Abstract

In recent years, biomass valorization (and, in general, waste treatment) and FC technology met in the so-called bioelectrochemical systems (BESs). BESs take advantage of biological capacities (microbes, enzymes, plants) for the catalysis of electrochemical reactions. They mainly include micro-electrolysis Cell (MECs) and microbial fuel cells (MFCs). While MECs can produce valuable compounds (like H2, CH4, etc.), providing a suitable potential at the electrodes, MFCs do not need any energetic input to convert chemical energy (stored in organic compounds) into electric power. In this “biologically-based-fuel–cells,” the fuel is made by different sources of organic compounds. Landfill leachate, municipal and agro-industrial wastewaters, sediments, solid organic wastes can be source of electric power and commodity chemicals. The use of MFC technology to waste treatment and valorization is, maybe, the most promising application of this newborn technology. Even though many researchers proved the reliable utilization of liquid waste as fuel in scaled MFCs, few attempts to apply MFCs to solid waste valorization have been done. In this paper, recent studies about the application of MFCs to solid substrates treatment and valorization and the contribution that BESs and MFC in particular could give to the development of a more sustainable waste management.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Organic fraction of municipal solid waste

- Microbial fuel cell

- Waste treatment

- Waste-to-energy technology

Introduction

It has been estimated that waste management contributes for about 3–5 % to green house gases (GHGs) emission being responsible for GHGs emission, mainly due to CH4, CO2, and N2O escapes from open dumps. Additional CO2 emissions are from upstream processes like waste collection and transportation (UNEP 2010). Nevertheless, an adequate waste management can save or reduce GHGs emissions in different ways: by primary materials avoidance through material recovery from waste, by energy production, by carbon storing in landfills and through the application of compost to soils. If we consider the recommendations by internationally recognized institutions, the future waste management should be essentially focused on the 3R concept (Reduce, Reuse, and Recycle), cleaner productions, circular economy establishment, waste prevention and, finally, the transformation of waste into a source of energy and materials (UNEP 2010). Besides of ecosystems alteration, air, water, and soil pollution, an inadequate waste management can represent a real threaten to human health. If toxic waste can have undiscussed effects on human health, the influence of Municipal Solid Waste (MSW) dumping and incineration on the population living near waste treatment facilities has not been fully clarified. Some studies gave evidence of a correlation between the proximity of local population at OFMSW facilities and few types of cancers, congenital anomalies, and low weight at birth (Rushton 2003). Nevertheless, the effects seem to vary according to the studied population, so a different approach could be used in the epidemiologic surveys in order to clarify if even the MSW treatment can be correlated without any doubt with human diseases (Giusti 2009; Porta et al. 2009). The problem related to an inadequate waste treatment is of a particular importance in developing Countries, where limited resources are destined to waste management. For this reason, in that Countries, dumping represents the most commonly used disposal method (often with no proper control) and consequent air, soil, and water pollution. It is clear that waste management represents one of the main issues mankind has to face nowadays. Nevertheless, waste can be a resource.

Waste: A Resource

Waste is a resource not only because of materials recovery (glass, metals, fibers, and plastics) and energy, but also because of oil saving. If we consider just the organic waste from agriculture (crop residues), the global energy that could be produced is estimated to be about of 50 billion tons of oil equivalent (UNEP 2010). The major issue is: how can we exploit this resource minimizing the environmental impacts and costs? UNEP indicates as a necessary prerequisite for an effective energy generation an adequate separation between organic and non organic waste: the organic residues are, in fact, responsible for the compromission of thermal technology effectiveness in terms of energy produced, besides of the GHGs emissions.

Organic Waste Treatment and Valorization

If we consider just the Organic Fraction of Municipal Solid Waste (OFMSW), the most commonly used technologies for its treatment and valorization are the Anaerobic Digestion (AD) and composting (UNEP 2010). These two waste treatments differ essentially for the microbial metabolism they are based on. Anaerobic Digestion (AD) is based on anaerobic microorganisms metabolism, with particular regards to methanogenic bacteria which can produce CH4 from CO2 to H2 (hydrogenotrophs) or from CH3COOH (acetoclastics). AD requires an appropriate temperature to occur: generally a temperature of 35 °C or 50–55 °C is realized in the reactor, even if a psicotrophic process is also possible (10–20 °C). As a result of the anaerobic digestion, a biogas rich in CH4 is produced while the resulting digestate is very often aerobically stabilized.

If AD needs energetic inputs (mainly to keep a constant temperature and leachate recirculation) a successful composting procedure needs oxygen insufflation sufficient to sustain the aerobic microorganisms and, at that same time, inhibiting anaerobic bacteria. If small amounts of residues can be easily composted, large-scale composting requires mechanical aeration, i.e., energetic imputs, varing according to the technology used (approximately 40–70 kW/t of waste) (Faaij et al. 1998). This energy is normally provided to the system, but facilities combining AD and a following digestate aerobic stabilization can provide the energy needed for the composting process from self-supplied methane. It has been estimated that if 25 % or more of the waste is anaerobically digested, whole treatment system can be self-sufficient (UNEP 2010). The main “product” of composting is the stabilized organic matter used, if free from contaminants, as a soil conditioner.

Compost in field application is assumed to reduce the utilization of synthetic fertilizer (about 20 % according to IPCC (2014). On the whole, in-field soil conditioner application has positive impact on GHGs emission from primary production (fertilazers production), but also on N2O emissions from soil and reduced irrigation, pesticides and tillage (Favoino and Hoggs 2008; Faaji 2006). Small, low-technology facilities handling only yard waste are inexpensive and generally problem-free. For developing Countries, the low cost and simplicity of composting make small-scale composting a promising solution (Faaji 2006). BESs (and, among them, MFCs) could represent a potentially low cost and effective technology for waste and wastewater technology and an important tool for waste management in poor Countries.

Bioelectrochemical Systems (BESs)

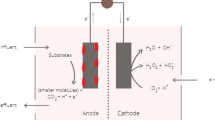

The ability of microorganisms to use inorganic molecules as electronic acceptor is widely spread in the environment: Ferribacterium limneticum and Geobacter spp, for example, are able to use Fe3+ as electronic acceptor, producing Fe2+. This process is normally associated with energy production in microbial cells (Coates et al. 2001; Cummings et al. 1999). BESs represent the attempt to manipulate this natural process to obtain electric power directly from the microbial metabolism, without any combustion. As based on microbial metabolism, BESs can be virtually fed with any organic compound, wastewater, urine, food waste and, even recalcitrant compounds like heavy metals, pesticides, hydrocarbons, dyes (ElMekawy et al. 2015; Nastro 2014; Pant et al. 2010; Shaoan and Chen 2011; Morris et al. 2009) and used with different purposes. BESs include microbial fuel cells (MFCs) and microbial electrolysis cells (MECs). microbial fuel cells (MFCs) are generally thought to provide electric power for small devices in deep see beds or remote areas using sediments and even urine or insects as feedstock (Jungh et al. 2014; Ieropoulos et al. 2005; Logan and Regan 2006). Recently, the reliable utilization of MFCs to charge the battery of a mobile has been demonstrated by Ieropoulos et al. (2013). Unlike MFCs, MECs require the set of an external potential at the electrodes in order to drive the electrochemical reactions to the synthesis of commodity compounds like caustic soda, hydrogen, methane. In the course of time, many different systems have been developed and tested all over the world. In general, different configurations are possible according to the geometry of the reactor, the materials used at the electrodes and for the chamber setup, the presence/absence of a cationic exchanging membrane, the application of an external potential, the nature of cathodic reactions, etc. A large overview of BESs has been given by Rabaey and Rozendal (2010) (Fig. 1).

A high-level overview of the concepts associated with bioelectrochemical systems (Rabaey and Rozendal 2010)

As biomass-based systems, BESs are considered carbon neutral (Oh et al. 2010) and the biotransformation of organic matter into chemicals by microbial metabolism allows CO2 emissions avoidance from primary production. Moreover, considering that MFCs do not involve CH4 production and combustion, the environmental advantages linked to a future development of this technology could compensate even a higher cost of production (Pant et al. 2011). In order to drive BESs technology to a full in-field application, the setup of electrodes materials and cell layouts are of primary importance to obtain adequate performances in terms of power density, organic load removal and chemicals production yield (Wei et al. 2011; Nastro 2014; Sleutels et al. 2012; Pant et al. 2012). As the setup of a new technology cannot exempt from the evaluation of the environmental impacts related to the whole life cycle and MFCs scientists are working also in that direction: recently, a stack of MFCs was designed and set up with all biodegradable products, opening the possibility to setup energy devices that could degrade harmlessly into the surroundings to leave no trace when their mission is complete (Winfield et al. 2015).

Application of BESs to Waste Management and Bioenergy

BESs have the potential to play a major role in developing sustainable waste recycling systems, with reduced use of energy and, at the same time, generating useful chemicals. For this reason, the number of liquid and solid waste from agro-industrial processes used as feedstock in BESs is increasing and increasing: a short list of agricultural substrates used in MFCs, with relative cells performances, is reported in Table 1. Among the other chemicals, hydrogen is maybe the best candidate as fuel for future technologies even because it can be the result of different processes catalyzed by bacteria like dark fermentation and bioelectrolysis (Chandrasekhar 2015). An intense research is actually being carried out to test biohydrogen production by micro-electrogenesis from different complex substrates like glycerol, milk, and starch in sight of a possible wide utilization of MECs to agro-industrial wastewaters, with biohydrogen or other chemicals production (Montpart 2015; Sleutels et al. 2012; Pant et al. 2012). Even if based on microbial metabolism, MFCs and MECs differ in many aspects, layouts and materials first of all. Cusick et al. (2010) carried out an interesting monetary evaluation of both MFC and MEC technologies applied to winery wastewater treatment concluding that energy recovery and organic removal from wastewater are more effective with MFCs than MECs, but hydrogen production from wastewater fed MECs can be cost effective. Besides of biohydrogen, the possibility to produce methane by MECs has being widely explored, with some encouraging results (Chandrasekhar et al. 2015; Villano et al. 2011). Even in this case, authors report a limitation of the performances linked to internal losses (high internal resistance, electrodes losses, etc.) that need to be overcome (Van Eerten-Jansen et al. 2012). MECs seems to be ready for a practical application to wastewater valorization (Sleutels et al. 2012) and, in fact, in recent years scaled prototypes for both municipal and industrial wastewaters valorization were set up in different countries allowing hydrogen peroxide, biohydrogen, methane, and caustic soda production using the chemical energy stored in municipal and industrial wastewaters. Nevertheless, the organic load removal from wastewater is still to be improved, being, for instance, up to 62 % in terms of COD removal in winery wastewaters, less than achieved with an activated sludge treatment plant (EU Commission 2013).

MFCs and Solid Waste Valorization

If a wide number of papers deal with the set up and the study of MFCs fed with wastewaters, few attempts to apply this newborn technology to solid organic waste treatment have been carried out. Mohan and Chandrasekhar published in 2011 a first paper dealing with the study of operational factors affecting the performances of MFCs fed with canteen food waste, focusing on electrodes distance and feedstock pH. Since then, other researchers started working on the application of MFCs to the Organic Fraction of Municipal Solid Waste (OFMSW) using different approaches: presence/absence of an inoculum, electrodes geometry, pH, temperature, oxygen availability, electrodes distance (Nastro et al. 2013; El-Chakhtoura 2014; Karluvali et al. 2015). Even if with different outcomes (Table 1), all researches confirm the effectiveness of MFC technology as tool for energy recovery and organic load removal from OFMSW, with particular regards to a low-temperature process (about 25 °C). Recently, Solid phase MFC (SMFCs) have been tested also in combination with a composting process of soybean, rice husk, leaf mold, and coffee residues used to prepare mixture with different C/N ratios (Wang et al. 2015). According to the authors, it is possible to combine the composting process with energy recovery by MFCs as the highest power density (Table 2) was achieved when the solid mixture C/N ratio was 30/1, able to sustain also a composting process. But SMFC are being tested also with agro-industrial substrates like Dried Distilled Grains with Solubles (DDGS), deriving from whisky production. Even in this case, laboratory scale tests confirmed the possibility to use MFC for waste valorization (Table 2). Further studies by Mohan gave evidence of the possible combination of MFC and biohydrogen production in a two-stage process (Chandrasekhar and Mohan 2014). Previously, Higgins et al. (2013) published an interesting research about the combination of MFCs and AD for solid organic waste treatment and valorization. If MFCs are fed with not pretreated OFMSW, they can represent a preliminary stage before a dark fermentation for biohydrogen production or a methanogenesis. MFCs can also be used as treatment for the anaerobic digestion leachate, still rich in organic matter: in this case, MFC treatment is placed downstream. So, it is more likely that the future of MFCs and MECs in solid waste management will be essentially linked to the optimization of biohydrogen and biomethane production, besides of energy recovery from biomass and leachate (Premier et al. 2012). With the overcome of issues related to the scaling-up in terms of electrodes materials and geometry as well as operational parameters (temperature, retention time, pH, etc.) a full in-field application will be possible and, then, all the potentialities of MFCs will be completely and definitely explored.

Towards Scaling-up: Modeling MFCs Performances

Like other BESs, MFCs performances are heavily affected by several operational parameters such as reactor configurations and scales, electrode materials, electrode surface areas and the nature of electron donors, if present. If a wide range of data about specific parameters are actually available in lab-scale experiment, few studies are available about the dynamics of the wide range of biotic and abiotic parameters affecting MFCs power production in waste treatment. Nevertheless, the main bottlenecks actually limiting the performances of scaled MFCs seem to reside in the interactions among the above-cited factors. According to some authors, mathematical modeling can represent a powerful platform, helping researchers in investigating the synergistic effects of multiple parameters, (including biofilm composition and structure, redox mediator transferring, substrate utilization rate, etc.) on MFCs performances in waste management (Recio-Garrido et al. 2016). In general, mathematical modeling is performed in two approaches: engineering modeling, based on Differential Equations (DEs) implementing engineering/physical/biochemical/electrochemical laws governing the system processes, and a statistical modeling, based on the analysis of experimental measurements (Luo et al. 2016). In this context, the development and utilization of appropriate softwares are an important prerequisite. An example of MFCs modeling framework is reported in Fig. 2. In it, the authors implements electrochemical, biological, and structural MFCs parameters using both data from the literature (to elaborate an expected scenario) and from experimental activities (real scenario) by the use of Excel®, Mathlab®, and COMSOL® Multiphysics softwares (Oyetunde et al. 2013). Moreover, complex dynamic models are being developed in order to optimize and control MFCs and, in general, BESs processes (Recio-Garrido et al. 2015).

Framework for investigating bioelectrochemical systems using COMSOL. Multiphysics (Oyetunde T et al. 2013)

Conclusions

The extraction of useful commodity chemicals, together with the production of energy, from any kind of organic waste and leftovers, is becoming more and more popular: it is a sustainable way to mitigate global warming, diversify energy sources and obtain chemicals, pharmaceuticals and food additives of high added value. BESs can represent a sustainable tool in waste management and bioenergy sector and recent researches confirm the high potentiality of such systems in terms of substrates to be treated and by-product that can be recovered, turning the “waste” into “resource.” Among BESs, MFCs represent a possible alternative/integration to the AD and recent studies confirm the possibility to realize multistep waste treatment systems working at a temperature ranging from 20 to 25 °C, with energy saving and biohydrogen/methane/electric power recovery. A strong research is being carried out in different disciplines to take BESs to an in-field application and the utilization of these systems in waste valorization and treatment is not so far.

References

Chandrasekhar K, Mohan SV (2014) Induced catabolic bio-electrohydrolysis of complex food waste by regulating external resistance for enhancing acidogenic biohydrogen production. Bioresour Technol 165:372–382

Chandrasekhar K, Lee Y, Lee D (2015) Biohydrogen production: strategies to improve process efficiency through microbial routes. Int J Mol Sci 16:8266–8293

Coates JD, Bhupathiraju VK, McInerney MI, Lovley DR, Achenbach LA (2001) Geobacter hydrogenophilus, geobacter chapellei and geobacter grbiciae, three new, strictly anaerobic, dissimilatory Fe(III)-reducers. Int J Syst Evol Micr 51:581–588

Cummings DE, Caccavo F, Spring S, Rosenzweig F (1999) Ferribacterium limneticum, gen. nov., sp. Nov., an Fe (III) reducing microorganism isolated from mining-impacted freshwater lake sediments. Arch Microbiol 171(3):183–188

Cusick Roland D, Kiely Patrick D, Logan Bruce E (2010) A monetary comparison of energy recovered from microbial fuel cells and microbial electrolysis cells fed winery or domestic wastewaters. Int J Hydrogen Energy 35:8855–8861

El-Chakhtoura J, El-Fadel M, Ananda Rao H, Ghanimeh S, Saikaly PE, Li D (2014) Electricity generation and microbial community structure of air-cathode microbial fuel cells powered with the organic fraction of municipal solid waste and inoculated with different seeds. Biomass Bioenergy 67(2014):24–31

El Mekawy A, Srikanth S, Bajracharya S, Hegab HM, Singh Nigam P, Singh A, Mohan SV, Pant D (2015) Food and agricultural wastes as substrates for bioelectrochemical system (BES): the synchronized recovery of sustainable energy and waste treatment. Food Res Int 73:213–225

European Commission (2013) Future brief: bioelectrochemical systems, wastewater treatment, bioenergy and valuable chemicals delivered by bacteria. Sci Environ Policy 5. http://ec.europa.eu/science-environment-policy

Faaji A (2006) Modern biomass conversion technologies. Mitigation Adapt Strateg Glob Chang. doi: 10.1007/s11027-005-9004-7

Faaij A, Hekkert M, Worrell E, van Wijk A (1998) Optimization of the final waste treatment system in the Netherlands. Resour Conserv Recy 22:47–82

Favoino E, Hoggs D (2008) The potential role of compost in reducing greenhouse gases. Waste Manage Res 26(1):61–69

Giusti L (2009) A review of waste management practices and their impact on human health. Waste Manag 29:2227–2239

Higgins SR, Lopez RJ, Pagaling E, Yan T, Cooney MJ (2013) Towards a hybrid anaerobic digester-microbial fuel cell integrated energy recovery system: an overview of the development of an electrogenic biofilm. Enzyme Microbial Technol 52:344–351

Ieropoulos I, Melhuish C, Greenman J, Horsfield I (2005) EcoBot-II: an artificial agent with a natural metabolism. Adv Robot Syst 2(4):295–300

Ieropoulos IA, Papaharalabos G, Ledezma P, Melhuish C, Stinchcombe A, Greenman J (2013) Waste to real energy: the first MFC powered mobile phone. Phys Chem Chem Phys 15:15312–15316

Jung SP, Yoon MH, Lee SM, Oh SE, Kang H, Yang JK (2014) Power generation and anode bacterial community compositions of sediment fuel cells differing in anode materials and carbon sources. Int J Electrochem Sci 9:315–326

Karluvali A, Köroglu EO, Manav N, Çetinkaya Afs_in Y, Özkaya B (2015) Electricity generation from organic fraction of municipal solid wastes in tubular microbial fuel cell. Separ Purif Technol 156:502–511

Logan BE, Regan JM (2006) Microbial fuel cells: challenges and applications. Environ Sci Technol 5172–5180

Luo S, Sun H, Ping Q, Jin R, He Z (2016) A review of modeling bioelectrochemical systems: engineering and statistical aspects. Energies 9:111

Mohan VS, Chandrasekhar K (2011) Solid phase microbial fuel cell (SMFC) for harnessing bioelectricity from composite food waste fermentation: influence of electrode assembly and buffering capacity. Bioresour Technol 102:7077–7085

Montpart N, Rago L, Baeza JA, Guisasola A (2015) Hydrogen production in single chamber microbial electrolysis cells with different complex substrates. Water Res 68:601–615

Morris JM, Jin S, Crimi B, Pruden A (2009) Microbial fuel cell in enhancing anaerobic biodegradation of diesel. Chem Eng J 146:161–167

Nastro RA, Dumontet S, Ulgiati S, Falcucci G, Vadursi M, Jannelli E, Minutillo M, Cozzolino R, Trifuoggi M, Erme G, De Santis E (2013) Microbial fuel cells fed by solid organic waste: a preliminar experimental study. In: European Fuel Cell Conference EFC 2013 – Rome, 11-13 December. Oral presentation. Article in book of proceedings, pp 139–140

Nastro RA (2014) Microbial fuel cells in waste treatment: recent advances. Int J Perform Eng 10(4):367–376

Nastro RA, Falcucci G, Toscanesi M, Minutillo M, Pasquale V, Trifuoggi M, Dumontet S, Jannelli E (2015a) Performances and microbiology of a microbial fuel cell (MFC) fed with the organic fraction of municipal solid waste (OFMSW). In: Proceedings of EFC15 Conference, Naples (Italy), 15–18 Dec 2015

Nastro RA, Falcucci G, Hodgson DM, Minutillo M, Trifuoggi M, Guida M, Avignone-Rossa Dumontet S, Jannelli E, Ulgiati S (2015b) Utilization of agro-industrial and urban waste as feedstock in microbial fuel cells (MFCs). In: Proceedings of the global cleaner production and sustainable consumption conference, Sitges (Spain), 1–4 Nov 2015

Oh ST, Kim JR, Premier GC, Lee TH, Kim C, Sloan WT (2010) Sustainable wastewater treatment: how might microbial fuel cells contribute. Biotechnol Adv 28:871–881

Oyetunde T, Ofiteru D, Rodriguez J (2013) Modeling bioelectrochemical systems for wastewater treatment and bioenergy recovery with COMSOL multiphysics®. In: Proceedings of the 2013 COMSOL conference in Boston

Pant D, Van Bogaert G, Diels L, Vanbroekhoven K (2010) A review of the substrates used in microbial fuel cells (MFCs) for sustainable energy production. Bioresource Technol 101:1533–1543

Pant D, Singh A, Van Bogaert G, Alvarez Gallego Y, Diels L, Vanbroekhoven K (2011) An introduction to the life cycle assessment (LCA) of bioelectrochemical systems (BES) for sustainable energy and product generation: relevance and key aspects. Renew Sust Energ Rev 15:1305–1313

Pant D, Singh A, Vanbroekhoven K, Van Bogaert G, Irving Olsen S, Singh Nigam P, Diels L (2012) Bioelectrochemical systems (BES) for sustainable energy production and product recovery from organic wastes and industrial wastewaters. RSC Adv 2:1248–1263

Porta D, Milani S, Lazzarino AI, Perucci CA, Forastiere F (2009) Systematic review of epidemiological studies on health effects associated with management of solid waste. Environ Health 8–60

Premier GC, Kim JR, Massanet-Nicolau J, Kyazze G, Esteves SRR, Penumathsaa BKV, Rodríguez J, Maddy J, Dinsdale RM, Guwy AJ (2012) Integration of biohydrogen, biomethane and bioelectrochemical systems. Renew Energy 49:188–192

Rabaey K, Rozendal RA (2010) Microbial electrosynthesis—revisiting the electrical route for microbial production. Nat Rev Microbiol 8(10):706–716

Recio-Garrido D, Perrier M, Tartakovsky B (2016) Modeling optimization and control of bioelectrochemical systems. Chem Eng J 289:180–190

Rushton L (2003) Health hazards and waste management. Br Med Bull 68:71

Shaoan LH, Chen Chen G (2011) Bioelectrochemical systems for efficient recalcitrant wastes treatment. J Chem Technol Biotechnol 86:481–491

Sleutels THJA, Ter Heijne A, Buisman CJN, Hamelers HVM (2012) Bioelectrochemical systems: an outlook for practical applications. ChemSusChem 5:1012–1019

UNEP - United Nations Environmental Programme (2010) Waste and Climate Change - Global trends and strategy framework. Available on http://www.unep.or.jp/ietc/Publications/spc/Waste&ClimateChange/Waste&ClimateChange.pdf. Accessed Dec 2015

Van Eerten-Jansen MCAA, Ter Heijne A, Buisman CJM, Hamelers HVM (2012) Microbial electrolysis cells for production of methane from CO2: long-term performance and perspectives. Int J Energy Res 36:809–819

Villano M, Monaco G, Aulenta F, Majone M (2011) Electrochemically assisted methane production in a biofilm reactor. J Power Sources 196:9467–9472

Wang C, Lee Y, Liao F (2015) Effect of composting parameters on the power performance of solid microbial fuel cells. Sustainability 7(9):12634–12643

Wei J, Liang P, Huang X (2011) Recent progress in electrodes for microbial fuel cells. Bioresour Technol 102:9335–9344

Winfield J, Chambers LD, Rossiter J, Stinchcombe A, Walter XA, Greenman J, Ieropoulos I (2015) Fade to green: a biodegradable stack of microbial fuel cells. ChemSusChem 8:2705–2712

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Nastro, R.A., Falcucci, G., Minutillo, M., Jannelli, E. (2017). Microbial Fuel Cells in Solid Waste Valorization: Trends and Applications. In: Sengupta, D., Agrahari, S. (eds) Modelling Trends in Solid and Hazardous Waste Management. Springer, Singapore. https://doi.org/10.1007/978-981-10-2410-8_9

Download citation

DOI: https://doi.org/10.1007/978-981-10-2410-8_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-2409-2

Online ISBN: 978-981-10-2410-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)