Abstract

As the process of products is developing, the contradiction between dimension quality and manufacturing cost should be balanced carefully. Excessive demands for higher quality would cause increase the production cost. Therefore, this paper will propose a new method of tolerance allocation based on NSGA-III. At the beginning, the assembly precedence diagram and subassembly identification are used to obtain feasible assembly sequences. The assembly variation analysis model of the conceptual design stage was established. Afterwards, the assembly tolerance function was used to analyze the quality of the assembly, and the exponential function was selected as the cost model. Based on the above functions, a multi-objective optimization model was established. The NSGA-III algorithm occurred, which can be used to optimize the tolerance allocation of the selected sequence, the optimal assembly sequence and the Pareto solution set of the multi-objective function. Finally, the auto-body floor can be used to illustrate the flowchart of tolerance allocation. The optimal solution is selected from the Pareto solution by the TOPSIS method. The results verify the feasibility and effectiveness of the proposed algorithm.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

101.1 Introduction

Assembly sequence planning plays an important role in computer aided design and is the core of sheet metal parts assembly process optimization [22]. An auto-body is usually composed of hundreds of sheet metal parts with complex curved surfaces. The assembly process is complicated, and the assembly variation is unavoidable. Auto-body is a mass production which has a complex manufacturing system. The assembly variation of the product has a significant impact both on the performance and manufacturing cost. How to reduce assembly variation is one of the main problems in the auto-body design and manufacture.

The reasonable and feasible assembly sequences can improve the assembly quality, reduce assembly costs and shorten assembly time. Assembly is of the vital importance the production time and the cost of the product (Shoval et al. 2017). Homen et al. (1990) evaluated assembly sequences based on assembly flexibility, assembly parallelism and assembly time cost. Jone et al. (1998) evaluated the assembly sequence by summarizing multiple assembly constraints. Xing et al. [22] applied the hybrid algorithm of genetic algorithm and particle swarm optimization to generate auto-body assembly sequences. Navaei and ElMaraghy [16] developed a mixed integer programming (MIP) algorithm, which can quickly find the optimal solution and the optimal sequence. The quality of the assembly in the actual assembly will directly lead to the difference in the performance of the product. Because different assembly sequences use different assembly features as assembly references in assembly operations, the assembly sequence reflects the process of variation accumulation. For example, Lu et al. (2006) used tolerances to predict deviations and evaluated assembly sequences. Tian et al. (2007) established the state space model of variations stream propagation in a multi-station assembly process of sheet metal.

The tolerance analysis, also known as the variation analysis, calculates the tolerance design process of assembly variation based on the assembly process relationship between known parts and fixtures. Tolerance analysis can be used to predict, evaluate and check the quality of assembly. Based on the analysis of the assembly variation of single position flexible sheet parts, the multistation assembly variation model is established by using the finite element method (Hsieh et al. 1977), the influence coefficient method (Liu et al. 1997), and the state space method in modern control theory (Jin and Shi 1999). Marziale et al. [15] introduced two main models for tolerance analysis, the Jacobian and the torsor. Qu et al. (2016) developed a more accurate variation propagation model in multistation assembly processes using a discrete time nonlinear state-space model to provide a mathematical representation for process-oriented locating datum system design. Hafezipour et al. [11] introduced uncertainty analysis for estimate deviations. Yin et al. (2017) applied Rcckwitz-Fiessler (R-F) reliability analysis method for assembly tolerance design of complex engineering problems. Tolerance analysis requires more efficient methods to calculate rates.

Tolerance allocation, also known as tolerance synthesis, is the reasonable allocation of key dimensional tolerances in assembly according to the assembly relations and process conditions of parts under the condition of known final product tolerance requirements. It is necessary to establish a reasonable tolerance distribution model. The tolerance allocation is optimized. The quality and other aspects of the assembly system are considered synthetically. Manufacturing cost is often used as the main criteria for evaluating the rationality of design tolerance allocation [3]. Dupinet et al. [10] used the method of fuzzy comprehensive evaluation to determine the tolerances of the parts of the special environment assembly. The sensitivity factor of the assembly function is required to establish the mathematical model of tolerance allocation. The tolerance allocation plays an important role in the analysis of tolerance. For different tolerance allocation models, scholars use various analytic methods or direct methods to solve them. In the early days, Lagrange multiplication and linear programming method were used to solve the problem. With the development of nonlinear algorithms, some intelligent algorithms were gradually applied in tolerance allocation, including simulated annealing algorithm [1], genetic algorithm [5], Monte Carlo simulation [21], neural network [12] and evolutionary algorithm [13]. The problem of tolerance allocation of single objective cannot meet the need of solving practical problems, so the development of objective optimization algorithm is introduced. For multi-objective optimization, it is required that some of the goals of contradictions and conflicts are optimized at the same time, and Pareto optimal solutions are widely used. Xing et al. [23] studied the assembly technology and introduced NSGA-II algorithm to optimize the assembly tolerance allocation and manufacturing cost. Balamurugan et al. [2] proposed a model for optimal tolerance allocation by considering both tolerance cost and the present worth of quality loss. Xu et al. [25] studied the application of improved NSGA-II algorithm in tolerance allocation.

The assembly process should not only analyze the cumulative dimensional variation of the closed-loop joint structure in the assembly, but also analyze the cumulative dimensional variation of the whole assembly. The tolerance of each constituent ring in the dimension chain is distributed reasonably if the assembly target is met. It is of great theoretical and practical significance to study the method of tolerance allocation. The allocation of tolerance focuses on reducing the processing cost and ignores the impact of quality loss. The analytic method usually requires the objective function to have definite gradient information, and it is difficult to solve the non-linear model. Sometimes intelligent algorithms are inefficient, and the evaluation function is difficult to construct.

Based on the assembly features of flexible thin-walled parts of the auto-body, the multi-objective optimization of the tolerance distribution of parts and fixtures of the flexible thin-walled auto-body was studied. To establish a reasonable tolerance distribution model, the efficient algorithms are selected for optimization of assembly tolerance allocation.

101.2 Assembly Tolerance Allocation Based on NSGA-III Algorithm

101.2.1 Application Analysis of Dimension Chain Model

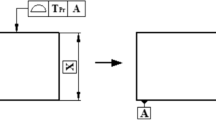

In the S1 sequence, part a is first assembled on the fixture, then part b is assembled on part a. Finally, part c is assembled on the fixture. Part a and b have cumulative but misalignment due to the presence of butt joints, but the overlapped joints between part b and c absorb variation, the final assembly variation of the key product features is 0 (Fig. 101.1).

In the S2 sequence, part b and part c are assembled on the fixture. Part a is assembled on the part b. There is no cumulative assembly variation between part b and part c because of the lap joint, but part a and part b are butt joints. The assembly deviation of the key product feature is the variation of part a (Fig. 101.2).

101.2.2 Tolerance Allocation Objective Function

By taking the manufacturing tolerance of each part as the design variable and setting the constraint conditions according to the stamping standard requirements, a multi-objective optimization of part tolerance was implemented with the objective functions of assembly tolerance and manufacturing cost. The tolerance analysis model adopts the Eqs. (101.1–101.8) for the assembly error modeling of sheet metal parts in the conceptual design stage. The root mean square method is adopted for the calculation method, and Eq. (101.9) is adopted for the tolerance-cost model.

101.2.3 Case of Auto-body Floor Subassembly

Suppose the tolerance-cost coefficient \( K_{1i} \) of parts are 10, 20, 30, 40 and 50, the tolerance-cost coefficient \( K_{2i} \) of parts are 1, 2, 3, 4 and 5 respectively.

-

(1)

From assembly sequence {4-(2,7)-(3,6)-1-5}, it can be considered as sequence {4-2-3-1-5}. The dimensional chain diagram of the auto-body floor of is shown as Fig. 101.3. The horizontal dimension chain consists of eight size loops from \( L_{0} \) to \( L_{7} \), the ith part corresponds to the ith dimension loop, and the ith dimension loop corresponds to \( L_{i} \)

According to this assembly sequence. The joint coefficient of this sequence is 1, 1, 0, 1, 1 and Eq. (101.9) into data, and get the tolerance allocation optimization model of this assembly sequence.

The evaluation function is non-linear, and the NSGA-III algorithm is used to solve the three-objective tolerance allocation optimization model. The maximum evolution algebra of this algorithm is represented by maxGen, the maxGen is 60. The population N is 200, the mutation rate \( \omega_{m} \) is 0.5, and the crossover rate \( \omega_{c} \) is 0.5. Manufacturing cost function, and quality loss function were applied to calculate the fitness value of the chromosome. Get the result is shown in Fig. 101.4.

-

I.

When the sequence is {4-(2,7)-1-(3,6)-5}, the dimensional chain diagram is shown in Fig. 101.5.

The optimization algorithm parameters remain the same, and get the result is shown in Fig. 101.6.

-

II.

When the sequence is {4-1-(2,7)-(3,6)-5}, the dimensional chain diagram is shown in Fig. 101.7.

According to this assembly sequence, the joint coefficient of this sequence is 1, 0, 1, 0, 1. The model is as follows.

The optimization algorithm parameters remain the same, and get the result is shown in Fig. 101.8.

Comparing the results of tolerance allocation for the above three assembly sequences, the optimal sequence is the third sequence, and the tolerance range is the smallest. And Figures 101.4, 101.6 and 101.8 shows the comparison of the Pareto solution set of the NSGA-III algorithm, the NSGA-II algorithm, the MOEA algorithm, MOPSO algorithm, and MOGA algorithm. The Pareto solution set of the NSGA-III algorithm is closer to the non-dominated front, the results show that the NSGA-III algorithm can get better Pareto solution set.

Through the above algorithm calculation, we get third sequence tolerance allocation Pareto solution set optimization results of NSGA-III algorithm, as shown in Table 101.1.

According to the Table 101.1, when the sort value is 0.068, we can achieve the most suitable tolerance allocation. The assembly tolerance is 0.324 and the cost is at 39.272.

101.3 Conclusions

In this paper, the three constraint conditions of assembly accumulation variation and manufacturing cost are presented. The application of the three constraints is more comprehensive than the previous two constraints. The tolerances are assigned using the NSGA-III algorithm to obtain the Pareto solution set for tolerance assignment. Comparing with the Pareto solution objective function values of the three sequences, different assembly sequences result in different tolerance allocation. As a result, a reasonable assembly sequence can improve product quality.

For the contradiction between assembly accumulation variation, manufacturing cost and quality loss in the process of sheet metal assembly design, multi-objective optimization of parts tolerance based on NSGA-III algorithm is proposed. Taking component tolerance as the design variable, the multi-objective optimization model is constructed based on the assembly variation analysis model, tolerance-cost model and quality loss model. An effective method to solve the tolerance allocation is proposed based on NSGA-III algorithm. Finally, the auto-body floor case is applied to illustrate the tolerance allocation process and obtain the Pareto solution set. The optimization results show that this method is effective on the optimization of the tolerance allocation strategy. It also provides the engineering staff with a flexible tolerance design selection scheme.

References

Ashiagbor, A., Liu, H.C., Nnaji, B.O.: Tolerance control and propagation for the product assembly modeler. Int. J. Prod. Res. 36(1), 75–93 (1998)

Balamurugan, C., Saravanan, A., Dinesh Babu, P., Jagan, S., Ranga Narasimman, S.: Concurrent optimal allocation of geometric and process tolerances based on the present worth of quality loss using evolutionary optimisation techniques. Res. Eng. Des. 28(2), 185–202 (2017)

Chase, K.W., Greenwood, W.H., Loosli, B.G., Hauglund, L.F.: Least cost tolerance allocation for mechanical assemblies with automated process selection. ASMS Manuf. Rev. 3(1), 49–59 (1990)

Chen, G.L., Lai, X.M., Lin, Z.Q., Mensssa, R.: A framework for automotive body assembly process design system. Comput. Aided Des. 38, 531–539 (2006)

Chen, T.C., Fischer, G.W.: A GA-based search method for the tolerance allocation problem. Artif. Intell. Eng. 14(2), 133–141 (2003)

Ciro, G.C., Dugardin, F., Yalaoui, F., Kelly, R.: A NSGA-II and NSGA-III comparison for solving an open shop scheduling problem with resource constraints. Int. Feder. Autom. Control 49(12), 1272–1277 (2016)

Deb, K., Jain, H.: An evolutionary many-objective optimization algorithm using reference-point-based nondominated sorting approach, Part I: solving problems with box constraints. IEEE Trans. Evol. Comput. 18(4), 577–601 (2014)

Dias, L.C., Antunes, C.H., Dantas, G., de Castro, N., Zamboni, L.: A multi-criteria approach to sort and rank policies based on Delphi qualitative assessments and ELECTRE TRI: the case of smart grids in Brazil. Omega Int. J. Manag. Sci. 76, 100–111 (2018)

Dwivedi, G., Srivastava, R.K., Srivastava, S.K.: A generalised fuzzy TOPSIS with improved closeness coefficient. Expert Syst. Appl. 96, 185–195 (2018)

Dupinet, E.: Tolerance allocation based on fuzzy logic and simulated annealing. J. Intell. Manuf. 7(6), 487–497 (1996)

Hafezipour, M., Khodaygan, S.: An uncertainty analysis method for error reduction in end-effector of spatial robots with joint clearances and link dimension deviations. Int. J. Comput. Integr. Manuf. 30(6), 653–663 (2017)

Jayaprakash, G., Sivakumar, K., Thilak, M.: FEA compliant parametric tolerance allocation of mechanical assembly using neural network and differential evolution algorithm. Int. J. Comput. Integr. Manuf. 25(7), 636–654 (2012)

Kumar, R., Padmanaban, K.P., Balamurugan, C.: Optimal tolerance allocation in a complex assembly using evolutionary algorithms. Int. J. Simul. Modell. 15(1), 121–132 (2016)

Lenormand, M.: Generating OWA weights using truncated distributions. Int. J. Intell. Syst. 33(4), 791–801 (2018)

Marziale, M., Polini, W.: A review of two models for tolerance analysis of an assembly: Jacobian and torsor. Int. J. Comput. Integr. Manuf. 24(1), 74–86 (2011)

Navaei, J., ElMaraghy, H.: Optimal operations sequence retrieval from master operations sequence for part/product families. Int. J. Prod. Res. 56(1–2), 140–163 (2018)

Spotts, M.F.: Allocation of tolerances to minimize cost of assembly. J. Eng. Ind. 95(3), 762–764 (1973)

Tavana, M., Li, Z.J., Mobin, M., Komaki, M., Teymourian, E.: Multi-objective control chart design optimization using NSGA-III and MOPSO enhanced with DEA and TOPSIS. Expert Syst. Appl. 50, 17–39 (2016)

Wang, G.D., Yao, Y., Wang, W., Si-Chao, L.V.: Variable coefficients reciprocal squared model based on multi-constraints of aircraft assembly tolerance allocation. Int. J. Adv. Manuf. Technol. 82, 227–234 (2016)

Wang, Y., Tian, D.: A weight assembly precedence graph for assembly sequence planning. Int. J. Adv. Manuf. Technol. 83, 99–115 (2016)

Wu, F.C., Dantan, J.Y., Etienne, A., Siadat, A., Martin, P.: Improved algorithm for tolerance allocation based on Monte Carlo simulation and discrete optimization. Comput. Ind. Eng. 56(4), 1402–1413 (2009)

Xing, Y.F., Wang, Y.S.: Assembly sequence planning based on a hybrid particle swarm optimisation and genetic algorithm. Int. J. Prod. Res. 50(24), 7303–7312 (2012)

Xing, Y.F., Wang, Y.S.: Design and optimisation of assembly technique for auto-body components. Int. J. Prod. Res. 51(22), 6515–6533 (2013)

Xing, Y.F., Chen, G.L., Lai, X.M., Jin, S., Zhou, J.: Assembly sequence planning of automobile body components based on liaison graph. Assemb. Autom. 27(2), 157–164 (2007)

Xu, S., Xing, Y.F., Chen, W.F.: Multi-objective optimization based on improved non-dominated sorting genetic algorithm II for tolerance allocation of auto-body parts. Adv. Mech. Eng. 9(9), 1–9 (2017)

Xue, W.T., Xu, Z.S., Zhang, X.L., Tian, X.L.: Pythagorean fuzzy LINMAP method based on the entropy theory for railway project investment decision making. Int. J. Intell. Syst. 33(1), 93–125 (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Xing, Y., Jiang, C., Luo, L. (2020). A New Approach of Manufacturing Tolerance Allocation Based on NSGA-III Algorithm for the In-Process Monitoring of Sheet Metal Parts. In: Ball, A., Gelman, L., Rao, B. (eds) Advances in Asset Management and Condition Monitoring. Smart Innovation, Systems and Technologies, vol 166. Springer, Cham. https://doi.org/10.1007/978-3-030-57745-2_101

Download citation

DOI: https://doi.org/10.1007/978-3-030-57745-2_101

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-57744-5

Online ISBN: 978-3-030-57745-2

eBook Packages: EngineeringEngineering (R0)