Abstract

An analysis of the literature on polyethylene terephthalate modification by low-temperature plasma treatment is presented. The use of modern instrumental methods (measurement of contact angles and calculations of surface energy and its components, X-ray photoelectron spectroscopy and FTIR spectroscopy, atomic force and scanning electron microscopy) for studying the properties of processed polymer samples is considered. The change in contact properties, chemical structure, and morphology of the modified surface of polyethylene terephthalate is shown. Data on studying hemocompatibility, antibacterial activity, and cell adhesion and proliferation after plasma treatment of polyethylene terephthalate are presented.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

For use in medicine and biology, polymeric materials have to be biocompatible; i.e., they must not cause side clinical manifestations and should induce a cellular or tissue response necessary to achieve a therapeutic effect [1–9].

Currently, polymers suitable for use in medicine and biology can be obtained both by synthesizing new materials and by modifying the existing ones using various chemical and physical methods. One of the most effective and technologically advanced methods of modification is treatment by low-temperature (cold) plasma [1, 10–13]. The advantage of this approach is its efficiency and environmental friendliness; it eliminates liquid processing methods associated with the use of chemical reagents. As a rule, the thickness of the modified layer is up to several tens of nanometers in this case [14]. Plasma devices for modifying polymer films, fabrics, fibers, and powders are widely used in world practice for processing large samples [1, 15–17].

Polyethylene terephthalate (PET) is a polyester of terephthalic acid and ethylene glycol, the structural formula of which is given below.

The polymer is characterized by chemical stability, hydrolysis resistance to steam, and plasticity; it has high mechanical strength and is abrasion resistant; the thermal degradation of PET occurs in the temperature range of 290–310°C. We have shown that direct-current discharge treatment of PET leads to significant hydrophilization of its surface, wherein the thickness of the modified layer is ≤20 nm [18].

In Russia, PET is mainly used for the manufacture of containers of various types and purposes (primarily, plastic bottles) and, to a lesser extent, for processing into fibers, films, and other products. In world practice, PET is mostly used for the production of threads, fibers, and films; lately, the polymer has become increasingly used in medicine and biology. In this regard, the surface of PET for a number of medical applications must be modified in such a way as to ensure cell adhesion, the absence of adverse reactions, and adsorption of blood proteins. In addition, other characteristics, such as oxidation stability, strength, and flexibility, are desirable depending on the intended use of the implant.

PROCEDURES AND DEVICES FOR PET SURFACE MODIFICATION BY COLD PLASMA

To modify the surface of PET by nonthermal plasma, various types of gas discharges are used: low-pressure discharges, such as radiofrequency (RF), microwave (MW), and direct current (DC) discharges and dielectric barrier discharge (DBD), with the latter being mainly practiced at atmospheric pressure.

Experiments are carried out using laboratory and industrial RF discharge devices operating at frequencies of 13.56 and 27.12 MHz [19–48]. Figure 1 shows a schematic diagram of a setup for modifying by low-pressure inductively coupled RF discharge plasma. An RF discharge is generated in reaction chamber 1 with RF power supply 2 and induction coil 3, and a sample to be modified (4) is placed in the plasma burning zone. The reactor is evacuated using pumping system 6; the pressure in the working chamber is controlled with vacuum gauge 5. The working gas is supplied from container 7 through leak-in system 8.

The use of treatment by low-pressure plasma of RF inductive discharge (27.12 MHz, power 150 W) to modify a PET film of a 125 μm thickness with O2 and N2 as plasma gases led to the formation of new oxygen- and nitrogen-containing groups on the surface and a change in its morphology, which provided a significant increase in hydrophilicity required for the successful attachment and growth of human umbilical vein endothelial cells [20].

Using a laboratory setup that included PET surface treatment by an RF discharge in O2 (13.56 MHz, 50 W, 1.33 Pa, 1–5 min) and the subsequent AC or DC magnetron sputtering deposition of silver, the possibility of obtaining antibacterial coatings was shown [35].

Among industrial RF discharge devices for modifying the PET surface, there are Edwards E306A (United Kingdom) [40], HD-1 (China) [43], Technics 800-11 (United States) [44], Anatech SP 100 (United States) [45], Denton DV-502 A (Switzerland) [46], and SurFx AtomfloTM 400L [47] and Atomflo 350 L [48] (United States) plasma sources.

Laboratory [49, 50] and industrial DC discharge devices Balzers SCD 050 and BAL-TEC SCD 050 (Germany) [51–53], as well as laboratory [54] and industrial microwave (2.45 GHz) discharge devices Plaslan 500 (Germany) [55], ASTEX (United Kingdom) [56], and Europlasma NV [57] are used for research purposes. In [56], a device for cathodic magnetron sputtering of silver (Angstrom Sciences, USA) was introduced into the vacuum chamber, and the modified sample was moved using a mechanical manipulator directly into the working chamber of a Kratos Axis 165 X-ray photoelectron spectrometer without being exposed to air. This arrangement made it possible to determine the most accurate type and number of new functional groups that are formed on the polymer surface and lead to its hydrophilization.

To modify PET, laboratory [58–65] and industrial [66–71] dielectric barrier discharge (DBD) devices operating at atmospheric or sufficiently high plasma gas pressure are used. Figure 2 shows a schematic of a DBD unit for modifying polymer samples. The discharge is powered from voltage source 1, and plasma zone 6 arises between upper electrode 2 and lower, grounded (5) electrode 4 on which sample 3 to be processed is placed. Atmospheric air is often used as the gas phase; as a rule, the room in this case must be of a high cleanliness class, since industrial units do not always have a reaction chamber. Such an arrangement is typical for devices that make it possible to treat large roll materials (films, fabrics, fibers). Modification of a PET film with a thickness of 50 μm using a laboratory DBD setup (the upper electrode is connected to a 10‑kHz AC power supply and the lower electrode is grounded through a resistance of 100 Ω) with the feed gas О2 (fed to the working chamber) led to significant hydrophilization of the surface, the water contact angle (θw) decreased from 75° to ~30°; the surface remained hydrophilic during exposure to air for a long time (2000 h) under ambient conditions [63]. The DBD treatment led to the formation of new oxygen-containing groups, which improved the contact properties of the polymer.

For research purposes, industrial DBD sources, such as APJet (United States) [66], Coating Star (Germany) [67], and Plasmatreat atmospheric-pressure plasma jet (APPJ) (Germany) [68–70] systems, are also used, and an industrial DBD Coating System (Germany) operating at a frequency of 26 kHz was successfully used for modifying large samples of PET fibers and fabrics (roll materials) in [71]. It was shown that the value of θw decreased from 80° to 42°, which led to an improvement in the antibacterial activity of the surface of the treated PET fabric.

There have been studies on the PET surface modified by laser or vacuum UV irradiation [72–75]. Results of a comparative study of the effect of irradiation in air using an ArF excimer laser (λ = 193 nm, Lambda Physik Compex, Germany) and in a high vacuum using an Nd : YAG laser (pulsed vacuum ultraviolet radiation) on the surface of a PET film with a thickness of 50 μm (Goodfellow, United Kingdom) showed that VUV radiation-induced changes in surface morphology led to a significant improvement in the adhesion and proliferation of Chinese hamster embryonic cells, where the excimer laser irradiation caused noticeably less changes in morphology and produced a smaller biological effect [72, 73]. The use of a pulsed CO2 laser (λ = 9.25 μm, Lumonics 103-2, Germany) and an excimer KrF laser (λ = 248 nm, Model 1812, Physics Instrumentation Center at the Russian Academy of Sciences) to modify a 70 μm PET film (Dupont) [74] caused hydrophilization of the surface and a change in its morphology, providing a significant increase in the adsorption and growth of L929 mouse fibroblast cells.

METHODS FOR INVESTIGATING THE PROPERTIES AND STRUCTURE OF PET SURFACE MODIFIED IN PLASMA AND BY LASER IRRADIATION

Studies of the modified PET surface are carried out using a variety of modern instrumental techniques. They include the study of surface hydrophilicity or hydrophobicity (wettability) by measuring contact angles using polar and nonpolar liquids with the calculation of the total surface energy and its polar and dispersive components; of changes in the chemical composition and chemical structure by X-ray photoelectron and Fourier-transform IR spectroscopy; and of changes in surface morphology by atomic force microscopy, profilometry, and scanning electron microscopy. Changes in the adhesive properties and moisture absorption of the modified polymer are also studied.

One of the most important results of the PET surface modification process is a significant increase in hydrophilicity, which ensures the growth of cell adhesion and proliferation on the polymer surface. The value of water contact angle (θw) for the initial polymer, depending on the method of obtaining the test samples (films, fibers, fabric, etc.), is 72°–87°, and the treatment in RF, microwave, DC, and dielectric barrier discharges, as well as laser irradiation, leads to its significant decrease [19–25, 27–33, 36–42, 44, 47–52, 55, 58–61, 63, 65–67, 70, 71, 74]. As an example, Table 1 shows data on the change in θw, total surface energy (γ), and its polar (γp) and dispersive (γd) components for PET films modified by RF discharge [29], DC discharge [49], and DBD [65] plasmas. It can be seen that for the modified films, there is a significant decrease in θw, a significant increase in γ, and a multiple increase in γp in all cases. Studies have shown that the increased surface hydrophilicity persists for a long time. For example, in the case of PET films modified by RF discharge (27.12 MHz, 200 W, 75 Pa, initial θw = 72°) in oxygen and nitrogen for 3 s, the contact angles measured immediately after treatment were θw = 8° (О2 plasma) and θw = 16° (N2 plasma) and increased during storage for 14 days to 20° and ~50°, respectively [24]. When PET films (θw = 74.8°) were treated by atmospheric-pressure DBD in air, the obtained value of θw = 33.4° increased to 58° after 200-h storage and the observed increase largely depended on storage conditions, humidity, and temperature [63]. In both of the above cases, the surface remained hydrophilic (θw <60°).

The action of laser radiation, for example, of a pulsed CO2 laser with a wavelength of 9.25 μm, on PET films (θw = 70.6° ± 0.6°) led to less pronounced hydrophilization of the surface (maximum up to θw = 62.7° ± 1.9°), the presence of which, with a simultaneous change in morphology, improved the adsorption and growth of L929 mouse fibroblast cells [74].

It should be noted that, for example, the problem of thrombogenicty of polymeric grafts can be solved by increasing either hydrophilicity or hydrophobicity of the surface. For example, Jaganjac et al. [22] modified the PET surface by RF discharge in CF4 and Pezzatini et al. [30], in C2F4. As a result, the value of θw increased from 75° to 110° in the former case and a superhydrophobic surface was obtained in the latter case, θw increased from 78° to 130°–160°. Experiments with coronary endothelial cells in stents (coating the stent scaffold with blood vessel-lining cells) have shown the promise of using such materials in vascular grafts.

Changes in the chemical composition and structure of the PET surface modified by cold plasma and under the influence of laser radiation using X-ray photoelectron spectroscopy (XPS) were studied in [19–27, 29–31, 33, 34, 39, 40, 42–45, 47–51 , 53, 55, 56, 58–64, 66, 68, 69, 71–73, 75, 77].

Treatment in a plasma of nonpolymerizable gases (air, He, Ar, N2, O2, etc.) leads to an increase in the amount of oxygen- and nitrogen-containing groups on the polymer surface. As an example, Table 2 presents the results obtained in the study of the modification of PET film samples by RF discharge [26] and PET fabric samples by DBD [71]. It can be seen that the number of C–C bonds decreases and the number of C–O and O=C–O groups increases on the surface after the treatment and, in addition, C–N and O=C–NH2 groups appear. Associated with the formation of these groups and an increase in their number is an increase in the hydrophilicity of the PET surface, leading to better adsorption of active substances, for example, nisin, and an increase in activity against pathogenic organisms, for example, S. aureus ATCC 6538 and its methicillin-resistant strains [71].

Laser irradiation leads to a decrease in the atomic oxygen content on the PET surface and significant morphological changes on micro- and nanoscales [72–74]. Bartnik et al. [73] showed that after irradiation with 9–70-nm vacuum ultraviolet radiation emitted from Kr plasma, the amount of oxygen decreased from 27.94 to 19.77%, apparently, due to a decrease in the amount of functional O–C=O groups. However, a significant increase in surface roughness was observed, which ensured the adsorption and growth of Chinese hamster ovary cells seeded on the PET surface modified by UV laser irradiation.

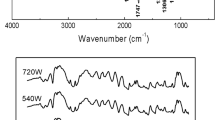

Changes in the chemical composition of the plasma-modified PET surface are also studied using IR spectroscopy methods, including the attenuated total reflection (ATR) IR technique, to determine the amount of oxygen-containing groups [37, 38, 40, 46, 62, 47, 65, 75] and establish the fact of deposition of a polymer film of a different chemical nature using the plasma polymerization of precursors [39, 41, 46, 55, 56]. In [37, 38], track-etched PET membranes were modified by RF discharge in a medium of nonpolymerizable gases (13.56 MHz; feed gases: air, N2, O2, and N2 + O2 mixtures; 70 W; 10 min). It was shown by ATR IR spectroscopy that the number of carboxyl groups on the surface increased significantly—the intensity of the absorption band at 1720 cm−1 increased, and the magnitude of the effect depended on the pressure in the gas phase. For example, the amount of oxygen increased by 19% at an air pressure of 4 Pa in the discharge and by 28% at 10.5 Pa. By IR spectroscopy, the deposition of thin films based on pyrrole [39], polyethylene glycol [41], allylamimine [55], or acrylic acid [56] by plasma polymerization on the PET surface was revealed, as well as the immobilization of fibrinogen [46].

Plasma treatment causes significant changes in PET surface morphology, which are studied using atomic force microscopy (AFM) [19, 20, 22–24, 27, 28, 30, 42, 45, 49–53, 59–61, 66, 68–71] and scanning electron microscopy (SEM) [20–22, 25, 28, 30–41, 43–46, 49–52, 55, 57–59, 62, 64, 65, 68, 69, 72–74].

Table 3 shows examples of changes in the surface morphology of PET films according to AFM data for polymer modification by RF [19], DC [49], and DB [69] discharges. It can be seen that in all cases there is an increase in the average (Ra) and the root-mean-square (Rms) surface roughness in comparison with the initial values. An increase in these parameters is observed with an increase in the plasma treatment time, and it also depends largely on the type of discharge used for the process and on the gas phase composition. The greatest changes are characteristic of the DBD modification of the polymer; in addition, significant degradation of the polymer is observed in this case.

The AFM method is also used to determine the roughness and thickness of the layer deposited on the surface during the plasma polymerization of precursors. For example, Ra was 2 ± 0.2 nm for a fluorine-containing coating (thickness 30 nm, θw = 105° ± 3°) deposited on the PET film surface by C2F4 polymerization by RF discharge (13.56 MHz), and the thickness of the deposited layer of the fluorocarbon polymer was 282 ± 120 nm (50-s deposition) and 526 ± 214 nm (90-s deposition) [30].

The SEM method is widely used to study changes in the surface morphology of PET in the form of films, fibers, and track-etched membranes modified by plasma. Using this method, morphological changes observed on the surface at the nano and micro levels were shown.

Thus, small spherulites appeared on the surface of PET films with a thickness of 125 µm treated by RF discharge in N2 (27.12 MHz, 150 W, 60 s), whereas the formation of nanosized threadlike structures was observed after similar treatment by O2 plasma [20]. The appearance of such entities can be associated with ion bombardment and predominant etching of the amorphous PET phase. In vitro studies have shown improved proliferation of human umbilical vein endothelial cells in all plasma modified samples. For PET films of a 20 μm thickness, modified by RF discharge on an Edwards E306A industrial unit (working gas air, 12 Pa, 10 MHz, 1.2 kV), the appearance of domain structures with an average size of ~15–17 nm at short treatment times was observed; an increase in the treatment time led to the formation of such structures up to ~60 nm in size [40].

When modifying PET fibers by RF discharge (13.56 MHz, 50 W, working gases Ar and O2, 13 Pa), a decrease in the fiber diameter by etching was revealed, while the porosity remained almost unchanged [21]. However, the use of DBD (atmospheric pressure, feed gases air, O2, N2, and Ar; 15 kV; 350 Hz; 10 s) had almost no effect on the fiber diameter [64].

An increase in the effective pore diameter by 15–20% and the formation of a nanostructured surface were found for track-etched PET membranes modified by plasma of nonpolymerizable gases [37, 38]. The possibility of using such membranes as a highly effective biocompatible explant drain for the surgical treatment of refractory glaucoma was shown. A significant decrease in the effective pore diameter was found for membranes on the surface of which chemically different coatings were deposited by plasma polymerization of pyrrole [39] or allylamine [55]. This change led to the appearance of conduction asymmetry [39] and an increase in the metabolic activity of human skin fibroblasts [55].

Irradiation of PET films with a pulsed UV laser (with a frequency of 10 Hz) and an ArF excimer laser (λ = 193 nm) caused the formation of various types of wavy microstructures (corrugated, conical, pile type) on the surface, which ensure high proliferation of Chinese hamster ovary cell [72, 73]. Irradiation of the surface of PET films with a pulsed CO2 laser (λ = 9.25 µm) and a KrF excimer laser (λ = 248 nm) led to morphological changes that promote a significant growth of mouse fibroblast cells L929 [74].

As a rule, the purpose of the modification of PET samples by nonthermal plasma is to improve the contact properties of the polymer in relation to the problems of improving its biocompatibility—adhesion and growth of the cell material on the surface. However, a number of works provide data on improving the adhesion of the polymer, including adhesion to various adhesives and in composite materials, which may be important for its practical application in various kinds of medical devices and instruments [32, 35, 40, 46, 48, 66, 69, 76]. Adhesion tests were performed according to ASTM D4541 and ASTM 1876-01 and using 3M Scotch®810 adhesive tape. Epoxy resins, urethane, silicone, and acrylic adhesives were used as adhesives. A significant increase in adhesion was shown; for example, the peel strength of the urethane adhesive increased from 4 MPa for the initial PET film to 11 MPa for its samples after treatment by RF discharge in helium [48]. High interfacial adhesion was found in the T-test for PET films modified by He/O2 and He/N2 plasmas and coated with an acrylate adhesive [66]. The adhesion of plasma-treated PET samples in contact with adhesives and a number of other polymers, measured by the T-test, increased significantly. Thus, for the of PET/PTFE (polytetrafluoroethylene) pair, DC discharge treatment led to an increase in the peeling strength from 10 ± 1 to 160 ± 19 (ED-20 epoxy resin) and up to 280 ± 24 N/m (polyurethane adhesive) [76].

The determination of the tensile strength of a poly(methyl methacrylate)-matrix composite, reinforced with RF plasma-treated PET fiber, on an INSTRON 4204 testing machine showed an increase of 20–30% at a treatment time of 5 s and a decrease at 20–90 s of treatment [32].

A significant increase in the adhesion of a silver layer applied onto PET fabric treated by RF oxygen plasma was shown; the coated fabric effectively retained its antimicrobial properties after 20 cycles of washing [35].

POSSIBILITIES OF USING MODIFIED PET IN MEDICINE AND BIOLOGY

The modification of PET by low-temperature plasma treatment opens up new opportunities for using the polymer in medicine and biology, significantly changing its biocompatibility.

One of the most important results is the improvement of polymer hemocompatibility for its use as vascular implants [19, 30, 33, 34, 46, 58, 65, 68, 77]. Thus, Vesel et al. [19] observed an increase in adhesion and proliferation of human umbilical vein endothelial cells (HUVEC) for polymer films treated in by 13.56-MHz RF SO2 plasma (150 W, 30 Pa, 20–180 s) and associated this effect with surface hydrophilization. The deposition of a nanostructured layer of a fluorocarbon polymer obtained by polymerization of C2F4 by RF discharge (13.56 MHz, 100 W, 200 Pa, 50 and 90 min) showed that the modified surface is characterized by increased attachment, viability, and growth of HUVEC cells and that such a polymer can serve as a better material for vascular graft than conventional PET [30]. A significant increase in HUVEC biocompatibility was also found for PET samples, treated by RF discharge plasma (13.56 MHz, 10 W, 67 Pa) in O2/H2 and NH3/H2 mixtures or in NH3, as a result of an increase in the amount of oxygen-containing groups or bonding new nitrogen-containing groups [34]. Due to improvement in the adhesion and proliferation of HUVEC cells on the PET surface modified by nitrogen and hydrogen plasma treatments, the surface thrombogenicity of small-caliber vascular grafts was reduced [77]. The impact of microplasma jets formed in atmospheric-pressure air DBD (9 kHz, 10 W, 16 kV) on large-area PET samples led to the formation on the polymer surface of a significant amount of oxygen- and nitrogen-containing groups providing hemocompatibility of the polymer [58]. For polymer films modified by treating in helium DBD (13.5 kHz, 40 W, 10 s), it was found that the DBD treatment makes it possible to prevent the degradation of the protein structure and dramatically increases the blood clotting time [65]. In the above examples (except for treatment by C2F4 plasma), the hydrophilicity of the modified polymer surface significantly increased.

After plasma treatment, PET acquires an important quality such as antibacterial activity [35, 36, 45, 62, 64]. Thus, the treatment of PET fabric by RF oxygen plasma (13.56 MHz, 50 W, 1.33 Pa, 1–5 min) followed by the deposition of a thin silver layer by magnetron sputtering in an argon atmosphere led to a significant increase in the resistance to S. aureus and E. coli bacteria [35]. Pre-activation by RF discharge in a mixture of air with O2 and N2 (1: 4) followed by the deposition of a thin carbonaceous coating layer in a C6H12 plasma ensured high resistance of track-etched PET membranes to gram-positive (S. aureus ATCC 29213) and gram-negative (E. coli ATCC 54383) strains of microorganisms [36]. Antibacterial properties against E. coli have been shown on PET samples modified by plasma with 4-vinylpyridine [45]. Data on a significant increase in the antibacterial activity of PET fabric (Thai Negoro, Thailand) modified by atmospheric-pressure air DBD plasma (12.5 kV, 325 Hz, 10 s) with the subsequent deposition of chitosan from solution are given in [62]. It was found that after 24 h of incubation, CFU (colony forming unit) on control samples and initial PET increased by 40–50%, while on PET + chitosan samples it decreased by ~1000 times for E. coli and more than 10 000 times for S. aureus.

A track-etched PET membrane (PET TM) manufactured by JINR (Dubna, Russia) was modified by RF discharge treatment (13.56 MHz, 100 W, 10 Pa, 10 min) using N2, air, and mixtures of N2 with O2 as working gases [37, 38]. Experimental and clinical studies of PET TM with a nanostructured surface as an explant drain for glaucoma surgery were carried out. The resulting membrane made it possible to avoid overgrowth of the surgically formed outflow tract due to the formation of a delicate capsule around the drain, which provides both filtration through its walls and free flow of ocular fluid. The visual acuity in the control group increased by 0.1–0.3 on average.

Modification of PET films by RF discharge (27.12 MHz, 200 W, 25 Pa, 30 s) in O2 or CF4 showed that hydrophilization (O2 plasma) or hydrophobization (CF4 plasma) of the polymer surface occurs, but the adsorption of proteins and amino acids improves in both cases [22]. The treatment with oxygen plasma leads to an increase in the adhesion of the protein, which forms a thick layer on the polymer surface, whereas specific conformational binding of proteins takes place after the CF4 plasma treatment. However, in both cases, the protein content on the surface has a beneficial effect on adhesion and increases the proliferation of human mammary epithelial cells by 25%.

The study of PET samples modified with plasma and by laser irradiation showed a significant improvement in the adsorption and proliferation of various cells, including fibroblasts, cells of the body’s connective tissue synthesizing the extracellular matrix, providing mechanical support for cells and transport of chemicals, which is especially important for wound healing [21, 44, 50, 51, 55, 72, 74].

Polyethylene terephthalate films of a 125 µm thickness were activated by RF argon discharge (13.56 MHz, 200 W, 3 min, 3 Pa), and then a layer of polyacrylic acid was grafted onto the surface (from solution under UV irradiation) [44]. On the obtained surface with an immobilized coating of chitosan or o-carboxymethylchitosan, the adsorption and growth of smooth muscle cells was studied, the proliferation of which ensures cytoskeletal organization. Studies of the viability of these cells showed that after 5 days, all modified materials had cell proliferation about two times higher than the data for the initial PET. The treatment of PET films by DC argon discharge (Balzers SCD sputter coater) followed by grafting of cysteamine from solution onto the modified surface significantly improved the cytocompatibility of the surface, increased adhesion and proliferation of human vascular smooth muscle cells [51]. Modification of PET samples by polymerization of allylamine in a microwave discharge (2.45 MHz, 400–1200 W, 50 Pa) in the plasma afterglow using Ar as a carrier gas (preliminary activation by Ar plasma for 30 s) led to the formation of amino groups on the surface, providing in vitro compatibility with human fibroblasts and greatly increasing their metabolic activity [55]. A study of the effect of a DC and a 40-kHz AC discharges on the surface properties of PET films (40 μm, PETLAIN BT 1010 E, Superfilm, Turkey) showed that plasma treatment and the subsequent immobilization of chitosan significantly increases the adhesion and growth of human mesenchymal stem cells [50].

Polyethylene terephthalate films modified by exposure to UV radiation from an ArF excimer laser (λ = 193 nm, 30 pulses with a fluence of 30 mJ/cm2) showed a noticeable increase in the adsorption of Chinese hamster ovary cells (CHO-K1 cell line) and their spreading on surface as compared to the untreated film [72]. The adhesion and proliferation of L929 fibroblast cells on the PET surface irradiated with a pulsed CO2 laser (λ = 9.25 μm) and an excimer KrF laser (λ = 248 nm) was studied in vitro [74]. The data obtained indicate that cell attachment and growth significantly increase after the modification of the polymer surface.

CONCLUSIONS

Thus, it is obvious that the modification of PET with low-temperature plasma and laser radiation leads to a significant improvement in the biocompatibility of the polymer. The new polymer properties are associated with changes in the chemical structure and morphology of the surface layer, leading to a change in the contact properties of the material. The data presented in the literature indicate that plasma-modified PET has a high metabolic activity with respect to human fibroblasts, good hemocompatibility, and antibacterial activity. In this regard, PET modified by low-temperature plasma certainly has good prospects for use in medicine and biology.

REFERENCES

Weltmann, K.-D., Kolb, J.F., Holub, M., Uhrlandt, D., Šimek, M., Ostrikov, K., Hamaguchi, S., Cvelbar, U., Černák, M., Locke, B., Fridman, A., Favia, P., and Becker, K., Plasma Process. Polym., 2019, vol. 16, no. 1, 1800118.

Bekeschus, S., Favia, P., Robert, E., and von Woedtke, T., Plasma Process. Polym., 2019, vol. 16, no. 1, 1800033.

Xaubet, M., Baudler, J.-S., Gerling, T., Giuliani, L., Minotti, F., Grondona, D., von Woedtke, T., and Weltmann, K.-D., Plasma Process. Polym., 2018, vol. 15, no. 8, 1700211.

Siow, K.S., Plasma Process. Polym., 2018, vol. 15, no. 9, 1800059.

Maitz, M.F., Biosurf. Biotribol., 2015, vol. 1, p. 161.

Shi, L., Guo, Z.G., and Liu, W.M., Biosurf. Biotribol., 2015, vol. 1, p. 81.

Kim, M.S., Kim, J.H., Min, B.H., Chun, H.J., Han, D.K., and Lee, H.B., Polym. Rev., 2011, vol. 51, no. 1, p. 23.

Yoshida, S., Hagiwara, K., Hasebe, T., and Hotta, A., Surf. Coat. Technol., 2013, vol. 233, p. 99.

Jacobs, T., Morent, R., and De Geyter, N., Plasma Chem. Plasma Process., 2012, vol. 32, no. 5, p. 1039.

Non-thermal Plasma Technology for Polymeric Materials: Applications in Composites, Nanostructured Materials, and Biomedical Fields, Thomas, S., Mozetič, M., Cvelbar, U., Špatenka, P., and Praveen, K.M., Eds., Amsterdam: Elsevier, 2019.

Nguyen, D.B., Mok, Y.S., Huynh, D.L., Jeong, D.K., and Lee, W.G., Plasma Process. Polym., 2019, vol. 16, no. 8, 1800173.

Vesel, A. and Mozetič, M., J. Phys. D: Appl. Phys., 2017, vol. 50, 293001.

Fabbri, P. and Messori, M., Modification of Polymer Properties, Jasso-Gastinel, C.F. and Kenny, J.M., Eds., Cambridge: William Andrew, 2016, p. 109.

Entsiklopediya nizkotemperaturnoi plazmy. Vvodnyi tom IV (Encyclopedia of Nonthermal Plasma: Introductory Volume IV) Fortov, V.E., Ed., Moscow: Nauka, 2000.

Arpagaus, C., Oberbossel, G., and von Rohr, P.R., Plasma Process. Polym., 2018, vol. 15, 1800133.

Plasma Science and Technology: Progress in Physical States and Chemical Reactions, Mieno, T., Ed., Rijeka: InTech, 2016.

Friedrich, J., The Plasma Chemistry of Polymer Surfaces: Advanced Techniques for Surface Design, Weinheim: Wiley, 2012.

Piskarev, M.S., Skryleva, E.A., Senatulin, B.R., Gilman, A.B., and Kuznetsov, A.A., High Energy Chem., 2020, vol. 54, no. 4, p. 199.

Vesel, A., Recek, N., Motaln, H., and Mozetic, M., Plasma, 2018, vol. 1, p. 12.

Cvelbar, U., Junkar, I., and Modic, M., Jpn. J. Appl. Phys., 2011, vol. 50, p. JF02.

Savoji, H., Lerouge, S., Ajji, A., and Wertheimer, M.R., Plasma Process. Polym., 2015, vol. 12, no. 4, p. 314.

Jaganjac, M., Vesel, A., Milkovic, L., Recek, N., Kolar, M., Zarkovic, N., Latiff, A., Kleinschek, K-S., and Mozetic, M., J. Biomed. Mater. Res., Part A, 2014, vol. 102, no. 7, p. 2305.

Oteyaka, M.O., Chevallier, P., Turgeon, S., Robitaille, L., and Laroche, G., Plasma Chem. Plasma Process., 2012, vol. 32, p. 17.

Junkar, I., Vesel, A., Cvelbar, U., Mozetic, M., and Strnad, S., Vacuum, 2010, vol. 84, p. 83.

Li, F., Wang, J., Sun, H., and Huang, N., Plasma Sci. Technol., 2010, vol. 12, no. 2, p. 235.

Vesel, A. and Mozetic, M., J. Phys.: Conf. Ser., 2008, vol. 100, 012027.

Vesel, A., Junkar, I., Cvelbar, U., Kovac, J., and Mozetic, M., Surf. Interface Anal., 2008, vol. 40, p. 1444.

Katsikogianni, M.G., Syndrevelis, C.S., Amanatides, E.K., Mataras, D.S., and Missirlis, Y.F., Plasma Process. Polym., 2007, vol. 4, p. 1046.

Papakonstantinou, D., Amanatides, E., Mataras, D., Ioannidis, V., and Nikolopoulos, P., Plasma Process. Polym., 2007, vol. 4, p. 1057.

Pezzatini, S., Morbidelli, L., Gristina, R., Favia, P., and Ziche, M., Nanotechnology, 2006, vol. 19, 275101.

Li, F., Wang, J., Sun, H., and Huang, N., Key Eng. Mater., 2005, vols. 288–289, p. 421.

Cioffi, M.O.H., Voorwald, H.J.C., and Mota, R.P., Mater. Charact., 2003, vol. 50, p. 209.

Pu, F.R., Williams, R.L., Markkula, T.K., and Hunt, J.A., Biomaterials, 2002, vol. 23, p. 2411.

Ramires, P.A., Mirenghi, L., Romano, A.R., Palumbo, F., and Nicolardi, G., J. Biomed. Mater. Res., 2000, vol. 51, p. 535.

Chen, Y.-H., Hsu, C.-C., and He, J.-L., Surf. Coat. Technol., 2013, vol. 232, p. 868.

Elinson, V., Lyamin, A., Kravets, L., Kikot, I., and Sylnitskaya, O., High Temp. Mater. Process., 2014, vol. 18, no. 3, p. 215.

Ryazantseva, T.V., Kravets, L.I., and Elinson, V.M., Inorg. Mater.: Appl. Res., 2012, vol. 3, no. 5, p. 408.

Ryazantseva, T.V., Kravets, L.I., and Elinson, V.M., Surf. Coat. Technol., 2011, vol. 205, p. 562.

Kravets, L.I., Gilman, A.B., Yablokov, M.Yu., Satulu, V., Mitu, B., and Dinescu, G., High Temp. Mater. Process., 2015, vol. 19, no. 1, p. 1.

Shcherbina, A.A. and Chalykh, A.E., Prot. Met. Phys. Chem. Surf., 2015, vol. 51, no. 3, p. 341.

Kumar, D.S., Fujioka, M., Asano, K., Shoji, A., Jayakrishnan, A., and Yoshida, Y., J. Mater. Sci.: Mater. Med., 2007, vol. 18, p. 1831.

Zhang, Y., Ishikawa, K., Mozeti, M., Tsutsumi, T., Kondo, H., Sekine, M., and Hori, M., Plasma Process. Polym., 2019, vol. 16, no. 6, 1800175.

Jingrun, R., Jin, W., Hong, S., and Nan, H., Appl. Surf. Sci., 2008, vol. 255, p. 263.

Zhu, A-P., Zhao, F., and Fang, N., J. Biomed. Mater. Res., 2008, vol. 86A, no. 2, p. 467.

Cen, L., Neoh, K.G., Ying, L., and Kang, E.T., Surf. Interface Anal., 2004, vol. 36, p. 716.

Chandy, T., Dasm G.S., Wilsonm R.F., and Rao, G.H.R, Biomaterials, 2000, vol. 21, p. 699.

Donegan, M., Milosavljevic, V., and Dowling, D.P., Plasma Chem. Plasma Process., 2013, vol. 33, p. 941.

Gonzalez, E., Barankin, M.D., Guschl, P.C., and Hicks, R.F., Langmuir, 2008, vol. 24, no. 21, p. 12636.

Piskarev, M.S., Gilman, A.B., Gatin, A.K., Gaidar, A.I., Kurkin, T.S., and Kuznetsov, A.A., High Energy Chem., 2019, vol. 57, no. 1, p. 76.

Demina, T.S., Piskarev, M.S., Romanova, O.A., Gatin, A.K., Senatulin, B.R., Skryleva, E.A., Zharikova, T.M., Gilman, A.B., Kuznetsov, A.A., Akopova, T., and Timashev, P.S., Materials, 2020, vol. 13, no. 3, p. 508.

Kolská, Z., Reznicková, A., Nagyová, M., Slepicková-Kasálková, N., Sajdl, P., Slepicka, P., and Svorcik, V., Polym. Degrad. Stab., 2014, vol. 101, p. 1.

Slepika, P., Slepicková-Kasálková, N., Stránská, E., Baáková, L., and Svorcik, V., eXPRESS Polym. Lett., 2013, vol. 7, no. 6, p. 535.

Kotal, V., Svorcık, V., Slepicka, P., Sajdl, P., Blahova, O., Sutta, P., and Hnatowicz, V., Plasma Process. Polym., 2007, vol. 4, p. 69.

Zaplotnik, R., Vesel, A., and Mozetič, M., Plasma Process. Polym., 2018, vol. 15, no. 9, 1800021.

Hamerli, P., Weigel, Th., Groth, Th., and Paul, D., Biomaterials, 2003, vol. 24, p. 3989.

Shi, M.K., Dunham, G., Gross, M.E., Graff, G.L., and Martin, P.M., J. Adhesion Sci. Technol., 2000, vol. 14, no. 12, p. 1485.

Gouveia, I.C., Antunes, L.C., and Gomes, A.P., J. Text. Inst., 2011, vol. 102, no. 3, p. 203.

Ni, W., Liu, D., Song, Y., Ji, L., Zhang, Q., and Niu, J., Eur. Phys. J. Appl. Phys, 2013, vol. 61, p. 10801.

Mui, T.S.M., Mota, R.P., Quade, A., de Oliveira, Hein L.R., and Kostov, K.G., Surf. Coat. Technol., 2018, vol. 352, p. 338.

Homola, T., Wu, L.Y.L., and Černák, M., J. Adhesion, 2014, vol. 90, no. 4, p. 296.

Yun, T.K., Kim, J.H., and Lee, D.K., Mol. Cryst. Liq. Cryst., 2014, vol. 586, no. 1, p. 188.

Sophonvachiraporn, P., Rujiravanit, R., Sreethawong, T., Tokura, S., and Chavadej, S., Plasma Chem. Plasma Process., 2011, vol. 31, p. 233.

De Geyter, N., Morent, R., and Leys, C., Nucl. Instrum. Methods Phys. Res., Sect. B, 2008, vol. 266, p. 3086.

Onsuratoom, S., Rujiravanit, R., Sreethawong, T., Tokura, S., and Chavadej, S., Plasma Chem. Plasma Process., 2010, vol. 30, p. 191.

Topala, I., Dumitrascu, N., and Pohoata, V., Plasma Chem. Plasma Process., 2007, vol. 27, p. 95.

Rezaei, F., Dickey, M.D., Bourham, M., and Hauser, P.J., Surf. Coat. Technol., 2017, vol. 309, p. 371.

Leroux, F., Perwuelz, A., Campagne, C., and Behary, N., J. Adhesion Sci. Technol., 2006, vol. 20, no. 9, p. 939.

Williams, T.S., Yu, H., and Hicks, R.F., Rev. Adhesion Adhesives, 2013, vol. 1, no. 1, p. 46.

Gotoh, K., Kobayashi, Y., Yasukawa, A., and Ishigami, Y., Colloid Polym. Sci., 2012, vol. 290, p. 1005.

Dumitrascu, N., Topala, I., and Popa, G., IEEE Trans. Plasma Sci., 2005, vol. 33, no. 5, p. 1710.

Kerkeni, A., Behary, N., Dhulster, P., Chihib, N.E., and Perwuelz, A., J. Appl. Polym. Sci., 2013, vol. 129, no. 2, p. 866.

Reisinger, B., Fahrner, M., Frischauf, I., Yakunin, S., Svorcik, V., Fiedorowicz, H., Bartnik, A., Romanin, C., and Heitz, J., Appl. Phys. A, 2010, vol. 100, p. 511.

Bartnik, A., Fiedorowicz, H., Jarocki, R., Kostecki, J., Szczurek, M., Bilinski, A., Chernyayeva, O., and Sobczak, J.W., Appl. Phys. A, 2010, vol. 99, p. 831.

Dadsetan, M., Mirzadeh, H., Sharifi-Sanjani, N., and Daliri, M., J. Biomed. Mater. Res., Part B, 2001, vol. 57, p. 183.

Wu, G., Paz, M.D., Chiussi, S., Serra, J., Gonzalez, P., Wang, Y.J., and Leon, B., J. Mater. Sci.: Mater. Med., 2009, vol. 20, p. 597.

Piskarev, M.S., Zinov’ev, A.V., Gilman, A.B., Kechek’yan, A.S., and Kuznetsov, A.A., Polym. Sci., Ser. D, 2019, vol. 12, no. 2, p. 159.

Mirenghi, L., Ramires, P.A., Pentassuglia, R.E., Rotolo, P., and Romito, A., J. Mater. Sci.: Mater. Med., 2000, vol. 11, p. 327.

Funding

This work was supported by the Ministry of Science and Higher Education of the Russian Federation and the Russian Foundation for Basic Research, project no. 18-32-00901.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by S. Zatonsky

Rights and permissions

About this article

Cite this article

Gilman, A.B., Piskarev, M.S. & Kuznetsov, A.A. Modification of Polyethylene Terephthalate by Low-Temperature Plasma for Use in Medicine and Biology. High Energy Chem 55, 114–122 (2021). https://doi.org/10.1134/S0018143921020065

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0018143921020065