Abstract

In this work, a woven PET with an antimicrobial activity was prepared by depositing chitosan on its surface. Firstly, the hydrophilic property of the PET surface was achieved by a plasma treatment using dielectric barrier discharge (DBD). The hydrophilic property of the PET surface was characterized by wickability and contact angle measurements. The XPS analysis revealed an increment of oxygen-containing polar groups, such as C–O and O–C=O, on the PET surface after the plasma treatment, resulting in an enhanced hydrophilic property. The plasma-treated PET specimen was further deposited with chitosan by immersing in a chitosan acetate aqueous solution. The effects of temperature, chitosan concentration, and number of rinses on the amount of deposited chitosan on the PET surface were investigated. The disappearance of the above-mentioned polar groups from the PET surface was clearly observed after the chitosan deposition, indicating the involvement of these functional groups in interacting with the chitosan. The chitosan-deposited plasma-treated woven PET possessed an exceptionally high antimicrobial activity against both E. coli (gram-negative bacteria) and S. aureus (gram-positive bacteria).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, polymers are used for a wide range of applications, especially as base and advanced materials in several technological aspects [1]. Nevertheless, various polymer surfaces are inherently hydrophobic and thus are not be able to well adhere to other materials. Because of this disadvantage, surface modification of polymers is required in order to render them adhesionable [2]. Polymer surface modification techniques are generally categorized into two approaches: physical modification and chemical modification. The physical modification is the modification of a polymer surface by a physical method, such as polymer blending and additive mixing; in contrast, the chemical modification is that of a polymer surface by altering its chemical structure by a chemical reaction, such as esterification, grafting, and crosslinking [3–5]. Particularly, in polymer-based textile industry, conventional liquid-phase chemical modification processes have been more preferably used; however, large amounts of modifying agents and solvents are required, resulting in undesired high-cost drying and pollutant-treating steps. Alternatively, plasma technology becomes a more increasingly attractive polymer surface modification technique, as described in a literature review by Morent et al. [6] for many polymers. It provides many advantages over the conventional chemical processes. Especially, the plasma modification process of a polymer surface does not require the use of any chemicals, thereby being in a more economical and ecologically benign process. Moreover, another important advantage of the plasma modification process is to significantly reduce harmful pollutants and wastes generated, leading to a corresponding reduction of effluent treatment cost. Thus, it can be considered to be an environmentally friendly technology [2, 7].

Poly(ethylene terephthalate) (PET) is a light-weight thermoplastic polymer of the polyester family, which possesses a good impact resistance and outstanding processability. It is mainly used in manufacturing synthetic sheets and films, as well as for food packaging, and beverage and other liquid containers [8]. Apart from these, PET can also be processed into fiber forms, which are further used in textile and carpet applications [9]. However, the main drawback of PET surface is its low hydrophilic property, low wettability, and poor adhesionability [2]. In particular, to use fibered PET in the carpet application, it is extremely necessary to modify its surface by some modification techniques in order to alter properties of the resulting product. Dielectric barrier discharge (DBD) plasma modification is a promising technique for producing a wide range of high-quality functionalized PET surface [10]. In addition, there is a growing demand for an antimicrobial property of the PET carpet as the consumers have been being aware of this potential advantage, which can be improved by immobilizing an antimicrobial agent on its surface. In our previous work, it was found that the hydrophilic property enhancement of a woven PET surface could be successfully obtained by using a DBD plasma treatment (without altering its morphological and mechanical properties), and the plasma-treated woven PET surface was subsequently loaded with silver, i.e. an antimicrobial agent, which exhibited a high antimicrobial activity [11].

We still continuously seeks for a more eco-friendly and biocompatible antimicrobial agent to substitute such inorganic material, e.g. silver. Chitosan, which is a natural cationic polysaccharide derived from chitin (a main component in shells of crustaceans, such as shrimp, crab, and lobster, as well as in exoskeletons of mollusks and insects, and in cell walls of some fungi [12, 13]), offers a versatile potential to be used for various purposes due to its biodegradability, biocompatibility, low toxicity, and unique chemical and physical properties, as well as exceptionally high antimicrobial activity [14]. Up to now, there have been some studies reporting the chitosan deposition on PET surface by using many techniques, i.e. oxygen glow plasma treatment followed by acrylic acid graft polymerization and chitosan deposition [15], radio frequency plasma treatment followed by UV-induced acrylamide graft polymerization and chitosan deposition with the aid of glutaradehyde crosslinking agent [16], 60Co-γ-ray treatment followed by acrylic acid graft polymerization and chitosan deposition [17], alkali hydrolysis treatment followed by chitosan deposition [18, 19], aminolysis pretreatment followed by acid hydrolysis treatment and layer-by-layer assembly of polyelectrolyte and chitosan [20], ozone treatment followed by chitosan deposition [21], and electrospinning of a mixture of PET and chitosan dissolved in solvents [22, 23]. However, to our knowledge, the research on chitosan deposition on the woven PET surface simply modified by the DBD plasma for improving antimicrobial property has not yet been extensively examined.

In this work, the woven PET was plasma-treated with the DBD plasma under the following base conditions: an electrode gap distance of 4 mm, a plasma treatment time of 10 s, an applied voltage of 12.5 kV, an input frequency of 325 Hz, and under air environment. In order to deposit chitosan on the woven PET surface, the plasma-treated specimen was immersed into a chitosan acetate aqueous solution at various concentrations. The surface properties of the plasma-treated specimens without and with chitosan deposition were characterized by using wickability measurement, contact angle measurement, X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM), calorimetric analysis using Amido Black 10B, and Kjeldahl method. The antimicrobial activity of all the prepared specimens was also tested against gram-negative Escherichia coli (E. coli) and gram-positive Staphylococcus aureus (S. aureus) using both disk diffusion and colony forming count methods.

Experimental

Chitosan Preparation

The shells of the Litopeneous vannamei shrimp, supplied by Surapon Food Public Co., Ltd., Thailand, were firstly cleaned and dried under sunlight before grinding into small pieces. The shrimp shell chips were decalcified by immersing in a 1 M HCl solution for 2 days with an occasional stirring. The decalcified product was then repeatedly washed with distilled water until the pH of washing water was neutral. Afterwards, the decalcified product was deproteinized by boiling in a 4 wt% NaOH solution at 80–90°C for 4 h, followed by repeatedly washing with deionized water, in the same manner as aforementioned, to obtain chitin. The chitin product was deacetylated by heating in a 50 wt% NaOH solution containing 0.5 wt% sodium borohydride to prevent depolymerization in an autoclave at 110°C for 1 h. The chitin-to-NaOH solution ratio was maintained at 1 g of the chitin to 10 ml of the NaOH solution. The deacetylated product was then repeatedly washed with deionized water. The resulting chitosan flakes were dried in an oven at 60°C for 24 h prior to use.

Experimental Set-up and Procedure

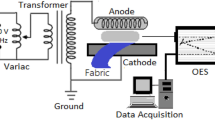

A woven PET specimen (pore size of 0.1 mm and thickness of 0.26 mm), supplied by Thai Negoro Co., Ltd., Thailand, was plasma-treated using a DBD system at atmospheric pressure and ambient temperature, around 25°C (room temperature), under an air environment at a constant pressure of 30 psig. The schematic of the DBD system is shown in our previous work [11]. The DBD system consisted of a 2-mm-thick dielectric glass plate placed between two parallel stainless steel electrodes, on the lower electrode. The gap distance between the electrodes was fixed at 4 mm. The input power used to generate uniform filamentary discharges over the entire electrode surfaces in the electrode gap was domestic alternating current (AC), 220 V and 50 Hz, which was transmitted to a high voltage current via a power supply system. The description of the power supply system is given elsewhere [24]. The output voltage and frequency were controlled by the function generator. The input voltage at the low voltage side was measured instead of that at the high voltage side across the electrodes. A power analyzer (Extech®) was used to measure voltage and frequency at the low voltage side of the power supply system. The high side voltage was calculated by multiplying by a factor of 250, according to a specification of the transformer used. In this present work, the following base conditions for the plasma treatment were used: an electrode gap distance of 4 mm, a plasma treatment time of 10 s, an applied voltage of 12.5 kV, and an input frequency of 325 Hz. Afterwards, the plasma-treated woven PET specimens were immediately immersed into a chitosan acetate aqueous solution at various concentrations. Then, the specimens were washed with distilled water and vacuum-dried in a desiccator. The washing step was repeated several times until achieving a constant amount of deposited chitosan before the specimens were taken for antimicrobial activity tests.

Characterization Techniques

The prepared chitosan was analyzed by a FTIR spectrophotometer (Nicolet, Nexus 670). Sample absorbances were recorded at a spectral resolution and wave number precision of 0.09 and 0.01 cm−1, respectively. A sample was placed into the sample compartment of the spectrophotometer and was continuously purged with a dry air. For each spectrum, 64 scans were acquired at a spectrum resolution of 4 cm−1.

The method used to determine degree of deacetylation of chitosan was based on an infrared spectrophotometric measurement, as described by Baxter et al. [25]. The degree of deacetylation (%DD) was calculated by using the following equation:

where A1,655 and A3,450 are absorbances at wavenumbers of 1,655 and 3,450 cm−1, respectively, obtained from the FTIR analysis.

The viscosity of chitosan was determined by using a capillary viscometer (Cannon, Ubbelohde-type No. 75) and used for the calculation of viscosity-average molecular weight of chitosan by the method described by Wang et al. [26]. The viscosity-average molecular weight of chitosan was calculated via the Mark-Houwing equation, as follows:

where [η] is intrinsic viscosity (dl/g), and Mv is viscosity-average molecular weight. The intrinsic viscosity was determined from the interception of the plots between [ηsp]/C versus C and ln[ηrel]/C versus C, where [ηsp] is specific viscosity (dl/g), [ηrel] is relative viscosity (dl/g), and C is chitosan concentration (g/dl). The reported values of viscosity-average molecular weight were calculated from the average of three measurements of the viscosity.

The wickability measurement of woven PET specimens before and after the DBD plasma treatment was carried out to indicate the degree of hydrophilicity, or wettability, of the PET surface. The specimens were vertically dipped into a methyl orange dye aqueous solution, and the time required for the aqueous solution to adsorb onto the woven PET surface until reaching a specified height of 1 cm was recorded. The reported values of adsorption time were the average of five measurements.

Contact angle measurement was carried out by using a contact angle analyzer (KRUSS, DSA10 MK2), and the goniometric method was used to calculate the contact angle between the droplet of water and woven PET surface before and after the plasma treatment. The drop image was stored via a monochrome video camera using PC-based control acquisition and data processing. In this work, distilled water was used as the working liquid. The static contact angle values reported were the average of three measurements.

X-ray photoelectron spectroscopy (XPS, JEOL, JPS-9000MX) was employed to analyze the surface chemical state and compositions of the plasma-treated woven PET specimens before and after the chitosan deposition. XPS spectra were recorded with a MgKα radiation at 10 kV and 10 mA using C1s level at 285.0 eV as an internal standard.

Scanning electron microscopy (SEM, JEOL, JSM-5200) was performed using gold-coated samples, which were obtained using a polaron sputter coater (JEOL, JFC-1110E). A SEM operating condition at 10–15 kV was employed for surface morphology study. Samples were mounted onto a sample holder, sputter-coated with gold, and finally used for the SEM analysis.

Calorimetric analysis of amino groups in chitosan molecule using Amido Black 10B was applied for the qualitative determination of chitosan deposited on the woven PET surface. The Amido Black 10B is an amino acid-staining diazo dye normally used in the biochemical research to stain total amino groups in chitosan.

The Kjeldahl method was used for the quantitative determination of chitosan deposited on the woven PET surface. The Kjeldahl method consisted of three steps, which were carefully performed in the following sequence: (1) the sample containing chitosan molecules was digested in a strong sulfuric acid in the presence of a 0.1 g copper (II) sulfate catalyst, which helped convert the amine nitrogen to ammonium ions; (2) the ammonium ions were then converted to ammonia gas, heated, and distilled, and the ammonia gas was allowed to pass through a 0.01 M HCl trapping solution, in which it dissolved and became the ammonium ions once again; and (3) the amount of the trapped ammonia ions was determined by back-titrating with a standard 0.01 M NaOH solution, and the number of nitrogen molecules was then calculated to finally obtain the amount of deposited chitosan.

Antimicrobial Activity Testing

Antimicrobial activity of the plasma-treated woven PET specimens without and with the chitosan deposition was investigated against E. coli as the model gram-negative bacteria and S. aureus as the model gram-positive bacteria, both purchased from the Microbiological Resources Centre, Thailand Institute of Scientific and Technological Research (TISTR). The antimicrobial activity of all the prepared woven PET specimens was carried out by two methods: disk diffusion and colony forming count.

Disk Diffusion Method

This method was performed in a Luria–Bertani (LB) medium solid agar petri dish. The woven PET specimens were cut into a square shape of 2 × 2 cm2, sterilized by autoclaving at 120°C for 15 min, and placed on E. coli- or S. aureus-cultured agar plate, which was then incubated at 37°C for 24 h. Finally, the distance of inhibition zone, or clear zone, around the specimens was measured to indicate the antimicrobial activity.

Colony Forming Count Method

The woven PET specimens with a square shape of 1 × 1 cm2 were sterilized by autoclaving at 120°C for 15 min before being tested for the antimicrobial activity. The sterilized specimens were divided into two groups; each group consisted of four pieces. The first group was seeded with 1 cm3 sterile nutrient broth containing 3 g of beef extract and 5 g of pentone (Difco™) as the control. The second group was seeded with fresh E. coli or S. aureus culture at a concentration of 108 colony forming units per cm3 (cfu/cm3) in the sterile nutrient broth, and then was incubated in a shaking incubator at 37°C for 24 h. After the incubation, a quantity of 500 cm3 of saline (Aldrich Chemical) was added to each group, and then all tubes were vortexed. An amount of 0.05 cm3 of homogenized solution was withdrawn from each tube having a plasma-treated woven PET specimen without or with the chitosan deposition, and then transferred onto a nutrient agar plate, which was incubated at 37°C for 24 h for colony forming counts. The same procedure was performed using an original woven PET specimen. The reduction percentage in bacterial count was calculated by the following equation [27]:

Results and Discussion

Preparation and Characterization Results of Chitosan

Since the shrimp shells consist of three major components, which are chitin, calcium carbonate, and protein, calcium carbonate and protein have to be consecutively removed to obtain chitin as the only remaining substance. In this work, the shrimp shells were decalcified using a 1 M HCl solution to remove calcium carbonate and then were deproteinized using a 4 wt% NaOH solution to remove protein. Table 1 shows the yield of product after the decalcification step and that of chitin after the deproteinization step, which were found to be approximately 49.7 and 30.6%, respectively. Since chitosan is a partially (or completely) deacetylated form of chitin, the obtained chitin was deacetylated using a 50 wt% NaOH solution to remove acetyl groups of N-acetyl glucosamine repeating units for four times. As also shown in Table 1, the yields of chitosan after the 1st, 2nd, 3rd, and 4th deacetylation steps were about 23.4, 22.0, 18.8, and 14.7%, respectively. It can be observed that the 4th deacetylation step was required in order to sufficiently obtain an almost complete degree of deacetylation (%DD). This was confirmed by the results of %DD calculated from the FTIR spectra (Fig. 1). As summarized in Table 2, the %DD of chitosan increased with increasing number of alkali treatment times (deacetylation times) from 85% after the 1st alkali treatment to 98% after the 3rd alkali treatment; however, after that, the %DD of chitosan became almost constant at 98%. Therefore, four times of alkali treatment (4th deacetylation) were used to prepare the chitosan in this work in order to ensure the almost complete %DD.

In addition, the results of viscosity-average molecular weight of chitosan after various alkali treatment times are included in Table 2. It was observed that when the number of alkali treatment increased, the molecular weight of chitosan decreased, which was in the opposite trend to the %DD due to the removal of acetyl groups from the chitosan molecular structure.

Characterization Results of Plasma-Treated Woven PET

The results of hydrophilic property of the PET surface obtained from the wickability and contact angle measurements are shown in Table 3. It can be clearly seen that the water adsorption time and contact angle drastically decreased after the plasma treatment. These results verify that the hydrophilicity of the PET surface can be significantly increased by the DBD plasma treatment. This can be possibly explained in that the plasma operation under an air environment induces the generation of various active species (e.g. atomic oxygen, ozone, neutral and meta-stable molecules, and radicals), and these generated active species plays a crucial role in introducing oxygen-containing polar groups onto the PET surface [10, 28], resulting in an observed increase in the hydrophilicity of the PET surface.

The inclusion of oxygen-containing polar groups on the PET surface after the plasma treatment was validated by the XPS analysis. Figure 2 shows the C1s spectra of the PET surface before and after the plasma treatment. Each of the C1s spectra can be deconvoluted into three main peaks: the 1st peak at ~285 eV can be attributed to the carbons in C–C and C–H groups; the 2nd peak at ~287 eV can be attributed to the carbon in C–O group; and the 3rd peak at ~289 eV can be attributed to the carbon in O–C=O group [10, 15]. It was found that the functional group distribution on the PET surface before the plasma treatment (Fig. 2a) comprised 76.84% C–C and C–H groups, 7.88% C–O group, and 6.37% O–C=O group, whereas after the plasma treatment (Fig. 2b), the concentration of the oxidized carbon components (C–O and O–C=O) increased to 11.02 and 16.54% for the C–O and O–C=O groups, respectively, while that of the C–C and C–H groups decreased to 68.28%. These results imply that the DBD plasma containing the aforementioned oxygen active species principally attacks the C–C and C–H groups on the PET surface to produce a higher amount of C–O and O–C=O groups. The increased amounts of these polar C–O and O–C=O groups led to an enhanced hydrophilicity of the PET surface after the plasma treatment, as discussed above.

Chitosan Deposition Results

Qualitative Analysis of Chitosan Deposited on PET Surface

To verify the chitosan deposition on the woven PET surface, the qualitative determination by the colorimetric analysis of amino groups in chitosan molecule using the Amido Black 10B was performed. The plasma-treated woven PET specimens without and with chitosan deposition were stained with the Amido Black 10B. There was no color observed for the plasma-treated PET specimen without chitosan deposition, whereas a blue color was observed for the plasma-treated PET specimen with chitosan deposition, indicating that the chitosan was successfully deposited on the PET surface. A darker blue color was clearly perceived when a higher chitosan concentration was used in the deposition step after the plasma treatment. These results suggest that the plasma treatment can improve the adhesion of chitosan on the woven PET surface.

Effects of Temperature, Chitosan Concentration, and Number of Rinses on the Amount of Deposited Chitosan

The effects of temperature, chitosan concentration, and number of rinses were investigated in order to find their suitable values used for the chitosan deposition step. Figure 3 shows the amount of deposited chitosan determined by the Kjeldahl method as a function of temperature. Two investigated temperatures of room temperature (25°C) and 50°C were comparatively used for the chitosan deposition. The results show that at any given chitosan concentration, the temperature had an insignificant effect on the amount of deposited chitosan. Therefore, the room temperature was used for further experiments due to the ease of operation without external energy required.

The amount of deposited chitosan as a function of chitosan concentration used for the chitosan deposition was next investigated, as shown in Fig. 4. It can be clearly seen that the amount of deposited chitosan increased with increasing chitosan concentration from 0.1 to 2 wt./vol.%, and it then remained almost unchanged with further increasing chitosan concentration. Therefore, a 2 wt./vol.% chitosan concentration was considered to be the minimum value to provide the highest saturated amount of chitosan deposited on the woven PET surface. An excess chitosan concentration higher than 2 wt./vol.% is not necessary for the chitosan deposition. The saturated amount of deposited chitosan on the plasma-treated woven PET surface was found to be approximately 27 mg/g of sample.

The effect of number of rinses on the amount of deposited chitosan with the chitosan concentrations up to 2 wt./vol.% was further examined. Figure 5 shows a relationship between the number of rinses and the amount of deposited chitosan. It can be observed that at any given chitosan concentration, the amount of deposited chitosan gradually decreased with increasing number of rinses, and at least three rinsing cycles were required to achieve a constant amount of deposited chitosan. This is possibly because there was an excessive amount of chitosan loosely adhered on the PET surface or on the external surface of chitosan strongly adhered on the PET surface. The results indicate that it is possible to acquire the permanent chitosan adhesion on the plasma-treated PET surface for real applications, including antimicrobial purpose in this present work, as can be clearly seen from the unchanged amount of deposited chitosan after repeated rinsing. In addition, the amount of permanently deposited chitosan (at three or higher rinsing cycles) increased with increasing chitosan concentration up to 2 wt./vol.%, as expected. Thus, three rinsing cycles were used for the chitosan deposition on the plasma-treated woven PET surface to be further applied for antimicrobial tests.

Characterization Results of Chitosan-Deposited Plasma-Treated Woven PET

Figure 6 depicts comparatively the surface morphology obtained from the SEM analysis of the original PET surface and the plasma-treated PET surface without and with the chitosan deposition. It was clearly found that without (before) the plasma treatment, there was no change in surface morphology of the PET surface after immersing in a chitosan solution (Fig. 6b) as compared to that of the original PET surface (Fig. 6a), indicating that no chitosan was deposited on the PET surface without the plasma treatment. Interestingly, it can be seen that the plasma treatment can induce the deposition of chitosan on the PET surface, as shown in Fig. 6c. These results verify that the plasma treatment can enhance the chitosan deposition, possibly due to the higher hydrophilicity of the PET surface obtained during the plasma treatment being necessary for the chitosan deposition.

The chitosan-deposited plasma-treated woven PET was also characterized by the XPS analysis. Figure 7 shows the C1s spectra of the plasma-treated PET surface deposited with chitosan at various concentrations. Figure 7a shows the C1s spectrum of the plasma-treated PET surface without chitosan deposition, which was deconvoluted into three main peaks, as mentioned above. Figure 7b and c show the C1s spectra of the plasma-treated PET surfaces deposited with 0.5 and 2 wt./vol.% chitosan concentrations, respectively. The results reveal that the ester carbon peak of the O–C=O group at ~289 eV decreased when depositing with a chitosan concentration of 0.5 wt./vol.% (Fig. 7b) and finally disappeared completely at a chitosan concentration of 2 wt./vol.% (Fig. 7c). These results suggest that the primary amine group of chitosan strongly and preferentially interacted with the O–C=O group on the PET surface, resulting in the formation of amide group (CO–NH) [15, 18].

Figure 8 shows the N1s spectra of the plasma-treated woven PET surface deposited with chitosan at various concentrations. The peak located at ~ 400 eV can be attributed to the nitrogen in the aforementioned amide group of the deposited chitosan [15, 18]. The results show that the peak intensity increased with increasing chitosan concentration, thereby confirming the successful deposition of a higher amount of chitosan on the PET surface.

Antimicrobial Activity Results

Disk Diffusion Method

The antimicrobial activity of the plasma-treated woven PET without and with the chitosan deposition against E. coli and S. aureus was firstly investigated by the disk diffusion method. The effects of chitosan concentration and degree of deacetylation (%DD) on the antimicrobial activity in terms of distance of clear zone are shown in Fig. 9. It was experimentally found that in the case of the plasma-treated woven PET deposited with a chitosan solution with %DD of 85%, there was no clear zone observed at all chitosan concentrations for both E. coli and S. aureus. On the other hand, the plasma-treated woven PET deposited with a chitosan solution with %DD of 98% exhibited a clear zone at a chitosan concentration of 0.75 wt./vol.% in the case of E. coli and 0.5 wt./vol.% in the case of S. aureus, and the distance of clear zone increased with increasing chitosan concentration for both bacteria. However, no clear zone was observed for the plasma-treated woven PET without the chitosan deposition (zero chitosan concentration). Thus, these results clearly indicate the antimicrobial activity plausibly originated from the deposited chitosan, not from the PET itself. Moreover, it was observed that the antimicrobial activity against E. coli was lower than that against S. aureus, probably due to the difference in cell wall characteristic between gram-positive and gram-negative bacteria. A main structural difference between gram-negative and gram-positive bacteria can be distinguished from the molecular structure of the outer cell membrane, and the electric charge interaction between the chitosan and cell membrane is a decisive factor influencing bacterial growth inhibition, cell destruction, and activity depression [29]. For the gram-negative bacteria, phospholipids, lipopolysaccharides, and proteins primarily exist in the outer cell membrane; therefore, the electric charge interaction of the chitosan hardly affects the inner cell membrane. On the contrary, for the gram-positive bacteria, the electric charge interaction can directly interact with the inner cell membrane to cause a lower probability of the cell survival [30, 31].

Colony Forming Count Method

The plasma-treated woven PET without and with the chitosan deposition was also tested for the antimicrobial activity against E. coli and S. aureus by using the colony forming count method. No bacterial growth was observed from the sterile control. The viable counts recovered from all the woven PET specimens before and after incubation are shown in Table 4. After 24 h of incubation, there were 99.90 and 99.99% reductions in viable cell counts of E. coli and S. aureus, respectively, on the chitosan-deposited plasma-treated woven PET. For the original woven PET, there was no reduction in viable counts; in contrast, there were 38.71 and 44.44% increases in the viable cell counts of E. coli and S. aureus, respectively. Hence, the DBD plasma treatment of the woven PET surface followed by the chitosan deposition can be recognized to be a promising technique for manufacturing woven PET with an acceptably high antimicrobial activity for various biocompatible applications.

Conclusions

In this work, the enhancement of the hydrophilicity of the woven PET surface was firstly accomplished by the DBD plasma treatment, as confirmed by the wickability and contact angle measurements, as well as by the XPS analysis. The plasma-treated PET specimen was further immersed into a chitosan acetate aqueous solution in order to deposit chitosan on its surface. The effects of temperature, chitosan concentration, and number of rinses were systematically investigated on the amount of deposited chitosan. The temperature was found to have no effect on the amount of deposited chitosan; whereas the chitosan concentration of 2 wt./vol.% was found to provide the highest saturated amount of deposited chitosan, and three rinsing cycles were required to obtain the permanently deposited chitosan on the plasma-treated woven PET surface. The XPS analysis also revealed that the chitosan could be successfully deposited on the plasma-treated woven PET surface. Subsequently, the chitosan-deposited plasma-treated woven PET was found to exhibit an extraordinarily high antimicrobial activity against both E. coli (gram-negative bacteria) and S. aureus (gram-positive bacteria).

References

Ko TM, Cooper SL (1994) Frontiers of polymers and advanced materials. Plenum Press, New York

Strobel M, Lyons CS, Mittal KL (1994) Plasma surface modification of polymers: relevance to adhesion. VSP, Utrecht

Wypych J (1988) Polymer modified textile materials. Wiley, New York

Chan CM (1994) Polymer surface modification and characterization. Hanser, New York

Meister J (2000) Polymer modification: principles, technique, and application. Maarcel Dekker, New York

Morent R, De Geyter N, Verschuren J, De Clerck K, Kiekens P, Leys C (2008) Surf Coat Technol 202:3427

Carneiro N, Souto AP, Silva E, Marimba A, Tena B, Ferreira H, Magalhaes V (2001) Color Technol 117:298

Brooks D, Giles GA (2002) PET packaging technology. Sheffield Academic, England

Scheirs J, Long TE (2003) Modern polyesters: chemistry and technology of polyesters and copolyesters. Wiley, New York

De Geyter N, Morent R, Leys C (2006) Surf Coat Technol 201:2460

Onsuratoom S, Rujiravanit R, Sreethawong T, Tokura S, Chavadej S (2010) Plasma Chem Plasma Process 30:191

Muzzarelli RAA (1977) Chitin. Pergamon Press, New York

Roberts GAF (1992) Chitin chemistry. Macmillan Press, London

Dunn ET, Li Q, Grandmaison EW, Goosen MFA (1997) Applications of chitin and chitosan. Technomic Publishing Company, Inc, Lancaster

Huh MW, Kang IK, Lee DH, Kim WS, Lee DH, Park LS, Min KE, Seo KH (2001) J Appl Polym Sci 81:2769

Yang MR, Chen KS, Tsai JC, Tseng CC, Lin SF (2002) Mater Sci Eng C 20:167

Jou CH, Lee JS, Chou WL, Yu DG, Yang MC (2005) Polym Advan Technol 16:821

Zhang X, Bai R (2003) J Appl Polym Sci 90:3973

Liu Y, He T, Gao C (2005) Colloid Surface B: Biointerf 46:117

Fu J, Ji J, Yuan W, Shen J (2005) Biomaterials 26:6684

Li J, Wang J, Li P, Weng Y, Ren L, Fei X, Sun H, Huang N (2007) Key Eng Mater 342–343:809

Jung KH, Huh MW, Meng W, Yuan J, Hyun SH, Bae JS, Hudson SM, Kang IK (2007) J Appl Polym Sci 105:2816

Lopes-da-Silva JA, Veleirinho B, Delgadillo I (2009) J Nanosci Nanotechnol 9:3798

Chavadej S, Kiattubolpaiboon W, Rangsunvigit P, Sreethawong T (2007) J Mol Catal A: Chem 263:128

Baxter A, Dillon M, Taylor KDA, Roberts GAF (1992) Inter J Biol Macromol 14:166

Wang W, Bo S, Li S, Qin W (1991) Inter J Biol Macromol 13:281

Li Y, Leung P, Yao L, Song QW, Newton E (2006) J Hosp Infect 62:58

Kogelschatz U (2003) Plasma Chem Plasma Process 23:1

Takahashi T, Imai M, Suzuki I, Sawai J (2008) Biochem Eng J 40:485

Sudardshan NR, Hoover DG, Knorr D (1992) Food Biotechnol 6:257

Liu H, Du Y, Wang X, Sun L (2004) Inter J Food Microbiol 95:147

Acknowledgments

The authors would like to thank Thai Negoro Co., Ltd., Thailand; the Sustainable Petroleum and Petrochemicals Research Unit, Center for Petroleum, Petrochemicals, and Advanced Materials, Chulalongkorn University, Thailand; and the Petrochemical and Environmental Catalysis Research Unit under the Ratchadapisek Somphot Endowment Fund, Chulalongkorn University, Thailand. The authors would also like to thank Dr. Hideaki Nagahama, Department of Chemistry and Materials Engineering, Faculty of Chemistry, Materials, and Bioengineering, Kansai University, Japan for his assistance in the XPS analysis.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Sophonvachiraporn, P., Rujiravanit, R., Sreethawong, T. et al. Surface Characterization and Antimicrobial Activity of Chitosan-Deposited DBD Plasma-Modified Woven PET Surface. Plasma Chem Plasma Process 31, 233–249 (2011). https://doi.org/10.1007/s11090-010-9276-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-010-9276-x