Abstract

As paper has become an important part of global consumption, there is a necessity to find a balance between production and resources, when an increase in paper production has been observed within past decades. Diverse technologies are being used for paper production one of them being use of enzyme of microbial origin for better bio-pulping and bio-bleaching results along with easier fibre grafting and de-inking. Though there are many applications of such enzymes in this industry, they are still at early development stage. The most essential feature of using enzymes is that it helps in eco-friendly bio-bleaching of pulps. Xylanase, cellulose free xylanase and occasionally use of laccase are the enzymes being used as a better alternative for reduction in the amount of environmental-polluting chlorine. Endo-β-xylanases, belonging to xylanases, is the key enzyme required for the enzymatic bleaching. The main purpose to adopt such techniques is to reduce the requirement of chlorine containing chemicals for bleaching. Enzymes further increases the pulp brightness making it easier for the industry to go chlorine free, along with improving fibre quality, producing better quality fibre. We will now discuss about the pulp industry and how xylanase enzyme helps in improving the productivity and revolution of the industry in detail in this chapter.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

An important part of global economy is the paper industry but a right balance needs to be maintained between the production (cost and materials used) and profit especially when there has been an over-all increase in paper consumption. Presently a key research topic is to improve paper productivity by finding an alternative method of using the raw material thus, reducing the amount of pollutants released during the manufacturing process. The primary source of paper manufacturing is the plant biomass majorly formed of different assemblies of polysaccharides, structural proteins and phenylpropanoids that majorly contributes in forming the plant biomass (Carpita and Gibeaut 1993; Popper and Fry 2008; Roppolo et al. 2011). During the last 2–3 decades, many advancements have been witnessed in the manufacturing process of paper. Some advancements for improving the efficiency of the manufacturing process include discovery of enzymatic de-inking, fibre engineering, use of “xylanase” in bleaching etc. as it is considered to play important role in limiting the resources required for the production of paper at the same cost. This will aid in reducing the impact of these industries on nature thus, help in its preservation the basis of achieving such a goal depends on understanding the biosynthetic pathways involved in production of various wood components and improving the quality of fibre using conventional breeding methods or using leading-edge biotechnology–based techniques.

Enzyme–based methods have been used as a process aide for fibre modification in the paper industry. A study on patents displayed a high number of documents have been and are being published correlated to this technology. The enzymes like xylanase, cellulase–free xylanase, cellulase etc. show a huge potential of being used in the pulp and paper processes to boost the process of bleaching by fibre engineering. Improving the thermostability of these enzymes along with increasing their alkalinity strength forms the current trends of study and research. Microbial cellulase, contributes to 10% of global enzyme demand and its usage can give rise to newer opportunities in making paper industries grow commercially.

However certain criteria need to be followed before using any enzyme–based method in the manufacturing process. The criteria that must be followed includes:

-

Fibre quality and processing of fibre should either be improved or be maintained

-

Using enzyme should result in economic benefits

-

The enzyme preparation used should be available at reasonable price and in a large quantity for use by industries

-

The enzyme should not be responsible for any unlikely changes in the process it is used in

Fibre properties can be improved or newer properties can be created by fibre surface target modification using enzyme treatment or by combined enzymatic and chemical treatment. This can be used not only to improve paper manufacturing but also to improve other non-paper manufacturing processes (Fig. 1).

The structure and composition of plant cell wall (https://images.app.goo.gl/qrhMXZKWcNVxZhp89). Dburkhammer cell project. Cell wall, protects the plant cell, the outermost layer [photograph], Retrieved from: https://dprojectmiller.weebly.com/cell-wall.html

Plant Cell Wall

The primary wall of plant cells, play an essential role in its support and other physiological processes, is rich in polysaccharides, as seen in Table 1 (Carpita and Gibeaut 1993; Taiz and Zeiger 2002). The cell wall that develops during the cell differentiation and elongation stages is known as the “primary cell wall” whose composition shows great variation depending on the cell and tissue type and developmental stage the cell is in (Pauly and Keegstra 2008; Höfte and Voxeur 2017).

A cell wall for extra support develops towards the inner surface of the primary wall, displacing it as can be seen in Fig. 2. It is known as the “secondary cell wall” and its constituents are similar in both hardwood and softwood trees. The secondary wall differs from the primary wall in both composition and concentration of components as can be seen in Table 1 (O’Neill and York 2003; Vogel 2008; Chundawat et al. 2011; Meents et al. 2018). The composition and the proportion of components of secondary cell wall vary among different species.

The difference in composition of plant primary and secondary cell wall (https://www.google.co.in/url?sa=i&rct=j&q=&esrc=s&source=images&cd=&ved=2ahUKEwiasK6jjfjkAhWNb30KHXByA-IQjRx6BAgBEAQ&url=http%3A%2F%2Fwww.ifasonline.com%2FNEET-AIIMS-COACHING%2FBiology%2FNeet-Biology-topic-15.jsp&psig=AOvVaw1PPksFuB5XxC2fWFKHJKgY&ust=1569917497299480).Ifas biology. Cell boundaries, cell wall [photograph], retrieved from: http://www.ifasonline.com/NEET-AIIMS-COACHING/Biology/Neet-Biology-topic-15.jsp

The Components of Cell Wall

Cellulose

It is considered as the most abundant biological polymer with cellobiose as its central repeating unit as can be seen in Fig. 3a. D-glucose monomers connected by β-1,4 glycoside bonds forms the building blocks of cellulose. The component is synthesized by a multi-enzyme complex known as the “cellulose synthase” that can add upto 2000–25000 glucose monomers to form the chains of cellulose (Turner and Kumar 2018). 30–36 linear chains of cellulose polymer connected to each other parallelly by hydrogen bonds forms the cellulose microfibril that provides additional mechanical strength and protects cellulose against enzymatic degradation (Carpita and Mccann 2000).

The molecular structure of different components of the plant cell wall (https://images.app.goo.gl/BitmTaC2yTJD4YCc9). Alonso et al. 2012, Structure of lignocellulosic biomass with cellulose, hemicellulose, and lignin represented, retrieved from: https://www.researchgate.net/publication/321075806_A_study_of_the_uncertainty_associated_with_tar_measurement_and_an_investigation_of_tar_evolution_and_composition_during_the_air-blown_fluidised_bed_gasification_of_torrefied_and_non-torrefied_grassy_b

Hemicellulose

Hemicellulose provides additional support to the cell wall by preventing sliding–over of cellulose chains and is considered to be the next most abundant plant carbohydrate after cellulose. It is microfibrils to prevent the collapse of cell wall due to cellulose chains sliding over each other. Individual hemicellulose chains (100–200 residue) remains cross-linked to cellulose, in a matrix composed of pectin (primary wall) or lignin (secondary wall) (Abramson et al. 2010; Van Der Weijde et al. 2017). Several hemicellulose variants are present depending on whether it is composed of D–xylose (pentose) or D–mannose or D–glucose (hexose) that are linked to each other by β-1,4 glycoside bonds as can be seen in Fig. 3b (Meents et al. 2018).

Hemicellulose that is abundant in non-commelinid monocots or eudicots is the ‘xyloglucan’, characterised by α-(1,6)-bonded xylose monomers branched off from β-1,4-D-glucose backbone that may further be linked to galactose, fucose, arabinose or other sugars (Pauly and Keegstra 2016).

Xylan, primary hemicellulose in Poaceae, is characterised by different branching of glucuronic acid pattern as seen in Fig. 4a and arabinose from the linear β-1,4-D-xylose chain. Four fundamental groups of xylans can be considered (Biswal et al. 2018):

-

Arabinoxylans, having just side chains of single terminal units of α-L-arabino-furanosyl substituents. In the specific instance of oats, arabinoxylans vary in the level of arabinosyl substitution, with either 2-O-and 3-O-mono-substituted or twofold (2-O-, 3-O-) substituted xylosyl residues

-

Glucuronoxylans, majorly linear polymers of xylose residues bonded by (1→4) glycoside, has several units substituted at C-2 or C-3 or both by a glucuronate residue, often methylated at C-4

-

Glucuronoarabinoxylan, formed of linear xylose polymer has α-D-glucuronic (often methylated) or α-L-arabinose substitutions on xylose residues

-

Galacto-glucurono-arabinoxylans, is the hemicellulose of perennial plants, characterised by closeness of the terminal β-D-galacto-pyranosyl residues on the branched chains of xylans

The molecular structure of the two major classes of Hemicellulose (https://images.app.goo.gl/pmVHSACMfQdNfr2H6). Lee HV, Hamid SB, Zain SK (2014), conversion of Lignocellulosic biomass to nanocellulose: structure and chemical process, retrieved from: https://www.ncbi.nlm.nih.gov/pubmed/25247208

Mixed–linkage glucans or β-glucans are also found in abundance in the cell wall of grasses. They are unbranched glucose polymer characterized by alternating short sequences of β-1,4-glucan with a single residue of β-1,3-glucans (Turner and Kumar 2018; Oliveira et al. 2016).

The third most essential hemicellulose is found in charophytes and are known as mannans and glucomannans. As can be seen in Fig. 4b, glucomannan formed of non-repeating units of mannose and glucose has a linkage of β-1,4-glycoside between them (like in galacto–glucomannans) (Srivastava and Kapoor 2017).

Lignin

Lignin, the most abundant non-polysaccharide in plants, is present in the secondary wall of specialised tissues (vessels, cortex, etc.) of plants and is responsible for about 15–40% plant dry weight. It forms the plant matrix that interact with both cellulosic microfibrils and hemicellulose. It is a phenol derivative as can be seen in Fig. 3c which protects plants against physiological stress, pathogens or other abiotic stress and provides rigidity to plants (Nguyen et al. 2016; Santos and Ferrarese 2008).

Pectin

Pectin, present in the primary wall’s middle lamella, is a structural polysaccharide having branched chains formed of neutral sugars (like galactose, arabinose and rhamnose) and acidic sugars (like glucuronic and galacturonic acid). ‘Homogalacturonan’, the linear, most abundant pectin as represented in Fig. 5 is formed of α-1,4 glycoside linked galacturonic acid monomers. Other pectin types can involve xylogalacturonan, rhamnogalacturonan I and II etc. (Biswal et al. 2018; Mohnen 2008)

The molecular structure of pectin (https://images.app.goo.gl/ZRGffnLnceK9EUov7). Mario Aguedo (2011), Pectic oligosaccharides: production and possible applications, retrieved from: https://www.researchgate.net/figure/Structure-primaire-dun-homogalacturonane-Primary-structure-of-a-homogalacturonan_fig1_50235213

Pectin confers plant rigidity and defence against pathogens. It also helps in cell adhesion and maintaining the water content in the plant cell. Pectin has a huge potential to be used in different industries like in paper industry, drug industry, in cosmetics etc. Pectin percentage of about 30% is found in dicots and non-commelinid monocots that is observed to be far greater than its percentage in Poaceae and commelinid monocots (2–10% pectin) (Mohnen 2008; Voragen et al. 2009).

The Glycoside Enzymes

CAZymes (Carbohydrate–active enzymes) have the ability to modify complex polysaccharides and are organized into the families of GHs (glycoside hydrolase), GT (glycosyl transferase), CE (carbohydrate esterase), PL (polysaccharide lyase) and auxiliary activities [including oxidative enzymes CDH (cellobiose dehydrogenase) and LPMO (lytic polysaccharide mono-oxygenase) (Lombard et al. 2014; Bourne and Henrissat 2001). CAZymes are examples of modular proteins, formed of different domains like the ‘catalytic domain’ (for enzyme activity) and a ‘carbohydrate–binding domain (CBM)’. The CBM is the site of association of the insoluble substrate to the enzyme and is found in the enzymes that can degrade xylans, mannans, glucomannans, galactans, pectins, and arabinans (Hashimoto 2006; Boraston et al. 2004; Terrapon et al. 2017).

Ligninases

Ligninases are enzymes that can hydrolyse lignin into simpler compounds for easier microbial assimilation. Ligninase is majorly classified into:

-

(a)

Laccases–they are Cu-containing glycoproteins, formed of a single, double or a quadruple polymer, that are involved in lignin degradation by oxidizing phenolic compounds. This results in the yield of compounds with lower molecular weight like quinine and other ions and radicles like phenoxyl radicals (Biswal et al. 2018). Some microbes that are known to produce this enzyme includes Aspergillus nidulans, Phellinus ribis, Phanerochaete chrysosporium etc. (Mohnen 2008)

-

(b)

Peroxidases–Lignin Peroxidase, an iron-containing protein, is an oxidoreductase that uses hydrogen peroxide to depolymerise lignin. They are observed to show a high potential of oxidation–reduction at an optimum pH of around 3 (Mohnen 2008), but generally shows a low substrate specificity

-

(c)

Manganese peroxidases, is another type of Peroxidase, that are observed to use Mn2+ for oxidation of phenolics to yield phenoxyl radicals (Nguyen et al. 2016)

Cellulase

It is an important enzyme for cellulose degradation, used in different industries, that can hydrolyse the β-1,4-glycosidic bonds between glucose monomers. It has a huge potential to be used in food sectors, paper industries, in cosmetics etc. (Sette et al. 2008). It is characterized by three essential synergistic enzymatic activities of exoglucanase and cellobiohydrolase (removes cellobiose from non-reducing and reducing end respectively from the crystalline portion), endoglucanase (cleaves glycosidic bond from the non-crystalline portion) and β-glucosidase (Segato et al. 2017; Segato et al. 2014).

Cellobiohydrolase can remove cellobiose from cellulose’s non-reducing end. It can hydrolyse cellodextrins (intermediate cellulose degradation product), but not the soluble derivatives of cellulose (CMC and hydroxyethyl cellulose) (Segato et al. 2014).

Endoglucanase are known to degrade both carboxymethyl cellulose (CMC) and cellodextrins to form cellobiose (simplest unit of cellulose) and glucose. (Begum et al. 2009).

β-glucosidase cleaves cellobiose thus removing glucose from the non-reducing end of cellulose (end with free -OH group at C-4) and can also hydrolyse the aryl and alkyl β-glucosides.

Fungal Cellulases

Fungi, among the microbes, are the principal cellulose decomposers, responsible for about 80% of cellulose degradation particularly in forest ecosystem. The fungal families that can actively degrade cellulose are found belonging to phylum Ascomycota, Deuteromycota, Basidiomycota and some Chytridiomycota occurring in the animal rumen. Some of the Competent cellulolytic fungal species are Penicillium, Aspergillus, Trichoderma, Alternaria, Fusarium, Myrothecium and so on (Sajith et al. 2016). Aerobic fungal cellulases unlike anaerobic fungal cellulase and other microbial cellulase that are membrane–bound, are extracellular, secreted in large quantities and adaptive in nature for which it is economical and are usually preferred by different industries (Mathew et al. 2008).

Aspergillus, Penicillium, Trichoderma and Sclerotium are the species that are commercially exploited for cellulase production (Milala et al. 2005). Fungal cellulase like other cellulases, has a ‘catalytic domain’ (for enzyme activity) and a CBM connected by a poly–linker that is rich in serine and threonine (Payne et al. 2015). The CBD is rich in polar and aromatic amino acid and thus aids in substrate immobilization during catalysis while the catalytic domain houses the active site for substrate hydrolysis (Hildén and Johansson 2004). In the last 2–3 decades, an aerobic fungi Trichoderma reesei is extensively studied for its capability to hydrolyse native cellulose due to the presence of genes encoding for cellulase genes encoding exoglucanase, 8 coding endoglucanases and 7 coding glucosidases (Singhania et al. 2006; Sukumaran et al. 2005).

Nowadays, thermophilic fungi are significantly studied because of the tendency of cellulose fibres to bulge out at high temperatures, making it accessible to the hydrolytic enzymes (Li et al. 2011; Murray et al. 2004). Talaromyces emersonii is one such thermophilic fungi from which cellulase active at 70 °C can be isolated (Murray et al. 2004). Chaetomium thermophilum, two strains of Penicillium, Thermoascus aurantiacus and Sporotrichum thermophile are among the thermophilic fungal species that have the potential to be used for the commercial production of thermo-stable cellulase enzyme (Picart et al. 2007).

Use in Paper and Pulp Industry

Cellulases are used in paper industries for pulping and de-inking of waste papers. Nowadays, bio-mechanical method using enzymes are being widely used to acquire the fibre suspensions from wood (i.e. the pulp). Cellulase can improve the physical properties (like inter-fibre bonding and mechanical strength) of the final product thus, increasing the energy efficiency of the process (Chen et al. 2012). It further makes the process environment-friendly by limiting the usage of harmful chemicals. For instance, bleached Eucalyptus globules kraft pulp can be effectively refined by cellulase as it enhances the pulp drain-ability by about 80% without changing the energy consumption (Gil et al. 2009). It can further be used in fibre modification of Kraft (sulphate pulp) to improve the properties of the final sheets (Cui et al. 2015).

Cellulase can be used during deinking of waste papers as it can hydrolyse cellulose thus releasing the ink attached to the surface of cellulose. This results in peeling of individual fibre or bundles (Lee et al. 2011). Waste papers often act as an important raw material for the paper industries, as recycling them reduces amount of solid-waste produced and also helps in forest conservation by lowering deforestation for wood fibres (Singh et al. 2012). Enzymatic deinking using a commercial mixture of cellulase and hemicellulase is used for improving the over-all brightness and quality of recycled paper (Ibarra et al. 2012).

Cellulases can dissolve clogged fibre residues thus improving drainage of paper mills (Kuhad et al. 2011). Furthermore, commercial cellulase preparation have been used in the manufacture of easily biodegradable cardboards, tissue and sanitary papers (Hsu and Lakhani 2002).

Hemicellulose

It is another group of carbohydrate esterases represented by xylanases, β-xylosidases, β-mannanases and arabino-furanosidases. Xylan, constituting about 33% of the total global polysaccharide and 70% of all hemicelluloses known, is hydrolysed by xylanases and β-xylosidases to xylose. Other hemicellulases like mannanases and arabinases can be used for further degradation process depending on the chemical composition of hemicelluloses (Dashtban et al. 2009).

Xylanase

They are glycoside hydrolase (GH) that can break the β-1,4 glycoside bonds of xylosides forming sugar hemiacetal and non-sugar aglycone. Xylanases can be classified depending on its molecular weight, chemical and physical properties, isoelectric point (pI) and structure (Collins et al. 2005). Xylanase are predominantly found in both prokaryotes and eukaryotes. They have been derived from different marine and terrestrial organisms like microbes, protozoa, algae, snails, shellfish, insects and seeds of terrestrial plants and so on (Walia et al. 2013).

Endo-1-4-β-xylanases

The bonds cleaved by endo-xylanase depends on chain length, the degree of branching etc of Xylan (Li et al. 2000) resulting in release of different products (like xylose, xylobiose, xylotriose and arabinose). This forms the basis of classifying different endo-xylanase. Xylanases can both liberate arabinose or not liberate arabinose, but several organisms tend to produce both of them for maximum hydrolysis efficiency (Wu et al. 2006; Okazaki et al. 2005).

The endo-xylanases are generally observed to show maximum activity when temperature is between 40–80 °C and pH 4.0–6.5. Individually fungi and bacteria can exhibit a fine diversity of endo-xylanases. Three or more enzyme activities were separated from a single culture as was proposed by (Polizeli et al. 2005). It was noted that endo-xylanases fall into two main classes (Corral and Villasenor-Ortega 2006).

-

with molecular weight <30 kDa; they are basic in nature

-

with molecular weight values >30 kDa; they are acidic in nature

β-Xylosidases

β-Xylosidases are classified based on their affinities to degrade the end products formed when xylan undergoes through successive hydrolysis by other xylanases. Successive hydrolysis often results in accumulation of β-D-xylo-pyranosyl that are further broken down using β-xylosidases to prevent these short oligomers from inhibiting endo-xylanases (Andrade et al. 2004). They are produced by both bacteria and fungi and can cleave artificial substrates (p-nitrophenyl, o-nitrophenyl-β-D-xylo-pyranoside etc.) (Polizeli et al. 2005; Corral and Villasenor-Ortega 2006).

β-Xylosidases can show peak activity when temperature varies from 40 to 80 °C, making them highly thermo-stable depending on their source organism. One such enzyme that can retain 100% activity when stored at 60 °C for 4 h was isolated from Aspergillus phoenicis, (Rizzatti et al. 2001).

α-Arabino-Furanosidases

It hydrolyses L-arabinose, without degrading the xylan backbone, from C- 2/C-3 of β-D-xylo-pyranosyl. They have two distinct mode of action (De Vries et al. 2000).

-

They can degrade p-nitrophenyl-α-L-arabino-furanosides and branched arabinans (exo-α-L-arabino-furanosidase)

-

They can only hydrolyse linear arabinans (endo-1, 5-α-L-arabinase)

Acetyl-Xylan Esterase

It acts on acetylated xylans and removes the O-acetyl group that are present at carbon position 2 or 3 of xylose residues. Removal of acetyl side-groups is necessary as it sterically hinders the enzymatic degradation of the backbone (Corral and Villasenor-Ortega 2006).

α–Glucuronidases

They recognize the α-1, 2 bonds of glucuronoxylan present between glucuronic acid and β-D-xylo-pyranosyl residues. Some glucuronidases can even hydrolyse intact polymer. It has been observed that α-glucuronidase activity can partially be hindered by the presence of acetyl groups near the glucuronosyl substituents. (Tenkanen and Siika-aho 2000).

Extremophilic Xylanases

Xylanase generally has high activity at mesophilic conditions of 40–60 °C temperature and neutral or slightly acidic pH in case of bacterial xylanase and fungal xylanase respectively (Walia et al. 2014). Extremophilic xylanase are a new group of xylanases that are under study as they are active under extreme conditions of pH 2–11 and temperature from 5 to 105 °C. Some thermophilic microbes like Thermotoga sp., Bacillus stearothermophilus, Rhodothermus marinus, Thermoascus aurantiacus was found to synthesize xylanase that can show stable enxymatic activity at temperature as high as 105 °C (Song et al. 2013). One such xylanase showing better activity at 30% concentration of NaCl and temperature of 55–65 °C was isolated from an extreme halophilic archaeon, Halorhabdus utahensis (Wainø and Ingvorsen 2003).

Bacterial Xylanases

Xylanases are observed to be produced by both free–living bacteria as well as endosymbionts like those present in ruminants, insects etc. Bacterial xylanases are mainly isolated from the genera Bacillus, Microbacterium, Staphylococcus, Cellulomonas, Micrococcus, Arthrobacter, and Rhodothermus (Chapla et al. 2012). Some of the bacterial xylanases that are well studied includes:

-

Xylanase isolated from Bacillus subtilis (CXJZ) is reported to show the highest activity of 36633 IU/mg when the substrate used for its culture is Xylan derived from oat spelt or birchwood. This enzyme was found to show optimum activity at 60 °C temperature and a pH of 5.8 i.e. slightly acidic conditions. When purification of enzyme was initially carried out using ultracentrifugation followed by gel-filtration chromatography, it was found that cellulase-free Xylanase (pI of 9.63) could be isolated that was stable even at a temperature of 70 °C. This bacterial strain was found to be abundant in “ramie stems” that are submerged partially in river (Guo et al. 2012).

-

Xylanase that was isolated from a different Bacillus genus—Bacillus halodurans (TSEV1), an extremophile, using Xylan derived from oat spelt, birchwood or beechwood as the substrate for its culture was a thermo-stable endo-xylanase which was cellulase-free. It is usually observed to degrade Xylan derived from soft wood. This enzyme was observed to have maximum activity at 80 °C temperature and a pH between 8.0–12 (optima at 9.0). Endo-xylanase isolated from this strain was better in activity and stability as compared to other Bacillus halodurans strains. Enzyme purification of 13.5-fold was reported when anion-exchange was used followed by gel-filtration chromatography along with a yield of 30%. Because of its alkaline nature, it can be used in paper industries for de-inking and bio-bleaching (Kumar and Satyanarayana 2012; Kumar and Satyanarayana 2013).

-

Xylanase gene from a different Bacillus halodurans strain (C-125), was expressed for its thermo-stability along with its cellulase-free nature in Pichia pastoris. This enzyme was observed to have maximum activity at 70 °C temperature and a pH of 9.0. Because of its alkaline nature along with its thermo-stability, it can be used in paper industries for bio-bleaching. It was reported that using this xylanase for the pre-treatment of pulp derived from wheat straw, improved the brightness of the paper along with improving paper strength and quality (Lin et al. 2013).

-

An endo-xylanase is synthesized by Bacillus brevis (ATCC 8246), when wheat straw is used as the substrate for its culture. It is usually observed to degrade xylan derived from soft wood. This enzyme was observed to have maximum activity at 45–95 °C temperature (optimum at 55 °C) and at a pH of 7.0. Enzyme purification of 2.4-fold was reported when precipitation using ammonium sulphate and anion-exchange was used followed by gel-filtration chromatography. Because of its thermo-stability, it can be used in bio-bleaching in paper industries using kraft pulp (Bai et al. 2014).

-

Xylanase isolated from Paenibacillus macerans (IIPSP3A) is reported to show an activity of 4170 U/mg approx. when the substrate used for its culture is Xylan derived from beechwood. This enzyme was found to show optimum activity at 50 °C temperature and a pH of 4.5 i.e. acidic conditions, but can also show stable activity for a few hours when the temperature is 90 °C and pH is 9.5. This stability at high temperature and alkaline nature allows it to be used in paper industries. The combination of techniques used for enzyme purification included cation-exchange that was immediately followed by gel-filtration chromatography. This bacterial strain was found to be abundant in the gut of termites (Dheeran et al. 2012).

-

Paenibacillus barcinonensis (BP-23), produces a Xylanase named as (Xyn11E), that in presence of the lipoprotein, synthesized by the same organism, named as–––LppX, shows high activity when E. coli (DH5α) is used as the vector for expression. This enzyme was observed to have maximum activity at 50 °C temperature and at a pH of 6.5. Enzyme purification was carried out by metal–affinity chromatography using Histidine–trap columns. It was reported that using this xylanase for the pre-treatment of pulp derived from flax, Eucalyptus and sisal, improved the paper along with quality as it led to formation of pulps free from chlorine and having a high content of cellulose (Valenzuela et al. 2014).

-

Xylanase gene isolated from Thermotoga petrophila (RKU-1), an extremophile, was expressed in the vector E. coli (BL21) to produce a thermo-stable endo-xylanase. The oil reservoirs primarily found in Japan, was observed to be the source of this bacteria. This enzyme was observed to have maximum activity at 95 °C temperature and a pH of 6.0. The combination of techniques used for enzyme purification included thermal treatment that was immediately followed by ion-exchange chromatography. It, due to its stability at higher temperature can be used in paper industries (Ul Haq et al. 2012).

-

Soil rich in decomposed products of rice straw was found to be rich in Streptomyces rochei and S. chromofuscus both organisms being able to synthesize xylanase when the substrate used for its culture is cotton stalk or Papyrus pulp. Enzyme activity was found to be greater in S. chromofuscus as compared to S. rochei. When S. chromofuscus was used for treatment of pulp formed of cotton stalk, it was observed that it can decrease lignin percentage from 24.5% to 11.2% and increase brightness percentage from 9% to 17%, when the pulp was treated using EDTA. These results were superior to the ones received when S. rochei was used instead (Nagieb et al. 2014).

-

Streptomyces thermocyaneoviolaceus (M049), was reported to produce a xylanase that was able to retain 65% of its activity at 70 °C. StxII (S. thermoviolaceus) and XlnB (S. lividans)—was used as probes to bring about amplification of the xylanase–producing gene. This amplified gene was named as “xynB” as its N-terminal sequence shows high similarity to the probes used and was replicated in E. coli [BLR(DE3)] for the expression of protein that is much more thermally stable and easier for purification. This enzyme was observed to have maximum activity at 60 °C temperature and a pH of 5.0. A combination of techniques like precipitation using ammonium sulphate which was then followed by ion-exchange along with gel–filtration was used for purification of xylanase. Due to it showing 90% of enzyme activity even at high temperature, it has a potential of being used in different industries including paper industries (Shin et al. 2009).

Some of the commercially available xylanases that are present in market are given in Table 2

Fungal Xylanases

-

Aspergillus usamii (E001), produces a xylanase—AuXyn11A, which by itself does not show thermal stability but when its N-terminal domain is replaced by that of a “thermo-stable family 11” Xylanase—Syxyn11, that was found to share codon bias with Pichia pastoris (GS115). The amplified AuXyn11A along with the synthesized Syxyn11 was expressed in the vector E. coli (JM109). It was reported that about three replaced amino acids of the N-terminal, conferred the thermo-stability of this engineered xylanase. This enzyme was observed to have maximum activity at 75 °C temperature when enzyme purification was carried out using a combination of different techniques like precipitation using ammonium sulphate immediately followed by gel and ultra-filtration (Zhang et al. 2014).

-

Aspergillus niger, having a putative gene of Xylanase—xyl10, was replicated in Pichia pastoris to optimize the codons before cloning it in a vector for optimization, post which, it was inserted in Pichia pastoris (X33), under the promoter–glyceraldehyde-3-phosphate dehydrogenase (GAP), for its expression. This enzyme was observed to have maximum activity of 32000 U/mg at 60 °C temperature and a pH of 5.0 when enzyme purification was carried out using the technique of size–exclusion chromatography. Due to it showing 90% of enzyme activity even at high temperature, it has a potential of being used in different industries including paper industries (Zheng et al. 2013).

-

Aspergillus terricola xylanase and that of A. ochraceus, are observed to be cellulase-free when Xylan derived from oat spelt, wheat bran or birchwood is used as a substrate, wheat bran being the most favourable in comparison. Highest enzyme activity of 50% was reported when the optimum conditions of 60 °C temperature and 6.5 pH was maintained for A. terricola, while 65 °C temperature and pH of 5.0 was maintained for A. ochraceus. The xylanases, being stable at an alkaline pH shows potential of being used in cellulose pulp bio-bleaching. Delignification of 36.4% and 14.3% in case of A. ochraceus and A. terricola respectively was observed with an over-all increase in the brightness by 2.4–3.4% (Michelin et al. 2010).

-

Schizophyllum, found in abundance in rotten wood, was observed to produce an endo-xylanase. Gene was replicated in Pichia pastoris (GS115) for its expression when it was marked using a Histidine tag at the C-terminal. This enzyme was observed to have maximum activity at 50 °C temperature and a pH of 5.0 when enzyme purification was carried out using the technique of Ni-NTA–affinity chromatography. Due to its stability at high temperature and ability to use cations (potassium, lithium, cobalt, sodium etc.) to enhance its activity, it has the potential of being used in paper industries for degradation of lignocellulose (Song et al. 2013).

-

Xylanases was isolated from fungi Trichoderma harzianum (mesophilic) and Chaetomium thermophilum (thermophilic), when the substrate used was birchwood or oat spelt for their culture. It was observed that enzyme shows high activity when the temperature is 60 °C and pH is 5.0–6.0 when its source was Trichoderma harzianum while enzyme isolated from Chaetomium thermophilum shows maximum activity at 70 °C at the same pH. They have the potential of being used in bio-bleaching in paper industry as they can reduce the amount of toxic chemicals like chlorine oxides, that are formed as wastes, thus, helping in reducing impact on environment (Ahmed et al. 2012).

-

Talaromyces versatilis, was found to produce a varied range of cellulases and xylanases (like xynB, xynC). Two novel genes from its genome identified as xynE and xynF have been cloned for its expression in the yeast Pichia pastoris to compare their properties with those of previously reported xynC and xynB, previously reported. All four of the recombinant enzymes showed high expression of xylanase that has maximum activity when the pH ranges between 3.5–4.5 and temperature was maintained between 50–60 °C., with XynF showing highest thermal-stability (Lafond et al. 2014).

-

Pichia pinus (a newly discovered yeast strain), was observed to produce a thermostable xylanase that is cellulase free. This strain of yeast, isolated from decayed wood as its major source, shows best xylanase production when oat spelt or bagasse is used as a substrate. It was observed that enzyme shows highest activity at 55 °C temperature and 4.5 pH even though low concentration of β-xylosidase as well as α-L-arabino-furanoside was reported in the crude preparation. It has the potential of being used for bio-bleaching and improving paper quality in paper industries. It was reported to be able to reduce the requirement of using harmful chemicals in paper manufacturing thus, reducing impact on environment (Ravindra et al. 2007).

Difference Between Bacterial and Fungal Xylanase

The xylanases produced by bacteria are considered to be more effective in industrial processes as compared to xylanases of fungi. Table 3 mentions few of the key points of comparison between the xylanases produced by both bacteria and fungi (Mathur et al. 2015; Subramanian and Prema 2002; Dashtban et al. 2009).

Endo-xylanases of both bacteria and fungi are observed to have their pI (isoelectric point) within the range of 4.0 and 10.3 with majority of them bring glycosylated (Polizeli et al. 2005).

Cellulase-Free Xylanases

Cellulase-free xylanases play a major role in pulp bio-bleaching as a substitute for noxious chlorinated compounds, they caused by releasing organic halogens in atmosphere which is hazards for environmental and cause developing many health issues.

Xylanases, that are cellulase-free, are more favourable agents because of their lesser use of chlorine in bio-bleaching for paper pulps production. Though, there are still need for taking precautions to prevent the unwanted hydrolysis of cellulose on a large scale. It is important to do selective hydrolysis of xylan specifically re-precipitated xylan, without affecting the viscosity of pulp facilitates by exclusion of lignin through using mild oxidative agents (Valls et al. 2010).

The substrate used for production of xylanases plays a very important role in selecting the fermentation process, like purified xylans that are excellent inducers of xylanase production because of their low molecular weight, resulting in higher yield of the enzyme. However, use of purified substrates is not always economically–feasible in processes occurring at large-scale hence, different substitutes must be considered (Singh et al. 2013). Some alternative sources like corn cobs, straw, barley husk and wheat bran, when used as substrates are observed to have resulted in a significant increase in yield. Use of agro-chemical residues that are present in abundance results in lessening the overall cost of bio-bleaching and manufacturing of paper thus making paper industries eco-friendly.

It is rare to find a fungus producing xylanases having low cellulase activity. Aspergillus fumigatus (AR1), is one such alkali-tolerant fungus, that is capable of producing xylanases showing no growth in presence of carboxymethyl cellulose (CMC) as a substrate. The enzyme is observed to have a high index of stability but shows highest activity at pH ranging between 6.0–6.5 and at 60 °C temperature (Anthonya et al. 2003).

Use in Paper and Pulp Industry

Bio-pulping

It includes treating the wood chips with combinations of fungi found in decaying wood or other lignocellulosic components before it is sent to conventional pulping for lignin removal. The wood is chipped, screened and debarked and briefly streamed to reduce the amount of natural microorganism in them, after which, they are cooled in order to inoculate with the fungal strains selected for bio-pulping. Pre-treatment of inoculated chips (forming a heap and ventilating with humidified air for 1 month) and loss of yield are the major challenges faced in the paper industries. Dissemination of NaOH from wood can be improved using xylanase pre-treatment thus enhancing conventional process of pulping (Khonzue et al. 2011).

This process is mechanically plausible and financially savvy as it reduces electrical energy utilization and increases the manufactory throughput for mechanical pulping thus improving the quality of paper and minimizes harm caused to the environment (Khonzue et al. 2011). The utilization of bio-pulping as a pre-treatment for the Kraft procedure is as yet an open research issue. This technique can be used for different substrates, for example, non-woody plants like straw, and corn stalks likewise need a lot of consideration (Woldesenbet et al. 2012).

Bio-bleaching

The main concern in using the conventional process of pulping is cellulose degradation as it modifies the cellulosic fibre thus, affecting the paper quality (Shatalov and Pereira 2008). The system of pulp dying by chemical treatment was given in Fig. 6. It clarifies that the utilization of chemical can't completely expel the lignin from the fibre (A, B, C) a few pieces of lignin get re-precipitated on to the fibre surfaces (D). Thus, the resultant mash gets a trademark dark coloured shading because of the nearness of lingering lignin and its derivatives.

Diagrammatic representation of chemical treatment on paper pulp (L lignin). Abhishek Walia, Shiwani Guleria, Preeti Mehta, Anjali Chauhan, Jyoti Parkash (2017), microbial xylanases and their industrial application in pulp and paper biobleaching: a review, retrieved from: https://springerlink.bibliotecabuap.elogim.com/article/10.1007/s13205-016-0584-6

Enzymatic treatment of pulp using xylanase is 2–3 times more helpful than other glycoside hydrolases as it lowers the costs and improves fibre characteristics (Shatalov and Pereira 2008). To acquire brilliant white pulp necessary for manufacturing high quality paper, it is important to bleach out lignin and its degradation products, resins and metal ions (Azeri et al. 2010). The xylanase pre-treatment before conventional bleaching helps in breaking the linkage hemicellulose forms with residual lignin to enhance the pulp accessibility to bleaching, thus improving lignin removal (Azeri et al. 2010; Walia et al. 2015).

For bio-bleaching process of pulp in paper industries bacterial xylanases from different organism like Staphylococcus sp. (SG-13), B. pumilus, B. coagulans, B. subtilis (ASH) and so on have been used (Gupta et al. 2000; Kaur et al. 2011; Choudhury et al. 2006; Sanghi et al. 2009).

-

Gupta et al. was able to isolate a Staphylococcus sp. (SG-13) xylanase that was alkali-stable and showed high activity when the temperature was maintained at 50 °C and pH at 9.5–10.0. Xylanase pre-treatment was able to enhance bleaching of kraft pulps that resulted in 8% reduction in use of hypochlorite and 30% reduction in kappa particles along with enhancing the brightness and paper quality (Gupta et al. 2000).

-

Kaur et al. reported that a decline of 8.5% in kappa particle and 25% reduction in chloride usage without any decline in the brightness was observed when Kraft pulp was pre-bleached using a xylano-pectinolytic enzyme isolated from Bacillus pumilus. The action of the enzyme also resulted in an enhancement of properties of pulp like burst factor (by 9%), CED viscosity (by 11.8%), tear factor (by 4.6%) etc (Kaur et al. 2011).

-

Torres et al. (2000) was able to isolate a xylanase from Bacillus sp. (BP-23) that was able to enhance bleaching of Kraft pulp, made up of eucalyptus, resulting in 30% reduction in use of chlorine and 16% decline in kappa particles along with increasing the brightness by 1% without requirement of any pre-treatment.

-

Dhiman et al. carried out an analytical study on the bio-bleaching potential of xylanase used independently or in combination with pectinase in the presence of similar temperature (70 °C) and pH (9.5) conditions. They observed that bio-bleaching using the combination treatment resulted in redeeming of chlorine dioxide, about 35.71% more efficiently, along with improvement of other properties of pulp like strength (by 25.70%), burst factor (by 20.00%), tear factor (by 6.61%) and so on (Dhiman et al. 2009).

-

Arthrobacter sp. produces a heat and alkali stable, xylanase that is free of cellulase activity Bleaching, using xylanase, of kraft pulp results in 29% reduction in chloride usage and 20% decline in kappa particle, without having any decline in the brightness (Khandeparkar and Bhosle 2007).

-

B. megaterium produces a heat-stable xylanase, as reported by Sindhu et al., that showed high activity when the conditions maintained was 50 °C temperature and a pH of 8.0. Bleaching of Kraft pulp was enhanced by using Xylanase resulting in 31% reduction in chloride usage, 8.12% increase in the brightness and 13.67% decline in kappa particle (Sindhu et al. 2006).

-

Beg et al. was able to isolate a Streptomyces sp. (QG-11-3) cellulase-free xylanase that showed high activity when the condition maintained was 50 °C temperature and pH at 8.5. Bleaching, using xylanase, of kraft pulp made from eucalyptus results in 4.5% reduction chloride usage, 20% increase in the brightness, 25% decline in kappa particles and improving the over-all paper quality (Beg et al. 2000).

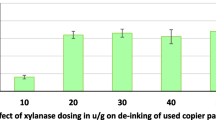

De-inking of Waste Papers

De-inking is one of the more essential steps carried out during recycling waste-paper which is characterised by dislodging ink from the waste-paper. Traditionally, de-inking of paper required use of large amount of chlorine or its derivatives like NaOH, H2O2, hypochlorite, sodium silicate and other agents that has given rise to hazardous effluents creating several problem in its disposal (Maity et al. 2012). Use of enzymes like xylanase and laccase, in recent times, have provided us with an alternative method of removing ink from the effluents that have been generated by the processes carried out in the paper industries (Dhiman et al. 2014).

Gupta et al., attempted to use a combination laccase and xylanase, produced during the co-culturing of B. halodurans (FNP135) and Bacillus sp., to remove ink from old newsprints. This approach significantly increased the paper brightness (by 11.8%) and whiteness (by 39%) besides enhancing other recycled paper properties like burst factor (by 2.77%), tear factor (by 2.4%) etc. Synergistic action of the combination of laccase and xylanase improves the recycled paper properties unlike the process of chemical deinking that negatively influences its freeness and strength (Gupta et al. 2015).

Kumar and Satyanarayana carried out a similar experimentation using xylanase or commercially available cellulase and xylanase combinations, isolated from Bacillus halodurans (TSEV1). They found out that the combination was efficiently able to de-ink when the conditions of 9.0 pH and 70 °C temperature was maintained (Kumar and Satyanarayana 2014).

Future-Scope

A noteworthy rise in usage of the industrial enzymes like cellulase has been observed in these recent years. The main holdup for the commercialization of cellulase is lacuna in the economically feasible process and to improve the functioning/catalysis of cellulase in tune with the demand. Utilizing lignocellulosic waste has shown a great alternative to be consider for the future. With the increase demand there are still room for exploration of sustainable strategies for substrates, fermentation and microorganisms to get higher quality product with economic feasibility.

The paper industry is constantly growing resulting in the increase in use of different environmentally–harmful chemicals which are not economical feasible. In this chapter we have talked about different microbial enzyme and process that are involve in making paper, it also highlights the hazardous chemical compound that has been used in the industry. Cellulase-free xylanases in bio-bleaching have shown effective results in reducing the consumption of chlorine compounds. Due the high quality of paper with lesser use of deinking chemical, cellulases, xylanases and amylases are now highly in demand. By using rot fungi in bio-pulping and enzymatic refining in cellulases and xylanases, can also help in reducing the mechanical energy consumption. Therefore, applications of microbial technology have been proved to be a cost effective and eco-friendly alternative for chemical intensive steps in the pulp and paper industry

Bacterial xylanases, when paralleled against fungal xylanases, was found to be more efficient due to its heat and alkaline stability and cellulase-free nature. But to produce a xylanase that is stable in a wider temperature and alkaline range along with having low activity of cellulase and higher degradative potential towards xylans, selectively hydrolysing only arabinoxylan is very taxing and is a tedious job. Producing super-xylanases that have all the essential functions is not always possible leading to production of enzymes with very few essential properties that makes industrial processing more expensive. Strain improvement using random UV mutation or through mutations using chemical mutagens has been used for the longest time for improving xylanase by stimulating essential and inhibiting undesirable characters.

Recently, engineering the microbial strains, producing xylanase for industrial usage, was made possible due to the presence of genome sequencing data and information on metabolic pathways. The techniques like molecular dynamics simulation, in-silico mutagenesis etc. can be of great importance in designing of super-xylanases with numerous catalytic activities, required for degradation of biomass.

However, basic research on isolating novel microbial strains having potentially high yield of enzyme is the primary challenge. Using genomic information for selecting the ecological–niche of the target organism is necessary to know about whether genes for xylanase production is present or not. Thus, using different techniques for developing super-xylanase for industrial perspective has become an essential area of research in recent times.

References

Abramson M, Shoseyov O, Shani Z (2010) Plant cell wall reconstruction toward improved lignocellulosic production and processability. Plant Sci 178:61–72

Ahmed S, Imdad SS, Jamil A (2012) Comparative study for the kinetics of extracellular xylanases from Trichoderma harzianum and Chaetomium thermophilum. Electron J Biotechnol 15(3):717–3458

Andrade SV, Polizeli MLTM, Terenzi HF, Jorge JA (2004) Effect of carbon source on the biochemical properties of the β-xylosidase produced by Aspergillus versicolor. Process Biochem 39:1931–1938

Anthonya T, Chandra Raj K, Rajendrana A, Gunasekaranb P (2003) High molecular weight cellulase-free xylanase from alkali-tolerant Aspergillus fumigatus (AR1). Enzym Microb Technol 32:647–654

Azeri C, Tamer AU, Oskay M (2010) Thermoactive cellulase-free xylanase production from alkaliphilic Bacillus strains using various agro-residues and their potential in biobleaching of kraft pulp. Afr J Biotechnol 9(1):63–72

Bai W, Xue Y, Zhou C, Ma Y (2014) Cloning, expression and characterization of a novel alkali-tolerant xylanase from alkaliphilic Bacillus sp. SN5. Biotechnol Appl Biochem 62(2):208–217

Beg QK, Bhushan B, Kapoor M, Hoondal GS (2000) Enhanced production of a thermostable xylanase from Streptomyces sp. QG-11-3 and its application in biobleaching of eucalyptus kraft pulp. Enzyme Microb Technol 27:459–466

Begum F, Absar N, Alam MS (2009) Purification and characterization of extracellular cellulase from A. oryzae ITCC-4857.01. JASR 5:1645–1651

Biswal AK, Atmodjo MA, Li M et al (2018) Sugar release and growth of biofuel crops are improved by downregulation of pectin biosynthesis. Nat Biotechnol 36(3):249–257

Boraston AB, Bolam DN, Gilbert HJ et al (2004) Carbohydrate-binding modules: fine-tuning polysaccharide recognition. Biochem J 382:769–781

Bourne Y, Henrissat B (2001) Glycoside hydrolases and glycosyltransferases families and functional modules. Curr Opin Struct Biol 11:593–600

Carpita NC, Gibeaut DM (1993) Structural models of primary cell walls in flowering plants: consistency of molecular structure with the physical properties of the walls during growth. Plant J Cell Mol Biol 3(1):1–30

Carpita NC, Mccann MC (2000) The cell wall. In: Buchanan BB, Gruissem W, Jones RL (eds) Biochemistry and molecular biology of plants. American Society of Plant Physiologists, Rockville, p 1367

Chapla D, Patel H, Madamwar D, Shah A (2012) Assessment of a thermostable xylanase from Paenibacillus sp. ASCD2 for application in prebleaching of eucalyptus kraft pulp. Waste Biomass Valor 3:269–274

Chen Y, Wan J, Zhang X, Ma Y, Wang Y (2012) Effect of beating on recycled properties of unbleached eucalyptus cellulose fiber. Carbohydr Polym 87:730–736

Choudhury B, Chauhan S, Singh S et al (2006) Production of Xylanase of Bacillus coagulans and its bleaching potential. World J Microbiol Biotechnol 22:283

Chundawat SPS, Beckham GT, Himmel ME et al (2011) Deconstruction of lignocellulosic biomass to fuels and chemicals. Annu Rev Chem Biomol Eng 2:121–145

Collins T, Gerday C, Feller G (2005) Xylanases, xylanase families and extremophilic xylanases. FEMS Microbiol Rev 29(1):3–23

Corral OL, Villasenor-Ortega F (2006) Xylanases. Adv Agri Food Biotechnol 6:305–322

Cui L, Meddeb-Mouelhi F, Laframboise F, Beauregard M (2015) Effect of commercial cellulases and refining on kraft pulp properties: correlations between treatment impacts and enzymatic activity components. Carbohydr Polym 115:193–199

Dashtban M, Schraft H, Qin W (2009) Fungal bioconversion of lignocellulosic residues; opportunities & perspectives. IJBS 5:578

De Vries RP, Kester HC, Poulsen CH, Benen JA, Visser J (2000) Synergy between enzymes from Aspergillus involved in the degradation of plant cell wall polysaccharides. Carbohydr Res 327(4):401–410

Dheeran P, Nandhgopal N, Kumar S, Jaiswal YK, Adhikari DK (2012) A novel thermostable xylanase of Paenibacillus macerans IIPSP3 isolated from termite gut. J Ind Microbiol Biotechnol 39:851–860

Dhiman SS, Garg G, Mahajan R, Garg N, Sharma J (2009) Single lay out and mixed lay out enzymatic processes for biobleaching of kraft pulp. Bioresour Technol 100:4736–4741

Dhiman SS, Garg G, Sharma J, Kalia VC, Kang YC, Lee JK (2014) Reduction in acute ecotoxicity of paper mill effluent by sequential application of xylanase and laccase. PLoS One 9:1–13

Gil N, Gil C, Amaral ME, Costa AP, Duarte AP (2009) Use of enzymes to improve the refining of a bleached Eucalyptus globulus kraft pulp. Biochem Eng J 46:89–95

Guo G, Liu Z, Xu J, Liu J, Dai X, Xie D et al (2012) Purification and characterization of a xylanase from Bacillus subtilis isolated from the degumming line. J Basic Microbiol 52:419–428

Gupta S, Bhushan B, Hoondal GS (2000) Isolation, purification and characterization of xylanase from Staphylococcus sp. SG-13 and its application in biobleaching of Kraft pulp. J Appl Microbiol 88:325–334

Gupta V, Garg S, Capalash N, Gupta N, Sharma P (2015) Production of thermo-alkali-stable laccase and xylanases by co-culturing of Bacillus sp. and B. halodurans for biobleaching of kraft pulp and deinking of waste paper. Bioprocess Biosyst Eng 38:947–956

Hashimoto H (2006) Recent structural studies of carbohydrate-binding modules. Cell Mol Life Sci 63:2954–2967

Hildén L, Johansson G (2004) Recent developments on cellulases and carbohydrate-binding modules with cellulose affinity. Biotechnol Lett 26:1683–1693

Höfte H, Voxeur A (2017) Plant cell walls. Curr Biol 27:R865–R870

Hsu J, Lakhani N (2002) Softer and higher strength paper products and methods of making such products. US Patent 20020162635 A1

Ibarra D, Monte MC, Blanco A, Martínez AT, Martínez MJ (2012) Enzymatic deinking of secondary fibers: cellulases/hemicellulases versus laccase-mediator system. J Ind Microbiol Biotechnol 39:1–9

Kaur A, Mahajan R, Singh A, Garg G, Sharma J (2011) Application of cellulase free xylano-pectinolytic enzymes from the same bacterial isolate in biobleaching of kraft pulp. Bioresour Technol 101:9150–9155

Khandeparkar R, Bhosle NB (2007) Application of thermoalkalophilic xylanase from Arthrobacter sp. MTCC 5214 in biobleaching of kraft pulp. Bioresour Technol 98:897–903

Khonzue P, Laothanachareon T, Rattanaphan N, Tinnasulanon P, Apawasin S, Paemanee A, Ruanglek V, Tanapongpipat S, Champreda V, Eurwilaichitr L (2011) Optimization of xylanase production from Aspergillus niger for biobleaching of eucalyptus pulp. Biosci Biotechnol Biochem 75(6):1129–1134

Kuhad RC, Gupta R, Singh A (2011) Microbial cellulases and their industrial applications. Enzyme Res 2011:280696

Kumar V, Satyanarayana T (2012) Thermo-alkali-stable xylanase of a novel polyextremophilic Bacillus halodurans TSEV1 and its application in biobleaching. Intern Biodet Biodegrad 75:138–145

Kumar V, Satyanarayana T (2013) Biochemical and thermodynamic characteristics of thermo-alkali-stable xylanase from a novel polyextremophilic Bacillus halodurans TSEV1. Extremophiles 17:797–808

Kumar V, Satyanarayana T (2014) Production of endoxylanase with enhanced thermostability by a novel polyextremophilic Bacillus halodurans TSEV1 and its applicability in waste paper deinking. Proc Biochem 49:386–394

Lafond M, Guais O, Maestracci M, Bonnin E, Giardina T (2014) Four GH11 xylanases from the xylanolytic fungus Talaromyces versatilis act differently on (arabino) xylans. Appl Microbiol Biotechnol 98:6339–6352

Lee C, Ibrahim D, Ibrahim CO, Daud WRW (2011) Enzymatic and chemical deinking of mixed office wastepaper and old newspaper: Paper quality and effluent characteristics. BioResources 6:3859–3875

Li K, Azadi P, Collins R, Tolan J, Kim JS, Eriksson Karl-Erik L (2000) Relationships between activities of xylanases and xylan structures. Enzyme Microb Technol 27:89–94

Li DC, Li AN, Papageorgiou AC (2011) Cellulases from thermophilic fungi: recent insights and biotechnological potential. Enzyme Res 2011:308730

Lin XQ, Han SY, Zhang N, Hu H, Zheng SP, Ye YR et al (2013) Bleach boosting effect of xylanase A from Bacillus halodurans C-125 in ECF bleaching of wheat straw pulp. Enzyme Microb Technol 52:91–98

Lombard V, Ramulu HG, Drula E et al (2014) The carbohydrate-active enzymes database (CAZy). Nucleic Acids Res 42:D490–D495

Maity C, Ghosh K, Halder SK, Jana A, Adak A, Mohapatra PKD, Pati BR, Mondal KC (2012) Xylanase Isozymes from the Newly Isolated Bacillus sp.CKBx1D and optimization of its deinking potentiality. Appl Biochem Biotechnol 167:1208–1219

Mathew GM, Sukumaran RK, Singhania RR, Pandey A (2008) Progress in research on fungal cellulases for lignocellulose degradation. JSIR 67:898

Mathur N, Goswami GK, Pathak AN (2015) In silico study of Bacillus brevis xylanase—structure prediction and comparative analysis with other bacterial and fungal xylanase. Biomed Data Min 4:112

Meents MJ, Watanabe Y, Samuels AL (2018) The cell biology of secondary cell wall biosynthesis. Ann Bot 121(6):1107–1125

Michelin M, Peixoto-Nogueira SC, Betini JHA et al (2010) Production and properties of xylanases from Aspergillus terricola Marchal and Aspergillus ochraceus and their use in cellulose pulp bleaching. Bioprocess Biosyst Eng 33:813–821

Milala M, Shugaba A, Gidado A, Ene A, Wafar J (2005) Studies on the use of agricultural wastes for cellulase enzyme production by Aspergillus niger. RJABS 1:325–328

Mohnen D (2008) Pectin structure and biosynthesis. Curr Opin Plant Biol 11:266–277

Murray P, Aro N, Collins C, Grassick A, Penttilä M et al (2004) Expression in Trichoderma reesei and characterisation of a thermostable family 3 β-glucosidase from the moderately thermophilic fungus Talaromyces emersonii. PEP 38:248–257

Nagieb ZA, Milegy MGE, Faat HMR, Isis KB (2014) Effect of EDTA on production of xylanase by Streptomyces species and their bleaching effect on papyrus and cotton stalk pulp. Int J For Wood Sci 1(1):2–9

Nguyen TN, Son S, Jordan MC et al (2016) Lignin biosynthesis in wheat (Triticum aestivum L.): its response to waterlogging and association with hormonal levels. BMC Plant Biol 16:1–16

O’Neill MA, York WS (2003) The composition and structure of plant primary cell walls. The plant cell wall 8:1–54

Okazaki F, Shiraki K, Tamaru Y, Araki T, Takagi M (2005) The first thermodynamic characterization of beta-1,3-xylanase from a marine bacterium. Protein J 24:413–421

Oliveira DM, Finger-Teixeira A, Mota TR et al (2016) Ferulic acid: a key component in grass lignocellulose recalcitrance to hydrolysis. Plant Biotechnol J 13:1224–1232

Pauly M, Keegstra K (2008) Cell-wall carbohydrates and their modification as are source for biofuels. Plant J 54:559–568

Pauly M, Keegstra K (2016) Biosynthesis of the plant cell wall matrix polysaccharide xyloglucan. Annu Rev Plant Biol 67:235–259

Payne CM, Knott BC, Mayes HB, Hansson H, Himmel ME et al (2015) Fungal cellulases. Chem Rev 115:1308–1448

Picart P, Diaz P, Pastor FI (2007) Cellulases from two Penicillium sp. strains isolated from subtropical forest soil: production and characterization. Lett Appl Microbiol 45:108–113

Polizeli MLTM, Rizzatti ACS, Monti R, Terenzi HF, Jorge JA, Amorim DS (2005) Xylanases from fungi:properties and industrial applications. Appl Microbiol Biotechnol 67:577–591

Popper ZA, Fry SC (2008) Xyloglucan-pectin linkages are formed intra-protoplasmically, contribute to wall-assembly, and remain stable in the cell wall. Planta 227(4):781–794

Ravindra BM, Raghvendra S, Vijay Kumar S (2007) Production of Cellulase-Free Xylanase from a Novel Yeast Strain Used for Biobleaching in Paper Industry. Res J Microbiol 2:24–33

Rizzatti ACS, Jorge JA, Terenzi HF, Rechia CGV, Polizeli MLTM (2001) Purification and properties of a thermostable extracellular β-xylosidase produced by a thermotolerant Aspergillus phoenicis. J Ind Microbiol Biotech 26:156–160

Roppolo D, De Rybel B, Tendon VD, Pfister A, Alassimone J, Vermeer JE, Yamazaki M, Stierhof YD, Beeckman T, Geldner N (2011) A novel protein family mediates Casparian strip formation in the endodermis. Nature 473(7347):380–383

Sajith S, Priji P, Sreedevi S, Benjamin S (2016) An overview on fungal cellulases with an industrial perspective. J Nutr Food Sci 6:461

Sanghi A, Garg N, Kuhar K, Kuhad RC, Gupta VK (2009) Enhanced production of cellulase-free xylanase by alkalophilic Bacillussubtilis ASH and its application in biobleaching of kraft pulp. BioResources 4:1109–1129

Santos WDD, Ferrarese MDLL (2008) Ferulic acid: an allelochemical troublemaker. Funct Plant Sci Biotechnol 2:47–55

Segato F, Damásio AR, De Lucas RC et al (2014) Genomics review of holocellulose deconstruction by Aspergilli. Microbiol Mol Biol Rev 78:588–613

Segato F, Dias B, Berto GL et al (2017) Cloning, heterologous expression and biochemical characterization of a non-specific endoglucanase family 12 from Aspergillus terreus NIH2624. Biochim Biophys Acta Proteins Proteom 1865:395–403

Sette LD, De Oliveira VM, Rodrigues MFA (2008) Microbial lignocellulolytic enzymes: industrial applications and future perspectives. Microbiology Australia 29:18–20

Shatalov AA, Pereira H (2008) Effect of xylanases on peroxide bleachability of eucalypt (E. globulus) kraft pulp. Biochem Eng J 40:19–26

Shin JH, Choi J-H, Lee O-S et al (2009) Thermostable xylanase from Streptomyces thermocyaneoviolaceus for optimal production of xylooligosaccharides. Biotechnol Bioprocess Eng 14(4):391–399

Sindhu I, Chhibber S, Caplash N, Sharma P (2006) Production of cellulase free xylanase from Bacillusmegaterium by solid state fermentation for biobleaching of pulp. Curr Microbiol 53:167–172

Singh A, Yadav RD, Kaur A, Mahajan R (2012) An ecofriendly cost effective enzymatic methodology for deinking of school waste paper. Bioresour Technol 120:322–327

Singh V, Pandey VC, Agrawal S (2013) Potential of Laceyella sacchari strain B42 crude xylanase in biobleaching of kraft pulp. Afr J Biotechnol 12(6):570–579

Singhania RR, Sukumaran RK, Pillai A, Prema P, Szakacs G et al (2006) Solid-state fermentation of lignocellulosic substrates for cellulase production by Trichoderma reesei NRRL 11460. Indian J Biotechnol 5:332–336

Song Y, Lee YG, Choi IS, Lee KH, Cho EJ, Bae HJ (2013) Heterologous expression of endo-1,4-β-xylanase A from Schizophyllum commune in Pichia pastoris and functional characterization of the recombinant enzyme. Enzyme Microb Technol 52:170–176

Srivastava PK, Kapoor M (2017) Production, properties, and applications of endo-β-mannanases. Biotechnol Adv 35:1–19

Subramanian S, Prema P (2002) Biotechnology of microbial xylanases: enzymology, molecular biology and application. Crit Rev Biotechnol 22:33–46

Sukumaran RK, Singhania RR, Pandey A (2005) Microbial cellulases production, applications and challenges. J Sci Ind Res 64:832

Taiz L, Zeiger E (2002) Plant physiology. Sinauer Associates Publishers, Sunderland

Tenkanen M, Siika-aho M (2000) An alpha-glucuronidase of Schizophyllum commune acting on polymeric xylan. J Biotechnol 78(2):149–161

Terrapon N, Lombard V, Drula E et al (2017) The CAZy database/the carbohydrate-active enzyme (CAZy) database: principles and usage guidelines. In: Aoki-Kinoshita K (ed) A practical guide to using glycomics databases. Springer, Tokyo, pp 117–131

Torres AL, Roncero MB, Colom JF, Pastor FIJ, Blanco A, Vidal T (2000) Effect of a novel enzyme on fiber morphology during ECF bleaching of oxygen delignified eucalyptus kraft pulps. Bioresour Technol 74:135–140

Turner S, Kumar M (2018) Cellulose synthase complex organization and cellulose microfibril structure. Philos Trans 376:20170048

Ul Haq I, Hussain Z, Khan MA, Muneer B, Afzal S, Majeed S et al (2012) Kinetic and thermodynamic study of cloned thermostable endo-1,4-β-xylanase from Thermotoga petrophila in mesophilic host. Mol Biol Rep 39:7251–7261

Valenzuela SV, Diaz P, Pastor FIJ (2014) Xyn11E from Paenibacillus barcinonensis BP-23: A LppX-chaperone-dependent xylanase with potential for upgrading paper pulps. Appl Microbiol Biotechnol 98:5949–5957

Valls C, Vidal T, Roncero MB (2010) The role of xylanases and laccases on hexenuronic acid and lignin removal. Proc Biochem 45:425–430. https://doi.org/10.1016/j.procbio.2009.10.015

Van Der Weijde T, Dolstra O, Visser RG et al (2017) Stability of cell wall composition and saccharification efficiency in Miscanthus across diverse environments. Front Plant Sci 7:2004

Vogel J (2008) Unique aspects of the grass cell wall. Curr Opin Plant Biol 11(3):301–307

Voragen AGJ, Coenen GJ, Verhoef RP et al (2009) Pectin, a versatile polysaccharide present in plant cell walls. Struct Chem 20:263–275

Wainø M, Ingvorsen K (2003) Production of beta-xylanase and beta-xylosidase by the extremely halophilic archaeon Halorhabdus utahensis. Extremophiles 7(2):87–93

Walia A, Mehta P, Chauhan A, Shirkot CK (2013) Optimization of cellulase-free xylanase production by alkalophilic Cellulosimicrobium sp. CKMX1 in solid-state fermentation of apple pomace using central composite design and response surface methodology. Ann Microbiol 63:187–198

Walia A, Mehta P, Chauhan A, Kulshrestha S, Shirkot CK (2014) Purification and characterization of cellulase-free low molecular weight endo β-1, 4 xylanases from an alkalophilic Cellulosimicrobium cellulans CKMX1 isolated from mushroom compost. World J Microbiol Biotechnol 30:2597–2608

Walia A, Mehta P, Guleria S, Shirkot CK (2015) Modification in the properties of paper by using cellulase-free xylanase produced from alkalophilic Cellulosimicrobium cellulans CKMX1 in biobleaching of wheat straw pulp. Can J Microbiol 61(9):671–681

Woldesenbet F, Virk AP, Gupta N, Sharma P (2012) Effect of microwave irradiation on xylanase production from wheat bran and bio-bleaching of eucalyptus kraft pulp. Appl Biochem Biotechnol 167(1):100–108

Wu SC, Halley JE, Luttig C, Fernekes LM, Gutierrez-Sanchez G, Darvill AG, Albersheim P (2006) Identification of an endobeta-1,4-D-xylanase from Magnaporthe grisea by gene knockout analysis, purification, and heterologous expression. Appl Environ Microb 72:986–993

Zhang H, Li J, Wang J, Yang Y, Wu M (2014) Determinants for the improved thermostability of a mesophilic family 11 xylanase predicted by computational methods. Biotechnol Biofuels 7:3

Zheng J, Guo N, Wu L, Tian J, Zhou H (2013) Characterization and constitutive expression of a novel endo 1,4- β-D-xylanohydrolase from Aspergillus niger in Pichia pastoris. Biotechnol Lett 35:1433–1440

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Vermani, M., Chauhan, V., Yadav, S.S., Roy, T., Singh, S. (2020). Role of Glycoside Hydrolases in Pulp and Paper Industries. In: Shrivastava, S. (eds) Industrial Applications of Glycoside Hydrolases . Springer, Singapore. https://doi.org/10.1007/978-981-15-4767-6_7

Download citation

DOI: https://doi.org/10.1007/978-981-15-4767-6_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-4766-9

Online ISBN: 978-981-15-4767-6

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)