Abstract

The surface modification of poly (ethylene terephthalate) (PET) film was carried out using an atmospheric pressure plasma (APP) jet device with three reactive gases: air, N2, and Ar. The water contact angles on the PET film were found to decrease considerably after the APP exposure. The changes in the advancing and receding contact angles of water on the APP-exposed PET film with aging time were examined by the wetting force measurements employing the Wilhelmy method. The hydrophobic recovery due to the rinsing with water as well as the aging in air was observed only for the advancing angle, which was probably caused by the dissolution of low molecular weight oxidized materials into water, the loss of volatile oxidized species to the atmosphere and the reorientation and the migration of polymer chains. The wettability and the surface free energy of the APP-exposed PET film after diminishing hydrophobic recovery was sufficiently large compared with the untreated film. X-ray photoelectron spectroscopy confirmed that the PET film surface was oxidized due to the APP exposure. When N2 gas was used for the APP exposure, the surface nitrogen concentration was found to increase with decreasing D. The surface oxygen concentration on the APP-exposed PET film was reduced by rinsing with water, in accordance with the hydrophobic recovery behavior. From atomic force microscopy, surface topographical change due to the APP exposure was observed. The changes in the PET surface properties due to the APP exposure as mentioned above were remarkable for using N2 gas.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

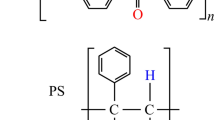

Poly (ethylene terephthalate), PET, which possesses superior strength and resilience, a good impact resistance and outstanding processability, has been mainly used in manufacturing synthetic films and sheets for making food packaging materials, biomaterials, electronic substrates, etc. In addition, fibrous PET has been most widely used for textiles such as apparel wearing, curtain, and carpet. However, PET is chemically inert and requires a pretreatment step before adhesive bonding or painting in various industrial fields. Therefore, the modification and control of the surface properties of PET is a research topic for materials processing in the last decades. The oxidation and the etching of the PET surface have been attempt by the dry processes such as UV radiation [1–6] and plasma exposure [7–10], which produce no toxic or hazardous liquids from the treatment processes.

Recently, there has been an intense development in cold plasma surface processing systems at atmospheric pressure, which overcome the disadvantages of vacuum environment and the associated high cost [11–14]. Atmospheric pressure plasmas with various gases and gas mixtures can produce a number of high-density active species such as electrons, free radicals, ions, and photons [15, 16]. Bárdos and Baránková [14] have described the difference between low-pressure and atmospheric pressure plasmas and reviewed limitation and new abilities of atmospheric pressure plasma. Atmospheric pressure plasma (APP) jet devices have attracted significant attention [17–21] because they generate plasma plumes in open space, have no limitations on the sizes of the objects to be treated, and can achieve continuous in-line material processing at high speed. Schütze et al. [17] have reported that the APP jet exhibits the great similarity to a low-pressure glow discharge compared with other plasmas and can be used in a number of materials applications that are now limited to vacuum.

In the last decade, many investigations of polymer surface modification by the APP treatment have been carried out [22–30]. Most of these studies have been performed using non-jet-type plasma equipment, and hence there is still much left to be studied hereafter about the effects of the APP jet-exposure conditions on the characteristics of the treated surface. Moreover, the wettability of the treated surface has been discussed in terms of the advancing contact angle of water measured by the sessile drop method. The receding contact angle corresponding to the intrinsic contact angle on the treated surface region [31] has not been examined. Chemical analysis of the treated surface has been mainly carried out by X-ray photoelectron spectroscopy (XPS). However, XPS analysis of polymer surfaces is sometimes insufficient in distinguishing between the functional groups with small chemical shift difference [32]. Therefore, there is not enough of the necessary basic data with respect to the APP jet treatment of the PET surface.

In the present paper, the modification of the PET film surface was performed using an APP jet device with three different reactive gas sources: air, N2, and Ar. In the dry processing such as plasma treatment, there is a serious problem on the stability of the treated surface [31]. Therefore, the change in the wettability due to the APP exposure and the subsequent aging in air was determined by the Wilhelmy technique, which enabled us to measure high-precision advancing and receding contact angles calculated from the wetting force [33]. Surface characterization with respect to the chemical composition and the roughness was carried out by the XPS and atomic force microscopy (AFM), respectively. For semiquantitative estimation of functional groups on the treated PET film, the derivatization technique in conjunction with XPS was used [32, 34]. The effect of reactive gas source on the experimentally determined surface characteristics of the APP-exposed PET film was discussed.

Experimental

Materials

Biaxially oriented PET film with 188 μm in thickness (EMBLET SA-188, Unitika, Japan) was used in the present study. Before use, the PET film was ultrasonically cleaned twice in water.

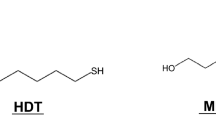

Water, diiodomethane, ethylene glycol, and n-pentane were used for the contact angle measurement. The carboxyl derivatization of the PET film was carried out using trifluoroethanol (TFE), pyridine, and dicyclohexylcarbodiimide (DCC). All chemicals were extrapure grade reagents and were used without further purification. The water was purified (resistivity of 18 MΩcm) using a Direct-Q UV apparatus (Millipore, MA, USA).

Atomospheric pressure plasma exposure

The APP exposure was performed using a plasma pretreatment equipment (Plasmatreat GmbH, Germany) consisting of a plasma generator (FG1001), a high-voltage transformer (HTR1001), and a rotating nozzle jet (RD1004). The APP was generated by means of a high-voltage discharge inside the nozzle jet coupled to the stepped high-frequency pulse current power supply (plasma generator) [35]. The reactive gases used were air, N2, and Ar, which were regulated; the pressure and the flow rate to be 0.3 MPa and 20>30 l/min, respectively, at room temperature. The plasma nozzle, from which a jet of 20 mm in diameter was emitted, was set vertically. The film surface was horizontally displaced from the nozzle at a separation distance, D, which was varied between 5 and 30 mm. During the exposure, the film was reciprocated in the horizontal direction at 0.16 m/s (total exposure time: 0.25 s), which were chosen as uniformly treatable conditions with references to the experimental results in the previous paper [31].

The PET film was cut off in about 0.5 mm in width and was exposed to the APP jet on both sides for the measurement by the Wilhelmy method. For the other measurements, the APP jet was exposed to only one side of the film of 15 mm in width. After the exposure, the PET films were stored in a desiccator maintained at 20 ± 1 °C and 30 ± 2%RH.

Contact angle measurements

To examine the dependence of D on the contact angle, the sessile drop experiment was carried out using a video contact angle system equipped with a CCD camera (VCA-2500, AST Products, USA). After placing 2–3 μl water drop on the PET film surface, the drop image was stored in a computer every second for a duration of 30 s and the contact angle was determined automatically.

Figure 1 shows the changes in the water contact angles on the PET films before and after the APP exposure with time. In the initial stage, the angle gradually decreased linearly with time and therefore the contact angle at 1 s was obtained as the approximate value of the advancing contact angle [36]. Water drops were individually placed on 20 different locations on the same PET film sample (15 × 50 mm) and the arithmetic mean contact angle per sample was obtained.

The advancing and receding contact angles on the PET film were examined by the Wilhelmy technique using an electrobalance (Model C-2000, Cahn Instruments Inc., USA) and a stepping motor (MP-20 L, MICOS, Germany). A PET film (about 0.5 mm in width and 10 mm in length) was suspended from the arm of the electrobalance and a beaker containing liquid was placed just below the PET film. A continuous weight recording during immersion–emersion cycles was obtained at the moving velocity of the PET/water/air three-phase line of 0.3 mm/min [33].

Figure 2 shows the typical weight recordings of the PET films before and after the APP exposure. The points “a”, “b”, and “c” show the moments when the water surface touched the lower edge of the film, when the direction of the motion of the water surface was reversed and when the water surface was separated from the lower edge of the film, respectively. The changes in weight at the points “a” and “c” correspond to the advancing and receding wetting forces, respectively. For the untreated PET film, the reproducible weight recording was obtained for the first and the second runs. After the APP exposure, considerable increases in both advancing and receding wetting forces were observed. The advancing and receding contact angles were calculated from the advancing and receding wetting forces, respectively, using the Wilhelmy relation [37] and the effective perimeter of the film calculated from the wetting force at the n-pentane/air interface.

Contact angle measurements were carried out in a room maintained at 20 ± 1 °C and 65%RH.

Determination of surface free energy

The components of the surface free energy of the PET film were determined by the contact angle measurements with three probe liquids, water, diiodomethane, and ethylene glycol, by the Wilhelmy method. The Lifshitz-van der Waals component and the Lewis acid and base parameters were calculated by substituting the measured advancing contact angles of the probe liquids and their referential surface free energy components into the van Oss-Chaudhury-Good equation [38].

X-ray photoelectron spectroscopy

X-ray photoelectron spectroscopy (XPS) analysis was carried out using an Axis-Ultra DLD spectrometer (Kratos, UK) using monochromated Al Kα radiation at 1486.7 eV (120 W) with charge neutralization. Survey spectra and high-resolution spectra of the core levels of C1s, N1s, and O1s were acquired with a pass energy of 80 and 20 eV, respectively, and a slot aperture (0.8 × 2.0 mm). Spectra were collected at a photoelectron take-off angle of 90°. The pressure in the analytical chamber was maintained around 10−8 Pa. All XPS binding energies were referenced to the C1s peak of adventitious carbon at a binding energy of 284.8 eV. The collected spectra were deconvoluted with a Gaussian–Lorenzian approximation after Shirley background subtraction using Vision 2 software.

Detection of carboxyl group on polymer surface was carried out by derivatization technique. Carboxyl derivatization of the PET film untreated and exposed to APP with N2 gas prior to the XPS analysis was performed by the vapor-phase derivatization reaction [34]. The PET samples placed on a glass slide and a multiple-dose container containing TFE (200 mg), pyridine (320 μl) and DCC (50 mg) were injected into the 100 ml perfluoroalkyoxy-polymer vessel. The vessel was then sealed and the reaction was allowed to proceed at 65 °C for 8 h.

Atomic force microscopy

The atomic force microscopy images were collected using a Nanoscope IIIa (Digital Instruments, USA) in a tapping mode. The surface roughness parameters, root mean square roughness, average roughness, and maximum roughness depth, were determined from the images obtained in a 1 × 1 μm area.

Results and discussion

Effect of exposure distance on contact angle

Figure 3 shows the effect of the distance between the nozzle jet and the PET film, D, on the water contact angles on the PET films exposed to APP with air, nitrogen gas, and argon gas, which were determined by the sessile drop and the Wilhelmy methods. For all reactive gas sources, the advancing angles determined by the Wilhelmy method, which were in good agreement with the sessile drop angles, were found to decrease with decreasing D. For the APP exposure with air and N2 gas, the advancing angles increased again at D = 5 mm. This may be caused by partial melting of the PET film at high temperature because the sample for the Wilhelmy method was cut off to a fine strip prior to the APP exposure. The optimum D to enhance hydrophilic nature of the PET film was considered to be 7 mm, where the advancing contact angles were in the following order: N2 gas < air < Ar gas. Surprisingly, the receding angle was almost the same (~20°), independent of D and gas source.

Stability of the wettability after the APP exposure

In general, the stability of the treated surface is very desirable in the surface modification. The changes in the advancing and receding contact angles of water on the APP-exposed (D = 7 mm) PET film with aging time are shown in Fig. 4. For any gas source, the advancing angles obtained from second run of the weight recording were about 20° higher than those from the first run. This is probably caused by dissolution of low molecular weight oxidized materials (LMWOM) [39–42] on the APP-exposed PET surface into water during the first run of the wetting force measurement. In other words, the advancing contact angles obtained from the first and second runs are corresponding to those on the APP-exposed PET film with and without the hydrophilic LMWOM, respectively. In both cases, the advancing angles increased with aging time, probably due to the loss of volatile oxidized species to the atmosphere and the reorientation and the migration of polymer chains in the PET surface layer [43, 44]. Such hydrophobic recovery almost disappeared within several days.

Surprisingly, the receding contact angles showed almost a constant value (~20°), independent of the existence of LMWOM and the aging in air. Such difference in the hydrophobic recovery behavior between the advancing and receding contact angles can be explained on the basis of the calculation on the model heterogeneous surface consisting of two regions having different intrinsic contact angles by Johnson and Dettre [31, 45, 46].

Change in surface chemical composition due to plasma exposure

Figures 5A shows surface elemental composition obtained from XPS survey spectra for the PET films untreated and APP-exposed (D = 7 mm) with air, N2 gas, and Ar gas. For the untreated PET film, the O/C ratio was 0.36, in fairly agreement with the theoretical values from the chemical structure (0.4 [47]) and the experimental value of Mylar™ PET film (0.39 [7]). After the APP exposure (aging time of 1 week), the oxygen concentration increased by several% with any gas source and 1–2% nitrogen was detected with air and N2. The oxygen and nitrogen concentrations on APP-exposed PET was in the following order: N2 gas < air < Ar gas, which was not in contradiction with the advancing contact angles 1 week after the APP exposure (see Fig. 4). Unexpectedly, the XPS results indicate that the atoms incorporated into the PET surface by the APP exposure are not consistent precisely with reactive gas species.

Atomic concentrations obtained from XPS survey spectra for the PET films untreated and exposed to APP (D = 7 mm) with air, N2 gas, and Ar gas (A) and nitrogen concentration on PET film surfaces exposed to APP with N2 gas as a function of the distance between the nozzle and the film surface, D (B). The APP-exposed films are aged for 1 week

Lommatzsch et al. [48] have pointed out the possibilities of diffusion of oxygen or water vapor into the plasma jet and subsequent incorporation into the polymer surface. Therefore, the activation mechanism for the APP jet needs to be taken into account not only plasma-surface reaction but also post-plasma processes with ambient gas atmosphere. To confirm this experimentally, the APP exposure with N2 gas was carried out at various separation distances between the nozzle jet and the PET film surface. Although the oxygen concentrations after the APP exposure were almost the same, the nitrogen concentration was found to increase with decreasing separation distance (Fig. 5B). Therefore, it is considered that the above plasma-surface reaction can enhance in the vicinity of the nozzle jet.

Figure 6 illustrates the survey spectra and the high-resolution C1s, O1s, and N1s spectra for the PET film before and after the APP exposure with N2 gas (D = 7). It was clearly observed from the survey spectra (Fig. 6A) that the peak ratio of O1s to C1s considerably increased and the N1s peak appeared after the APP exposure. The curve fitting of C1s and O1s spectra (Fig. 6B and C, respectively) revealed the increases in C–O and O–C=O and the increase in O–C, respectively, due to the APP exposure. The results suggest that the oxygen containing functional groups were introduced to the PET surface by the APP exposure. In Fig. 6D, the N1s peak around 400 eV may be attributed to NH2 and nitrile [48].

The high-resolution F1s spectrum of TFE-derivatized PET (APP exposure sample) is illustrated in Fig. 7 in comparison with the TFE-derivatized PET (untreated sample). The appearance of an F1s peak after the APP exposure indicates the formation of carboxyl groups on the PET surface because TFE-derivatized reaction predominantly labels carboxyl groups and hydroxyl groups have low reactivity toward TFE.

The effects of the rinse with water, to remove LMWOM, on the surface chemical composition of the PET film 1 day or 1 week after the APP exposure was also examined by XPS. The oxygen concentration on the APP-exposed PET surface was significantly reduced by rinsing with water (Fig. 8A). The curve fitting results of C1s spectrum are summarized in Fig. 8B. The increase in C–C and the decrease in O–C=O were found by rinsing with water. Such XPS results were consistent with the hydrophobic recovery due to dissolution of LMWOM into water as shown in Fig. 4B. Unexpectedly, no significant difference in chemical composition between 1-day and 1-week aging was observed in Fig. 8. The volatile oxidized species on the APP-exposed PET surface, which cause hydrophobic recovery, might have evaporated during the XPS measurements because the pressure inside the chamber was maintained around 10−8 Pa [31].

Change in surface roughness due to plasma exposure

The AFM images of the PET film untreated and APP-exposed (D = 7 mm) with air, N2 gas, and Ar gas are presented in Fig. 9. Considerable topographical change due to the APP exposure was observed. The surface roughness parameters of the PET film, which was obtained from the AFM images, increased after the APP exposure, especially with N2 gas. The roughness with inert Ar gas was not so large as well-known knowledge [26]. Moreover, no significant increase in the surface roughness was observed when the film was exposed to APP with Ar gas at D = 5 mm (data are not shown). Therefore, in the present system, the direct Ar plasma-surface reaction is not a main cause of the surface modification as mentioned above.

The above change in surface roughness due to the APP exposure cannot affect on the contact angle determined by the Wilhelmy method, because it is a thermodynamically significant Young contact angle at the three-phase contact line [33].

Change in surface free energy due to plasma exposure

Figure 10 compares the Lifshitz-van der Waals component and the Lewis acid and base parameters of the surface free energy of the PET film untreated and exposed to APP (D = 7 mm) with air, N2 gas, and Ar gas. After the APP exposure, a slight decrease in the Lifshitz–van der Waals component and a drastic increase in the base parameter were found. The order of magnitude in the base parameter of the APP-exposed PET film with different gas sources was Ar < air < N2, which was the same as that of the wettability under the same experimental condition (water contact angles after aging for 1 week and rinsing with water in Fig. 4). Therefore, it was concluded that the increase in the base parameter of the surface free energy due to the introduction of the oxygen-containing surface functional groups by the APP exposure resulted in the wettability increase of the PET film surface.

The Lifshitz–van der Waals component, γ LW, Lewis acid parameter, γ +, and Lewis base parameter, γ −, of the surface free energy calculated from the advancing contact angles of water, diiodomethane, and ethylenegrycol for PET films untreated and exposed to APP (D = 7 mm) with air, N2 gas, and Ar gas. The APP-exposed films are aged for 1 week and rinsed with water to remove LMWOM

Conclusions

The APP jet exposure with three different reactive gas sources: air, N2, and Ar, was applied to modify the PET film surface. The advancing and receding contact angles of water on the PET film decreased drastically after the APP exposure. The advancing contact angle on the APP-exposed PET surface was found to increase again after aging in air or rinsing with water. XPS results were consistent with the wettability changes due to the APP exposure and the subsequent aging and rinsing. The derivatization XPS showed that the carboxyl groups produced on the PET surface after the APP exposure. The topographical change in the PET surface due to APP exposure was confirmed by AFM observation. The changes in the wettability, the surface free energy, the surface chemical composition, and the surface roughness due to the APP exposure with three gas sources were in the following order: N2 gas > air > Ar gas.

References

Lazare S, Srinivasan R (1986) Surface properties of poly (ethylene terephthalate) films modified by far-ultraviolet radiation at 193 nm (laser) and 185 nm (low intensity). J Phys Chem 90:2124–2131

Watanabe H, Takata T (1994) Surface modification of poly (ethylene terephthalate) fiber by excimer light. J Adhes Sci Technol 8:1425–1437

Zhang J-Y, Boyd IW, Esrom H (1996) Surface modification of polyethylene terephthalate with excimer UV radiation. Surf Interface Anal 24:718–722

Wong W, Chan K, Yeung KW, Lau KS (2001) Chemical modification of poly(ethylene terephthalate) induced by laser treatment. Textile Res J 71:117–120

Tokarev VN, Lazare S, Belin C, Debarre D (2004) Viscous flow and ablation pressure phenomena in nanosecond UV laser irradiation of polymers. Appl Phys A79:717–720

Kan CW (2008) A study of laser treatment on polyester substrates. Fiber Polym 9:166–170

Le QT, Pireaux JJ, Caudano R, Leclere P, Lazzaroni R (1998) XPS/AFM study of the PET surface modified by oxygen and carbon dioxide plasmas: Al/PET adhesion. J Adhes Sci Technol 12:999–1023

Almazán-Almazán MC, Paredes JI, Pérez-Mendoza M, Domingo-García M, López-Garzón FJ, Martínez-Alonso A, Tascón JMD (2005) Effects of oxygen and carbon dioxide plasmas on the surface of poly(ethylene terephthalate). J Colloid Interface Sci 287:57–66

Almazán-Almazán MC, Paredes JI, Pérez-Mendoza M, Domingo-García M, López-Garzón FJ, Martínez-Alonso A, Tascón JMD (2006) Surface characterisation of plasma-modified poly(ethylene terephtharate). J Colloid Interface Sci 293:353–363

Vassallo E, Cremona A, Ghezzi F, Ricci D (2010) Characterization by optical emission spectroscopy of an oxygen plasma used for improving PET wettability. Vacuum 84:902–906

Selwyn GS, Herrmann HW, Park J, Henins I (2001) Materials processing using an atmospheric pressure, RF-generated plasma source. Contrib Plasma Phys 6:610–619

Fridman A, Chirokov A, Gutsol A (2005) Non-thermal atmospheric pressure discharges. J Phys D: Appl Phys 38:R1–R24

Chang JS (2006) Physics and chemistry of atmospheric plasma. J Plasma Fusion Res 82:682–692

Bárdos L, Baránková H (2009) Plasma processes at atmospheric and low pressures. Vacuum 83:522–527

Yamakawa K, Hori M, Goto T, Den S, Katagiri T, Kano H (2005) Ultrahigh-speed etching of organic films using microwave-excited nonequilibrium atmospheric-pressure plasma. J Appl Phys 98:043311

Moravej M, Yang X, Hicks RF, Penelon J, Babayan SE (2006) A radio-frequency nonequilibrium atmospheric pressure plasma operating with argon and oxygen. J Appl Phys 99:093305

Schütze A, Jeong JY, Babayan SE, Jaeyoung P, Selwyn GS, Hicks RF (1998) The atmospheric-pressure plasma jet: a review and comparison to other plasma sources. IEEE Trans Plasma Sci 26:1685–1694

Förster S, Mohr C, Viöl W (2005) Investigations of an atmospheric pressure plasma jet by optical emission spectroscopy. Surf CoatTechnol 200:827–830

Lu X, Laroussi M (2006) Dynamics of an atmospheric pressure plasma plume generated by submicrosecond voltage pulses. J Appl Phys 100:063302

Lu X, Xiong Q, Xiong Z, Hu J, Zhou F, Gong W, Xian Y, Zou C, Tang Z, Jiang Z, Pan Y (2009) Propagation of an atmospheric pressure plasma plume. J Appl Phys 105:043304

Jiang N, Ji A, Cao Z (2009) Atmospheric pressure plasma jet: Effect of electrode configuration, discharge behavior, and its formation mechanism. J Appl Phys 106:013308

Drnovská H, Lapčík L Jr, Buršíková V, Zemek J, Barros-Timmons AM (2003) Surface properties of polyethylene after low-temperature plasma treatment. Colloid Polym Sci 281:1025–1103

Novák I, Florián S (2004) Investigation of long-term hydrophobic recovery of plasma modified polypropylene. J Mater Sci 39:2011–2036

Yang S, Gupta MC (2004) Surface modification of polyethyleneterephthalate by an atmospheric-pressure plasma source. Surf CoatTechnol 187:172–176

Park S-J, Lee H-Y (2005) Effect of atmospheric-pressure plasma on adhesion characteristics of polyimide film. J Colloid Interface Sci 285:267–272

Kwon O-J, Myung S-W, Lee C-S, Choi H-S (2006) Comparison of the surface characteristics of polypropylene films treated by Ar and mixed gas (Ar/O2) atmospheric pressure plasma. J Colloid Interface Sci 295:409–416

Shibahara M, Inagaki K, Yamamura K (2007) Surface modification od poly ethylene terephthalate sheet by atmospheric plasma treatment. J Surf Finish Soc Jpn 58:124–129

Leroux F, Campagne C, Perwuelz A, Gengembre L (2009) Atmospheric air plasma treatment of polyester textile materials. Textile structure influence on surface oxidation and silicon resin adhesion. Surf CoatTechnol 203:3178–3183

Noeske M, Degenhardt J, Strudthoff S, Lommatzsch U (2004) Plasma jet treatment of five polymers at atmospheric pressure: surface modifications and the relevance for adhesion. Int J Adhes Adhes 24:171–177

Gonzalez E, Barankin MD, Guschl PC, Hicks RF (2008) Remote atmospheric-pressure plasma activation of the surfaces of polyethylene terephthalate and polyethylene naphthalate. Langmuir 24:12636–12643

Gotoh K, Yasukawa A, Taniguchi K (2011) Water contact angles on poly (ethylene terephthalate) film exposed to atmospheric pressure plasma. J Adhes Sci Technol 25:307–322

Nakayama Y, Takahagi T, Soeda F (1988) XPS Analysis of NH3 Plasma-treated polystyrene films utilizing gas phase chemical modification. J Polym Sci 26:559–572

Tagawa M, Yasukawa A, Gotoh K, Tagawa M, Ohmae N, Umeno M (1992) Local deviation in contact angles on heterogeneous fibrous solids. J Adhes Sci Technol 6:763–776

Chilkoti A, Ratner BD, Briggs D (1991) Plasma-deposited polymeric films prepared from carbonyl-containing volatile precursors: XPS chemical derivatization and static SIMS surface characterization. Chem Mater 3:51–61

Takemura Y, Yamaguchi N, Hara T (2008) Study on surface modification of polymer films by using atmospheric plasma jet source. Jpn J Appl Phys 47:5644–5647

Gotoh K, Tagawa M, Ohmae N, Tagawa M (2000) Wettability of polyimide films modified by exposure to atomic oxygen polymer surface modification. In: Mittal KL (ed) Relevance to Adhesion vol. 2. VSP, Utrecht, The Netherlands, pp 445–457

Tagawa M, Gotoh K, Yasukawa A, Ikuta M (1990) Estimation of surface free energies and Hamaker constants for fibrous solids by wetting force measurements. Colloid Polym Sci 268:589–594

van Oss CJ, Good RJ, Chaudhury MK (1988) Additive and nonadditive surface tension components and the interpretation of contact angles. Langmuir 4:884–891

Walzak MJ, Flynn S, Foerch R, Hill JM, Karbashewski E, Lin A, Strobel M (1995) UV and ozone treatment of polypropylene and poly (ethylene terephthalate). J Adhes Sci Technol 9:1229–1248

Everaert EP, van der Mei HC, Busscher HJ (1996) Hydrophobic recovery of repeatedly plasma-treated silicone rubber. Part 2. A comparison of the hydrophobic recovery in air, water, or liquid nitrogen. J Adhes Sci Technol 10:351–359

Strobel M, Jones V, Lyons CS, Ulsh M, Kushner MJ, Dorai R, Branch MC (2003) A comparison of corona-treated and flame-treated polypropylene films. Plasma Polym 8:61–95

Strobel M, Lyons CS (2003) The role of low-molecular-weight oxidized materials in the adhesion properties of corona-treated polypropylene film. J Adhes Sci Technol 17:15–23

Owen MJ, Smith PJ (1994) Plasma treatment of polydimethylsiloxane. J Adhes Sci Technol 8:1063–1075

Kim BK, Kim KS, Cho K, Park CE (2001) Retardation of the surface rearrangement of O2 plasma-treated LDPE by a two-step temperature control. J Adhes Sci Technol 15:1805–1816

Johnson RE Jr, Dettre RH (1964) Contact angle hysteresis, III. Study of an idealized heterogeneous surface. J Phys Chem 68:1744–1750

Johnson RE Jr, Dettre RH (1965) Contact angle hysteresis. IV. Contact angle measurements on heterogeneous surfaces. J Phys Chem 69:1507–1515

Kim E-Y, Kong J-S, An S-K, Kim H-D (2000) Surface modification of polymers and improvement of the adhesion between evaporated copper metal film and a polymer. 1. Chemical modification of PET. J Adhes Sci Technol 14:1119–1130

Lommatzsch U, Pasedag D, Baalmann A, Ellinghorst G, Wager H-E (2007) Atmospheric pressure plasma jet treatment of polyethylene surfaces for adhesion improvement. Plasma Process Polym 4:S1041–S1045

Acknowledgment

Gratitude is expressed to the Ministry of Education, Sports, Culture, Science and Technology, Japan for a Grant-in-Aid for Scientific Research to carry out this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gotoh, K., Kobayashi, Y., Yasukawa, A. et al. Surface modification of PET films by atmospheric pressure plasma exposure with three reactive gas sources. Colloid Polym Sci 290, 1005–1014 (2012). https://doi.org/10.1007/s00396-012-2600-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-012-2600-7