the least concentration of unsaturated fatty acids (oleic and linoleic acids) with 19.61%. In contrast, palm olein contained the highest % of oleic and linoleic acids (55.12%). Addition of palm olein to unrefined MLCT fat upon short path distillation contributed to the presence of significant amount of palmitic, oleic, and linoleic acids in the MLCT fat. Unrefined MLCT fat solidified quickly in the feeding tank, and the purification could not be carried out. Thus, the addition of palm olein at ratio 1:1 (MLCT/palm olein) to this fat was done to decrease the solidification temperature. These details are also included in the “Purification in a Pilot-Scale Short Path Distillation”. Several factors such as temperature fluctuation, inefficient separation, and vacuum pressure during fractionation may cause the differences in values for the proportion of palmitic acid in palm stearin and oleic acid in the palm olein.

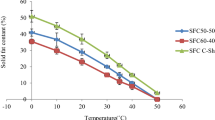

Solid Fat Content

The solid fat content of commercial and MLCT-enriched binary formulations are shown in Fig. 1. Commercial shortening (Pillsbury, USA) had flat SFC curve within temperatures of 0 to 25 °C. This indicated that the commercial shortening had broad plastic ranges compared to MLCT-enriched binary formulations. The solid fat of commercial shortening (22.8–16.2%) was lower than all MLCT-enriched formulations between these temperatures. It might be related to the high linoleic acid in the soybean and sunflower oils. SFC% of commercial shortening decreased steadily between 25 and 50 °C before all the solid fat completely melted. SFC% of the MLCT-enriched formulations decreased as the proportion of MLCT fat increased from 40% to 90%. Although MLCT fat had higher solid fat at any temperature compared to palm stearin, the increase in MLCT% led reduction in SFC% (data is not shown). This may be due to the solubility of the high-melting TAG into low-melting TAG. All solids completely melted at 55 °C. The high melting temperature is related to the high LCSFA content in the MLCT-enriched formulations (50–60%; Table 5).

According to Berger and Pollitt (1974), for shortening to perform well in baking, it should have a SFC in the range between 15% and 25% at usage temperature. Formulations of MS 73, MS 82, and MS 91 were found to contain 18.24–24.93% of solid fat at 25 °C, which represented the workable temperature. However, four ternary formulations of MSO 451, MSO 442, MSO 541, and MSO 532 were then produced as an effort to improve shortening production cost as MLCT fat production is considered expensive (Fig. 2). Three formulations that contained SFC within 15–25% at 25 °C were MSO 442, MSO 541, and MSO 532, and they were subsequently chosen to produce the cake shortening.

As shown in Fig. 1, it can be observed that there were differences in the slopes observed for binary MLCT-enriched formulations. Shortenings with formulations of MS 46, MS 55, and MS 64 have similar solid fat profile trends. There was a small region with a less accentuated slope shown at temperatures between 0 and 15 °C. The SFC% then decreased at a linear fashion from 15 to 30 °C, and similar patterns as low temperature melting slopes were seen between temperatures of 30 and 50 °C. These were then followed by a small tail after 50 °C. Unlike MS 46, MS 55, and MS 64 formulations, a sharp decrease was found in MS 73, MS 82, and MS 91 formulations between temperatures of 0 and 30 °C. At temperatures from 30 to 40 °C, the SFC% decreased gradually, and a short tail was observed afterward. As for ternary formulations, a small region was observed between 5 and 15 °C with less accentuated slope (Fig. 2). The SFC% then decreased sharply at temperatures between 15 and 25 °C and continuously decreased at temperatures 25 to 55 °C with similar slopes to those at lower temperatures. These changes might be contributed by various TAG fractions present in the material. Litwinenko et al. (2002) found similar observation for their commercial vegetable oil-based shortening composed mainly of partially hydrogenated soybean and palm oil where the slope of the SFC varied at particular temperatures (0–50 °C) range. These changes were due to contributions of the various TAG fractions comprising of low- and high-melting fats and oils in the materials.

Heating Profiles

Figure 3 illustrates the heating thermograms of MLCT fat, palm stearin, and palm olein. The endset, peak, and onset temperatures of MLCT fat were 27.86, 18.01, and 1.62 °C. These values indicated that MLCT fat was dominated by the low-melting fraction. MLCT fat showed two distinct peaks (peaks a and b) representing high- and low-melting TAG. This fat was completely melted at temperatures (57.5 °C), which were higher than palm stearin (52.48 °C) due to the high% of stearic acid present. Palm stearin and palm olein were dominated by high- and low-melting point fats and oils, respectively.

Figure 4 shows the heating curves of binary MLCT-enriched shortening formulations. The heating thermograms of MLCT fat and palm stearin mixtures showed different melting onset due to molecular species interaction among the constituents. Jin et al. (2008) reported similar observation for blends of palm kernel olein, tallow, and palm olein blends. The increment of MLCT fat percentages decreased the melting peak temperatures of the binary formulations, which were contributed by the presence of capric, oleic, and linoleic acids in the MLCT fat. However, the complete melting points of the binary formulations shifted to higher temperatures (51.37–55.93 °C; Table 6) when the proportion of MLCT fat increased (40–90%). This is associated with the high LCSFA content in MLCT-enriched formulations (Table 5). Heating curves of the MLCT-enriched formulations had numerous shoulders, which were not separable from the peaks. These are more likely due to the complex nature of fats and oil that comprised of various types of TAG. Two endothermic peaks of intermediate and high-melting fraction (peaks a and b) were observed on the MS 46 and MS 55 thermograms. However, the two peaks disappeared when the % of MLCT increased. In addition, broad melting ranges in the lower temperature region (−10–30 °C) were observed with increasing MLCT fat proportions. This trend was due to the dispersion of high-melting fat into the low-melting fraction. The fatty acids in low-melting TAG were capric, oleic, and linoleic acids. This finding was in agreement with the solid fat content results obtained.

Heating thermograms of ternary formulations are illustrated in Fig. 5. Similar observations were observed for MSO 451, MSO 442, and MSO 541 formulations. Two endothermic peaks (peaks a and b) were viewed on the thermogram of those ternary formulations. On the contrary, MSO 532 formulation did not show similar results where only one peak can be seen. Substituting 20% of palm stearin with palm olein in MS 55 formulation caused solubility of the melting fraction into low-melting fat to produce broader endothermic peak. When palm olein was used in the formulations, the melting temperature of the ternary formulations shifted to the left (decrease in temperature) due to the presence of high oleic and linoleic acids in palm olein (Table 6). Most of the formulations produced had melting temperatures higher than that of the commercial shortening. The heating thermograms of binary formulations were not much different with ternary melting curves. It may be due to the fact that only small amounts of palm stearin were substituted with palm olein. Moreover, palm olein and palm stearin are fractionated products of palm oil which have similar fatty acid and TAG types.

Sensory Attributes

The results of QDA are shown in Table 7. QDA was done to describe the attributes of the products by giving them a score. Higher score indicated that the samples had good quality for that particular attribute. Cakes made from commercial shortening showed significant (P < 0.05) higher in score for color compared to those made from MLCT-enriched shortenings. Color formation of cakes was due to the reaction between amino acids and reducing sugars in the presence of heat and so-called Maillard reaction. The differences in the color for cakes made from commercial and MLCT-enriched shortenings may be contributed by the emulsifier content of the shortening. The color changes for the rice cakes was found to be significantly (P ≤ 0.001) affected by the emulsifier concentration (Turabi et al. 2008). Panelists rated cakes made from commercial and MSO 442 shortenings significantly (P < 0.05) higher compared to those made from MSO 541 and MSO 532 shortenings for texture, indicating that the former were softer in texture. Samples made from commercial and MSO 442 shortenings were rated similar (P > 0.05) in terms of texture. High % of liquid fat at room temperature in commercial (16.22%) and MOS 422 (22.69%) shortenings might contribute to the texture of cake. Moistness of the cakes made from commercial and MLCT-enriched shortenings showed no significant (P > 0.05) differences, with cakes made from commercial shortening having the highest score among all the samples. The high score of moistness may affect the high score obtained for texture attribute. Turabi et al. (2008) reported that the texture of the cakes were associated with their moisture content. The oiliness for cakes made from MSO 442 and MSO 541 shortenings were significantly (P < 0.05) higher compared to those made from commercial and MSO 532 shortenings, indicating that the former was less oily. High % of liquid oil remaining at body temperature in MSO 532 shortening (more than 90%) might contribute to the oiliness of the cake made from this shortening. Similar results were obtained for commercial shortening. The high concentration of low-melting fraction in commercial shortening as observed from DSC heating curve indicated that more liquid oil was present at 37.9 °C and had caused the oiliness in the mouth during ingestion (Fig. 3).

In terms of denseness, cakes made from commercial and MSO 442 shortenings were significantly (P < 0.05) less dense than cakes made from MSO 541 and MSO 532 shortenings. This was due to the moderate % of SFC in commercial (7.8%) and MSO 442 (8.5%) shortenings at 40 °C, which was necessary to support the cake structure formation. The score of denseness for cakes made from commercial and MSO 442 shortenings were in agreement with texture attribute confirming the soft texture of the cakes. Lakshminarayan et al. (2006) stated that in increased specific volume of the cakes, softer texture of cakes was obtained. As specific volume is closely related to the cake expansion, it can be used as an indicator for denseness of the cakes. Trained panelists gave higher scores for taste to cakes made from MLCT-enriched shortenings, indicating that the cakes had good taste compared to the cakes made from commercial shortening. Similar pattern was observed for aroma properties as the panelists rated cakes made from MLCT-enriched shortenings higher.

Principle component analysis (PCA) is a useful multivariate analysis procedure to describe interrelationships between multiple variables (Jaworska et al. 2005). Principle component 1 (PC1) and principle component 2 (PC2) described 36% and 25%, respectively, of the variance. The loading plot for component 1 and 2 is shown in Fig. 6. The attributes that had a major influence on differentiation of samples were color, SFC, melting temperature, aroma, and denseness. Oiliness showed a minor influence on sample differentiation. Taste was strongly and positively correlated with the melting temperature and SFC. The correlation between the treatments and sensory attributes were determined. The QDA attributes of cakes made from MSO 442 and MSO 531 shortenings and MSO 531 and MSO 532 shortening were found to be highly correlated to each other with R 2 = 0.70 and R 2 = 0.86, respectively. QDA attributes of cakes made from commercial and MLCT-enriched shortenings showed low correlation coefficient values.

Table 8 illustrates the scores given by 100 untrained panelists to determine the acceptability of the Madeira cakes made from commercial and MLCT-enriched shortenings. Panelists were asked to rate the products in terms of texture, taste, and overall acceptability. They had to evaluate the attributes between the 1 to 9 scales, with the lowest number representing “extremely dislike” and the highest value representing “extremely like”. In terms of texture, samples made from commercial, MSO 541, and MSO 532 shortenings were significantly (P < 0.05) higher compared to cakes made from MSO 442 shortening. Similar observations were found for taste and overall acceptability. Although no significant differences (P > 0.05) were seen in cakes made from commercial, MSO 541, and MSO 532 shortening, cakes made from MSO 532 shortening had the highest score of acceptability for all the sensory properties. These suggest that cakes made from MSO 532 shortening with scores of 6.51 (texture), 6.78 (taste), and 6.69 (overall acceptability) was the best sample among all the shortenings. In acceptance test, the cakes made from MSO 442 and MSO 532 shortenings had low correlation, with R 2 = 0.51. In contrast, the cakes made from MSO 442 and MSO 541 shortenings (R 2 = 0.98), as well as the cakes made from MSO 541 and MSO 532 shortenings (R 2 = 0.68) were highly correlated.

Conclusion

Fatty acid composition of the MLCT-enriched formulations had great influence on solid fat content and heating behaviors. All solids fat melted at temperature higher than 55 °C, while melting DSC temperatures were found to be higher than 50 °C. This may associate to the high proportion of palmitic and stearic acids in the formulations. Panelists (trained and untrained) of sensory evaluations rated Madeira cake made from MSO 532 formulation shortening the highest, indicating that the cake had good sensory properties as well as high degree of liking. As a conclusion, we can say that MLCT-enriched shortenings can be formulated to produce Madeira cake that is desired by consumers.

References

AOCS. (1993). The AOCS Official Methods and Recommended Practices of the American Oil Chemists’ Society, 4th edn. In D. Firestone (Ed.). Champaign: AOCS Press.

Aoyama, T., Nosaka, N., & Kasai, M. (2007). Research on the nutritional characteristics of medium-chain fatty acids. Journal of Medical Investigation, 54, 385–388. doi:10.2152/jmi.54.385.

Beermann, C., Jelinek, J., Reinecker, T., Hauenschild, A., Boehm, G., & Klor, H. U. (2003). Short term effects of dietary medium-chain fatty acids and n-3 long-chain polyunsaturated fatty acids on the fat metabolism of healthy volunteers. Lipids in Health and Disease, 2(10), 1–10.

Berger KG, Pollitt RJM. (1974) the physical structure of shortening. Paper presented at Mini Symposium, Oils and Fats. 10th Anniversary Symposium of Institute of Food Science and Technology, UK.

Danthine, S. B., & Deroanne, C. (2004). Influence of SFC, microstructure and polyphorphism on texture (hardness) of binary blends of fats involved in the preparation of industrial shortening. Food Research International, 37, 941–948. doi:10.1016/j.foodres.2004.06.003.

Danthine, S. B., & Deroanne, C. (2006). Determination of solid fat content (SFC) of binary fat blends and use of these data to predict SFC of selected ternary fat blends containing low-eruric rapeseed oil. Journal American Oil Chemist Society, 83(7), 571–581.

Jaworska, D., Bozena, WR., Kolanowski, W., & Swiderski, F. (2005) Relative importance of texture properties in the sensory quality and acceptance of natural yoghurts. International Journal of Dairy Technology, 58(1), 39–46.

Jin, Q., Zhang, T., Shan, L., Liu, Y., & Wang, X. (2008). Melting and solidification properties of palm kernel oil, tallow, and palm olein blends in the preparation of shortening. Journal of the American Oil Chemists’ Society, 85, 23–28. doi:10.1007/s11746-007-1152-3.

Kasai, M., Nosaka, N., Maki, H., Negishi, S., Aoyama, T., Nakamura, M., et al. (2003). Effect of dietary medium- long chain triacylglycerols (MLCT) on accumulation of body fat in healthy humans. Asia Pacific Journal of Clinical Nutrition, 12(2), 151–160.

Koh SP, Tan CP, Lai OM, Arifin N, Yusoff MSA & Long K (2008) Enzymatic Synthesis of Medium-and Long-Chain Triacylglycerols (MLCT): Optimization of Process Parameters Using Response Surface Methodology. Food Bioprocess Technology. doi:10.1007/s11947-008-0073-y

Kosmark, R. (1996). SALATRIM: Properties and applications. Food Technology, 4, 98–101.

Lai, O. M., Low, C. T., & Akoh, C. C. (2005). Lipase-catalyzed acidolysis of palm olein and caprylic acid in a continuous bench-scale packed bed bioreactor. Food Chemistry, 92, 527–533.

Lakshminarayan, S. M., Rathinam, V., & KrishnaRau, L. (2006). Effect of maltodextrin and emulsifiers on the viscosity of cake batter and on the quality of cakes. Journal of the Science of Food and Agriculture, 86(5), 706–712.

Litwinenko, J. W., Rojas, A. M., Gerschenson, L. N., & Marangoni, A. G. (2002). Relationship between crystallization behavior, microstructure, and mechanical properties in a palm oil-based shortening. Journal American Oil Chemist’ Society, 79(7), 647–654.

Liu, L., Liu, P., Li, L., & Sun, J. (2008). Production of structured lipids by enzymatic incorporation of caprylic acid into soybean oil. In Proceedings of the 2nd Bioinformatics and Biomedical Engineering Conference 2008, ICBBE 2008, 16-18 May 2008, Shanghai.

Matsuo, T., Matsuo, M., Kasai, M., & Takeuchi, H. (2001). Effects of a liquid diet supplement containing structured medium-and long chain triacylglycerols on body fat accumulation in healthy young subjects. Asia Pacific Journal of Clinical Nutrition, 10(1), 46–50.

Meilgaard, M., Civille, G. V., & Carr, B. T. (2000). Sensory evaluation techniques. Boca Raton: CRC.

Nor Aini, I., Berger, K. G., & Ong, A. S. H. (1989). Evaluation of shortenings based on various palm oil products. Journal Science and Food Agriculture, 46, 481–493.

Noor Lida, H. M. D., Chong, C. L., Mamot, S., & Aminah, A. (2003). Polymorphic behaviour of blends of palm oil and palm olein with sunflower oil and palm kernel olein as affected by blending and interesterification. Oil Palm Bulletin, 47, 28–36.

Nosaka, N., Maki, H., Suzuki, Y., Haruna, H., Ohara, A., Kasai, M., et al. (2003). Effects of margarine containing medium-chain triacylglycerols on body fat reduction in humans. Journal Atherosclerosis and Thrombosis, 10(5), 290–298.

Osborn, H. T., & Akoh, C. C. (2002). Structured lipids-novel fats with medical, nutraceutical and food applications. Comprehensive Reviews in Food Science and Food Safety, 1, 93–103.

Sandrou, D. K., & Arvanitoyannis, I. S. (2000). Low-fat/calorie foods: Current state and perspectives. Critical Reviews Food Science Nutrition, 40, 427–447.

SAS (2000) SAS User’s Guide: Statistic (version 8.2). SAS Institute, Cary, North Carolina, USA.

Shinohara, H., Shimada, H., Noguchi, O., Kubota, F., & Aoyama, T. (2002). Effect of medium-chain fatty acids-containing dietary oil on hepatic fatty oxidation enzyme activity in rats. Journal Oleo Science, 51(10), 621–626.

Turabi, E., Sumnu, G., & Sahin, S. (2008). Optimization of baking of rice cakes in infrared-microwave combination oven by response surface methodology. Food Bioprocess Technology, 1, 64–73.

Yankah, V. V., & Akoh, C. C. (2000). Lipase-catalyzed acidolysis of tristearin with oleic or caprylic acids to produce structured lipids. Journal American Oil Chemist’ Society, 77(5), 495–500.

Acknowledgments

Financial support for this work from Golden Hope Sdn. Bhd. is gratefully acknowledged. The authors would like to thank Mr Azmi and Ms Mary Goh from MARDI, Serdang, Mr. Hadi from UPM, Serdang and Mrs Hanirah from MPOB, and Bandar Baru Bangi for their kind technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arifin, N., Cheong, LZ., Koh, SP. et al. Physicochemical Properties and Sensory Attributes of Medium- and Long-Chain Triacylglycerols (MLCT)-Enriched Bakery Shortening. Food Bioprocess Technol 4, 587–596 (2011). https://doi.org/10.1007/s11947-009-0204-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-009-0204-0