Abstract

Ice cream is a popular dessert, which owes its sensorial properties (mouth feel) to its complex microstructure. The microstructure is a result of the combination of the ingredients and the production process. Ice cream is produced by simultaneous freezing and shearing of the ice cream mix, which results in the formation of ice crystals, air bubbles and a viscous serum phase. The amount and the size of the ice crystals and air bubbles have significant contributions to the mouth feel, the melting behavior, ease of spooning, etc. It also affects the shelf-life of the products. Therefore, control of the particle size and volume fraction is crucial. The ice crystals have a large influence on the hardness of the ice cream. The particle size, which is normally in the range of 30–50 μm, determines the degree of coldness, which can be controlled by the temperature of the production process. A wide particle distribution will have a negative influence on the shelf-life, as Ostwald ripening and recrystallization will occur more often. Once the recrystallization processes lead to the growth of larger ice crystals above 100 μm, the ice cream will feel icy and gritty. Therefore, to increase mouth feel and shelf-life, a narrow size distribution of small ice crystals is preferred. The air bubbles, in the size range of 20–50 μm, provide the softness and decrease the coldness of the ice cream, and are usually present in high volume fractions. Due to a high volume fraction, the air bubbles are in close proximity, thereby enhancing coalescence. Once coalescence has led to the increase in air bubble size and the formation of channels, the air can escape and the ice cream collapses. Ostwald ripening, due to a wide particle size distribution, will enhance this effect. Once the air has escaped, the ice cream will become harder. As the air is non-conductive, the presence of air slows down the heat transfer, leading to a warmer mouth feel for ice cream with a high volume fraction of air. The collapse of the ice cream will therefore also change the mouth feel from a slightly warmer to a colder ice cream. To increase the shelf-life and mouth feel, the air bubbles should be stabilized. This can be accomplished by coating the air bubbles with fat globules. During the production process, the fat globules will partially coalesce, thereby forming a fat layer around the air bubbles. The process is enhanced by a decrease in fat globule size (to sizes below a micrometer), which is controlled by homogenization of the ice cream mix. To enhance shelf-life and control mouth feel, the particle size and its distribution is important for all elements in the ice cream.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

9.1 Introduction

Ice cream is a popular frozen dessert consumed the world over. It is typically enjoyed as a cool warm-weather treat, and a range of varieties can be found across many cultures. Although everyone loves ice cream, Australians and New Zealanders, who eat the frozen treat all year long, seem to have the largest annual per capita consumption with 17 and 16 L, respectively. Ice cream is essentially milk, water, cream and sugar. But change the ingredients slightly and standard ice cream can become gelato (custard-based ice cream), sorbet (nondairy, fruit-based frozen dessert), sherbet (fruit-based frozen dessert with some dairy products), frozen yoghurt, or fruit ice. Ice cream is popular because of its mouth feel, conveying a sensation of decadence on the tongue. Just out of the freezer, it is cold and hard, and as it melts, it turns into a smooth, creamy liquid. The combination of flavor, texture and the cooling sensation in the mouth will determine whether we like it. Although most ice creams have similar ingredients, the mouth feel and the sensations they impart are different. Sorbets, for example, normally feel a bit colder than ice creams, and their texture is completely different. Some ice creams melt very easily and disappear very quickly on the tongue, while others last. Why are there so many differences?, and where do these differences come from? The mouth feel of ice creams and its related sensations are determined by the microstructure of the food product, which is a result of the interplay between the ingredients.

9.1.1 Ingredients

The ingredients of ice cream can be classified into three different groups:

-

Components (major) that are present in substantial amounts (about 1–25 %), such as milk proteins, sugar, fat and water.

-

Components (minor) that are present in small quantities (less than about 1 %), such as emulsifiers, stabilizers, colors and flavors.

-

Extra ingredients, such as chocolate, wafers, fruit pieces, nuts, etc.

The ingredients can be obtained from a variety of raw materials, such as milk, skimmed milk, low- and high-fat cream, yoghurt, buttermilk, milk powder, vegetable fat or butterfat. The total amount of ingredients other than water, such as proteins, fat, and stabilizers, is defined as the total solids. The total amount of solids has a large influence on the quality of the ice cream and can be used to control the mouth feel of the ice cream. In Table 9.1, a standard ice cream formulation is given. A good quality ice cream often contains a total solid content between 30 % and 40 %. Ice cream, with such a high amount of solids, often feel more creamy and smooth. Ice cream that contains lower amounts of solids often feels watery and icy.

9.1.2 Manufacture of Ice Cream

Ice cream is produced by four different steps: (1) mix preparation, including blending, pasteurization and homogenization (2) aging, (3) freezing and (4) hardening. The mixing process is designed to blend, disperse and hydrate the ingredients. Liquid ingredients are dosed first (water, milk, cream) into the mix tank and then heated. The temperature should be kept lower than the denaturation temperature of the proteins to avoid aggregation of the proteins, and should therefore not exceed 65 °C. Solid fats are melted before addition and dry ingredients are added next. The ingredients are mixed in the mix tank. The low shear forces in the tank produce a coarse oil-in-water emulsion with relatively large fat droplets of approximately 2–10 μm. The mix is then pasteurized to reduce the number of micro-organisms. The hot mix is then transferred to a homogenizer to reduce the size of the fat droplets to sizes below 1 μm, which increases the surface area of the fat tremendously. In industry, mostly high pressure homogenizers are used (up to 200 bar), as these apparatus are most effective in decreasing the fat droplet size. However, most small-scale ice-cream producers (craftsman) use high shear mixing devices. During homogenization, the milk proteins adsorb onto the surface of the fat droplets. In the aging step, the mixture is cooled down to 4 °C. During this stage, some of the proteins are replaced by emulsifiers. This allows the fat droplets/particles to come close together, leading to partial coalescence. Since the fat particles are not completely liquid but partially solid, they can only merge to a certain extent and do not result in the formation of a single particle. Instead, this results in large aggregates, in which the fat particles are partially merged creating a strong link between the particles. This process is known as partial coalescence, and is only observed for partially solid particles. Due to their hydrophobic nature, the fat globules are mainly present at the air-water interface. The partial coalescence of the fat globules on the air-water interface leads to the formation of a solid layer around the air bubbles. This takes place during the freezing step, in which the final microstructure of the ice cream is determined. During this step, the mix is aerated and frozen to generate ice crystals, air bubbles and the matrix. Ice cream makers are surface heat exchangers equipped with scrapers. They are designed to extract heat from the viscous solution at the outside of the barrel (the refrigerant is often ammonia or Freon). Inside the barrel, there is a rotating dasher/scraper that scrapes the frozen mix from the wall and redisperses it into the unfrozen ice cream mix. The outlet temperature of the ice cream maker determines the total amount of ice. As the ice cream leaves the freezer, there is a pressure drop of appr. 4 atm. As a result, the air bubbles will expand, which will increase the total volume of air that is incorporated in the system. The temperature of the ice cream is approximately −5 °C when it leaves the ice cream maker, and is transferred to a freezer to harden. In this step, the existing ice crystals will grow until a temperature of −20 °C is reached.

9.2 Structure

Looking closer at ice cream, we can recognize that these frozen products are complex systems whose microstructure can be described as ice crystals and air bubbles embedded in an unfrozen sugar solution, as depicted in Fig. 9.1 [12]. The unfrozen sugar solution is often referred to as the freeze-concentrated matrix, as upon freezing, water is removed from the solution as ice, effectively increasing the sugar concentration in the unfrozen phase. The structure of ice cream – whether it is ice cream, gelato or sorbet – is determined by the proportion of these different specific ingredients and the process by which the ice cream is produced. The microstructure of the ice cream is important because it determines the dessert’s sensorial properties, such as hardness, coldness, rate of melting, creaminess, and fluffiness. It thus determines how we perceive ice cream when we eat it, the ease with which the ice cream can be scooped from its container, and how long the ice cream can be stored without losing its characteristic texture. An understanding of how all these elements are interrelated can help us manipulate ice cream’s properties to achieve certain sensorial effects.

Microstructure of ice cream [12] (Reproduced with permission; copyright Elsevier Ltd.)

The volume fraction of ice crystals, air bubbles and serum phase depends on the ingredients and the production of the ice cream. In a conventional ice-cream, the volume fraction of air is roughly 30 %, the volume fraction of ice 40 %, the serum phase 20 % and the fat phase 10 %. However, the composition depends on the ingredients and the production process. For example, industrially-produced ice cream often has an air bubble fraction of over 50 %, whereas craftsman ice-cream usually does not exceed an air bubble fraction of 20 %. This has an effect on the perception of the ice cream and the changes during storage. A very low solid content often has a lower serum phase fraction and a higher ice fraction, leading to a watery and icy feeling.

9.2.1 Ice Crystals

The most important element in ice cream is the ice – solid crystalline water. Usually, 65 % out of the ice cream mix (water + water soluble ingredients) turns into ice. The ice crystal volume fraction is controlled by the ingredients that influence the freezing point depression and the total amount of dry solids that are added to the ice cream mix. A certain amount of sugar is used to control the freezing point depression. This can be done by a combination of different types of sugar, such as sucrose, lactose (from milk), dextrose, saccharose, fructose, etc. Each of these sugars has their own contribution to the freezing point depression and sweetness. (Lactose for example has the same influence on the freezing point depression as sucrose, but has a smaller effect on the sweetness. Fructose has a larger effect on the freezing point depression, but also has a larger effect on the sweetness). In a typical ice cream, the total sweetness is controlled between values of 16–20, where the value is calculated asFootnote 1:

During freezing and hardening, the average size of the ice crystals is determined commonly to be roughly 30–50 μm, but values of 1 and 150 μm have also been observed [6, 7, 9, 21]. Since the added sugars do not only play a role in the flavor of the ice-cream but also play a major role in the determination of the total ice fraction, replacement of sugar by artificial sugar is not a straightforward exercise. When regular sugars are replaced by artificial sweeteners, the gained freezing point depression will not be large enough to decrease the ice crystal formation, leading to a very hard and grainy ice cream.

9.2.1.1 Crystal Shape and Size

The size and the shape of the ice crystals are determined by the production process. The type of freezer and the temperature at which the ice cream is prepared will affect both the ice crystal size and shape. Faster cooling leads to smaller crystal sizes. Crystals appear and grow as a result of a thermodynamic process, in which the energy gain of creating a bulk phase is counteracted by the energy cost of creating a surface. Once the radius of the crystal is larger than a certain critical size, r c , the growth of the crystal will lead to an energy gain. Crystals, smaller than this critical radius, will melt again and disappear. This critical size will therefore determine to a large extend when crystals will be formed. The smaller the critical size, the easier crystals will be formed, and as a result, more and smaller crystals will appear. The critical size is related to certain parameters, as the interfacial tension, γ, the enthalpy of fusion, Δ F H, the melting temperature of the ice cream mix, T 0 m , and the difference in temperature (ΔT) between the ice cream mix and the freezer as

The larger the difference in temperature between the ice cream mix and the ice cream maker, the smaller the (critical) size of the ice crystals. Therefore, the temperature of the ice cream maker has a large influence on the size, as it becomes smaller for lower temperatures of the ice cream maker. Ice cream prepared with liquid nitrogen (−196 °C) will therefore produce much smaller ice crystals than conventional ice cream makers. However, the very fast freezing in liquid nitrogen is not convenient to include large volume fractions of air. Therefore it is mainly used for the production of water ice, in which air is not incorporated. To incorporate larger volume fractions of air, the mix is cooled down slower, and stirred at the same time. Ice cream makers often exist of surface scrapers that will redistribute the ice crystals back into the ice cream mix, which will partially melt the ice crystals and create new ones on the surface. During the process, air is captured in the ice cream mix. The rate of cooling not only affects the size, but has also shown to affect the crystal shape. The crystal shape of ice crystals has easily been studied by investigating the growth of ice crystals placed on a capillary tube and visualized by light microscopy. The growth of the ice crystals reveal their change in shape as a function of the temperature as is depicted in Fig. 9.2 [27]. The shape of the ice crystals in ice cream depend on the production method and the formulation of the ice cream mix.

Ice crystal growth at −0.2 °C (a), −0.7 °C (b) and −2.0 °C (c) [27] (Reproduced with permission; copyright Elsevier Ltd.)

It has been shown that the rate of cooling has an effect of the final crystal shape. With high cooling rate, dendritic or needle-like shaped ice crystals are often formed [7, 8, 27]. With lower cooling rates, hexagonal (1 h prismatic crystal) or disc-like shaped crystals are more often formed [6, 8]. The shape can also change from one form to another as a result of the production process. Dendritic ice crystals that are created on the freezer surface and redistributed into the warmer ice cream mix by the dasher blades, can partially melt and transform from a dendritic into a disc-like shape [6].

9.2.2 Fat Globules

Since ice cream is prepared with dairy product, it contains fat usually between 5 % and 10 %. Fat plays a large role in the structure of the ice cream as the fat globules stabilize the air bubbles. The stability is increased by the aggregation of the fat globules around the air bubbles, which leads to a certain fraction of a solid layer around the air bubbles. To enhance the effect of the aggregates, also called partially-coalesced fat, the droplets preferably are of small particle size. Therefore, the homogenization step and the aging step in the production process are important. The homogenization step ensures the decrease in the droplet size, which increases the surface area needed for the partial coalescence to take place. However, the dairy proteins present on the fat surface inhibit the coalescence of the fat globules. To increase the coalescence, the proteins have to be removed from the fat surface, which is accomplished in the aging step. During the aging step, the emulsifiers replace the proteins from the surface, which enhances the coalescence, leading to partially-coalesced fat aggregates. The size of the fat globules around the air bubbles and between the air bubbles have an effect on the melting behavior of the ice cream. When the fat aggregates are large enough to form a network between the air bubbles, it will slow down the melting behavior. When the fat aggregates are too small, they will flow out of the matrix. Therefore good control over the size and the coalescence of the fat particles and agglomerates is important. Besides playing a role in the microstructure of the ice cream, fat also plays an important part in the flavor formation of the ice cream. As the fat is of hydrophobic nature, the fat globules hold all the hydrophobic flavor molecules, and provide the dairy taste of the ice cream.

9.2.3 Air Bubbles

The air bubbles are created during the production process as a result of the simultaneous freezing and stirring (scraping) of the ice cream mix. The shear, laminar and turbulent forces within the freezer decrease the air bubbles size, [4, 12, 25] which is roughly found to be around 20–50 μm after the freezing and hardening step of the ice cream [5, 6, 12]. The stability of the air bubbles depends on the amount and the type of stabilizers used. The fat globules play a large role in the stability of the air bubbles by forming a solid fat layer around the air bubbles, thereby increasing the stability [14, 29]. The type of fat, the shape and the size of the fat crystals have shown to have an effect on the air bubbles [14, 15]. On average, the volume fraction of air varies from a low 20 % to 30 % to values higher than 50 %. The overrun of the ice cream, i.e. the volume increase of the ice cream mix by inclusion of air, is usually calculated using the density of the ice cream, ρ ice − cream , and the density of the ice cream mix, ρ mix , as:

The main function of the air in ice cream is to make the ice cream softer and smoother. Since the air bubbles scatter light, they also influence the color of the ice cream. The more air bubbles the ice cream contains, the whiter the ice cream appears. Since air has very poor conductive properties, air delays the transfer of heat; a larger volume fraction of air will inhibit the heat transfer to a larger extent. The heat transfer plays an important role in the rate of melting, and the sensory properties of the ice cream. Therefore, the amount and the stability of the air bubbles have a large influence on the shelf-life, the rate of melting, the smoothness and the coldness of the ice cream.

9.2.4 Serum Phase

As the ice cream mix freezes and the volume fraction of ice crystals becomes larger, the concentration of the sugar in the unfrozen water increases, also known as the unfrozen serum phase. Starting at a conventional total concentration of approximately 25 % of sugar, this concentration increases to nearly 70 % at freezer temperature, as 65 % of water turns into ice. The serum phase therefore consists of a highly concentrated sugar solution, which is close to its saturation concentration and glass transition. However, sugar molecules are rather small and do not have the ability to form a polymer network. A polymer network as a result of high molecular weight ingredients will change the microstructure of the serum phase into an even more viscous serum phase or even a gel-like structure. The presence of polymer networks affects the textural properties (mouth-feel) as each network has its own rheological behavior, such as a brittle, elastic or gummy behavior. These polymer networks are often created by polysaccharides, such as guar gum (GG), locust bean gum (LBG), sodium alginate, pectin, and carboxymethyl cellulose (CMC). The presence of polysaccharides has shown to affect several properties, such as melting behavior, shelf-life, hardness, overrun, etc. [26].

When dairy products (as cream and milk) are used in the production of ice cream, lactose is also present in the unfrozen serum phase next to the other sugars used. Lactose is a natural sugar (a disaccharide of dextrose and galactose) and has a relatively low solubility. Whilst soluble at concentrations in the ice cream mix, its solubility decreases as the concentration increases due to freezing. As a result, the lactose will crystallize out of the solution, creating large arrowhead- or diamond-shaped crystals (see Fig. 9.3). These crystals are larger than 30 μm. Due to their large size, they provide a very unpleasant “sandy” texture. Therefore, care must be taken that not too much lactose from milk or cream is present in the recipe. At high concentrations of sugar, the sucrose can also crystallize out of the solution, forming large aggregates of sugar crystals. These crystals often show up as “white” spots, which are typically seen in water ice. However, since sucrose crystallization is rather slow, it will take a considerable amount of time before these white spots are visible.

9.3 Rheological Properties

The rheological behavior of ice cream is much more complicated than that of simple liquids. The matrix is a solution of small (sugar) and large (polysaccharides) molecules, in which particles of other phases (ice crystals, fat droplets and air bubbles) are suspended. And the volume fraction of these particles even change with temperature. Before the freezing process, the ice cream mix is a solution that contains fat particles, sugar molecules and polysaccharides. The fat particles will increase the viscosity of the mix in a similar way that spherical hard spherical particles do as described in the Krieger-Dougherty equation (see Chap. 2). The large flexible polysaccharides often give the ice cream a shear thinning behavior. With higher shear rates, the polysaccharides line out in the direction of the flow, creating an easier movements, and therefore a lower viscosity. Once the ice cream is frozen, the system will change. Due to the formation of a large volume fraction of ice crystals, the serum phase concentrates, increasing the effective volume fraction of the polysaccharides towards network formation above its overlap concentration. At this moment, the serum phase transforms from a fluid-like to a gel-like system. The increase in polysaccharide concentration will lead to a tremendous increase in its viscosity. The degree of the viscosity increase is very dependent on the type of the polysaccharide used. Some polysaccharides give a very tough and gummy behavior to the ice cream, whereas others make it more brittle.

Ice cream shows a viscoelastic behavior. Its rheological properties can be measured by using large deformation experiments (using a texture analyzer), or small deformation oscillation experiments. In large deformation tests, the ice creams are deformed to large extent to investigate their fracture behavior. From the fracture behavior, their hardness can be deduced. Small deformation tests are often used to measure the rheological behavior over a wide range of temperatures. In small deformation test, the ice cream is placed in between two parallel plates, of which one oscillates in a sinusoidal fashion. The rate of the oscillation is expressed as the frequency, and the magnitude of the sinusoidal curve is referred to as the amplitude. When the samples are subjected to an oscillating strain (deformation), the stress on the sample is measured. Depending on the properties of the sample, the sinusoidal stress measured is in or out of phase with the applied sinusoidal curve. This is a result of the energy dissipation within the material. Material with a purely elastic behavior (rubber-like material) will result in a curve which is in phase. Material in which some of the energy is dissipated in order to deform the material (viscous flow) shows a curve which is out of phase. From the lag time, the elastic and viscous properties can be deduced. The elastic properties are expressed as G’ (storage modulus), and are mostly related to the solid-like behavior of the material, whereas the viscous properties are expressed as G” (loss modulus), and are related to the viscous (flow) behavior of the material. For ice cream, the solid-like response, G’, is believed to be correlated to hardness and stiffness, and the viscous-like response, G”, is more representative for the liquid-like response, which is correlated to the scoopability of the sample. Figure 9.4 gives an example of these two parameters as a function of the temperature.

The storage modulus, G’, (upper line) and the loss modules, G”, of ice cream at different temperatures [28] (Reproduced with permission; copyright Elsevier Ltd.)

As can be seen, the rheological behavior can be divided into three different zones: [28]

-

Zone I: at low temperatures, the volume fraction of the ice crystals is relatively high and thereby dominates the behavior of the ice cream. In this zone, G’ is related to the amount of ice crystals and their connectivity. The loss modulus, G”, is often related to viscosity of the serum phase and the overrun of the ice cream. A higher volume fraction of air will increase the scoopability, which is measured as a lower G”.

-

Zone II: as the temperature increases, the volume fraction of the ice crystals decreases, and both moduli decrease. The slope gives an indication of the melting behavior of the ice cream. The steeper the slope, the faster the ice cream melts. The melting behavior is determined by the shape of the crystals and the stability of the air bubbles.

-

Zone III: as the temperature reaches values above the freezing point, the ice crystals have completely disappeared. Both moduli will reach their plateau value. The rheological behavior is now determined by the viscosity of the melted sample, which is determined by the network formation of the polysaccharide, the volume fraction of fat particles, and the volume fraction of incorporated air. The higher the overrun, the larger is the loss modulus, G”.

9.4 Sensorial Properties

The sensorial properties of ice cream are a result of the microstructure of the ice cream. It is a combination of all phases present and their size distribution: the ice crystals, the air bubbles, the fat particles and the viscous matrix.

9.4.1 Effect of Ice Crystal Size

The main function of the ice crystals is to provide the cooling sensation of ice cream and sorbets. The latent heat (heat needed to melt the ice crystals) determines the heat that will be removed from the mouth and the palate to create the sense of coldness. The amount of heat is determined by the amount of the ice crystals, but also by the size distribution. A similar total volume of ice crystals with a smaller size distribution will contain more surface area. The larger the surface area, the larger is the contact with the body, and the more heat is extracted. Therefore, an ice cream prepared with liquid nitrogen (containing smaller ice crystals due to a smaller critical radius) will feel colder than ice cream prepared at higher temperatures, even though they have the same recipe (and therefore the same total amount of ice) and have been equilibrated at the same temperature. This is particularly noticeable in sorbets that do not contain fat. Small ice spheres prepared with liquid nitrogen (such as Solero shots and Calippo shots) melt very fast in the mouth leading to a very large sensation of coldness. Ice crystals larger than 100 μm are easily detected in the mouth, and are often perceived as a very icy and gritty texture. Recrystallization of ice cream, often due to temperature fluctuations, will therefore lead to a negative influence on the sensory properties.

9.4.2 Effect of Air Bubble Size

The role of the air bubbles is to make the ice cream softer and smoother. The air bubbles interrupt the solid network of the ice crystals and the very viscous serum phase; the more air bubbles are present, the more the solid network is interrupted and the softer and smoother it becomes. The presence of air bubbles will therefore have a large effect on the ease of spooning. They will also have a large effect on the mouth feel. As the air bubbles are not conductive, heat transfer is prevented within the ice cream due to the presence of air. This will decrease the rate of melt, but it will also decrease the heat extraction from the body. An ice cream with more air will therefore feel less cold. The more stable the air bubbles are, the larger the effect will be noticed. As the air bubbles are stabilized primarily by fat globules, the presence of fat will have a large influence on the meltdown rate and the sense of coldness. Ice cream with a network of fat around the air bubbles will increase the stability, thereby decrease the meltdown rate and decrease the sense of coldness. This also explains the difference in coldness between a sorbet and a dairy ice cream. As sorbets do not contain any fat, the air bubbles are less stabilized, leading to a faster heat transfer. A sorbet will therefore always feel colder than a dairy ice cream, even though the total ice crystal content and the size distribution are the same. Sorbets are therefore more preferred on a warm day, while dairy ice creams are more popular on colder days. A change in air bubble size will influence the mouth feel and the ease of spooning. The smaller the air bubbles, the softer and creamier they will feel. Especially when the ice cream melts, smaller air bubbles will last longer in the molten mix and increases the sense of creaminess. Large air bubbles are often more prone to coalescence and escape from the ice cream, thereby decreasing the amount of air and the softness of the ice cream. An increase in air bubble size is a result of pressure fluctuations or time. As soon as the air bubbles form a connecting network, their coalescence can lead to open channels that allow the air to escape and eventually the collapse of the ice cream. This will decrease their spoonability and the smoothness (softness) significantly.

9.4.3 Effect of Fat

As discussed, the addition of fat has an effect on the meltdown rate and the sensation of coldness as it is closely related to the stability of air bubbles. Besides these two important properties, the fat also contributes to the creaminess of the ice cream. The fat leaves a coating in the mouth during melting, thereby giving a creamy sensation, even after the ice cream has completely melted. The fat also contains all fat-soluble flavors, and therefore it also greatly contributes to the taste of ice cream.

9.4.4 Effect of Serum Phase

The matrix viscosity will have an effect on the gumminess and the thickness of the ice cream. When the ice cream is in its frozen state, the texture is partly dominated by the very concentrated serum phase, besides the presence of the ice crystals and the air bubbles. The properties of the serum phase are determined by the type of network formation, and its rheological behavior. The network is a result of the entanglements of the polysaccharides added and their concentration. This network varies for different polysaccharides used, and the type will therefore influence the mouth feel and the spoonability of the ice cream, e.g., some polysaccharides will make the ice cream more brittle than others. When the ice cream melts, it will transform from a solid-like into a liquid-like material. The amount of sugars and polysaccharides (besides proteins and fats) determines the viscosity of the molten ice cream, and will determine the sensorial properties such as thickness and gumminess.

In the molten state, also the amount of air and the amount of fat in the serum phase plays an important role. The fat usually provides the certain creaminess. When the air bubbles are small enough, they can fulfill the same role as the fat, and creaminess is often enhanced when a large amount of air is still present. Therefore, it is important to keep the air bubbles as small and stable as possible.

9.5 Shelf Life

The shelf life of ice cream is largely determined by the microstructure of the ice cream and the ingredients. For a long shelf-life, the size of the ice crystals and the air bubbles should not change over time.

9.5.1 Effect of Ice Crystal Size

When ice crystals become larger, this often has a negative influence on the texture of the ice cream; it becomes watery and icy. The change in ice crystals is a result of Ostwald ripening, accretion and recrystallization. Ostwald ripening occurs as a result of a wide size distribution of the ice crystals. The solubility of the ice is determined by the size of the ice crystals as:

in which V m is the molar volume of the solute, γ is the interfacial tension, S(∞) is the solubility of the solute in the continuous phase for a droplet with infinite curvature and S(r) is the solubility of the solute when contained in a spherical crystal of radius r. For smaller crystals, the solubility is therefore higher than for larger crystals. Since there is always an equilibrium between melting and freezing of water molecules, the melting will occur faster around small molecules, and the freezing faster around large molecules. This will eventually decrease the size of the small ice crystals and increase the size of the large ice crystals. Accretion is the process in which two ice crystals touch, forming a neck in between the ice crystals and the two crystals finally transform into one. Both these processes lead to an increase in the ice crystal size over time, even at low temperatures. Temperature fluctuations will enhance the processes just mentioned. When the temperature is raised (by taking the ice cream from the freezer), the total volume fraction of the ice crystals will decrease, and therefore the surface of the ice crystals will melt. Some of the small crystals will hereby completely disappear, whereas the larger ones only partially melt. When the temperature is decreased again (by putting the ice cream back into the freezer), only the still existing ice crystals can recrystallize, thereby leading to a shift in the crystal size distribution. The small ones disappear, and the larger ones grow. This is therefore an accelerated Ostwald ripening process and will eventually also lead to faster accretion. To increase the shelf life of the ice cream, temperature fluctuations should therefore be minimized, and recrystallization, Ostwald ripening and accretion should be avoided as much as possible. This is usually accomplished by the addition of polysaccharides. The addition of polysaccharides will increase the viscosity of the serum phase, thereby inhibiting the diffusion of water and sucrose. It also acts as a barrier between the ice crystals inhibiting the accretion of the ice crystals. Recently, also other ingredients have been shown to slow down the process dramatically by changing the size and the shape of the ice crystals. These novel ingredients are known as ice structuring proteins (ISP) or anti-freeze proteins, extracted from plants, insects and fish that survive in very cold climates [18, 23, 24]. These ice structuring proteins have the ability to adsorb onto the ice crystal surface, thereby changing the surface properties, and inhibiting further growth of the crystals. As they prevent ice formation to a certain extent, these proteins are referred to as having icephobic properties.

9.5.2 Effect of Air Bubble Size

Similar to the change in ice crystal size, the size distribution of air will also change when stored. The two mechanisms for coarsening of the air bubbles are coalescence (similar to accretion) and disproportionation (similar to Ostwald ripening). Coalescence occurs when two bubbles come into close contact and disproportionation occurs due to a difference in pressure between the two air bubbles. As the pressure of small air bubbles is larger than the pressure of large air bubbles, air will diffuse through the matrix from small air bubbles into large air bubbles. As a result, large air bubbles will grow at the expense of the smaller ones, leading to a growth of the air bubble size. Just as the ice crystals are sensitive to temperature fluctuations, air bubbles are pressure sensitive as a result of a difference in atmospheric pressure at different altitudes. When the pressure is low, the volume will increase, thereby expanding the ice cream. This leads to rupture of the matrix, increasing coalescence between air bubbles, forming a continuous network, and the escape of air through the emerging channels. This eventually leads to the collapse of the ice cream. The change in air bubble size can be prevented by adsorption of proteins or fat on the surface. When the fat partially coalesces, a three dimensional structure stabilizes the air bubbles and will increase its shelf-life.

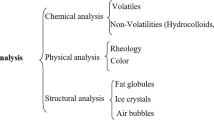

9.6 Measuring Techniques

9.6.1 Ice Crystals

Particle size of the ice crystals can easily be determined by light microscopy, as the ice crystal size is often in the range of tens of micrometers. The microscope should be mounted with a cold stage to ensure a frozen state of the sample. Both Brightfield and Fluorescence microscopy is used, often in combination with appropriate filters [1, 3, 22]. The cryomicroscopes are often placed in a refrigerated glove box to ensure low temperatures [16]. For a more detailed image of the ice crystals, Low Temperature Scanning Electron Microscopy (LT-SEM) or Cryoscanning Electron Microscopy (Cryo-SEM) are often used [1, 10]. Previously prepared ice cream samples are first placed into liquid nitrogen after which a small piece is fractured and placed into the SEM specimen holder. The samples are then often sputter coated with gold in a cryo-preparation unit to prevent melting of the samples. Figure 9.5 gives an example of such a LT-SEM image from a standard ice cream formulation.

LT-SEM micrographs of a conventional ice cream formulation containing (a) no emulsifier and (b) 0.3 % emulsifier. The bar is 30 μm. [1] (Reproduced with permission; copyright John Wiley and Sons)

Figure 9.5 shows the microstructure of ice cream, in which the dark smooth regions are the ice crystals. As can be seen, the ice crystals are rather polydisperse in size, and the average size is often found to be in the range between 30 and 50 μm. Similar to SEM, Transmission Electron Microscopy (TEM) can also be used to visualize the samples, from which the crystal size can be deduced. Sample preparation is also done under low temperatures to prevent the samples from changing [21]. The images show similar results.

A disadvantage of these microscopy techniques is that the pictures are often 2D and the preparation of the samples is rather destructive. A lot of the preparation methods (slicing, fracturing, etc.) can lead to artifacts in the system, and therefore the visualization of the microstructure with microscopy is not always accurate. Recently, new methods have been proposed to study the microstructure of the ice cream, and to measure the ice crystal size online. One method involves X-ray micro-tomography, which can be used to visualize the microstructure of the ice cream in 3D. The method uses an image processing protocol, and is described in details by Pinzer and co-workers [20]. With this technique, they investigated the average ice crystal size at different temperatures, going from an ice percentage of 21.9–48.7 %. When the ice crystals would grow homogenously, the size is expected to increase by a factor of 1.3 only. However, they found that the ice crystal size increased by a factor of 4, which can only be explained by a connectivity of the ice crystals of previously unconnected ice crystals. The opposite is the case when the temperature is increased (thereby lowering the ice volume fraction). The partial melting leads to the decrease of the ice crystals, but also breaking up of the ice crystals. This technique was used to follow the coarsening of the ice crystals as a function of temperature fluctuations, and shows that the mechanism for coarsening is presumably a partial melting refreezing mechanism.

Another method that was recently discussed is the focused beam reflectance measurement (FBRM) technology [2]. This method allows measurement of the size distribution of the ice crystals online. The technique is based on the use of a rotating or vibrating laser beam that is focused just behind a window. A sensor detects the light reflected by particles, registers the time period of reflection, and represents the reflection times as a chord length distribution (CLD) related to particle size distribution (PSD). The advantage of this method is that the method is suitable for in situ measurements of particles at high concentrations of 40 %. However, discarding the volume fraction of air, and taking into account the liquid and solid fraction only, the volume fraction of ice is close to 70 %. This is much larger than the technique allows. Therefore, the technique is more useful for measuring the particle size distribution in situ when the ice cream is transferred from the ice cream maker at draw temperature before the hardening step.

9.6.2 Fat Globules

The particle size of the fat globules is important for the stability and the sensorial properties of ice cream. As a high surface area of fat is preferred to induce partial coalescence and formation of an aggregated network around the air bubbles, fat globules in dairy products have to be reduced. The size of the fat droplets is controlled by the homogenization of the ice cream mix. High pressure homogenization often leads to a change from a bimodal to a monomodal particle size distribution and a reduction in the mean particle diameter. The particle size of emulsion and fat droplet can be measured with a variety of techniques. The most common ones are dynamic light scattering (DLS) and laser diffraction (LD) (see also Chap. 3 and [19]). DLS techniques measure the size based on the Brownian motion of the particles. The scattered light is detected by one or two detectors, and the intensity is measured as a function of time and interpreted as an auto-correlation or cross-correlation function; through the diffusion coefficient, particles size distribution is calculated. The particle size range of the DLS technique is 0.002–2 μm. LD uses the fact that particles of a certain size scatter light with specific intensities at different angles. Mie theory is used to calculate the particle size distributions. The particle size range of LD is roughly 100 nm–1 mm. Besides light scattering, also other techniques can be used to measure the particle size. One example is the use of nuclear magnetic resonance (NMR) with the use of the Earth’s magnetic field (EF) [11]. After applying a pulse field gradient, a NMR signal intensity is measured, which can be related to the diffusion coefficient of the material or the relaxation time. For dairy emulsions (milk, cream), LD or DLS are used most frequently. The particle size is often given as the volume mean, D 4,3, or the surface mean, D 3,2. Figure 9.6 gives an example of the fat particle size as a function of the homogenization pressure. The pressure was changed from 15 MPa (B) to 97 MPa (C). Figure A gives the particle size distribution of unhomogenized cream in which the droplet size shows a bimodal distribution, which is expected for the untreated dairy products. After the homogenization step, the droplet size is considerable lowered and shows a more monomodal distribution with a smaller particle size [17].

Representative volume-weighted distributions of ice cream mix samples by DLS measurement: (a) unhomogenized. (b) homogenized at 15 MPa, and (c) homogenized at 97 MPa. [17] (Reproduced with permission; copyright Elsevier Ltd.)

The change in the droplet size has a significant effect on the viscosity of the ice cream mix. As the droplet size decreases, the viscosity of the ice cream mix will significantly increase [17].

9.6.3 Air Bubbles

As the air bubble size is usually larger than 20 μm, the air bubbles can be seen with conventional microscopy techniques. For a more detailed visualization, LT-SEM, cryo-SEM or TEM are also used. These techniques are used to provide details of the fat globules around the air bubbles. Figure 9.7 shows micrographs of different ice cream formulations containing fat particles, dairy proteins and emulsifiers. As can be seen, the small fat globules are surrounding the air bubbles. In some of the images they appear to be spherical, whereas in others they appear to be more coalesced, thereby forming larger fat aggregates. Depending on the amount of emulsifiers added, the fat aggregation (partial coalescence) is more pronounced, due to replacement of the dairy proteins. The fat coalescence is clearly seen in Figure F (indicated by the arrow), in which a larger amount of emulsifier was added. The pictures B and D contain less emulsifier, which results in the presence of more globular fat particles [13].

Micrographs of frozen ice mixes at two different magnifications. In the top set (a, c, e), the bar is equal to 15 μm, in the lower set (b, d, f), the scale bar is equal to 5 μm. a refers to air bubbles, f to fat globules, i to ice crystals and s to serum phase. [13] (Reproduced with permission; copyright Elsevier Ltd.)

9.7 Definitions

Accretion | Formation of a solid bridge in between adjacent crystals leading to a single particles |

Aggregation | Formation of an assemblage of primary particles through strong physical attractive forces and/or chemical bridges |

Coalescence | Collision of droplets in an emulsion following by merging to a larger droplet |

Partial Coalescence | Collision of fat droplets in an emulsion following by a partial merging of the droplets. The result is the presence of agglomerates with a very strong connection |

Ostwald ripening | Growth of larger crystals in suspensions at the expense of smaller ones, due to dissolution and re-crystallization as a result of differences in solubility |

Overrun | % increase of ice cream volume over that of the starting mix due to air inclusion |

Cryo-SEM | Cryogenic scanning electron microscopy |

CLD | Chord length distribution |

DLS | Dynamic light scattering |

EF | Earth’s magnetic field |

FBRM | Focused beam reflectance measurement |

LD | Laser diffraction |

LT-SEM | Low-temperature scanning electron microscopy |

NMR | Nuclear magnetic resonance |

PSD | Particle size distribution |

SEM | Scanning electron microscopy |

TEM | Transmission electron microscopy |

D | Particle size |

D 3,2 | Sauter mean diameter, area-weighted mean size, mean value of an area-based PSD |

D 4,3 | Volume-weighted mean size, mean value of a volume-based PSD |

Δ F H | Enthalpy of fusion (J/g) |

r | Radius of crystal sphere (m) |

R | Gas constant: (8.3 J/molK) |

S | Solubility |

T | Temperature (K) |

T m | Melting temperature (K) |

V m | Molar volume |

γ | Interfacial tension (N/m) |

ρ | Density (kg/L) |

Notes

- 1.

A 20 % sugar solution has a total sweetness of 20; a 20 % solution of lactose has a total sweetness of roughly 5.

References

Aleong, J.M., Frochot, S., et al.: Ice recrystallization inhibition in ice cream by propylene glycol monostearate. J. Food Sci. 73(9), E463–E468 (2008)

Arellano, M., Benkhelifa, H., et al.: Online ice crystal size measurements during sorbet freezing by means of the focused beam reflectance measurement (FBRM) technology. Influence of operating conditions. J. Food Eng. 113(2), 351–359 (2012)

Bolliger, S., Wildmoser, H., et al.: Relationships between ice cream mix viscoelasticity and ice crystal growth in ice cream. Int. Dairy J. 10(11), 791–797 (2000)

Chang, Y., Hartel, R.W.: Development of air cells in a batch ice cream freezer. J. Food Eng. 55(1), 71–78 (2002)

Chang, Y., Hartel, R.W.: Stability of air cells in ice cream during hardening and storage. J. Food Eng. 55(1), 59–70 (2002)

Cook, K.L.K., Hartel, R.W.: Mechanisms of ice crystallization in ice cream production. Compr. Rev. Food Sci. Food Safety 9(2), 213–222 (2010)

Cook, K.L.K., Hartel, R.W.: Effect of freezing temperature and warming rate on dendrite break-up when freezing ice cream mix. Int. Dairy J. 21(6), 447–453 (2011)

Donhowe, D.P., Hartel, R.W.: Recrystallization of ice in ice cream during controlled accelerated storage. Int. Dairy J. 6(11–12), 1191–1208 (1996)

Flores, A.A., Goff, H.D.: Ice crystal size distributions in dynamically frozen model solutions and ice cream as affected by stabilizers. J. Dairy Sci. 82(7), 1399–1407 (1999)

Flores, A.A., Goff, H.D.: Recrystallization in ice cream after constant and cycling temperature storage conditions as affected by stabilizers. J. Dairy Sci. 82(7), 1408–1415 (1999)

Fridjonsson, E.O., Flux, L.S., et al.: Determination of mean droplet sizes of water-in-oil emulsions using an Earth’s field NMR instrument. J. Magn. Reson. 221, 97–102 (2012)

Goff, H.D.: Formation and stabilisation of structure in ice-cream and related products. Curr. Opin. Colloid Interface Sci. 7(5–6), 432–437 (2002)

Goff, H.D., Verespej, E., et al.: A study of fat and air structures in ice cream. Int. Dairy J. 9(11), 817–829 (1999)

Granger, C., Leger, A., et al.: Influence of formulation on the structural networks in ice cream. Int. Dairy J. 15(3), 255–262 (2005)

Granger, C., Schoppe, A., et al.: Influence of formulation on the thermal behavior of ice cream mix and ice cream. J. Am. Oil Chem. Soc. 82(6), 427–431 (2005)

Hagiwara, T., Hartel, R.W., et al.: Relationship between recrystallization rate of ice crystals in sugar solutions and water mobility in freeze-concentrated matrix. Food Biophys. 1(2), 74–82 (2006)

Innocente, N., Biasutti, M., et al.: Effect of high-pressure homogenization on droplet size distribution and rheological properties of ice cream mixes. J. Dairy Sci. 92(5), 1864–1875 (2009)

Kontogiorgos, V., Regand, A., et al.: Isolation and characterization of ice structuring proteins from cold-acclimated winter wheat grass extract for recrystallization inhibition in frozen foods. J. Food Biochem. 31(2), 139–160 (2007)

Merkus, H.G.: Particle size measurements; fundamentals, practice, quality. Springer, New York (2009)

Pinzer, B.R., Medebach, A., et al.: 3D-characterization of three-phase systems using X-ray tomography: Tracking the microstructural evolution in ice cream. Soft Matter 8(17), 4584–4594 (2012)

Regand, A., Goff, H.D.: Effect of biopolymers on structure and ice recrystallization in dynamically frozen ice cream model systems. J. Dairy Sci. 85(11), 2722–2732 (2002)

Regand, A., Goff, H.D.: Structure and ice recrystallization in frozen stabilized ice cream model systems. Food Hydrocolloid. 17(1), 95–102 (2003)

Regand, A., Goff, H.D.: Freezing and ice recrystallization properties of sucrose solutions containing ice structuring proteins from cold-acclimated winter wheat grass extract. J. Food Sci. 70(9), E552–E556 (2005)

Regand, A., Goff, H.D.: Ice recrystallization inhibition in ice cream as affected by ice structuring proteins from winter wheat grass. J. Dairy Sci. 89(1), 49–57 (2006)

Sofjan, R.P., Hartel, R.W.: Effects of overrun on structural and physical characteristics of ice cream. Int. Dairy J. 14(3), 255–262 (2004)

Soukoulis, C., Chandrinos, I., et al.: Study of the functionality of selected hydrocolloids and their blends with kappa-carrageenan on storage quality of vanilla ice cream. Lwt-Food Sci. Technol. 41(10), 1816–1827 (2008)

Teraoka, Y., Saito, A., et al.: Ice crystal growth in supercooled solution. Int. J. Refrig. 25(2), 218–225 (2002)

Wildmoser, H., Scheiwiller, J., et al.: Impact of disperse microstructure on rheology and quality aspects of ice cream. Lebensm-Wiss. Technol. 37(8), 881–891 (2004)

Zhang, Z., Goff, H.D.: Protein distribution at air interfaces in dairy foams and ice cream as affected by casein dissociation and emulsifiers. Int. Dairy J. 14(7), 647–657 (2004)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Scholten, E. (2014). Ice Cream. In: Merkus, H., Meesters, G. (eds) Particulate Products. Particle Technology Series, vol 19. Springer, Cham. https://doi.org/10.1007/978-3-319-00714-4_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-00714-4_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-00713-7

Online ISBN: 978-3-319-00714-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)